-

Effect of Heat Treatments and Related Microstructural Modifications on High-Cycle Fatigue Behavior of Powder Bed Fusion–Laser Beam-Fabricated Ti-6Al-2Sn-4Zr-6Mo Alloy

Effect of Heat Treatments and Related Microstructural Modifications on High-Cycle Fatigue Behavior of Powder Bed Fusion–Laser Beam-Fabricated Ti-6Al-2Sn-4Zr-6Mo Alloy -

Point Defects in MoNbTi-Based Refractory Multi-Principal-Element Alloys

Point Defects in MoNbTi-Based Refractory Multi-Principal-Element Alloys -

Residual Stress and Corrosion Performance in L-PBF Ti6Al4V: Unveiling the Optimum Stress Relieving Temperature via Microcapillary Electrochemical Characterisation

Residual Stress and Corrosion Performance in L-PBF Ti6Al4V: Unveiling the Optimum Stress Relieving Temperature via Microcapillary Electrochemical Characterisation -

The Effect of Mo and Al Substitution in Cryomilled and Cold-Rolled FeNi Alloys

The Effect of Mo and Al Substitution in Cryomilled and Cold-Rolled FeNi Alloys

Journal Description

Metals

Metals

is an international, peer-reviewed, open access journal published monthly online by MDPI. The Portuguese Society of Materials (SPM), and the Spanish Materials Society (SOCIEMAT) are affiliated with Metals and their members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), Inspec, Ei Compendex, CAPlus / SciFinder, and other databases.

- Journal Rank: JCR - Q2 (Metallurgy and Metallurgical Engineering) / CiteScore - Q1 (Metals and Alloys)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 18 days after submission; acceptance to publication is undertaken in 2.6 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Companion journals for Metals include: Compounds and Alloys.

Impact Factor:

2.5 (2024);

5-Year Impact Factor:

2.8 (2024)

Latest Articles

Reproducible Thermo-Fluid–Solid-Coupled Modeling of Wet Milling of Al6061: Parametric Influence and Surface Integrity Assessment

Metals 2025, 15(11), 1256; https://doi.org/10.3390/met15111256 (registering DOI) - 17 Nov 2025

Abstract

►

Show Figures

Wet milling of aluminum alloys involves complex interactions among thermal, fluid, and mechanical fields that strongly affect cutting temperature, stress distribution, and surface integrity. To achieve reproducible and physics-based predictions of these coupled phenomena, this study develops a three-dimensional thermo–fluid–solid-coupled Eulerian–Lagrangian (CEL) framework

[...] Read more.

Wet milling of aluminum alloys involves complex interactions among thermal, fluid, and mechanical fields that strongly affect cutting temperature, stress distribution, and surface integrity. To achieve reproducible and physics-based predictions of these coupled phenomena, this study develops a three-dimensional thermo–fluid–solid-coupled Eulerian–Lagrangian (CEL) framework for the wet milling of Al6061. The model system in this study evaluated the effects of milling cutter feed rate and spindle speed, feed per tooth of the milling cutter, axial cutting depth, and coolant flow rate on equivalent stress and peak milling temperature., as well as their correlation with surface roughness metrics (Ra, Sa). Simulation results reveal that higher feed rates significantly raise Tpeak (+12.9%) while reducing σeq (−22.7%) and deteriorating surface quality (Ra +104.2%, Sa +29.9%). Increasing spindle speed lowers both Tpeak (−2.2%) and σeq (−8.5%) and improves surface finish (Ra −39.3%, Sa −16.6%). A greater depth of cut amplifies mechanical and thermal loads, increasing Tpeak (+10.3%) and σeq (+17%). Enhanced coolant flow reduces Tpeak (−23.5%) and σeq (−6.1%) and markedly improves surface quality (Ra −88.8%, Sa −51.3%). Research findings indicate that coolant coverage is the dominant factor determining surface integrity. Although experimental data for Tpeak and σeq were not directly validated, this framework clearly articulates modeling assumptions, quantifies parameter sensitivities, and provides a reproducible methodology for future experimental-numerical verification.

Full article

Open AccessArticle

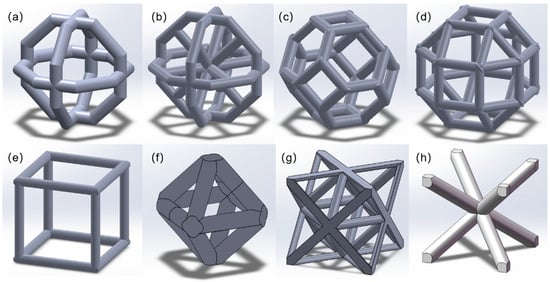

Quasi-Static Compression and Tensile Behavior of Additively Manufactured Al-Mg-Sc-Zr Alloy Lattices: The Role of Cell Topology

by

Jingwen Li, Zhiwei Luo, Yanwu Guo, Zhenyu Yan and Yangwei Wang

Metals 2025, 15(11), 1255; https://doi.org/10.3390/met15111255 - 17 Nov 2025

Abstract

►▼

Show Figures

To achieve lightweight objectives in the aerospace sector, this paper systematically investigates the influence of unit cell topology on the quasi-static mechanical properties of Al-Mg-Sc-Zr alloy lattice structures fabricated by Selective Laser Melting (SLM). A comparative analysis of the mechanical response and failure

[...] Read more.

To achieve lightweight objectives in the aerospace sector, this paper systematically investigates the influence of unit cell topology on the quasi-static mechanical properties of Al-Mg-Sc-Zr alloy lattice structures fabricated by Selective Laser Melting (SLM). A comparative analysis of the mechanical response and failure mechanisms of eight distinct unit cell topologies was conducted through a combination of quasi-static compression and tensile experiments, finite element (FE) simulation, and fractography via Scanning Electron Microscopy (SEM). The results demonstrate that the mechanical performance is highly dependent on the unit cell topology. Under compression, the structures exhibited a layer-by-layer collapse, whereas under tension, they failed through sequential fracture of multiple struts initiated by stress concentration. Finite element simulations effectively predicted the general trends of the mechanical behavior; however, the actual strength and ductility of the SLM-fabricated specimens were lower than the simulated values due to intrinsic process-induced defects such as pores and lack of fusion. Analysis using the Maxwell index revealed that stretching-dominated structures possess superior specific modulus and specific strength compared to bending-dominated ones. Furthermore, among structures with similar Maxwell indices, those incorporating vertical struts demonstrated higher load-bearing efficiency. This study provides significant experimental and theoretical foundations for the design and application of high-performance lattice materials in lightweight structures.

Full article

Figure 1

Open AccessArticle

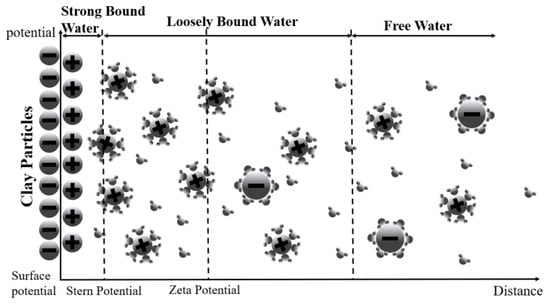

Effect of (NH4)2SO4 Solution Concentration on Bound Water Content in Ion Adsorption Rare-Earth Raw Ore

by

Yuehua Liang, Jie Wang, Zhikui Fei, Chenliang Peng, Hourui An and Zhanfeng Fan

Metals 2025, 15(11), 1254; https://doi.org/10.3390/met15111254 - 17 Nov 2025

Abstract

Ion adsorption rare-earth (IARE) ores, a strategic metal resource, are extracted by leaching with ammonium sulfate [(NH4)2SO4] solution, our samples have ∑REO grades of 0.032–0.079% wt%. IARE sandstone, mudstone, clay, and strongly weathered rock were selected as test materials.

[...] Read more.

Ion adsorption rare-earth (IARE) ores, a strategic metal resource, are extracted by leaching with ammonium sulfate [(NH4)2SO4] solution, our samples have ∑REO grades of 0.032–0.079% wt%. IARE sandstone, mudstone, clay, and strongly weathered rock were selected as test materials. Surface-related physicochemical parameters were determined, and bound water was determined by volumetric flask pycnometry. For each IARE lithology, we also obtained particle size distributions and evaluated bound water variation in (NH4)2SO4 solutions at 0, 1, 2, and 3 wt%. Based on the Gouy–Chapman theory, the relationship between the surface bound water and solution concentration, as well as the surface charge of IARE samples, and other influencing factors was explored. The experimental results show the following: ① The surface charge per unit area of four types of IARE samples, namely mudstone, sandstone, clay, and strongly weathered rock, are 0.7072 × 10−2 mmol/m2, 1.9620 × 10−2 mmol/m2, 1.5418 × 10−2 mmol/m2, and 2.1003 × 10−2 mmol/m2, respectively, with strongly weathered rock having the highest and mudstone having the lowest. ② As the concentration of aqueous (NH4)2SO4 increases (0, 1, 2, 3 wt%), the total volume reduction in free water ∆V in the system increases, and the mass of adsorbed bound water per unit mass of IARE sample also increases. ③ As the concentration of the solution increases, the thickness of the diffusion double layer on the surface of the IARE sample is compressed, the total amount of adsorbed anions and cations on the surface increases, and the density of the surface water film also increases, leading to a corresponding increase in the quality of adsorbed bound water. ④ Under the same solution concentration, the variation trend of adsorbed bound water mass per unit area of IARE samples is strongly weathered rock > sandstone > clay > mudstone, which is consistent with the trend of surface charge per unit area of IARE samples. A higher lixiviant concentration increases bound water, shrinks the effective pore throats of the ore body, reduces hydraulic conductivity, and consequently diminishes leaching efficiency.

Full article

(This article belongs to the Special Issue Advances in Recycling of Valuable Metals—2nd Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

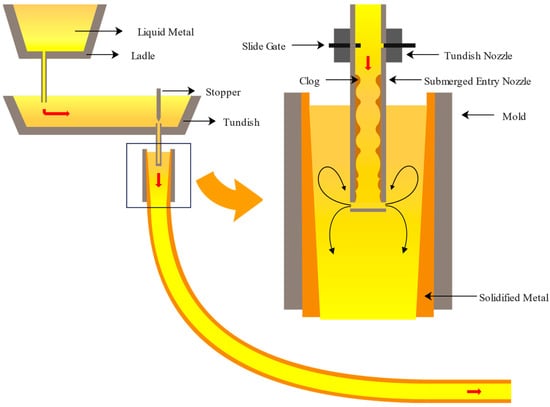

The Time–Frequency Analysis and Prediction of Mold Level Fluctuations in the Continuous Casting Process

by

Mohan Cai, Meixia Fu, Wei Li, Qu Wang, Na Chen, Zhangchao Ma, Lei Sun, Ronghui Zhang, Hongbin Wang and Jianquan Wang

Metals 2025, 15(11), 1253; https://doi.org/10.3390/met15111253 - 17 Nov 2025

Abstract

Mold level fluctuation significantly affects the stability and quality of the slab during the continuous casting process. However, traditional mechanism models are insufficient for providing accurate time-series predictions under complex and multivariable operating conditions. Additionally, the dynamic interdependencies between process variables and transient

[...] Read more.

Mold level fluctuation significantly affects the stability and quality of the slab during the continuous casting process. However, traditional mechanism models are insufficient for providing accurate time-series predictions under complex and multivariable operating conditions. Additionally, the dynamic interdependencies between process variables and transient abnormal fluctuation events have been largely overlooked in existing studies. To address these limitations, we propose an integrated time–frequency characterization and prediction framework that combines multi-domain feature extraction with a long-sequence Informer model. First, the preprocessing pipeline transforms heterogeneous sensor data into standardized time series through normalization and standardization, thereby establishing a robust foundation for subsequent feature extraction and predictive modeling. Second, the time–domain and frequency–domain feature extraction methods are integrated to capture essential patterns in casting signals with improved resolution and interpretability. Third, the fusion features are embedded into a time-series prediction model, which performs robust forecasting of mold level behavior and enhances the identification of root causes behind fluctuation anomalies. Compared with conventional LSTM and Transformer models, the proposed framework achieves over 90% reduction in prediction error and provides interpretable insights into the correlations between casting parameters and mold level variations. Finally, real industrial experimental results demonstrate the performance of the proposed framework in enhancing prediction reliability and providing insight into fluctuations with scalable implementation.

Full article

(This article belongs to the Section Metal Casting, Forming and Heat Treatment)

►▼

Show Figures

Figure 1

Open AccessArticle

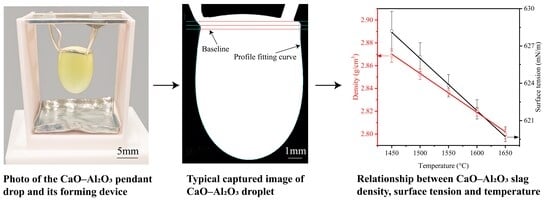

Determination of Density and Surface Tension of CaO–Al2O3 Molten Slag Using Pendant Drop Method

by

Jian Chen and Yunming Gao

Metals 2025, 15(11), 1252; https://doi.org/10.3390/met15111252 - 16 Nov 2025

Abstract

►▼

Show Figures

The pendant drop method is often used to determine the surface tension of liquids. However, in the process of calculating surface tension, corresponding density data are required, which brings a series of problems to the determination of the surface tension of high-temperature slag,

[...] Read more.

The pendant drop method is often used to determine the surface tension of liquids. However, in the process of calculating surface tension, corresponding density data are required, which brings a series of problems to the determination of the surface tension of high-temperature slag, especially. So far, there have been few reports on determining the two properties of density and surface tension by the pendant drop method in a single experiment. In this work, CaO–50% Al2O3 slag was taken as the research object, a novel ring-shaped-pendant drop-forming device constructed with Pt–10% Ir alloy was employed, and the outer diameter of the alloy ring at experimental temperatures was determined as a reference scale by pixel analyses of images. The density and surface tension of the slag within the range of 1450 to 1650 °C were simultaneously determined under heating and cooling modes, respectively, and the effect of slag mass on measurement results was also investigated. The results show that the measurement mode (heating or cooling) has little effect under experimental conditions, whereas the slag mass has a certain effect when it is small. The average density and surface tension values obtained both decrease with increasing temperature, and the temperature coefficients are −3.406 × 10−4 g/(cm3⋅°C) and −4.2 × 10−2 mN/(m⋅°C), respectively. The density and surface tension of the slag at 1550 °C are 2.836 g/cm3 and 624 mN/m, respectively. In addition, the combined standard uncertainties of the measured density and surface tension are 0.01 g/cm3 and 4 mN/m, respectively. The density and surface tension values are basically consistent with literature data. This work can provide an experimental basis for the development of a pendant drop method used to determine the density and surface tension properties of molten slag.

Full article

Graphical abstract

Open AccessReview

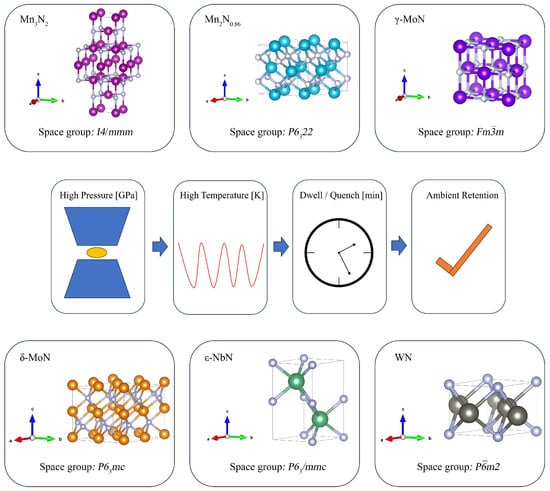

Elastic Origins of Hardness in Quenchable High-Pressure Metal Nitrides: A Unified Structure-Elasticity Baseline

by

Shoufeng Zhang, Yuhao Liu, Zhaoqing Wang, Jinming Zhu, Jiaman Wu and Kuo Bao

Metals 2025, 15(11), 1251; https://doi.org/10.3390/met15111251 - 16 Nov 2025

Abstract

We review bulk transition-metal nitrides synthesized at high pressure–high temperature and recoverable at ambient conditions. We establish an elasticity-anchored framework that links crystal structure and bonding to elastic descriptors and hardness at the phase-resolved level, enabling fair cross-study comparison. Overall, hardness shows a

[...] Read more.

We review bulk transition-metal nitrides synthesized at high pressure–high temperature and recoverable at ambient conditions. We establish an elasticity-anchored framework that links crystal structure and bonding to elastic descriptors and hardness at the phase-resolved level, enabling fair cross-study comparison. Overall, hardness shows a robust association with the shear modulus G, while the Pugh ratio k = G/B modulates relative rankings across phases. When metallic bonding or non-stoichiometry/defects are pronounced, systematic deviations arise; accordingly, elasticity-based models are best used for cross-phase trends and qualitative guidance rather than absolute predictions, especially for metallic or defect-rich phases. Building on this baseline, we outline application pathways and future research directions, and we propose a minimal reporting checklist to improve reproducibility and cross-study comparability.

Full article

(This article belongs to the Special Issue Recent Insights into Mechanical Properties of Metallic Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

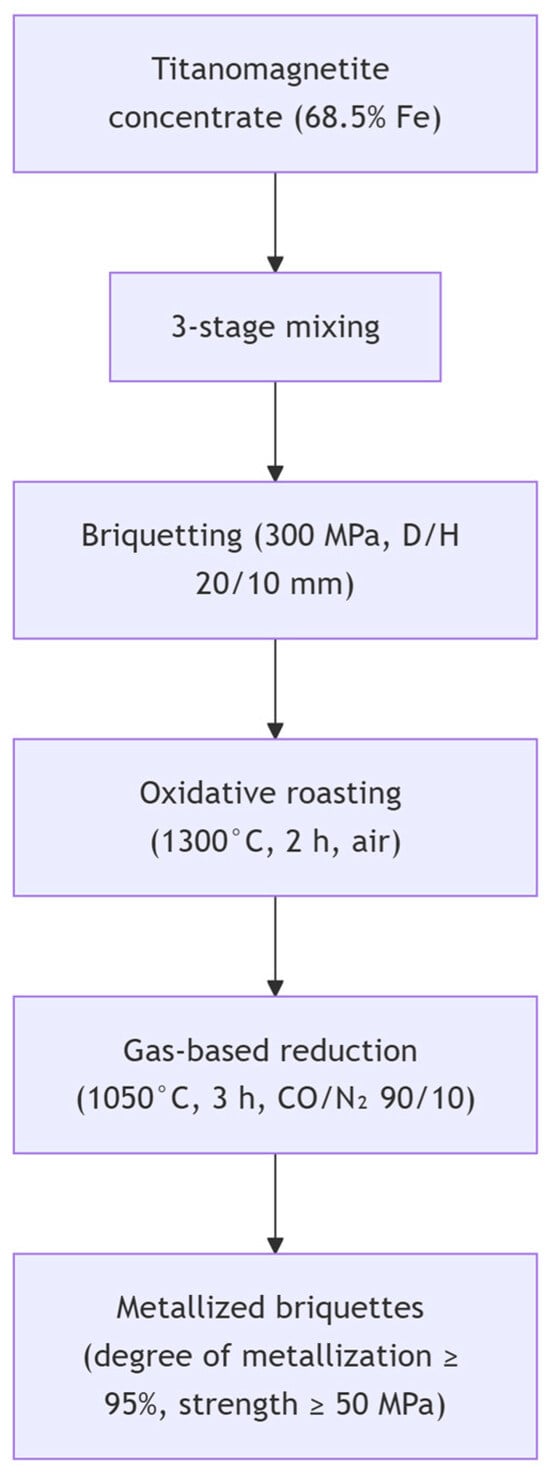

Investigation of the Possibility of Obtaining Metallized Titanomagnetite Briquettes Suitable for Utilization in the Steelmaking Process

by

Andrey N. Dmitriev, Galina Yu. Vitkina, Elena A. Vyaznikova, Roman V. Alektorov, Vladimir V. Kataev, Larisa A. Marshuk and Yulia E. Burova

Metals 2025, 15(11), 1250; https://doi.org/10.3390/met15111250 - 16 Nov 2025

Abstract

►▼

Show Figures

The present study explores the production of metallized titanomagnetite briquettes, with a view to addressing two key issues. Firstly, it seeks to address the growing shortage of high-quality iron-bearing raw materials. Secondly, it looks at how to meet the increasingly stringent environmental constraints.

[...] Read more.

The present study explores the production of metallized titanomagnetite briquettes, with a view to addressing two key issues. Firstly, it seeks to address the growing shortage of high-quality iron-bearing raw materials. Secondly, it looks at how to meet the increasingly stringent environmental constraints. The conventional blast-furnace treatment of titanomagnetite is hindered by the formation of refractory Ti-rich slags. It is hereby proposed that a single-cycle briquetting process in conjunction with a thermal reduction route should be utilized. This approach enables precise regulation of the Fe/flux ratio. Experiments were conducted on a low-grade titanomagnetite concentrate (68.5% Fe) from the Pervouralsk deposit (Russia). Cylindrical briquettes (D 15–20 mm, h 8–10 mm) were subjected to a pressure of 300 MPa during the pressing process, with the utilization of diverse binders comprising rubber cement, CaO, graphite + water, and basic oxygen-furnace (BOF) slag + sodium silicate. Following an oxidative pre-heating process at 1300 °C for two hours, followed by a gas-based reduction process at 1050 °C for three hours, with a CO/N2 ratio of 90/10, the products demonstrated an oxidation rate of 85–95% and a cold compression strength of 16–80 MPa. The highest observed strength (80 MPa) was obtained with a binder comprising CaO·MgO·2SiO2 (diopside/merwinite), which forms a low-viscosity melt, fills 90% of pores and crystallizes as acicular Mg-SFCA-I during cooling. Conversely, the CaO·TiO2 and FeO·TiO2 + Fe3C associations yield brittle structures and a maximum strength of 16 MPa. The optimum briquette (0.55% CaO, D/H = 20/10 mm) exhibited a 95.7% metallization degree, a compressive strength of 48.9 MPa, and dimensional changes within acceptable limits, thus fulfilling the requirements for electric arc furnace feedstock. Further research is required in the form of a full Life Cycle Assessment and pilot-scale testing. However, the results obtained thus far confirm that titanomagnetite briquettes with a binder consisting of CaO, MgO and SiO2 are a promising alternative to pellets for low-carbon steelmaking.

Full article

Figure 1

Open AccessArticle

Effect of Aluminum Content on the Corrosion Behavior of Fe-Mn-Al-C Structural Steels in Marine Environments

by

Suotao Wang, Zhidong Sun, Dongjie Li, Qiang Yu and Qingfeng Wang

Metals 2025, 15(11), 1249; https://doi.org/10.3390/met15111249 - 15 Nov 2025

Abstract

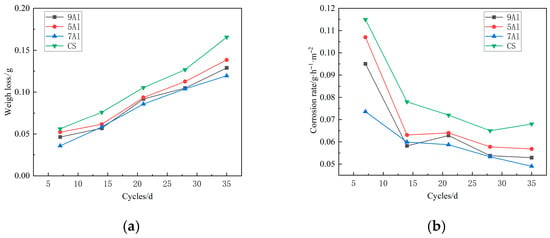

►▼

Show Figures

Fe-Mn-Al-C lightweight steel is an alternative to traditional low-alloy structural steels. It is lightweight and can be used to reduce the weight of structures without increasing their density. However, in the marine environment, traditional low-alloy structural steels can be damaged by chloride ions,

[...] Read more.

Fe-Mn-Al-C lightweight steel is an alternative to traditional low-alloy structural steels. It is lightweight and can be used to reduce the weight of structures without increasing their density. However, in the marine environment, traditional low-alloy structural steels can be damaged by chloride ions, which shortens their service life. We do not yet understand how aluminum, an important alloying element in lightweight steel, affects the process of corrosion. In this study, we examined Fe-Mn-Al-C lightweight steels with different amounts of aluminum. We used full-immersion simulated marine corrosion tests and multi-dimensional characterization techniques, such as microstructure observation and electrochemical measurements, to explore the relationship between aluminum content and the steel’s corrosion rate, corrosion product structure, and corrosion resistance. The results showed that, compared with CS, the weight loss and rate of corrosion of steels that contain aluminum were a lot lower. While the corrosion rate of CS is approximately 0.068 g·h−1·m−2, that of 7Al steel is reduced to 0.050 g·h−1·m−2. The stable phases α-FeOOH and FeAl2O4 are formed in the corrosion products when Al is added. As the Al content increases, so does the relative content of these phases. Furthermore, FeAl2O4 acts as a nucleation site that refines corrosion product grains, reduces pores and cracks, and significantly improves the compactness of corrosion products. It also forms a dense inner rust layer that blocks the penetration of corrosive ions such as Cl−. This study confirmed that aluminum improves the corrosion resistance of steel synergistically by regulating the structure of the corrosion products, optimizing the phase composition, and improving the electrochemical properties. The optimal aluminum content for lightweight steel in marine environments is 7%, within a range of 5–9%.

Full article

Figure 1

Open AccessArticle

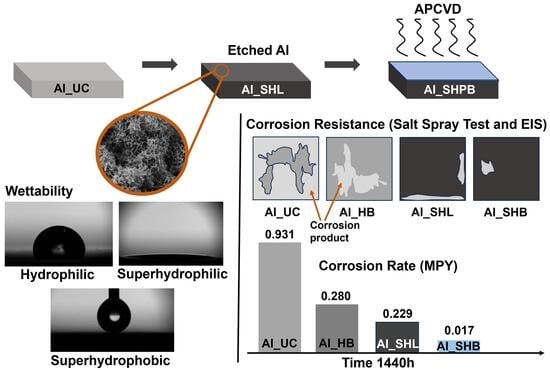

Scalable Advanced Dual-Engineered Superhydrophobic Aluminum Surfaces for Industrial-Grade Corrosion Protection

by

N. Rahul, Ho-Eon Sung, Sang Won Lee and Min-Suk Oh

Metals 2025, 15(11), 1248; https://doi.org/10.3390/met15111248 - 15 Nov 2025

Abstract

Superhydrophobic coatings on aluminum play a crucial role in enhancing corrosion resistance in harsh marine and chloride-rich environments. This study introduces a scalable fabrication method for superhydrophobic aluminum surfaces exhibiting outstanding corrosion resistance. The process involves a two-step technique combining chemical etching with

[...] Read more.

Superhydrophobic coatings on aluminum play a crucial role in enhancing corrosion resistance in harsh marine and chloride-rich environments. This study introduces a scalable fabrication method for superhydrophobic aluminum surfaces exhibiting outstanding corrosion resistance. The process involves a two-step technique combining chemical etching with atmospheric pressure chemical vapor deposition (AP-CVD) of perfluorooctyltriethoxysilane (PFOTES). Hierarchical micro- and nanostructures were created by HCl etching, followed by conformal PFOTES functionalization to impart low surface energy. The fabricated surfaces demonstrated water contact angles reaching as high as 175°, coupled with very-low-contact-angle hysteresis, indicative of the Cassie–Baxter wetting state. Electrochemical analyses in saline environments demonstrated a substantial increase in charge transfer resistance and a reduction in corrosion rates by more than an order of magnitude compared to uncoated aluminum, with inhibition efficiencies exceeding 98%. Extended salt spray testing corroborated the durability and efficacy of the dual-modified surfaces. This facile and cost-effective method offers promising prospects for multifunctional aluminum components in marine, infrastructure, and aerospace applications where long-term protection against aggressive environments is required.

Full article

(This article belongs to the Section Corrosion and Protection)

►▼

Show Figures

Graphical abstract

Open AccessArticle

Effect of H3PO4 Coating, Polyimide Binder, and MoS2/Graphite Lubricants on the Formability and Electromagnetic Properties of Fe-5.0 wt.%Si SMC Toroidal Cores

by

Seongsu Kang and Seonbong Lee

Metals 2025, 15(11), 1247; https://doi.org/10.3390/met15111247 - 14 Nov 2025

Abstract

This study examined the effects of phosphoric acid (H3PO4), polyimide (PI), and lubricants (MoS2, graphite) on the phase stability, microstructure, and magnetic performance of Fe-5.0 wt.%Si soft magnetic composites (SMCs). Warm compaction (≤550 °C) and annealing at

[...] Read more.

This study examined the effects of phosphoric acid (H3PO4), polyimide (PI), and lubricants (MoS2, graphite) on the phase stability, microstructure, and magnetic performance of Fe-5.0 wt.%Si soft magnetic composites (SMCs). Warm compaction (≤550 °C) and annealing at 700 °C were applied to samples prepared under a full factorial design. X-ray diffraction confirmed stable α-Fe(Si) phases without secondary phases. SEM and TEM–EDS revealed interfacial insulating layers mainly composed of Si-O, with localized phosphorus and carbon. Additive composition strongly influenced magnetic and physical properties. Increasing H3PO4 and PI reduced the density from 7.50 to 7.27 g/cm3 and lowered the permeability (from 189 at 1 kHz to 156), due to thicker interparticle layers that restricted metallic contact and domain wall motion. In contrast, Q-values rose significantly with frequency: for H3PO4 0.25 wt.% + PI 0.25 wt.% + graphite 0.3 wt.%, Q increased from 0.39 (1 kHz) to 2.91 (10 kHz), reflecting effective eddy current suppression. Lubricant type further influenced performance: graphite consistently outperformed MoS2, with 0.3 wt.% graphite providing the best balance of high density, permeability, and a frequency-stable Q-value. Overall, Fe-5.0 wt.%Si performance is governed not by bulk phase changes but by the trade-off between densification and insulation at particle interfaces. The optimal combination of low H3PO4 and PI with 0.3 wt.% graphite offers practical guidelines for designing high-frequency, high-efficiency motor materials.

Full article

(This article belongs to the Special Issue Metallic Magnetic Materials: Manufacture, Properties and Applications)

►▼

Show Figures

Graphical abstract

Open AccessArticle

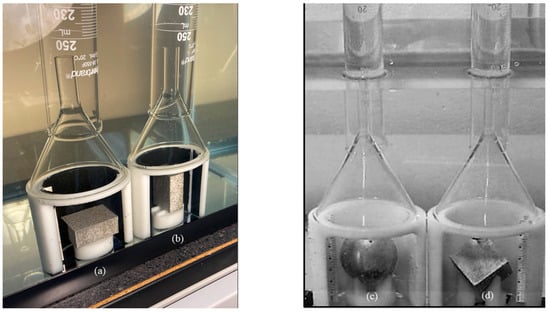

Geometric Effects and Boundary Condition Issues in the Corrosion of Magnesium

by

S. J. Horstemeyer, Lydia A. Jordan, H. J. Martin, W. S. Strasser, H. E. Cho and M. F. Horstemeyer

Metals 2025, 15(11), 1246; https://doi.org/10.3390/met15111246 - 14 Nov 2025

Abstract

A new experiment was conducted to determine the corrosion rates of different geometric structures (vertical plate, horizontal plate, cube, and sphere) with the same surface area of pure magnesium in a saltwater immersion environment of 3.5% NaCl for 108 h, illustrating a clear

[...] Read more.

A new experiment was conducted to determine the corrosion rates of different geometric structures (vertical plate, horizontal plate, cube, and sphere) with the same surface area of pure magnesium in a saltwater immersion environment of 3.5% NaCl for 108 h, illustrating a clear geometry effect arising from local boundary layer water flow. Magnesium was chosen as an idealized material because of its small electrochemical potential. The different corrosion mechanisms were analyzed and quantified by measuring the surface roughness (localized corrosion) via laser profilometry, mass loss (general corrosion) by weighing specimens, localized and intergranular corrosion via Scanning Electron Microscopy and Optical Microscopy, and total corrosion via hydrogen measurements. Although the corrosion rates were very similar at the beginning of the tests, the vertical and horizontal plates gave corrosion rates greater than the cube and sphere shortly after the tests started. Water circulation induced by hydrogen gas bubbles caused a greater corrosion rate at the edges of the plates and cube. These results indicate that a structure’s geometric edges should be made smoother to lessen corrosion effects in design. Also, when one is designing for corrosion resistance of a structural component, our results demonstrate that the designer must consider the fluid dynamics in the boundary value problem surrounding the structural component, since the geometric shape changes the corrosion rate.

Full article

(This article belongs to the Special Issue Erosion–Corrosion Behaviour and Mechanisms of Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Study on Combination Mechanism of Pretreatment Layer in Pre-Coated Metal Sheets

by

Changwen Liu, Jinwen Ye, Li Liao and Xueqiang Dong

Metals 2025, 15(11), 1245; https://doi.org/10.3390/met15111245 - 13 Nov 2025

Abstract

►▼

Show Figures

Pre-coated metal sheets (PCM), as a popular product in modern coating industries, offer significant advantages such as simple processing, lightweight properties, and excellent manufacturability. The pretreatment layer within its coating system has a significant impact on overall corrosion resistance. In this study, through

[...] Read more.

Pre-coated metal sheets (PCM), as a popular product in modern coating industries, offer significant advantages such as simple processing, lightweight properties, and excellent manufacturability. The pretreatment layer within its coating system has a significant impact on overall corrosion resistance. In this study, through a comparative analysis of two chromate-free pretreatment systems, we conducted a thorough investigation into the combination of the pretreatment layer and examined the impact on the corrosion performance of pre-coated metal sheets. It was found that the phytic acid-based pretreatment layer enhances the adhesion between the primer and the substrate by forming strong chemical bonds with the primer layer, which effectively inhibits the lateral diffusion of corrosive media to the metal surface. Consequently, pre-coated metal sheets with the phytic acid-based pretreatment exhibit superior anti-foaming performance compared to the system using the silane-based pretreatment layer. This provides a new insight into the design and development of Cr-free pretreatment systems with better corrosion resistance performance.

Full article

Figure 1

Open AccessArticle

Microstructure and Mechanical Properties of CoCrFeNiTax High-Entropy Alloy Prepared by Hot-Pressing Sintering

by

Aiyun Jiang, Yajun Zhou, Bo Ren, Jianxiu Liu, Changlin Li and Jiaqiang Qiao

Metals 2025, 15(11), 1244; https://doi.org/10.3390/met15111244 - 13 Nov 2025

Abstract

Aiming at the drawbacks of the classic CoCrFeNi high-entropy alloy (HEA)—low room-temperature strength and softening above 600 °C, which fail to meet strict material requirements in high-end fields like aerospace—this study used the vacuum hot-pressing sintering process to prepare CoCrFeNiTax HEAs (x

[...] Read more.

Aiming at the drawbacks of the classic CoCrFeNi high-entropy alloy (HEA)—low room-temperature strength and softening above 600 °C, which fail to meet strict material requirements in high-end fields like aerospace—this study used the vacuum hot-pressing sintering process to prepare CoCrFeNiTax HEAs (x = 0, 0.5, 1.0, 1.5, 2.0 atom, designated as H4, Ta0.5, Ta1.0, Ta1.5, Ta2.0, respectively). This process effectively inhibits Ta segregation (a key issue in casting) and facilitates the presence uniform microstructures with relative density ≥ 96%, while this study systematically investigates a broader Ta content range (x = 0–2.0 atom) to quantify phase–property evolution, differing from prior works focusing on limited Ta content or casting/spark plasma sintering (SPS). Via X-ray diffraction (XRD), scanning electron microscopy–energy-dispersive spectroscopy (SEM-EDS), microhardness testing, and room-temperature compression experiments, Ta’s regulatory effect on the alloy’s microstructure and mechanical properties was systematically explored. Results show all alloys have a relative density ≥ 96%, verifying the preparation process’s effectiveness. H4 exhibits a single face-centered cubic (FCC) phase. Ta addition transforms it into a “FCC + hexagonal close-packed (HCP) Laves phase” dual-phase system. Mechanically, the alloy’s inner hardness (reflecting the intrinsic property of the material) increases from 280 HV to 1080 HV, the yield strength from 760 MPa to 1750 MPa, and maximum fracture strength reaches 2280 MPa, while plasticity drops to 12%. Its strengthening mainly comes from the combined action of Ta’s solid-solution strengthening (via lattice distortion hindering dislocation motion) and the Laves phase’s second-phase strengthening (further inhibiting dislocation slip).

Full article

(This article belongs to the Special Issue Design, Processing and Characterization of Advanced Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Crystal Plasticity Simulations of Dislocation Slip and Twinning in α-Ti Single and Polycrystals

by

Evgeniya Emelianova, Maxim Pisarev, Ruslan Balokhonov and Varvara Romanova

Metals 2025, 15(11), 1243; https://doi.org/10.3390/met15111243 - 13 Nov 2025

Abstract

A crystal plasticity finite element model is developed and implemented to numerically study the deformation behavior of hexagonal close-packed metals using α-titanium as an example. The model takes into account micromechanical deformation mechanisms through dislocation slip along prismatic, basal, and first-order <c

[...] Read more.

A crystal plasticity finite element model is developed and implemented to numerically study the deformation behavior of hexagonal close-packed metals using α-titanium as an example. The model takes into account micromechanical deformation mechanisms through dislocation slip along prismatic, basal, and first-order <c+a> pyramidal systems, as well as tensile twinning. Twin initiation follows a two-conditional criterion requiring that both the resolved shear stress in a twin system and the accumulated pyramidal slip simultaneously reach their critical values. Three-dimensional polycrystalline models are generated using the step-by-step packing method. The crystal plasticity constitutive model describing the deformation behavior of grains is integrated into the boundary-value problem of continuum mechanics, including dynamic governing equations. The three-dimensional problem is solved numerically using the finite element method. The micromechanical model is tested for an α-titanium single crystal along the [0001] direction and a polycrystal consisting of 50 grains. The numerical results reveal that twin propagation is controlled by the critical value of accumulated pyramidal slip, emphasizing the need for experimental calibration. The agreement between numerical and experimental results provides the model validation at the meso- and macroscales.

Full article

(This article belongs to the Section Computation and Simulation on Metals)

►▼

Show Figures

Figure 1

Open AccessArticle

Corrosion and Anodic Oxidation of Alloy 690 in Simulated Primary Coolant of a Small Modular Reactor Studied by In Situ Electrochemical Impedance Spectroscopy

by

Martin Bojinov, Iva Betova and Vasil Karastoyanov

Metals 2025, 15(11), 1242; https://doi.org/10.3390/met15111242 - 12 Nov 2025

Abstract

The effect of KOH concentration as a boron-free coolant for prospective use in Small Modular Reactors (SMRs) on the corrosion of Alloy 690 is studied by in situ impedance spectroscopy at 280 °C/9 MPa during 168 h exposure in a flow-through cell connected

[...] Read more.

The effect of KOH concentration as a boron-free coolant for prospective use in Small Modular Reactors (SMRs) on the corrosion of Alloy 690 is studied by in situ impedance spectroscopy at 280 °C/9 MPa during 168 h exposure in a flow-through cell connected to a high-temperature/high-pressure loop. To follow further oxidation of the passive film, the samples were subsequently polarized up to potentials 0.5 V more positive than the corrosion potential. The formed oxides were analyzed ex situ by measuring the atomic concentration of the constituent elements via glow discharge optical emission spectroscopy (GDOES) depth profiling. The Mixed-Conduction Model for Oxide Films (MCM) was employed to quantitatively interpret the impedance results. The estimated parameters are used to quantify the influence of KOH concentration and anodic polarization on oxide formation and soluble product release rates. Results are compared to those obtained in the nominal primary chemistry of pressurized water reactors and indicate that Alloy 690 can also be successfully used as a steam generator tube material in SMRs.

Full article

(This article belongs to the Special Issue Corrosion Mechanisms and Cutting-Edge Protection Technologies for Advanced Alloy Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Effects of Hydrogen-Rich Gas Injection on Combustion Characteristics in Blast Furnace Raceway and Thermal Load of Tuyere: A Numerical Simulation Study

by

Chun-Cheng Lai, Kuan-Yu Chen, Dai-Qui Vo, Hsuan-Chung Wu, Huey-Jiuan Lin, Bo-Jhih Lin, Tsung-Yen Huang and Shan-Wen Du

Metals 2025, 15(11), 1241; https://doi.org/10.3390/met15111241 - 12 Nov 2025

Abstract

►▼

Show Figures

Hydrogen-rich gas (HRG) injection is a promising low-carbon solution for blast furnace ironmaking. This study conducted numerical simulations in the lower part of a blast furnace to analyze the combustion behavior of coinjected coke oven gas (COG) and pulverized coal (PC) within the

[...] Read more.

Hydrogen-rich gas (HRG) injection is a promising low-carbon solution for blast furnace ironmaking. This study conducted numerical simulations in the lower part of a blast furnace to analyze the combustion behavior of coinjected coke oven gas (COG) and pulverized coal (PC) within the raceway and the associated thermal load on the tuyere. A three-dimensional computational fluid dynamics model incorporating fluid–thermal–solid coupling and the GRI-Mech 3.0 chemical kinetic mechanism (validated for 300–2500 K) was established to simulate the lance–blowpipe–tuyere–raceway region. The simulation results revealed that moderate COG injection accelerated volatile release from PC and enlarged the high-temperature zone (>2000 K). However, excessive COG injection intensified oxygen competition and shortened the residence time of PC, ultimately decreasing the burnout rate. Notably, although COG has high reactivity, its injection did not cause an increase in tuyere temperature. By contrast, the presence of an unburned gas layer near the upper wall of the tuyere and the existence of a strong convective cooling effect contributed to a reduction in tuyere temperature. An optimized cooling water channel was designed to enhance flow distribution and effectively suppress localized overheating. The findings of this study offer valuable technical insights for ensuring safe COG injection and advancing low-carbon steelmaking practices.

Full article

Figure 1

Open AccessEditorial

Novel Insights and Advances in Steels and Cast Irons

by

Annalisa Fortini and Chiara Soffritti

Metals 2025, 15(11), 1240; https://doi.org/10.3390/met15111240 - 12 Nov 2025

Abstract

The manufacturing sector relies extensively on ferrous alloys, with steels and cast irons serving as essential materials for structural and functional components across a wide range of industries, including automotive, energy generation, and civil engineering [...]

Full article

(This article belongs to the Special Issue Novel Insights and Advances in Steels and Cast Irons)

Open AccessArticle

First-Principles Study of Irradiation Defects in γ′-U2Mo

by

Yuxin Wang, Zhixiao Liu, Guangdong Liu, Dan Sun and Wenjie Li

Metals 2025, 15(11), 1239; https://doi.org/10.3390/met15111239 - 12 Nov 2025

Abstract

Understanding defect behavior and fission gas transport in uranium-molybdenum (U-Mo) fuels is key to explaining their swelling during reactor operation. In this study, we employed density functional theory (DFT) to systematically investigate the point defect structures and self-diffusion mechanisms in U2Mo,

[...] Read more.

Understanding defect behavior and fission gas transport in uranium-molybdenum (U-Mo) fuels is key to explaining their swelling during reactor operation. In this study, we employed density functional theory (DFT) to systematically investigate the point defect structures and self-diffusion mechanisms in U2Mo, with particular emphasis on the diffusion behavior of fission gas atoms Xe. Among intrinsic defects, vacancies and substitutional defects are the most stable, combining low formation energies with relatively small migration barriers; as a result, they largely control defect-mediated processes. Further analysis shows that self-diffusion in U2Mo is strongly element-dependent, as U atoms migrate predominantly through vacancy-mediated mechanisms, while Mo atoms diffuse primarily via substitutional pathways. In addition, Xe atoms migrate through two distinct pathways: by combining with vacancies to form stable complexes and diffusing via vacancy-assisted migration, or by migrating as interstitial species along the Tetrahedral → Octahedral → Tetrahedral path between interstitial sites, eventually moving outward along defect channels and leading to gas release. Self-diffusion and fission gas transport in U-Mo fuels are governed by point defects, linking defect behavior to the swelling resistance of advanced nuclear materials.

Full article

(This article belongs to the Section Computation and Simulation on Metals)

►▼

Show Figures

Figure 1

Open AccessArticle

Direct Experimental Calibration of Hosford–Coulomb and Modified Mohr–Coulomb Damage Criteria in AHSS Using Digital Image Correlation

by

Rui Pereira, Nuno Peixinho and Sérgio L. Costa

Metals 2025, 15(11), 1238; https://doi.org/10.3390/met15111238 - 11 Nov 2025

Abstract

This study presents a Digital Image Correlation (DIC)-based experimental framework for the calibration of the Hosford-Coulomb (HC) and Modified-Mohr Coulomb (MMC) damage initiation criteria in an Advanced High Strength Steel (AHSS) DP1000. Three characteristic loading conditions in sheet metal forming—pure shear, uniaxial tension,

[...] Read more.

This study presents a Digital Image Correlation (DIC)-based experimental framework for the calibration of the Hosford-Coulomb (HC) and Modified-Mohr Coulomb (MMC) damage initiation criteria in an Advanced High Strength Steel (AHSS) DP1000. Three characteristic loading conditions in sheet metal forming—pure shear, uniaxial tension, and plane strain tension—were reproduced using flat specimens in a universal tensile testing machine, thus eliminating the need for costly and time-consuming tooling systems. An additional notch tension specimen was employed to validate the stress-state sensitivity of the proposed calibration approach. By integrating full-field strain data from DIC with tensile test results, stress–strain relationships were directly obtained without finite element modeling. The results confirm the effectiveness of dogbone, mini shear, and plane strain tension specimens in achieving proportional loading path histories up to fracture initiation, with constant stress state evolution during deformation. Comparison of the HC and MMC damage criteria reveals similar fracture loci, with the HC model exhibiting slightly higher resistance between shear and uniaxial tension conditions. This study discusses the suitability of a fully experimental DIC-based methodology for the calibration of stress-state-dependent damage initiation criteria. The results highlight the ability of the proposed methodology as a simplified and lower time-consuming alternative to traditional numerical assisted frameworks.

Full article

(This article belongs to the Special Issue Feature Papers in Metal Failure Analysis)

►▼

Show Figures

Figure 1

Open AccessArticle

Effect of Composition and Temperature on the Viscosity and Electrical Conductivity of Ferronickel Slags

by

Kyu-Dong Lee, Wi-Geol Seo, Aman Gupta and Shi-Hoon Choi

Metals 2025, 15(11), 1237; https://doi.org/10.3390/met15111237 - 10 Nov 2025

Abstract

►▼

Show Figures

The electrical behavior of the electric smelting furnace (ESF) in ferronickel production is primarily governed by slag conductivity, which is closely linked to ionic mobility. This study examines the relationship between slag viscosity and electrical conductivity through experimental measurements and thermodynamic modeling. The

[...] Read more.

The electrical behavior of the electric smelting furnace (ESF) in ferronickel production is primarily governed by slag conductivity, which is closely linked to ionic mobility. This study examines the relationship between slag viscosity and electrical conductivity through experimental measurements and thermodynamic modeling. The viscosity and conductivity of actual ferronickel slags were measured, and synthetic slags with similar compositions were analyzed to isolate the effects of individual oxides. Results show that viscosity decreases with increasing basicity and FeO content, while solid-phase formation at lower temperatures sharply increases viscosity. Electrical conductivity rises with temperature due to reduced viscosity and enhanced ionic transport, and increases markedly up to 17 wt.% FeO owing to higher Fe ion concentrations and partial electronic conduction. Actual ferronickel slags exhibited slightly higher conductivity than synthetic ones, likely due to minor oxides such as NiO. These findings provide insight into the coupled thermophysical and electrical behavior of ferronickel slags, offering guidance for optimizing ESF efficiency and operation.

Full article

Figure 1

Journal Menu

► ▼ Journal Menu-

- Metals Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Photography Exhibition

- Instructions for Authors

- Special Issues

- Topics

- Sections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Society Collaborations

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Alloys, Materials, Metals

Development of Light Alloys with Excellent Mechanical Properties

Topic Editors: Zhirou Zhang, Isaac ChangDeadline: 31 December 2025

Topic in

JFB, Materials, Metals, Nanomanufacturing, Nanomaterials

Physical Methods for the Synthesis of Materials and Their Applications

Topic Editors: Vincenzo Amendola, Gregory GuisbiersDeadline: 31 March 2026

Topic in

Applied Sciences, Buildings, Construction Materials, CMD, Materials, Metals

Construction Materials: Corrosion, Prevention and Protection

Topic Editors: Sergio Lorenzi, Marco OrmelleseDeadline: 1 May 2026

Topic in

Analytica, Metals, Molecules, Processes, Separations

Advances in Solvent Extraction

Topic Editors: Guoquan Zhang, Weizao LiuDeadline: 31 May 2026

Conferences

Special Issues

Special Issue in

Metals

Editorial Board Members’ Collection Series: “Structural Adhesives for Similar or Dissimilar Materials”

Guest Editors: Aleksander Lisiecki, Guido Di BellaDeadline: 20 November 2025

Special Issue in

Metals

Advances in Metal Cutting and Machining Processes

Guest Editor: Nikolaos A. FountasDeadline: 20 November 2025

Special Issue in

Metals

Deformation of Metals and Alloys: Theory, Simulations and Experiments—2nd Edition

Guest Editors: Roberto G. A. Veiga, Alejandro ZúñigaDeadline: 20 November 2025

Special Issue in

Metals

Microstructure, Deformation and Fatigue Behavior in Metals and Alloys

Guest Editors: Yao Chen, Haizhou LiDeadline: 25 November 2025