Journal Description

Alloys

Alloys

is an international, peer-reviewed, open access journal on all aspects of alloys science and engineering, published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus and other databases.

- Journal Rank: CiteScore - Q2 (Metals and Alloys)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 19.1 days after submission; acceptance to publication is undertaken in 3.8 days (median values for papers published in this journal in the second half of 2025).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

- Alloys is a companion journal of Metals.

Latest Articles

Compositional Design of High-Entropy Alloys: Advances in Structural and Hydrogen Storage Materials

Alloys 2026, 5(1), 3; https://doi.org/10.3390/alloys5010003 - 7 Jan 2026

Abstract

High-entropy alloys (HEAs) present a vast compositional design space, characterized by four core effects—high configurational entropy, sluggish diffusion, severe lattice distortion, and the cocktail effect—which collectively underpin their exceptional potential for both structural and hydrogen storage applications. This mini-review synthesizes recent advances in

[...] Read more.

High-entropy alloys (HEAs) present a vast compositional design space, characterized by four core effects—high configurational entropy, sluggish diffusion, severe lattice distortion, and the cocktail effect—which collectively underpin their exceptional potential for both structural and hydrogen storage applications. This mini-review synthesizes recent advances in the compositional design of HEAs with emphasis on structural materials and hydrogen storage. Firstly, it provides an overview of the definition of HEAs and the roles of principal alloying elements, then synthesizes solid solution formation rules based on representative descriptors—atomic size mismatch, electronegativity difference, valence electron concentration, mixing enthalpy, and mixing entropy—together with their applicability limits and common failure scenarios. A brief introduction is provided to the preparation methods of arc melting and powder metallurgy, which have a strong interaction with the composition. The design–structure–property links are then consolidated for structural materials (mechanical properties) and for hydrogen storage materials (hydrogen storage performance). Furthermore, the rules for the combined design of control systems for HEAs and the associated challenges were further discussed, and the future development prospects of HEAs in structural materials and hydrogen storage were also envisioned.

Full article

(This article belongs to the Special Issue High-Entropy Alloys)

►

Show Figures

Open AccessArticle

A Novel Approach to Friction Extrusion of Aluminum Alloy 2024

by

Alexander Eliseev and Olga Novitskaya

Alloys 2026, 5(1), 2; https://doi.org/10.3390/alloys5010002 - 1 Jan 2026

Abstract

►▼

Show Figures

Friction extrusion technology was first developed and patented in 1991 at The Welding Institute, but it remained largely unexplored for many years. Over the past decade, this technology has gained popularity due to its ability to recycle chips and produce composite materials. Typically,

[...] Read more.

Friction extrusion technology was first developed and patented in 1991 at The Welding Institute, but it remained largely unexplored for many years. Over the past decade, this technology has gained popularity due to its ability to recycle chips and produce composite materials. Typically, in friction extrusion, the applied force and extrusion direction are opposite; this configuration is commonly referred to as reverse extrusion. Additionally, the tool feed rate is often used as a control parameter. However, this approach introduces technological challenges and results in a heterogeneous product structure. This paper proposes a novel friction extrusion method in which the applied force and extrusion direction are co-directional, and no tool is used. Moreover, a constant load is maintained throughout the extrusion process. Experimental results demonstrate that the proposed scheme is feasible and enables wire extrusion without macroscopic defects. Although the current efficiency is low and the maximum sample size achieved is 45 mm, the cross-sectional microhardness of the samples remains stable. The material strength reached approximately 90% of that of the initial 2024 aluminum alloy.

Full article

Figure 1

Open AccessArticle

DFT Calculation of the Electronic Properties of Cubic Ti3Sb Crystals with Adsorbed and/or Partially Substituted Nitrogen

by

Mirsalim M. Asadov, Solmaz N. Mustafaeva and Saida O. Mammadova

Alloys 2026, 5(1), 1; https://doi.org/10.3390/alloys5010001 - 24 Dec 2025

Abstract

►▼

Show Figures

Intermetallic alloys based on A15-type compounds, including cubic Ti3Sb, attract increasing interest due to their tunable electronic properties and potential for surface-related functional applications. Here, the interaction of nitrogen with Ti3Sb is systematically investigated using spin-polarized density functional theory

[...] Read more.

Intermetallic alloys based on A15-type compounds, including cubic Ti3Sb, attract increasing interest due to their tunable electronic properties and potential for surface-related functional applications. Here, the interaction of nitrogen with Ti3Sb is systematically investigated using spin-polarized density functional theory within the GGA-PBE approximation. Nitrogen adsorption was analyzed on the Ti3Sb (111), (100), and (110) surfaces by considering top, bridge, and hollow sites at different surface coverages. Low nitrogen coverage was found to minimize lateral adsorbate interactions, allowing reliable evaluation of single-atom adsorption energies. Among the studied configurations, nitrogen adsorption at the hollow site of the Ti3Sb (111) surface is energetically most favorable. In addition, partial substitution of Ti or Sb atoms by nitrogen in Ti3Sb supercells was examined to assess its effect on bulk electronic properties. Nitrogen incorporation leads to pronounced modifications of the electronic band structure, density of states, and local magnetic moments, with a strong dependence on crystallographic direction. The calculated results reveal distinct electronic anisotropies originating from direction-dependent band dispersion and associated effective carrier masses. These findings clarify the role of nitrogen in tailoring both surface and bulk electronic characteristics of Ti3Sb and provide a theoretical basis for the targeted design of A15-type intermetallic materials for sensing, catalytic, and energy-related applications.

Full article

Figure 1

Open AccessArticle

Directional Solidification of a Refractory Complex Concentrated Alloy (RCCA) Using Optical Floating Zone (OFZ) Solidification Processing: Implications for Alloy Design and Development

by

Nik Tankov, Claire Utton and Panos Tsakiropoulos

Alloys 2025, 4(4), 29; https://doi.org/10.3390/alloys4040029 - 18 Dec 2025

Abstract

Some cast metallic alloys for ultra-high-temperature structural applications can have better mechanical properties compared with Ni-based superalloys. Research on the directional solidification (DS) of such alloys is limited. The production of DS components of these alloys with “tailor-made” microstructures in different parts of

[...] Read more.

Some cast metallic alloys for ultra-high-temperature structural applications can have better mechanical properties compared with Ni-based superalloys. Research on the directional solidification (DS) of such alloys is limited. The production of DS components of these alloys with “tailor-made” microstructures in different parts of the component has not been considered. This paper attempts to address these issues. A bar of the RCCA/RM(Nb)IC with nominal composition 3.5Al–4Crc6Ge–1Hf–5Mo–36Nb–22Si–1.5Sn–20Ti–1W (at.%) was directionally grown using OFZ processing, where the growth rate R increased from 1.2 to 6 and then to 15 cm/h. The paper studies how the macrosegregation of the elements affected the microstructure in different parts of the bar. It was shown that the synergy of macrosegregation and growth rate produced microstructures from the edge to the centre of the OFZ bar and along the length of the OFZ bar that differed in type and chemical composition as R increased. Contamination with oxygen was confined to the “root” of the part of the bar that was grown with R = 1.2 cm/h. The concentrations of elements in the bar were related (a) to each of the parameters VEC, Δχ, and δ for different sections, (i) across the thickness and (ii) along the length of the bar, or to each other for different sections of the bar, and demonstrated the synergy and entanglement of processing, parameters, and elements. In the centre of the bar, the phases were the Nbss and Nb5Si3 for all R values. In the bar, the silicide formed with Nb/(Ti + Hf) less or greater than one. There was synergy of solutes in the solid solution and the silicide for all R values, and synergy and entanglement of the two phases. Owing to the synergy and entanglement of processing, parameters, elements, and phases, properties would “emerge” in each part of the bar. The creep and oxidation properties of the bar were calculated as guided by the alloy design methodology NICE. It was suggested that, in principle, a component based on a metallic UHTM with “functionally graded” composition, microstructure and properties could be directionally grown.

Full article

(This article belongs to the Collection Feature Paper Collection on Solidification, Deformation, and Mechanical Properties of Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Structural, Mechanical and Corrosion Properties of AZ31 Alloy Produced by Electron-Beam Additive Manufacturing

by

Veronika Utyaganova, Alexey Goncharov, Andrey Sliva, Dmitry Shishkin, Boris Zotov, Leonid Fedorenko and Viktor Semin

Alloys 2025, 4(4), 28; https://doi.org/10.3390/alloys4040028 - 5 Dec 2025

Abstract

►▼

Show Figures

A thin-walled product made of AZ31 magnesium alloy was successfully fabricated using wire-feed electron-beam additive manufacturing. The microstructure of the initial wire, used as a precursor, comprises a α-Mg(Al, Zn) solid solution and a minor amount of the Al8Mn5 intermetallic

[...] Read more.

A thin-walled product made of AZ31 magnesium alloy was successfully fabricated using wire-feed electron-beam additive manufacturing. The microstructure of the initial wire, used as a precursor, comprises a α-Mg(Al, Zn) solid solution and a minor amount of the Al8Mn5 intermetallic phase. The microstructure of the as-printed AZ31 alloy exhibits a three-phase structure: α-Mg(Al, Zn), Al8Mn5, and β-Mg17Al12. It was proposed that the secondary β-phase was formed via a primary solidification process upon the cooling of the welded layers. The texture effect was evident in the <01

Figure 1

Open AccessArticle

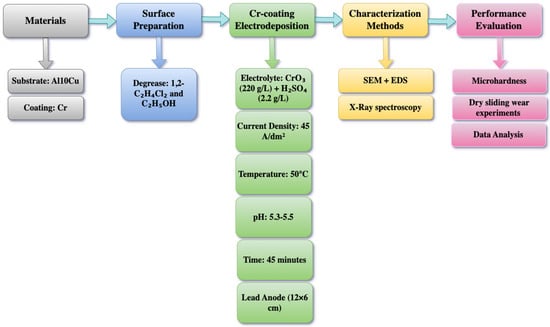

Dry Sliding Wear Behavior and Microstructural Characterization of Chromium-Coated Al10Cu Alloy

by

Mihail Kolev, Vladimir Petkov, Rumyana Lazarova, Veselin Petkov, Krasimir Kolev and Shaban Uzun

Alloys 2025, 4(4), 27; https://doi.org/10.3390/alloys4040027 - 3 Dec 2025

Abstract

Aluminum–copper alloys have garnered significant attention in modern engineering applications due to their exceptional strength-to-weight ratio, corrosion resistance, and thermal conductivity properties. This study investigates the tribological performance optimization of Al10Cu alloys through chromium coating deposition, focusing on coefficient of friction and mass

[...] Read more.

Aluminum–copper alloys have garnered significant attention in modern engineering applications due to their exceptional strength-to-weight ratio, corrosion resistance, and thermal conductivity properties. This study investigates the tribological performance optimization of Al10Cu alloys through chromium coating deposition, focusing on coefficient of friction and mass wear analysis in dry sliding conditions. Cr-coated Al10Cu alloys were fabricated through powder metallurgy and electrodeposition techniques, with comprehensive tribological characterization performed using scanning electron microscopy combined with energy-dispersive X-ray spectroscopy, X-ray diffraction analysis, microhardness measurements, and dry sliding wear testing. The chromium coating exhibited exceptional surface hardness of 720.9 HV, representing a remarkable 15-fold improvement over the uncoated Al10Cu matrix hardness. Tribological evaluation demonstrated outstanding wear resistance with the Cr-coated Al10Cu system achieving only 0.10 mg mass loss compared to 0.55 mg for the uncoated alloy, representing an exceptional 81.8% reduction in material removal. Despite a nominal increase in the coefficient of friction from 0.618 to 0.733, the chromium coating effectively transformed the wear mechanism from severe material removal to a controlled mild wear regime. The results establish the Cr-coated Al10Cu system as a highly effective solution for applications requiring extended operational lifespans under dry sliding conditions.

Full article

(This article belongs to the Collection Feature Paper Collection on Solidification, Deformation, and Mechanical Properties of Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Reduction Kinetics of Vanadium-Titanium Magnetite Sinter When Shale Gas Is Injected into the Blast Furnace

by

Xudong Gao, Jian Chen and Yuelin Qin

Alloys 2025, 4(4), 26; https://doi.org/10.3390/alloys4040026 - 4 Nov 2025

Abstract

►▼

Show Figures

Although the composition of hearth gas in a blast furnace is still composed of CO, H2, and N2, after injecting shale gas, which replaces some pulverized coal, the proportion of CO, H2, and N2 in the

[...] Read more.

Although the composition of hearth gas in a blast furnace is still composed of CO, H2, and N2, after injecting shale gas, which replaces some pulverized coal, the proportion of CO, H2, and N2 in the hearth gas will change with the introduction of H2. Further, the reduction process of vanadium-titanium magnetite sinter (VTMS) will be significantly impacted. Hence, the energy–mass balance and replacement ratio model was used to calculate the composition of hearth gas under different injection conditions using production data from a VTM blast furnace in the Panxi area of China. In order to investigate how shale gas injection affects the reduction process, the weight loss rates of VTMS under various reduction atmospheres were obtained through a series of thermogravimetric experiments. Additionally, X-ray diffraction (XRD) analysis was performed on select reduced samples to determine the alterations in sinter phases before and after the reaction. The impact of shale gas injection on the reduction process of VTMS was analyzed by phase transformation and kinetic analysis. The results of the research show that the reduction process of VTMS is improved with the increase in shale gas injection. Using the ln-ln analytical method, the linear relationship between ln(−ln(1 − α)) and lnt under different cases was found. The reaction mechanism of VTMS under shale gas injection circumstances is characterized by random nucleation, which is subsequently followed by growth. The integration formula associated with its dynamic function is G(α) = [−ln(1 − α)]3/4.

Full article

Figure 1

Open AccessArticle

Structural and Phase Characteristics of LaNi5-Based Materials Modified with Ti, Mn, and Co

by

Arman Miniyazov, Mazhyn Skakov, Nuriya Mukhamedova, Igor Sokolov, Aisara Sabyrtayeva, Ospan Oken, Riza Zhakiya and Zhanna Ospanova

Alloys 2025, 4(4), 25; https://doi.org/10.3390/alloys4040025 - 4 Nov 2025

Cited by 1

Abstract

►▼

Show Figures

In this work, the results of the structural and phase state of LaNi5-based alloys modified with Ti, Mn, and Co elements, obtained by mechanical alloying and subsequent spark plasma sintering, are presented. X-ray diffraction analysis was carried out to determine the

[...] Read more.

In this work, the results of the structural and phase state of LaNi5-based alloys modified with Ti, Mn, and Co elements, obtained by mechanical alloying and subsequent spark plasma sintering, are presented. X-ray diffraction analysis was carried out to determine the phase composition, lattice parameters, microstrain, and average crystallite size, as well as to study the morphology and microstructure of the synthesized samples. It was established that the ball-to-powder ratio (BPR) and the milling speed affect the degree of intermetallic phase formation and the level of accumulated microstrains. The optimal mechanical alloying parameters make it possible to form the necessary precursor components for subsequent spark plasma sintering (SPS). It was determined that the SPS process effectively promotes the formation of intermetallic phases such as TiNi, LaNi4Mn, LaNi3Mn2, and LaNi4Co, ensuring high crystallinity and a reduction in defects accumulated during mechanical alloying. The morphology and microstructure of the samples with titanium, manganese, and cobalt additions showed that at the mechanical alloying stage, all systems are characterized by a dispersed and agglomerated structure, a wide particle size distribution, and a developed surface. After SPS, all series exhibited material consolidation and the formation of a dense matrix with distinct grain boundaries.

Full article

Figure 1

Open AccessArticle

Microstructural Inheritance in Thick Slabs of Low-Carbon Microalloyed Steel and Its Impact on the Quality of Heavy Plates

by

Andrei Filatov, Eugene Goli-Oglu, Vitaliy Naumenko and Alexander Kazarin

Alloys 2025, 4(4), 24; https://doi.org/10.3390/alloys4040024 - 23 Oct 2025

Abstract

►▼

Show Figures

The quality of heavy plates produced from low-carbon steel is directly linked to the structural characteristics inherited from the initial continuously cast thick slabs. This study explores how different casting technologies affect the morphology and distribution of allotriomorphic ferrite along prior austenite grain

[...] Read more.

The quality of heavy plates produced from low-carbon steel is directly linked to the structural characteristics inherited from the initial continuously cast thick slabs. This study explores how different casting technologies affect the morphology and distribution of allotriomorphic ferrite along prior austenite grain boundaries (PAGBs) within these slabs. Using quantitative microstructural analysis based on advanced computer vision techniques (OpenCV), the research identifies significant variations in ferrite boundary thickness and volume fraction associated with different casting methods. These microstructural differences strongly correlate with variations in Charpy V-notch impact energy (KVZ20) and susceptibility to microcrack formation during subsequent rolling processes. The results obtained allow us to evaluate the influence of the cast structure on the formation of the initial structural characteristics of the material, especially on the formation of microcracks of the slab microstructure and their propagation during further processing.

Full article

Figure 1

Open AccessArticle

Effect of the Cooling Rate on the Solidification Structure and Phase of a 2:17 Samarium–Cobalt Alloy

by

Zhi Zhu, Yikun Fang, Wei Wu and Bo Zhao

Alloys 2025, 4(4), 23; https://doi.org/10.3390/alloys4040023 - 21 Oct 2025

Cited by 1

Abstract

►▼

Show Figures

Understanding the way samarium–cobalt alloys solidify at varying cooling rates and the regularities in alloying element distribution is crucial for optimizing subsequent homogenization and annealing processes, leading to an enhancement in the overall quality of the product. The study investigates the effects of

[...] Read more.

Understanding the way samarium–cobalt alloys solidify at varying cooling rates and the regularities in alloying element distribution is crucial for optimizing subsequent homogenization and annealing processes, leading to an enhancement in the overall quality of the product. The study investigates the effects of rapid water-cooled copper mold (600 °C/min), medium-speed copper mold (100 °C/min), and slow furnace cooling (10 °C/min) on the microstructural evolution, element distribution, and phase transformation of samarium–cobalt (Sm-Co) alloys. The results of the research show that the phase transition temperatures obtained via differential scanning calorimetry (DSC) closely matched those observed in situ by high-temperature laser scanning confocal microscopy (HT-LSCM). Higher cooling rates resulted in notable dendritic refinement and reduced precipitate size. Elemental analysis revealed that Co and Fe exhibited negative segregation, whereas Sm, Cu, and Zr showed positive segregation, with segregation intensity increasing alongside the cooling rate. The principal phases identified included Cu-rich and Zr-rich constituents, the matrix phase, and a gray phase morphologically distinct from the matrix. These correspond to the (Sm, Co, Fe, Cu, Zr)5 phase, (Sm, Zr)(Co, Fe, Cu)3 phase, Sm2(Co, Fe, Cu, Zr)17 phase, and Sm(Co, Fe, Cu, Zr)7 phase. The phase constitution remained consistent across different cooling rates.

Full article

Figure 1

Open AccessArticle

Deep Learning-Driven Insights into Hardness and Electrical Conductivity of Low-Alloyed Copper Alloys

by

Mihail Kolev, Juliana Javorova, Tatiana Simeonova, Yasen Hadjitodorov and Boyko Krastev

Alloys 2025, 4(4), 22; https://doi.org/10.3390/alloys4040022 - 10 Oct 2025

Abstract

►▼

Show Figures

Understanding the intricate relationship between composition, processing conditions, and material properties is essential for optimizing Cu-based alloys. Machine learning offers a powerful tool for decoding these complex interactions, enabling more efficient alloy design. This work introduces a comprehensive machine learning framework aimed at

[...] Read more.

Understanding the intricate relationship between composition, processing conditions, and material properties is essential for optimizing Cu-based alloys. Machine learning offers a powerful tool for decoding these complex interactions, enabling more efficient alloy design. This work introduces a comprehensive machine learning framework aimed at accurately predicting key properties such as hardness and electrical conductivity of low-alloyed Cu-based alloys. By integrating various input parameters, including chemical composition and thermo-mechanical processing parameters, the study develops and validates multiple machine learning models, including Multi-Layer Perceptron with Production-Aware Deep Architecture (MLP-PADA), Deep Feedforward Network with Multi-Regularization Framework (DFF-MRF), Feedforward Network with Self-Adaptive Optimization (FFN-SAO), and Feedforward Network with Materials Mapping (FFN-TMM). On a held-out test set, DFF-MRF achieved the best generalization (R2_test = 0.9066; RMSE_test = 5.3644), followed by MLP-PADA (R2_test = 0.8953; RMSE_test = 5.7080) and FFN-TMM (R2_test = 0.8914; RMSE_test = 5.8126), with FFN-SAO slightly lower (R2_test = 0.8709). Additionally, a computational performance analysis was conducted to evaluate inference time, memory usage, energy consumption, and batch scalability across all models. Feature importance analysis was conducted, revealing that aging temperature, Cr, and aging duration were the most influential factors for hardness. In contrast, aging duration, aging temperature, solution treatment temperature, and Cu played key roles in electrical conductivity. The results demonstrate the effectiveness of these advanced machine learning models in predicting critical material properties, offering insightful advancements for materials science research. This study introduces the first controlled, statistically validated, multi-model benchmark that integrates composition and thermo-mechanical processing with deployment-grade profiling for property prediction of low-alloyed Cu alloys.

Full article

Figure 1

Open AccessArticle

Microstructure Evolution and Mechanical Performance of AA6061-7075 Heterogeneous Composite Fabricated via Additive Friction Stir Deposition

by

Qian Qiao, Hongchang Qian, Zhong Li, Dawei Guo, Chi Tat Kwok, Shufei Jiang, Dawei Zhang and Lam Mou Tam

Alloys 2025, 4(4), 21; https://doi.org/10.3390/alloys4040021 - 30 Sep 2025

Abstract

►▼

Show Figures

An AA6061-7075 composite with a heterogeneous structure was fabricated via the additive friction stir deposition (AFSD) method, and in situ processing data were monitored during the manufacturing process. The results show that the cross-section of the composite subjected to AFSD exhibits a lower

[...] Read more.

An AA6061-7075 composite with a heterogeneous structure was fabricated via the additive friction stir deposition (AFSD) method, and in situ processing data were monitored during the manufacturing process. The results show that the cross-section of the composite subjected to AFSD exhibits a lower degree of plastic deformation behavior compared to the surface and side of the composite, owing to serious heat accumulation during the layer-by-layer stacking process. The denser, heterogeneous structure, consisting of finer (softer) and coarser (harder) grains, which correspond to AA6061 and AA7075, was formed according to transmission electron microscopy (TEM) analysis. Furthermore, the obtained composite subjected to AFSD in this work presents outstanding mechanical properties compared to other as-fabricated AA6061/AA7075 depositions acquired by other additive manufacturing methods along the horizontal building direction, with the ultimate tensile strength (266 MPa) being 89% of that of AA6061-T6 and the elongation 1.1 times that of AA7075-T6. The findings provide useful guidelines for the in situ preparation of Al-based composites and offer ideas for manufacturing high-strength heterostructures for large-scale practical engineering applications.

Full article

Figure 1

Open AccessArticle

Inhibition of Microbiologically Influenced Corrosion of 304 Stainless Steel by Artemisia annua L. in Simulated Seawater

by

Gloria Zlatić Jelić, Ivana Martinović and Zora Pilić

Alloys 2025, 4(4), 20; https://doi.org/10.3390/alloys4040020 - 23 Sep 2025

Abstract

The combination of electrochemical, surface, and spectroscopic techniques revealed that Pseudomonas aeruginosa biofilm accelerated corrosion of 304 stainless steel (SS), leading to localized pitting with depths up to 3.75 μm. Such damage did not occur on 304 SS treated with P. aeruginosa in

[...] Read more.

The combination of electrochemical, surface, and spectroscopic techniques revealed that Pseudomonas aeruginosa biofilm accelerated corrosion of 304 stainless steel (SS), leading to localized pitting with depths up to 3.75 μm. Such damage did not occur on 304 SS treated with P. aeruginosa in the presence of Artemisia annua L. extract, or in sterile seawater. Introducing A. annua into biotic seawater hindered biofilm development and prevented the formation of porous Fe(III) corrosion products. Instead, a compact Fe3O4 layer formed, indicating a shift in corrosion product morphology and stability. ATR-FTIR analysis confirmed phenolic groups from the extract were adsorbed onto the steel interface, supporting the dual inhibitory role of A. annua through both surface modification and antimicrobial action. A. annua extract demonstrated a 74.4 ± 4.4% reduction in MIC-induced corrosion of 304 SS in marine conditions.

Full article

(This article belongs to the Special Issue New Alloys for Surface Engineered Coatings, Interfaces and Films)

►▼

Show Figures

Graphical abstract

Open AccessArticle

The Effect of Interrupted Loading on the Lüder Phenomena in AISI 1524 Steel Alloy

by

Mohamed Almatroushi, Salman Pervaiz and Wael A. Samad

Alloys 2025, 4(3), 19; https://doi.org/10.3390/alloys4030019 - 17 Sep 2025

Abstract

►▼

Show Figures

Under specific temperature and strain rate conditions, certain materials, such as low-carbon steels and select magnesium and aluminum alloys, experience a localized deformation phenomenon known as the Lüders effect. This behavior manifests as a well-defined yield point, after which the stress–strain response transitions

[...] Read more.

Under specific temperature and strain rate conditions, certain materials, such as low-carbon steels and select magnesium and aluminum alloys, experience a localized deformation phenomenon known as the Lüders effect. This behavior manifests as a well-defined yield point, after which the stress–strain response transitions into a plateau phase. Experimentally observed through full-field tests, the Lüders effect appears in the form of a band(s). This manuscript presents, for the first time, a systematic study of interrupted loading on the Lüders phenomenon in AISI 1524 hot-rolled steel, using uniaxial tensile testing combined with digital image correlation (DIC). While similar approaches have been applied to other alloys, no prior work has reported on AISI 1524 steel under unloading–reloading cycles during the Lüders plateau. Interruptions in loading involved unloading at 25%, 50%, and 75% of the total plateau region independently until stress approached zero, followed by reloading at the same rate until failure. Each unloading case was subjected to two tests, alongside two additional control tests where loading proceeded without interruption. Based on the findings of this study, it can be inferred that the Lüders phenomenon in AISI 1524 steel exhibits a decrease in strain intensity upon unloading, along with an extension of the Lüders plateau when interrupted loading occurs up to halfway through the plateau region. However, implementing an interrupted loading regime at three-quarters of the plateau had minimal to no discernible effect on the phenomenon. The majority of samples displayed two Lüders bands, a few exhibited either a single band or three bands, suggesting a complex relationship with material heterogeneity and specific impurities present in each sample. The novelty of this work lies in showing how controlled unloading–reloading cycles alter both the propagation and characteristics of Lüders bands in AISI 1524 steel.

Full article

Figure 1

Open AccessReview

Recent Advances in Ceramic-Reinforced Aluminum Metal Matrix Composites: A Review

by

Surendra Kumar Patel and Lei Shi

Alloys 2025, 4(3), 18; https://doi.org/10.3390/alloys4030018 - 30 Aug 2025

Cited by 11

Abstract

Aluminium metal matrix composites (AMMCs) incorporate aluminium alloys reinforced with fibres (continuous/discontinuous), whiskers, or particulate. These materials were engineered as advanced solutions for demanding sectors including construction, aerospace, automotive, and marine. Micro- and nano-scale reinforcing particles typically enable attainment of exceptional combined properties,

[...] Read more.

Aluminium metal matrix composites (AMMCs) incorporate aluminium alloys reinforced with fibres (continuous/discontinuous), whiskers, or particulate. These materials were engineered as advanced solutions for demanding sectors including construction, aerospace, automotive, and marine. Micro- and nano-scale reinforcing particles typically enable attainment of exceptional combined properties, including reduced density with ultra-high strength, enhanced fatigue strength, superior creep resistance, high specific strength, and specific stiffness. Microstructural, mechanical, and tribological characterizations were performed, evaluating input parameters like reinforcement weight percentage, applied normal load, sliding speed, and sliding distance. Fabricated nanocomposites underwent tribometer testing to quantify abrasive and erosive wear behaviour. Multiple investigations employed the Taguchi technique with regression modelling. Analysis of variance (ANOVA) assessed the influence of varied test constraints. Applied load constituted the most significant factor affecting the physical/statistical attributes of nanocomposites. Sliding velocity critically governed the coefficient of friction (COF), becoming highly significant for minimizing COF and wear loss. In this review, the reinforcement homogeneity, fractural behaviour, and worn surface morphology of AMMCswere examined.

Full article

(This article belongs to the Topic Microstructure and Properties in Metals and Alloys, 3rd Volume)

►▼

Show Figures

Figure 1

Open AccessArticle

Modeling and Analysis of Corrosion of Aluminium Alloy 6060 Using Electrochemical Impedance Spectroscopy (EIS)

by

Aikaterini Baxevani, Eleni Lamprou, Azarias Mavropoulos, Fani Stergioudi, Nikolaos Michailidis and Ioannis Tsoulfaidis

Alloys 2025, 4(3), 17; https://doi.org/10.3390/alloys4030017 - 29 Aug 2025

Cited by 2

Abstract

►▼

Show Figures

Aluminum is widely used in many industries like automotive, aerospace and construction because of its low weight, good mechanical strength and resistance to corrosion. This resistance comes mainly from a passive oxide layer that forms on its surface. However, when aluminum is exposed

[...] Read more.

Aluminum is widely used in many industries like automotive, aerospace and construction because of its low weight, good mechanical strength and resistance to corrosion. This resistance comes mainly from a passive oxide layer that forms on its surface. However, when aluminum is exposed to harsh environments, especially those containing chloride ions in marine environments, this layer can break down and lead to localized corrosion, such as pitting. This study examined aluminum profiles at different processing stages, including homogenization and aging, anodizing and pre-anodizing followed by painting. Corrosion behavior of samples was studied using two electrochemical methods. Potentiodynamic polarization was used to measure corrosion rate and current density, while Electrochemical Impedance Spectroscopy (EIS) helped to understand the behavior of protective layers and corrosion progression. Tests were carried out in a 3.5% NaCl solution at room temperature. EIS results were analyzed using equivalent circuit models to better understand electrochemical processes. Overall, this study shows how surface treatment affects corrosion resistance and highlights advantages of EIS in studying corrosion behavior in a more reliable and repeatable way.

Full article

Figure 1

Open AccessReview

The Role of Metal Foams for Sustainability and Energy Transition

by

Alessandra Ceci, Girolamo Costanza, Fabio Giudice, Andrea Sili and Maria Elisa Tata

Alloys 2025, 4(3), 16; https://doi.org/10.3390/alloys4030016 - 13 Aug 2025

Abstract

The global pursuit of a sustainable and decarbonized energy landscape requires the development of novel materials capable of supporting lightweight construction, advanced energy conversion, storage, and thermal management technologies. Among these, metal foams have emerged as a versatile class of porous materials, offering

[...] Read more.

The global pursuit of a sustainable and decarbonized energy landscape requires the development of novel materials capable of supporting lightweight construction, advanced energy conversion, storage, and thermal management technologies. Among these, metal foams have emerged as a versatile class of porous materials, offering a unique combination of low density, high surface area, three-dimensional (3D) interconnected porosity, and favorable thermal and electrical conductivities. These attributes make them highly suitable for a broad range of applications critical to the ongoing energy transition, assuming an increasingly central role in enabling clean, efficient, and resilient energy infrastructures. From this key perspective, the present review highlights the relevance of the adoption of metal foams in several fields crucial for the energy transition. By presenting methodologies and outcomes of research results, mainly from the last five years, the paper underscores the potential of low-weight, high-surface, and high-performance porous materials in contemporary and future industry, supporting sustainable development and, more generally, energy transition and circular economy. The approach also aims to minimize negative impacts and promote sustainability, for example, by recycling and transforming waste materials.

Full article

(This article belongs to the Special Issue Lightweight Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Reactive Sintering of Cemented Carbides

by

Victor I. Stanciu, Alexandre Mégret, Anne Mouftiez, Véronique Vitry and Fabienne Delaunois

Alloys 2025, 4(3), 15; https://doi.org/10.3390/alloys4030015 - 25 Jul 2025

Abstract

Cemented carbides are among the primary materials for tools and wear parts. Today, energy prices and carbon emissions have become key concerns worldwide. Cemented carbides consist of tungsten carbide combined with a binder, typically cobalt, nickel, or more recently, various high-entropy alloys. Producing

[...] Read more.

Cemented carbides are among the primary materials for tools and wear parts. Today, energy prices and carbon emissions have become key concerns worldwide. Cemented carbides consist of tungsten carbide combined with a binder, typically cobalt, nickel, or more recently, various high-entropy alloys. Producing tungsten carbide involves reducing tungsten oxide, followed by carburization of tungsten at 1400 °C under a hydrogen atmosphere. The tungsten carbide produced is then mixed with the binder, milled to achieve the desired particle size, and granulated to ensure proper flow for pressing and shaping. This study aims to bypass the tungsten carburizing step by mixing tungsten, carbon, and cobalt; shaping the mixture; and then applying reactive sintering, which will convert tungsten into carbide and consolidate the parts. The mixtures were prepared by planetary ball milling for 10 h under different conditions. Tests demonstrated that tungsten carburization successfully occurs during sintering at 1450 °C for 1 h. The samples exhibit a typical cemented carbide microstructure, characterized by prismatic grains with an average size of 0.32 μm. Densification reached 92%, hardness is approximately 1800 HV30, and toughness is 10.9 ± 1.15 MPa·m1/2.

Full article

(This article belongs to the Special Issue New Alloys for Surface Engineered Coatings, Interfaces and Films)

►▼

Show Figures

Figure 1

Open AccessArticle

Microstructure, Phase Transformation, and Mechanical Properties of Ni-Ti-Hf-La Alloys

by

Dorjsuren Bolormaa and Maashaa Dovchinvanchig

Alloys 2025, 4(3), 14; https://doi.org/10.3390/alloys4030014 - 21 Jul 2025

Abstract

This research investigates the effects of the addition of the rare-earth element La on the microstructure, phase transformation, and mechanical properties of Ni50Ti30Hf20−xLax (x = 0, 0.5, 1, 2) alloys. The results show that a primary

[...] Read more.

This research investigates the effects of the addition of the rare-earth element La on the microstructure, phase transformation, and mechanical properties of Ni50Ti30Hf20−xLax (x = 0, 0.5, 1, 2) alloys. The results show that a primary matrix composed of Ni-Ti-Hf and featuring La-rich second phases formed. The temperature at which the martensitic phase transformation starts decreases with an increase in La content. As the amount of La increases, hardness decreases slightly, while the elastic modulus increases.

Full article

(This article belongs to the Topic Microstructure and Properties in Metals and Alloys, 3rd Volume)

►▼

Show Figures

Figure 1

Open AccessArticle

Ultrasonic-Assisted Face Turning of C45 Steel: An Experimental Investigation on Surface Integrity

by

Thanh-Trung Nguyen

Alloys 2025, 4(3), 13; https://doi.org/10.3390/alloys4030013 - 10 Jul 2025

Abstract

►▼

Show Figures

This study investigates the effect of ultrasonic vibration applied in the cutting speed direction on surface quality during face turning of C45 steel. The experiments were performed using an ultrasonic generator operating at a frequency of 20 kHz with an amplitude of approximately

[...] Read more.

This study investigates the effect of ultrasonic vibration applied in the cutting speed direction on surface quality during face turning of C45 steel. The experiments were performed using an ultrasonic generator operating at a frequency of 20 kHz with an amplitude of approximately 10 µm. The cutting parameters used in the experiments included spindle speeds of 700, 1100, and 1300 rpm, feed rates of 0.1 and 0.15 mm/rev, while the depth of cut was fixed at 0.2 mm. Surface quality was evaluated based on the roughness parameters Ra and Rz, as well as surface topography was observed using a Keyence VHX-7000 digital microscope. The results show that ultrasonic-assisted face turning (UAFT) significantly improves surface finish, particularly in the central region of the workpiece where the cutting speed is lower and built-up edge (BUE) formation is more likely. The lowest Ra value recorded was 0.91 µm, representing a 71% reduction compared to conventional turning (CT). Furthermore, at the highest spindle speed (1300 rpm), the standard deviations of both Ra and Rz were minimal, indicating improved surface consistency due to the suppression of BUE by ultrasonic vibration. Topographical observations further confirmed that UAFT generated regular and periodic surface patterns, in contrast to the irregular textures observed in CT.

Full article

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

6 November 2025

MDPI Launches the Michele Parrinello Award for Pioneering Contributions in Computational Physical Science

MDPI Launches the Michele Parrinello Award for Pioneering Contributions in Computational Physical Science

2 February 2026

MDPI INSIGHTS: The CEO's Letter #31 - MDPI 30 Years, 500 Journals, UK Summit, Z-Forum Conference, APE

MDPI INSIGHTS: The CEO's Letter #31 - MDPI 30 Years, 500 Journals, UK Summit, Z-Forum Conference, APE

Topics

Topic in

Alloys, Applied Sciences, Coatings, Crystals, Materials

Environmental Sensitivity and Safety Assessment of Materials, 2nd Edition

Topic Editors: Jian Chen, Daokui Xu, Fanjiang Meng, James Noël, Baojie WangDeadline: 25 February 2026

Topic in

Materials, Applied Sciences, JCM, Alloys

Implants in Orthopaedics and Dentistry: Recent Achievements and Future Perspectives

Topic Editors: Mateusz Kopec, Zbigniew Kowalewski, Grzegorz Szczȩsny, Gaetano MarenziDeadline: 30 April 2026

Topic in

Alloys, Applied Mechanics, Crystals, J. Compos. Sci., Powders, Nanomaterials

Multiscale Characterization, Mechanical Behavior and Computational Simulation of Bulk Materials, Metallic Powders and/or Nanoparticles

Topic Editors: Xiangnan Pan, Qing Peng, Hui Qi, Raj DasDeadline: 30 June 2026

Topic in

Materials, Metals, Applied Sciences, JMMP, Alloys

Numerical Modelling on Metallic Materials, 2nd Edition

Topic Editors: Shuwen Wen, Yongle Sun, Xin ChenDeadline: 31 August 2026

Conferences

Special Issues

Special Issue in

Alloys

Lightweight Alloys

Guest Editor: Konstantinos GeorgarakisDeadline: 31 August 2026

Special Issue in

Alloys

High-Entropy Alloys

Guest Editors: Peter Hodgson, Daniel Fabijanic, Jithin JosephDeadline: 31 December 2026

Special Issue in

Alloys

New Alloys for Surface Engineered Coatings, Interfaces and Films

Guest Editors: Christopher C. Berndt, Andrew AngDeadline: 31 December 2026

Topical Collections

Topical Collection in

Alloys

Feature Paper Collection on Solidification, Deformation, and Mechanical Properties of Alloys

Collection Editors: Nikki Stanford, Panos Tsakiropoulos, Hans-Eckhardt Schaefer, Yingzhi Chen