Abstract

The present study explores the production of metallized titanomagnetite briquettes, with a view to addressing two key issues. Firstly, it seeks to address the growing shortage of high-quality iron-bearing raw materials. Secondly, it looks at how to meet the increasingly stringent environmental constraints. The conventional blast-furnace treatment of titanomagnetite is hindered by the formation of refractory Ti-rich slags. It is hereby proposed that a single-cycle briquetting process in conjunction with a thermal reduction route should be utilized. This approach enables precise regulation of the Fe/flux ratio. Experiments were conducted on a low-grade titanomagnetite concentrate (68.5% Fe) from the Pervouralsk deposit (Russia). Cylindrical briquettes (D 15–20 mm, h 8–10 mm) were subjected to a pressure of 300 MPa during the pressing process, with the utilization of diverse binders comprising rubber cement, CaO, graphite + water, and basic oxygen-furnace (BOF) slag + sodium silicate. Following an oxidative pre-heating process at 1300 °C for two hours, followed by a gas-based reduction process at 1050 °C for three hours, with a CO/N2 ratio of 90/10, the products demonstrated an oxidation rate of 85–95% and a cold compression strength of 16–80 MPa. The highest observed strength (80 MPa) was obtained with a binder comprising CaO·MgO·2SiO2 (diopside/merwinite), which forms a low-viscosity melt, fills 90% of pores and crystallizes as acicular Mg-SFCA-I during cooling. Conversely, the CaO·TiO2 and FeO·TiO2 + Fe3C associations yield brittle structures and a maximum strength of 16 MPa. The optimum briquette (0.55% CaO, D/H = 20/10 mm) exhibited a 95.7% metallization degree, a compressive strength of 48.9 MPa, and dimensional changes within acceptable limits, thus fulfilling the requirements for electric arc furnace feedstock. Further research is required in the form of a full Life Cycle Assessment and pilot-scale testing. However, the results obtained thus far confirm that titanomagnetite briquettes with a binder consisting of CaO, MgO and SiO2 are a promising alternative to pellets for low-carbon steelmaking.

1. Introduction

1.1. Problem Statement and Research Background

In the context of the escalating paucity of high-quality iron ore materials and the imposition of increasingly stringent environmental restrictions within the metallurgical industry, there is an imperative to identify alternative sources of iron and efficacious methods for their processing. Titanomagnetite ores represent a relatively prevalent titanium-vanadium iron ore raw material, with industrial reserves predominantly concentrated in Panzhihua (China), the Urals and Kola Peninsula (Russia), New Zealand, Malaysia, and Egypt [1,2,3]. The ores are constituted of fine-grained (20–150 µm) intergrown aggregates of magnetite and ulveshpinel Fe2TiO4 with ilmenite inclusions [4]. The total iron content ranges from 52 to 62%, with titanium dioxide (TiO2) ranging from 3 to 18% and vanadium pentoxide (V2O5) ranging from 0.4 to 1.8% [1]. The composition of the ore in question renders titanomagnetite a valuable polymetallic resource; however, it simultaneously engenders technological difficulties in the context of conventional blast furnace processing.

The primary issue pertains to refractory slag, which is predominantly attributable to the presence of titanium carbides and oxynitrides. These compounds undergo vigorous formation during the interaction of slag with the coke gas burner. Consequently, the furnace becomes clogged with refractory titanium compounds, thereby reducing the filterability of coke gas burner and hindering the merging and flow of the liquid phases formed (i.e., drops of cast iron and slag) [5]. Furthermore, the presence of vanadium in cast iron necessitates additional processing, thereby increasing the cost of steel [2,6]. Pellets and sinter produced from titanomagnetite are characterized by low cold strength (i.e., they have a strength of less than 1500 N/pellet when a minimum of 2200 N/pellet is required, i.e., a tumble index (TI) of less than 74%, with a required value of more than 78%, according to ISO 3271 [7]). Furthermore, they are difficult to reduce (i.e., the degree of metallization from magnetite is up to 25%, since in the presence of TiO2, the equilibrium pressure of CO2/CO shifts, causing TiO2 to form thin (1–3 μm) films on the FeO surface, thus blocking CO access) [8]. Consequently, the quest for alternative methodologies for the preparation of raw materials for metallurgical processing continues to be a matter of significance.

One such method is briquetting, which involves the production of compressed materials (briquettes) of uniform mass and shape with specified physical and mechanical properties from a crushed mixture of ore (concentrate) and binder, without a sintering stage. The technology has the capacity to combine briquetting and reduction in a single process cycle (with a carbon-containing reducing agent) and allows for the precise composition of the final product [9,10,11]. The application of pressure at a range of 50–200 MPa results in a briquette density of 1.8–3.4 g/cm3, which is adequate for transportation and subsequent processing [12,13]. Self-hardening briquettes with cement or liquid glass binders have been observed to undergo a reduction in strength at temperatures ranging from 800 to 1000 °C [10]. In contrast, hot ore-coal briquettes, which possess adequate strength, have been shown to achieve a metallization degree of 70–92% [14,15,16].

The mechanism of carbothermal reduction of titanomagnetite at temperatures ranging from 900 to 1300 °C involves the sequential conversion of Fe3O4 to FeO and then Fe, whilst simultaneously undergoing the decomposition of Fe2TiO4 into metallic iron and titanium dioxide [17,18]. The activation energy of the transformation of FeO to Fe is reported to be within the range of 120–160 kJ/mol. However, the introduction of 2–3% CaF2 has been shown to reduce this energy to 95 kJ/mol, a result attributable to the destruction of the refractory silicate film on the surface of the particles [19]. At partial carbon monoxide pressures of less than 0.3, the formation of titanium carbides and carbonitrides may occur, thereby impeding the separation of iron and titanium [20,21].

The reduction of hydrogen at temperatures ranging from 700 to 1000 °C is selective in nature. This process leads to the complete reduction of iron oxides, while titanium dioxide (TiO2) remains present in the slag. This phenomenon facilitates the subsequent extraction of vanadium and titanium into separate products [21,22,23]. The degree of metallization achieved is 88–94%, yet this process necessitates protracted exposure times of 2–4 h, in addition to maintaining a low water vapor content of <5% [22,23]. In the context of industrial applications, the utilization of pure hydrogen is not currently a viable option. Consequently, the employment of hydrogen mixtures, comprising natural gas and hydrogen in a ratio of 1:1 (H2/CH4), is regarded as a potentially viable alternative. This approach is expected to yield a comparable degree of metallization while incurring a cost reduction of 20% [21].

The nature of the reducing agent has been shown to have a significant effect on the reaction rate. Biochar and charcoal exhibit high reactivity (specific surface area of 250–400 m2/g), yet contain up to 12% ash, which increases slag yield [10,24]. Coke and anthracite, on the other hand, are less active but provide a stable heat balance and low ash content [3,15]. It is considered that a mixed reducing agent is optimal, composed of 60% anthracite and 40% biochar, which results in 90% metallization with an ash content of <8% [15,24].

The addition of fluxes and catalysts to briquettes is a crucial step in the process, as it enables the precise control of slag mode and reduction rate. The addition of CaO, MgO, and SiO2 to the slag results in a change in its basicity (CaO/SiO2 = 0.8–1.4) and a consequent reduction in the softening temperature from 1280 to 1180 °C [5,25,26]. The introduction of 0.3–0.5% Co2O3 or 0.2% NiO has been shown to accelerate reduction by forming defects in the Fe3O4 lattice [15]. Vanadium itself exhibits catalytic activity due to the V3+/V4+ pair [27]. The addition of organic binders, such as humic acids in concentrations ranging from 0.5 to 1%, has been shown to enhance the strength of briquettes in a dry state by 35–40%. This enhancement is attributed to the formation of a carbon framework that exhibits resistance to thermal shock [28,29].

Titanium magnetite briquettes with 12–15% carbon and a basicity of 1.1 have been observed to soften at 1160–1190 °C, subsequently melting at 80–100 °C (in contrast to the 150–180 °C melting point of pellets) and generating a gas flow resistance of 600–800 Pa, which is below the critical level of 1000 Pa for a blast furnace [5,12,16]. The formation of the liquid metal phase is complete at 1300 °C, with the production of Fe-C melt containing 2.1–3.2% C and up to 0.6% V [16,26].

A summary of the results from over twenty laboratory and pilot experiments [15,16,19,20,22,30,31] demonstrates that, at temperatures ranging from 1200 to 1250 °C and coal ash contents of less than 10%, the degree of metallization achieves a range of 85–92%. During the subsequent processing stage, metallic iron accounts for 55–60% of the briquette mass, while TiO2 is concentrated in the slag (45–50%), which opens up the possibility of its further processing using the sulfate or chloride method [2,20]. The distribution of vanadium is as follows. It has been determined that 75–80% of the substance is absorbed by the metal, 15–20% remains in the slag, and less than 5% is released with the gas [6,32].

Metallized briquettes have been found to be a viable component in steelmaking units. In EAF, utilizing up to 30% of briquettes with a metallization degree >85% within the charge does not result in a reduction in productivity; there is merely an increase in specific energy consumption of 25 kWh/t, which is counterbalanced by the heat introduced by the carbon from the briquette [24,29]. In the context of oxygen converters (OC), the incorporation of 5–7% briquettes has been shown to result in a reduction of molten iron consumption by 15–20 kg/t, accompanied by a decrease in blowing time by 30–40 s [13,33]. The primary constraints pertain to the regulation of melt temperature (>1580 °C) and the viscosity of slag. In the context of induction and plasma furnaces, the utilization of briquettes (measuring 10–25 mm in diameter) has been demonstrated to be a successful methodology for the smelting of alloy steels. This approach has been shown to yield vanadium reducing rates of up to 90%, with titanium being introduced in the form of ferrotitanium [6,31].

From an environmental perspective, the substitution of 1 ton of iron ore pellets with metallized briquettes has been demonstrated to engender a reduction in CO2 emissions of 180–220 kg, a consequence of the elimination of the calcination stage and the partial utilization of biochar [10,21,24]. Furthermore, it has been demonstrated that dust emissions during transportation are reduced by 2.2–2.5 times as a consequence of the dense form of the briquette [11,29]. A review of the extant literature reveals that economic calculations for China and Kazakhstan demonstrate that the payback period for investments in briquetting is 3.5–4 years [2,13].

However, when transitioning to metallized briquettes, a number of issues must be addressed. There is an absence of long-term data concerning the behavior of briquettes in EAF with a capacity in excess of 150 MW·A and variable loads. There is no uniform classification of briquette quality for steelmaking (Fetotal, S, P, TiO2, ash content). The available information on the scalability of pressing (>50 t/h) and the thermal stability of molds during storage for periods exceeding six months is limited. To date, no comprehensive life cycle assessment (LCA) has been conducted for the transition to 100% briquettes in the charge. A systematic comparative analysis has not been undertaken from start to finish for the entire technological chain, which comprises the extraction and transport of raw materials, briquette production, smelting in EAF or OC, finished steel production and waste disposal. This analysis should include the introduction of metallized titanomagnetite briquettes into the charge in the range from 0 to 100%.

1.2. Requirements for Metallization

The metallization process imposes strict requirements on the characteristics of iron ore briquettes, which can be divided into several groups [34,35].

1. Physical requirements [36,37]

- –

- the compressive strength of the briquettes must be a minimum of 50 kg/cm2, as measured under standard conditions for cold briquettes (ISO 4700:2015 [38]).

- –

- it is imperative to note that the abrasion loss of mass during drum testing should be no greater than 5–8%.

- –

- it is imperative to ensure porosity falls within the range of 20–25% in order to guarantee gas permeability during the reduction process.

- –

- the parameters of measurement and configuration are to be considered.

- –

- the requirement for geometric uniformity is ±2 mm.

2. Chemical requirements [5,9]

- –

- the iron content of the feedstock must be a minimum of 65 %, with the exception of commercial briquettes, for which a lower percentage is permitted.

- –

- the content of harmful impurities is stipulated as follows, mass. %: S ≤ 0.03, P ≤ 0.04, Cu ≤ 0.1, Zn ≤ 0.01, SiO2 ≤ 5–7, and Al2O3 ≤ 3.

3. Structural requirements [13]

- –

- the components are distributed uniformly, i.e., there is no stratification.

- –

- the structure is to be examined for the presence of cracks and other defects.

- –

- the optimal density of the material is between 3.8 and 4.5 g/cm3, the precise value depending on the method of metallization.

4. Special requirements

- –

- the substance exhibits elevated gas permeability.

- –

- it is evident that no fine fraction is present, with a diameter of less than 3 mm (ISO 11257:2022 [39]).

- –

- in order to achieve a reduction in carbon and thermal activity, it is essential to establish an optimal Fe/C ratio of 5:1, whilst ensuring a uniform distribution of carbon.

5. Technological requirements [10,40]

- –

- the moisture content of the charge prior to compression is in the range of 5–10%.

- –

- the application of pressure is to be conducted within the range of 100–300 MPa, with the precise pressure value to be determined by the composition of the substance.

- –

- quality control encompasses a range of assessments, including mechanical tests that evaluate parameters such as strength and abrasion resistance. In addition, chemical analysis and X-ray structural analysis are employed to ascertain the composition and internal structure of the material under scrutiny.

Adherence to these requirements is known to ensure process stability, high recovery rates (≥92%), minimized energy consumption, and the production of high-quality metallized products.

In the case of titanomagnetite briquettes, the content of TiO2 (≤8%) and vanadium, which affect the temperature and reduction rate, is additionally controlled.

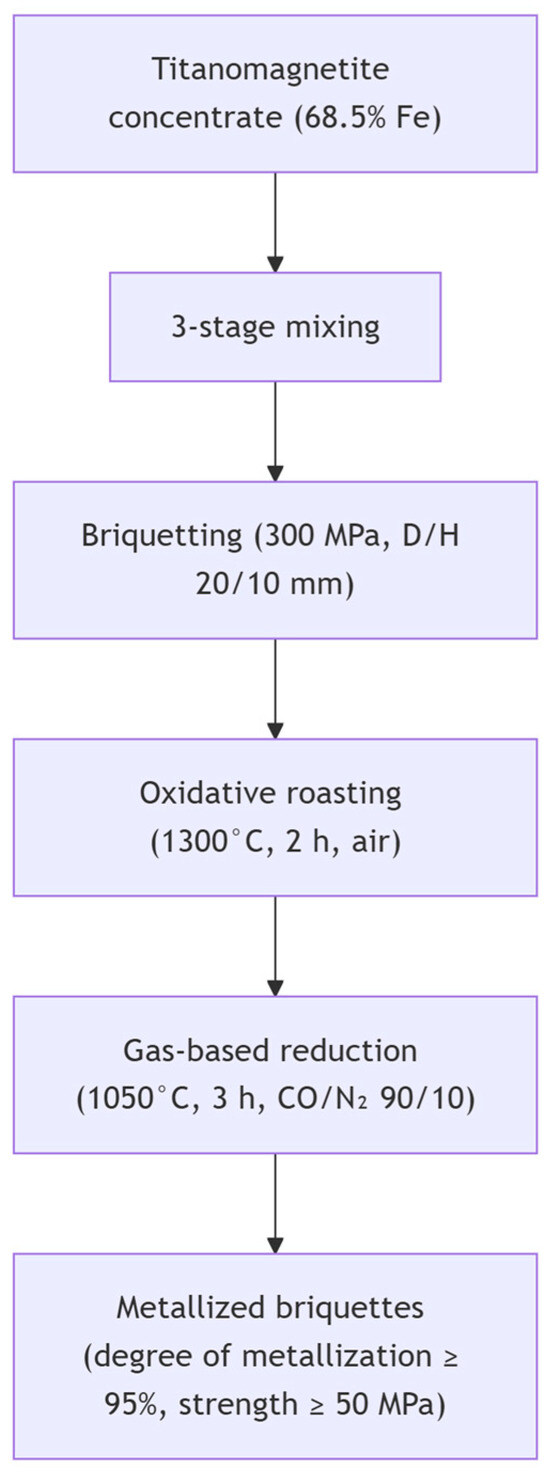

1.3. Proposed Process and Methodology

Figure 1 presents the flowsheet of the single-cycle briquetting and thermal reduction process proposed in this study. The technology combines briquetting of titanomagnetite concentrate with binder, oxidative firing to develop a strong silicate bond, and gas-based reduction to produce metallized briquettes suitable for EAF feedstock. This approach enables precise control of the Fe/binder ratio and avoids the formation of refractory Ti-rich slags that plague conventional blast furnace processing.

Figure 1.

Process flowsheet for metallized titanomagnetite briquette production.

1.4. Research Objectives and Novelty

The primary objectives of this research are to develop a composition for titanomagnetite briquettes with optimal reducing agent, flux, and binder content; to investigate the influence of reduction parameters (temperature, gas composition, time) on metallization degree and phase composition; and to evaluate the physical and mechanical properties of the produced briquettes. The novelty lies in identifying the Mg-SFCA-I phase as the key bonding mechanism and demonstrating that CaO-MgO-SiO2 binder can achieve >95% metallization with compressive strength exceeding 50 MPa, meeting EAF requirements.

2. Materials and Methods

The present study examined poor-grade iron ore titanomagnetite concentrate obtained as a result of ore enrichment at the Pervouralskoye deposit (Sverdlovsk Region, Russia).

2.1. Characterization of Titanomagnetite Concentrate

The chemical analysis was conducted using a titrimetric method (Table 1). The determination of Fetotal was performed in accordance with the standards set forth in the Russian National Standard 32517.1-2013 [41], while the determination of Femet and FeO was conducted in accordance with the standards set forth in the Russian National Standard R 53657-2009 [42].

Table 1.

Chemical composition of the initial concentrate for briquette production.

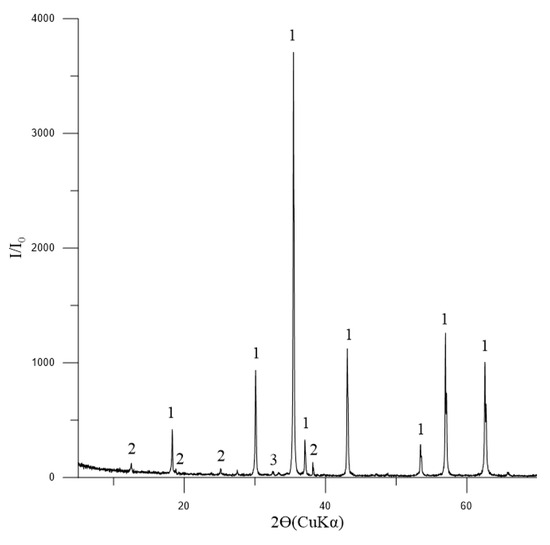

The phase composition of the samples was determined using an X-ray diffraction (XRD) instrument, the XRD-7000S (Shimadzu, Kyoto, Japan), with CuKα radiation and a graphite monochromator. The identification of phases was conducted using the PDF4 database, which is maintained by the International Centre for Diffraction Data (ICDD) in Newtown Square, PA, USA.

The phase composition of the initial enriched concentrate is illustrated in Figure 2.

Figure 2.

Diffractogram of the initial concentrate (1—Fe3O4 [01-088-0315], 2—(Mg,Al)6(Si,Al)4O10(OH)8 [00-052-1044]; 3—FeTiO3 (ilmenite) [01-075-0519]).

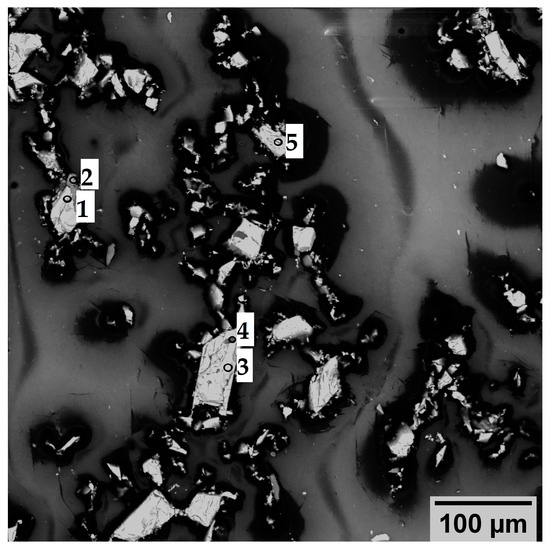

To study the mineralogical composition, the samples were subjected to micro-X-ray structure analysis using a scanning electron microscope (SEM) and an optical microscope (Figure 3). The SEM was a Jeol LTD model JSM-5900LM from Tokyo, Japan, while the optical microscope was an Olympus GX-51 from Shinjuku, Tokyo, Japan.

Figure 3.

Specific electron microscopic image of initial concentrate (1—magnetite; 2—Fe,Ca,Mg-silicate; 3, 5—titanomagnetite; 4—hercynite).

2.2. Binder Materials

Laboratory studies were conducted and an enrichment scheme was tested to obtain iron ore titanomagnetite concentrate (68.5% Fetotal) [43] (using a 3-stage grinding process to a size of 98.21% of the −0.071 mm class and a 3-stage enrichment process).

The following substances were utilized in the production of binders:

- -

- rubber adhesive in conjunction with gasoline;

- -

- calcium oxide (CaO) and lime (0.55% of the briquette weight);

- -

- slag (obtained from a ladle furnace). The composition of the slag (mass %) was determined to be CaO 38.7, SiO2 8.7, Al2O3 16.6, MnO 0.08, MgO 4.7, Cr2O3 0.03, FeO 0.3, with the addition of liquid glass (L) and water (W) in a ratio of L:W of 1:2.

2.3. Briquetting Procedure

The concentrate, with a mass of 100 ± 0.5 g, was amalgamated with the binder in a three-stage process. The initial step involves the dry mixing of ore and fluxes for a period of five minutes at a speed of 60 revolutions per minute. This is followed by the addition of a binder solution and subsequent mixing for a duration of 10 min. The final stage of the process is a three-minute homogenization period. The mixture was then immediately compacted using a laboratory hydraulic press (PLG-12, 0–12 tf) with cylindrical dies of 20 mm and 15 mm diameter. The parameters that were found to be significant in this study included the loading rate (10 MPa/s), the final pressure (300 ± 10 MPa), the dwell time (30 s), and the unloading rate (20 MPa/s). The dimensions of the briquettes were measured with a caliper, with a margin of error of ±0.01 mm. The weight of each briquette was measured to be 11.0 ± 0.2 g (Ø20 mm) and 6.0 ± 0.1 g (Ø15 mm).

The resulting briquettes were then subjected to a drying process in an oven at a temperature of 200 °C for a duration of two hours. Following drying at 200 °C and subsequent cooling in ambient laboratory air, a slight increase in mass was observed in the samples. This was attributed to the re-adsorption of atmospheric moisture and oxygen on the high-surface-area titanomagnetite. The effect is contingent upon the binder and is reversible. XRD analysis revealed no evidence of chemical oxidation, as indicated by the absence of hematite formation. It has been demonstrated that the adsorbed species are fully eliminated during heating above 300 °C and do not influence oxidative roasting at 1300 °C.

The data pertaining to the number and mass of briquettes for each batch are presented in Table 2. The term “PB” is used to denote Pervouralskoye briquettes.

Table 2.

Briquetting conditions and briquette characteristics.

2.4. Oxidative Firing Procedure

The dried briquettes were then subjected to a controlled cycle of heating in a muffle furnace (Trekhgorny, Chelyabinsk Region, Russia) at a rate of 15 °C/min to 1300 ± 10 °C. This was followed by an isothermal hold for 120 ± 5 min in air (flow rate 5 L/min), and subsequently by cooling at 10–15 °C/min to room temperature. The term “PFB” is used to denote fired briquettes.

2.5. Gas Reduction Procedure

The metallization process was conducted within an electric tube furnace (“Analitpribor”, Smolensk, Russia), which had a usable volume of 600 mm in diameter and 800 mm in length. A batch of 10 briquettes (approximately 100 g) was loaded into a wire-mesh basket and placed in the furnace hot zone. The reducing gas mixture (CO/N2 90/10, purity 99.9%) was supplied at a rate of 0.5 ± 0.02 L/min via a mass flow controller. The temperature program comprised the following steps: heating at 10 °C/min to 1050 ± 5 °C, isothermal reduction for 180 min, and cooling in N2 flow to below 150 °C.

Isothermal tests at 1050 °C were selected to facilitate a fundamental understanding of the kinetics and to exclude extraneous variables. This approach is considered a standard technique in fundamental research [12,13].

2.6. Strength Testing Methods

Compression tests were conducted in accordance with ISO 4700 [38] requirements using a universal testing machine BT1-FR050THW.A1K (Zwick GmbH, Ulm, Germany) at a speed of 10 mm/min, with deformation diagram recording. Prior to the compression test, the briquettes were weighed individually on ATL-220d4-1 electronic scales manufactured by ACCULAB Ltd., Nouvelle-France, Mauritius, with an accuracy of ±0.0003.

2.7. Calculation of Metallization Degree

The weight of the samples was measured prior to and following the metallization process. The degree of metallization (φmet) was calculated as φmet = (Femet/Fetotal) × 100%, where Femet is metallic iron content determined by the titrimetric method previously mentioned with precision ±0.15% abs., and Fetotal is total iron content with precision ±0.12% abs. The combined uncertainty was calculated using the error propagation law:

Δφ = φmet·√[(ΔFemet/Femet)2 + (ΔFetotal/Fetotal)2].

2.8. Statistical Analysis

All measurements were performed in triplicate at a minimum. For dimensional and structural parameters, at least 35–50 measurements per sample were conducted using systematic random sampling. Results are presented as mean ± standard deviation (SD). 95% confidence intervals (CI) were calculated using Student’s t-distribution.

2.9. CO Diffusion Coefficient Calculation

The effective CO diffusion coefficient (Deff) was determined by the Wagner–Rosen model: Deff = D0·(ε/τ)·(T/273)1.75·(1 atm/P), where ε is porosity, τ is tortuosity factor (2.1–2.5), and D0 = 0.2 cm2/s.

2.10. Scale-Up Considerations

The laboratory experiments were designed to simulate industrial conditions. The application of pressure (250–300 MPa) aligns with the specifications of the roller press. Reduction parameters (1050 °C, 3 h) correspond to rotary hearth furnace operation with residence time.

2.11. Safety and Environmental Controls

The CO/N2 reduction was conducted within a sealed tube furnace, with continuous CO monitoring (IR sensor, ±1 ppm accuracy). The system was engineered to maintain negative pressure with the purpose of preventing the occurrence of leaks. It is noteworthy that all experiments were conducted in strict accordance with the provisions of the Russian National Standard 12.1.005-88 [44], which stipulates a permissible exposure limit (PEL) of 20 mg/m3 for this particular substance.

3. Results

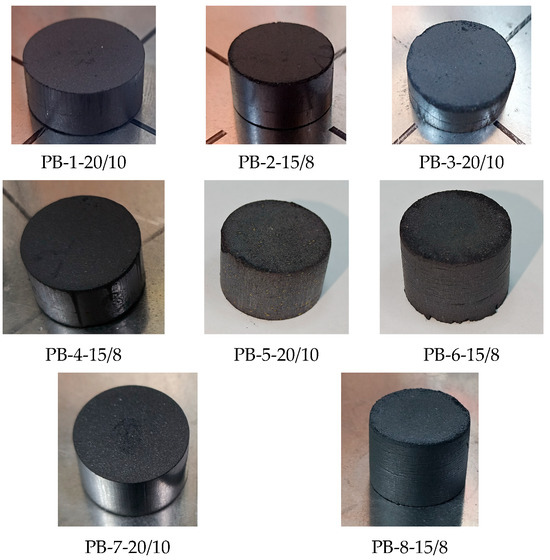

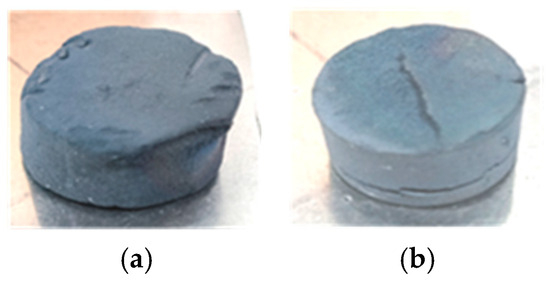

Figure 4 presents a photograph of the briquettes obtained.

Figure 4.

Appearance of manufactured briquettes (before compression strength testing).

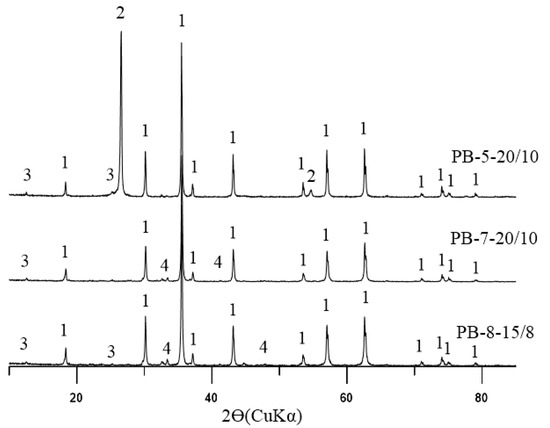

The phase composition of the briquettes is found to be essentially equivalent to that of the initial enriched concentrate, with the exception of several batches, as illustrated in Figure 5. As demonstrated, the composition varies for different batches solely in terms of the presence of phases of the binding component.

Figure 5.

Diffractogram of briquettes (1—Fe3O4 [01-088-0315], 2—C [03-065-6212], 3—(Mg,Al)6(Si,Al)4O10(OH)8 [00-052-1044]); 4—3CaO·MgO·2SiO2 [01-074-0382]).

The outcomes of the briquette compression strength tests are outlined in Table 3. Batches PB-5 and PB-6 (which contained graphite) were not subjected to strength testing, as they failed to retain their shape during the testing process (PFB—Pervouralsk fired briquettes).

Table 3.

Results of measuring the compressive strength of briquettes (* arithmetic mean of 4 measurements; ** test on one sample; *** no destruction at a compressive force of 50 kN (max for BT1-FR050THW.A1K, Zwick GmbH, Ulm, Germany)).

The compressive strength of pressed iron ore briquettes must be a minimum of 15–25 MPa [38]. The investigation revealed that all briquettes from the batches that were tested for compressive strength exhibited satisfactory results.

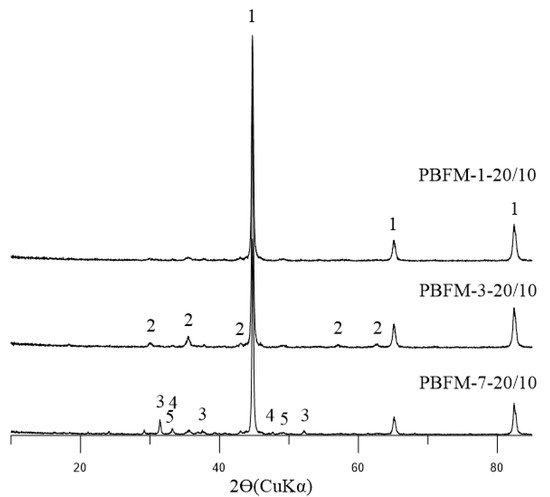

The phase analysis of the fired briquettes was the subject of study (Figure 6). The presence of Fe2O3 and Ca2.3Mg0.8Al1.5Fe8.3Si1.1O20 following the oxidative firing of briquettes at 1300 °C can be attributed to three concurrent processes: the oxidation of iron oxides, the decomposition of hydrosilicates, and the formation of a liquid slag phase.

Figure 6.

Diffractogram of fired briquettes: 1—Fe2O3 (hematite) [01-071-5088], 2—Ca2.3Mg0.8Al1.5Fe8.3Si1.1O20 [00-046-0037].

The general mechanism of SFCA-I, as well as the Mg-SFCA-I formation during rapid cooling, is consistent with established pelletization literature [8,12,13].

The reaction 4Fe3O4 + O2 ↔ 6γ-Fe2O3 is exothermic and proceeds at 400 °C, reaching completion at 1000 °C. It has been established that at an elevated temperature of 1300 °C, the transformation of γ-Fe2O3 to α-Fe2O3 is complete [8]. The volume expansion that accompanies oxidation (ΔV ≈ +7%) creates a network of microcracks that facilitates the access of oxygen and molten flux to the inner layers of the grains. Chloritoid decomposes according to the following scheme: (Mg,Al)6(Si,Al)4O10(OH)8 → (Mg,Al)6(Si,Al)4O13 + 4H2O↑, which leads to the opening of the crystal structure and an increase in the reaction surface [40,43,45]. The onset of melting in the CaO-MgO-Al2O3-Fe2O3-SiO2 system occurs at 1150–1180 °C; at 1300 °C, the liquid phase reaches 15–20 vol.% and fills the pores between the Fe2O3 grains [11]. When cooled from 1300 to 1100 °C, the melt crystallizes into needle-like crystals of magnesium-enriched calcium–aluminum silicoferrite. The composition of the crystals corresponds to the structural formula Ca2.3Mg0.8Al1.5Fe8.3Si1.1O20 (Mg-SFCA-I).

The elevated Fe3+ content is stabilized by high partial oxygen pressure; Mg and Al reduce the thermal expansion coefficient and increase the softening temperature of the bond to 1280 °C, which prevents secondary liquefaction during subsequent reduction heating.

The sequence “magnetite + merwinite/chloritoid → hematite + Mg-SFCA-I” has been identified as a classic mechanism of structure formation during oxidative firing of titanomagnetite briquettes [37]. Iron oxidation provides a high-valence source of Fe3+, while dihydroxylation (removal of hydroxyl groups) and melting create conditions for the crystallization of a strong, needle-like binder. This binder provides the necessary mechanical strength and thermal stability of the briquette.

The chemical composition of metallized briquettes (PBM) and metallized fired briquettes (PBFM) is presented in Table 4.

Table 4.

Chemical composition of metallized briquettes, mass. %.

The highest degree of metallization was obtained for briquettes from batch No. 3, with dimensions D/H 20/10 mm, achieving a result of 95.68%. In order to recommend briquettes for use in production, it is necessary to consider all characteristics in combination.

The outcomes of the compressive strength assessments conducted on metallized briquettes are outlined in Table 5. It should be noted that the testing of other samples was not possible due to the fact that the device does not allow for compression testing due to force limitations. Briquettes from batch No. 2 (15/8 mm) and batch No. 3 (20/10 mm) demonstrated compressive strength that met the requirements for metallized materials.

Table 5.

Results of testing metallized briquettes for strength under axial compression depending on binding additives.

Statistical parameters of compressive strength are presented in Table 6.

Table 6.

Statistical parameters of the metallized briquettes’ compressive strength.

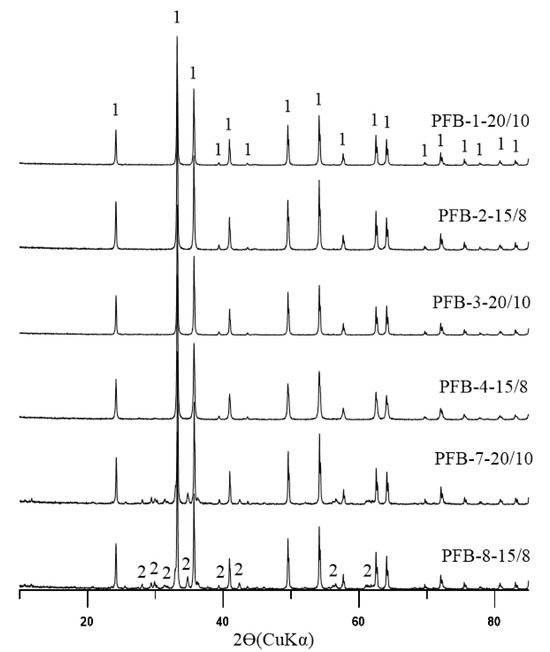

The phase composition of metallized briquettes is illustrated in Figure 7.

Figure 7.

Diffractogram of metallized briquettes: 1—α-Fe [01-080-3816]; 2—Fe3O4 [01-088-0315]; 3—Fe3C [01-074-3835]; 4—C [03-065-6212]; 5—2CaO·Al2O3·SiO2 [01-087-0970]; 6—CaO·TiO2 [01-082-0228]; 7—FeO·TiO2 [01-075-0519].

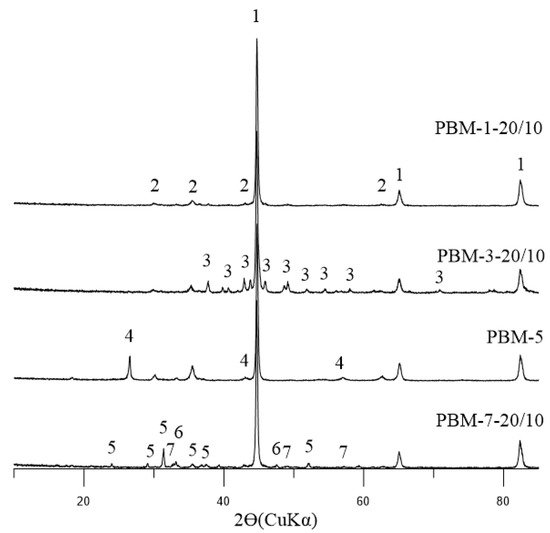

The phase composition of metallized briquettes (fired) is illustrated in Figure 8.

Figure 8.

Diffractogram of metallized briquettes (fired): 1—α-Fe [01-080-3816]; 2—Fe3O4 [01-088-0315]; 3—2CaO·Al2O3·SiO2 [01-087-0970]; 4—CaO·TiO2 [01-082-0228]; 5—FeO·TiO2 [01-075-0519].

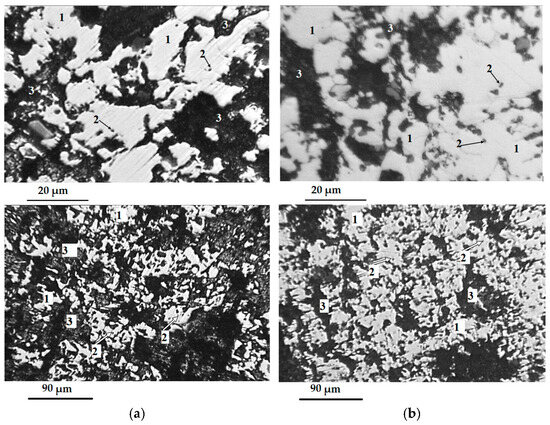

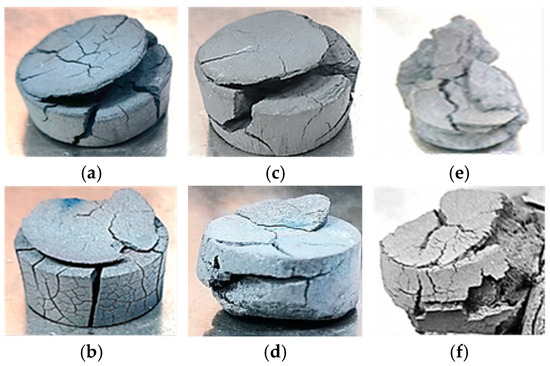

As demonstrated in Figure 9, Figure 10, Figure 11, Figure 12, Figure 13 and Figure 14, under reducing conditions, the briquettes exhibited a loss of shape and anisotropy in the reduction deformation process was observed. Following the reduction process, the briquettes exhibited alterations in their linear dimensions, as illustrated in Figure 9, Figure 11 and Figure 13. Specifically, the diameter increased by 15%, while the height exhibited a 30.65% increase (Figure 9a), a 19.25% increase (Figure 9b), a 10.3% increase (Figure 11a), a 34.88% increase (Figure 11b), a 25.33% increase (Figure 13a), and a 45.32% increase (Figure 13b), respectively. Additionally, a 12.7% increase in diameter was observed, accompanied by a 45.32% increase in height (Figure 13b).

Figure 9.

Photo of the appearance of pressed briquettes with a binding additive (rubber glue + gasoline) after reduction with dimensions: d = 23.8 mm, h = 13.99 mm (a) and d = 16.05 mm, h = 9.54 mm (b).

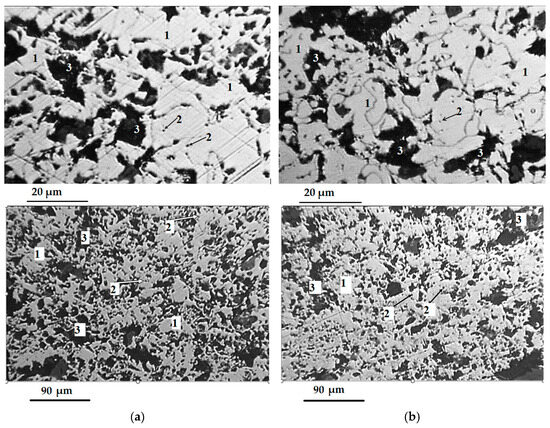

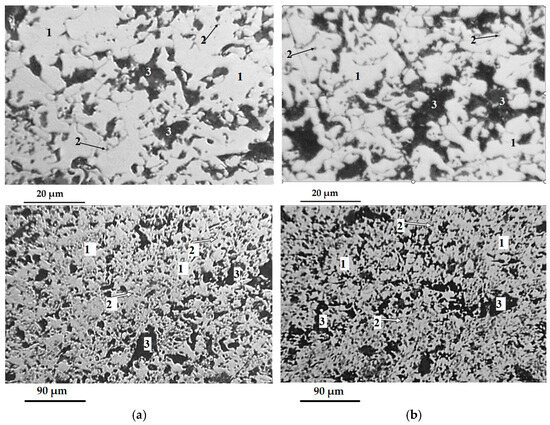

Figure 10.

Typical microstructure of the central part of pressed briquettes with a binding additive (rubber glue + gasoline) after reduction with dimensions: d = 23.8 mm, h = 13.99 mm (a); d = 16.05 mm, h = 9.54 mm (b): 1—metallic iron; 2—oxides; 3—pores.

Figure 11.

Photo of the appearance of pressed briquettes with a binding additive (CaO) after reduction with dimensions: d = 20 mm, h = 11.03 mm (a) and d = 16.0 mm, h = 10.85 mm (b).

Figure 12.

Typical microstructure of the central part of pressed briquettes with a binding additive (CaO) after reduction with dimensions: d = 20 mm, h = 11.03 mm (a); d = 16 mm, h = 10.85 mm (b): 1—metallic iron; 2—oxides; 3—pores.

Figure 13.

Photo of the appearance of pressed briquettes with a binding additive (slag + liquid glass) after reduction with dimensions: d = 23 mm, h = 12.99 mm (a) and d = 16.8 mm, h = 11.83 mm (b).

Figure 14.

Typical microstructure of the central part of pressed briquettes with a binding additive (slag + liquid glass) after reduction with dimensions: d = 23 mm, h = 12.99 mm (a); d = 16.8 mm, h = 11.83 mm (b): 1—metallic iron; 2—oxides; 3—pores.

In all the briquettes studied, after metallization, the process of reduction of magnetite to metallic iron is optically diagnosed. In the central part of the briquette (Figure 10 and Figure 12a,b), metallic iron grains (1) and oxides (2) inside the grains are observed in the microstructure. The boundaries of the metallic iron grains are interconnected, and a number of grains are encircled by substantial pores (3). The structure of the reduced iron is characterized by the presence of branched and angular pores.

The microstructure (Figure 14a,b) consists of separate oxides (2) inside grains of metallic iron (1). The grains are separated by complex-shaped pores (3), which are a series of narrow channels with sharp bulges.

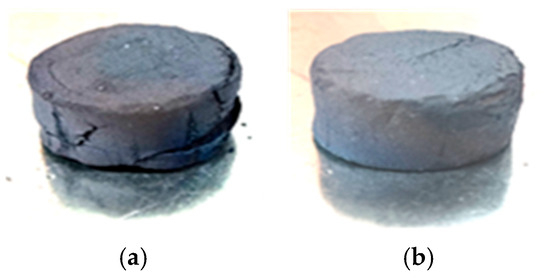

As illustrated in Figure 15a–f, a series of photographs depicts the destruction of cylindrical pressed briquettes, manufactured from a variety of binding additives and varying in dimensions, following exposure to oxidative firing and reduction. The most probable cause of the destruction of the briquettes was the presence of elevated stresses during the heating and cooling processes under reducing conditions.

Figure 15.

Photos of the appearance of pressed briquettes with binding additives: (a,b)—rubber adhesive + gasoline; (c,d)—CaO; (e,f)—slag + liquid glass, after oxidative firing and reduction with dimensions after pressing: d = 20 mm, h = 10 mm (a,c,e) and d = 15 mm, h = 8 mm (b,d,f).

As illustrated in Table 7, the analysis data pertaining to the dimensions and proportions of the structural components of metallized briquettes from batches No. 1, 2, 3, 4, 7, and 8 is also presented. The average pore size is subject to variation depending on the binder and briquette size. It has been observed that, in certain binders, there is a propensity for the pore size to increase in proportion to the decrease in briquette size. It is important to note that the change in linear pore size after processing also varies significantly. For instance, the change in pore size for the CaO binder is relatively insignificant (an observation that is favorable), whilst for cement, a substantial increase is observed (+25.33% and +45.3%). Batch No. 3, conversely, exhibited the lowest pore fraction of 6%. The indicator of change in the linear dimensions of briquettes after heat treatment is expressed as RSI = (V1 − V0)/V0·100%. The RSI indicator is utilized to evaluate the shrinkage/growth of briquettes during reduction. The recommended value is less than 10%, since an RSI > 10% indicates structural instability.

Table 7.

Table of results of analysis of sizes and proportions of structural components of metallized briquettes.

4. Discussion

4.1. Mechanism of Strength Formation in CaO-MgO-SiO2 Bonds

The following explanation is proposed [9,19,24,26,29,45]. Diopside (CaMgSi2O6) and merwinite (3CaO·MgO·2SiO2) have complete melting temperatures of 1250–1300 °C, which is lower than that of calcium titanates (CaO·TiO2, 1460 °C) or carbide-ferrite bonds (>1350 °C). At temperatures ranging from 1200 to 1280 °C, the viscosity of the melt is measured to be in the range of 3–7 Pa·s. It has been observed that the melt flows readily into the pore space between Fe and Fe3C grains, forming thin (1–2 μm) glassy films. These films undergo a transformation into a strong glass-crystalline body upon cooling. The pore filling density is reported to be 90%, which leaves less than 5% of open pores. This has been shown to double the compressive strength.

The linear thermal expansion coefficient (LTEC) of diopside is 7·10−6 K−1, which is close to the LTEC of metallic iron (12·10−6 K−1). However, for CaO·TiO2 and Fe3C, the difference is 20–25·10−6 K−1. When cooled from 1300 to 25 °C in the CaO-MgO-SiO2 system, there are no observable volume jumps (unlike the Fe3C → α-Fe + C transformation), suggesting minimal microcrack formation and the maintenance of intact bonds.

The presence of Mg2+ cations within the surface layer of the melt has been shown to result in a significant reduction in surface tension, from 0.45 to 0.28 N·m−1. This phenomenon occurs as the melt spreads over the iron grains, leading to the formation of strong chemical bridges (Ca-O-Fe, Mg-O-Fe bridges).

The evolution of α-Fe during reduction is a process that occurs in stages. In the initial stage (0–30 min), α-Fe nuclei are formed at the boundaries of Fe3O4 grains, resulting in the filling of micropores. The local degree of metallization can vary from 15 to 45% in the center and at the periphery of the briquette. Subsequently (30–120 min), α-Fe grains undergo growth through a process known as diffusion sintering. The α-Fe content reaches 60–70%. The magnitude of strength exhibited increases in proportion to the volume fraction of α-Fe. In the final stage (120–180 min), reduction is completed and a continuous α-Fe framework is formed (82–95%). The metallization heterogeneity exhibited a decline from 18% to 4% upon utilization of a CaO-MgO-SiO2 binder, attributable to the uniform distribution of the melt.

The formation of Mg-SFCA-I (Ca2.3Mg0.8Al1.5Fe8.3Si1.1O20) during the cooling process is of significant importance. Despite the fact that the literature search conducted [5,8,12,13] did not reveal any specific studies on the dependence of the cooling rate of Mg-SFCA-I in titanomagnetite systems, it is known that similar SFCA-I phases in conventional iron ore pellets require a cooling rate of 8–15 °C/min for the formation of needle-like structures [46].

4.2. The Influence of Ti-Containing Phases on Strength Formation

In the case of CaO·TiO2, the contact angle with Fe is measured at 60°, indicating that the melt remains isolated and Fe3C exhibits minimal wetting (angle > 90°), suggesting the presence of weak bonding between the grains.

When cooled rapidly (10–15 °C/min), the formation of high-aluminum silicate glass with diopside microcrystals (20–50 nm) is observed. The structure exhibits high crack resistance, as evidenced by the critical stress intensity factor under plane strain conditions (K Ic = 1.2 MPa·m½), and substantial microhardness (HV = 7 GPa). These properties contribute to the briquette’s enhanced resistance to local failure under compression.

In the context of titanate bonds (CaO·TiO2, FeO·TiO2) at temperatures below 1200 °C, the precipitation of needle-like crystals of pseudobrookite Fe2TiO5 occurs, thereby acting as stress concentrators and resulting in a reduction in strength by 20–30%. In the carbide-ferrite system, Fe3C is characterized by brittle behavior when exposed to its ambient environment (K Ic ≈ 0.3 MPa·m½). However, upon cooling, the material undergoes an expansion of approximately 4%, which results in the formation of microcracks and a consequent reduction in strength to 16 MPa.

4.3. Influence of Briquette Geometry on Reduction Kinetics

The study revealed the following patterns. The optimal ratio D/H = 20/10 (2.0) is key to ensuring uniform reduction. The effective CO diffusion coefficient was found to be 0.18 cm2/s, and the CO concentration gradient across the cross-section was determined to be less than 8%.

The ratio of 15 to 8 (1.875) has been demonstrated that there has been an increase in the concentration gradient to 12%, and that the reducing rate has decreased by 15% due to higher mass transfer resistance.

Optimal open porosity of 20–25% (the range recommended for metallized materials), the reducing rate is at its maximum. In materials with a porosity of less than 15%, the rate of CO diffusion is limited (Deff decreases to 0.08 cm2/s). At porosities greater than 30%, however, there is an observed decrease in mechanical strength.

The optimal performance, characterized by expeditious carbon dioxide access and maintained strength, is achieved through a pore distribution comprising micropores with a diameter of less than 5 μm and macropores measuring between 50 and 100 μm.

4.4. Problems of Bundle Segregation and Ways to Solve Them

Segregation of the bond is an integral part of the pressing process. At a pressure of 300 MPa, bonds comprising CaO, MgO and SiO2 (with a density of 2.8 g/cm3) can segregate from titanomagnetite (with a density of 4.7 g/cm3). In the context of optimal distribution, the melt adopts a continuous thin film (1–2 μm) configuration between Fe grains. Conversely, under segregation conditions, the melt forms isolated islands, resulting in a 25–30% reduction in strength.

Segregation leads to the formation of local areas with melt viscosity ranging from 2 to 15 Pa·s, which creates uneven pore filling (from 75 to 95%). Alternatively, multi-stage mixing (three stages) using a high-shear mixer can be proposed, which will ensure uniform distribution of the binder.

4.5. Scalability Analysis and Industrial Applicability

While this study is laboratory-scale, the results are transferable to industrial settings based on equipment availability, consistent thermodynamic parameters, positive economic indicators, and proven safety protocols for CO handling. Table 8 summarizes scale-up parameters and references industrial implementations of similar briquetting technologies.

Table 8.

Scale-up parameters and references of industrial implementations.

4.6. Environmental and Safety Aspects of CO/N2 Use at High Temperatures

Although carbon monoxide CO is recognized as a toxic substance (PEL 20 mg/m3), the utilization of CO/H2 mixtures in industrial DRI processes has been a practice for over five decades, with no recorded incidents of safety concerns. The technology under discussion incorporates multiple layers of safety, including continuous carbon monoxide monitoring with automatic shutoff, catalytic oxidation of off-gases, negative pressure operation, and emergency ventilation.

5. Conclusions

In the context of a laboratory experiment, two sizes of cylindrical iron ore titanomagnetite briquettes were obtained: 20/10 and 15/8, with the diameter in the numerator and the briquette height in the denominator. A variety of binders were utilized in the production process, including rubber adhesive mixed with gasoline, calcium oxide (0.55% of the briquette mass), crushed carbon (graphite) combined with water, 10% slag and liquid glass.

Briquettes comprising a range of binders exhibited substantial variations in compressive strength (from 16.42 to 80.28 MPa). The highest strength was observed in briquettes with CaO·MgO·2SiO2 phases as a binder after reduction, and the lowest strength was observed in briquettes with CaO·TiO2 or FeO·TiO2 + Fe3C phases after firing and metallization.

The metallization process has been shown to have a significant effect on the strength of briquettes. It is logical to hypothesize that an increase in the volume fraction of α-Fe would result in an increase in strength, since α-Fe is a metallic phase.

The optimal formulation was identified as PBM-3-20/10 (0.55% CaO binder, 20/10 mm briquettes), achieving 95.7% metallization, 48.9 MPa compressive strength, and RSI = 10.3%, fully meeting EAF requirements.

The following limitations must be noted, as well as the need for further research in this area. It is imperative that pilot testing is conducted in EAF with a capacity exceeding 150 MW·A. This testing should encompass an evaluation of long-term storage stability, extending beyond the initial six-month period. Furthermore, a comprehensive life cycle analysis (LCA) must be undertaken, along with an economic assessment, to ascertain the viability of transitioning to 100% briquettes within the charge.

Preliminary assessment indicates a payback period of 3.5–4 years and operational cost savings of 20–25% compared to pelletizing. However, a full-scale feasibility study is required to validate these projections under specific regional conditions.

Author Contributions

Conceptualization, A.N.D. and G.Y.V.; methodology, A.N.D.; software, Y.E.B.; validation, A.N.D., E.A.V. and L.A.M.; formal analysis, Y.E.B. and V.V.K.; investigation, E.A.V. and V.V.K.; resources, L.A.M.; data curation, R.V.A.; writing—original draft preparation, Y.E.B. and E.A.V.; writing—review and editing, R.V.A., G.Y.V.; visualization, R.V.A.; supervision, G.Y.V.; project administration, G.Y.V.; funding acquisition, A.N.D. All authors have read and agreed to the published version of the manuscript.

Funding

This study was carried out within the framework of the State Assignment of the Vatolin Institute of Metallurgy, Ural Branch of the Russian Academy of Sciences, under the Program of Fundamental Research of State Academies. The equipment of the Ural-M Collective Use Centre of the Vatolin Institute of Metallurgy was used.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors would like to express their gratitude to researchers of the Vatolin Institute of metallurgy of the Ural Branch of the Russian Academy of Sciences, Agafonov S.N. and Dolmatov A.V., Smirnova V.G. and Potapova Yu.A.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Leveneur, J.; Trompetter, W.J.; Chong, S.V.; Rumsey, B.; Jovic, V.; Kim, S.; McCurdy, M.; Anquillare, E.; Smith, K.E.; Long, N.; et al. Ironsand (Titanomagnetite-Titanohematite): Chemistry, Magnetic Properties and Direct Applications for Wireless Power Transfer. Materials 2021, 14, 5455. [Google Scholar] [CrossRef]

- Dzurkanov, Z.; Naimanbaev, M.; Kuldeyev, Y.; Lokhova, N.; Baltabekova, Z. Complex processing of the titanium magnetite concentrate with receiving vanadium-bearing cast iron and standard titan slag. Int. Multidiscip. Sci. GeoConference SGEM 2017, 17, 811–817. Available online: https://www.proquest.com/openview/959ac04f9207459de03fefbe9298ae5b/1?pq-origsite=gscholar&cbl=1536338 (accessed on 19 October 2025).

- Sarkar, B.K.; Dastidar, M.G.; Dey, R.; Das, G.C. A study on isothermal reduction kinetics of titaniferous magnetite ore using coke dust, an industrial waste. Can. Metall. Q. 2019, 58, 299–307. [Google Scholar] [CrossRef]

- Zhong, X.; Hu, H.; Li, S.; Gao, J.; Shi, Z.; Zhu, F. Mineralogical Characteristics of Baima Vanadium Titanomagnetite during Magnetic Separation Upgrading. Separations 2023, 10, 574. [Google Scholar] [CrossRef]

- Zhao, W.; Chu, M.S.; Guo, H.W.; Liu, Z.G.; Yan, B.J. Softening–melting–dripping characteristics and evolution mechanism of vanadium-bearing titanomagnetite carbon composite briquette used as novel blast furnace burden. J. Iron Steel Res. Int. 2021, 28, 1082–1094. [Google Scholar] [CrossRef]

- Naimanbayev, M.A.; Jurkanov, J.K.; Abisheva, A.E.; Baltabekova, Z.A. Titanium magnetite concentrates reduction smelting technology. In Proceedings of the Sustainable Industrial Processing Summit, Antalya, Turkey, 4–9 October 2015; pp. 146–149. Available online: https://www.researchgate.net/profile/Madali-Naimanbayev/publication/330873826_TITANIUM_MAGNETITE_CONCENTRATES_REDUCTION_SMELTING_TECHNOLOGY/links/5c594e8d92851c22a3aa7df7/TITANIUM-MAGNETITE-CONCENTRATES-REDUCTION-SMELTING-TECHNOLOGY.pdf (accessed on 14 October 2025).

- ISO 3271:2015; Iron Ores for Blast Furnace and Direct Reduction Feedstocks–Determination of the Tumble and Abrasion Indices. ISO: Switzerland, Geneva, 2015.

- Chen, W.; Dong, Z.; Jiao, Y.; Liu, L.; Wang, X. Preparation, Sintering Behavior and Consolidation Mechanism of Vanadium-Titanium Magnetite Pellets. Crystals 2021, 11, 188. [Google Scholar] [CrossRef]

- Ning, X.; Ren, Z.; Zhang, N.; Wang, G.; Zhang, X.; Wu, J.; Liu, J.; Karasev, A.; Wang, C. Reduction Study of Carbon-Bearing Briquettes in the System of Multiple Reductants. Materials 2025, 18, 4408. [Google Scholar] [CrossRef]

- Pascoal, A.d.L.; Rossoni, H.A.V.; Kaffash, H.; Tangstad, M.; Henriques, A.B. Study of the Physical Behaviour and the Carbothermal Reduction of Self-Reducing Briquettes Developed with Iron Ore Fines, Charcoal and Silica Fume Residues. Sustainability 2022, 14, 10963. [Google Scholar] [CrossRef]

- Singh, V.; Singh, A. Briquetting Technologies for Minerals and Metallurgical Applications: A Review. Miner. Process. Extr. Metall. Rev. 2025, 1–20. [Google Scholar] [CrossRef]

- Zhao, W.; Chu, M.; Wang, H.; Liu, Z.; Tang, J.; Ying, Z. Volumetric shrinkage characteristics and kinetics analysis of vanadium titanomagnetite carbon composite hot briquette during isothermal reduction. ISIJ Int. 2018, 58, 823–832. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, H.T.; Liu, Z.G.; Chu, M.S.; Ying, Z.W.; Tang, J. Preparation and optimization of vanadium titanomagnetite carbon composite hot briquette: A new type of blast furnace burden. JOM 2017, 69, 1737–1744. [Google Scholar] [CrossRef]

- Tang, H.; Sun, Y.; Rong, T. Experimental and Numerical Investigation of Reaction Behavior of Carbon Composite Briquette in Blast Furnace. Metals 2020, 10, 49. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, Y.; Zhao, Z.; Yuan, F. Effects of Fe2O3 on Reduction Process of Cr-Containing Solid Waste Self-Reduction Briquette and Relevant Mechanism. Metals 2019, 9, 51. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, H.; Liu, Z.; Chu, M.; Ying, Z.; Tang, J. Investigation of reduction mechanism and kinetics of vanadium titanomagnetite carbon composite hot briquette at 1173–1373 K. Steel Res. Int. 2017, 88, 1600306. [Google Scholar] [CrossRef]

- Hu, T.; Lv, X.; Bai, C.; Lun, Z.; Qiu, G. Reduction behavior of Panzhihua titanomagnetite concentrates with coal. Metall. Mater. Trans. B 2013, 44, 252–260. [Google Scholar] [CrossRef]

- Hu, T.; Lü, X.W.; Bai, C.G.; Qiu, G.B. Isothermal reduction of titanomagnetite concentrates containing coal. Int. J. Miner. Metall. Mater. 2014, 21, 131–137. [Google Scholar] [CrossRef]

- Xing, X.; Du, Y.; Zheng, J.; Chen, Y.; Ren, S.; Ju, J. Experimental Study on Strengthening Carbothermic Reduction of Vanadium-Titanium-Magnetite by Adding CaF2. Minerals 2020, 10, 219. [Google Scholar] [CrossRef]

- Yu, W.; Wen, X.; Chen, J.; Kuang, J.; Tang, Q.; Tian, Y.; Fu, J.; Huang, W.; Qiu, T. Preparation of Direct Reduced Iron and Titanium Nitride from Panzhihua Titanomagnetite Concentrate Through Carbothermic Reduction-Magnetic Separation. Minerals 2017, 7, 220. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, R.; You, Z.; Yu, W.; Dang, J.; Bai, C. Use of Hydrogen–Rich Gas in Blast Furnace Ironmaking of V-bearing Titanomagnetite: Mass and Energy Balance Calculations. Materials 2022, 15, 6078. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Li, H.; Wang, S.; Chen, M.; Tang, W.; Guo, Y.; Wen, Y.; Yang, L. Reduction Disintegration Behavior and Mechanism of Vanadium–Titanium Magnetite Pellets During Hydrogen-Based Reduction. Metals 2025, 15, 700. [Google Scholar] [CrossRef]

- El-Hussiny, N.; El-Amir, A.; Abdel-Rahim, S.T.; El Hossiny, K.; Shalabi, M.E.H. Kinetics of Direct Reduction Titanomagnetite Concentrate Briquette Produced from Rossetta-Ilmenite via Hydrogen. Open Access Libr. J. 2014, 1, 1–11. Available online: https://www.academia.edu/download/69656406/oalib.pdf (accessed on 20 October 2025).

- Ahmed, H.; Elsadek, M.; Lundgren, M.; Öqvist, L.S. Reduction Behavior of Biochar-in-Plant Fines Briquettes for CO2-Reduced Ironmaking. Metals. 2025, 15, 973. [Google Scholar] [CrossRef]

- Tang, H.; Yun, Z.; Fu, X.; Du, S. Modeling and Experimental Study of Ore-Carbon Briquette Reduction under CO-CO2 Atmosphere. Metals 2018, 8, 205. [Google Scholar] [CrossRef]

- Zhao, W.; Chu, M.; Wang, H.; Liu, Z.; Tang, J.; Ying, Z. Reduction behavior of vanadium-titanium magnetite carbon composite hot briquette in blast furnace process. Powder Technol. 2019, 342, 214–223. [Google Scholar] [CrossRef]

- Zhang, J.; Qi, Y.; Yan, D.; Wang, F.; Cheng, X. Investigation of vanadium titanomagnetite concentrate activated reduction. Metallurgist 2022, 65, 1235–1244. [Google Scholar] [CrossRef]

- Li, G.; Zhang, Y.; Zhang, X.; Meng, F.; Cao, P.; Yi, L. Effect of Humic Acid Binder on the Preparation of Oxidized Pellets from Vanadium-Bearing Titanomagnetite Concentrate. Sustainability 2023, 15, 6454. [Google Scholar] [CrossRef]

- Vitikka, O.; Iljana, M.; Heikkilä, A.; Tkalenko, I.; Koriuchev, N.; Shehovsov, D.; Malkki, A.; Fabritius, T. Suitability of Auger Pressing Briquettes for Blast Furnace Use Based on Laboratory Tests. Minerals 2022, 12, 868. [Google Scholar] [CrossRef]

- Hu, T.; Lv, X.; Bai, C. Enhanced Reduction of Coal-Containing Titanomagnetite Concentrates Briquette with Multiple Layers in Rotary Hearth Furnace. Steel Res. Int. 2016, 87, 494–500. [Google Scholar] [CrossRef]

- Zulhan, Z.; Sutandar, C.L.; Suryani, I.; Basuki, E.A. Effect of temperature patterns on iron nugget formation in fluxless processing of titanomagnetite. Sci. Rep. 2022, 12, 8941. [Google Scholar] [CrossRef] [PubMed]

- Naimanbayev, M.; Dzurkanov, Z.; Lokhova, N.; Maldybayev, G. Complex processing of a titanium magnetite concentrate with receiving the products containing iron, the titan and vanadium. IOP Conf. Ser. Earth Environ. Sci. 2016, 44, 052001. [Google Scholar] [CrossRef]

- Zhao, W.; Chu, M.; Liu, Z.; Wang, H.; Tang, J.; Ying, Z. High-temperature interactions between vanadium-titanium magnetite carbon composite hot briquettes and pellets under simulated blast furnace conditions. Metall. Mater. Trans. B 2019, 50, 1878–1895. [Google Scholar] [CrossRef]

- Zhu, K.S.; Cheng, X.K.; Lin, Y.H.; Zhao, Y.T.; Yin, G.L.; Li, J.W.; Cao, L. Pre-reduction of carbon-containing pellets of high chromium vanadium–titanium magnetite at different temperatures. High Temp. Mater. Process. 2022, 41, 296–305. Available online: https://www.degruyterbrill.com/document/doi/10.1515/htmp-2022-0006/html (accessed on 19 October 2025). [CrossRef]

- Bizhanov, A.M.; Zagaynov, S.A. Briquetting Technologies in Ferrous Metallurgy; Infra-Engineering: Moscow, Vologda, 2020; p. 256. [Google Scholar]

- Bizhanov, A.M.; Zagainov, S.A. Tests of briquettes for mechanical strength. Metallurgist 2021, 3, 11–18. [Google Scholar] [CrossRef]

- Patrick, T.R.C.; Lovel, R.R. Leaching dicalcium silicates from iron ore sinter to remove phosphorus and other contaminants. ISIJ Int. 2001, 41, 128–135. [Google Scholar] [CrossRef]

- ISO 4700:2015; Iron Ore Pellets for Blast Furnace and Direct Reduction Feedstocks—Determination of the Crushing Strength. ISO: Switzerland, Geneva, 2015.

- ISO 11257:2022; Iron Ores for Shaft Direct-Reduction Feedstocks—Determination of the Low-Temperature Reduction-Disintegration Index and Degree of Metallization. ISO: Switzerland, Geneva, 2022.

- Bizhanov, A.M. Theory and Practice of Briquetting in Metallurgy; Infra-Engineering: Moscow, Vologda, 2024; p. 516. [Google Scholar]

- 32517.1-2013 (ISO 2597-1:2005); Iron Ores–Determination of Total Iron Content–Part 1: Titrimetric Method After Tin (II) Chloride Reduction. Russian National Standard: Russian Federation, Moscow, 2014.

- R 53657-2009; Iron Ores, Concentrates, Agglomerates and Pellets. Method for Determination of Divalent Iron Calculated as Ferrous Oxide. Russian National Standard: Russian Federation, Moscow, 2009.

- Dmitriev, A.N.; Vitkina, G.Y.; Zlobin, V.G.; Vyaznikova, E.A.; Marshuk, L.A.; Burova, Y.E.; Alektorov, R.V.; Kataev, V.V. A Study of the Possibility of Producing Annealed and Metallized Pellets from Titanomagnetite Concentrate. Materials 2024, 17, 5338. [Google Scholar] [CrossRef] [PubMed]

- 12.1.005-88; Occupational Safety Standards System. General Sanitary Requirements for Working Zone Air. Russian National Standard: Russian Federation, Moscow, 2008.

- Chen, S.Y.; Chu, M.S. Metalizing reduction and magnetic separation of vanadium titano-magnetite based on hot briquetting. Int. J. Miner. Metall. Mater. 2014, 21, 225–233. [Google Scholar] [CrossRef]

- Pownceby, M.I.; Clout, J.M.F. Importance of fine ore chemical composition and high temperature phase relations: Applications to iron ore sintering and pelletising. Miner. Process. Extr. Metall. 2003, 112, 44–51. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).