Point Defects in MoNbTi-Based Refractory Multi-Principal-Element Alloys

Abstract

1. Introduction

2. Experimental Methods

2.1. Sample Preparation and Irradiation

2.2. Microstructural Characterization

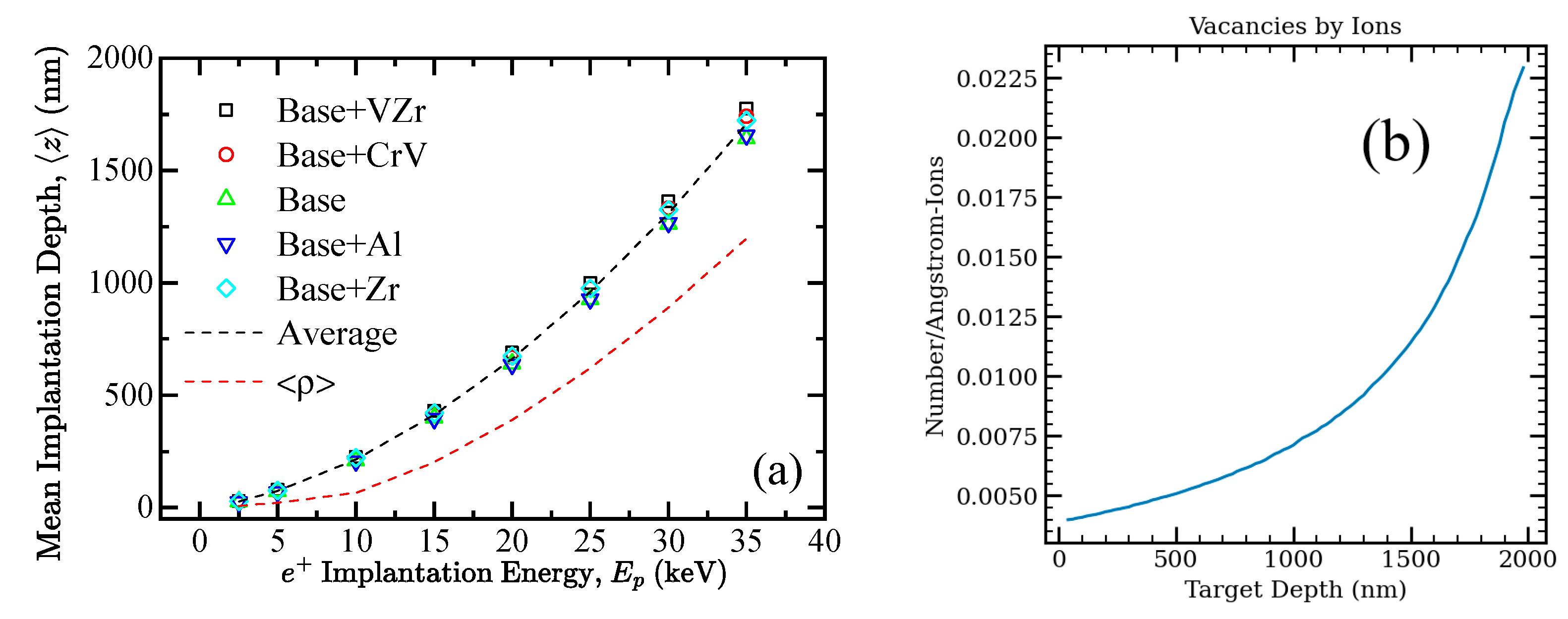

2.3. PAS Measurements

3. Results and Discussion

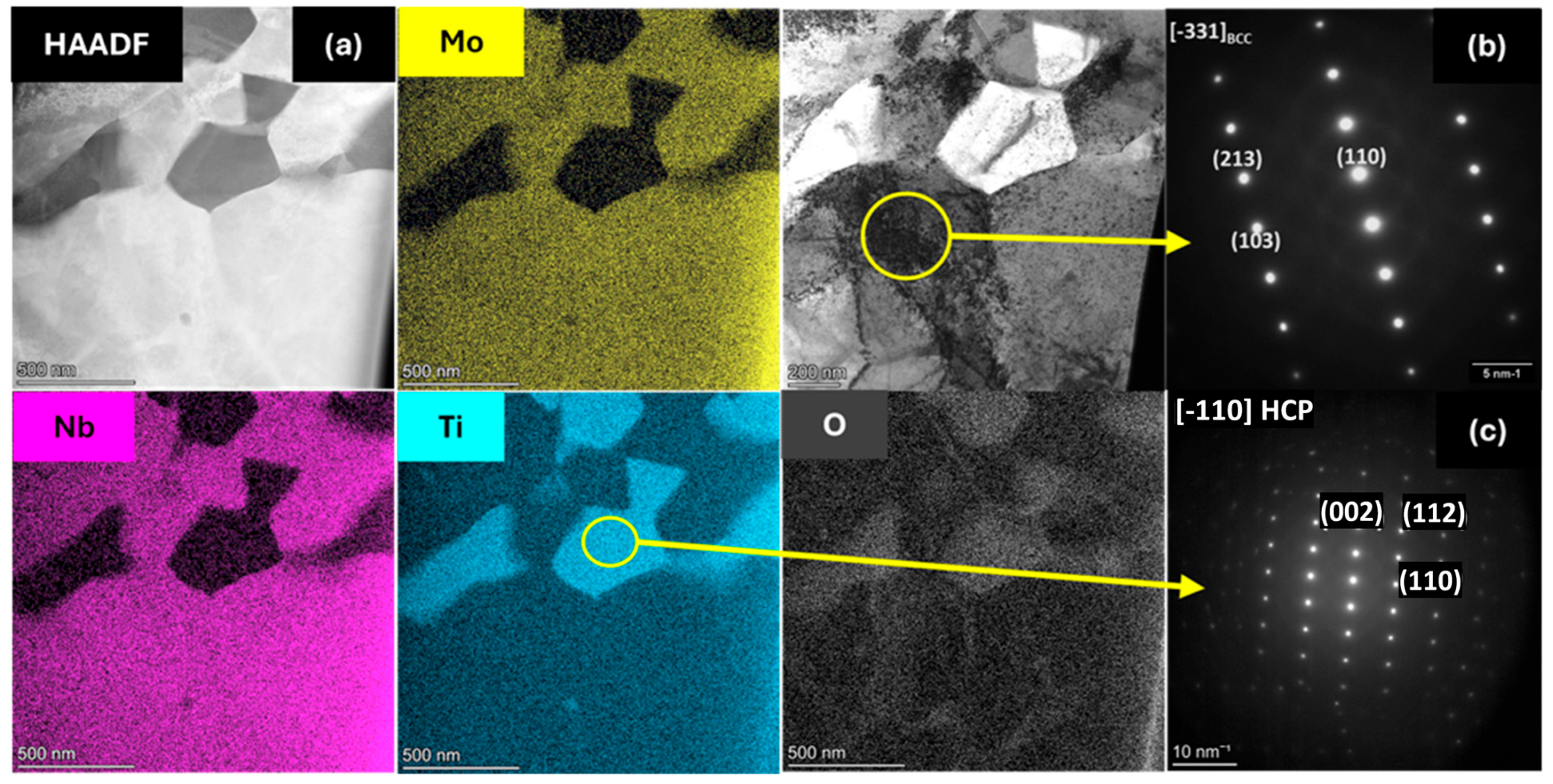

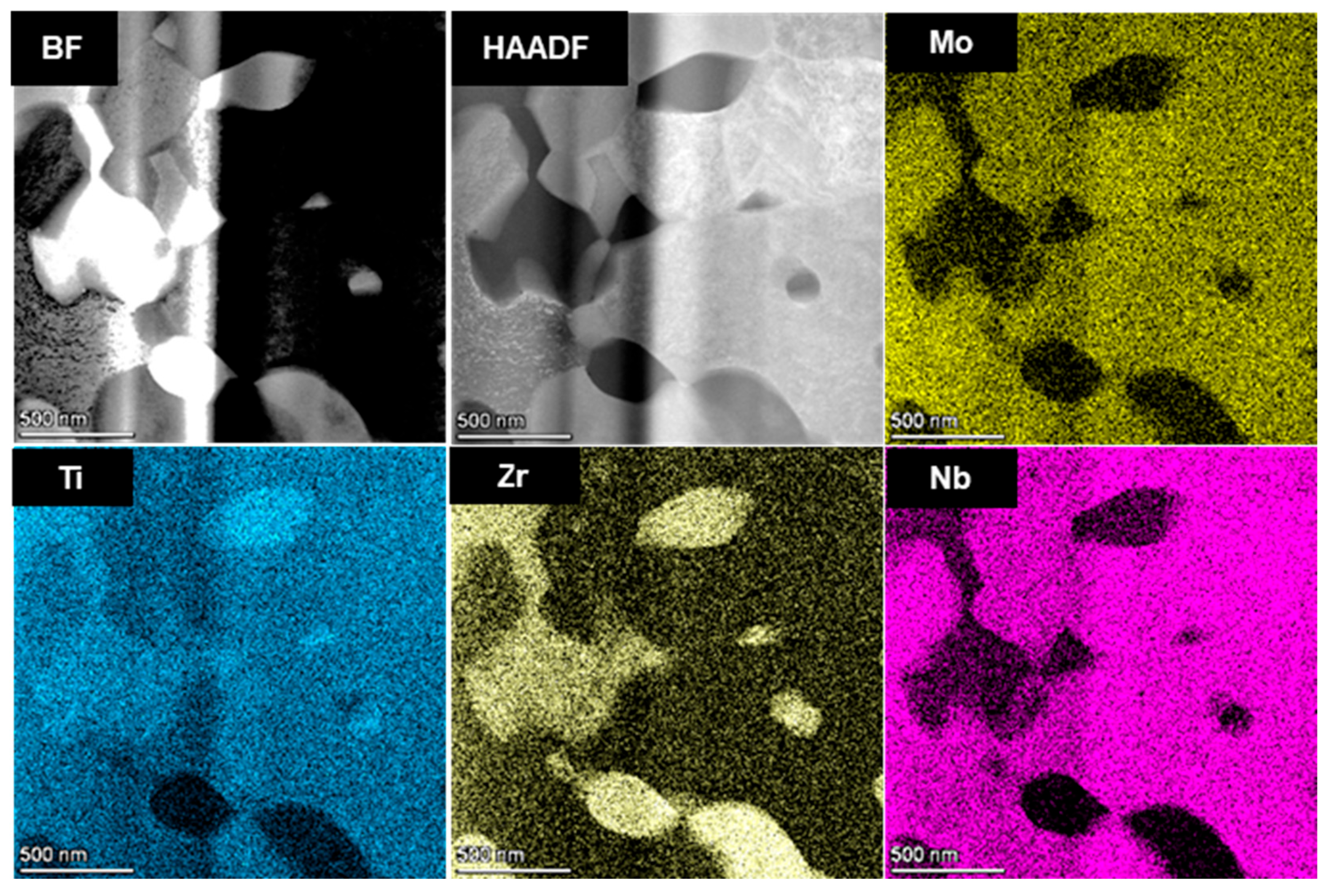

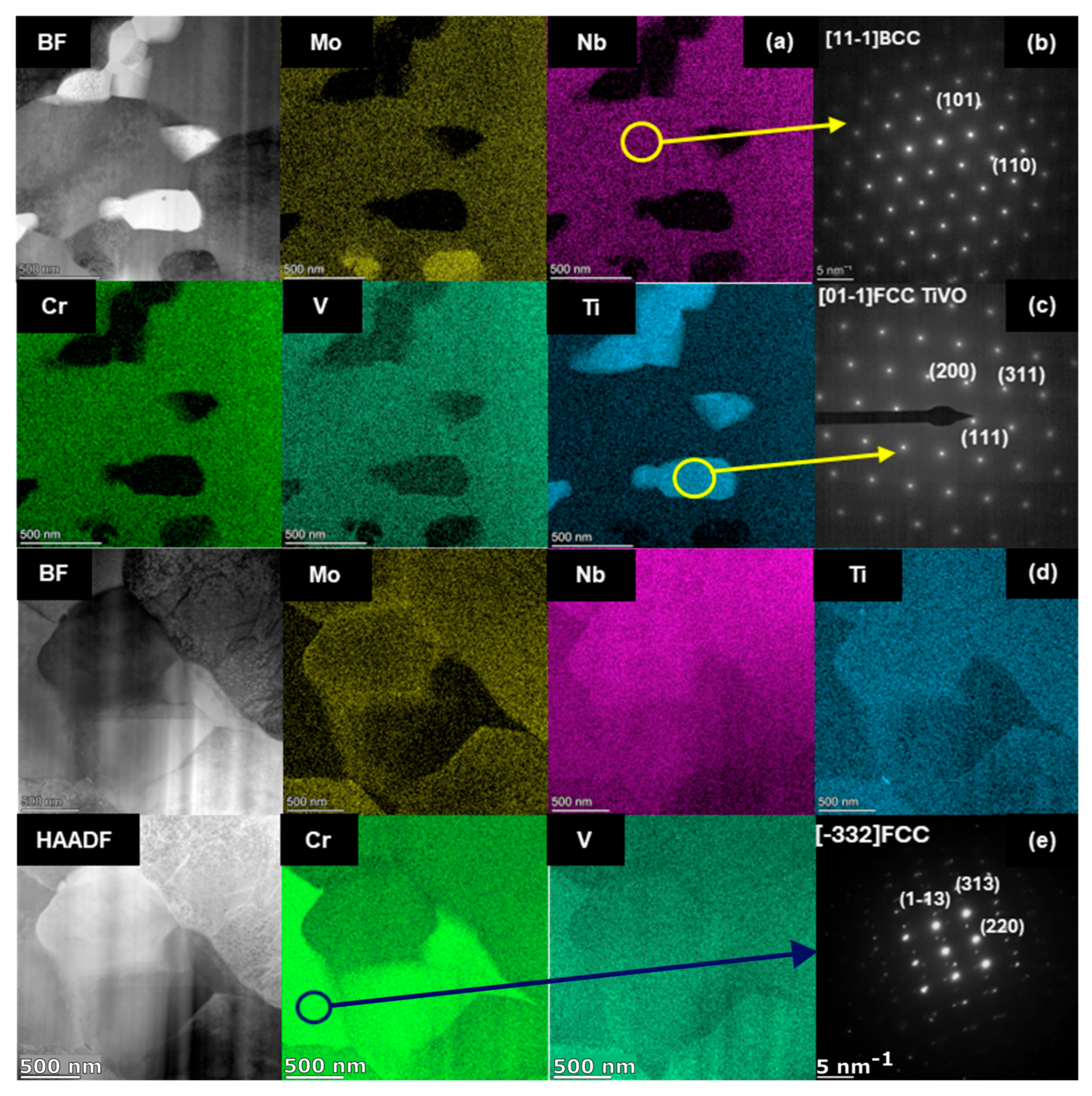

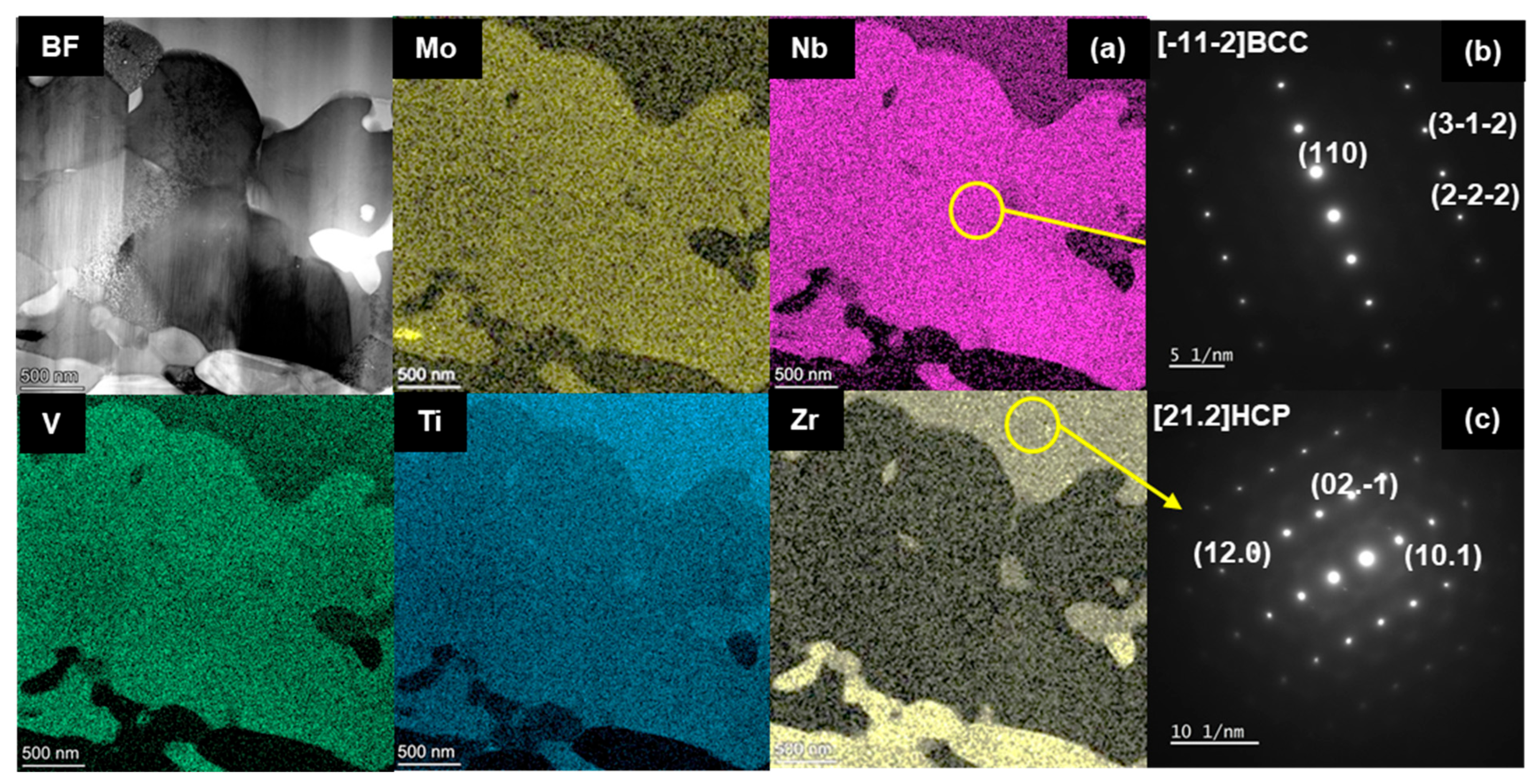

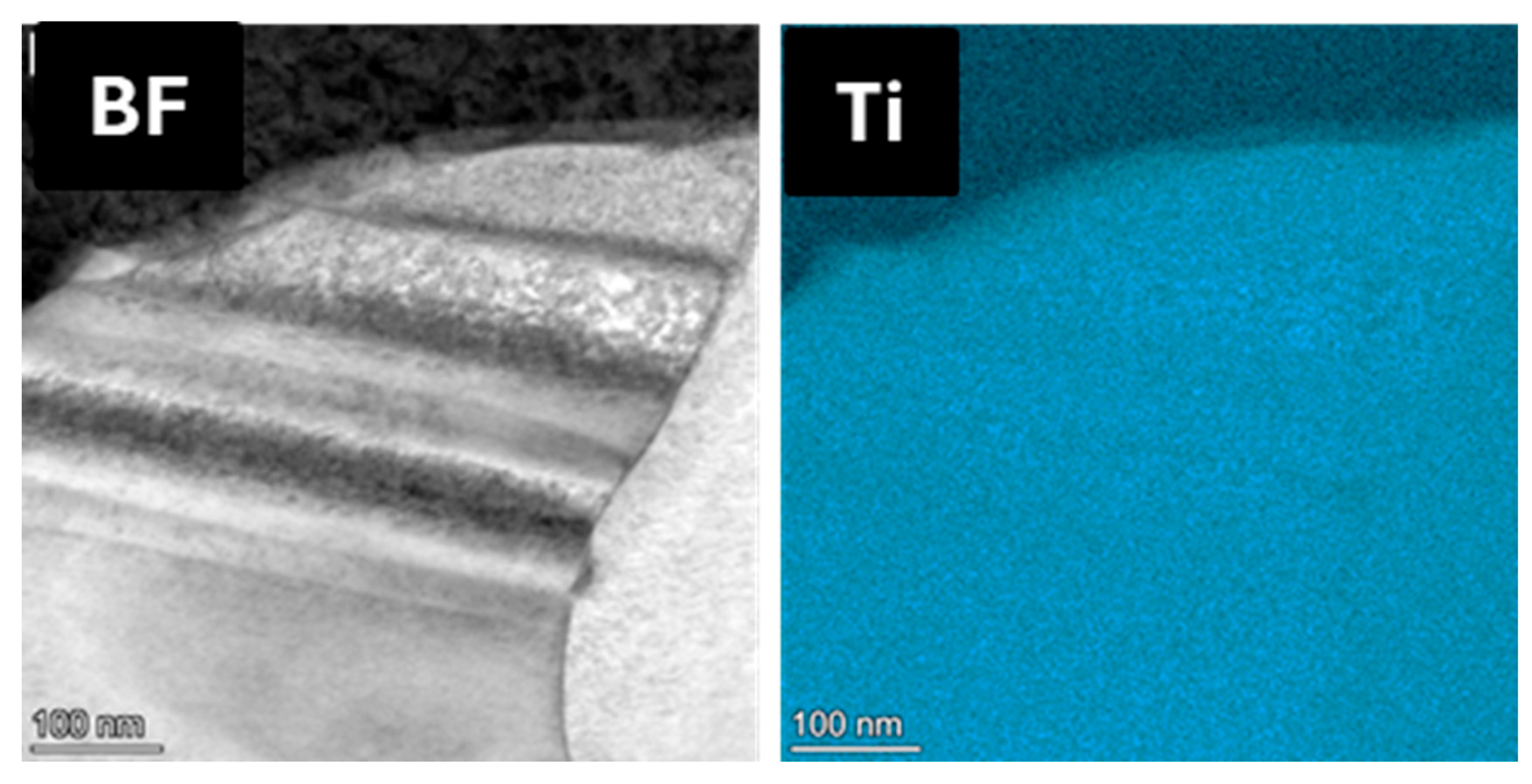

3.1. Microstructural and Phase Analysis

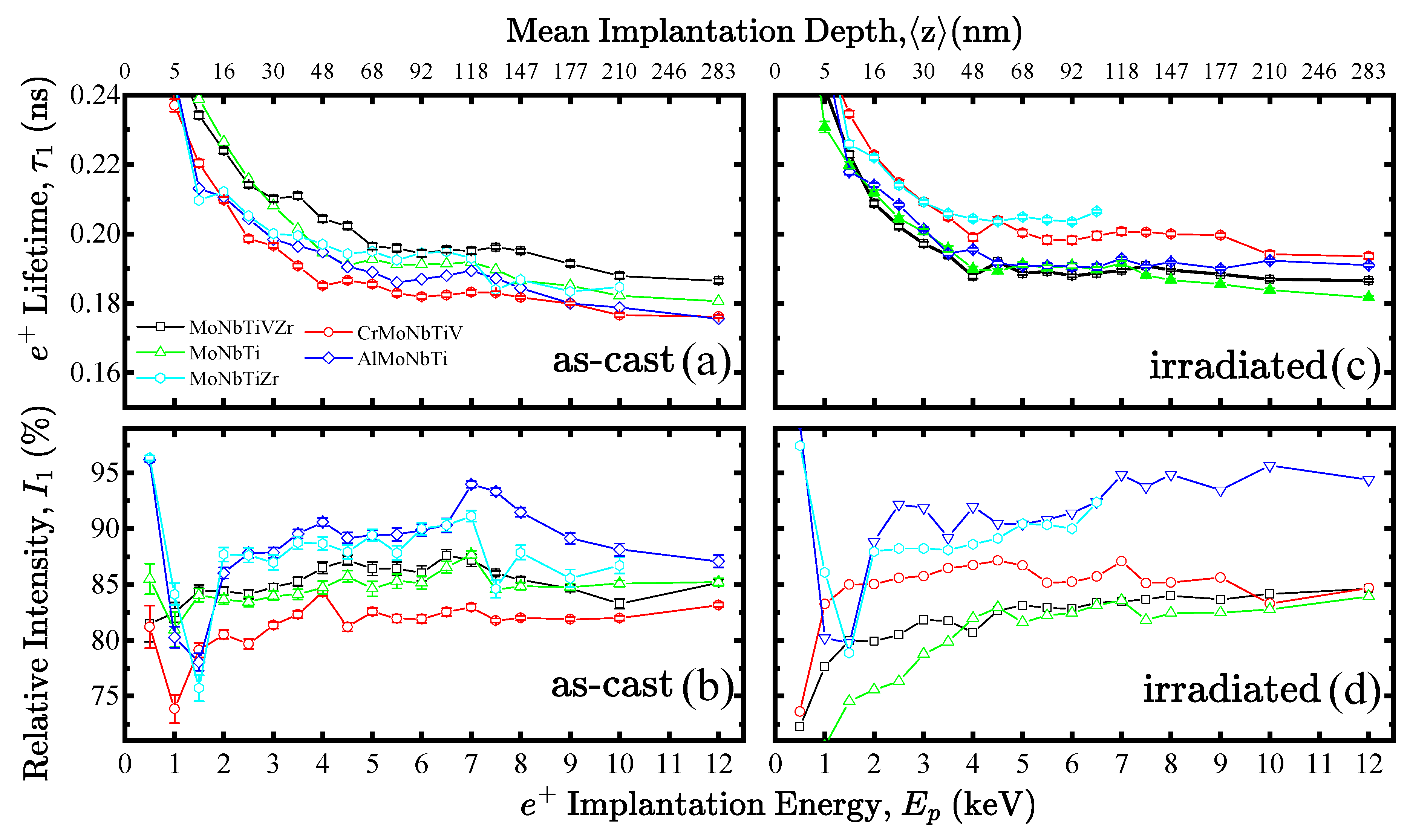

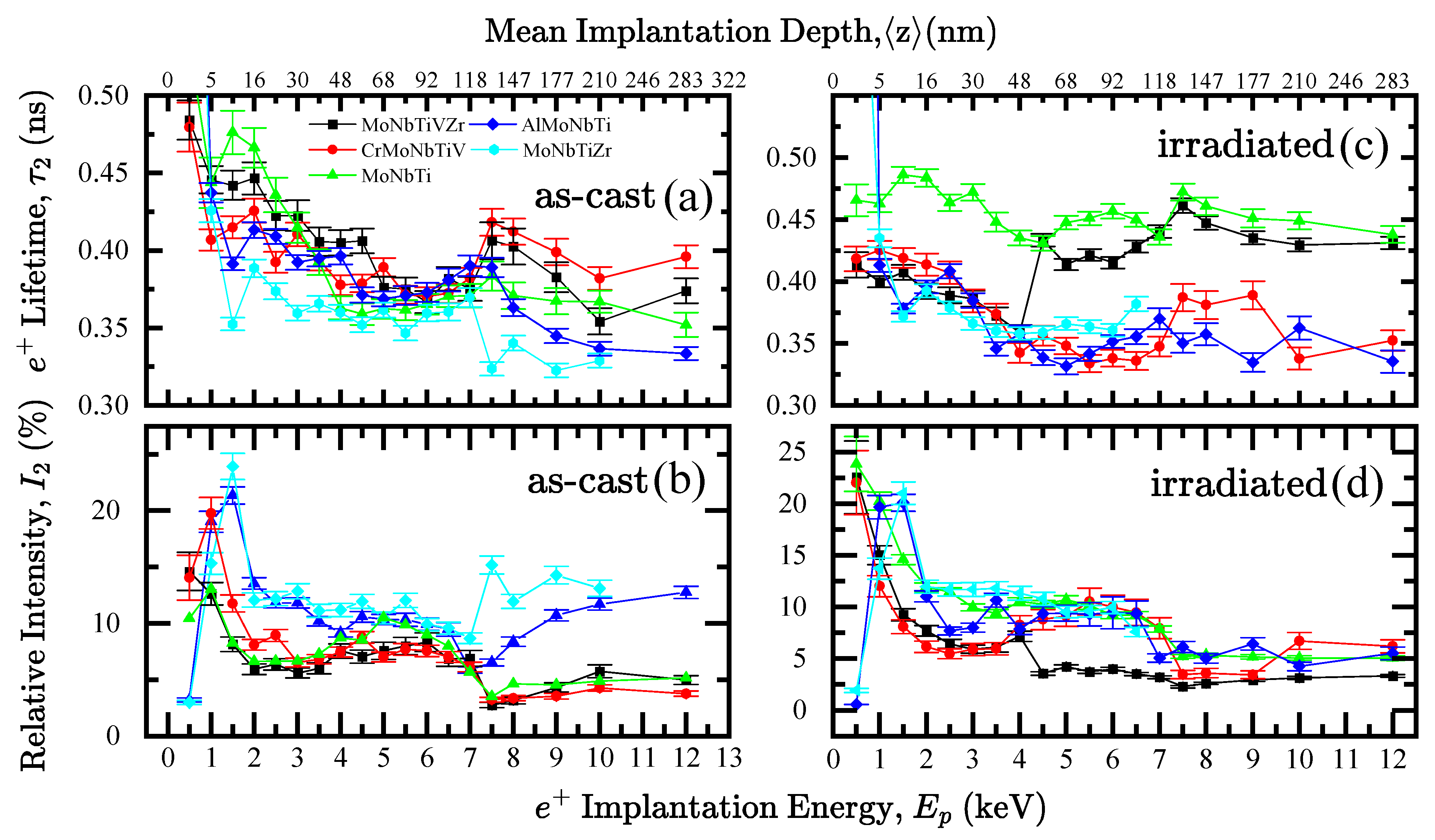

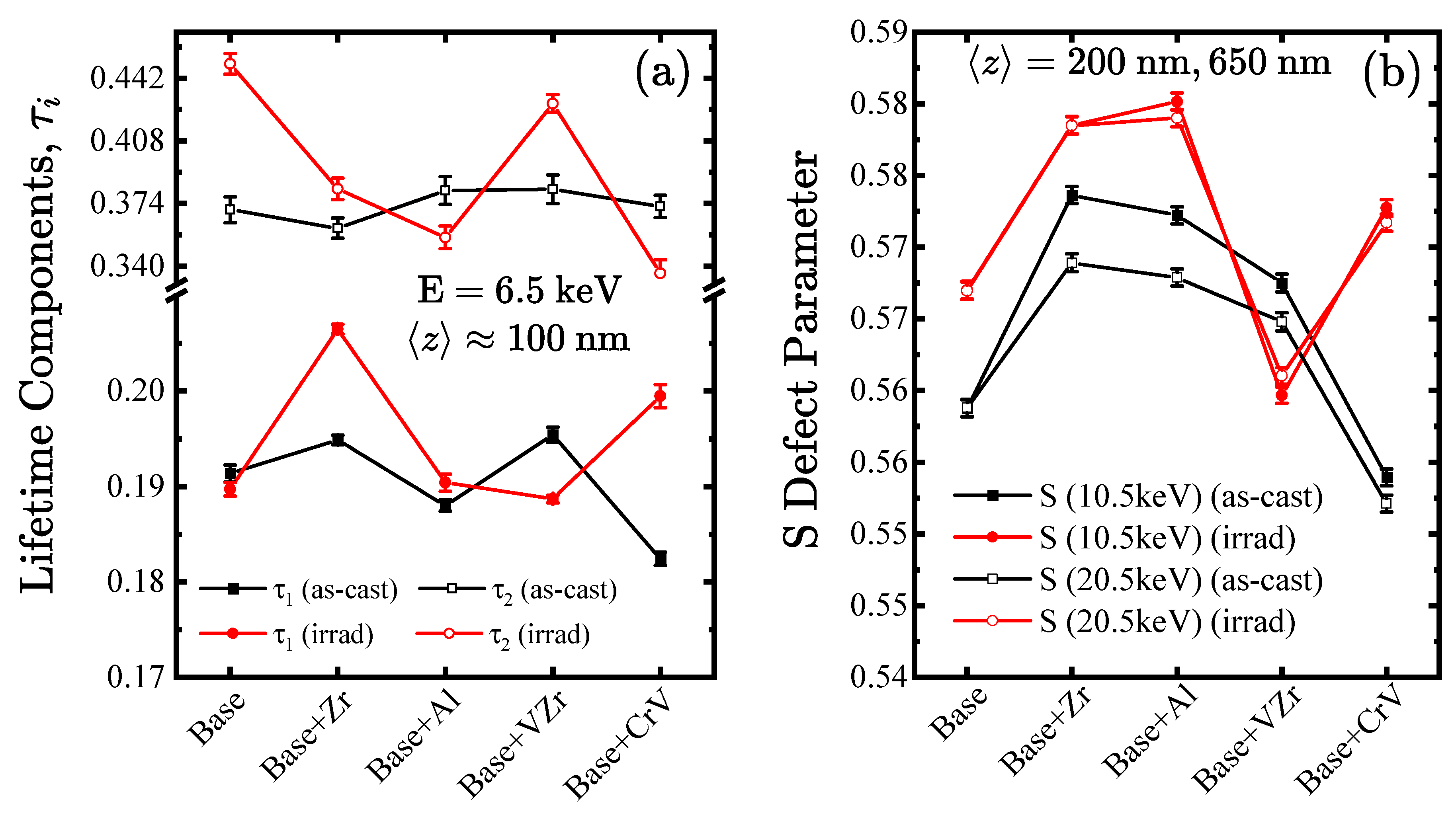

3.2. Defect and PALS Analysis

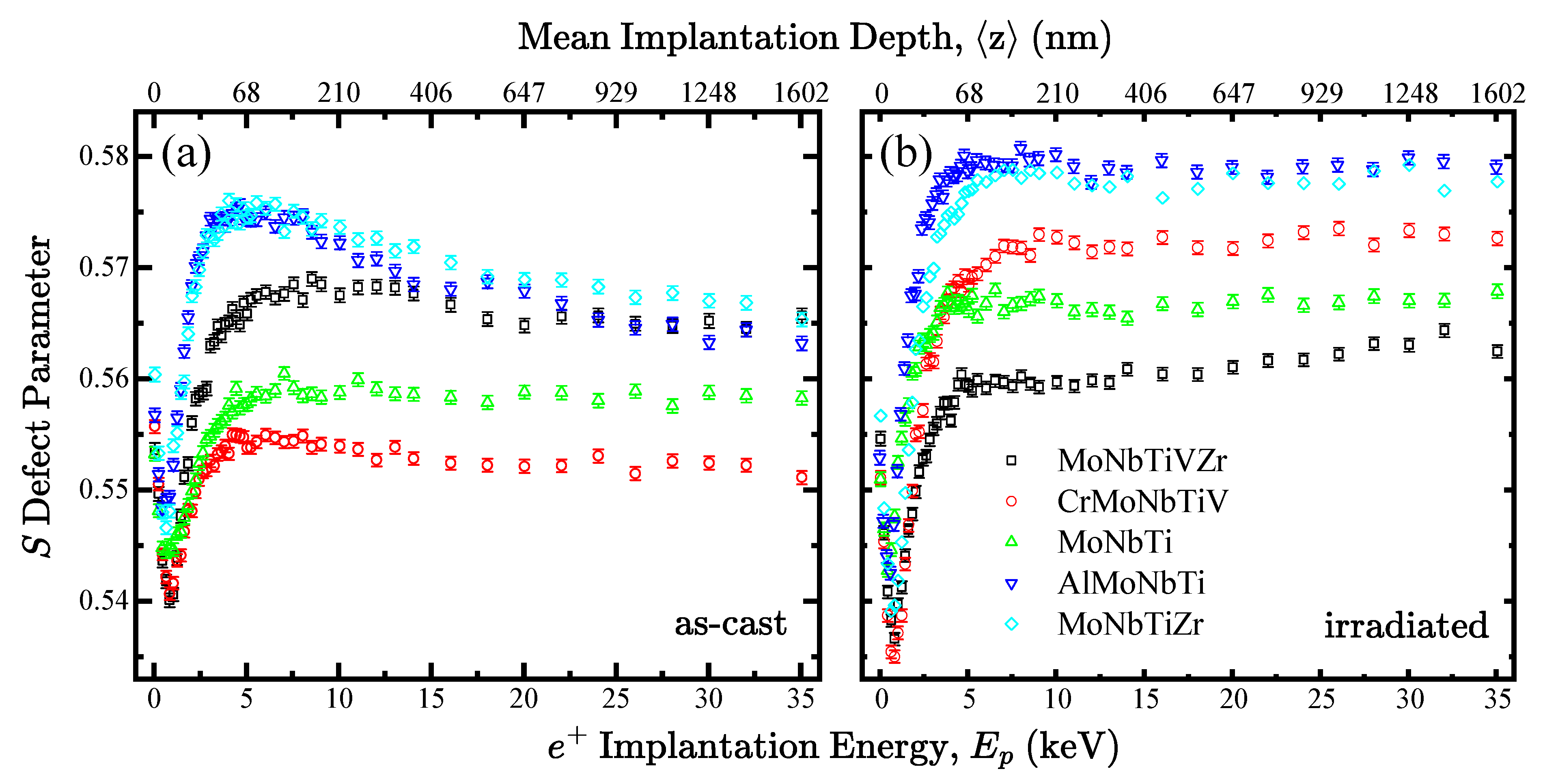

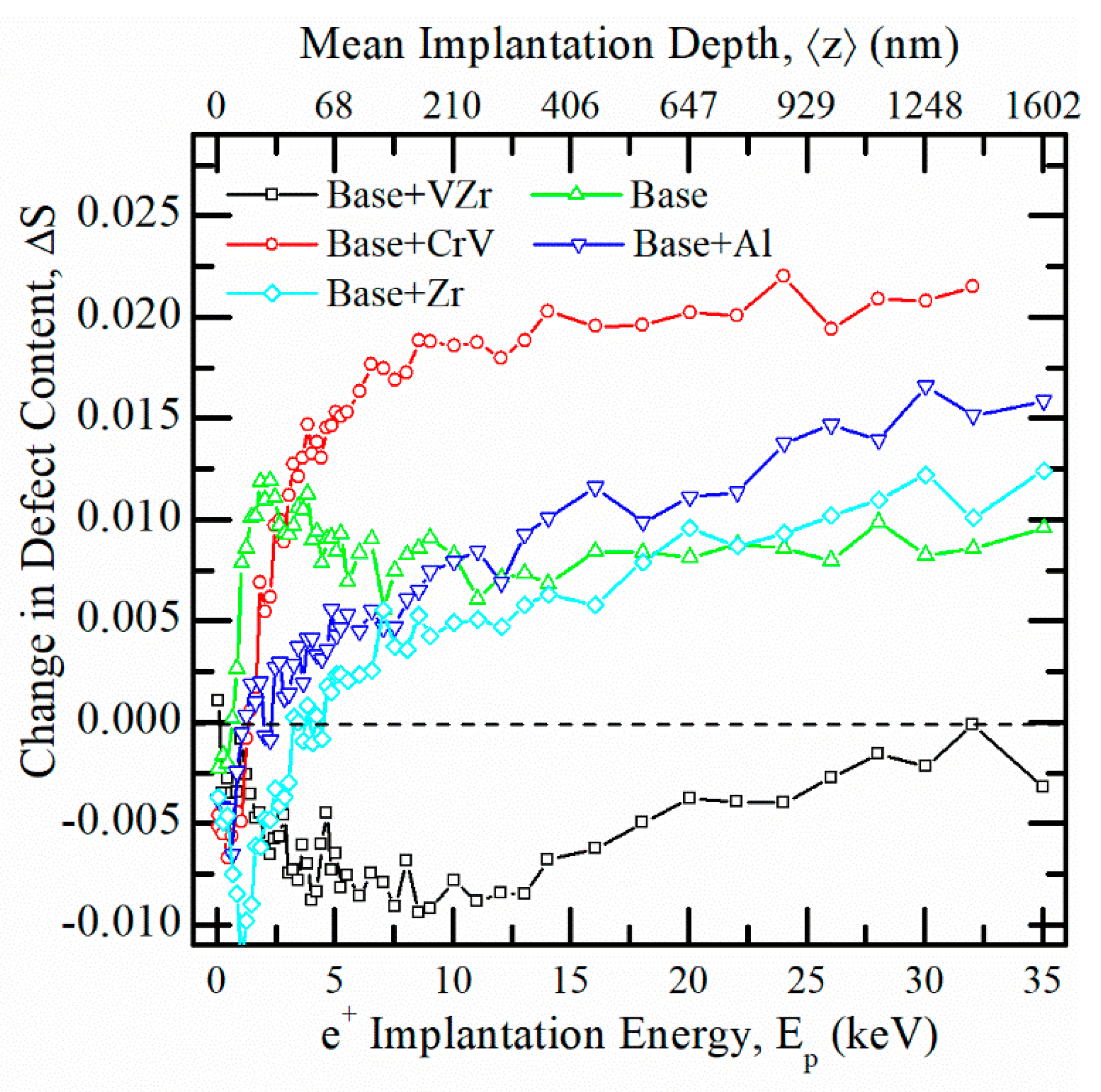

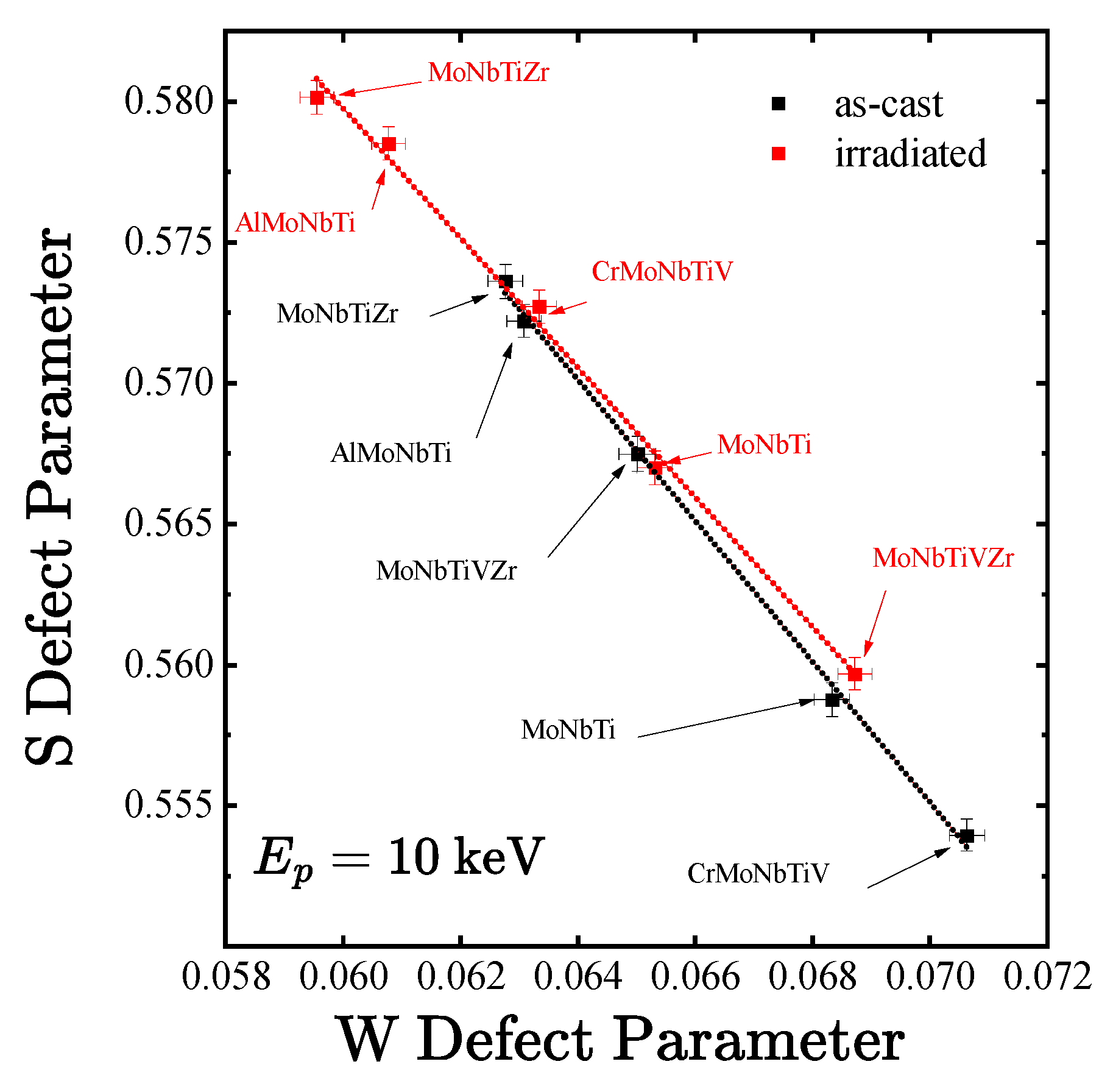

3.3. DBS Analysis

3.4. Characteristics of Defects in As-Cast Samples

3.5. Characterization of Defects in Irradiated Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Y.; Han, J.; Wang, X.; Jiang, W.; Liu, C.-T.; Zhang, Z.; Liaw, P.K. Nanoprecipitate-Strengthened High-Entropy Alloys. Adv. Sci. 2021, 8, 2100870. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy Design and Properties Optimization of High-Entropy Alloys. JOM 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.; Liu, W.; Kai, J.; Liu, C. L12-Strengthened High-Entropy Alloys for Advanced Structural Applications. J. Mater. Res. 2018, 33, 2983–2997. [Google Scholar] [CrossRef]

- Tong, C.-J.; Chen, M.-R.; Yeh, J.-W.; Lin, S.-J.; Lee, P.-H.; Shun, T.-T.; Chang, S.-Y. Mechanical Performance of the AlXCoCrCuFeNi High-Entropy Alloy System with Multiprincipal Elements. Metall. Mater. Trans. A 2005, 36, 1263–1271. [Google Scholar] [CrossRef]

- Iroc, L.K.; Tukac, O.U.; Tanrisevdi, B.B.; El-Atwani, O.; Tunes, M.A.; Kalay, Y.E.; Aydogan, E. Design of Oxygen-Doped TiZrHfNbTa Refractory High Entropy Alloys with Enhanced Strength and Ductility. Mater. Des. 2022, 223, 111239. [Google Scholar] [CrossRef]

- Kumar, N.A.P.K.; Li, C.; Leonard, K.J.; Bei, H.; Zinkle, S.J. Microstructural Stability and Mechanical Behavior of FeNiMnCr High Entropy Alloy under Ion Irradiation. Acta Mater. 2016, 113, 230–244. [Google Scholar] [CrossRef]

- El Atwani, O.; Vo, H.T.; Tunes, M.A.; Lee, C.; Alvarado, A.; Krienke, N.; Poplawsky, J.D.; Kohnert, A.A.; Gigax, J.; Chen, W.-Y.; et al. A Quinary WTaCrVHf Nanocrystalline Refractory High-Entropy Alloy Withholding Extreme Irradiation Environments. Nat. Commun. 2023, 14, 2516. [Google Scholar] [CrossRef] [PubMed]

- Li, T.-X.; Miao, J.-W.; Guo, E.-Y.; Huang, H.; Wang, J.; Lu, Y.-P.; Wang, T.-M.; Cao, Z.-Q.; Li, T.-J. Tungsten-Containing High-Entropy Alloys: A Focused Review of Manufacturing Routes, Phase Selection, Mechanical Properties, and Irradiation Resistance Properties. Tungsten 2021, 3, 181–196. [Google Scholar] [CrossRef]

- Egami, T.; Guo, W.; Rack, P.D.; Nagase, T. Irradiation Resistance of Multicomponent Alloys. Metall. Mater. Trans. A 2014, 45, 180–183. [Google Scholar] [CrossRef]

- Tsai, M.-H. Three Strategies for the Design of Advanced High-Entropy Alloys. Entropy 2016, 18, 252. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory High-Entropy Alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A Critical Review of High Entropy Alloys and Related Concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-Component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical Properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 Refractory High Entropy Alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinie, J.-P. Development and Exploration of Refractory High Entropy Alloys—A Review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef]

- Lee, C.; Xie, D.; Kyle Derby, B.; Kevin Baldwin, J.; Tandoc, C.; EI Atwani, O.; Hu, Y.-J.; Valdez, J.A.; Li, N.; Fensin, S.J. An Experimentally Driven High-Throughput Approach to Design Refractory High-Entropy Alloys. Mater. Des. 2022, 223, 111259. [Google Scholar] [CrossRef]

- Selim, F.A. Positron Annihilation Spectroscopy of Defects in Nuclear and Irradiated Materials—A Review. Mater. Charact. 2021, 174, 110952. [Google Scholar] [CrossRef]

- Kim, H.; Chancey, M.R.; Chung, T.; Brackenbury, I.; Liedke, M.O.; Butterling, M.; Hirschmann, E.; Wagner, A.; Baldwin, J.K.; Derby, B.K.; et al. Interface Effect of Fe and Fe2O3 on the Distributions of Ion Induced Defects. J. Appl. Phys. 2022, 132, 105901. [Google Scholar] [CrossRef]

- Agarwal, S.; Butterling, M.; Liedke, M.O.; Yano, K.H.; Schreiber, D.K.; Jones, A.C.L.; Uberuaga, B.P.; Wang, Y.Q.; Chancey, M.; Kim, H.; et al. The Mechanism behind the High Radiation Tolerance of Fe–Cr Alloys. J. Appl. Phys. 2022, 131, 125903. [Google Scholar] [CrossRef]

- Elsayed, M.; Krause-Rehberg, R.; Eisenschmidt, C.; Eißmann, N.; Kieback, B. Defect Study in CoCrFeMnNi High Entropy Alloy by Positron Annihilation Lifetime Spectroscopy. Phys. Status Solidi A 2018, 215, 1800036. [Google Scholar] [CrossRef]

- Xu, Q.; Zhu, T.; Zhong, Z.H.; Cao, X.Z.; Tsuchida, H. Investigation of Irradiation Resistance Characteristics of Precipitation Strengthened High-Entropy Alloy (CoCrFeNi)95Ti1Nb1Al3 Using Slow Positron Beam. J. Alloys Compd. 2021, 888, 161518. [Google Scholar] [CrossRef]

- Čížek, J.; Vlasák, T.; Melikhova, O. Characterization of Lattice Defects in Refractory Metal High-Entropy Alloy HfNbTaTiZr by Means of Positron Annihilation Spectroscopy. Phys. Status Solidi A 2022, 219, 2100840. [Google Scholar] [CrossRef]

- Tuomisto, F.; Makkonen, I.; Heikinheimo, J.; Granberg, F.; Djurabekova, F.; Nordlund, K.; Velisa, G.; Bei, H.; Xue, H.; Weber, W.J.; et al. Segregation of Ni at Early Stages of Radiation Damage in NiCoFeCr Solid Solution Alloys. Acta Mater. 2020, 196, 44–51. [Google Scholar] [CrossRef]

- Zhang, Y.; Stocks, G.M.; Jin, K.; Lu, C.; Bei, H.; Sales, B.C.; Wang, L.; Béland, L.K.; Stoller, R.E.; Samolyuk, G.D.; et al. Influence of Chemical Disorder on Energy Dissipation and Defect Evolution in Concentrated Solid Solution Alloys. Nat. Commun. 2015, 6, 8736. [Google Scholar] [CrossRef]

- Lwai, T.; Sekimura, N.; Garner, F.A. Void Swelling Behavior in Ion-Irradiated Vanadium Alloys. J. Nucl. Mater. 1996, 239, 157–161. [Google Scholar] [CrossRef]

- Zhang, Z.; Armstrong, D.E.J.; Grant, P.S. The Effects of Irradiation on CrMnFeCoNi High-Entropy Alloy and Its Derivatives. Prog. Mater. Sci. 2022, 123, 100807. [Google Scholar] [CrossRef]

- Xia, S.Q.; Yang, X.; Yang, T.F.; Liu, S.; Zhang, Y. Irradiation Resistance in AlxCoCrFeNi High Entropy Alloys. JOM 2015, 67, 2340–2344. [Google Scholar] [CrossRef]

- Ayyappan, S.; Forrester, J.S.; Selim, F.; Beausoleil, G.; Kaoumi, D. Effect of Al Addition to the Multi-Principal Elemental AlxCrFeNiCu Alloy System in Terms of the Resulting Microstructure and Ion Irradiation Response. J. Alloys Compd. 2025, 1031, 180882. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C.; Miracle, D.B. Microstructure and Properties of Aluminum-Containing Refractory High-Entropy Alloys. JOM 2014, 66, 2030–2042. [Google Scholar] [CrossRef]

- Beausoleil, G.L.; Parry, M.E.; Mondal, K.; Kwon, S.; Gomez-Hurtado, L.R.; Kaoumi, D.; Aguiar, J.A. Spark Plasma Sintered, MoNbTi-Based Multi-Principal Element Alloys with Cr, V, and Zr. J. Alloys Compd. 2022, 927, 167083. [Google Scholar] [CrossRef]

- Robles, J.M.C.; Ogando, E.; Plazaola, F. Positron Lifetime Calculation for the Elements of the Periodic Table. J. Phys. Condens. Matter 2007, 19, 176222. [Google Scholar] [CrossRef]

- Schultz, P.J.; Lynn, K.G. Interaction of Positron Beams with Surfaces, Thin Films, and Interfaces. Rev. Mod. Phys. 1988, 60, 701–779. [Google Scholar] [CrossRef]

- Selim, F.A.; Wells, D.P.; Harmon, J.F.; Kwofie, J.; Erikson, G.; Roney, T. New Positron Annihilation Spectroscopy Techniques for Thick Materials. Radiat. Phys. Chem. 2003, 68, 427–430. [Google Scholar] [CrossRef]

- Selim, F.A.; Wells, D.P.; Harmon, J.F.; Williams, J. Development of Accelerator-Based γ-Ray-Induced Positron Annihilation Spectroscopy Technique. J. Appl. Phys. 2005, 97, 113539. [Google Scholar] [CrossRef]

- Selim, F.A.; Wells, D.P.; Harmon, J.F.; Scates, W.; Kwofie, J.; Spaulding, R.; Duttagupta, S.P.; Jones, J.L.; White, T.; Roney, T. Doppler broadening measurements of positron annihilation using bremsstrahlung radiation. Nucl. Instrum Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2002, 192, 197–201. [Google Scholar] [CrossRef]

- Weber, M.H.; Selim, F.A.; Solodovnikov, D.; Lynn, K.G. Defect Engineering of ZnO. Appl. Surf. Sci. 2008, 255, 68–70. [Google Scholar] [CrossRef]

- Wagner, A.; Butterling, M.; Liedke, M.O.; Potzger, K.; Krause-Rehberg, R. Positron Annihilation Lifetime and Doppler Broadening Spectroscopy at the ELBE Facility. AIP Conf. Proc. 2018, 1970, 040003. [Google Scholar] [CrossRef]

- Saadatkia, P.; Agarwal, S.; Hernandez, A.; Reed, E.; Brackenbury, I.D.; Codding, C.L.; Liedke, M.O.; Butterling, M.; Wagner, A.; Selim, F.A. Point and Extended Defects in Heteroepitaxial β−Ga2O3 Films. Phys. Rev. Mater. 2020, 4, 104602. [Google Scholar] [CrossRef]

- Winarski, D.J.; Anwand, W.; Wagner, A.; Saadatkia, P.; Selim, F.A.; Allen, M.; Wenner, B.; Leedy, K.; Allen, J.; Tetlak, S.; et al. Induced Conductivity in Sol-Gel ZnO Films by Passivation or Elimination of Zn Vacancies. AIP Adv. 2016, 6, 095004. [Google Scholar] [CrossRef]

- Haseman, M.; Saadatkia, P.; Winarski, D.J.; Selim, F.A.; Leedy, K.D.; Tetlak, S.; Look, D.C.; Anwand, W.; Wagner, A. Effects of substrate and post-growth treatments on the microstructure and properties of ZnO thin films prepared by atomic layer deposition. J. Electron. Mater. 2016, 45, 6337–6345. [Google Scholar] [CrossRef]

- Ghosh, V.J. Positron Implantation Profiles in Elemental and Multilayer Systems. Appl. Surf. Sci. 1995, 85, 187–195. [Google Scholar] [CrossRef][Green Version]

- Osei-Agyemang, E.; Balasubramanian, G. Surface Oxidation Mechanism of a Refractory High-Entropy Alloy. Npj Mater. Degrad. 2019, 3, 20. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, Y.; Liu, B.; Zhang, W.; Wang, J.; Du, M. Effects of Al and Mo on High Temperature Oxidation Behavior of Refractory High Entropy Alloys. Trans. Nonferrous Met. Soc. China 2019, 29, 1476–1483. [Google Scholar] [CrossRef]

- Siemek, K.; Horodek, P.; Skuratov, V.A.; Waliszewski, J.; Sohatsky, A. Positron Annihilation Studies of Irradiation Induced Defects in Nanostructured Titanium. Vacuum 2021, 190, 110282. [Google Scholar] [CrossRef]

| RMPEA | Mo | Nb | Ti | V | Cr | Zr | Al |

|---|---|---|---|---|---|---|---|

| MoNbTi | 32% | 31% | 37% | ||||

| AlMoNbTi | 37% | 35% | 18% | 10% | |||

| MoNbTiZr | 22% | 25% | 30% | 23% | |||

| CrMonbTiV | 17% | 18% | 21% | 22% | 22% | ||

| MoNbTiVZr | 18% | 19% | 21% | 24% | 18% |

| Element | Bulk (ps) | Monovacancy (ps) | RMPEA | (ps) | (ps) |

|---|---|---|---|---|---|

| Mo | 106 | 170 | MoNbTi | 126.62 | 201.64 |

| Nb | 120 | 210 | MoNbTiZr | 136.04 | 214.46 |

| Ti | 150 | 222 | AlMoNbTi | 124.72 | 200.76 |

| V | 124 | 191 | MoNbTiVZr | 132.66 | 208.32 |

| Cr | 120 | 150 | CrMoNbTiV | 124.80 | 210.78 |

| Zr | 164 | 252 | |||

| Al | 165 | 244 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chung, T.h.; Liedke, M.O.; Ayyappan, S.; Butterling, M.; Ferguson, R.C.; Jones, A.C.L.; Wagner, A.; Hattar, K.; Kaoumi, D.; Selim, F.A. Point Defects in MoNbTi-Based Refractory Multi-Principal-Element Alloys. Metals 2025, 15, 989. https://doi.org/10.3390/met15090989

Chung Th, Liedke MO, Ayyappan S, Butterling M, Ferguson RC, Jones ACL, Wagner A, Hattar K, Kaoumi D, Selim FA. Point Defects in MoNbTi-Based Refractory Multi-Principal-Element Alloys. Metals. 2025; 15(9):989. https://doi.org/10.3390/met15090989

Chicago/Turabian StyleChung, Thai hang, Maciej Oskar Liedke, Saikumaran Ayyappan, Maik Butterling, Riley Craig Ferguson, Adric C. L. Jones, Andreas Wagner, Khalid Hattar, Djamel Kaoumi, and Farida A. Selim. 2025. "Point Defects in MoNbTi-Based Refractory Multi-Principal-Element Alloys" Metals 15, no. 9: 989. https://doi.org/10.3390/met15090989

APA StyleChung, T. h., Liedke, M. O., Ayyappan, S., Butterling, M., Ferguson, R. C., Jones, A. C. L., Wagner, A., Hattar, K., Kaoumi, D., & Selim, F. A. (2025). Point Defects in MoNbTi-Based Refractory Multi-Principal-Element Alloys. Metals, 15(9), 989. https://doi.org/10.3390/met15090989