Effect of H3PO4 Coating, Polyimide Binder, and MoS2/Graphite Lubricants on the Formability and Electromagnetic Properties of Fe-5.0 wt.%Si SMC Toroidal Cores

Abstract

1. Introduction

- Setting Additive Conditions: H3PO4 was selected as the insulating coating agent, polyimide as the binder, and MoS2 and graphite as lubricants, with the range of each additive amount established.

- Experimental Design and Specimen Fabrication: Experimental arrangements were organized according to the set content combinations, and all specimens were fabricated into a toroidal core shape under identical processing conditions.

- Macroscopic Property Evaluation: The density and electromagnetic properties (permeability, quality value (Q-value)) of the fabricated specimens were quantitatively measured.

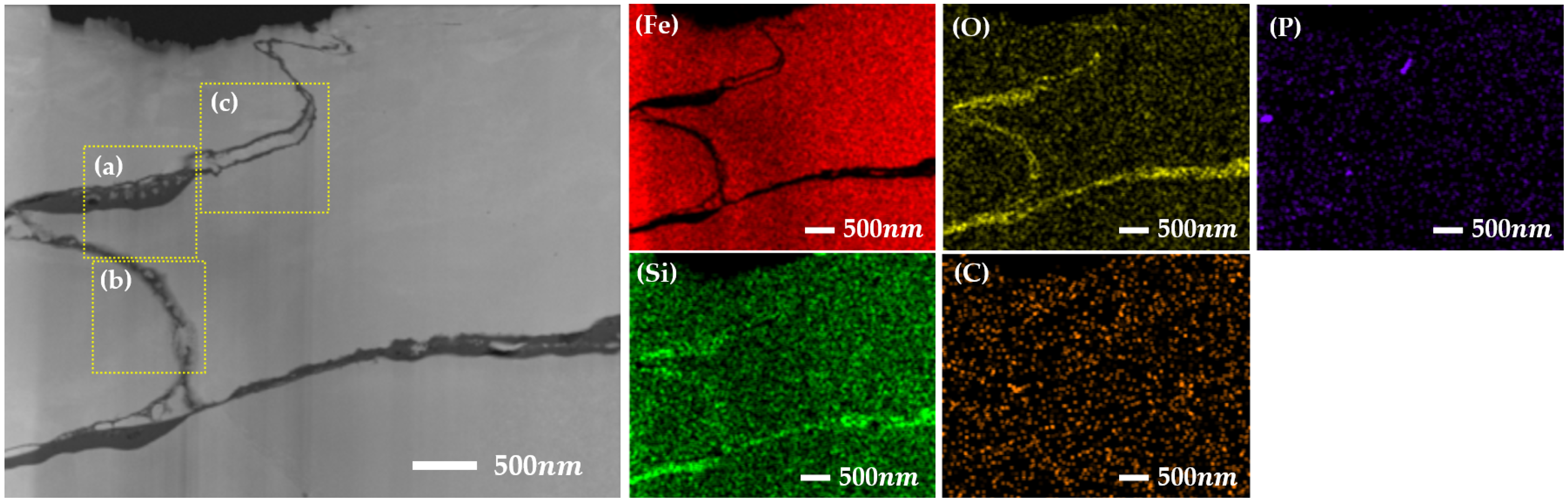

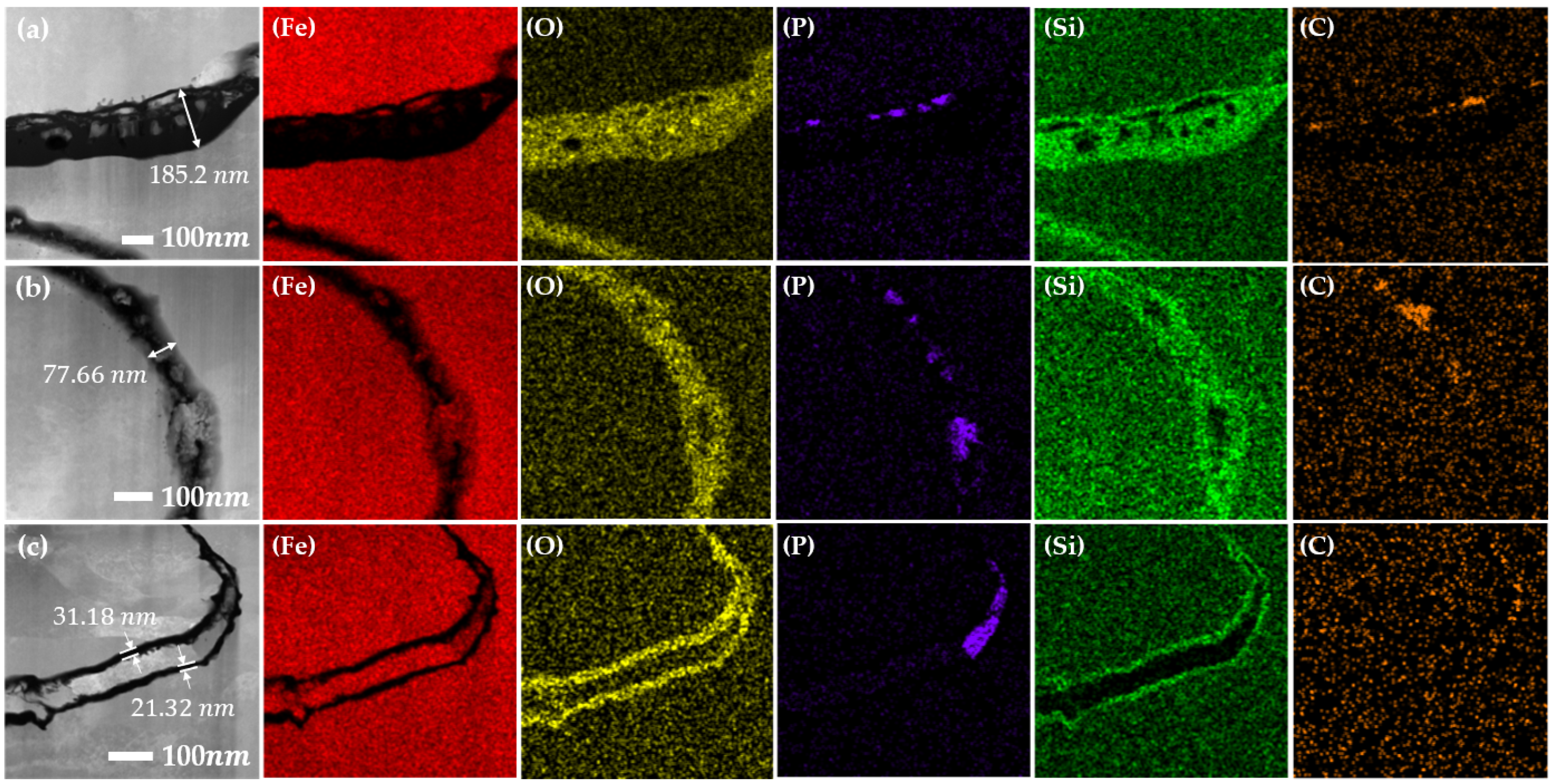

- Microstructure Analysis: Representative specimens were selected, and the morphology and composition of the insulating layer were analyzed using SEM-EDS and TEM.

- Comprehensive Analysis: Based on the measured results, the effects of varying each additive’s content on density and electromagnetic performance were systematically examined.

2. Materials and Methods

2.1. Fe-Si Powder Materials

2.2. Experimental Methods

2.2.1. Design of Experiment

2.2.2. Sample Preparation

2.3. Measurement Methods

3. Results

3.1. Effect of H3PO4-PI–Lubricant Content on Phases of Fe-5.0 wt.%Si SMC

3.2. Microstructural Analysis of the Compacted Samples

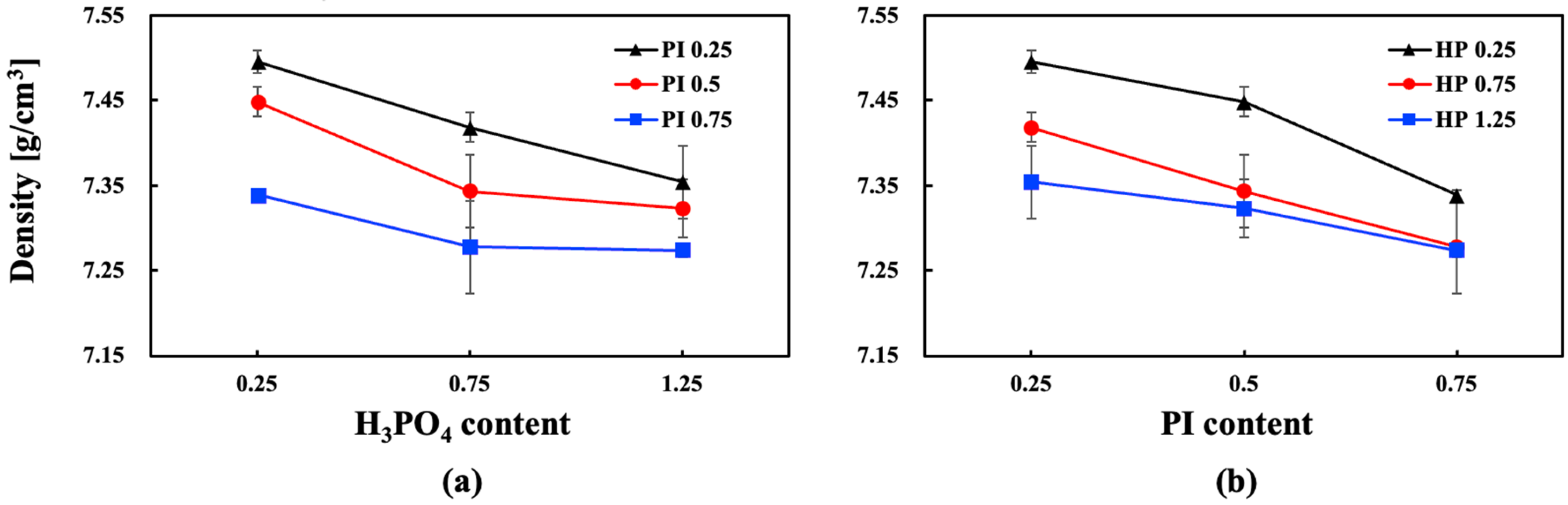

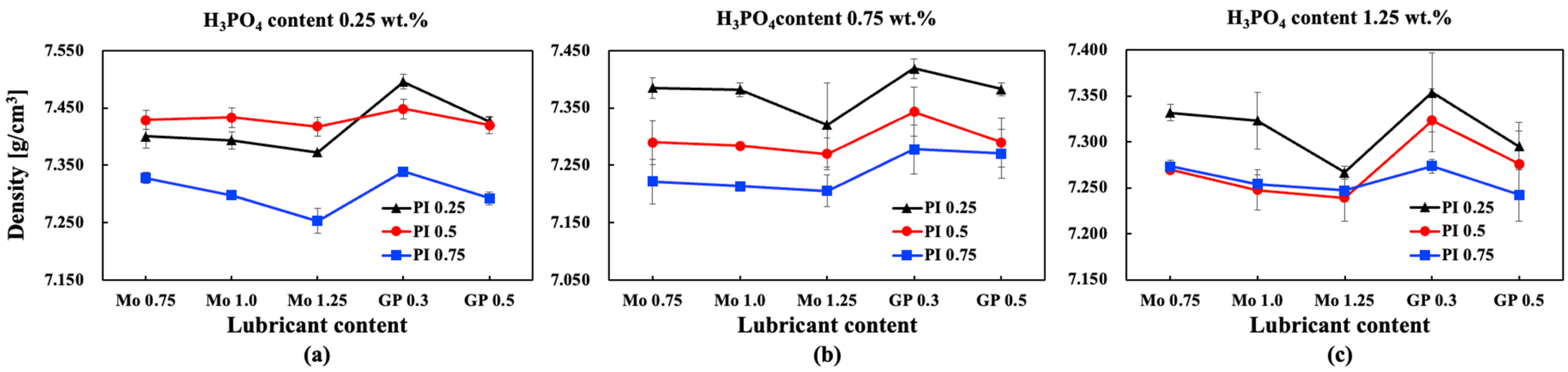

3.3. Effect of Additive Content on Density of Fe-5.0 wt.%Si SMCs

3.4. Trend of Changes in Magnetic Properties According to Additive Content

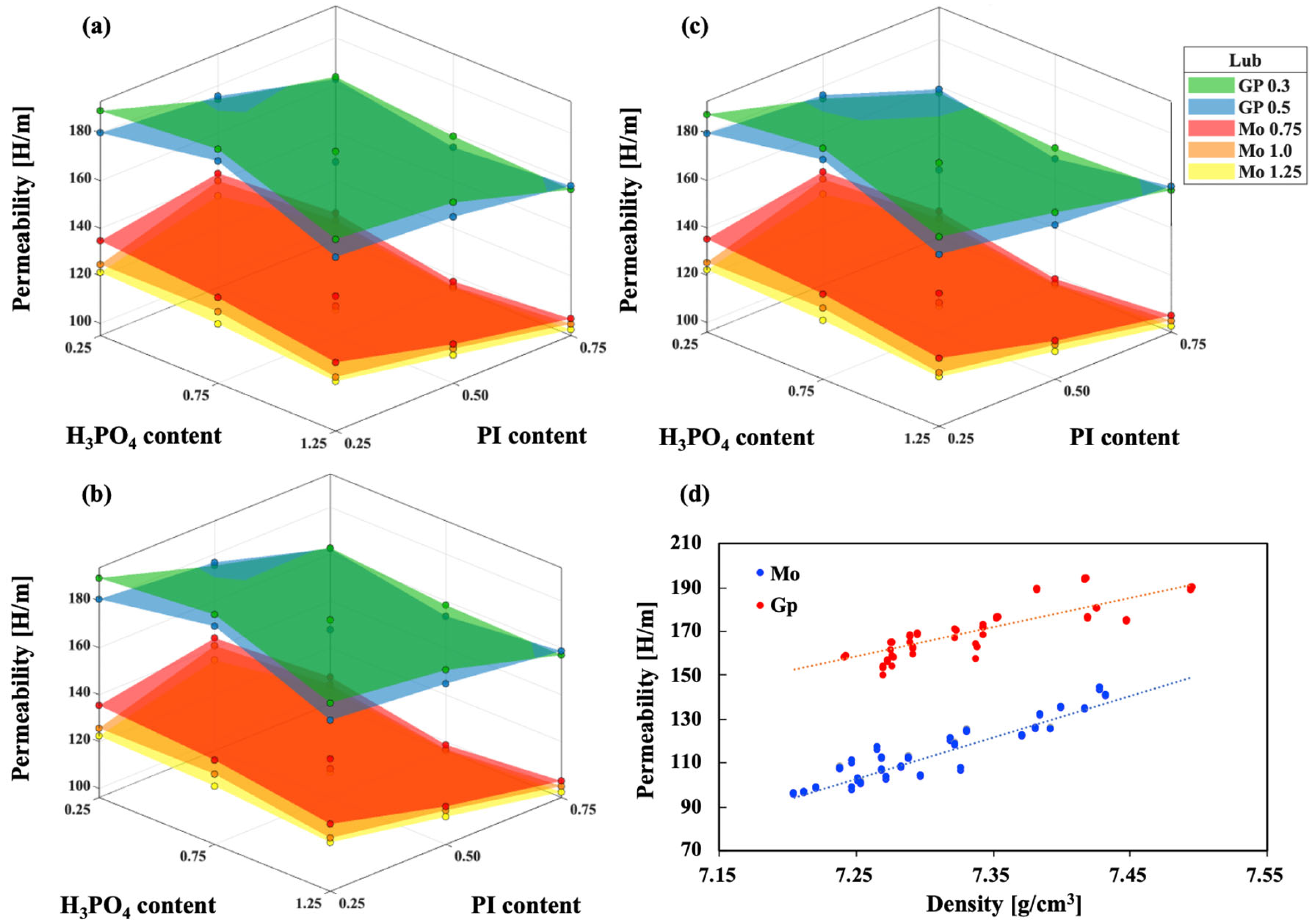

3.4.1. Permeability Trend of Fe-5.0 wt.%Si SMCs

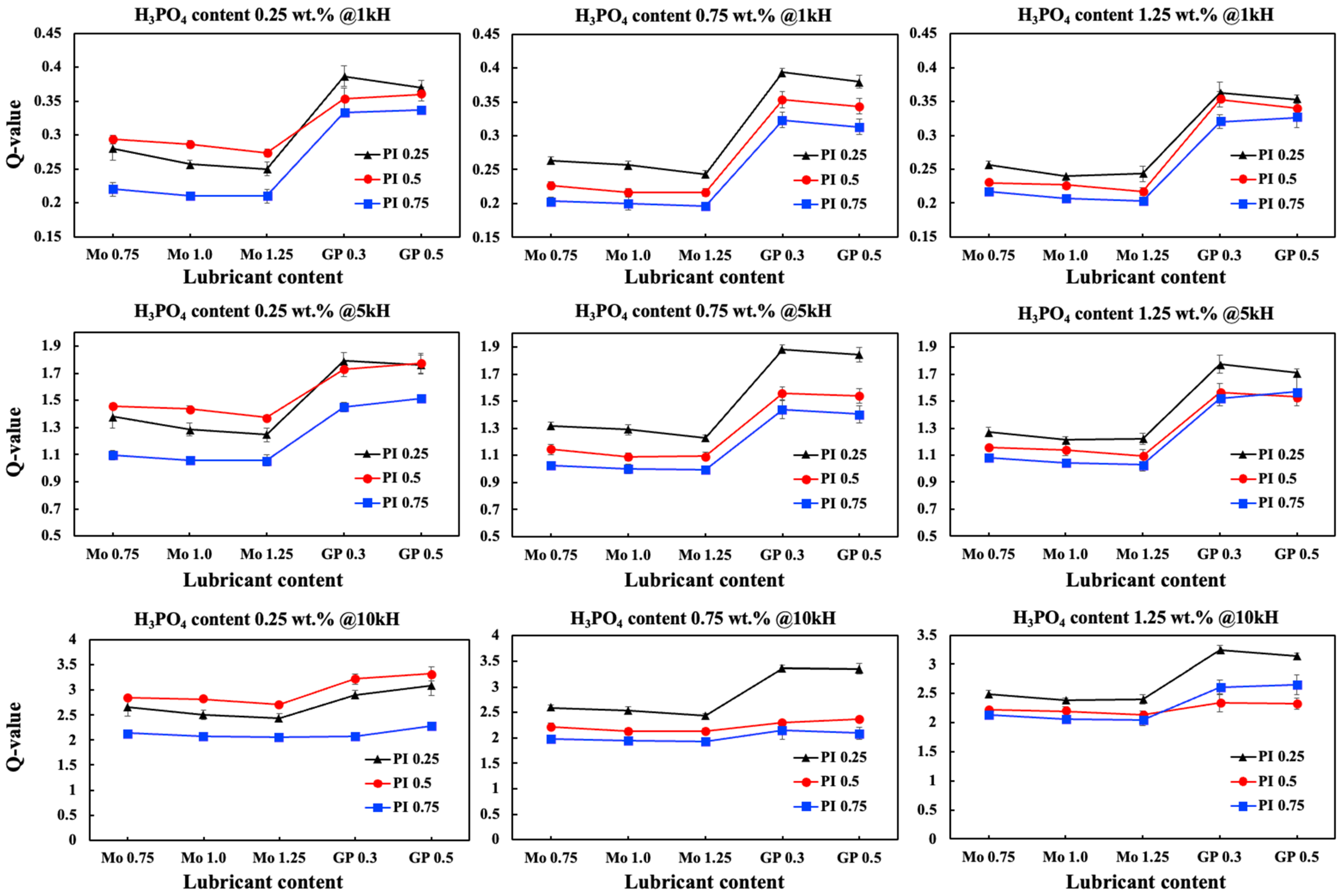

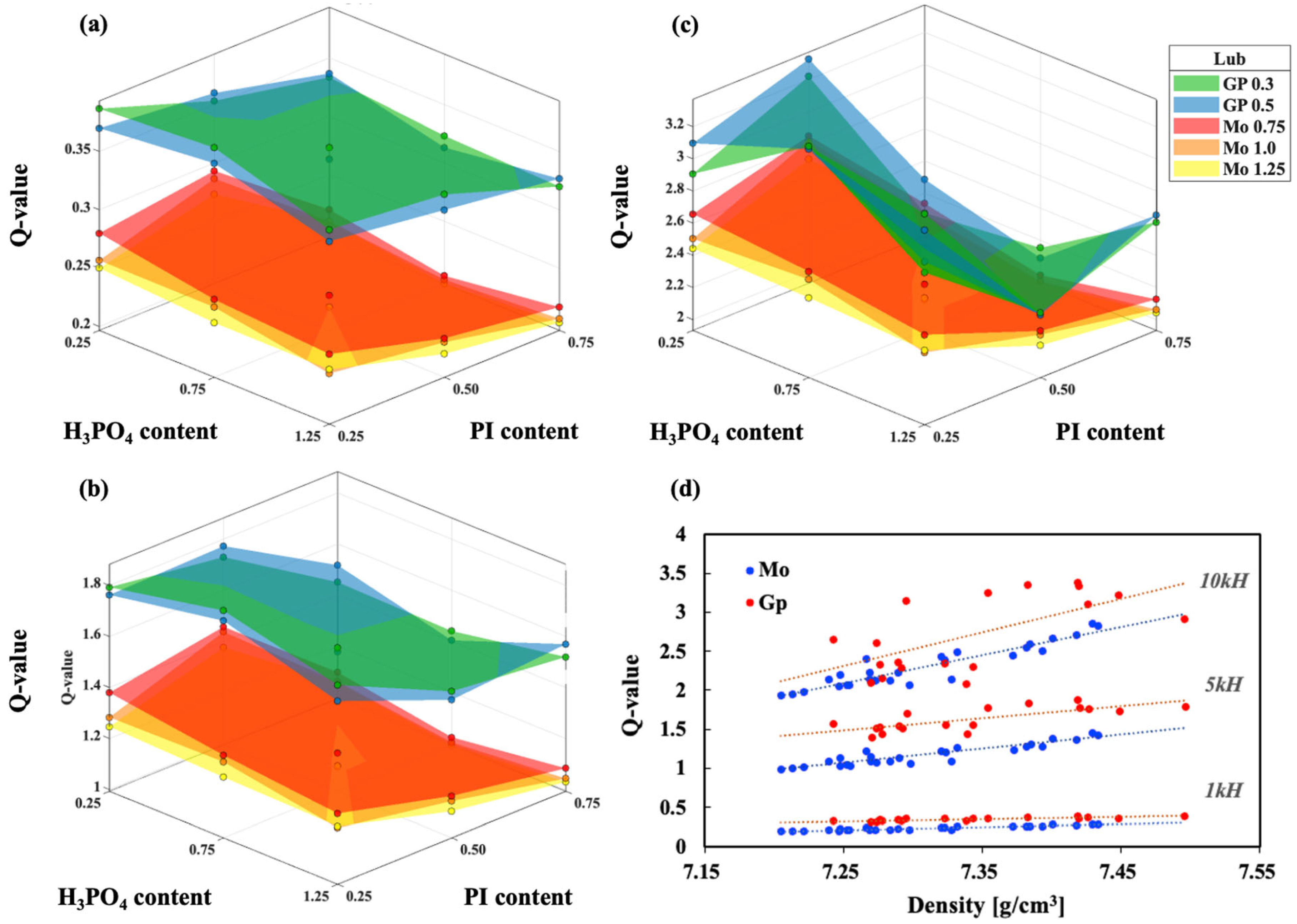

3.4.2. Q-Value Trend of Fe-5.0 wt.%Si SMCs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IEA. Global EV Outlook 2025; IEA: Paris, France, 2025; Available online: https://www.iea.org/reports/global-ev-outlook-2025 (accessed on 23 September 2025).

- De Palma, A.; Lindsey, R.; Riou, Y. Meeting the European Union’s zero-CO2-emissions target for cars in France. Transp. Res. Part A Policy Pract. 2025, 199, 104531. [Google Scholar] [CrossRef]

- Birel, T.; Breeman, G.; van Buitenen, A.; Vijver, M. Defueling the impasse: EU political discourse on e-fuels. Energy Policy 2024, 187, 114022. [Google Scholar] [CrossRef]

- Zeyen, E.; Kalweit, S.; Victoria, M.; Brown, T. Shifting burdens: How delayed decarbonisation of road transport affects other sectoral emission reductions. Environ. Res. Lett. 2025, 20, 044044. [Google Scholar] [CrossRef]

- Guo, Y.; Ba, X.; Liu, L.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. A review of electric motors with soft magnetic composite cores for electric drives. Energies 2023, 16, 2053. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, L.; Ba, X.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. Designing high-power-density electric motors for electric vehicles with advanced magnetic materials. World Electr. Veh. J. 2023, 14, 114. [Google Scholar] [CrossRef]

- He, J.; Yuan, H.; Nie, M.; Guo, H.; Yu, H.; Liu, Z.; Sun, R. Soft magnetic materials for power inductors: State of art and future development. Mater. Today Electron. 2023, 6, 100066. [Google Scholar] [CrossRef]

- Ferraris, L.; Franchini, F.; Pošković, E.; Grande, M.A.; Bidulský, R. Effect of the temperature on the magnetic and energetic properties of soft magnetic composite materials. Energies 2021, 14, 4400. [Google Scholar] [CrossRef]

- Kumar, M.; Kant, R.; Chand, S.; Prakash, U.; Sehgal, S.; Saxena, K.K.; Davim, J.P.; Prakash, C. High-temperature corrosion performance of FeAl-based alloys containing carbon in molten salt. Metals 2021, 11, 2040. [Google Scholar] [CrossRef]

- Airiskallio, E.; Nurmi, E.; Heinonen, M.H.; Väyrynen, I.J.; Kokko, K.; Ropo, M.; Punkkinen, M.P.J.; Pitkänen, H.; Alatalo, M.; Kollár, J.; et al. High temperature oxidation of Fe-Al and Fe-Cr-Al alloys: The role of Cr as a chemically active element. Corros. Sci. 2010, 52, 3394–3404. [Google Scholar] [CrossRef]

- Li, J.; Qin, C.; Ge, J.; Hu, X.; Zeng, L.; Pei, R. Magnetic behavior of high permeability materials over wide temperature range. AIP Adv. 2025, 15, 035223. [Google Scholar] [CrossRef]

- Park, J.-H.; Kim, H.-R.; Lee, J.-W.; Jeong, J.-W. Improved soft magnetic properties in FeNi@MgO composites by sol-gel-based surface coating and high-temperature heat treatment. Metals 2023, 13, 1383. [Google Scholar] [CrossRef]

- Liu, J.; Dong, Y.; Jia, X.; Chi, Q.; He, A.; Li, J.; Man, Q.; Shen, B. Effect of FeNi powder on the magnetic properties of FeSiBNbCu nanocrystalline soft magnetic powder cores. J. Mater. Sci. Mater. Electron. 2025, 36, 1699. [Google Scholar] [CrossRef]

- Zhou, B.; Yang, Y.; Qin, Y.; Yang, G.; Wu, M. Fabrication of equiatomic FeCo alloy parts with high magnetic properties by fields activated sintering. Manuf. Rev. 2022, 9, 7. [Google Scholar] [CrossRef]

- Lee, H.; Park, J.; Lee, H.; Choi-Yim, H. Correlation between soft magnetic properties and microstructure according to heat treatment in FeCo-2V electrical steel. J. Compos. Sci. 2025, 9, 61. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, B.; Cao, Y.; Yu, R.H. Preparation and magnetic properties of novel hybrid magnetic powder cores. Mater. Res. Innov. 2014, 18 (Suppl. S4), S4-610–S4-614. [Google Scholar] [CrossRef]

- Peng, Y. Effects of Nano-SiO2 on microstructure and magnetic properties of FeSi soft magnetic composites. J. Mater. Sci. Mater. Electron. 2024, 35, 1652. [Google Scholar] [CrossRef]

- Lauda, M.; Füzer, J.; Füzerová, J.; Kollár, P.; Strečková, M.; Fáberová, M. Magnetic properties of soft magnetic FeSi composite powder cores. Acta Phys. Pol. A 2014, 126, 144–145. [Google Scholar] [CrossRef]

- Backes, C.; Kahlert, M.; Vollmer, M.; Smaga, M.; Niendorf, T.; Beck, T. Microstructure and magnetic domain structure of additively manufactured Fe-Si soft magnetic alloys with 3 and 9 wt.% Si. J. Mater. Res. Technol. 2024, 29, 1691–1702. [Google Scholar] [CrossRef]

- Wu, L.; Xia, X.; Yin, W.; Tang, X.; Ju, J.; Du, Y.; Chen, R.; Xu, Z.; Zhang, Y.; Che, S.; et al. Effect of ferromagnetic Fe96.5Si3.5 dopant on microstructure and magnetic properties of hot-deformed Nd-Fe-B magnets. J. Magn. Magn. Mater. 2023, 569, 170433. [Google Scholar] [CrossRef]

- Shi, G.; Zang, J.; Chen, R.; Wang, X.; Wang, L.; Wang, M.; Cheng, Y. Differences in the magnetic properties of Finemet/FeSi soft magnetic composites prepared with epoxy resin/nano-oxide composite coating layers. Mater. Today Commun. 2024, 40, 110177. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, W.; Ju, J.; Xu, P.; Li, M.; Zhang, X.; Wang, J.; Zou, Z.; Su, H. Hot-compacted Fe-Si soft magnetic composite with low loss at low frequency. J. Mater. Sci. Mater. Electron. 2023, 34, 1523. [Google Scholar] [CrossRef]

- Li, K.; Cheng, D.; Yu, H.; Liu, Z. Process optimization and magnetic properties of soft magnetic composite cores based on phosphated and mixed resin coated Fe powders. J. Magn. Magn. Mater. 2020, 501, 166455. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, L.; Chen, Y.; Chen, F.; Qu, X.; Xie, C.; Zhang, L. Magnetic properties of iron-based soft magnetic composites prepared by utilizing polyimide insulating layer. J. Magn. Magn. Mater. 2019, 486, 165287. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Sun, H.; Chen, F.; Zhang, P.; Qu, X.; Fan, E. Enhanced magnetic properties of iron-based soft magnetic composites with phosphate-polyimide insulating layer. J. Alloys Compd. 2020, 813, 152205. [Google Scholar] [CrossRef]

- Kang, S.; Lee, S. Optimizing the manufacturing process control of Si-based soft magnetic composites. Materials 2025, 18, 2321. [Google Scholar] [CrossRef]

- Lu, D.; Wang, L.; Dong, W.; Chen, C.; Li, Z.; Rehman, S.U.; Zou, H. MoS2 composite FeSiCr soft magnetic alloy materials and their wave-absorbing properties. J. Alloys Compd. 2024, 1010, 177835. [Google Scholar] [CrossRef]

- Liu, C.; Yin, Y.; Tong, B.; Zhang, G. Tribological properties of MoS2 powder-lubricated interface. Ind. Lubr. Tribol. 2021, 73, 839–845. [Google Scholar] [CrossRef]

- Li, N.; Feng, S.; Kan, X.; Liu, X.; Zhang, C.; Zhu, Y.; Chi, S.; Sun, W. The preparation and magnetic properties of FeSiCr/MoS2 soft magnetic composites. Phys. Scr. 2024, 99, 0659d1. [Google Scholar] [CrossRef]

- Kumar, R.; Hussainova, I.; Rahmani, R.; Antonov, M. Solid lubrication at high-temperatures-A review. Materials 2022, 15, 1695. [Google Scholar] [CrossRef]

- Hedayati, H.; Mofidi, A.; Al-Fadhli, A.; Aramesh, M. Solid lubricants used in extreme conditions experienced in machining: A comprehensive review of recent developments and applications. Lubricants 2024, 12, 69. [Google Scholar] [CrossRef]

- Lapierre-Boire, L.-P.; Blais, C.; Pelletier, S.; Chagnon, F. Improvement of flow of an iron-copper-graphite powder mix through additions of nanoparticles. Powder Technol. 2016, 299, 156–167. [Google Scholar] [CrossRef]

- Kang, S.; Lee, S. Formability and electromagnetic performance comparison of Fe-P-based SMC and Fe-5.0 wt.%Si powders. Materials 2025, 18, 4405. [Google Scholar] [CrossRef] [PubMed]

- Ulusoy, U. A Review of Particle Shape Effects on Material Properties for Various Engineering Applications: From Macro to Nanoscale. Minerals 2023, 13, 91. [Google Scholar] [CrossRef]

- Luo, P.; Yu, H.; Wang, C.; Yuan, H.; Liu, Z.; Wang, Y.; Yang, L.; Wu, W. Properties Optimization of Amorphous Soft Magnetic Composites Based on the Powders with Double Layer Inorganic Coating by Phosphating and Sodium Silicate Treatment. Metals 2023, 13, 560. [Google Scholar] [CrossRef]

- Long, H.; Wu, X.; Lu, Y.; Zhang, H.; Hao, J. Effect of Polyimide-Phosphating Double Coating and Annealing on the Magnetic Properties of Fe-Si-Cr SMCs. Materials 2022, 15, 3350. [Google Scholar] [CrossRef]

- KS D 0033; Method for Determination of Density of Metal Powder Sintered Materials. Korean Standards Association: Seoul, Republic of Korea, 2021.

- Polcarová, M.; Kadečková, S.; Bradler, J.; Godwod, K.; Ba̧k-misiuk, J. Lattice Parameters of Fe-Si Alloy Single Crystals. Phys. Status Solidi A 1988, 106, 17–23. [Google Scholar] [CrossRef]

- Ohnuma, I.; Abe, S.; Shimenouchi, S.; Omori, T.; Kainuma, R.; Ishida, K. Experimental and thermodynamic studies of the Fe-Si binary system. ISIJ Int. 2012, 52, 540–548. [Google Scholar] [CrossRef]

- Muñoz, Á.S.; Burgos, N.; Zhukova, V.; Talaat, A.; Martín, J.M.; González, J.; Osinalde, M. Magnetic properties and power losses of inorganic, organic and hybrid-based soft magnetic composites. Ceram. Int. 2024, 50, 55099–55112. [Google Scholar] [CrossRef]

- Pan, Y.; Peng, J.; Qian, L.; Xiang, Z.; Lu, W. Effects of compaction and heat treatment on the soft magnetic properties of iron-based soft magnetic composites. Mater. Res. Express 2020, 7, 016115. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, A.; Li, Y.; Song, D.; Li, Y.; Cheng, L. Thermal Decomposition Behavior of Polyimide Containing Flame Retardant SiO2 and Mg(OH)2. Polymers 2022, 14, 2791. [Google Scholar] [CrossRef]

- Hsiang, H.-I.; Fan, L.-F.; Hung, J.-J. Phosphoric acid addition effect on the microstructure and magnetic properties of iron-based soft magnetic composites. J. Magn. Magn. Mater. 2018, 447, 1–8. [Google Scholar] [CrossRef]

| Element | Fe | Si | O | Average Particle Size |

|---|---|---|---|---|

| wt.% | 94.85 | 5.02 | 0.13 | 79.136 μm |

| Description [wt.%] | Level | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| H3PO4 | 0.25 | 0.75 | 1.25 | ||

| Polyimide | 0.25 | 0.5 | 0.75 | ||

| Lubricant | MoS2 0.75 | MoS2 1.0 | MoS2 1.25 | Graphite 0.3 | Graphite 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.; Lee, S. Effect of H3PO4 Coating, Polyimide Binder, and MoS2/Graphite Lubricants on the Formability and Electromagnetic Properties of Fe-5.0 wt.%Si SMC Toroidal Cores. Metals 2025, 15, 1247. https://doi.org/10.3390/met15111247

Kang S, Lee S. Effect of H3PO4 Coating, Polyimide Binder, and MoS2/Graphite Lubricants on the Formability and Electromagnetic Properties of Fe-5.0 wt.%Si SMC Toroidal Cores. Metals. 2025; 15(11):1247. https://doi.org/10.3390/met15111247

Chicago/Turabian StyleKang, Seongsu, and Seonbong Lee. 2025. "Effect of H3PO4 Coating, Polyimide Binder, and MoS2/Graphite Lubricants on the Formability and Electromagnetic Properties of Fe-5.0 wt.%Si SMC Toroidal Cores" Metals 15, no. 11: 1247. https://doi.org/10.3390/met15111247

APA StyleKang, S., & Lee, S. (2025). Effect of H3PO4 Coating, Polyimide Binder, and MoS2/Graphite Lubricants on the Formability and Electromagnetic Properties of Fe-5.0 wt.%Si SMC Toroidal Cores. Metals, 15(11), 1247. https://doi.org/10.3390/met15111247