Effect of Heat Treatments and Related Microstructural Modifications on High-Cycle Fatigue Behavior of Powder Bed Fusion–Laser Beam-Fabricated Ti-6Al-2Sn-4Zr-6Mo Alloy

Abstract

1. Introduction

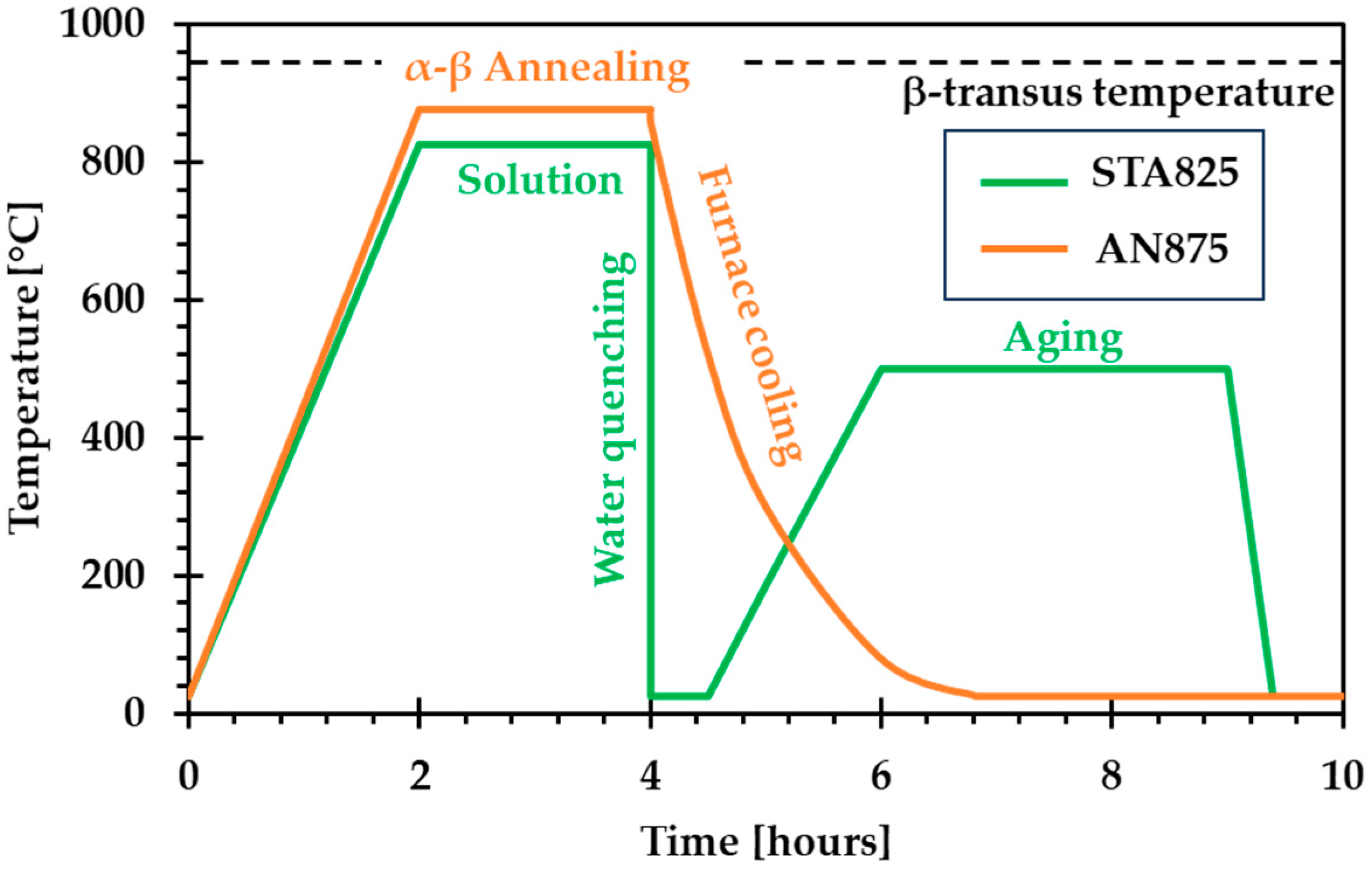

2. Materials and Methods

2.1. Sample Production

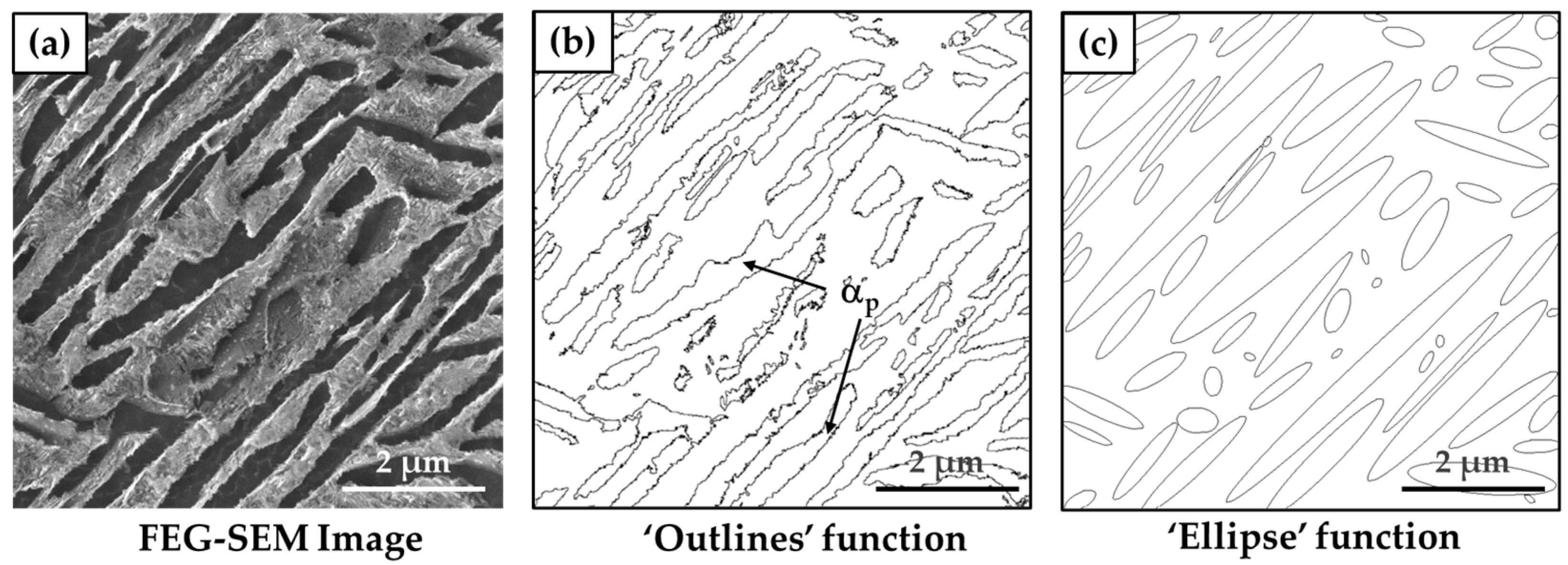

2.2. Microstructural Characterization

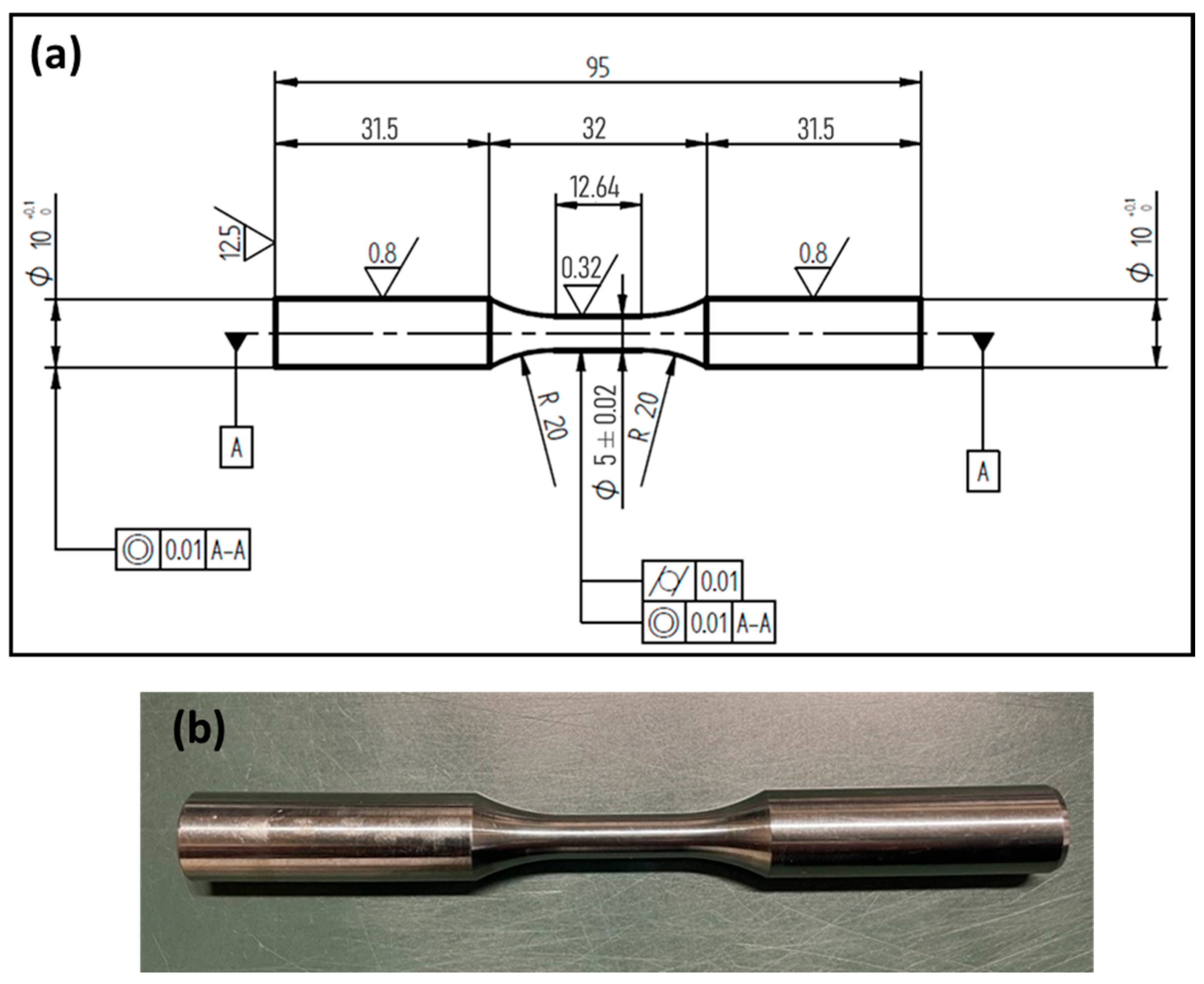

2.3. Fatigue, Hardness Tests, and Fractographic Analyses

3. Results and Discussion

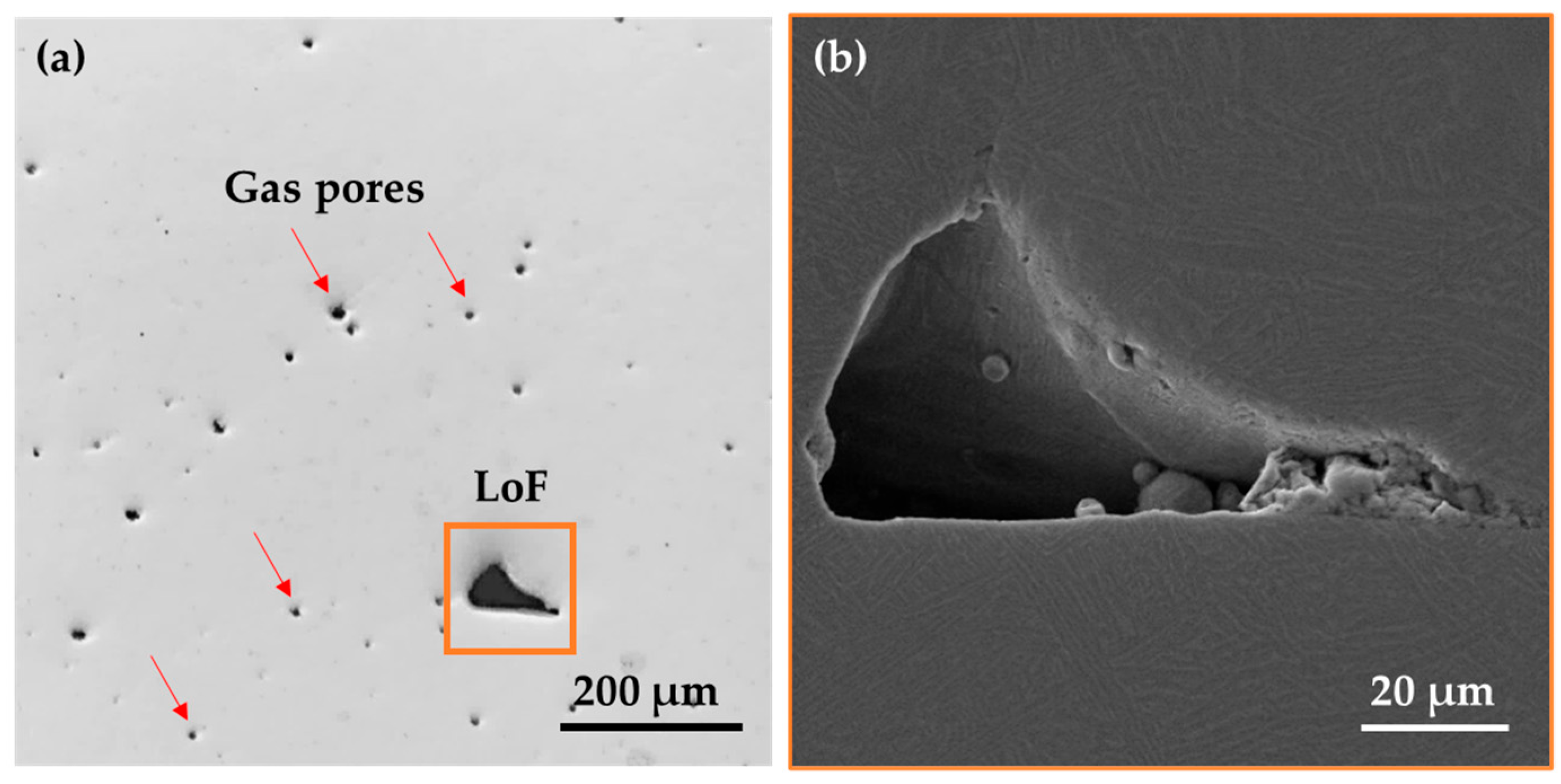

3.1. Microstructural Characterization

3.2. Fatigue Behavior

4. Conclusions

- (i)

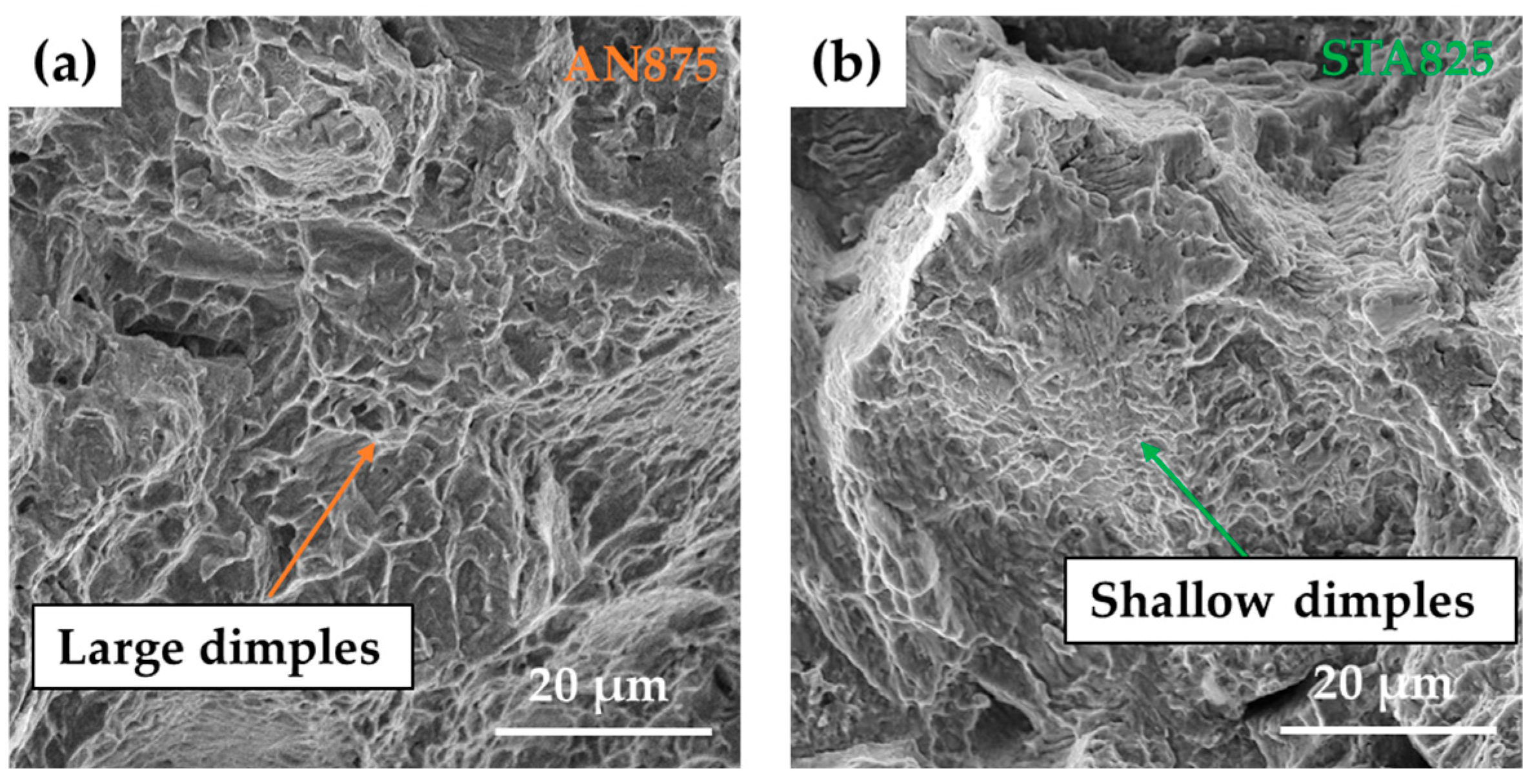

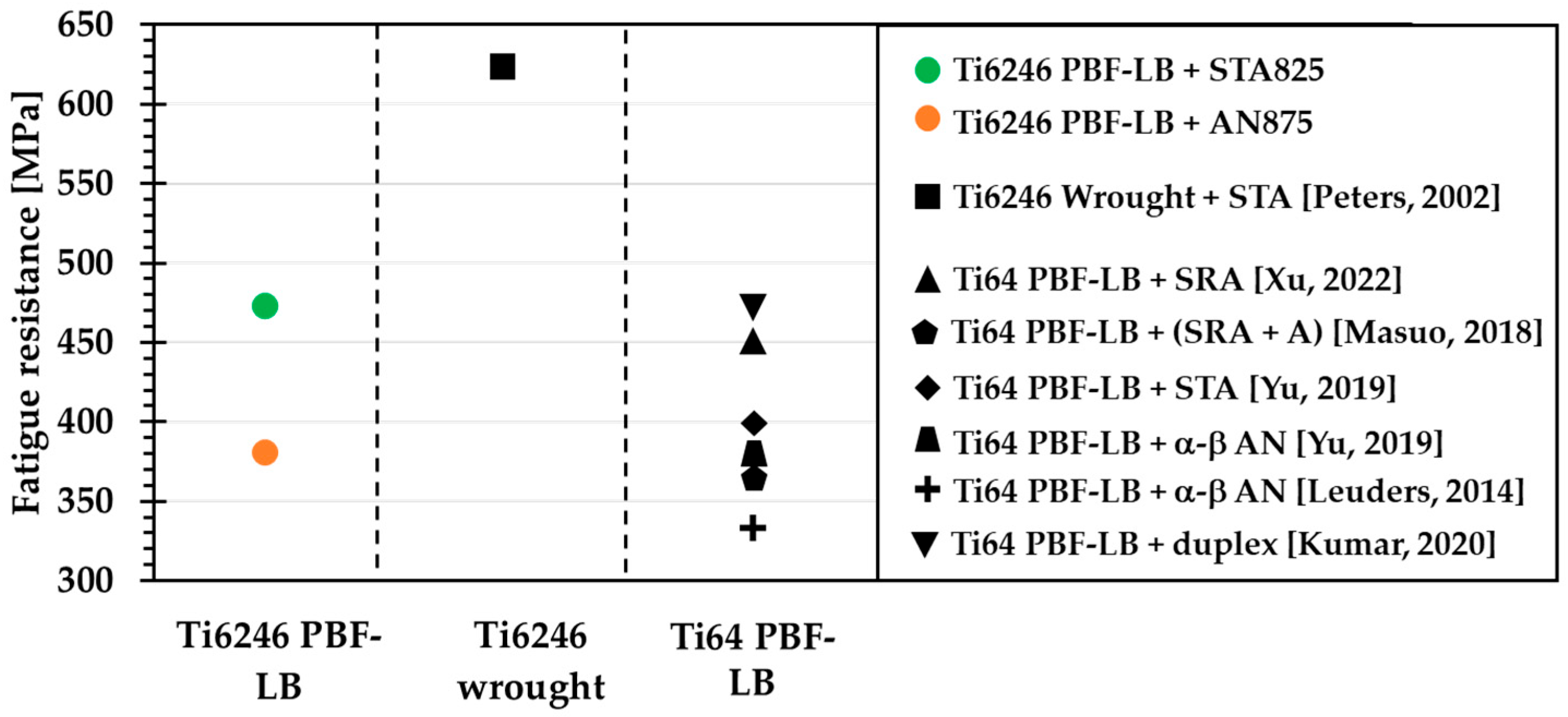

- The AN875-treated samples exhibited the lowest fatigue strength (σd,50% = 382 ± 15 MPa), primarily due to the low mechanical properties associated with significant microstructural coarsening caused by the high annealing temperature, slow furnace cooling rate, and the absence of strengthening precipitates. The low strength primarily affected crack initiation, while the coarse primary α (αp) phase facilitated crack propagation.

- (ii)

- The STA825-treated samples demonstrated the highest fatigue strength (σd,50% = 474 ± 15 MPa), corresponding to an improvement of nearly 25% over the AN875 condition. This enhancement is attributed to the presence of strengthening precipitates, the refinement of αp lamellae, and the formation of ultrafine, homogeneously distributed secondary α lamellae within the β phase (αs + β), which hinder fatigue crack nucleation and early-stage propagation.

- (iii)

- Both heat treatment conditions exhibited a similar σD,50%/UTS ratio, ranging between 35% and 36%, demonstrating a clear correlation between static and fatigue properties.

- (iv)

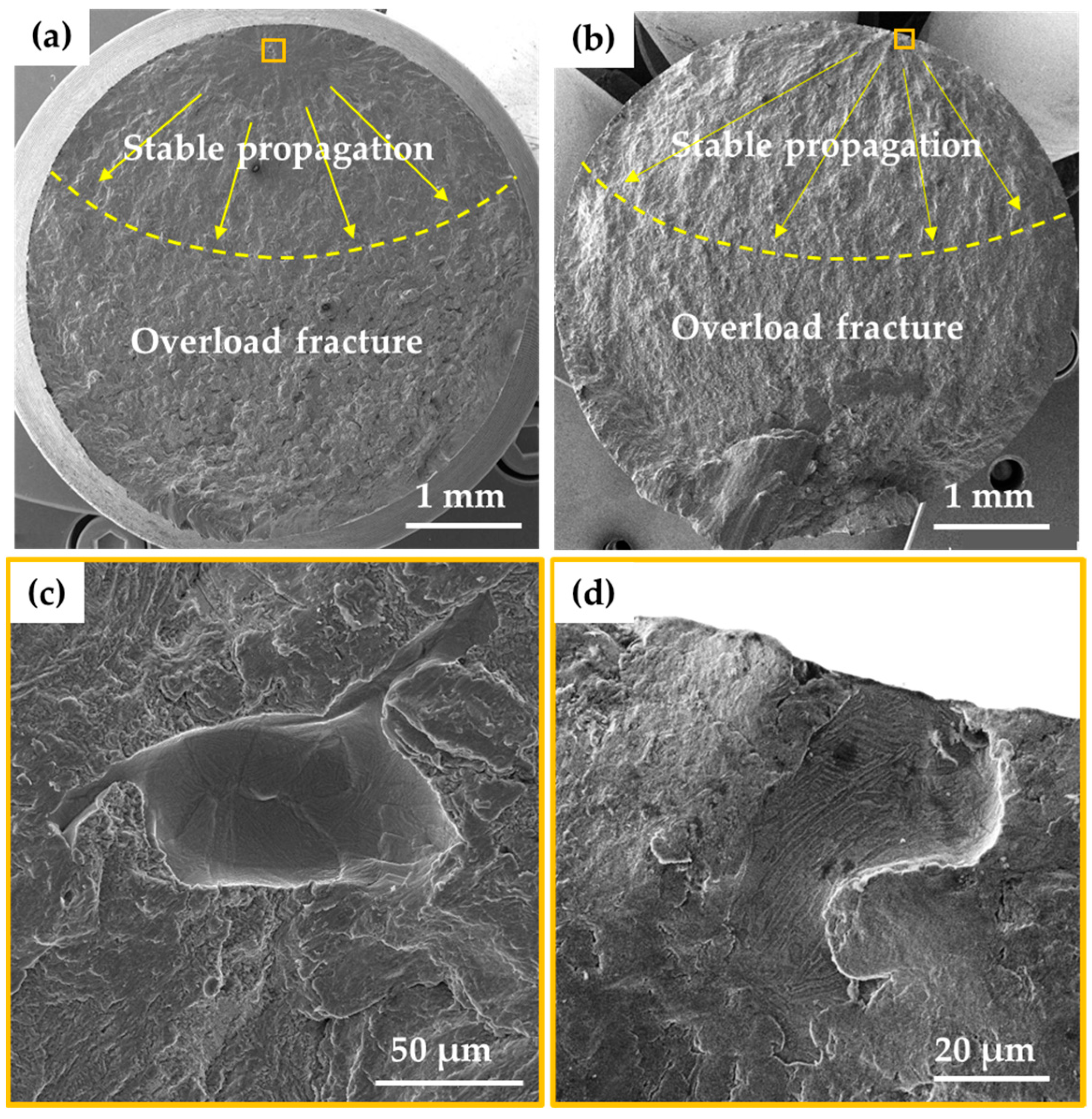

- In both heat treatment conditions, fatigue crack nucleation consistently occurred at surface or subsurface lack of fusion defects. These process-induced defects represent the primary limiting factor in the fatigue performance of PBF-BF Ti6246 compared to its conventionally produced counterpart.

- (v)

- Crack propagation behavior was strongly influenced by defect location. Subsurface defects triggered an initial low-speed propagation (LSP) region characterized by a “mackerel pattern”, likely due to the high microcrack growth resistance in the early propagation stage at αp/(αs + β) interfaces. This was followed by a high-speed propagation (HSP) region exhibiting quasi-cleavage fracture. In contrast, surface-initiated cracks propagated directly through quasi-cleavage mechanisms from the crack tip. Fatigue striations were observed in the HSP zone.

- (vi)

- El-Haddad’s best-fit parameters derived from the Kitagawa–Takahashi diagrams confirmed the beneficial role of the fine bilamellar microstructure of the STA825 condition in enhancing fatigue performance, with an increase of 19% in the intrinsic fatigue limit (Δσth,0) and 77% in the threshold stress intensity factor (ΔKth,lc).

- (vii)

- The STA825-treated Ti6246 alloy exhibited superior fatigue strength compared to PBF-LB Ti-6Al-4V subjected to various heat treatments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | additive manufacturing |

| PBF-LB | Powder Bed Fusion–Laser Beam |

| HCF | high cycle fatigue |

| STA | solution treating and aging |

| LoF | lack of fusion |

| KT | Kitagawa–Takahashi |

| GD-OES | Glow Discharge Optical Emission Spectroscopy |

| OM | optical microscope |

| FEG-SEM | Field Emission Gun–Scanning Electron Microscope |

| LSP | low-speed propagation |

| HSP | high-speed propagation |

References

- Zhao, Q.; Sun, Q.; Xin, S.; Chen, Y.; Wu, C.; Wang, H.; Xu, J.; Wan, M.; Zeng, W.; Zhao, Y. High-strength titanium alloys for aerospace engineering applications: A review on melting-forging process. Mater. Sci. Eng. A 2022, 845, 143260. [Google Scholar] [CrossRef]

- Nyamekye, P.; Rahimpour Golroudbary, S.; Piili, H.; Luukka, P.; Kraslawski, A. Impact of additive manufacturing on titanium supply chain: Case of titanium alloys in automotive and aerospace industries. Adv. Ind. Manuf. Eng. 2023, 6, 100112. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Yang, N.; Shan, M.; Shi, G.; Guo, H.; Xiong, S.; Luo, M.; Zhang, D.; Cui, M. Physicochemical State Classification of Heat-treated TC4 Samples Based on Laser-induced Breakdown Spectroscopy (LIBS). At. Spectrosc. 2024, 45, 324–335. [Google Scholar] [CrossRef]

- Li, G.; Chandra, S.; Rahman Rashid, A.; Palanisamy, S.; Ding, S. Machinability of additively manufactured titanium alloys: A comprehensive review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Carrozza, A.; Aversa, A.; Fino, P.; Lombardi, M. A study on the microstructure and mechanical properties of the Ti-6Al-2Sn-4Zr-6Mo alloy produced via Laser Powder Bed Fusion. J. Alloys Compd. 2021, 870, 159329. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Rani, S.U.; Kesavan, D.; Kamaraj, M. Evaluation of influence of microstructural features of LPBF Ti-6Al-4 V on mechanical properties for an optimal strength and ductility. J. Alloys Compd. 2023, 960, 170575. [Google Scholar] [CrossRef]

- Yumak, N.; Aslantaş, K. A review on heat treatment efficiency in metastable β titanium alloys: The role of treatment process and parameters. J. Mater. Res. Technol. 2020, 9, 15360–16280. [Google Scholar] [CrossRef]

- Alluaibi, M.H.I.; Cojocaru, E.M.; Rusea, A.; Șerban, N.; Coman, G.; Cojocaru, V.D. Microstructure and mechanical properties evolution during solution and ageing treatment for a hot deformed, above β-transus, Ti-6246 alloy. Metals 2020, 10, 1114. [Google Scholar] [CrossRef]

- Sauer, C.; Lütjering, G. Processing, Microstructure and Properties of Ti-6246. 1999. Available online: https://cdn.ymaws.com/titanium.org/resource/resmgr/ZZ-WTCP1999-VOL1/1999_Vol.1-4-Processing,_Mic.pdf (accessed on 1 April 2024).

- Peters, J.O.; Lütjering, G.; Nalla, R.K.; Altenberger, I.; Ritchie, R.O. High-Cycle Fatigue of Beta Titanium Alloys. 2002. Available online: https://www2.lbl.gov/ritchie/Library/poster/1_Fatigue2002-HCFofBetaTitaniumAlloys.pdf (accessed on 6 February 2025).

- Jeong, D.; Kwon, Y.; Goto, M.; Kim, S. High cycle fatigue and fatigue crack propagation behaviors of β-annealed Ti-6Al-4V alloy. Int. J. Mech. Mater. Eng. 2017, 12, 1. [Google Scholar] [CrossRef]

- Liu, Z.; Dash, S.S.; Zhang, J.; Lyu, T.; Lang, L.; Chen, D.; Zou, Y. Fatigue crack growth behavior of an additively manufactured titanium alloy: Effects of spatial and crystallographic orientations of α lamellae. Int. J. Plast. 2024, 172, 103819. [Google Scholar] [CrossRef]

- Yu, H.; Li, F.; Wang, Z.; Zeng, X. Fatigue performances of selective laser melted Ti-6Al-4V alloy: Influence of surface finishing, hot isostatic pressing and heat treatments. Int. J. Fatigue 2019, 120, 175–183. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, A.; Wang, X. Fatigue performance differences between rolled and selective laser melted Ti6Al4V alloys. Mater. Charact. 2022, 189, 111963. [Google Scholar] [CrossRef]

- Sing, S.L.; Huang, S.; Yeong, W.Y. Additive Manufacturing of Titanium and Titanium Alloy Biomedical De-vices. In Additive Manufacturing in Biomedical Applications; ASM International: West Conshohocken, PA, USA, 2022; pp. 192–200. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.; Maier, H. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Zhang, X.; Xue, K.; Liu, L.; Xiao, J.; Liu, J.; Jin, F.; Luo, M.; Zhan, M.; Li, H. Effect of electrical pulse treatment on the microstructural and mechanical responses of heterogeneous linear friction welded TC17/TC4 dissimilar joint. J. Mater. Res. Technol. 2025, 35, 1–12. [Google Scholar] [CrossRef]

- Li, P.; Warner, D.; Fatemi, A.; Phan, N. Critical assessment of the fatigue performance of additively manufactured Ti-6Al-4V and perspective for future research. Int. J. Fatigue 2016, 85, 130–143. [Google Scholar] [CrossRef]

- Butt, M.M.; Laieghi, H.; Kvvssn, V.; Uddin, Z.; Shah, M.; Ansari, P.; Salamci, M.U.; Patterson, A.E.; Kizil, H. Fatigue performance in additively manufactured metal alloys. Prog. Addit. Manuf. 2024, 10, 1809–1841. [Google Scholar] [CrossRef]

- Wycisk, E.; Solbach, A.; Siddique, S.; Herzog, D.; Walther, F.; Emmelmann, C. Effects of defects in laser additive manufactured Ti-6Al-4V on fatigue properties. Phys. Procedia 2014, 56, 371–378. [Google Scholar] [CrossRef]

- Pirro, G.; Martucci, A.; Morri, A.; Lombardi, M.; Ceschini, L. A novel solution treatment and aging for powder bed fusion-laser beam Ti-6Al-2Sn-4Zr-6Mo alloy: Microstructural and mechanical characterization. Int. J. Miner. Met. Mater. 2025, 32, 414–424. [Google Scholar] [CrossRef]

- Carrozza, A.; Aversa, A.; Fino, P.; Lombardi, M. Towards customized heat treatments and mechanical properties in the LPBF-processed Ti-6Al-2Sn-4Zr-6Mo alloy. Mater. Des. 2022, 215, 110512. [Google Scholar] [CrossRef]

- Cao, F.; Zhang, T.; Ryder, M.A.; Lados, D.A. A Review of the Fatigue Properties of Additively Manufactured Ti-6Al-4V. JOM 2018, 70, 349–357. [Google Scholar] [CrossRef]

- Zanni, M.; Di Egidio, G.; Tonelli, L.; Morri, A.; Ceschini, L. An analysis of the influence of heat treatments and surface finishing conditions on the high cycle fatigue behaviour of W360 hot work tool steel produced by Powder Bed Fusion–Laser Beam. Mater. Sci. Eng. A 2025, 932, 148237. [Google Scholar] [CrossRef]

- Lampman, S. Wrought Titanium and Titanium Alloys. In Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM International: West Conshohocken, PA, USA, 1990; pp. 592–633. [Google Scholar] [CrossRef]

- BS ISO 1143:2021; Rotating Bar Bending Fatigue Testing. European Standards: Bruxelles, Belgium, 2021.

- Gammon, L.M.; Briggs, R.D.; Packard, J.M.; Batson, K.W.; Boyer, R.; Domby, C.W. Metallography and Microstructures of Titanium and Its Alloys. In Metallography and Microstructures; ASM International: West Conshohocken, PA, USA, 2004; pp. 899–917. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- ISO 12107:2012; Metallic Materials-Fatigue Testing-Statistical Planning and Analysis of Data. European Standards: Bruxelles, Belgium, 2012.

- Murakami, Y.; Masuo, H.; Tanaka, Y.; Nakatani, M. Defect Analysis for Additively Manufactured Materials in Fatigue from the Viewpoint of Quality Control and Statistics of Extremes. Procedia Struct. Integr. 2019, 19, 113–122. [Google Scholar] [CrossRef]

- Murakami, Y.; Beretta, S. Small Defects and Inhomogeneities in Fatigue Strength: Experiments, Models and Statistical Implications. Extremes 1999, 2, 123–147. [Google Scholar] [CrossRef]

- El Haddad, M.H.; Smith, K.N.; Topper, T.H. Fatigue crack propagation of short cracks. J. Eng. Mater. Technol. 1979, 101, 42–46. [Google Scholar] [CrossRef]

- Bu, H.; Chen, L.; Duan, Y. Effect of Solution Heat Treatment on the Porosity Growth of Nickel-Based P/M Superalloys. Metals 2022, 12, 1973. [Google Scholar] [CrossRef]

- Di Egidio, G.; Ceschini, L.; Morri, A.; Martini, C.; Merlin, M. A Novel T6 Rapid Heat Treatment for AlSi10Mg Alloy Produced by Laser-Based Powder Bed Fusion: Comparison with T5 and Conventional T6 Heat Treatments. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2022, 53, 284–303. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Withers, P.; Todd, I.; Prangnell, P. Porosity regrowth during heat treatment of hot isostatically pressed additively manufactured titanium components. Scr. Mater. 2016, 122, 72–76. [Google Scholar] [CrossRef]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef]

- Ter Haar, G.M.; Becker, T.H. Selective laser melting produced Ti-6Al-4V: Post-process heat treatments to achieve superior tensile properties. Materials 2018, 11, 146. [Google Scholar] [CrossRef]

- Lutjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; Chapter 7; pp. 302–314. [Google Scholar]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Yu, J.; Yin, Z.; Huang, Z.; Zhao, S.; Huang, H.; Yu, K.; Zhou, R.; Xiao, H. Effect of Aging Treatment on Microstructural Evolution and Mechanical Properties of the Electron Beam Cold Hearth Melting Ti-6Al-4V Alloy. Materials 2022, 15, 7122. [Google Scholar] [CrossRef]

- Szczepanski, C.; Jha, S.; Larsen, J.; Jones, J. Microstructural influences on very-high-cycle fatigue-crack initiation in Ti-6246. Metall. Mater. Trans. A Phys. Metall Mater Sci. 2008, 39, 2841–2851. [Google Scholar] [CrossRef]

- Gao, T.; Zhao, X.; Xue, H.; Sun, Z. Characteristics and micromechanisms of fish-eye crack initiation of a Ti-6Al-4V alloy in very high cycle fatigue regime. J. Mater. Res. Technol. 2022, 21, 3140–3153. [Google Scholar] [CrossRef]

- Gao, T.; Xue, H.; Sun, Z.; Retraint, D. Investigation of crack initiation mechanism of a precipitation hardened TC11 titanium alloy under very high cycle fatigue loading. Mater. Sci. Eng. A 2020, 776, 138989. [Google Scholar] [CrossRef]

- Li, W.; Zhao, H.; Nehila, A.; Zhang, Z.; Sakai, T. Very high cycle fatigue of TC4 titanium alloy under variable stress ratio: Failure mechanism and life prediction. Int. J. Fatigue 2017, 104, 342–354. [Google Scholar] [CrossRef]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Int. J. Fatigue 2018, 117, 163–179. [Google Scholar] [CrossRef]

- Leuders, S.; Lieneke, T.; Lammers, S.; Tröster, T.; Niendorf, T. On the fatigue properties of metals manufactured by selective laser melting—The role of ductility. J. Mater. Res. 2014, 29, 1911–1919. [Google Scholar] [CrossRef]

- Kumar, P.; Ramamurty, U. High cycle fatigue in selective laser melted Ti-6Al-4V. Acta Mater. 2020, 194, 305–320. [Google Scholar] [CrossRef]

| Elements [% wt.] | Ti | Al | Sn | Zr | Mo | Fe | N | O | H | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| Supplier composition | Bal. | 5.96 | 1.85 | 3.67 | 5.89 | 0.03 | 0.01 | 0.12 | 0.002 | Total max < 0.30 |

| Sample GD-OES | Bal. | 6.36 ± 0.13 | 2.06 ± 0.08 | 4.21 ± 0.09 | 5.85 ± 0.14 | 0.14 ± 0.01 | - | - | - | Total: 0.20 ± 0.06 |

| Standard composition | Bal. | 5.5 ÷ 6.5 | 1.75 ÷ 2.25 | 3.5 ÷ 4.5 | 5.5 ÷ 6.5 | max 0.15 | max. 0.04 | max. 0.15 | max. 0.0125 | Each max 0.10 Total max 0.40 |

| Power [W] | Scanning Speed [mm/s] | Hatch Distance [µm] | Layer Thickness [µm] | Scanning Strategy | Platform Temperature [°C] |

|---|---|---|---|---|---|

| 190 | 1250 | 100 | 30 | Standard 67° EOS strategy | 100 |

| YS [MPa] | UTS [MPa] | EL [%] | |

|---|---|---|---|

| STA825 | 1118 ± 12 | 1327 ± 1 | 10.1 ± 0.4 |

| AN875 | 936 ± 9 | 1085 ± 1 | 22.3 ± 0.5 |

| αp Content [%] | αp Thickness [μm] | |

|---|---|---|

| STA825 | 39.32 ± 0.69 | 0.29 ± 0.02 |

| AN875 | 69.99 ± 1.28 | 1.46 ± 0.10 |

| [MPa] | [MPa] | [%] | |

|---|---|---|---|

| STA825 | 474 | 15 | 35.7 |

| AN875 | 382 | 15 | 35.2 |

| Δσth,0 [MPa] | ΔKth,lc [MPa √m] | √area0 [μm] | |

|---|---|---|---|

| STA825 | 1170 | 14.5 | 116 |

| AN875 | 980 | 8.2 | 53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pirro, G.; Morri, A.; Martucci, A.; Lombardi, M.; Ceschini, L. Effect of Heat Treatments and Related Microstructural Modifications on High-Cycle Fatigue Behavior of Powder Bed Fusion–Laser Beam-Fabricated Ti-6Al-2Sn-4Zr-6Mo Alloy. Metals 2025, 15, 849. https://doi.org/10.3390/met15080849

Pirro G, Morri A, Martucci A, Lombardi M, Ceschini L. Effect of Heat Treatments and Related Microstructural Modifications on High-Cycle Fatigue Behavior of Powder Bed Fusion–Laser Beam-Fabricated Ti-6Al-2Sn-4Zr-6Mo Alloy. Metals. 2025; 15(8):849. https://doi.org/10.3390/met15080849

Chicago/Turabian StylePirro, Gianluca, Alessandro Morri, Alessandra Martucci, Mariangela Lombardi, and Lorella Ceschini. 2025. "Effect of Heat Treatments and Related Microstructural Modifications on High-Cycle Fatigue Behavior of Powder Bed Fusion–Laser Beam-Fabricated Ti-6Al-2Sn-4Zr-6Mo Alloy" Metals 15, no. 8: 849. https://doi.org/10.3390/met15080849

APA StylePirro, G., Morri, A., Martucci, A., Lombardi, M., & Ceschini, L. (2025). Effect of Heat Treatments and Related Microstructural Modifications on High-Cycle Fatigue Behavior of Powder Bed Fusion–Laser Beam-Fabricated Ti-6Al-2Sn-4Zr-6Mo Alloy. Metals, 15(8), 849. https://doi.org/10.3390/met15080849