Journal Description

Metals

Metals

is an international, peer-reviewed, open access journal published monthly online by MDPI. The Spanish Materials Society (SOCIEMAT) is affiliated with Metals and their members receive discounts on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), Inspec, Ei Compendex, CAPlus / SciFinder, and other databases.

- Journal Rank: JCR - Q2 (Metallurgy and Metallurgical Engineering) / CiteScore - Q1 (Metals and Alloys)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 18.7 days after submission; acceptance to publication is undertaken in 2.7 days (median values for papers published in this journal in the second half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Companion journals for Metals include: Compounds, Alloys and Iron.

Impact Factor:

2.5 (2024);

5-Year Impact Factor:

2.8 (2024)

Latest Articles

Research on the Edge Crack Suppression Mechanism of Magnesium Alloy Plates Processed by Lattice Severe Deformation Rolling

Metals 2026, 16(2), 164; https://doi.org/10.3390/met16020164 - 29 Jan 2026

Abstract

Edge cracking severely limits the rolling yield of magnesium alloy plates. A novel lattice severe deformation rolling (LSDR) process using corrugated rolls is proposed to suppress edge cracking. Numerical simulations, rolling experiments, and microstructural analyses were conducted, with results compared to conventional flat

[...] Read more.

Edge cracking severely limits the rolling yield of magnesium alloy plates. A novel lattice severe deformation rolling (LSDR) process using corrugated rolls is proposed to suppress edge cracking. Numerical simulations, rolling experiments, and microstructural analyses were conducted, with results compared to conventional flat rolling (FR), to elucidate the suppression mechanism. LSDR induces a multi-peak stress distribution and restricts metal flow, thereby reducing additional stresses responsible for edge cracking. Deformation heat generated in local severe deformation zones compensates for thermal loss, alleviates the temperature gradient between the plate edge and center, and enhances overall plasticity. According to the Cockcroft–Latham fracture criterion, LSDR effectively limits damage growth and confines damage within a single lattice, suppressing crack propagation, whereas FR produces damage values far exceeding the critical value of 0.43. Furthermore, fine grains formed in severe deformation zones, together with dislocation entanglement induced by twinning, impede crack propagation. This work demonstrates the effectiveness of LSDR and provides a new approach for mitigating edge cracking in rolled metal plates.

Full article

Open AccessArticle

Physics-Informed Machine Learning for Predicting Carburizing Process Outcomes in 20Cr2Ni4 Steel: A Cascade Modeling Approach

by

Chuansheng Liang, Peng Cheng and Chenxi Shao

Metals 2026, 16(2), 163; https://doi.org/10.3390/met16020163 - 29 Jan 2026

Abstract

Carburizing process optimization requires accurate prediction of multiple interrelated outcomes, yet existing models either oversimplify the physics or require prohibitively large datasets. Here, we present a physics-informed machine learning (PIML) cascade model for vacuum carburizing of 20Cr2Ni4 gear steel that predicts surface carbon

[...] Read more.

Carburizing process optimization requires accurate prediction of multiple interrelated outcomes, yet existing models either oversimplify the physics or require prohibitively large datasets. Here, we present a physics-informed machine learning (PIML) cascade model for vacuum carburizing of 20Cr2Ni4 gear steel that predicts surface carbon content, maximum hardness, and effective case depth through a three-stage sequential architecture. The model integrates Fick’s diffusion law and empirical carbon–hardness relationships with ensemble learning using physics-derived features to reduce data requirements while maintaining interpretability. Validation against experimental data yields coefficient of determination values of 0.968 (surface carbon, RMSE = 0.0023 wt%), 0.963 (maximum hardness, RMSE = 1.27 HV), and 0.999 (case depth, RMSE = 0.0053 mm) on physics-augmented test data; leave-one-out cross-validation (LOOCV) on original experimental data yields

Open AccessReview

Large Language Models for High-Entropy Alloys: Literature Mining, Design Orchestration, and Evaluation Standards

by

Yutong Guo and Chao Yang

Metals 2026, 16(2), 162; https://doi.org/10.3390/met16020162 - 29 Jan 2026

Abstract

High-entropy alloys (HEAs) present a fundamental design paradox: their exceptional properties arise from complex, high-dimensional composition–process–microstructure–property (CPMP) relationships, yet the knowledge needed to navigate this space is fragmented across a vast and unstructured literature. Large language models (LLMs) offer a transformative interface to

[...] Read more.

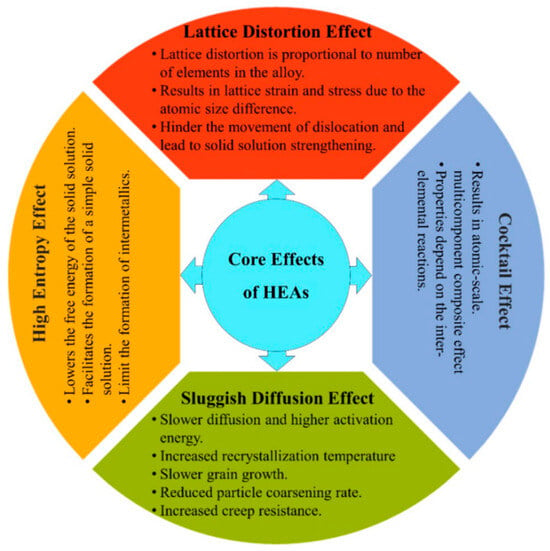

High-entropy alloys (HEAs) present a fundamental design paradox: their exceptional properties arise from complex, high-dimensional composition–process–microstructure–property (CPMP) relationships, yet the knowledge needed to navigate this space is fragmented across a vast and unstructured literature. Large language models (LLMs) offer a transformative interface to this complexity. By extracting structured facts from text, they can convert dispersed and heterogeneous evidence (i.e., findings scattered across many studies and reported with inconsistent test protocols or characterization standards) into queryable knowledge graphs. Through code generation and tool composition, they can automate simulation pipelines, surrogate model construction, and inverse design workflows. This review analyzes how LLMs can augment key stages of HEA research—from intelligent literature mining and multimodal data integration (using LLMs to automatically extract and structure data from texts and to combine information across text, images, and other data sources) to model-driven design and closed-loop experimentation—illustrated by emerging case studies. We propose concrete evaluation protocols that measure direct scientific utility, including knowledge-graph completeness, workflow setup efficiency, and experimental validation hit rates. We also confront practical limitations: data sparsity and noise, model hallucination, domain bias (where models may exhibit superior predictive performance for specific, well-represented alloy systems over others due to imbalances in training data), and the imperative for reproducible infrastructure. We argue that domain-specialized LLMs, embedded within grounded, verifiable research systems, can not only accelerate HEA discovery but also standardize the representation, sharing, and reuse of community knowledge.

Full article

(This article belongs to the Special Issue Advances in High-Entropy Alloys’ Microstructure, Properties and Preparation)

►▼

Show Figures

Figure 1

Open AccessReview

A State-of-the-Art Review on Metallic Hysteretic Dampers: Design, Materials, Advanced Modeling, and Future Challenges

by

Álvaro Gómez, Rodrigo Valle, Flavia Bustos and Víctor Tuninetti

Metals 2026, 16(2), 161; https://doi.org/10.3390/met16020161 - 29 Jan 2026

Abstract

Metallic seismic dampers are an effective tool for reducing structural damage during seismic events. While previous reviews have often focused on cataloging device types, this review presents a deep analysis of the underlying science governing their performance. Particular emphasis is placed on advanced

[...] Read more.

Metallic seismic dampers are an effective tool for reducing structural damage during seismic events. While previous reviews have often focused on cataloging device types, this review presents a deep analysis of the underlying science governing their performance. Particular emphasis is placed on advanced computational methods, such as non-linear kinematic hardening (e.g., Chaboche) and micromechanical damage models (e.g., GTN), which are essential for accurately predicting low-cycle fatigue and fracture. Furthermore, advances in materials science are analyzed, ranging from low-yield-strength (LYS) steels to self-centering shape memory alloys (SMAs). Finally, the influence of manufacturing processes (including additive manufacturing) is explored, and critical future challenges in design, modeling, and long-term durability are identified. This analysis provides a foundational resource for researchers seeking to advance beyond simple phenomenological design toward physics-based prediction of damper performance.

Full article

(This article belongs to the Special Issue Advanced Structural Metals: Integrating Mechanics, Processing, and Performance Characterization)

►▼

Show Figures

Figure 1

Open AccessArticle

Effects of the Scrap Steel Ratio and Bottom-Blowing Process Parameters on the Fluid Flow Characteristics in a Physical Model of a Steelmaking Converter

by

Fei Yuan, Xuan Liu, Anjun Xu and Xueying Li

Metals 2026, 16(2), 160; https://doi.org/10.3390/met16020160 - 29 Jan 2026

Abstract

►▼

Show Figures

The amount of scrap steel and selection of blowing process parameters are known to influence the fluid flow characteristics of the melt pool in converter steelmaking. However, few studies have considered the effects of scrap steel and blowing process parameters together. In this

[...] Read more.

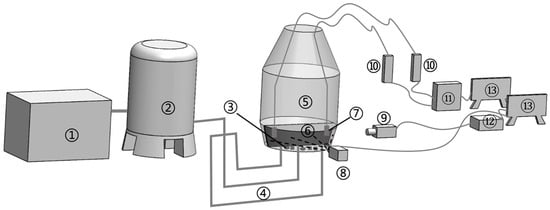

The amount of scrap steel and selection of blowing process parameters are known to influence the fluid flow characteristics of the melt pool in converter steelmaking. However, few studies have considered the effects of scrap steel and blowing process parameters together. In this study, a physical model of a converter is established to investigate the influences of the amount of scrap steel and bottom-blowing process parameters on the fluid flow characteristics of the melt pool. Particle image velocimetry is used to measure the velocity distribution in the melt pool, and the stimulus–response method is used to measure the mixing time of the melt pool under different operating conditions. The results show that increasing the scrap steel ratio worsens the dynamic conditions of the melt pool. The best of the explored combinations is achieved at a scrap steel ratio of 20% and with six nozzles. The mixing time decreases as the gas flow rate increases, but the rate of decrease also decreases. Based on the results, the mixing time can be predicted from the gas flow rate and the number of nozzles. A relationship between the stirring power and mixing time of a converter using the bottom-blowing process is established.

Full article

Figure 1

Open AccessArticle

Hydrogen-Induced Delayed Fracture Susceptibility in Ti–Nb–V Microalloyed Press-Hardened Steel Compared to Ti-Microalloyed Reference

by

Renzo Valentini, Leonardo Bertini, Fabio D’Aiuto, Michele Maria Tedesco and Hardy Mohrbacher

Metals 2026, 16(2), 159; https://doi.org/10.3390/met16020159 - 28 Jan 2026

Abstract

In alignment with the European Union’s 2050 carbon-neutrality targets, the automotive industry is intensifying efforts to adopt lightweight materials that ensure structural integrity without compromising safety. Press-hardened steels (PHS), offering a combination of ultra-high strength and formability, are at the forefront of these

[...] Read more.

In alignment with the European Union’s 2050 carbon-neutrality targets, the automotive industry is intensifying efforts to adopt lightweight materials that ensure structural integrity without compromising safety. Press-hardened steels (PHS), offering a combination of ultra-high strength and formability, are at the forefront of these developments. Standard PHS grades rely on Ti–B microalloying; however, further alloying with Nb and V has been proposed to enhance hydrogen embrittlement resistance via microstructural refinement and hydrogen trapping. This study investigates hydrogen transport and mechanical degradation in a Ti–Nb–V microalloyed PHS compared to a conventional Ti-only 22MnB5 grade. Electrochemical permeation, thermal desorption, and mechanical testing were employed to characterize hydrogen diffusivity, solubility, and trapping mechanisms. The Ti–Nb–V variant demonstrated lower hydrogen diffusivity, higher solubility, and improved resistance to delayed fracture, attributable to the presence of fine NbTiV precipitates.

Full article

(This article belongs to the Special Issue Microstructure and Mechanical Behavior of High-Strength Steel)

►▼

Show Figures

Figure 1

Open AccessArticle

A Numerical Simulation on the Melting Behavior of Ferrochrome Alloy in Molten Steel

by

Yuanhao Hai, Mengke Liu, Guojun Ma, Xiang Zhang and Dingli Zheng

Metals 2026, 16(2), 158; https://doi.org/10.3390/met16020158 - 28 Jan 2026

Abstract

Ferrochrome alloy is a crucial additive in steelmaking, significantly enhancing the strength, hardness, and corrosion resistance of steel; investigating the melting behavior of ferrochrome alloy could provide a theoretical foundation for producing stainless steel with improved properties. To gain insight into the melting

[...] Read more.

Ferrochrome alloy is a crucial additive in steelmaking, significantly enhancing the strength, hardness, and corrosion resistance of steel; investigating the melting behavior of ferrochrome alloy could provide a theoretical foundation for producing stainless steel with improved properties. To gain insight into the melting behavior and mechanism of ferrochrome alloy in molten steel, this paper employed a numerical simulation with ANSYS Fluent software to investigate the effects of bath temperature, bath chromium content, bath carbon content, alloy chromium content, alloy carbon content, alloy size, and alloy preheating temperature on the melting behavior of ferrochromium alloy. The results showed that when the ferrochrome alloy is immersed into the molten bath, a solidified layer formed on the surface of the alloy, and as immersion time increased, the thickness of the solidified layer initially increased and then decreased; subsequent to the complete melting of the solidified layer, the alloy body began to melt. The center temperature of the alloy remained the lowest throughout the melting process and raised with increasing immersion time. Additionally, as the bath temperature and bath carbon content increased, the formation time of the solidified layer on the surface of the alloy shortened, its maximum thickness decreased, the alloy’s melting rate accelerated from 0.49 × 10−4 m/s to 1.22 × 10−4 m/s, and the complete melting time decreased from 134.7 s to 41 s. Conversely, increasing the bath chromium content raised the melting point of the solidified layer, prolonged the time required for remelting, slowed the alloy’s melting rate from 2.47 × 10−4 m/s to 0.91 × 10−4 m/s, and increased the complete melting time from 67.6 s to 75.2 s. As the alloy carbon content and preheating temperature increased, the alloy chromium content and size decreased, the formation time of the solidified layer shortened, its maximum thickness initially increased and then decreased, the melting rate of the alloy accelerated from 0.47 × 10−4 m/s to 1.97 × 10−4 m/s, and the complete melting time reduced from 165.8 s to 18.1 s.

Full article

(This article belongs to the Section Computation and Simulation on Metals)

►▼

Show Figures

Figure 1

Open AccessArticle

The Coupling Relationship of Dynamic Recrystallization and Lamellar Globularization of the BT25y Alloy During High-Temperature Deformation

by

Xuemei Yang, Xiaojing Zong, Cheng Wang, Yueyu Sun, Jiayuan Wang, Boshi Zheng, Juncheng Fang, Xuewei Yan and Xiaonan Shi

Metals 2026, 16(2), 157; https://doi.org/10.3390/met16020157 - 28 Jan 2026

Abstract

In the aerospace field, the BT25y titanium alloy is recommended as a candidate material for manufacturing compressor discs and rotor blades of aircraft engines. The influence of hot deformation parameters on the microstructural evolution, recrystallization softening, and globularization mechanism of the BT25y alloy

[...] Read more.

In the aerospace field, the BT25y titanium alloy is recommended as a candidate material for manufacturing compressor discs and rotor blades of aircraft engines. The influence of hot deformation parameters on the microstructural evolution, recrystallization softening, and globularization mechanism of the BT25y alloy with an initial lamellar structure was studied. Furthermore, the coupling relationship between dynamic recrystallization and lamellar globularization was explored by means of EBSD, SEM, and TEM techniques. The experiment results indicate that the characteristics of initial lamellar α, α/α sub-grain boundaries within α lamellae, and the α/β phase boundary show significant variations due to the formation of equiaxed α grains during hot deformation. As the strain rate increases, the recrystallization mechanism of α phase gradually shifts from CDRX softening characterized by sub-grain evolution and lamellae fracture, to DDRX softening characterized by grain boundary arching and sub-grain boundary bridging. As the deformation temperature increases, the intense thermal activation promotes the accumulation of distortion storage energy, providing enhanced driving force for the occurrence of dynamic recrystallization. The research results will contribute to a deeper understanding of the relationship between dynamic recrystallization and lamellar globularization, providing theoretical guidance for the deformation process optimization and mechanical property control of the BT25y alloy.

Full article

(This article belongs to the Special Issue Advances in Metal Forming and Plasticity)

►▼

Show Figures

Figure 1

Open AccessReview

Separation Strategies for Indium Recovery: Exploring Solvent Extraction, Ion-Exchange, and Membrane Methods

by

Ewa Rudnik

Metals 2026, 16(2), 156; https://doi.org/10.3390/met16020156 - 27 Jan 2026

Abstract

Indium is a strategically important metal, essential for the production of transparent conductive oxides, flat panel displays, thin-film photovoltaics, and advanced optoelectronic devices. Due to its limited natural abundance and its occurrence in trace amounts alongside other metals in both primary and secondary

[...] Read more.

Indium is a strategically important metal, essential for the production of transparent conductive oxides, flat panel displays, thin-film photovoltaics, and advanced optoelectronic devices. Due to its limited natural abundance and its occurrence in trace amounts alongside other metals in both primary and secondary sources, the recovery of indium through efficient separation techniques has gained increasing attention. This review discusses three major separation strategies for indium recovery: solvent extraction, ion-exchange, and membrane processes, applied to both synthetic solutions and real leachates. D2EHPA has demonstrated its applicability as an effective agent for indium separation, not only in solvent extraction but also as an impregnating agent in polymer resins and membranes. While solvent extraction achieves high recovery rates, ion-exchange resins and membrane-based methods offer significant advantages in terms of reusability, reduced chemical consumption, and minimal environmental impact. The selective separation of indium from impurities such as Fe3+ and Sn2+ remains a key consideration, which can be addressed by optimizing feed solution conditions or adjusting the selective stripping stages. A comparative overview of these methods is provided, focusing on separation efficiency, operational conditions, and potential integration into close-loop systems. The article highlights recent innovations and outlines the challenges involved in achieving sustainable indium recovery, in line with circular economy principles.

Full article

(This article belongs to the Special Issue Cutting-Edge Innovations in Metal Recovery from Electronic Waste: Challenges, Techniques and Future Horizons)

Open AccessArticle

Effect of the Welding Electrode Geometry on the Peak Load, Energy Absorption, Fracture Type, and Microstructure of Resistance Spot-Welded Dissimilar Ultra-High Strength MS1500 and SPFC590 Steels

by

Mehmet Okan Görtan and Ümit Türkmen

Metals 2026, 16(2), 155; https://doi.org/10.3390/met16020155 - 27 Jan 2026

Abstract

In the present study, the effects of electrode geometry and welding current on the tensile-shear strength, failure energy, fracture type, and joint microstructure were investigated during the RSW of ultra-high-strength MS1500 steel to high-strength low-alloy SPFC590 steel, both 1.2 mm in thickness. Three

[...] Read more.

In the present study, the effects of electrode geometry and welding current on the tensile-shear strength, failure energy, fracture type, and joint microstructure were investigated during the RSW of ultra-high-strength MS1500 steel to high-strength low-alloy SPFC590 steel, both 1.2 mm in thickness. Three electrode geometries—designated as G0-6 mm, G0-8 mm, and A0—recommended for 1.2 mm sheets according to ISO 5821 were examined. It was found that in the G0-6 mm electrode geometry, which has the smallest contact area, excessive expulsion occurred at lower current levels compared to the other geometries. Consequently, this configuration resulted in lower maximum tensile-shear strength and failure energy values. The highest mechanical performance was achieved with the G0-8 mm electrode geometry, where the tensile-shear strength and failure energy were measured as 19.42 kN and 43.81 J, respectively. For the A0 electrode, although the maximum tensile-shear strength (19.68 kN) was comparable to that of the G0-8 mm geometry, the failure energy was approximately 7% lower (40.94 J). For all electrode geometries corresponding to maximum mechanical strength, a pull-out failure mode was observed, where the nugget region of the SPFC590 steel detached from the base metal and remained adhered to the ultra-high-strength MS1500 sheet.

Full article

(This article belongs to the Special Issue Advances in Welding Processes of Metallic Materials—2nd Edition)

Open AccessArticle

Accelerated Optimization of Superalloys by Integrating Thermodynamic Calculation Data with Machine Learning Models: A Reference Alloy Approach

by

Yubing Pei, Zhenhuan Gao, Junjie Wu, Liping Nie, Song Lu, Jiaxin Tan, Ziyun Wu, Longfei Li and Xiufang Gong

Metals 2026, 16(2), 154; https://doi.org/10.3390/met16020154 - 27 Jan 2026

Abstract

►▼

Show Figures

The multi-objective optimization of multicomponent superalloys has long been impeded by not only the complex interactions among multiple elements but also the low efficiency and high cost of traditional trial-and-error methods. To address this issue, this study proposed a thermodynamic calculation data-driven optimization

[...] Read more.

The multi-objective optimization of multicomponent superalloys has long been impeded by not only the complex interactions among multiple elements but also the low efficiency and high cost of traditional trial-and-error methods. To address this issue, this study proposed a thermodynamic calculation data-driven optimization framework that integrates machine learning (ML) and multi-objective screening based on domain knowledge. The core of this methodology involves introducing a commercial reference alloy and rapidly generating a large-scale thermodynamic dataset through ML models. After training, the ML models were verified to be more efficient at predicting phase transition temperatures and γ′ volume fractions than the CALPHAD methods. Focusing on the mechanical properties, critical strength indices, including solid solution strengthening, precipitation strengthening, and creep resistance based on the calculated γ/γ′ two-phase compositions, were compared with the reference alloy and set as the critical screen criteria. Optimal alloys were selected from the 388,000 candidates. Compared with the reference alloy, two new alloys were experimentally verified to have superior or comparable compressive yield strength and creep resistance at 900 °C at the expense of oxidation resistance and density, while maintaining comparable cost. This work demonstrates the significant potential of combining high-throughput thermodynamic data with intelligent multi-objective optimization to accelerate the development of new alloys with tailored property profiles.

Full article

Figure 1

Open AccessEditorial

Metallic Functional Materials: Development and Applications

by

Changlong Tan, Kun Zhang and Yan Feng

Metals 2026, 16(2), 153; https://doi.org/10.3390/met16020153 - 27 Jan 2026

Abstract

Metallic functional materials have become a strategic focus in contemporary material research, driven by the rising demand for intelligent, adaptive, and high-performance systems across energy conversion, aerospace actuation, biomedical devices, and next-generation flexible or micro-electromechanical technologies [...]

Full article

(This article belongs to the Special Issue Metallic Functional Materials: Development and Applications)

Open AccessArticle

High-Temperature Mechanical Properties and Friction-Wear Performance of CrAlN Coatings Prepared by Arc Ion Plating via Mo Doping

by

Rongjun Yang, Lingxin Zhou, Songjie Zhou, Hongwu Liu, Weilin Chen, Weizhou Li and Minming Jiang

Metals 2026, 16(2), 152; https://doi.org/10.3390/met16020152 - 27 Jan 2026

Abstract

CrAlN coatings are widely used for surface protection because of their excellent properties. Alloying with additional elements has been shown to effectively modify mechanical and tribological behavior of these coatings. In this study, CrAlMoxN coatings (x = 0–18.83 at%) were prepared

[...] Read more.

CrAlN coatings are widely used for surface protection because of their excellent properties. Alloying with additional elements has been shown to effectively modify mechanical and tribological behavior of these coatings. In this study, CrAlMoxN coatings (x = 0–18.83 at%) were prepared by an arc ion plating technology, corresponding to CrAlN and Mo-doped variants CrAlMoN-1, CrAlMoN-2 and CrAlMoN-3, respectively). The effects of Mo incorporation on the microstructure, mechanical properties, and friction-wear performance at both room and high temperature were systematically investigated. Results indicate that Mo dissolves into the CrAlN lattice to form a solid-solution structure, which induces lattice expansion as confirmed by the shift of XRD peaks toward lower angles. Furthermore, a moderate addition of Mo substantially improves the hardness, toughness, and crack propagation resistance of the coatings. All four coatings exhibit friction coefficients of approximately 0.5 at room temperature. However, at 600 °C, the CrAlMoN-2 coating demonstrates a much more stable friction coefficient curve and achieves the lowest average friction coefficient of 0.75, together with a wear rate of 3.94 × 10−6 mm3/N·m, indicating greatly improved high-temperature tribological performance.

Full article

(This article belongs to the Section Corrosion and Protection)

►▼

Show Figures

Figure 1

Open AccessArticle

Hot-Formed, High-Strength, Integrated Automotive Parts: Numerical Analysis and Process Optimization

by

Chunlin Li, Xin Xu, Xiao Liang, Li Lin, Rendong Liu and Xiaodong Li

Metals 2026, 16(2), 151; https://doi.org/10.3390/met16020151 - 26 Jan 2026

Abstract

Hot-forming, as a typical representative forming technology of high-strength steel (HSS), is one of the most effective ways to manufacture structural components for achieving automotive lightweighting goal. In this paper, a newly-developed commercial microalloyed hot-formed steel is selected and its hot-forming is studied

[...] Read more.

Hot-forming, as a typical representative forming technology of high-strength steel (HSS), is one of the most effective ways to manufacture structural components for achieving automotive lightweighting goal. In this paper, a newly-developed commercial microalloyed hot-formed steel is selected and its hot-forming is studied by experiments and simulations. The new steel has a wide undercooled austenite region, providing more suitable condition for the manufacturing of one-piece large-sized integrated parts. The high-temperature mechanical behaviors of the investigated steel show that the flow stress obviously decreases with the increase in deformation temperature, and it increases with the increasing strain rate. An integrated component assembly of the rear floor and longitudinal beam is selected as a typical one-piece integrated part when performing the hot-forming simulation to evaluate the formability. The influences of the key process parameters, namely forming velocity and frictional coefficient, on formability are further analyzed. Finally, the Latin Hypercube Sampling (LHS) method is used to generate the parameter combination and the Response Surface Method (RSM) is adopted in optimization. As a result, an optimal process parameter combination is obtained and its predicted result matches the simulated one very well, with a relative error of only 2.57%. The research results of this paper are favorable for understanding the mechanical behaviors of the hot-formed steel at elevated temperatures, improving the formability and providing a reference for the development of large-sized integrated hot-formed parts.

Full article

(This article belongs to the Special Issue Advanced Manufacturing and Processing Technology for Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Research on a High-Quality Welding Method for Multi-Layer Aluminum Foil Current Collectors Based on Laser Power Control

by

Jingang Liu, Yun Chen and Liang Guo

Metals 2026, 16(2), 150; https://doi.org/10.3390/met16020150 - 26 Jan 2026

Abstract

Reliable joining of multi-layer aluminum foil current collectors is crucial for enhancing the performance and safety of high-capacity lithium-ion batteries. However, laser welding of such thin-thick aluminum combinations is often hindered by porosity, cracks and unstable weld-pool behavior. In this study, a ring-mode

[...] Read more.

Reliable joining of multi-layer aluminum foil current collectors is crucial for enhancing the performance and safety of high-capacity lithium-ion batteries. However, laser welding of such thin-thick aluminum combinations is often hindered by porosity, cracks and unstable weld-pool behavior. In this study, a ring-mode fiber laser combined with sinusoidal oscillation and linearly gradient power modulation was employed to achieve high-quality lap welding between 80 layers of 1060 aluminum foil (1 mm in total thickness) and a 1.5 mm thick aluminum plate. Welding experiments and thermo-mechanical simulations were conducted to investigate the effects of welding speed (15–45 mm/s) and central-power modulation parameters (−2, 0, +2, +4) on weld morphology, defect formation, and mechanical properties. The results indicate that increasing the welding speed can effectively suppress cracks and improve the shear strength from 249.8 N to 403.9 N, but it also leads to an increase in porosity from 5.78% to 12.26% and deterioration of the weld reinforcement. Higher central-power modulation (+2, +4) transformed the weld-pool geometry from an ω shape to U shape, effectively suppressing fusion-line cracks but leading to increased porosity (up to 8.41%) and deteriorated surface morphology. Overall, a low welding speed of 15 mm/s combined with an optimized power modulation strategy achieves effective crack suppression while maintaining controlled porosity, resulting in a welded joint with superior comprehensive performance. This research provides a robust process solution for high-quality laser welding of multi-layer aluminum foil current collectors in power battery manufacturing.

Full article

(This article belongs to the Special Issue Advanced Laser Welding Technology of Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Corrosion Properties and Performance of Nanostructured Multilayered Chromium–Amorphous Carbon Coatings on HS6-5-2 Steel

by

Boriana Tzaneva, Yavor Sofronov, Krum Petrov, Valentin Mishev, Rayna Dimitrova, Antonio Nikolov, Milko Yordanov, Milko Angelov, Boyan Dochev and Krassimir Marchev

Metals 2026, 16(2), 149; https://doi.org/10.3390/met16020149 - 26 Jan 2026

Abstract

Magnetron-sputtered coatings consisting of multiple alternating layers of chromium and amorphous carbon (Cr/a-C)ml were deposited on HS6-5-2 steel with an intermediate chromium layer by varying deposition rates. Three series of coatings, S1, S2, and S3, with thicknesses of 1.74, 1.15, and 1.14 μm

[...] Read more.

Magnetron-sputtered coatings consisting of multiple alternating layers of chromium and amorphous carbon (Cr/a-C)ml were deposited on HS6-5-2 steel with an intermediate chromium layer by varying deposition rates. Three series of coatings, S1, S2, and S3, with thicknesses of 1.74, 1.15, and 1.14 μm and average chromium contents of 89.3, 66.0, and 59.7 wt.% Cr, respectively, were obtained. Open-circuit potential, cyclic potentiodynamic measurements, and electrochemical impedance spectroscopy were used to characterize their corrosion resistance in 3.5% NaCl. The surfaces were observed with optical and scanning electron microscopy before and after the corrosion tests, and changes in the elemental composition were monitored by energy-dispersive spectroscopy. The protective properties of coatings from series S2 and S3 are similar and significantly better than those of S1. They are characterized by a corrosion current below 1 μA cm–2 and a stable passive state up to over 0.9 VAg/AgCl. The coatings have cathodic behavior towards the substrate, and when the coatings are damaged, galvanic corrosion causes deep pits. Coatings deposited at lower rates and with higher carbon content demonstrate significantly enhanced corrosion resistance in 3.5% NaCl. All three series of Cr/(Cr/a-C)ml@HS6-5-2 exhibit identical corrosion behavior after compromising the coatings’ integrity.

Full article

(This article belongs to the Special Issue Recent Advances in Surface Modification of Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Effect of Weld Surface Quality on the Fatigue Performance of Q420 Steel Used in Offshore Wind Tower Tube

by

Jun Cao, Wubin Ren, Guodong Zhang, Shubiao Yin, Zhongzhu Liu and Xinjun Sun

Metals 2026, 16(2), 148; https://doi.org/10.3390/met16020148 - 25 Jan 2026

Abstract

The size of offshore wind turbine towers is increasing, and they are subjected to larger and more complex loads, which imposes more stringent requirements on the fatigue performance of welded plates in new offshore wind turbine towers. This study investigated the axial fatigue

[...] Read more.

The size of offshore wind turbine towers is increasing, and they are subjected to larger and more complex loads, which imposes more stringent requirements on the fatigue performance of welded plates in new offshore wind turbine towers. This study investigated the axial fatigue performance of 25 mm thick welded plates made of the new Q420 steel grade. Fractures in the Q420 welded plates occurred at the junction of the coarse-grained zone of the filler metal and the heat-affected zone. By analyzing the fatigue striation spacing across multiple regions, it was found that the proportion of cycles in the crack propagation stage within the total fatigue life did not exceed 11%, indicating that the crack initiation stage is the decisive factor in the fatigue life of the specimens. Removing surface quality defects at the weld toe significantly increased both the fatigue life and the fatigue strength limit of the Q420 welded plates.

Full article

(This article belongs to the Special Issue Feature Papers in Metal Failure Analysis)

►▼

Show Figures

Figure 1

Open AccessArticle

Path Optimization of Laser Welding for Large-Scale Tube-to-Tubesheet

by

Xuqiang Kang, Chuchuan Cao, Bingqi Wang and Anguo Huang

Metals 2026, 16(2), 147; https://doi.org/10.3390/met16020147 - 25 Jan 2026

Abstract

►▼

Show Figures

To address issues of residual stress concentration and deformation in large-scale multi-seam laser welding of tube-to-tubesheet, we established a 12 mm thick Q235 steel simulation model. The model considers the material’s high-temperature performance and mechanical properties. We designed three welding paths: sequential welding,

[...] Read more.

To address issues of residual stress concentration and deformation in large-scale multi-seam laser welding of tube-to-tubesheet, we established a 12 mm thick Q235 steel simulation model. The model considers the material’s high-temperature performance and mechanical properties. We designed three welding paths: sequential welding, block-by-block symmetrical welding, and inward–outward symmetrical radial welding. The welding simulation software InteWeld 4.0 was used to study the effects of these paths on deformation. Results showed that the inside-out symmetric radiation welding path disperses heat input effectively. It prevents stiffness reduction from local heat accumulation. By using symmetrically distributed shrinkage forces that offset each other, this path greatly inhibits deformation accumulation. The maximum deformation was only 1.6 mm—5.9% and 33% lower than with block-by-block symmetric welding (1.7 mm) and sequential welding (2.4 mm). This path also resulted in a uniform residual stress distribution, with a maximum stress of only 250 MPa, making it the best option for suppressing deformation.

Full article

Figure 1

Open AccessArticle

Technological and Chemical Drivers of Zinc Coating Degradation in DX51d+Z140 Cold-Formed Steel Sections

by

Volodymyr Kukhar, Andrii Kostryzhev, Oleksandr Dykha, Oleg Makovkin, Ihor Kuziev, Roman Vakulenko, Viktoriia Kulynych, Khrystyna Malii, Eleonora Butenko, Natalia Hrudkina, Oleksandr Shapoval, Sergiu Mazuru and Oleksandr Hrushko

Metals 2026, 16(2), 146; https://doi.org/10.3390/met16020146 - 25 Jan 2026

Abstract

This study investigates the technological and chemical causes of early zinc-coating degradation on cold-formed steel sections produced from DX51D+Z140 galvanized coils. Commercially manufactured products exhibiting early corrosion symptoms were used in this study. The entire processing route, which included strip preparation, cold rolling,

[...] Read more.

This study investigates the technological and chemical causes of early zinc-coating degradation on cold-formed steel sections produced from DX51D+Z140 galvanized coils. Commercially manufactured products exhibiting early corrosion symptoms were used in this study. The entire processing route, which included strip preparation, cold rolling, hot-dip galvanizing, passivation, multi-roll forming, storage, and transportation to customers, was analyzed with respect to the residual surface chemistry and process-related deviations that affect the coating integrity. Thirty-three specimens were examined using electromagnetic measurements of coating thickness. Statistical analysis based on the Cochran’s and Fisher’s criteria confirmed that the increased variability in zinc coating thickness is associated with a higher susceptibility to localized corrosion. Surface and chemical analysis revealed chloride contamination on the outer surface, absence of detectable Cr(VI) residues indicative of insufficient passivation, iron oxide inclusions beneath the zinc coating originating from the strip preparation, traces of organic emulsion residues impairing wetting and adhesion, and micro-defects related to deformation during roll forming. Early zinc coating degradation was shown to result from the cumulative action of multiple technological (surface damage during rolling, variation in the coating thickness) and environmental (moisture during storage and transportation) parameters. On the basis of the obtained results, a methodology was proposed to prevent steel product corrosion in industrial conditions.

Full article

(This article belongs to the Special Issue Corrosion Behavior and Surface Engineering of Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Effect of Heat Treatment Process on Microstructure and Mechanical Properties of As-Cast Mg-8Gd-1Y-2Sm-1.2Zn-0.5Mn Alloy

by

Zirui Qiao, Feng Wang, Chun Xue, Chaojie Che and Zhibing Chu

Metals 2026, 16(2), 145; https://doi.org/10.3390/met16020145 - 25 Jan 2026

Abstract

This study investigates the as-cast Mg-8Gd-1Y-2Sm-1.2Zn-0.5Mn (wt.%) alloy with high rare-earth content. Solution treatments were conducted at 480 °C, 520 °C, and 560 °C for 6–10 h. Microstructure and mechanical properties were characterized using OM, XRD, SEM-EDS, and compression testing. The as-cast alloy

[...] Read more.

This study investigates the as-cast Mg-8Gd-1Y-2Sm-1.2Zn-0.5Mn (wt.%) alloy with high rare-earth content. Solution treatments were conducted at 480 °C, 520 °C, and 560 °C for 6–10 h. Microstructure and mechanical properties were characterized using OM, XRD, SEM-EDS, and compression testing. The as-cast alloy shows a dendritic structure with continuous grain-boundary phases (Mg5RE, W, and LPSO), exhibiting a compressive yield strength of 145 MPa, ultimate strength of 238 MPa, and fracture strain of 12.66%. Solution temperature has a critical influence on phase dissolution and grain refinement. Notably, the overall plasticity of the material did not show a significant dependence on the specific solution temperature or holding time within the studied range. Treatment at 520 °C produces the most balanced microstructure: clear grain boundaries, extensive phase dissolution, refined grains, and enhanced solid-solution strengthening. Specifically, 520 °C for 10 h results in the finest and most uniformly distributed residual phases, a homogeneous matrix, the highest compressive strength, and suitable conditions for subsequent aging, thus being identified as optimal. Fractography reveals a transition from quasi-cleavage in the as-cast state toward enhanced ductility after solution treatment. However, small cleavage facets after 10 h are attributed to stress concentrations from rare-earth-rich regions and reduced deformation compatibility due to retained LPSO phases.

Full article

(This article belongs to the Special Issue Heat Treatment, Microstructures, and Mechanical Properties of Metallic Materials)

►▼

Show Figures

Figure 1

Journal Menu

► ▼ Journal Menu-

- Metals Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Photography Exhibition

- Instructions for Authors

- Special Issues

- Topics

- Sections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Society Collaborations

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

JFB, Materials, Metals, Nanomanufacturing, Nanomaterials

Physical Methods for the Synthesis of Materials and Their Applications

Topic Editors: Vincenzo Amendola, Gregory GuisbiersDeadline: 31 March 2026

Topic in

Applied Sciences, Buildings, Construction Materials, CMD, Materials, Metals

Construction Materials: Corrosion, Prevention and Protection

Topic Editors: Sergio Lorenzi, Marco OrmelleseDeadline: 1 May 2026

Topic in

Analytica, Metals, Molecules, Processes, Separations

Advances in Solvent Extraction

Topic Editors: Guoquan Zhang, Weizao LiuDeadline: 31 May 2026

Topic in

Applied Mechanics, Applied Sciences, Materials, Polymers, Solids, Metals

Multi-scale Modeling and Optimisation of Materials

Topic Editors: Mustafa Awd, Frank WaltherDeadline: 31 August 2026

Conferences

Special Issues

Special Issue in

Metals

Study on the Preparation and Properties of Metal Functional Materials

Guest Editor: Weiyi YangDeadline: 30 January 2026

Special Issue in

Metals

Quality Evaluation of Welding Processes for Metals

Guest Editor: Kang ZhouDeadline: 31 January 2026

Special Issue in

Metals

Advances in Directed Energy Deposition Technology for Metallic Materials

Guest Editors: Alessia Teresa Silvestri, Umberto Prisco, Giorgio de AlteriisDeadline: 31 January 2026

Special Issue in

Metals

Full-Cycle Innovation of Titanium Resources: From Mineral Development to High-End Material Manufacturing

Guest Editors: Lingxin Kong, Lei GaoDeadline: 31 January 2026