Theoretical Study on Error Compensation for Online Roll Profile Measurement Considering Roller System Deformation

Abstract

1. Introduction

2. Materials and Methods

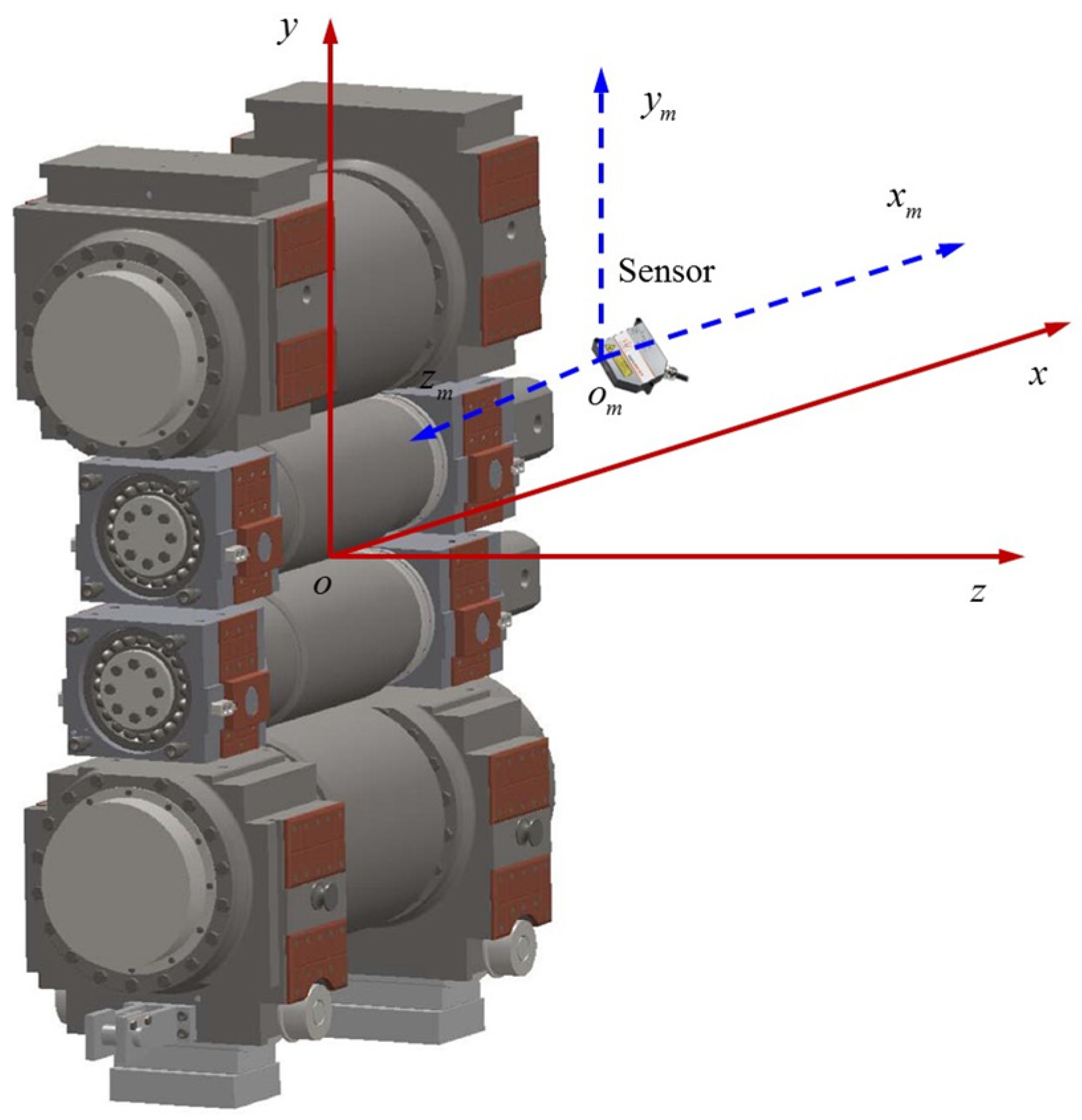

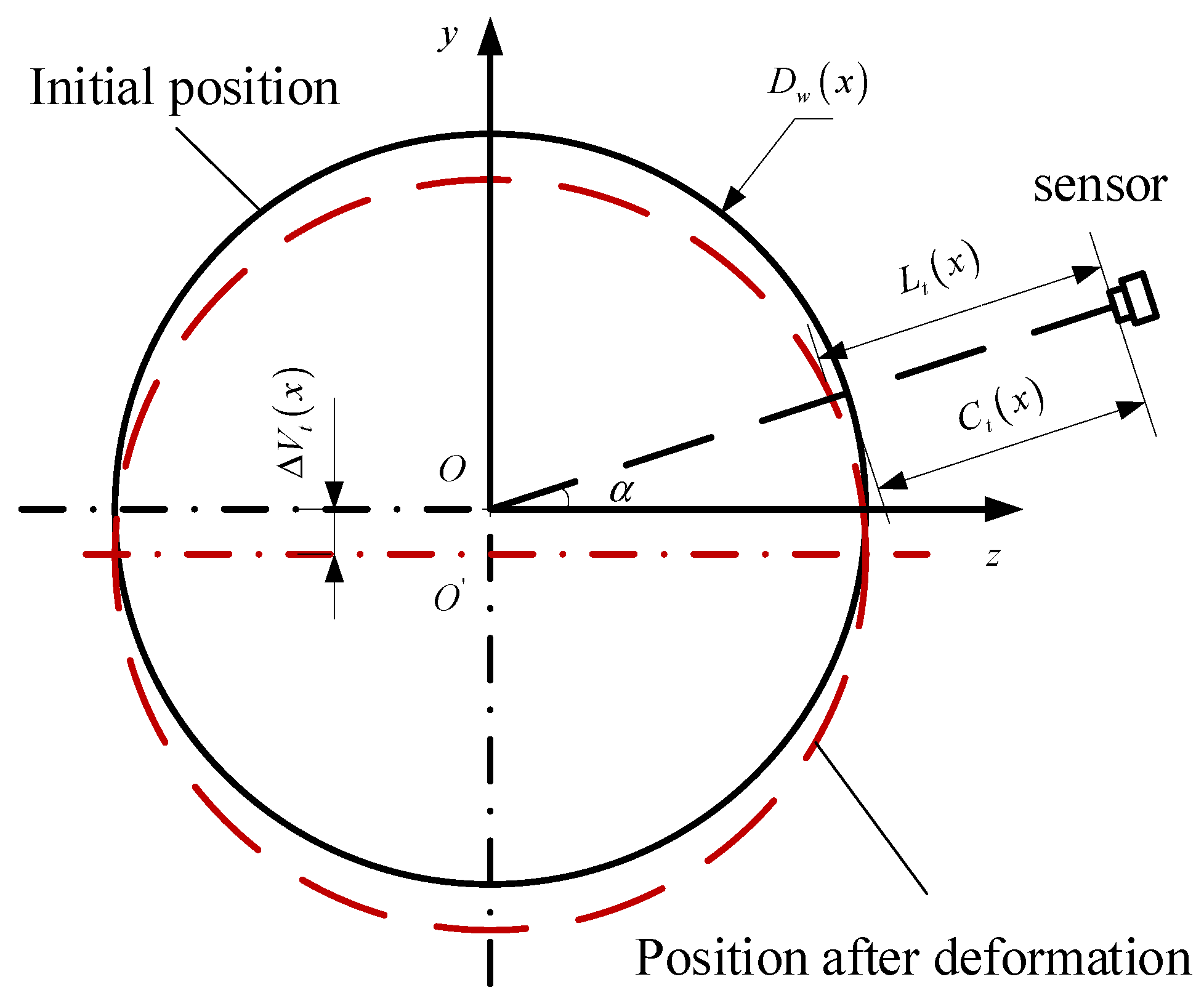

2.1. Rolling Mill Coordinate System and Measurement Coordinate System

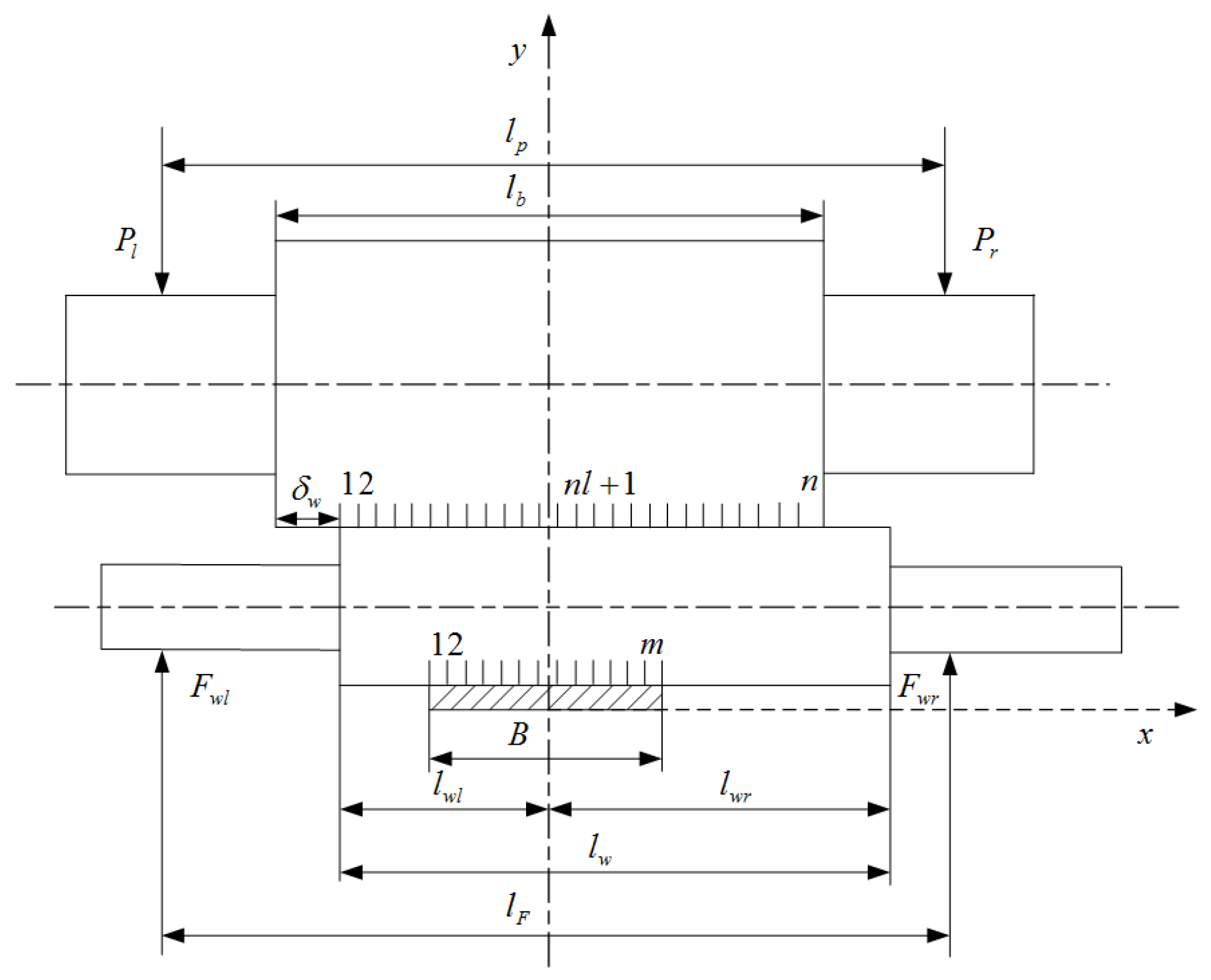

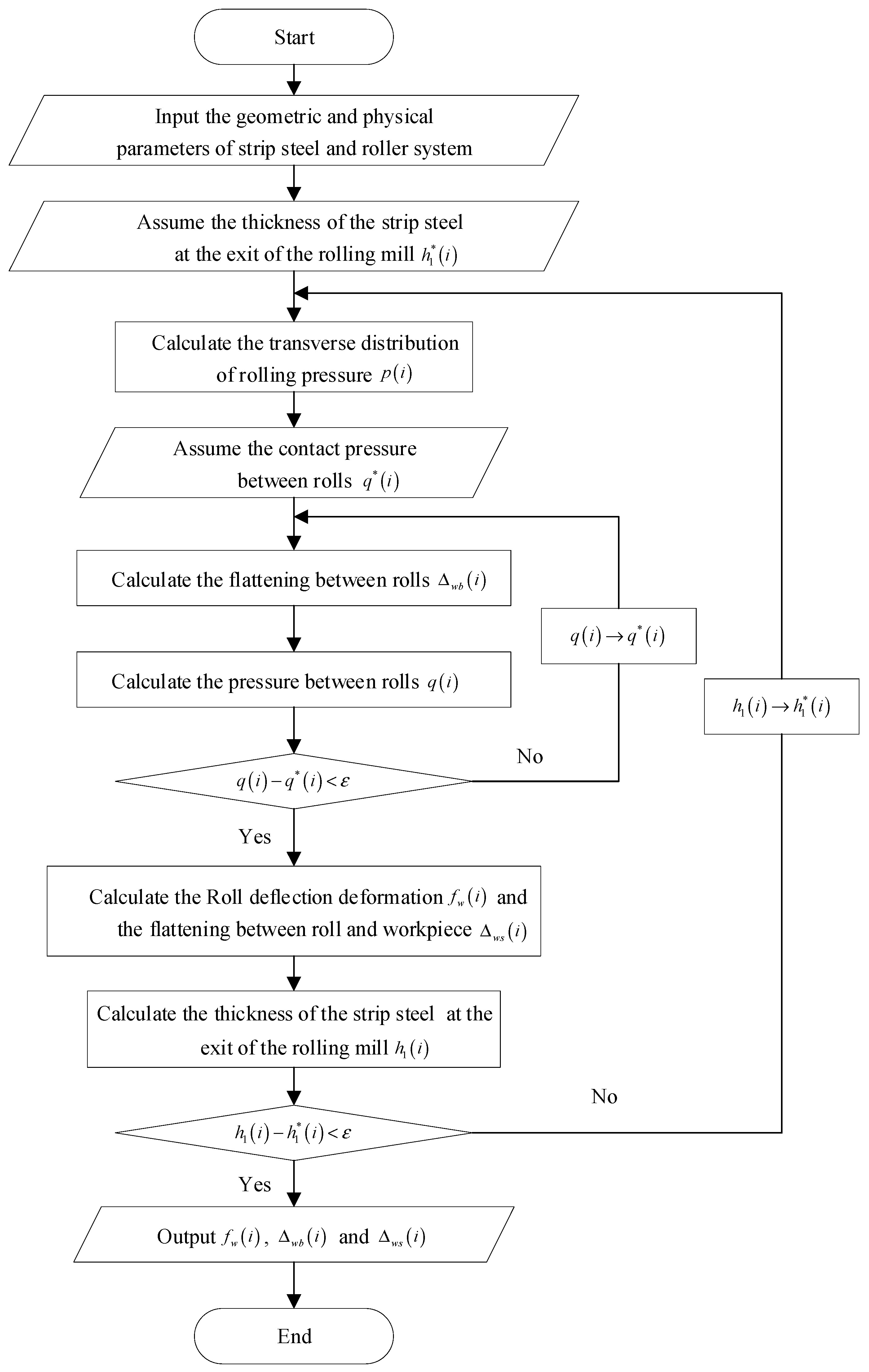

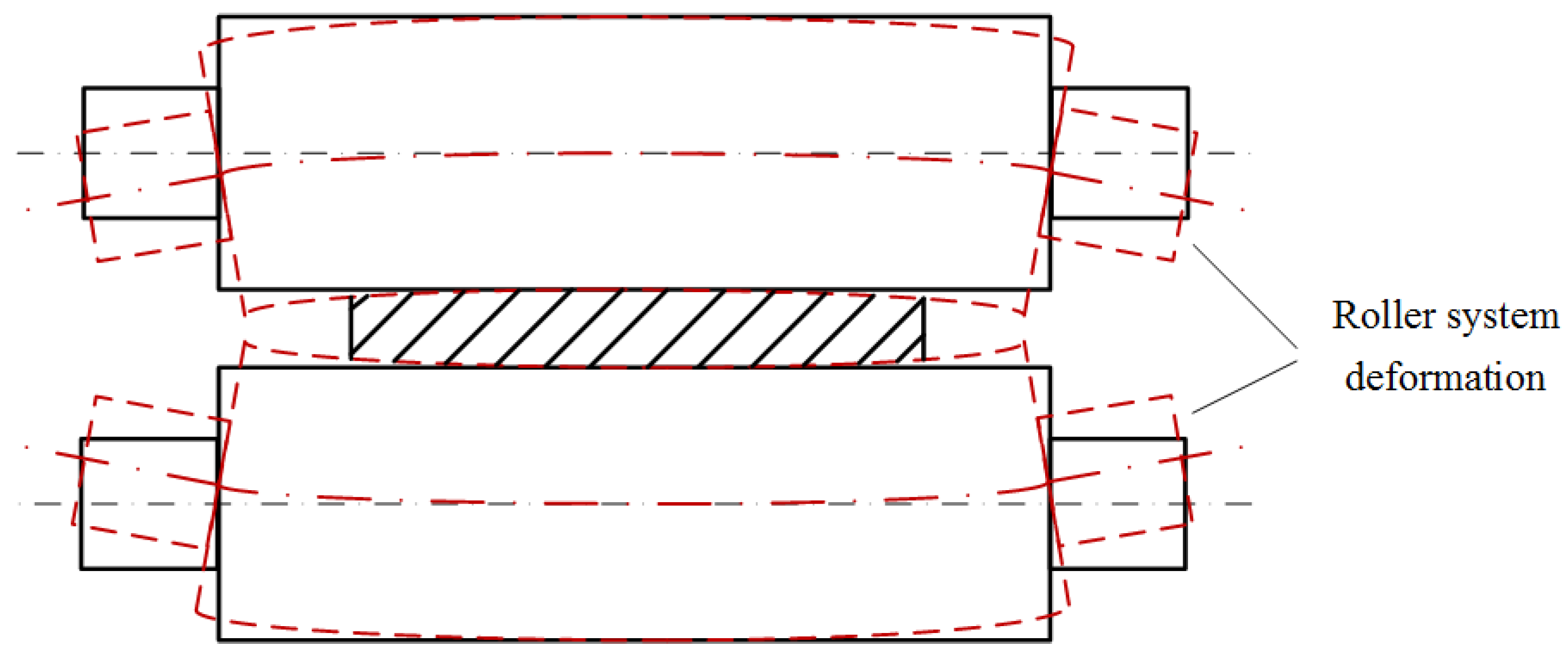

2.2. Roller System Deformation Model

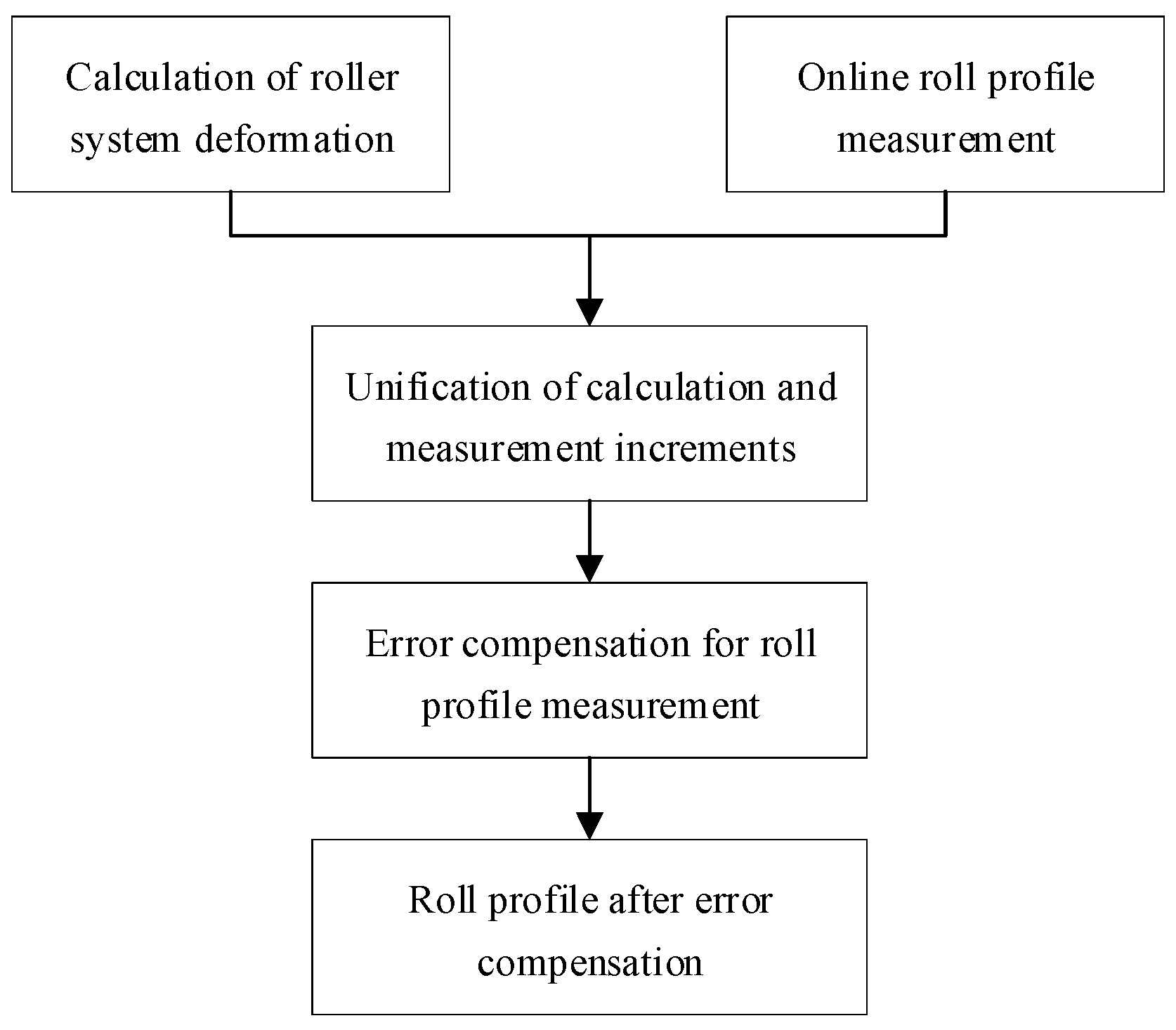

2.3. Unification of Calculation and Measurement Increments

2.4. Roll Profile Measurement Error Compensation Model

3. Numerical Simulations

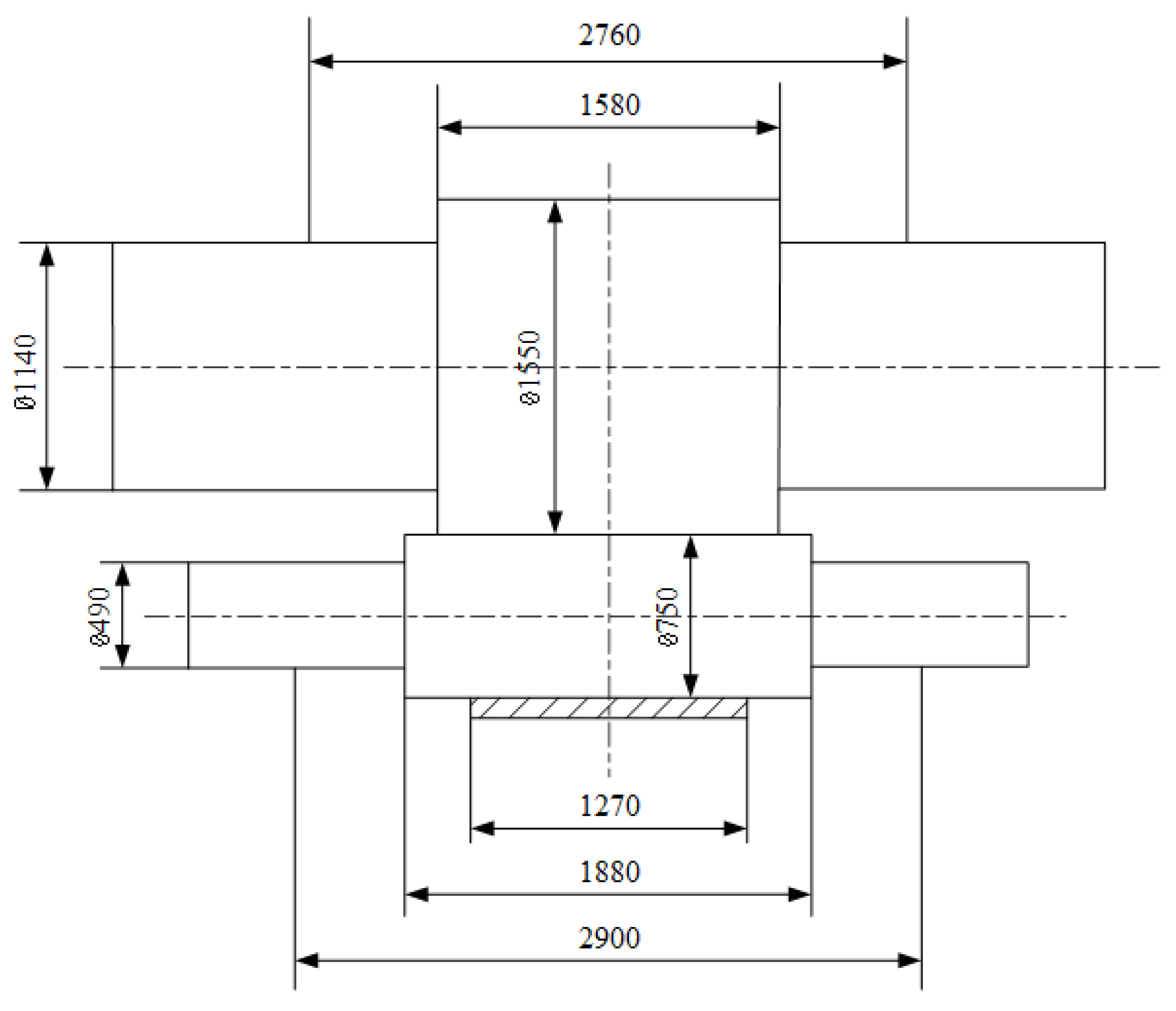

3.1. Parameters for Simulations

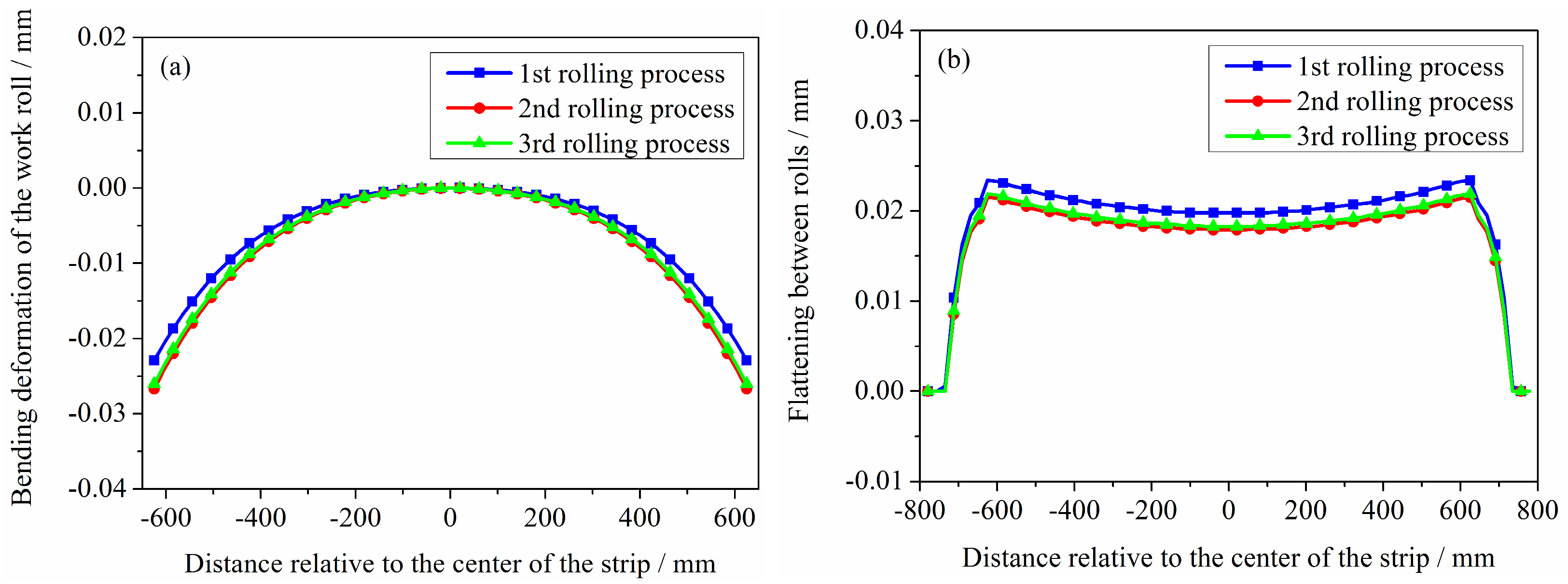

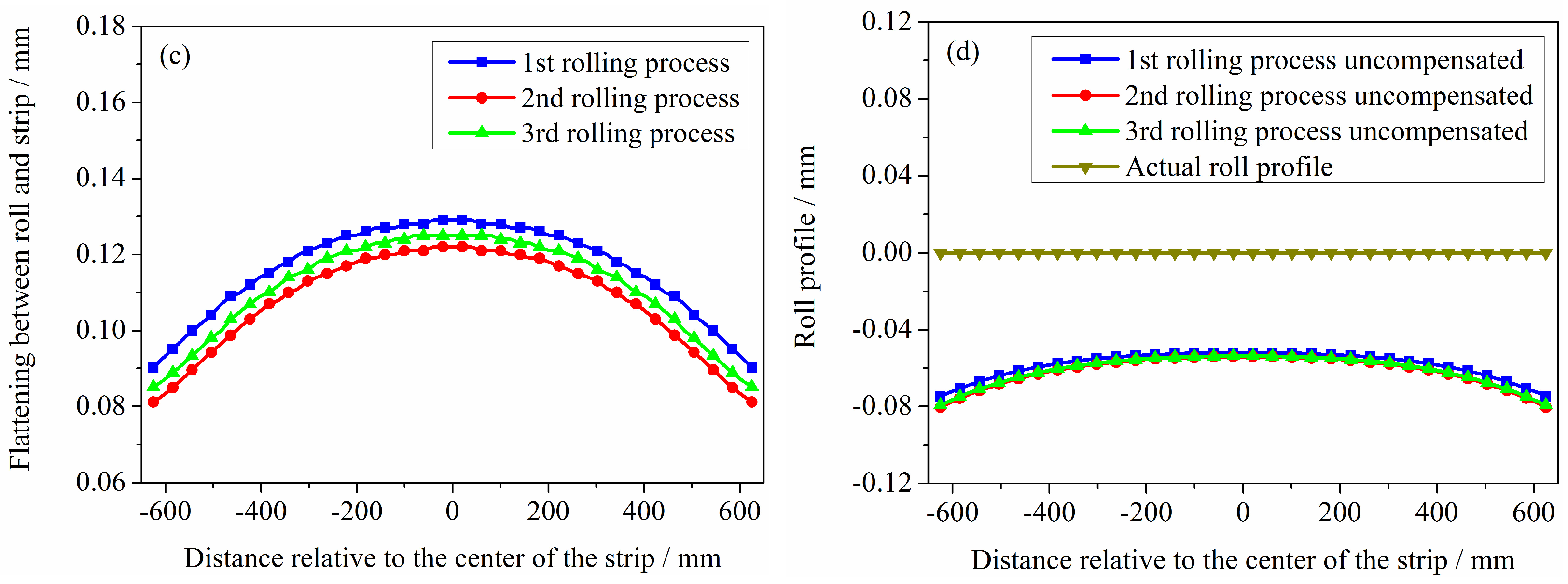

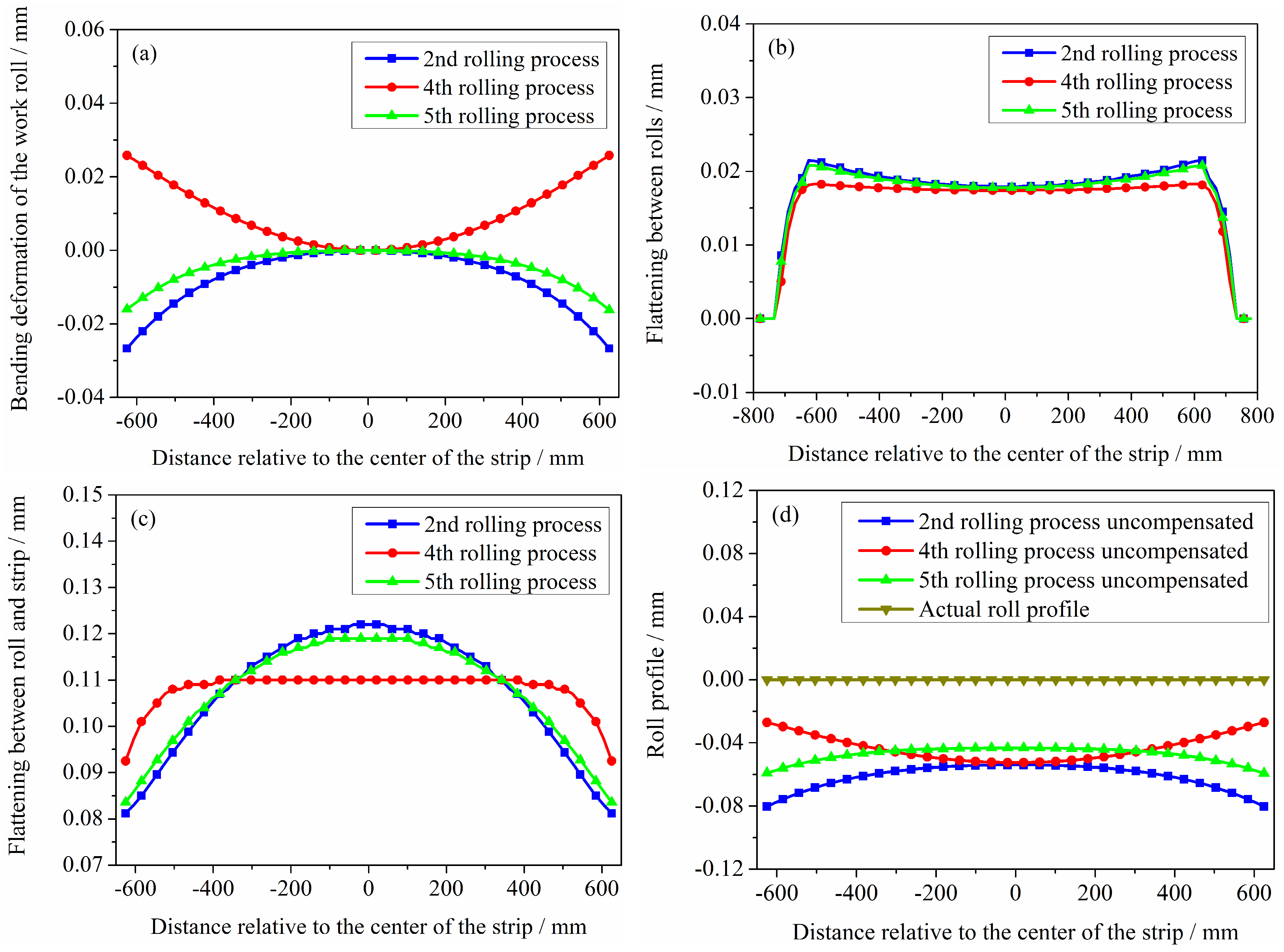

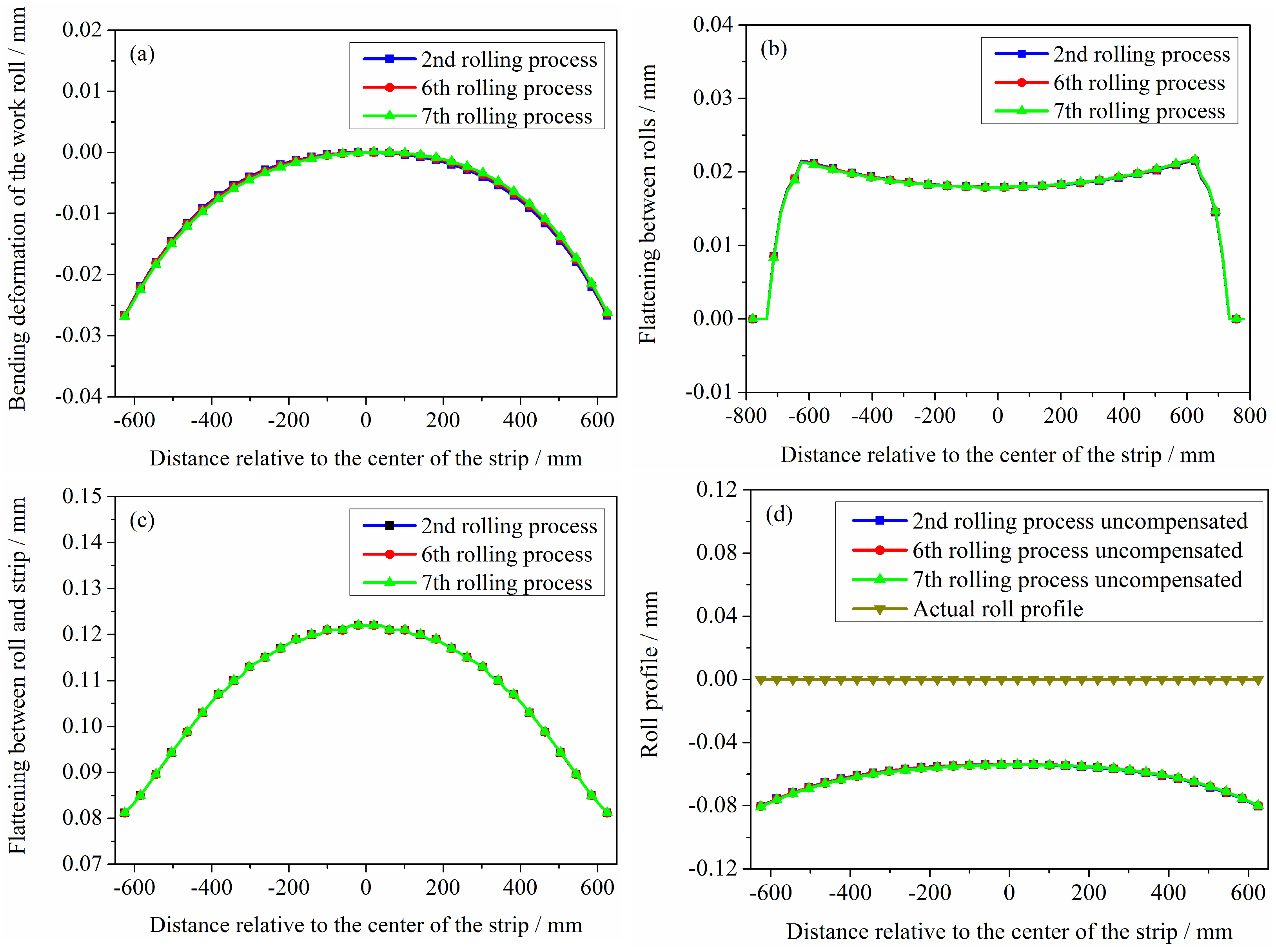

3.2. Results and Analysis

4. Conclusions

- During the rolling process, under the combined effects of rolling force and bending force, the work rolls undergo deflection deformation and elastic flattening. To ensure measurement accuracy during online roll profile measurement, it is necessary to compensate for the measurement errors caused by the roller system deformation.

- The pressing process and bending force have a significant impact on the roller system deformation. Roll profile measurement errors are associated with both the deflection deformation and the elastic flattening of the rolls. The roll profile curves without error compensation have a high correlation with the bending deformation of the rolls. The axial displacement of the rolls has a negligible effect on the rolls’ deflection and flattening and consequently exerts minimal influence on roll profile measurement errors. However, when the rolling mill adopts the axial displacement of the roll process, the roll profile measurement system requires displacement compensation in the -axis direction. The magnitude and direction of the compensation should be consistent with the displacement and direction of the corresponding roll.

- This paper primarily investigated the error compensation theory of online roll profile measurement considering the roller system deformation. This work was conducted on the premise that the sensor provides accurate measurements. Future research should focus on investigating the impact of factors such as sensor measurement accuracy, measurement system stability, and rolling mill vibration on measurement errors, thereby further enhancing the precision of roll profile measurement. Furthermore, research should be conducted into online roll grinding technology, integrating it with online roll profile measurement techniques to fully leverage the technical advantages of online roll grinding.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Q. Research progress on key equipment and technology of high quality steel plate and strip rolling. J. Mech. Eng. 2023, 59, 34–63. [Google Scholar]

- Wang, G.; Liu, Z.; Zhang, D.; Chu, M. Steel Enterprise Innovation Infrastructure (SEII) and its research development. Iron Steel 2023, 58, 2–14. [Google Scholar]

- Wang, G. Discussion on innovative direction of entire process and integrated process technology of steel. J. Iron Steel Res. 2018, 30, 1–7. [Google Scholar]

- Wen, X.; Shan, J.; He, Y.; Song, K. Steel surface defect recognition: A survey. Coatings 2023, 13, 17. [Google Scholar] [CrossRef]

- Peng, Y.; Shi, B.; Liu, C.; Xing, J. Review of the integrated development of strip rolling equipment-process-product quality control. J. Mech. Eng. 2023, 59, 96–118. [Google Scholar]

- Xu, S.; Sun, D. Production Processes and Equipment for Strip Steel; Metallurgical Industry Press: Beijing, China, 2008; pp. 1–2. [Google Scholar]

- Yin, R. Essence and common law of a process-oriented manufacturing process. Iron Steel 2023, 58, 1–7. [Google Scholar]

- Zhu, T.; Liu, X.; Wang, X.; He, H. Technical development and prospect for collaborative reduction of pollution and carbon emissions from iron and steel industry in China. Engineering 2023, 31, 37–49. [Google Scholar] [CrossRef]

- Yu, J.; Xu, R.; Zhang, J.; Zheng, A. A review on reduction technology of air pollutant in current China’s iron and steel industry. J. Clean. Prod. 2023, 414, 137659. [Google Scholar] [CrossRef]

- Zhang, F. Thoughts on path of developing new quality productive forces in iron and steel industry. Iron Steel 2024, 59, 1–11. [Google Scholar]

- Dong, Q.; Wang, Z.; He, Y.; Zhang, L.; Shang, F.; Li, Z. The effect of shifting modes on work roll wear in strip steel hot rolling process. Ironmak. Steelmak. 2023, 50, 67–74. [Google Scholar] [CrossRef]

- Hu, X.; Zhou, X.; Liu, H.; Song, H.; Wang, S.; Zhang, H. Enhanced predictive modeling of hot rolling work roll wear using TCN-LSTM-Attention. Int. J. Adv. Manuf. Technol. 2024, 131, 1335–1346. [Google Scholar] [CrossRef]

- LU, J.; Hao, L.; Wang, P.; Huang, H.; Li, X.; Hua, C.; Su, L.; Deng, G. Wear prediction model of hot rolling backup roll based on FEM plus ML algorithm. Int. J. Adv. Manuf. Technol. 2024, 131, 5923–5939. [Google Scholar] [CrossRef]

- Meng, L.; Ding, J.; Dong, Z.; Sun, J.; Zhang, D.; Gou, J. Prediction of roll wear and thermal expansion based on informer network in hot rolling process and application in the control of crown and thickness. J. Manuf. Process. 2023, 103, 248–260. [Google Scholar] [CrossRef]

- Peng, W.; Ding, C.; Liu, Y.; Sun, J.; Wei, Z.; Wang, W.; Zhang, D.; Sun, J. A novel paradigm for predicting and interpreting uneven roll wear in the hot rolling steel industry. Comput. Ind. 2025, 170, 104318. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, A. Research on the prediction of roll wear in a strip mill. Metals 2024, 14, 1180. [Google Scholar] [CrossRef]

- Xing, J.; Peng, Y.; Sun, J.; Liu, C.; Barella, S.; Gruttadauria, A.; Belfi, M.; Mapelli, C. Study on error compensation method of online roll profile measurement. Steel Res. Int. 2023, 94, 2300022. [Google Scholar] [CrossRef]

- Chen, L.; Qian, C. The ORG technique and its application in 1780 mm hot rolling mill. Shanghai Met. 2005, 4, 23–26. [Google Scholar]

- Wei, W. Improve surface quality by on-line roll grinding. Metall. Stand. Qual. 2005, 3, 35–56. [Google Scholar]

- Zhang, W.; Zhang, C. Application effect of on-line roll grinder on PC mill. Steel Roll. 2005, 1, 62–64. [Google Scholar]

- Zhou, S. Current status and development trends of hot rolling online roll grinding technology. Precise Manuf. Autom. 2005, 1, 9–11. [Google Scholar]

- Cai, Z.; Liu, X.; Wang, G.; Zhang, Q.; Yuan, J.; Xu, J. Development and utilization of on-line roll grinding system. Shanghai Met. 1995, 5, 21–26. [Google Scholar]

- Hayashi, K.; Shimazutsu, H.; Nishizaki, J. Development of on-line roll grinding system for hot strip mill. ISIJ Int. 1991, 31, 588–593. [Google Scholar] [CrossRef]

- Kinose, R.; Kondoh, S.; Mori, S. Development and application of build-in roll shaping machine for hot strip mill work rolls. Iron Steel Eng. 1997, 74, 32–36. [Google Scholar]

- Li, L. Feasibility Study of Roll Shape On-Line Ultrasonic Detection. Master’s Thesis, Yanshan University, Qinhuangdao, China, 1999. [Google Scholar]

- Shang, L. The study of the roll on-line measurement-using dual-frequency ultrasonic wave. Chin. J. Sens. Actuators 1999, 2, 104–108. [Google Scholar]

- Hua, Y. Theoretical and Experimental Studies on the Technology of On-Line Roll Profile Measuring for Hot Strip Continuous Rolling Mill. Doctoral Thesis, Yanshan University, Qinhuangdao, China, 2003. [Google Scholar]

- Hua, Y.; Peng, Y.; Liu, H.; Jiang, G.; Gu, T.; Fan, Q. Simulation experiment research on influencing factor of roll profile measuring on hot strip mill. Iron Steel 2004, 10, 46–49. [Google Scholar]

- Guo, J. Research on Theory of Roller Profile Noncontact Detection And practice with CCD. Doctoral Thesis, Yanshan University, Qinhuangdao, China, 2002. [Google Scholar]

- Hu, G. Research on Theory of On-Line Profile Measure System for Hot Strip Rolling Mill. Master’s Thesis, Northeastern University, Shenyang, China, 2004. [Google Scholar]

- Zhou, S. On-Line Roll Grinding Theory and Technology Research for Hot Strip Mill. Master’s Thesis, Northeastern University, Shenyang, China, 2006. [Google Scholar]

- Peng, Y. Theoretical Studies and Engineering Application of Shape Preset Control for HC Cold Mill Based on Strip Element Method. Doctoral Thesis, Yanshan University, Qinhuangdao, China, 2000. [Google Scholar]

- Lian, J.; Liu, H. Plate Thickness and Shape Control; Ordnance Industry Press: Beijing, China, 1996; pp. 41–75. [Google Scholar]

- Wang, G. Plate Shape and Plate Convexity Control; Chemical Industry Press: Beijing, China, 2016; pp. 69–149. [Google Scholar]

- Qi, X. Study on Pass Schedule and Mill Types Selection for New Plate and Strip Mill in Baosteel. Doctoral Thesis, Yanshan University, Qinhuangdao, China, 2002. [Google Scholar]

| Number | Initial Thickness /mm | Thickness After Rolling /mm | Front Tension /MPa | Post-Tension /MPa | Roll Bending Force /KN | Axial Displacement of the Roll /mm |

|---|---|---|---|---|---|---|

| 1 | 10.33 | 6.18 | 13.70 | 12.60 | 1000 | 0 |

| 2 | 8.75 | 5.50 | 14.80 | 13.90 | 1000 | 0 |

| 3 | 7.91 | 4.81 | 18.13 | 14.35 | 1000 | 0 |

| 4 | 8.75 | 5.50 | 14.80 | 13.90 | 0 | 0 |

| 5 | 8.75 | 5.50 | 14.80 | 13.90 | 800 | 0 |

| 6 | 8.75 | 5.50 | 14.80 | 13.90 | 1000 | 15 |

| 7 | 8.75 | 5.50 | 14.80 | 13.90 | 1000 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, J.; Peng, Y. Theoretical Study on Error Compensation for Online Roll Profile Measurement Considering Roller System Deformation. Metals 2025, 15, 1358. https://doi.org/10.3390/met15121358

Xing J, Peng Y. Theoretical Study on Error Compensation for Online Roll Profile Measurement Considering Roller System Deformation. Metals. 2025; 15(12):1358. https://doi.org/10.3390/met15121358

Chicago/Turabian StyleXing, Jiankang, and Yan Peng. 2025. "Theoretical Study on Error Compensation for Online Roll Profile Measurement Considering Roller System Deformation" Metals 15, no. 12: 1358. https://doi.org/10.3390/met15121358

APA StyleXing, J., & Peng, Y. (2025). Theoretical Study on Error Compensation for Online Roll Profile Measurement Considering Roller System Deformation. Metals, 15(12), 1358. https://doi.org/10.3390/met15121358