- Article

Modeling and Experimental Analysis of the Dislocation Structure Evolution During Deformation of High-Purity Aluminum

- Abbas Sadeghi,

- Robert Kahlenberg and

- Tomasz Wojcik

- + 4 authors

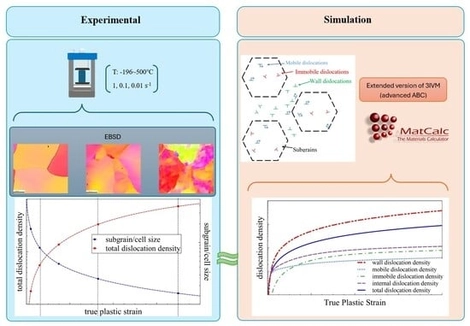

In this study, the three internal variables model (3IVM) for dislocation density evolution is further developed into the advanced ABC (advABC) model to simulate the thermo-mechanical behavior of high-purity aluminum (5N). In contrast to conventional FEM packages (e.g., ABAQUS, ANSYS), the present physically based ABC framework directly captures the evolution of the underlying dislocation structure, providing a more coherent prediction of flow behavior. The enhanced model extends the classical formulation by incorporating dislocation annihilation mechanisms and introducing the wall volume fraction as an evolving variable. Simulations are performed over a wide temperature range from −196 °C to 500 °C and at three strain rates of 1, 0.1, and 0.01 s−1. To validate the model, both stress–strain flow curves and microstructural observations obtained via Electron Backscatter Diffraction (EBSD) are used. The simulation results show excellent agreement with experimental data, successfully capturing the temperature- and strain-rate-dependence of the flow behavior, as well as the evolution of dislocation substructures. This work demonstrates the capability of the advABC model to describe both macroscopic and microscopic aspects of deformation. It provides a robust framework for predicting material behavior under complex thermo-mechanical conditions.

8 December 2025