New Model for Estimating the Volume of Martensite Transformed Using Acoustic Emission Measurements During an Induction Hardening Process †

Abstract

1. Introduction

2. Martensite Volume Estimation Model Based on AE

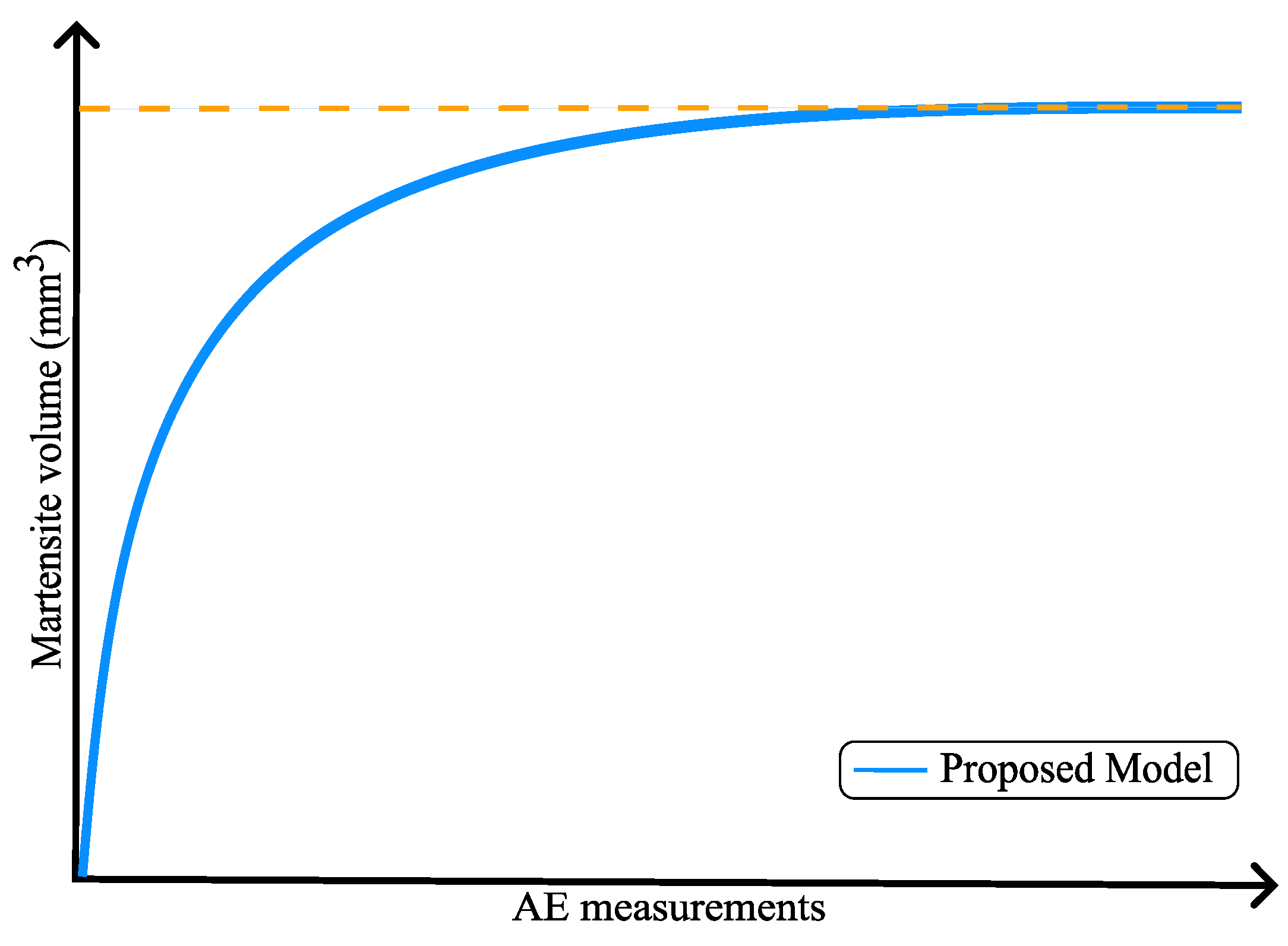

2.1. Proposed Model

2.2. Materials and Methods

2.2.1. Quenching Tests

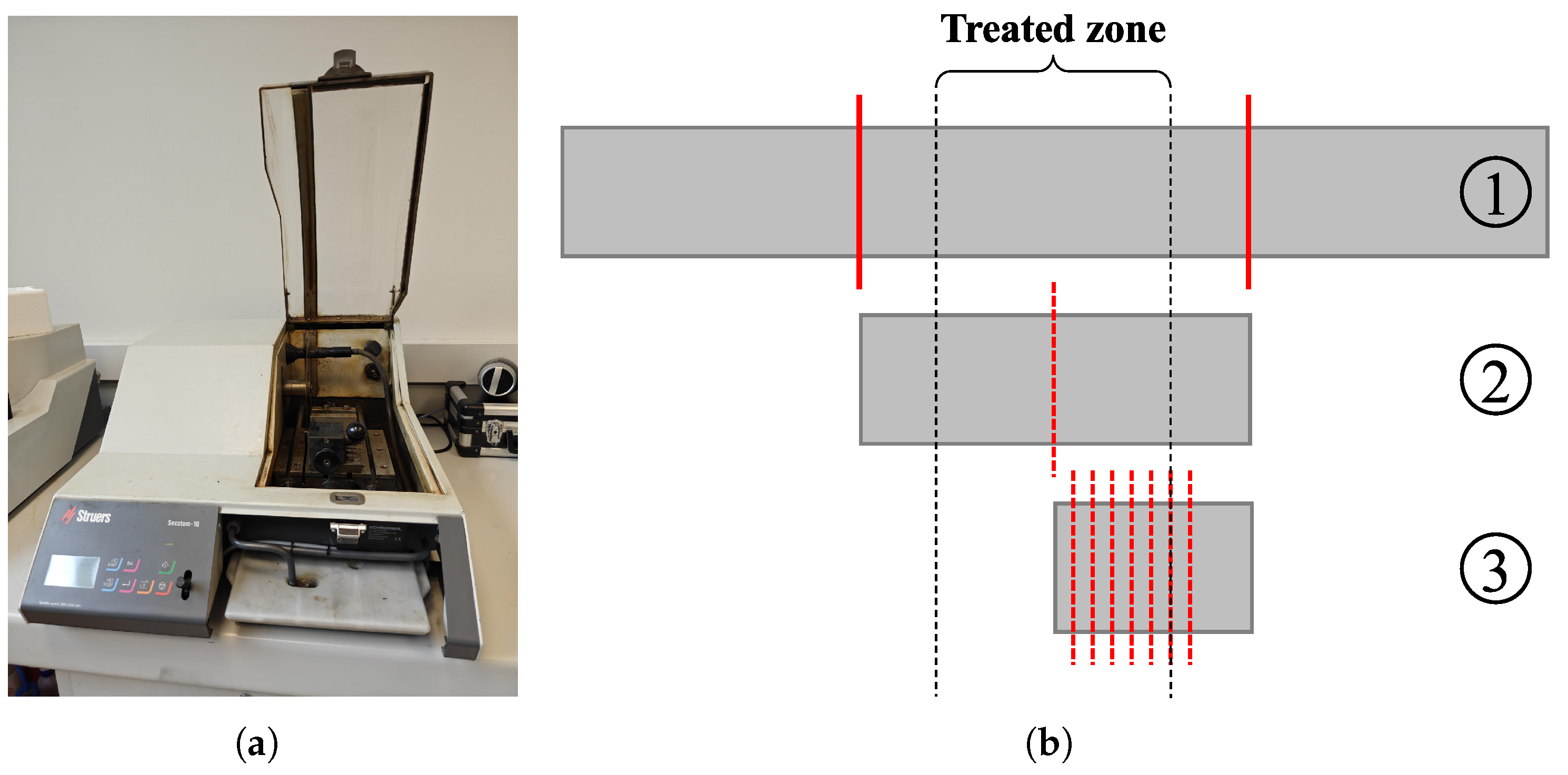

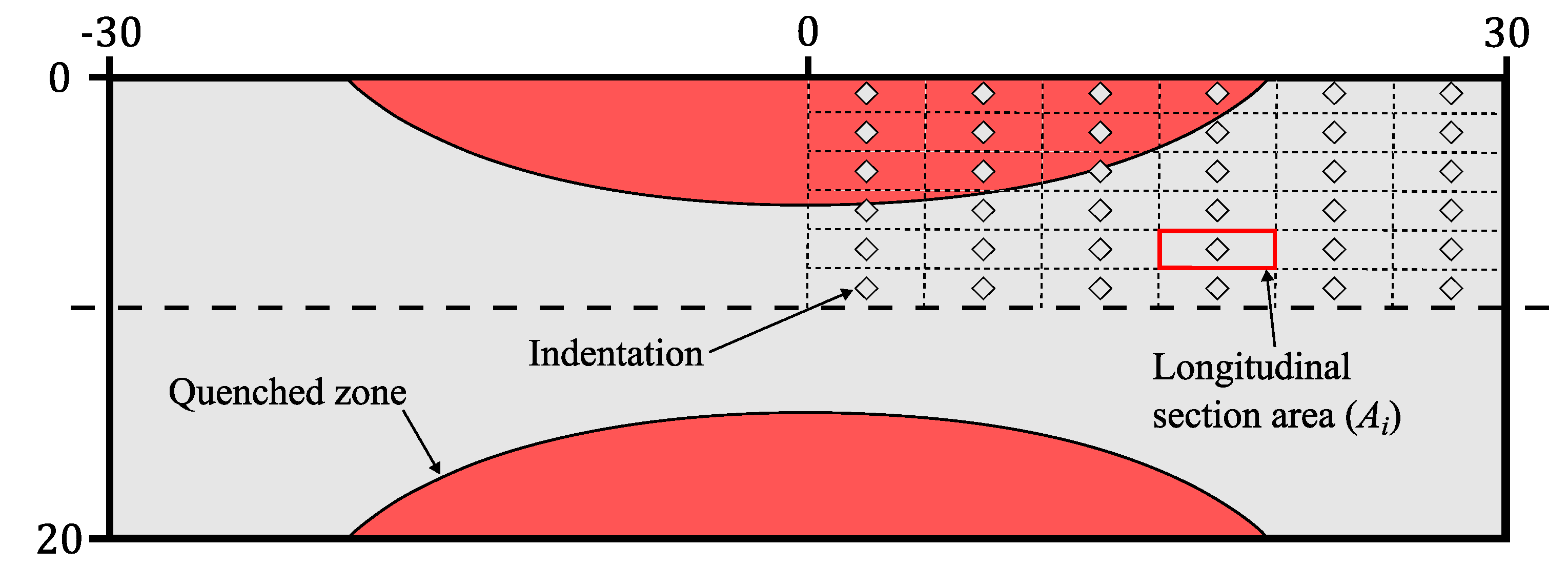

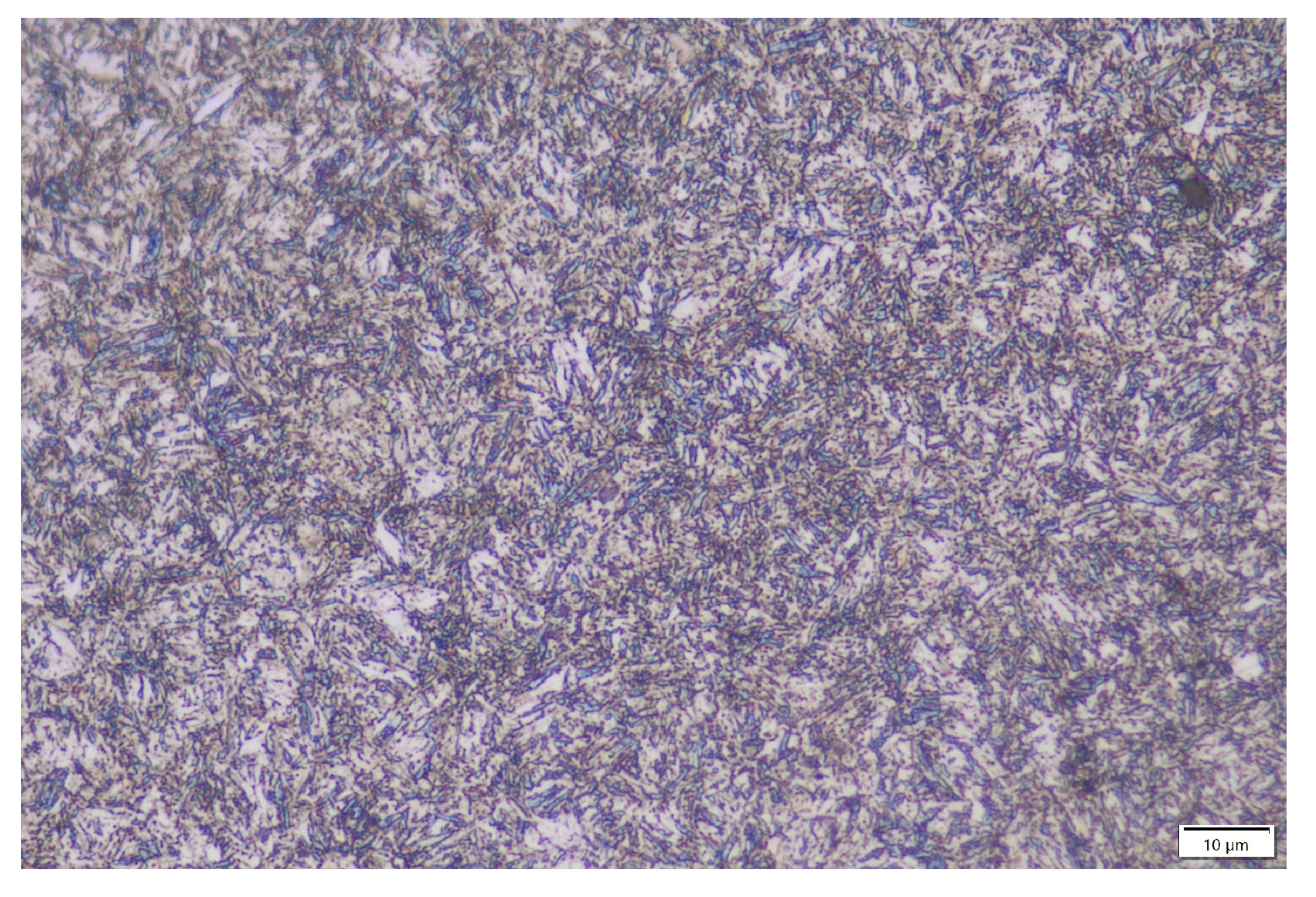

2.2.2. Metallographic Procedure

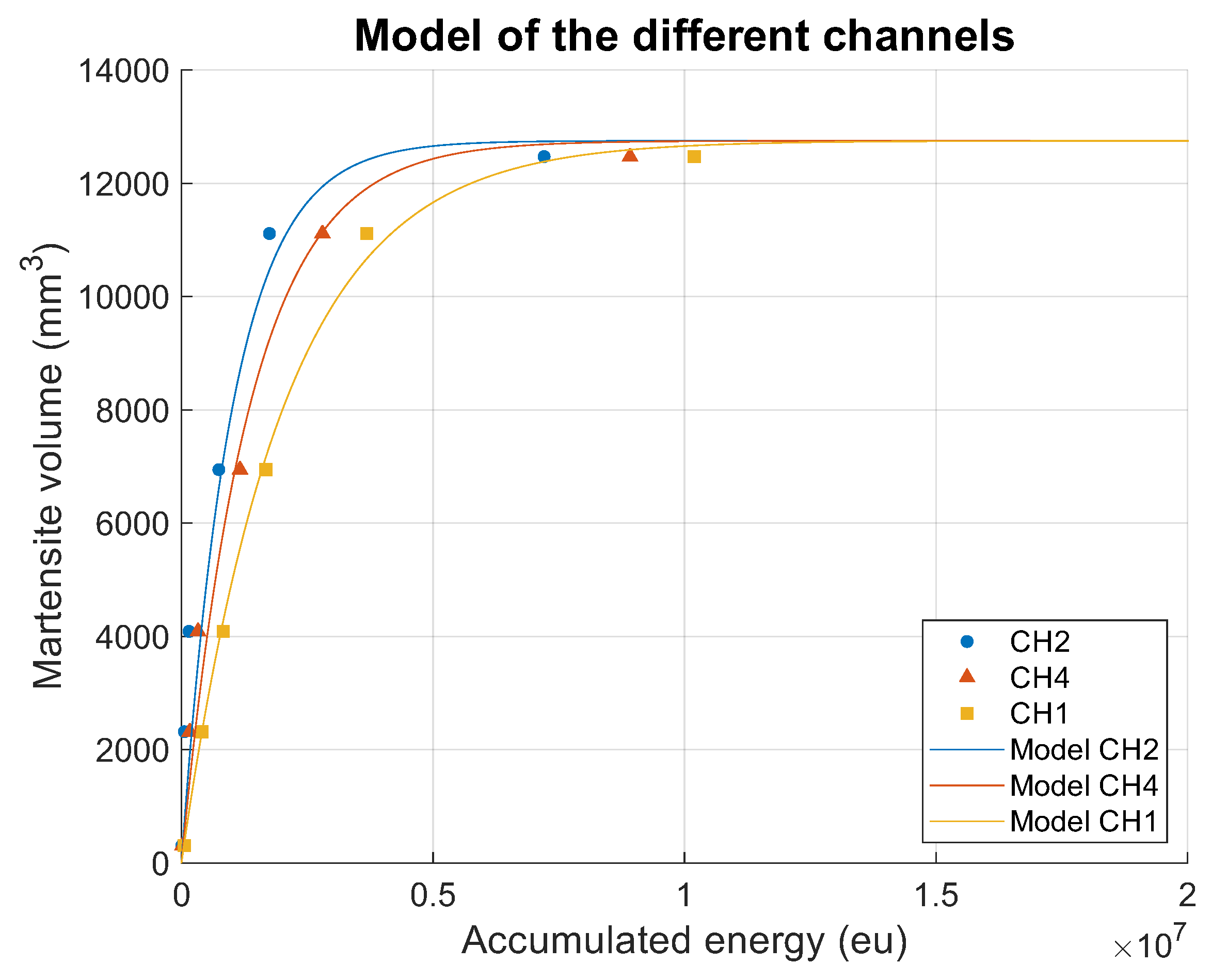

2.3. Martensite Volume Estimation Model

3. Results

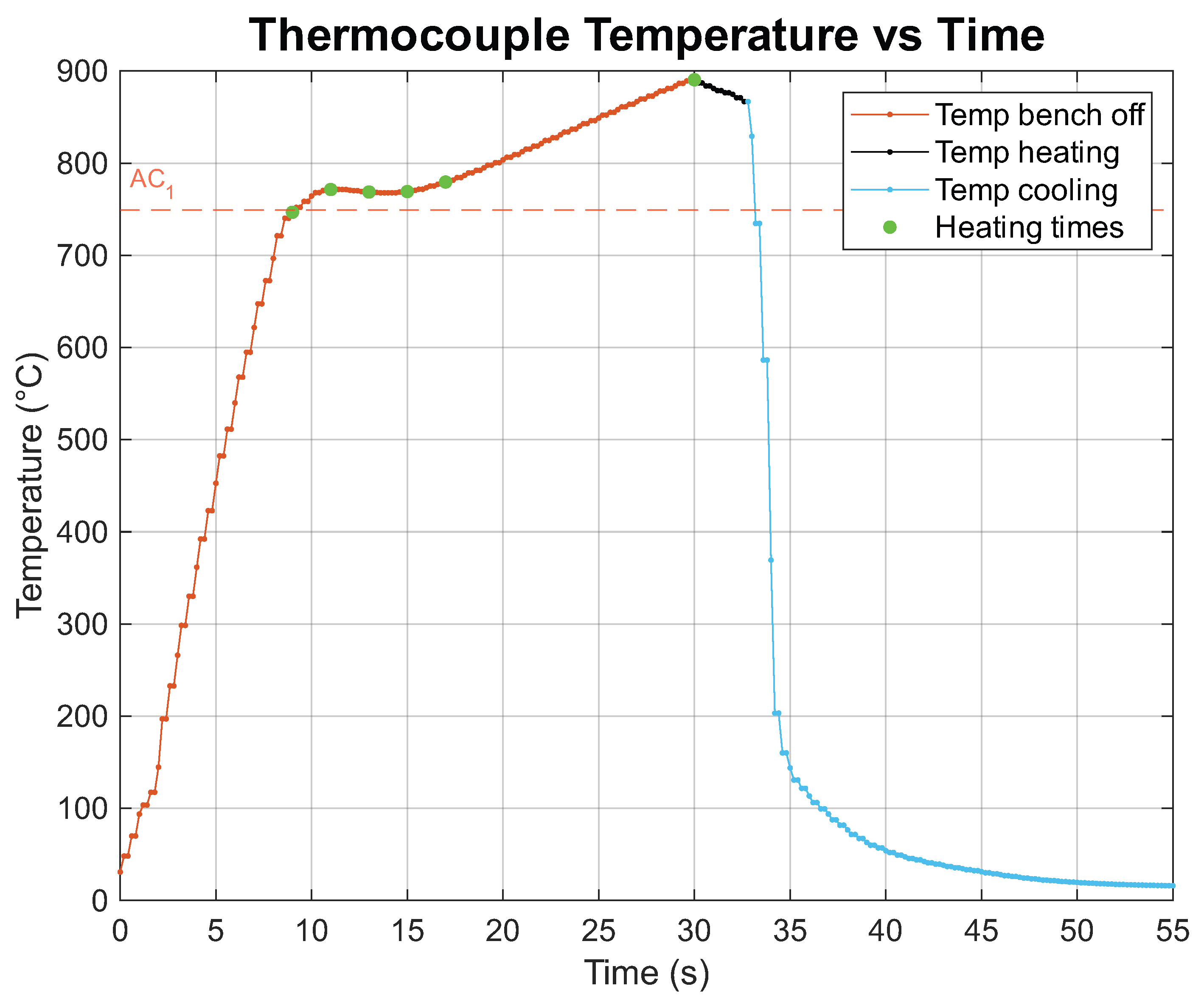

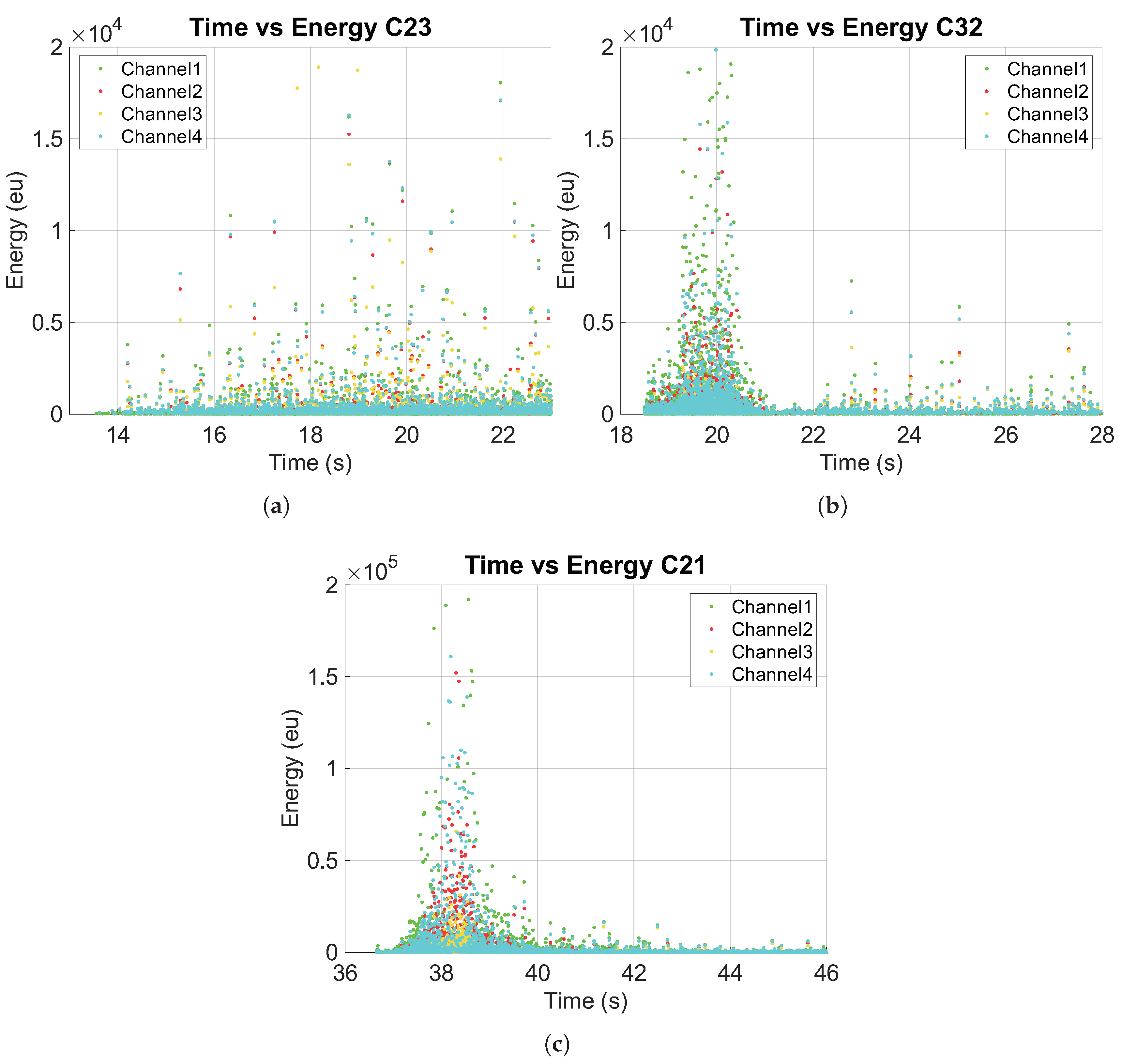

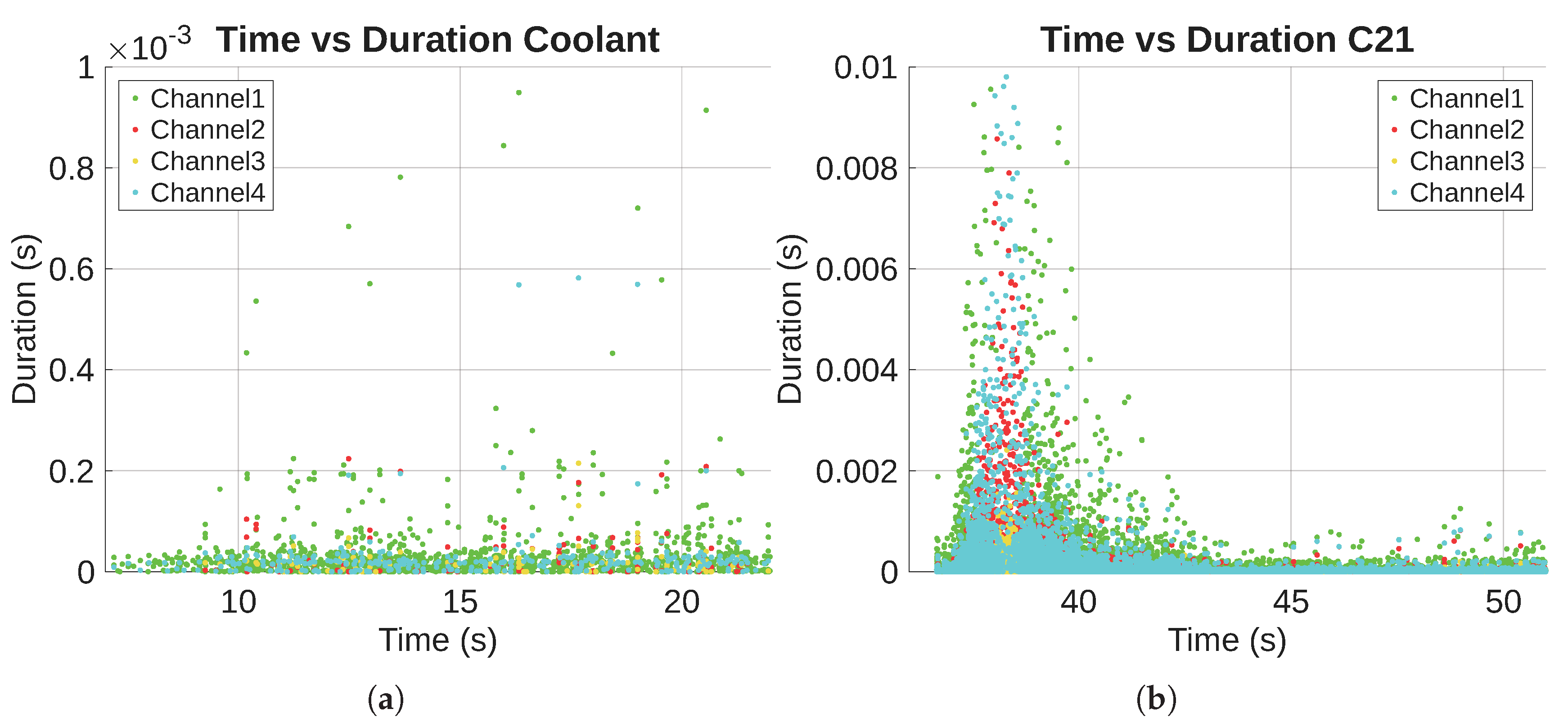

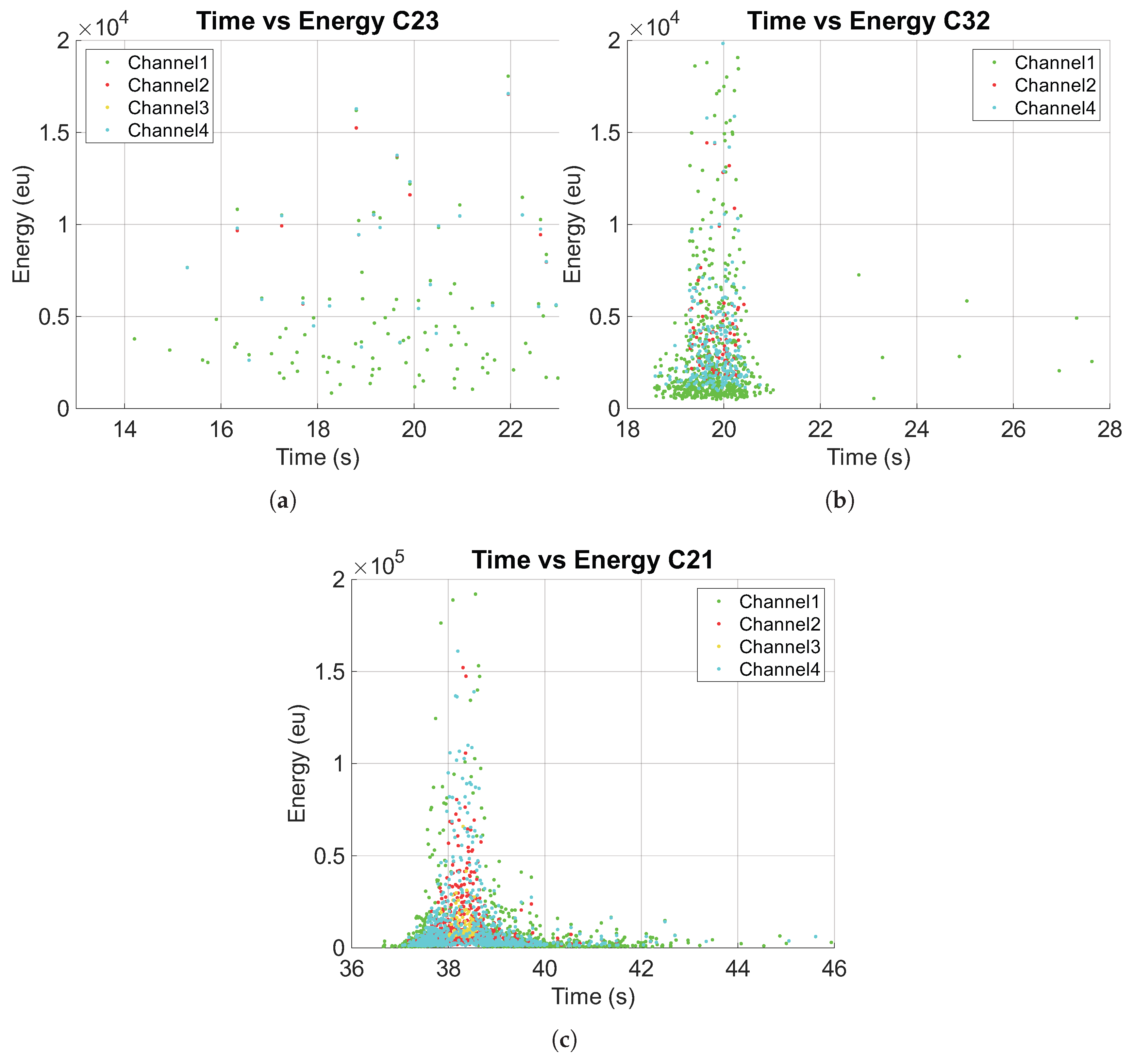

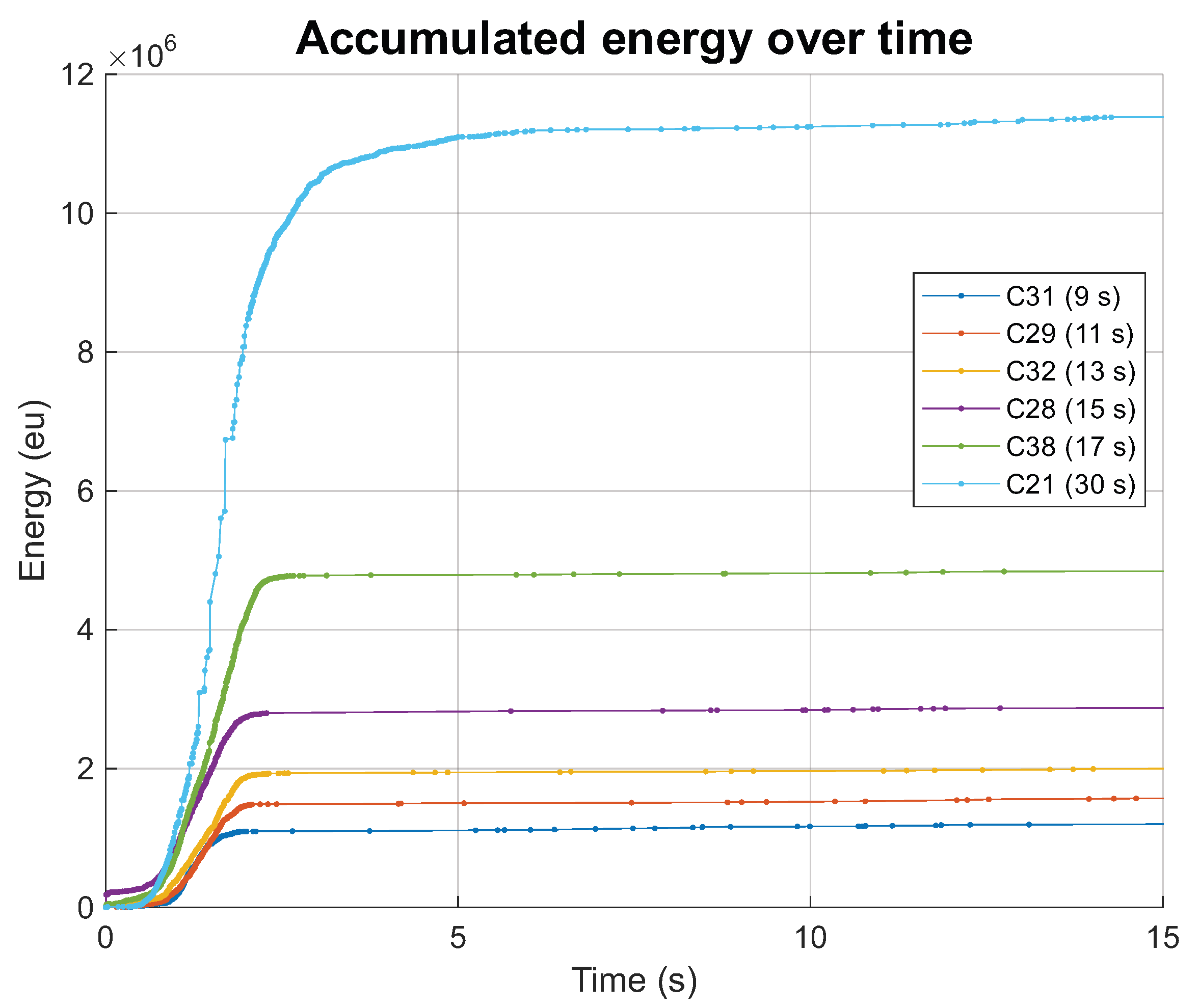

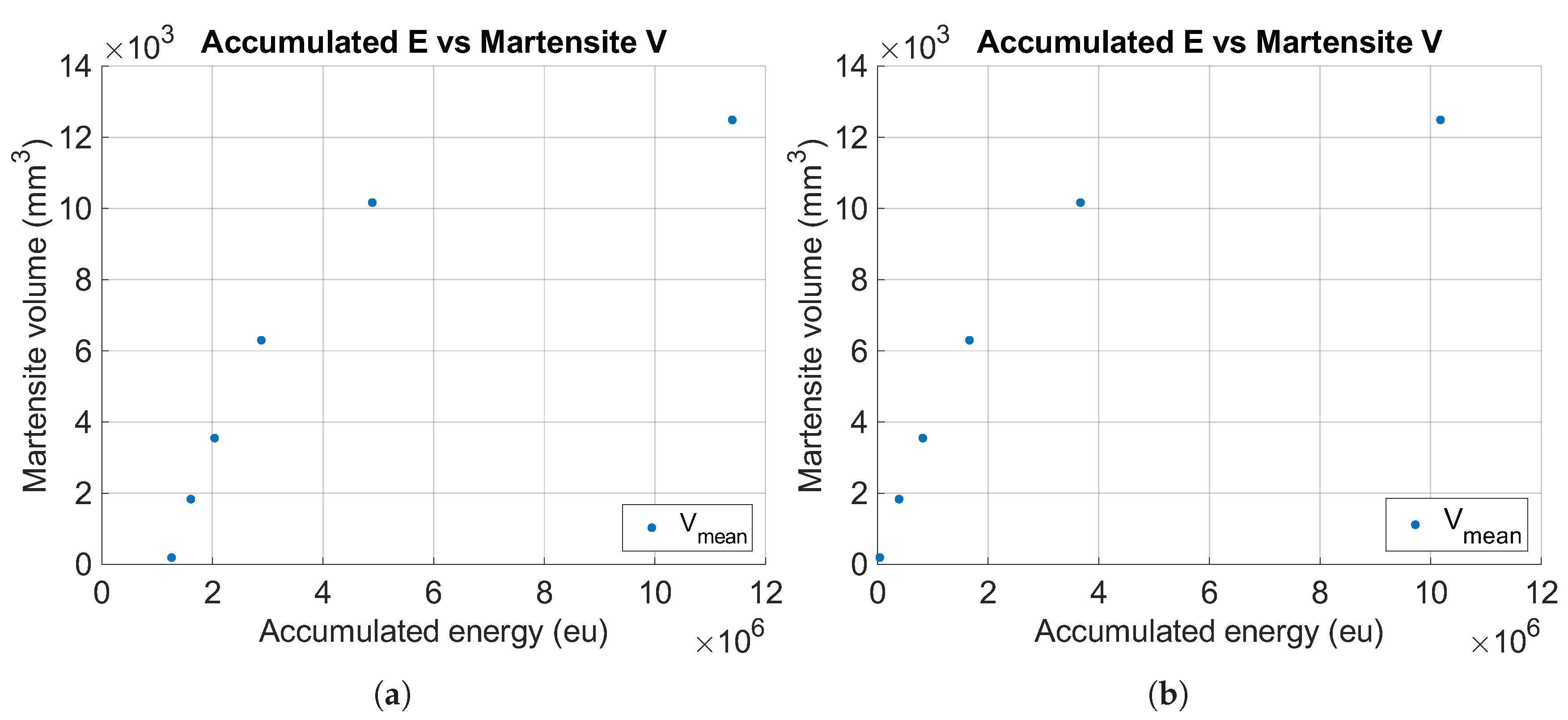

3.1. Quenching Tests and AE Measurements

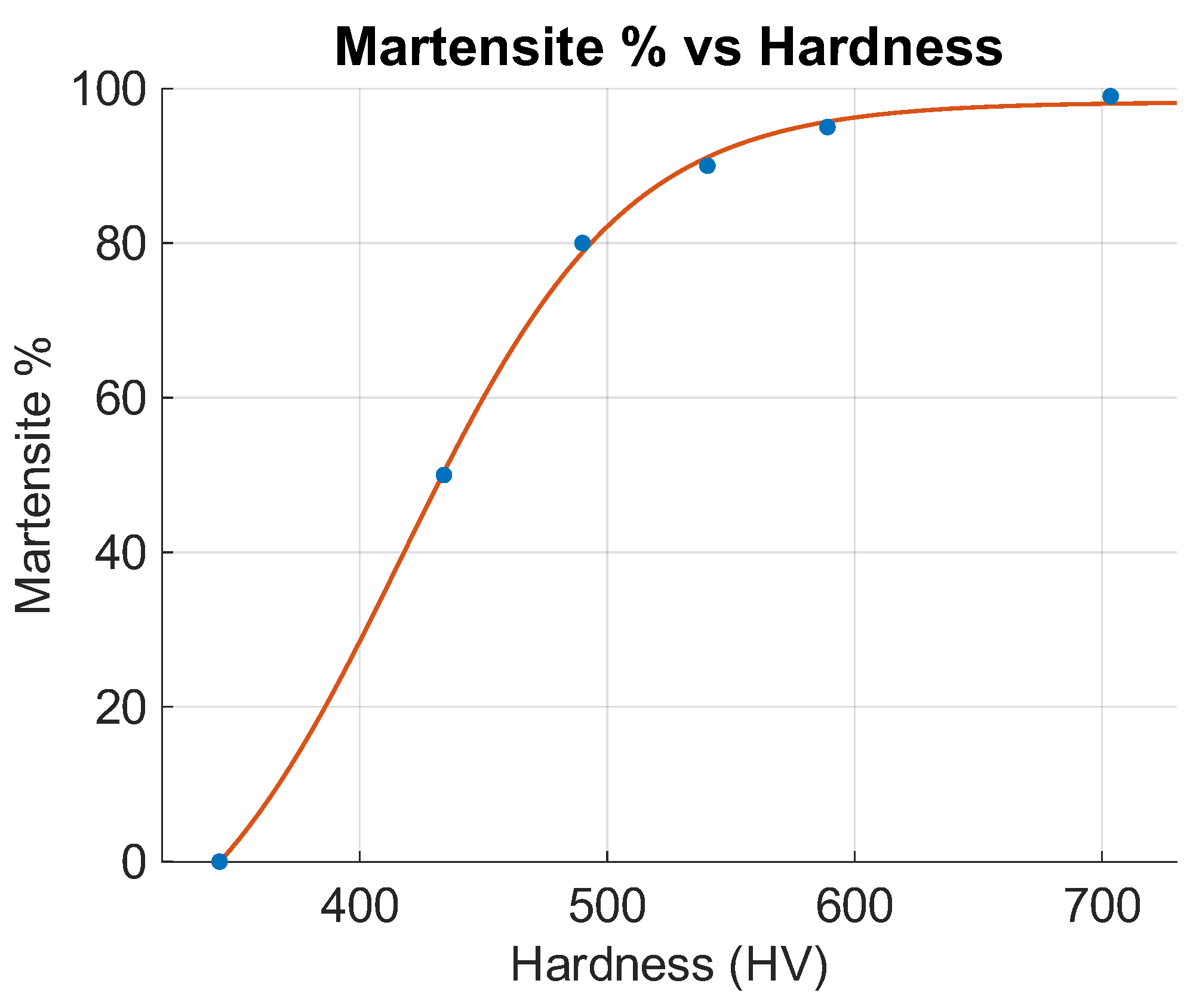

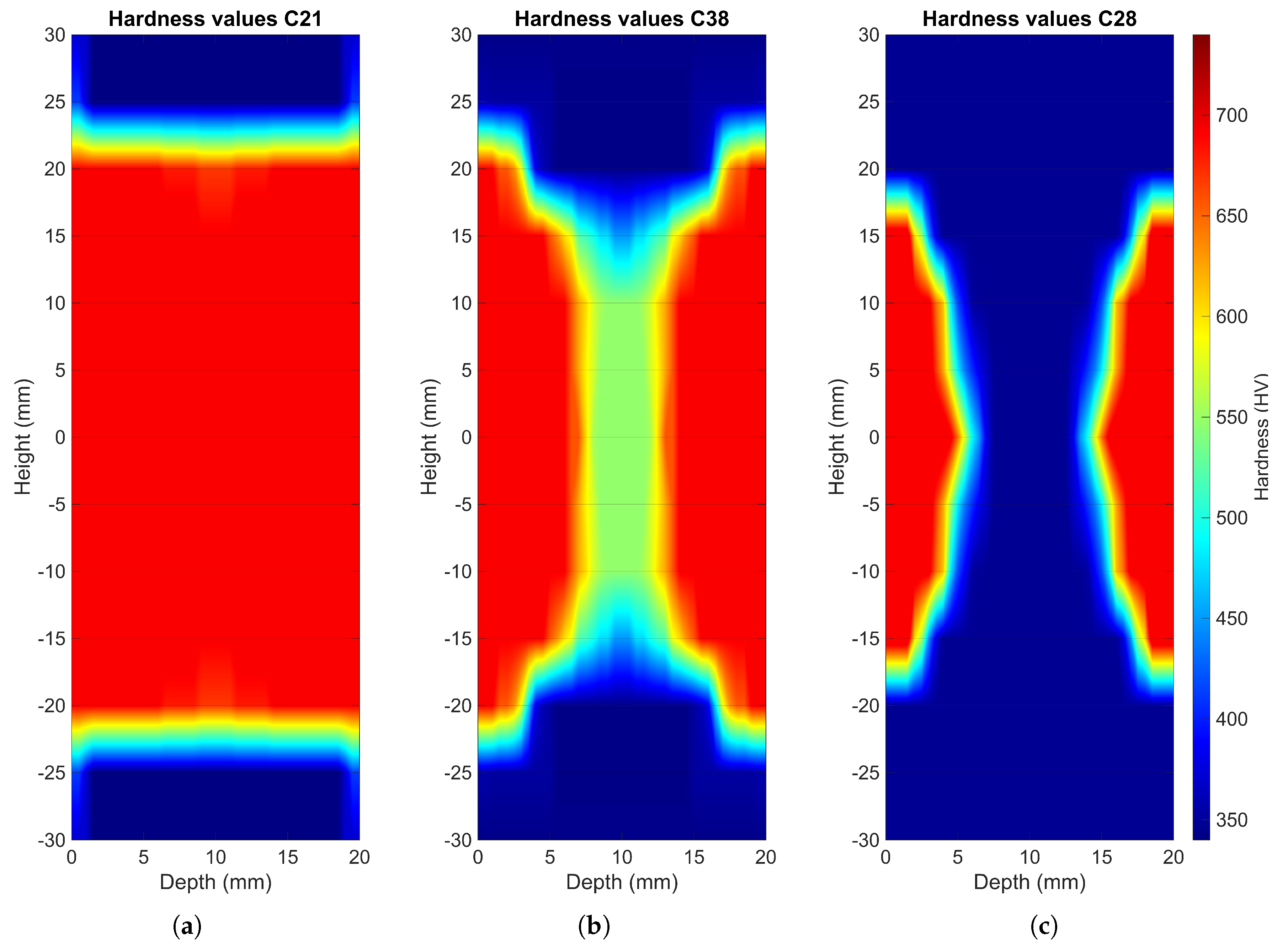

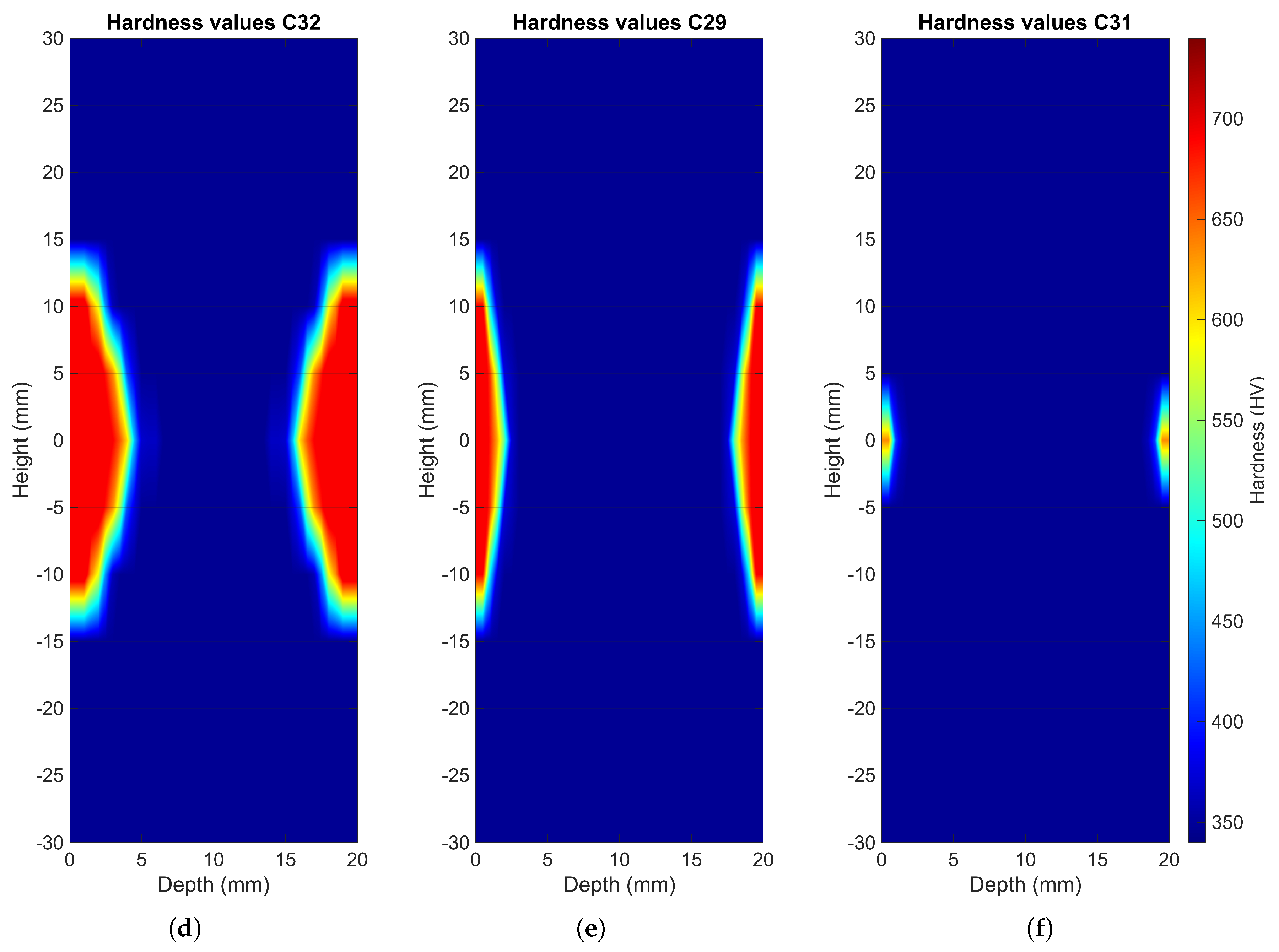

3.2. Metallographic Characterization

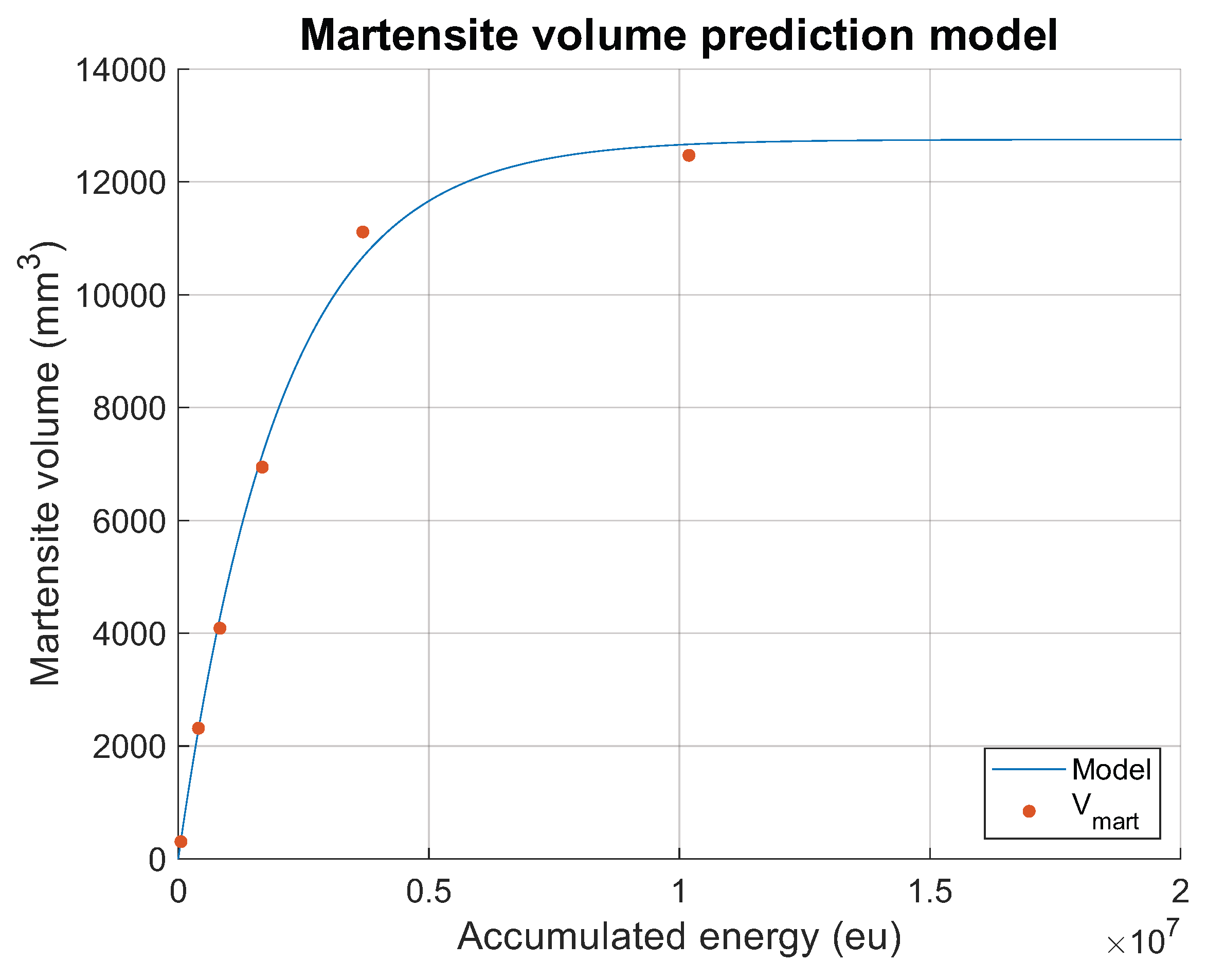

3.3. Model Fitting

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Negrín-Hernádez, L.I.; Pérez-Ruiz, E.A.; Rodríguez-Marcial, R.; Cárdenas-Olivier, N.; Duffus Scot, A. Temple del acero SAE/AISI 1045 usando aceites reutilizados como medio de enfriamiento. Ing. Mec. 2022, 25, 29–34. [Google Scholar]

- Alves, J.; Brandao, L.P.; Paula, A. The Influence of Sample Preparation on the Quantitative Analysis of the Volume Fraction of Martensite Formed in a 304L Trip Steel. Mater. Res. 2015, 18, 159–163. [Google Scholar] [CrossRef][Green Version]

- Pickering, E.; Collins, J.; Taylor, M. Dilatometer Quenching Tests. Available online: https://lightform-group.github.io/wiki/experiments/quenching-dilatometry (accessed on 5 September 2025).[Green Version]

- Koistinen, D.; Marburger, R. A General Equation Prescribing the Extent of the Austenite-Martensite Transformation in Pure Iron-Carbon Alloys and Plain Carbon Steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Lee, S.J.; Van Tyne, C.J. A Kinetics Model for Martensite Transformation in Plain Carbon and Low-Alloyed Steels. Metall. Mater. Trans. A 2012, 43, 422–427. [Google Scholar] [CrossRef]

- Huyan, F.; Hedström, P.; Höglund, L.; Borgenstam, A. A Thermodynamic-Based Model to Predict the Fraction of Martensite in Steels. Metall. Mater. Trans. A 2016, 47, 4404–4410. [Google Scholar] [CrossRef]

- Fang, G.; Zeng, P. Finite Element Simulation of Metal Quenching. Tsinghua Sci. Technol. 2004, 9, 555–559. [Google Scholar]

- Mu, W.; Rahaman, M.; Rios, F.L.; Odqvist, J.; Hedström, P. Predicting Strain-Induced Martensite in Austenitic Steels by Combining Physical Modelling and Machine Learning. Mater. Des. 2021, 197, 109199. [Google Scholar] [CrossRef]

- Speich, G.; Fisher, R. Acoustic Emission During Martensite Formation. In Acoustic Emission; ASTM International: West Conshohocken, PA, USA, 1972; pp. 140–151. [Google Scholar] [CrossRef]

- van Bohemen, S.M.C. An Acoustic Emission Study of Martensitic and Bainitic Transformations in Carbon Steel; Delft University Press: Delft, The Netherlands, 2004. [Google Scholar]

- Tóth, L.Z.; Daróczi, L.; Szabó, S.; Beke, D.L. Simultaneous Investigation of Thermal, Acoustic, and Magnetic Emission during Martensitic Transformation in Single-Crystalline Ni2MnGa. Phys. Rev. B 2016, 93, 144108. [Google Scholar] [CrossRef]

- Planes, A.; Mañosa, L.; Vives, E. Acousti Emission in Martensitic Transformations. J. Alloys Compd. 2013, 577, S699–S704. [Google Scholar] [CrossRef]

- Samy, N.M.; Daróczi, L.; Tóth, L.Z.; Beke, D.L.; Panchenko, E.; Chumlyakov, Y.; Surikov, N. Effect of Stress-Induced Martensite Stabilization on Acoustic Emission Characteristics and the Entropy of Martensitic Transformation in Shape Memory Ni51Fe18Ga27Co4 Single Crystal. Metals 2020, 10, 534. [Google Scholar] [CrossRef]

- Esmaeilzadeh, R.; Pandiyan, V.; Van Petegem, S.; Van Der Meer, M.; Nasab, M.H.; De Formanoir, C.; Jhabvala, J.; Navarre, C.; Schlenger, L.; Richter, R.; et al. Acoustic Emission Signature of Martensitic Transformation in Laser Powder Bed Fusion of Ti6Al4V-Fe, Supported by Operando X-ray Diffraction. Addit. Manuf. 2024, 96, 104562. [Google Scholar] [CrossRef]

- Asmaa, A.A.; Lajos, D.; László, Z.; Irina, V.K.; Yuriy, I.C.; Dezső, L.B. Acoustic Emission during Lüders-band Type Martensitic Transformation and Thermal Recovery in Cr20Mn20Fe20Co34.4Ni5.6 High Entropy Shape Memory Single Crystals. J. Alloys Compd. 2025, 1027, 180507. [Google Scholar] [CrossRef]

- Daróczi, L.; Kamel, S.; Tahara, M.; Chernenko, V.; Hosoda, H.; Tóth, L.; Beke, D. Acoustic Emission during Approaching the Critical Point on Stress-Temperature Diagram of Martensitic Transformation in Ni48Fe20Co5Ga27 (at.%) Single Crystal. Intermetallics 2024, 173, 108432. [Google Scholar] [CrossRef]

- Lehnert, R.; Remich, V.; Gerstein, G.; Motylenko, M.; Müller, M.; Krooß, P.; Niendorf, T.; Biermann, H.; Weidner, A. Unraveling Factors Affecting the Reversibility of Martensitic Phase Transformation in FeNiCoAlTi Shape Memory Alloys: Insights from HR-EBSD and Acoustic Emission Analysis. Acta Mater. 2024, 276, 120146. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, G.y.; Chen, L.b.; Lu, Y.p. Acoustic Emission Study of the Plastic Deformation of Quenched and Partitioned 35CrMnSiA Steel. Int. J. Miner. Metall. Mater. 2014, 21, 1196–1204. [Google Scholar] [CrossRef]

- Yasuda, T.; Kaisho, M.; Nishimoto, K.; Okumoto, Y. Monitoring of Laser Quenching of the Carbon Steel by Acoustic Emission. J. Jpn. Inst. Met. Mater. 2020, 84, 335–343. [Google Scholar] [CrossRef]

- Mojškerc, B.; Grum, J.; Kek, T. Acoustic Emission Characterisation of Specimen Surface-area-to-Volume Ratio During Immersion Quenching. Insight Non-Destr. Test. Cond. Monit. 2019, 61, 257–263. [Google Scholar] [CrossRef]

- Polakova, N.; Dostal, P.; Sustr, M.; Zacal, J.; Cerny, M. Detection of Hardening Process by Means of Acoustic Emission. In Proceedings of the 23rd International PhD Students Conference (MendelNet 2016), Brno, Czech Republic, 9–10 November 2016; pp. 910–915. [Google Scholar]

- ASM Handbook. 4: Heat Treating; ASM International: Materials Park, OH, USA, 2009; Volume 4. [Google Scholar]

- Sola, E.; Rodríguez, R.; Aguirre, M.; Luis-Pérez, C.J.; Cabello, M.J. Study of the Martensitic Transformation of Steel During the Induction Hardening Process by means of Acoustic Emissions. In Proceedings of the 36th Conference of the European Working Group on Acoustic Emission (EWGAE2024), Potsdam, Germany, 18–20 September 2024. [Google Scholar] [CrossRef]

| Chemical Composition 42CrMo4 | |||

|---|---|---|---|

| C % | Mn % | Cr % | Mo % |

| 0.410 | 0.870 | 1.070 | 0.233 |

| Quenching Tests | |||

|---|---|---|---|

| Identifier | Heating Time (s) | Identifier | Heating Time (s) |

| C21 | 30 | C30 | 17 |

| C22 | 8 | C31 | 9 |

| C23 | 6 | C32 | 13 |

| C24 | 11 | C33 | 17 |

| C25 | 15 | C34 | 9 |

| C26 | 13 | C35 | 15 |

| C27 | 9 | C36 | 13 |

| C28 | 15 | C37 | 11 |

| C29 | 11 | C38 | 17 |

| Acoustic Emission Measurement Parameters | ||||

|---|---|---|---|---|

| Channel | 1 | 2 | 3 | 4 |

| AE Sample Rate (MHz) | 10 | 10 | 10 | 10 |

| TR Sample Rate (MHz) | 5 | 5 | 5 | 5 |

| Duration Discrim. Time (µs) | 50 | 50 | 50 | 50 |

| Rearm Time (µs) | 50 | 50 | 50 | 50 |

| Threshold (dB) | 45 | 50 | 55 | 48.1 |

| Frequency range (kHz) | 295–446 | 295–446 | 295–446 | 295–446 |

| Gain (dB) | 34 | 34 | 34 | 34 |

| Martensite Volume () | ||||||

|---|---|---|---|---|---|---|

| Bar | C21 | C38 | C28 | C32 | C29 | C31 |

| V () | 1.2471 × | 1.1113 × | 6.9446 × | 4.0892 × | 2.3175 × | 306.9021 |

| % | 66.1607 | 58.9563 | 36.8422 | 21.6939 | 12.2947 | 1.6282 |

| % | 100 | 89.1108 | 55.6859 | 32.7897 | 18.5831 | 2.4610 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sola Llanos, E.; Rodríguez, R.; Aguirre, M.; Luis-Pérez, C.J.; Cabello, M.J. New Model for Estimating the Volume of Martensite Transformed Using Acoustic Emission Measurements During an Induction Hardening Process. Metals 2025, 15, 1228. https://doi.org/10.3390/met15111228

Sola Llanos E, Rodríguez R, Aguirre M, Luis-Pérez CJ, Cabello MJ. New Model for Estimating the Volume of Martensite Transformed Using Acoustic Emission Measurements During an Induction Hardening Process. Metals. 2025; 15(11):1228. https://doi.org/10.3390/met15111228

Chicago/Turabian StyleSola Llanos, Erlantz, Rafael Rodríguez, Marcos Aguirre, Carmelo Javier Luis-Pérez, and Mario Javier Cabello. 2025. "New Model for Estimating the Volume of Martensite Transformed Using Acoustic Emission Measurements During an Induction Hardening Process" Metals 15, no. 11: 1228. https://doi.org/10.3390/met15111228

APA StyleSola Llanos, E., Rodríguez, R., Aguirre, M., Luis-Pérez, C. J., & Cabello, M. J. (2025). New Model for Estimating the Volume of Martensite Transformed Using Acoustic Emission Measurements During an Induction Hardening Process. Metals, 15(11), 1228. https://doi.org/10.3390/met15111228