Abstract

Al–Cu–Mg composites reinforced with sub-micron tungsten carbide (WC) particles were synthesized by powder metallurgy and subjected to T6 heat treatment to clarify the interplay between dispersion strengthening and precipitation hardening. Composites with 1–3 wt.% WC (average size 0.8 μm) were solution-treated at 540 °C for 3 h, water-quenched, and aged at 195 °C for up to 100 h. Microstructural analyses confirmed a uniform distribution of WC and demonstrated that its presence did not modify the dissolution–precipitation sequence of the Al-Cu-Mg matrix. Transmission Electron Microscopy observations provided direct evidence of θ′ (Al2Cu) precipitates. The 3 wt.% WC composite reached peak hardness after 5 h (78 HRF), a 15% increase over the T6-treated unreinforced alloy, and exhibited a 40% higher yield strength (330 MPa). These improvements were attributed to the combined effects of Orowan strengthening and age-hardening precipitates (θ′). The results demonstrate that integrating powder metallurgy, sub-micron WC reinforcement, and T6 treatment is an effective route to enhance strength in Al–Cu–Mg alloys without delaying aging kinetics.

1. Introduction

The adoption of aluminum matrix composites (AMCs) across industrial sectors continues to rise, driven by their superior mechanical performance (including strength, stiffness, and wear resistance) compared to standard aluminum alloys [1,2,3]. Their high strength-to-weight ratio, fatigue resistance, and tribological performance make them suitable for demanding components in the automotive and aerospace industries, including engine parts, brake systems, and airframes [1,2,4,5]. A primary reason for their adoption is the significant weight reduction they offer, which improves fuel efficiency and reduces emissions [6,7,8,9].

Among AMCs, Al-Cu-Mg alloys are widely used due to their combination of low density, high toughness, and excellent fatigue resistance [10]. Nevertheless, their relatively low hardness and limited wear resistance restrict broader application in severe service conditions [2]. Among their principal strengthening mechanisms is precipitation hardening, typically involving solution heat treatment followed by artificial aging, which promotes the formation of θ precipitates that hinder dislocation motion [6,11,12,13,14,15].

The incorporation of ceramic particles has long been recognized as an effective strategy to enhance the stiffness, creep resistance, and tribological properties of AMCs [13,16,17,18]. Reinforcements such as Al2O3, SiC, TiC, and TiB2 are frequently used due to their high hardness and cost-effectiveness [13,19,20]. Although WC exhibits remarkable hardness (2242 HV), a high elastic modulus (550 GPa), and superior wear resistance, comparatively little attention has been devoted to its sub-micron form. In contrast, most earlier studies have relied on coarse WC particles with sizes ranging from 5 to 60 µm [21,22,23]. Thus, the behavior of sub-micron WC (average size 0.8 µm), which could provide superior strengthening but poses greater challenges in dispersion, remains insufficiently explored [24].

A significant challenge in fabricating AMCs, particularly via casting, is achieving adequate wettability and a uniform distribution of the reinforcement to prevent agglomeration [2,5]. Powder metallurgy (PM) has been widely adopted to circumvent these limitations, proving effective for synthesizing AMCs with challenging material combinations [25,26]. Previous work has demonstrated the feasibility of synthesizing an Al-Cu-Mg/WC composite via PM, overcoming the vast differences in density (2.70 vs. 15.63 g/cm3) and melting point (660 vs. 2870 °C) between the aluminum matrix and the reinforcement WC, a feat difficult to achieve with conventional melting and casting techniques [27]. However, a critical knowledge gap persists regarding the interaction between refractory ceramic reinforcements and precipitation hardening. Specifically, the influence of fine and/or submicron WC particles on precipitation kinetics, strengthening mechanisms, and optimal aging parameters in high-strength Al-Cu-Mg alloys remains a virtually unexplored gap. The interface between an aluminum matrix and fine WC particles is likely to provide preferential sites for precipitate nucleation and to hinder dislocation movement, resulting in a synergistic strengthening effect that improves peak strength and accelerates its development.

Therefore, this study aims to address this unexplored gap by systematically investigating how sub-micron WC particles influence the age-hardening behavior and underlying strengthening mechanisms of a PM-processed Al-4Cu-1.5Mg alloy. The novelty of this work lies in elucidating the dual role of WC reinforcements: modifying the precipitation sequence and enhancing mechanical performance through microstructural refinement and load-transfer effects. This research provides new insights into the design of high-strength Al-Cu-Mg-based composites for advanced structural applications.

2. Materials and Methods

AMCs based on an Al-4Cu-1.5Mg system were synthesized via PM. The raw materials consisted of high-purity elemental powders: aluminum (Al, 99.5%, 44 µm), copper (Cu, 99.5%, 149 µm), magnesium (Mg, 99.8%, 44 µm), and tungsten carbide (WC, 99.9% 0.8 µm). Four materials were synthesized: a reference Al-4Cu-1.5Mg alloy and three Al-4Cu-1.5Mg-based composites reinforced with 1, 2, and 3 wt.% WC. The selection of WC reinforcement levels (1–3 wt.%) was based on findings reported in the literature [28], where WC additions from 1 to 5 wt.% were investigated, and the best mechanical performance was achieved at 3 wt.%. WC.

The powder mixtures (8.2 g) were mechanically alloyed in a SPEX-8000M high-energy ball mill (SPEX SamplePrep, Metuchen, NJ, USA) (at 863 rpm) for 3 h, with the process conducted in an argon-filled chamber under no active gas flow to avoid oxidation. Milling was carried out using a hardened steel vial with steel balls at a ball-to-powder weight ratio of 5:1. To prevent excessive cold welding and particle agglomeration, 0.5 mL of methanol was added as a process control agent (PCA), a strategy commonly reported in the literature for the mechanical alloying of aluminum powders [29]. The milled powders were uniaxially compacted at 1868 MPa for 3 min using a hardened steel die (6 mm internal diameter). A total of ten green compacts were obtained for each composition, each with nominal dimensions of 6 mm in diameter and 12 mm in height. These specimens were subsequently sintered at 630 °C for 20 min in a Neytech Qex muffle furnace (Degussa-Ney Dental, Yucaipa, CA, USA) under a static argon atmosphere.

The experimental density of the composites was determined using Archimedes’ principle. Mass measurements were taken in air and while the samples were immersed in distilled water, employing a Sartorius CP2254D high-precision electronic balance(Sartorius AG, Göttingen, Germany) (accuracy ± 0.1 mg). The experimental density for each composition was obtained as the average of three specimens. The theoretical density was calculated using the rule of mixtures, and the porosity percentage was determined from the relative density [30].

Selected sintered samples underwent a standard T6 heat treatment, consisting of a solution heat treatment at 540 °C for 3 h, followed by quenching in water at room temperature, and isothermal aging at 195 °C for 30 to 6000 min to establish the complete aging curve. For this treatment, one specimen was used for each condition at every aging stage.

In all samples, structural characterization was performed using X-ray diffraction (XRD) with a Panalytical X’Pert PRO diffractometer(Malvern Panalytical, Almelo, Netherlands) (Cu Kα radiation, λ = 0.15406 nm, 40 kV, 35 mA). The conditions were 20–120 degrees, with a step size of 0.016° and a 100 s exposure time. Furthermore, microstructural examination was performed using a Hitachi SU3500 scanning electron microscope (SEM) (Hitachi High-Tech Corporation, Tokyo, Japan) equipped with an energy-dispersive X-ray spectroscopy (EDS) detector, operated at 15 kV. Specimens for microstructural characterization, microhardness testing, and SEM observation were prepared following standard metallographic procedures. A 3 mm-thick section was cut from each sample and subjected to a sequential preparation process (the specimens were not embedded in resin). This procedure consisted of grinding with SiC paper (grits #100–#2000) and polishing with a cloth to achieve a mirror finish. Finally, the specimens intended specifically for SEM analysis were etched with Keller’s reagent for 10 s to reveal the microstructure. Transmission electron microscopy specimens were prepared using a JEM-9320FIB Focused Ion Beam (FIB) (JEOL, Tokyo, Japan) and subsequently cleaned with a Fischione Instruments Model 1020 plasma cleaner(Fischione Instruments, Hanau, Germany) to remove surface contamination. TEM and STEM analyses were performed on a JEOL JEM-2200FS microscope (JEOL, Tokyo, Japan) operated at 200 kV.

The mechanical properties were evaluated through hardness and compression tests. Hardness Testing: Rockwell hardness (HRF) measurements were performed on a Wilson Rockwell 574 tester (Wilson, Norwood, MA, USA) using a 60 kgf load and a 1/16-inch steel ball indenter. One specimen was used for each condition at each stage, and at least 5 indentations were performed per sample. The average and the standard deviation (±) values are reported. Compression Testing: Compressive behavior was evaluated using an Instron universal testing machine(Instron, Norwood, MA, USA) operated at a constant crosshead speed of 0.5 mm/min. Cylindrical specimens (three for each condition) for compression testing were fabricated in strict compliance with the ASTM E9 standard. A critical aspect of this design is the slenderness ratio (length-to-diameter, L/D). In accordance with the standard, a nominal slenderness ratio of L/D = 2.0 was maintained for all specimens, and yield strength (YS) was calculated at the 0.2% offset strain criterion.

3. Results and Discussions

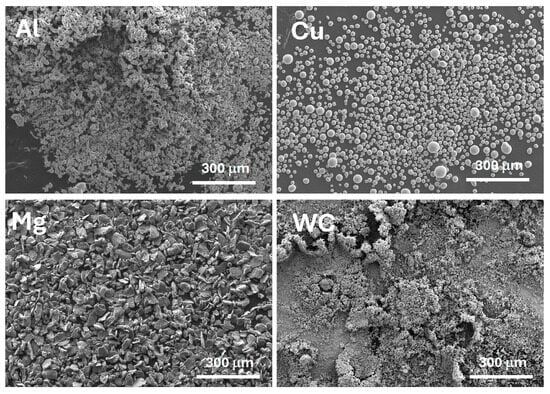

Figure 1 presents Scanning Electron Microscopy-Secondary Electron (SEM-SE) images of Al, Cu, Mg, and WC powders.

Figure 1.

Scanning Electron Microscopy-Secondary Electron (SEM-SE) images of Al, Cu, Mg, and WC powders.

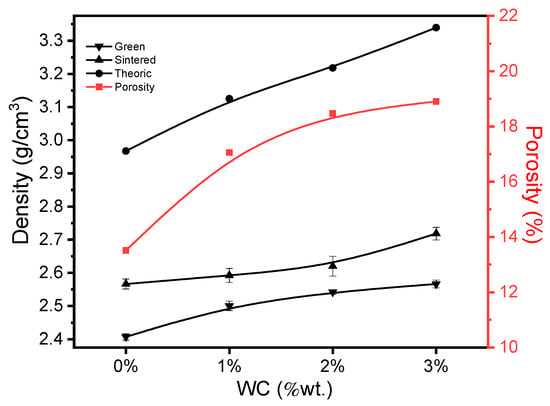

Figure 2 displays the experimental (Archimedes’ principle) and theoretical density values, along with the corresponding porosity (%) of the Al-Cu-Mg alloy and its WC-reinforced composites. The density of the green compacts increased progressively with WC content, reflecting the higher intrinsic density of WC (15.63 g/cm3) compared with that of the Al matrix (2.782 g/cm3). After sintering, all samples exhibited further densification; however, their measured densities remained slightly below theoretical values, indicating residual porosity. The porosity fraction increased with WC addition, attributed to reduced compressibility and sinterability of the powder compacts due to the presence of hard ceramic particles.

Figure 2.

Experimental (Green and Sintered) and theoretical density values, and porosity (%) of the Al-Cu-Mg alloy and the composites with 1, 2, and 3 WC (wt.%).

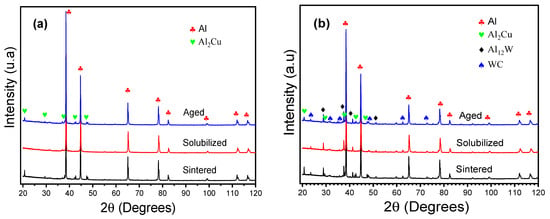

Figure 3 presents the XRD patterns for the unreinforced Al-Cu-Mg alloy (Figure 3a) and the WC-reinforced (3 wt.%) composite (Figure 3b) in three processing conditions: as-sintered, solution-treated, and aged. In the unreinforced alloy (Figure 3a), the diffraction patterns are dominated by the characteristic peaks of the α-Al matrix [31]. In the as-sintered state, the presence of the thermodynamically stable Al2Cu (θ) phase is clearly identified. Following solution heat treatment, dissolution of the Al2Cu phase is observed, indicating the successful formation of a homogeneous supersaturated solid solution (SSSS) [9,11,32,33,34]. Subsequent aging induces controlled decomposition of the SSSS, leading to the formation of fine-strengthening precipitates. The precipitation sequence of the Al2Cu phase evolves with aging time, progressing from Guinier–Preston zones (GP zones) and θ″ to θ′ and finally θ [11].

Figure 3.

XRD patterns of the (a) unreinforced Al-Cu-Mg alloy and (b) WC-reinforced (3 wt.%) composite. Both in the as-sintered, solution-treated, and aged conditions.

The XRD patterns for the composites (Figure 3b) exhibit additional peaks corresponding to the WC reinforcement, with WC peaks of relatively low intensity, consistent with its low weight fraction in the composite matrix. Furthermore, a minor Al12W intermetallic phase was identified. This phase is reported to be stable at room temperature and enhances mechanical properties, such as strength, oxidation resistance, and thermal stability [35,36]. Its presence suggests a limited interfacial reaction occurred during sintering, consistent with the processing temperatures used [36,37].

These findings indicate that the incorporation of WC does not alter the fundamental precipitation behavior of the Al-Cu-Mg matrix. Similar stability of the precipitation sequence has been reported for Al–based composites reinforced with TiC or SiC [38,39], in which the ceramic reinforcements acted primarily as mechanical barriers rather than as active nucleation sites for new phases. The identification of Al12W suggests mild interfacial interaction, comparable to reports for Al-WC systems processed under similar conditions, confirming that interfacial reactions remain limited when WC additions are below 5 wt.% [40].

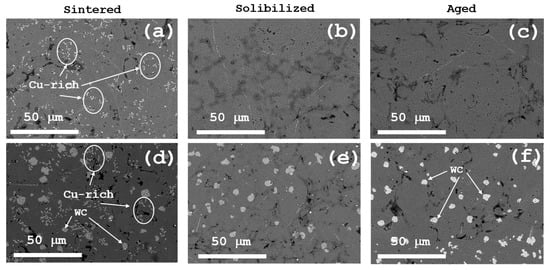

Figure 4 presents representative SEM micrographs of the Al-Cu-Mg alloy (Figure 4a–c) and the WC-reinforced (3 wt.%) composite (Figure 4d–f) under different processing conditions: as-sintered (Figure 4a,d), solution-treated (Figure 4b,e), and aged (Figure 4c,f). For the unreinforced alloy (Figure 4a–c), in the as-sintered condition (Figure 4a), coarse Cu-rich phases (1–3 μm) with irregular morphologies [27] are revealed. Following solution heat treatment (Figure 4b), these secondary phases dissolve, resulting in a homogeneous solid solution. For the sample in the aged condition, the microstructure is similar to the solution heat treatment condition, this is because the precipitates formed during aging are no possible to be resolved at this magnification; although the XRD results, mechanical data and TEM analysis confirm the formation of nanoscale strengthening precipitates such as θ′ (Al2Cu), consistent with the conventional T6 sequence in Al-Cu-Mg alloys [9,10,12,37,41,42,43,44]. For the WC-reinforced (3 wt.%) composite (Figure 4d–f), the aluminum matrix and secondary phase (Al2Cu) follow the same behavior as the unreinforced samples. SEM observations clearly show that the WC particles are uniformly distributed across all processing stages, with no evidence of severe clustering or agglomeration. Due to the sub-micron size of the particles, local effects on the surrounding matrix cannot be directly resolved in SEM; however, the observed uniform dispersion of WC supports its role in enhancing the composite’s mechanical performance [45]. The microstructural uniformity observed here is comparable to that reported for Al-SiC and Al-TiC composites fabricated by PM [46,47]. Such homogeneous dispersion is critical for effective load transfer between the matrix and the reinforcement. Moreover, the absence of clustering indicates that the processing parameters were appropriate to avoid sedimentation during sintering, consistent with observations in another research [27].

Figure 4.

SEM micrographs of samples under different conditions: (a–c) Al-Cu-Mg alloy and (d–f) WC-reinforced (3 wt.%) composite.

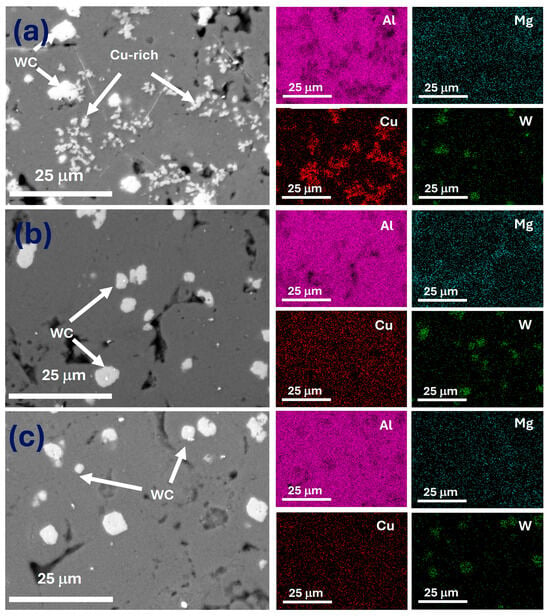

Figure 5 presents the EDS elemental mapping of the WC-reinforced (3 wt.%) composite in the three processing states: (Figure 5a) as-sintered, (Figure 5b) solution-treated, and (Figure 5c) aged. In the as-sintered condition (Figure 5a), EDS confirms the presence of micron-scale Cu-rich phases, in agreement with the θ-phase (Al2Cu) detected by XRD [6]. Following solution treatment (Figure 5b), complete dissolution of Cu into the α-Al matrix is observed, as evidenced by the homogeneous elemental distribution and the absence of detectable Cu-rich segregations, confirming the formation of a supersaturated solid solution (SSSS) [43]. In the aged condition (Figure 5c), nanoscale Cu-rich precipitates cannot be resolved by EDS due to its intrinsic spatial resolution (~1 μm) and limited compositional sensitivity [48]. Nevertheless, complementary XRD evidence is consistent with the precipitation of the Al2Cu phase. Across all processing conditions, EDS shows that WC particles remain relatively uniformly distributed, with no significant clustering, which is essential for the observed improvement in mechanical performance, as reported in previous studies [4]. These results corroborate microstructural observations and confirm that WC particles are chemically stable within the aluminum matrix. Similar elemental uniformity has been observed in Al-WC composites prepared via hot pressing [40], reinforcing the notion that tungsten carbide remains inert under the current thermal conditions and does not promote significant diffusion of W or C into the matrix.

Figure 5.

EDS elemental mapping (Al, Cu, Mg, W) for the WC-reinforced (3 wt.%) composite in the (a) as-sintered, (b) solution-treated, and (c) aged conditions.

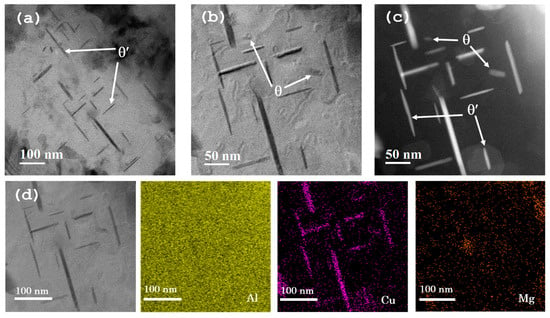

Figure 6 TEM observations of the Al-Cu-Mg/WC composite in the T6 condition (Figure 6a) showed a finely dispersed distribution of θ′ (Al2Cu) precipitates throughout the aluminum matrix, in agreement with prior studies [11,49]. These metastable precipitates displayed a characteristic platelet-shaped morphology; the θ′ phase is semi-coherent with the Al matrix [41] and constitutes the primary strengthening mechanism in the T6 condition [32,50].

Figure 6.

TEM and STEM characterization of the Al-Cu-Mg/WC composite in the T6 condition: (a) TEM image; (b) STEM image; (c) Dark-field TEM image; (d) EDS analysis.

In addition to the strengthening θ′ precipitates, coarser incoherent precipitates corresponding to the equilibrium θ phase (Al2Cu) were identified (Figure 6b,c, via STEM and dark-field TEM imaging, respectively). These precipitates typically exhibited a more massive and irregular morphology, with growth directions not strictly confined by the Al matrix crystallography, indicative of overaging [11,41].

EDS analysis (Figure 6d) confirmed the chemical identity of these coarser precipitates as the equilibrium θ phase (Al2Cu) and effectively ruled out the presence of the S phase (Al2CuMg). These EDS findings were consistent with XRD results, collectively confirming that the observed precipitates are θ’-phase (Al2Cu). The TEM results further confirm that the addition of WC does not alter the precipitation sequence, consistent with observations by Singh et al. [39] for another Al-Cu-based MMC. However, the uniform and refined dispersion of θ′ precipitates suggests that WC particles may locally enhance heterogeneous nucleation via strain fields or dislocation density, as has also been proposed for B4C-reinforced systems [51].

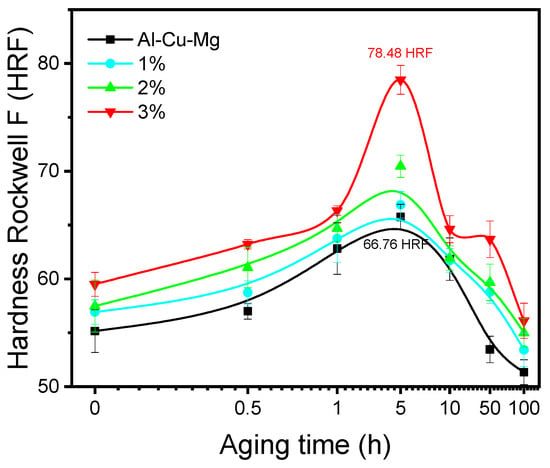

Figure 7 presents the evolution of HRF of the reference alloy, Al-4Cu-1.5Mg, and three Al-4Cu-1.5Mg-based composites, reinforced with 1, 2, and 3 wt.% WC as a function of aging time (30, 60, 300, 600, 3000 and 6000 min) at 195 °C. The aging curves for all materials exhibit classical precipitation hardening kinetics, characterized by well-defined under-aged, peak-aged, and over-aged regimes [41]. A rapid initial increase in hardness is observed during the early stages of aging, which is commonly attributed to the formation of solute clusters and Guinier–Preston–Bagaryatsky zones [15]. The unreinforced alloy and the composites reached peak hardness at 5 h of aging. This behavior contrasts with several reports where ceramic reinforcement is found to retard precipitation kinetics, thereby shifting the peak to longer times [11]. In the present case, the identical peak time indicates that the incorporation of sub-micron WC particles does not significantly alter the precipitation kinetics. All investigated materials exhibited significant age-hardening within the first 5 h of aging (Figure 7). This effect was most pronounced in the composites containing 2 and 3 wt.% WC, with the 3 wt.% composite achieving a peak hardness of 78 HRF. This value represents a substantial 15% increase over the peak hardness of the unreinforced matrix alloy, underscoring the efficacy of fine WC reinforcement in enhancing the age-hardening response. Prolonged isothermal exposure (5–100 h) resulted in a consistent decline in hardness across all specimens, characteristic of over-aging behavior [32,35]. This reduction is directly correlated to microstructural evolution, primarily the coarsening of strengthening precipitates and their eventual loss of coherency with the aluminum matrix [8,32].

Figure 7.

Variation of HRF with aging time at 195 °C for the Al-Cu-Mg alloy and composites with different WC weight percentages.

Overall, the WC-reinforced composites exhibited higher peak hardness than the unreinforced alloy, while maintaining the general aging curve profile. This behavior suggests that although WC particles contribute to hardening, they do not alter the precipitation sequence or the identity of the dominant θ′ phase. The peak hardness of 78 HRF was obtained for the 3 wt.% WC composite is comparable to values reported for Al-Cu-Mg/SiC (103 HV or 82HRF), although with 7.5% wt. SiC [38]. This behavior indicates that WC provides an efficient strengthening contribution even at lower reinforcement levels. In addition, studies on SiC-reinforced Al-Cu-Mg alloys have reported that although peak hardness values can be higher than the matrix, the time to reach peak aging is longer in the composites than in the unreinforced alloy, which is attributed to interfacial segregation and reduced vacancy concentration in the composite [52]. In the present case, the identical time to reach the aging peak in all materials suggests that the incorporation of sub-micron WC particles does not significantly alter the precipitation kinetics.

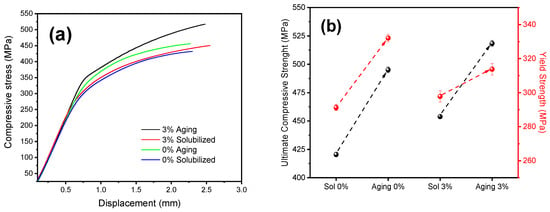

Figure 8 presents the results of compression tests. Compressive stress–strain curves response under different processing conditions (Figure 8a) and a comparative summary of key compressive properties (Figure 8b). The analysis includes solution-treated and aged conditions for both the unreinforced alloy and the WC-reinforced (3 wt.%) composite. Consistent with the hardness results, the aged specimens exhibited superior compressive performance, with YS approximately 20–25% higher than that of their solution-treated counterparts, along with an enhanced strain-hardening capacity. Notably, the 3 wt.% WC composite aged reached a YS 35–40% higher than that of the unreinforced alloy under the same conditions. This improvement can be attributed to the combined effect of WC particle reinforcement and precipitation hardening [30]. The YS shows a clear dependence on tungsten carbide (WC) content, increasing progressively with reinforcement addition until reaching approximately 330 MPa at 3 wt.% WC. This values trend parallels the hardness evolution shown in Figure 7, suggesting that similar strengthening mechanisms control both properties once a particle concentration is reached. A direct correlation is also observed among compressive strength, WC content, and the T6 treatment. The highest yield and ultimate compressive strengths were achieved in the aged composites, reflecting the synergistic effect of ceramic reinforcement and precipitation hardening. Similar strengthening effects in aluminum matrix composites reinforced with ceramic particles have been reported in the literature [45,53]. The incorporation of WC particles progressively enhances the material’s strength through the synergistic action of multiple mechanisms. The primary contributors are anticipated to be: (i) Orowan strengthening, (ii) effective load transfer to the rigid WC reinforcements, (iii) dislocation generation induced by the coefficient of thermal expansion (CTE) mismatch between the matrix and the particles, and (iv) grain size stabilization via a pinning effect exerted by the WC dispersoids [54,55]. The additional strength increment conferred by the T6 treatment is primarily due to conventional precipitation hardening, wherein a high density of nanoscale precipitates (θ′) acts as an effective barrier to dislocation motion [34,36,56]. To contextualize these findings, it is helpful to compare them with similar systems, such as B4C-reinforced Al–Zn–Mg alloys, which exhibit high interfacial dislocation density and promote differential precipitation (GP zones), demonstrating how ceramic particles can locally modify aging kinetics [50]. By contrast, in B4C/7A04Al composites, the precipitation sequence remained unchanged; however, the kinetics slowed down due to Mg depletion at the interface [57]. Overall, the present results confirm that WC addition, combined with T6 treatment, generates a robust strengthening synergy in Al-Cu-Mg alloys, retaining the conventional precipitation sequence while benefiting from both particle-induced and precipitation-related mechanisms.

Figure 8.

(a) Compressive stress–strain curves and (b) summary of compressive YS and ultimate compressive strength (UCS) for the unreinforced alloy and the WC-reinforced (3 wt.%) composite in solution-treated and aged conditions.

4. Conclusions

- Al-Cu-Mg/WC composites containing uniformly dispersed sub-micron WC particles (~0.8 μm) were successfully fabricated by PM, demonstrating good interfacial compatibility between the matrix and reinforcement.

- The 3 wt.% WC composite exhibited superior hardness and compressive strength compared to the unreinforced alloy.

- The addition of WC particles did not disrupt the characteristic aging sequence of the Al-Cu-Mg system, maintaining a homogeneous distribution of the reinforcement.

- XRD and TEM revealed that the strengthening precipitates correspond exclusively to the metastable θ′ (Al2Cu) phase under the applied aging conditions.

- Compression tests evidenced a synergistic strengthening effect from the combined action of aged precipitation and WC particle dispersion.

- The incorporation of sub-micron WC particles did not delay the aging kinetics; all composites reached peak hardness at the same time as the unreinforced alloy, demonstrating that fine WC reinforcement enhances mechanical strength without compromising heat-treatment efficiency.

Author Contributions

Conceptualization, G.R.-C., J.M.M.-D. and C.G.G.-R.; Methodology, G.R.-C., J.P.F.-D.l.R., J.F.L.d.L.-H., M.S.-C., H.M.M.P., J.M.M.-D., M.A.R.-E.-R., C.G.G.-R., S.G., A.M.-G., I.E.-G. and R.M.-S.; Validation, G.R.-C., J.P.F.-D.l.R., J.F.L.d.L.-H., M.S.-C., H.M.M.P., J.M.M.-D., M.A.R.-E.-R., C.G.G.-R., S.G., A.M.-G., I.E.-G. and R.M.-S.; Formal analysis, G.R.-C., J.M.M.-D. and C.G.G.-R.; Investigation, G.R.-C., J.M.M.-D. and C.G.G.-R.; Data curation, G.R.-C., J.P.F.-D.l.R., J.F.L.d.L.-H., M.S.-C., H.M.M.P., J.M.M.-D., M.A.R.-E.-R., C.G.G.-R., S.G., A.M.-G., I.E.-G. and R.M.-S.; Writing—original draft, G.R.-C., J.M.M.-D. and C.G.G.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

G. Rodríguez-Cabriales CVU 170573, gratefully acknowledges the Secretaría de Ciencia, Humanidades, Tecnología e Innovación (SECIHTI), México, for providing a postdoctoral fellowship. The authors thank A. I. Gonzalez-Jacquez, K. Campos-Venegas, and R. Bernal-Gonzalez for their valuable technical support throughout the study. The Research Center in Advanced Materials (CIMAV) supported this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gao, Y.Y.; Liu, Y.; Li, Y.L.; Zhang, A.; Teng, H.; Dong, Z.H.; Li, T.; Jiang, B. Preparation and Characterization of In Situ (TiC-TiB2)/Al-Cu-Mg-Si Composites with High Strength and Wear Resistance. Materials 2022, 15, 8750. [Google Scholar] [CrossRef]

- Bhowmik, A.; Dey, D.; Biswas, A. Comparative Study of Microstructure, Physical and Mechanical Characterization of SiC/TiB2 Reinforced Aluminium Matrix Composite. Silicon 2021, 13, 2003–2010. [Google Scholar] [CrossRef]

- Chakrapani, P.; Suryakumari, T.S.A. Mechanical properties of aluminium metal matrix composites—A review. Mater. Today Proc. 2020, 45, 2214–7853. [Google Scholar] [CrossRef]

- Huang, G.; Hou, W.; Shen, Y. Evaluation of the microstructure and mechanical properties of WC particle reinforced aluminum matrix composites fabricated by friction stir processing. Mater. Charact. 2018, 138, 26–37. [Google Scholar] [CrossRef]

- Karthikeyan, N.; Krishnan, B.R.; Vembathu Rajesh, A.; Vijayan, V. Experimental analysis of Al-Cu-Si metal matrix composite by powder-metallurgy process. Mater. Today Proc. 2020, 37, 2770–2774. [Google Scholar] [CrossRef]

- Esin, V.A.; Briez, L.; Sennour, M.; Köster, A.; Gratiot, E.; Crépin, J. Precipitation-hardness map for Al-Cu-Mg alloy (AA2024-T3). J. Alloys Compd. 2021, 854, 157164. [Google Scholar] [CrossRef]

- Kumar, N.S.; Pramod, G.K.; Samrat, P.; Sadashiva, M. A Critical Review on Heat Treatment of Aluminium Alloys. Mater. Today Proc. 2022, 58, 71–79. [Google Scholar] [CrossRef]

- Li, L.; Han, Z.; Gao, M.; Li, S.; Wang, H.; Kang, H.; Guo, E.; Chen, Z.; Wang, T. Microstructures, mechanical properties, and aging behavior of hybrid-sized TiB2 particulate-reinforced 2219 aluminum matrix composites. Mater. Sci. Eng. A 2022, 829, 142180. [Google Scholar] [CrossRef]

- Wu, L.; Yu, Z.; Liu, C.; Ma, Y.; Huang, Y.; Wang, T.; Yang, L.; Yan, H.; Liu, W. Microstructure and tensile properties of aluminum powder metallurgy alloy prepared by a novel low-pressure sintering. J. Mater. Res. Technol. 2021, 14, 1419–1429. [Google Scholar] [CrossRef]

- Lu, H.; Kadolkar, P.; Nakazawa, K.; Ando, T.; Blue, C.A. Precipitation Behavior of AA2618. Metall. Mater. Trans. A 2007, 38A, 2379–2388. [Google Scholar] [CrossRef]

- Gao, Z.H.; Gao, H.J.; Zhang, Y.D.; Wu, Q. Experiment and mechanism investigation on the effect of heat treatment on residual stress and mechanical properties of SiCp/Al-Cu-Mg composites. Mater. Sci. Eng. A 2023, 884, 145555. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J.; Gao, N. Precipitation hardening in Al-Cu-Mg alloys revisited. Scr. Mater. 2006, 54, 287–291. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Jin, Q.; Li, Z.; Li, L.; Sun, Y. Study on the Mechanism of CNTs Regulating the Microstructures and Properties of Al-Cu-Mg Alloy. Crystals 2024, 14, 165. [Google Scholar] [CrossRef]

- Ma, S.; Wang, Y.; Wang, X. Microstructures and mechanical properties of an Al-Cu-Mg-Sc alloy reinforced with in-situ TiB2 particulates. Mater. Sci. Eng. A 2020, 788, 139603. [Google Scholar] [CrossRef]

- Chen, X.; Kim, D.; Marioara, C.D.; Andersen, S.J.; Lervik, A.; Holmestad, R.; Kobayashi, E. Effect of pre-deformation on age-hardening behaviors in an Al-Mg-Cu alloy. Mater. Sci. Eng. A 2021, 820, 141557. [Google Scholar] [CrossRef]

- Sharath, B.N.; Venkatesh, C.V.; Afzal, A.; Baig, M.A.A.; Kumar, A.P. Study on effect of ceramics on dry sliding wear behavior of Al-Cu-Mg based metal matrix composite at different temperature. Mater. Today Proc. 2021, 46, 8723–8733. [Google Scholar] [CrossRef]

- Adediran, A.A.; Akinwande, A.A.; Balogun, O.A.; Olorunfemi, B.J.; Kumar, M.S. Optimization studies of stir casting parameters and mechanical properties of TiO2 reinforced Al 7075 composite using response surface methodology. Sci. Rep. 2021, 11, 19860. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Fan, J.; Liu, Y.; Nie, J.; Yang, Z.; Kang, Y. Strengthening and Weakening Effects of Particles on Strength and Ductility of SiC Particle Reinforced Al-Cu-Mg Alloys Matrix Composites. Materials 2021, 14, 1219. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T.L. A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. J. Manuf. Process. 2020, 56, 1059–1074. [Google Scholar] [CrossRef]

- Bedolla-Becerril, E.; Garcia-Guerra, J.; Lopez-Morelos, V.H.; Garcia-Renteria, M.A.; Falcon-Franco, L.A.; Martinez-Landeros, V.H.; García-Villarreal, S.; Flores-Villaseñor, S.E. Tribological Behaviour of Al-2024/TiC Metal Matrix Composites. Coatings 2023, 13, 77. [Google Scholar] [CrossRef]

- Schiopu, A.G.; Girish, B.M.; Satish, B.M.; Shubha, S. Wear and Hardness Characterization of Hot Forged Tungsten Carbide Reinforced Aluminium 6061 Composite Materials. Eng. Technol. Appl. Sci. Res. 2023, 14, 12688–12693. [Google Scholar] [CrossRef]

- Jayakanth, J.J.; Mamidi, V.K.; Pugazhenthi, R.; Anbuchezhiyan, G.; Ponshanmugakumar, A. An investigation on wear properties of SiC/WC strengthened aluminium alloy hybrid composites. Mater. Today Proc. 2020, 46, 3542–3545. [Google Scholar] [CrossRef]

- Anand, P.; Rajesh, D.; Lenin, N.; Balaji, V.; Raja, V.B.; Palanikumar, K. Enhancement of mechanical characterization of aluminum alloy with tungsten carbide metal matrix composite by particulate reinforcements. Mater. Today Proc. 2021, 46, 3690–3692. [Google Scholar] [CrossRef]

- Abood, A.S.; Jayanthi, M.; Thethi, H.P.; Singh, S.; Chahuan, N. Advancing Aluminum-Based Composite Manufacturing: Leveraging WC Reinforcement through Stir Casting Technique. In Proceedings of the E3S Web of Conferences, Nagpur, India, 23–24 February 2024; Volume 507. [Google Scholar]

- Cai, Y.; Su, Y.; Liu, K.; Hua, A.; Wang, X.; Cao, H.; Zhang, D.; Ouyang, Q. Effect of Sc microalloying on fabrication, microstructure and mechanical properties of SiCp/Al-Cu-Mg-Sc composites via powder metallurgy. Mater. Sci. Eng. A 2023, 877, 145152. [Google Scholar] [CrossRef]

- Wang, T.; Huang, Y.; Ma, Y.; Wu, L.; Yan, H.; Liu, C.; Liu, Y.; Liu, B.; Liu, W. Microstructure and mechanical properties of powder metallurgy 2024 aluminum alloy during cold rolling. J. Mater. Res. Technol. 2021, 15, 3337–3348. [Google Scholar] [CrossRef]

- Rodríguez-Cabriales, G.; Lometo-Sánchez, A.M.; Guía-Tello, J.C.; Medrano-Prieto, H.M.; Gutiérrez-Castañeda, E.J.; Estrada-Guel, I.; Garay-Reyes, C.G.; Hernández-Rivera, J.L.; Cruz-Rivera, J.J.; Maldonado-Orozco, M.C.; et al. Synthesis and characterization of Al-Cu-Mg system reinforced with tungsten carbide through powder metallurgy. Mater. Today Commun. 2020, 22, 100758. [Google Scholar] [CrossRef]

- Gowda, K.P.; Prakash, J.N.; Gowda, S.; Babu, B.S. Effect of Particulate Reinforcement on the Mechanical Properties of Al2024-WC MMCs. J. Miner. Mater. Charact. Eng. 2015, 3, 469–476. [Google Scholar] [CrossRef]

- Othman, A.R.; Sardarinejad, A.; Masrom, A.K. Effect of milling parameters on mechanical alloying of aluminum powders. Int. J. Adv. Manuf. Technol. 2014, 76, 1319–1332. [Google Scholar] [CrossRef]

- Rodríguez-Cabriales, G.; Garay-Reyes, C.G.; Guía-Tello, J.C.; Medrano-Prieto, H.M.; Estrada-Guel, I.; García-Hernández, L.J.; Ruiz-Esparza-Rodríguez, M.A.; Mendoza-Duarte, J.M.; García-Aguirre, K.A.; Gonzáles-Sánchez, S.; et al. Abrasive Wear Behavior of Al-4Cu-1.5Mg-WC Composites Synthesized through Powder Metallurgy. Lubricants 2023, 11, 103. [Google Scholar] [CrossRef]

- Bhowmik, A.; Sen, B.; Beemkumar, N.; Chohan, J.S.; Bains, P.S.; Singh, G.; Kumar, A.V. Development and wear resistivity performance of SiC and TiB2 particles reinforced novel aluminium matrix composites. Results Eng. 2024, 24, 102981. [Google Scholar] [CrossRef]

- Patela, A.; Patelb, A.; Parmarc, S.; Jadav, H. Review on Effect of Heat Treatment on Properties of AA 2024. In Special Edition ICRPMSME 2022; Gandhinagar University: Kalol, India, 2022; Volume 14, pp. 51–59. [Google Scholar]

- Kvackaj, T. Aluminium Alloys: Theory and Applications; BoD–Books on Demand: Hamburg, Germany, 2011. [Google Scholar]

- Elias Junior, P.J.O.; das Neves, E.B.; Biehl, L.V.; Baierle, I.C.; Martins, C.O.D.; Medeiros, J.L.B. Study of the Effect of Tin Addition in Aluminum–Copper Alloys Obtained from Elemental Powders. Metals 2025, 15, 559. [Google Scholar] [CrossRef]

- Sarker, S.; Haque, M.S.; Alvy, M.S.A.; Abir, M.M.H. The effects of solution heat treatment on the microstructure and hardness of an aluminum-4% copper alloy with added nickel and tin. J. Alloys Metall. Syst. 2023, 4, 100042. [Google Scholar] [CrossRef]

- Singh, G.; Sharma, N. Study on the influence of T4 and T6 heat treatment on the wear behavior of coarse and fine WC particulate reinforced LM28 Aluminium cast composites. Compos. Part C Open Access 2021, 4, 100106. [Google Scholar] [CrossRef]

- Simon, A.; Lipusz, D.; Baumli, P.; Balint, P.; Kaptay, G.; Gergely, G.; Sfikas, A.; Lekatou, A.; Karantzalis, A.; Gácsi, Z. Microstructure and Mechanical Properties of Al-WC Composites. Arch. Metall. Mater. 2015, 60, 1517–1521. [Google Scholar] [CrossRef]

- Wąsik, A.; Leszczyńska-Madej, B.; Madej, M.; Goły, M. Effect of Heat Treatment on Microstructure of Al4Cu-SiC Composites Consolidated by Powder Metallurgy Technique. J. Mater. Eng. Perform. 2020, 29, 1841–1848. [Google Scholar] [CrossRef]

- Wang, Z.; Li, C.; Wang, H.; Zhu, X.; Wu, M.; Li, J.; Jiang, Q. Aging Behavior of Nano-SiC/2014Al Composite Fabricated by Powder Metallurgy and Hot Extrusion Techniques. J. Mater. Sci. Technol. 2016, 32, 1008–1012. [Google Scholar] [CrossRef]

- Ghasali, E.; Pakseresht, A.H.; Agheli, M.; Marzbanpour, A.H.; Ebadzadeh, T. WC-Co Particles Reinforced Aluminum Matrix by Conventional and Microwave Sintering. Mater. Res. 2015, 18, 1197–1202. [Google Scholar] [CrossRef]

- Heugue, P.; Larouche, D.; Breton, F.; Martinez, R.; Chen, X.G. Evaluation of the Growth Kinetics of θ′ and θ″-Al2Cu Precipitates in a Binary Al-3.5 Wt Pct Cu Alloy. Metall. Mater. Trans. A 2019, 50, 3048–3060. [Google Scholar] [CrossRef]

- Wang, F.; Zeng, Y.; Xiong, B.; Zhang, Y.; Li, X.; Li, Z.; Liu, H. Effect of Si addition on the microstructure and mechanical properties of Al-Cu-Mg alloy. J. Alloys Compd. 2014, 585, 474–478. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg–(Li) based alloys. Int. Mater. Rev. 2005, 50, 193–215. [Google Scholar] [CrossRef]

- Zhou, Y.; Chang, T.; Fang, X.; Chen, R.; Li, Y.; Huang, K. Tailoring the mechanical properties and thermal stability of additive manufactured micro-alloyed Al-Cu alloy via multi-stage heat treatment. Mater. Des. 2023, 233, 112287. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Angadi, S.; Malik, V.; Saxena, K.K.; Prakash, C.; Dixit, S.; Mohammed, K.A. Mechanical and Tribological Properties of Aluminum-Based Metal-Matrix Composites. Materials 2022, 15, 6111. [Google Scholar] [CrossRef]

- Zeng, X.; Liu, W.; Xu, B.; Shu, G.; Li, Q. Microstructure and Mechanical Properties of Al-SiC Nanocomposites Synthesized by Surface-Modified Aluminium Powder. Metals 2018, 8, 253. [Google Scholar] [CrossRef]

- Hasan, L.K.; Jiaad, S.M.; Salman, K.D.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Wear Characteristics of (Al/B4C and Al/TiC) Nanocomposites Synthesized via Powder Metallurgy Method. Appl. Sci. 2023, 13, 12939. [Google Scholar] [CrossRef]

- Bilsland, C.; Barrow, A.; Ben Britton, T. Correlative statistical microstructural assessment of precipitates and their distribution, with simultaneous electron backscatter diffraction and energy dispersive X-ray spectroscopy. Mater. Charact. 2021, 176, 111071. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, H. Precipitation Behavior during Aging Operations in an Ultrafine-Grained Al-Cu-Mg Alloy Produced by High-Strain-Rate Processing. Materials 2022, 15, 8687. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Papadimitriou, I.; Lin, F.X.; LLorca, J. Precipitation during high temperature aging of Al-Cu alloys: A multiscale analysis based on first principles calculations. Acta Mater. 2019, 167, 121–135. [Google Scholar] [CrossRef]

- Wu, C.; Ma, K.; Zhang, D.; Wu, J.; Xiong, S.; Luo, G.; Zhang, J.; Chen, F.; Shen, Q.; Zhang, L.; et al. Precipitation phenomena in AlZn-Mg alloy matrix composites reinforced with B4C particles. Sci. Rep. 2017, 7, 9589. [Google Scholar]

- Pal, S.; Mitra, R.; Bhanuprasad, V.V. Aging behaviour of Al-Cu-Mg alloy-SiC composites. Mater. Sci. Eng. A 2008, 480, 496–505. [Google Scholar] [CrossRef]

- Rajaram, S.; Subbiah, T.; Mahali, P.K.; Thangaraj, M. Effect of Age-Hardening Temperature on Mechanical and Wear Behavior of Furnace-Cooled Al7075-Tungsten Carbide Composite. Materials 2022, 15, 5344. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A Review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Bignon, M.; Bernacki, M. Particle pinning during grain growth—A new analytical model for predicting the mean limiting grain size but also grain size heterogeneity in a 2D polycrystalline context. Acta Mater. 2024, 227, 120174. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Velonaki, Z.; Stergiou, C.I.; Kourkoulis, S.K. Effect of artificial ageing on the work hardening stages of precipitation hardened wrought Al-Cu-Mg alloy. Mater. Sci. Eng. A 2017, 700, 457–467. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, G.; Zhu, S.; Wang, D.; Xiao, B.; Ma, Z. Two-stage aging treatment to accelerate aging kinetics without impairing strength in B4C/7A04Al composite. Sci. China Technol. Sci. 2024, 67, 2485–2492. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).