An Investigation into the Influence of Weld Bead Sequence on Residual Stress Distribution in a High-Speed Train Bogie Beam Using Thermo-Elastic–Plastic Finite Element Analysis

Abstract

1. Introduction

2. Experimental Procedure

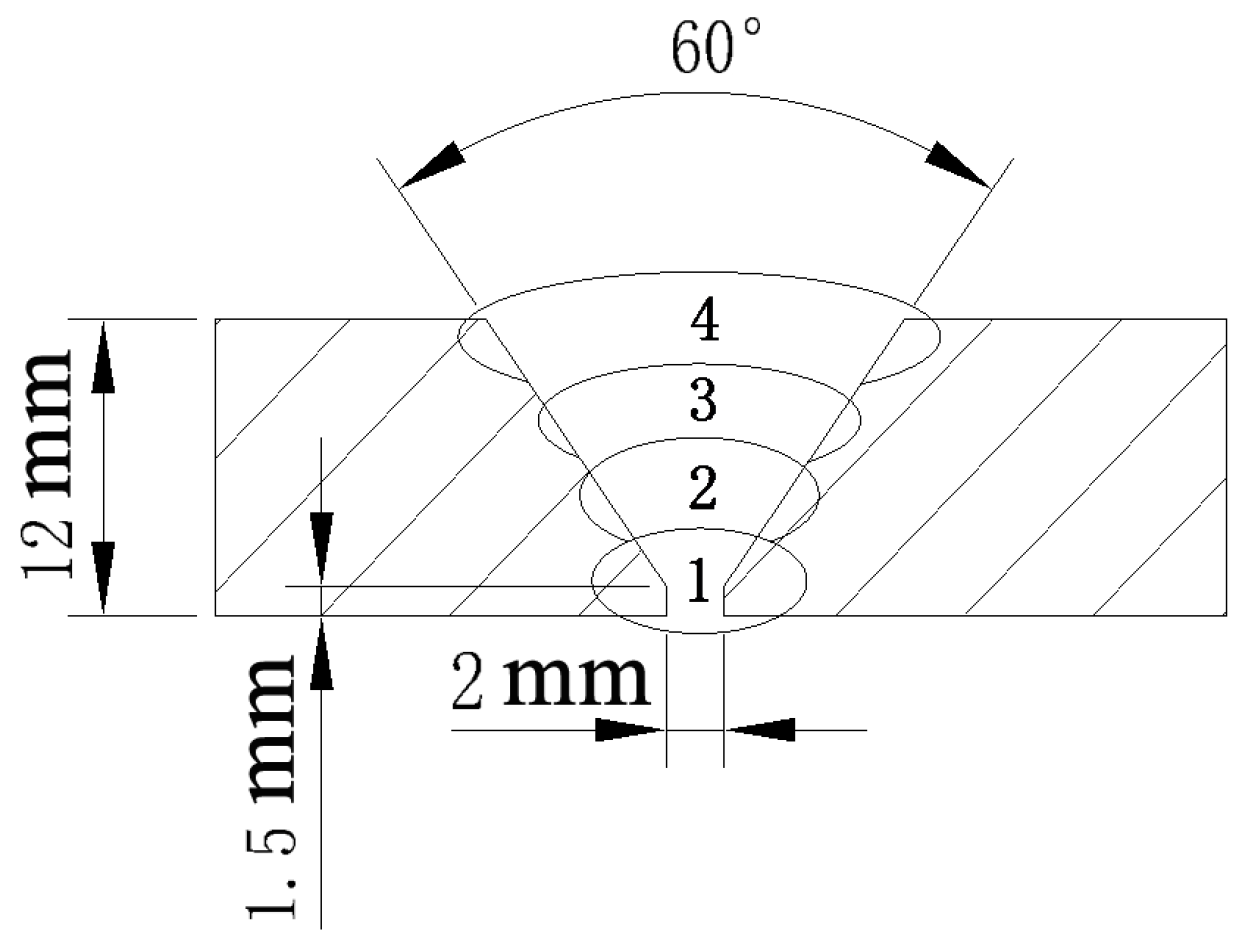

2.1. Fabrication of the Butt-Welded Joint

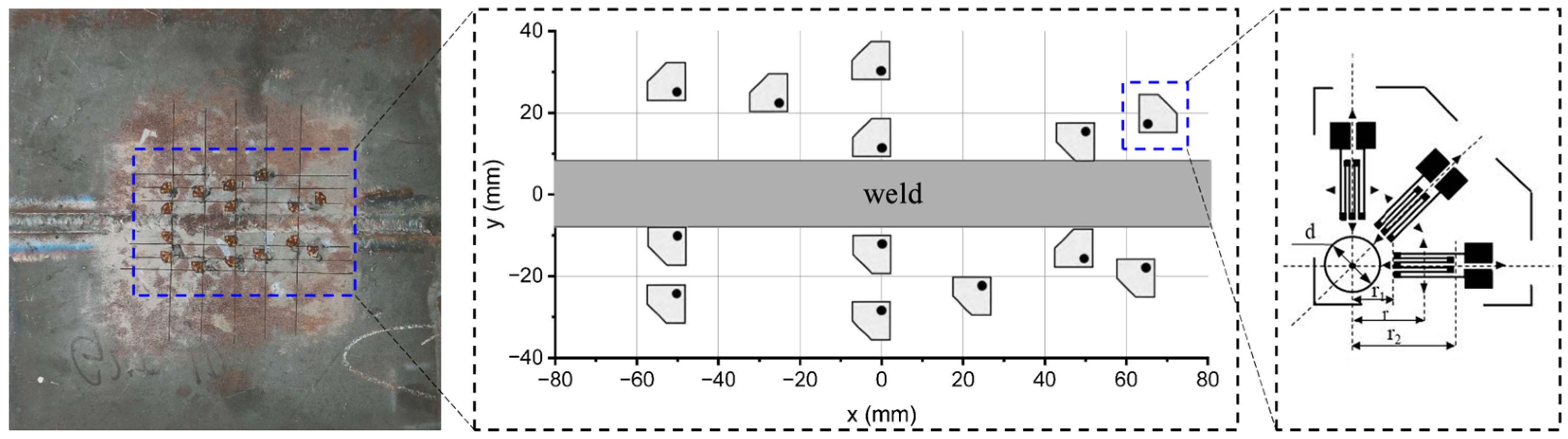

2.2. Residual Stress Measurement

3. Thermal Elastic Plastic Finite Element Method and Simulation Cases

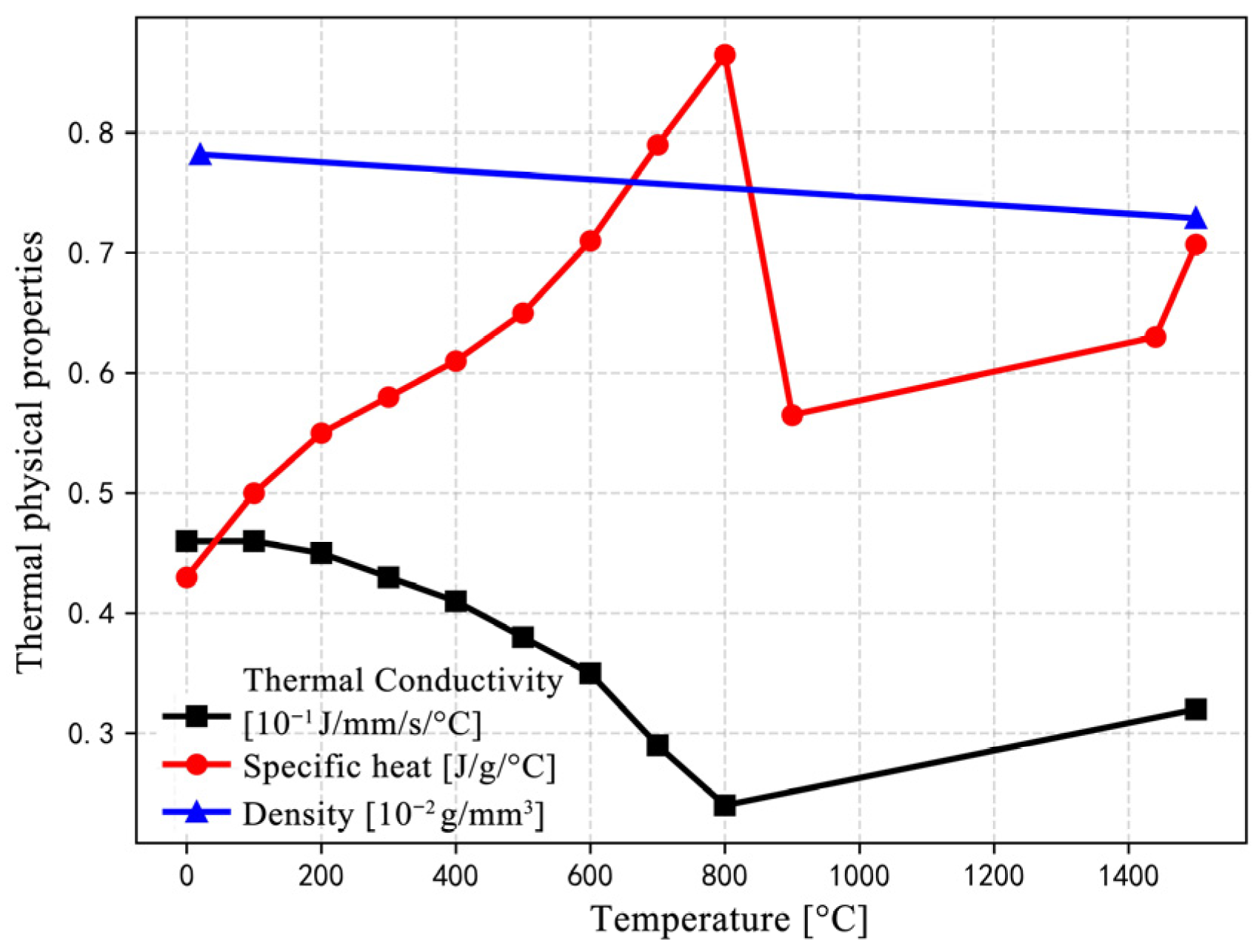

3.1. Simulation of Welding Temperature Field

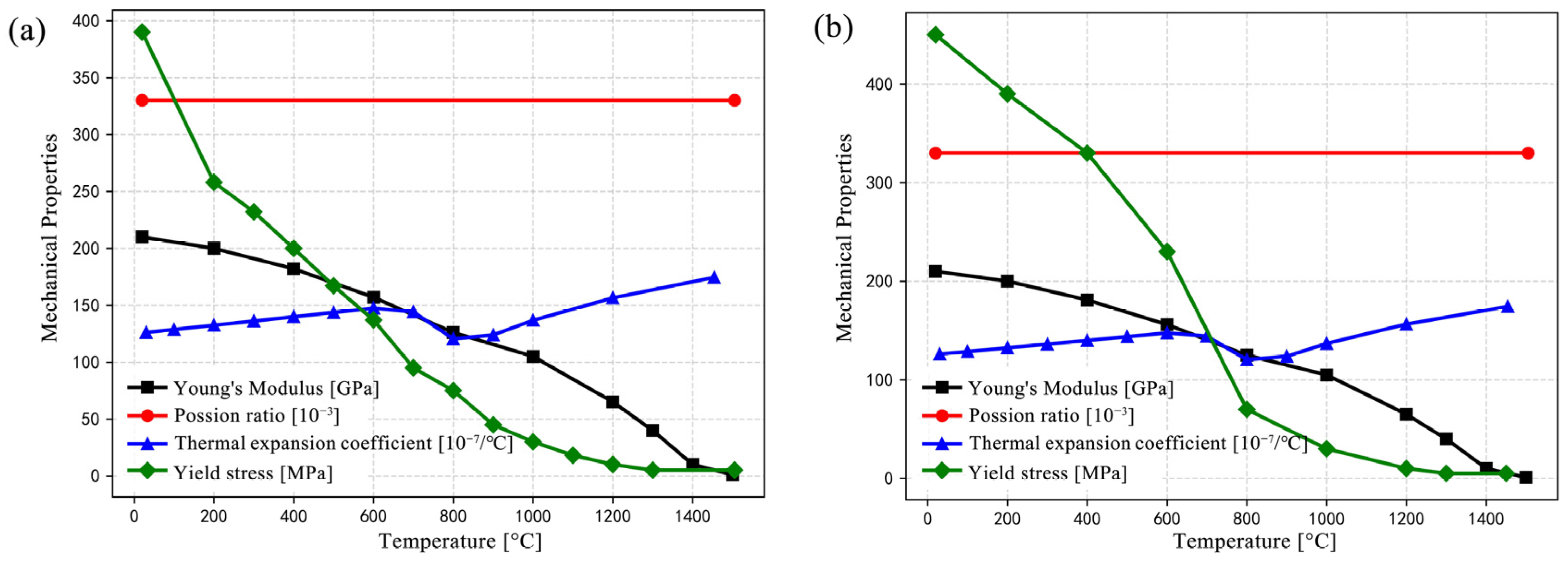

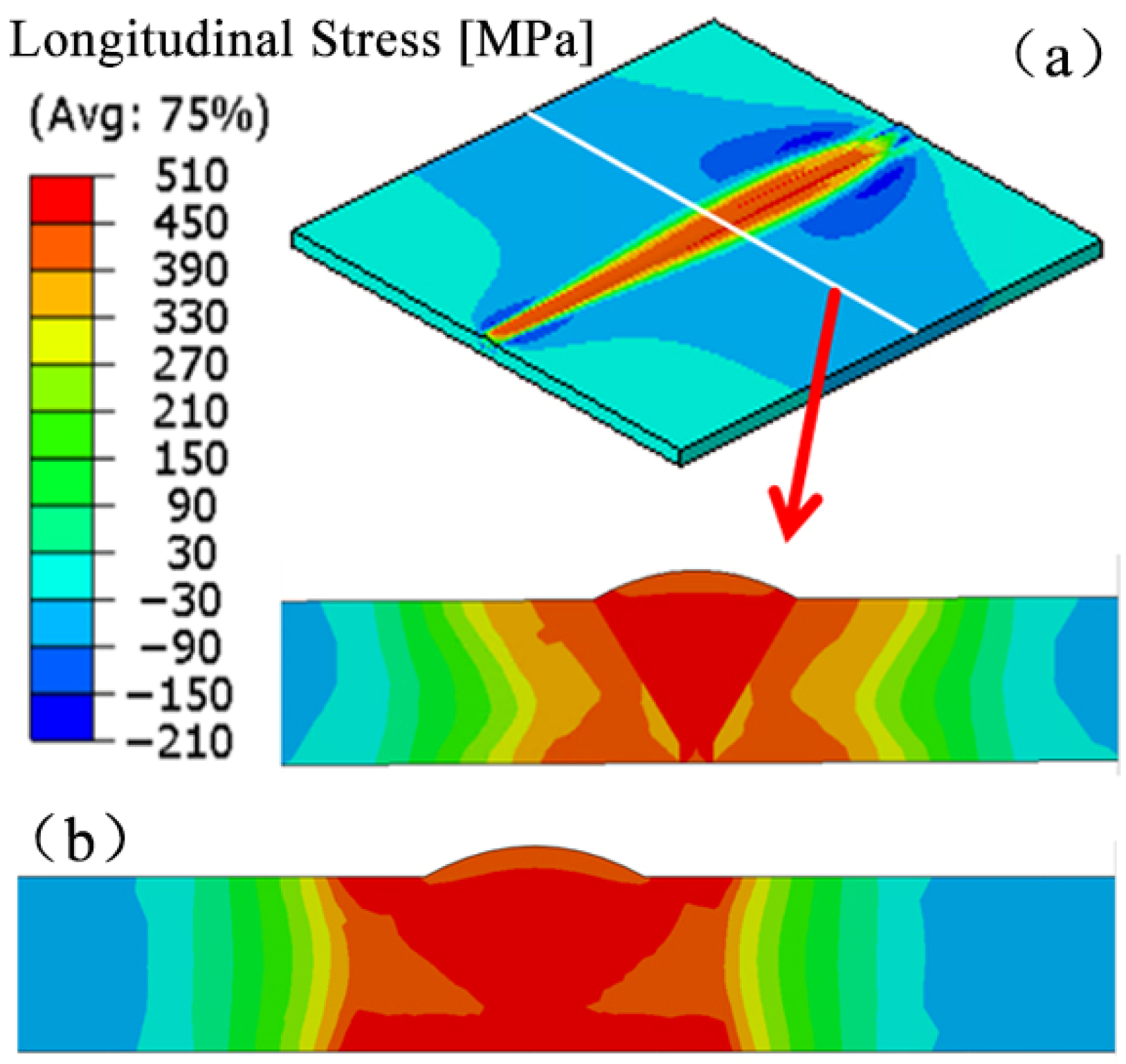

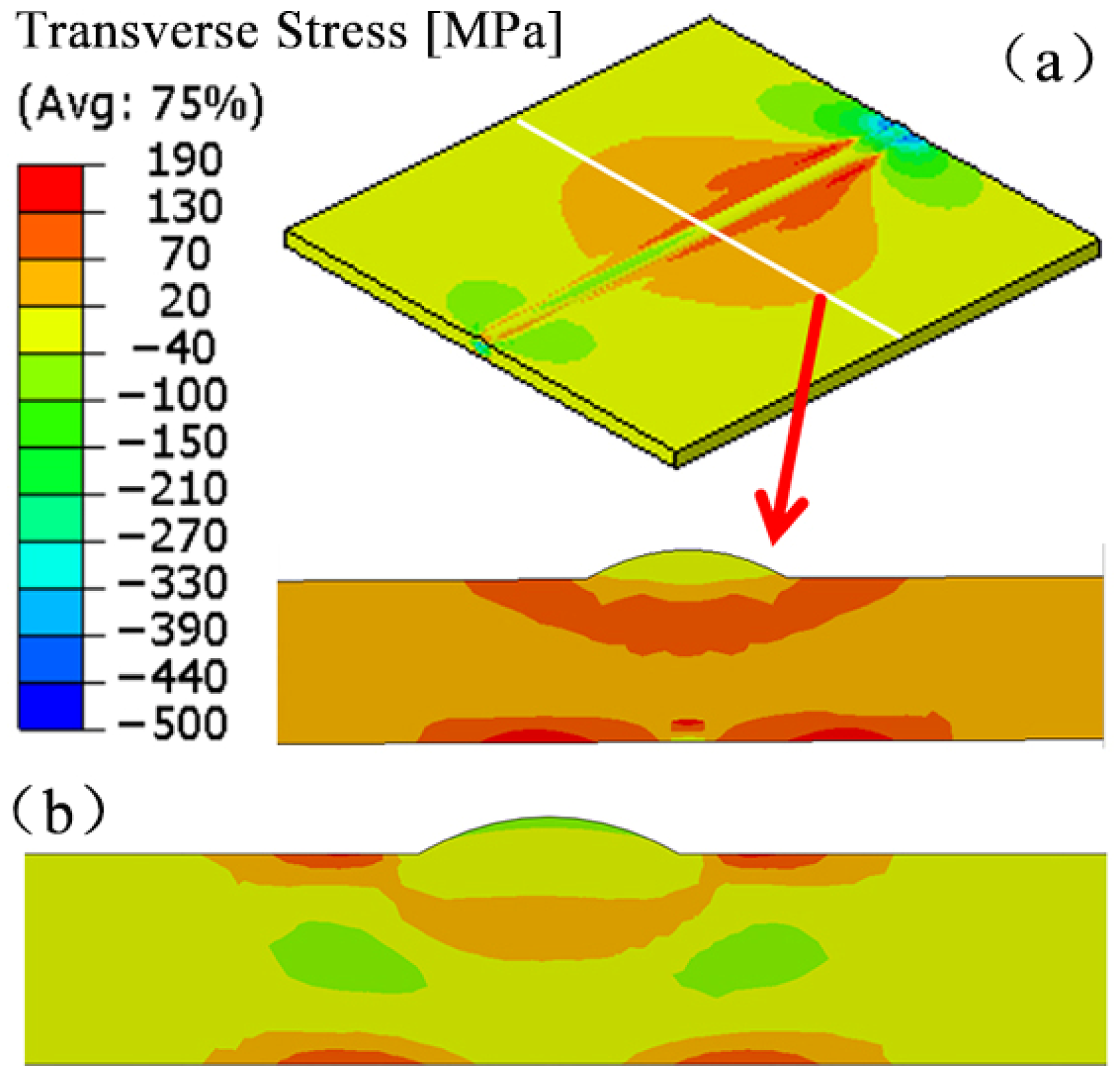

3.2. Analysis of Welding Stress Field

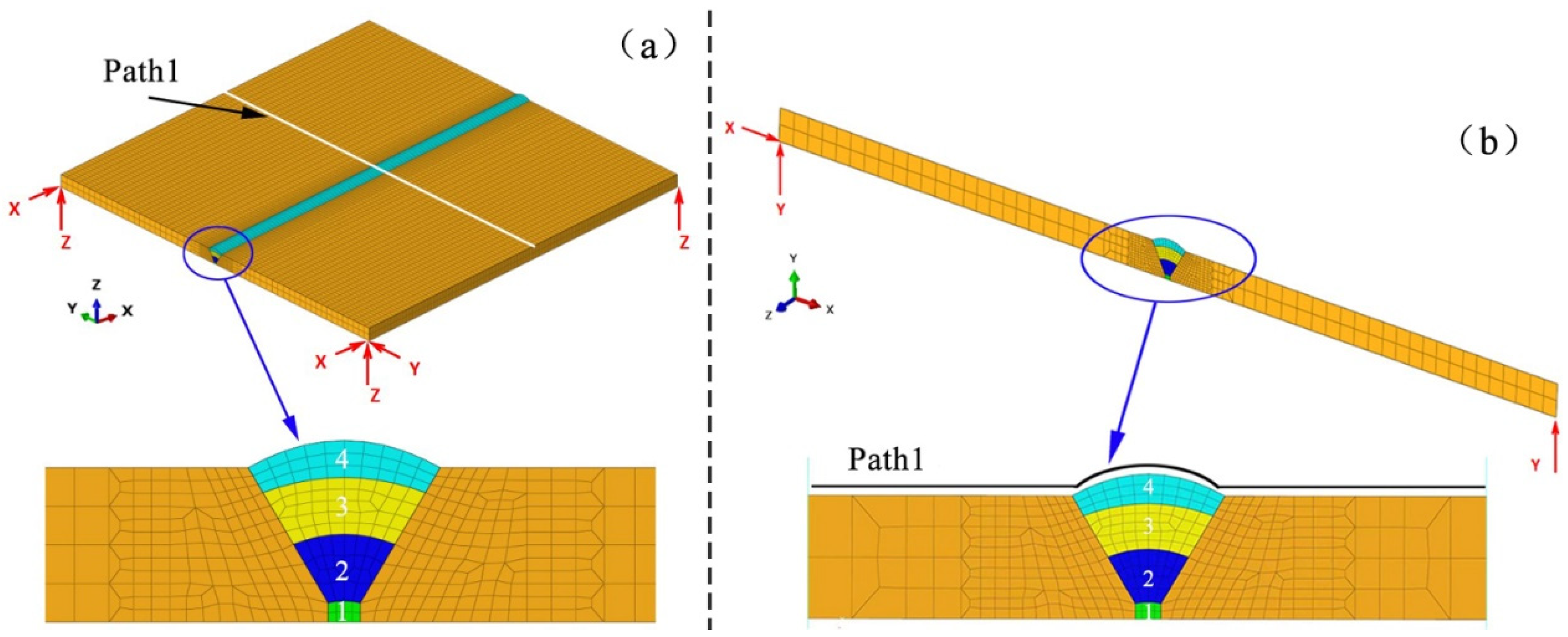

3.3. Finite Element Models and Simulation Cases

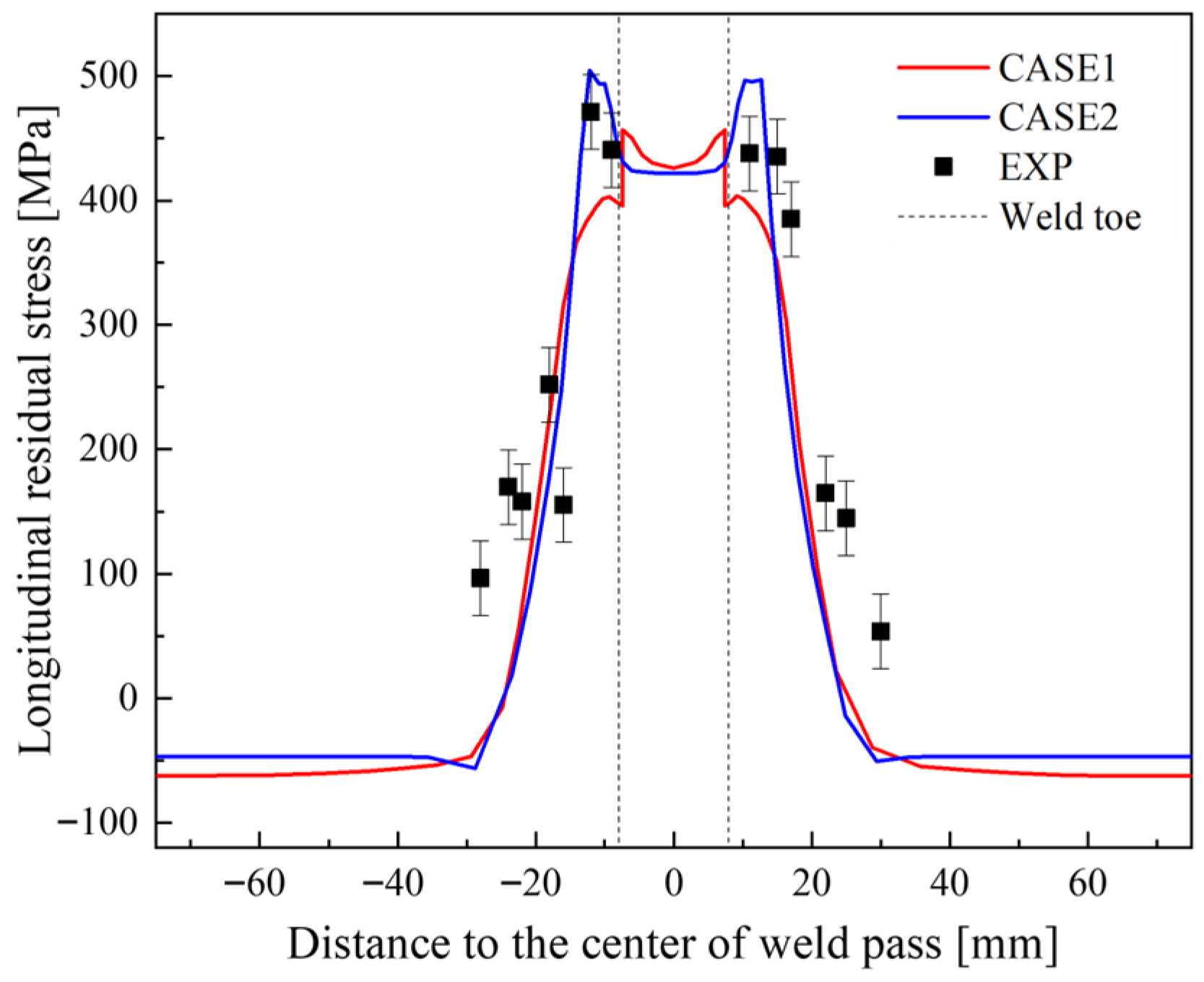

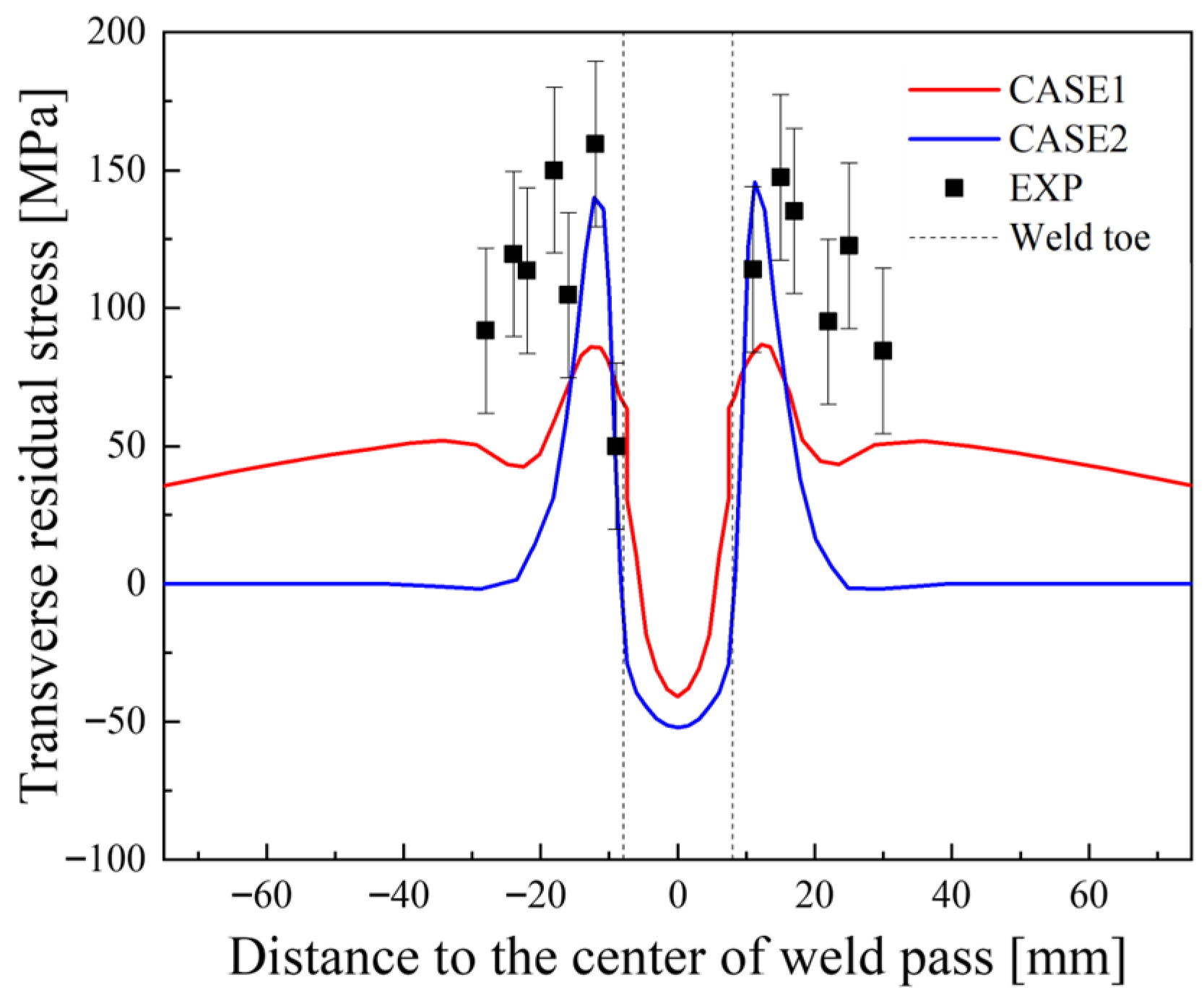

3.4. Comparative Evaluation of Simulation Results and Measured Data for the Butt-Welded Joint

4. Numerical Simulation of Residual Stress Distribution in the Bogie Beam

4.1. Welding Procedure of the Bogie Beam

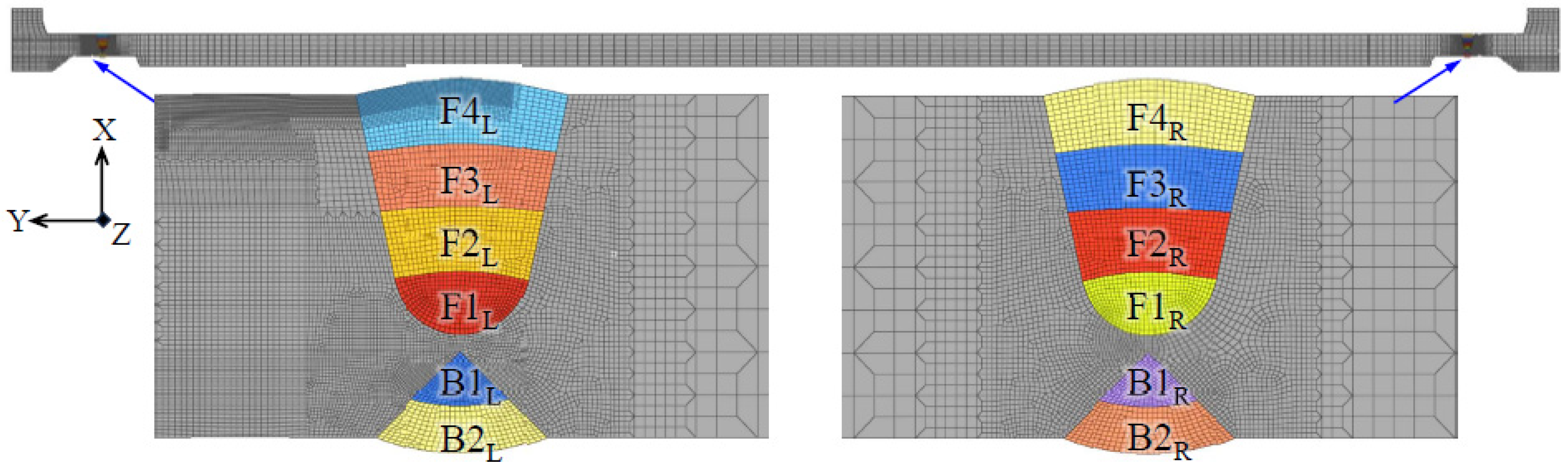

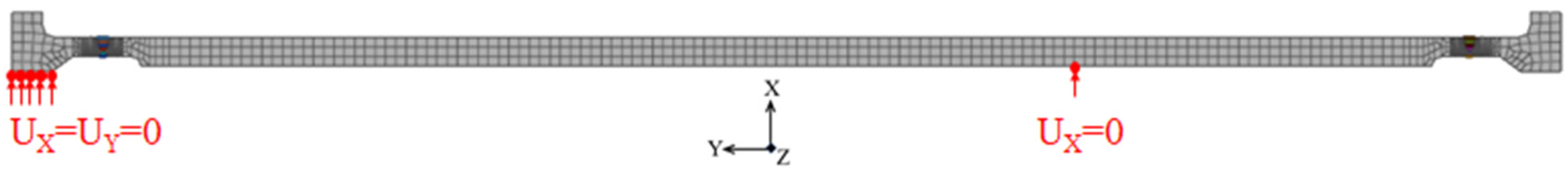

4.2. Two-Dimensional Axisymmetric Model and Simulation Cases

4.3. Results of Welding Residual Stress and Discussion

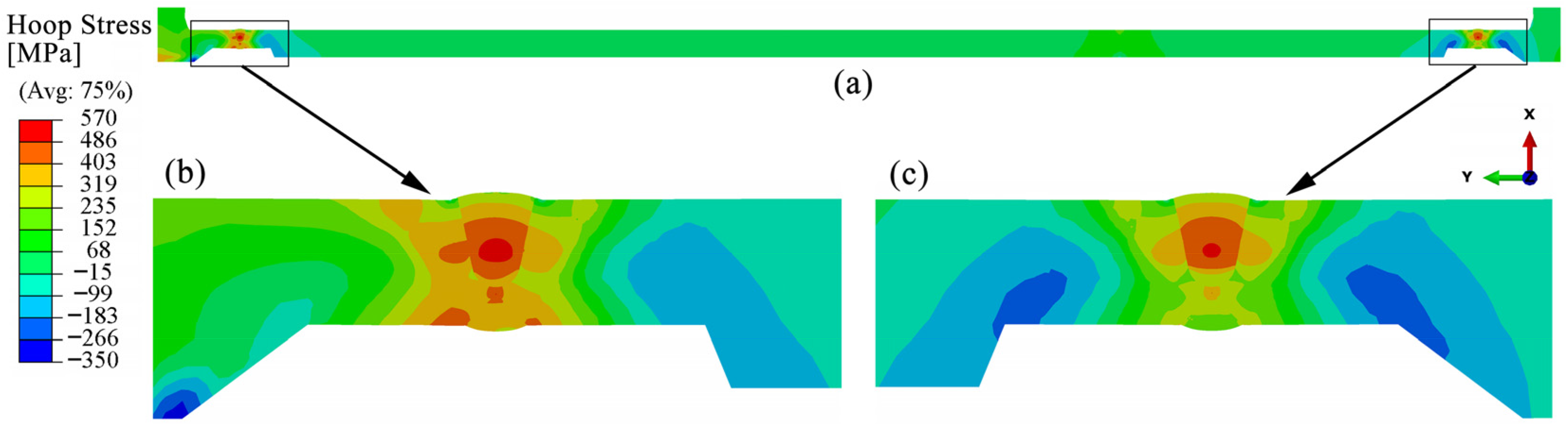

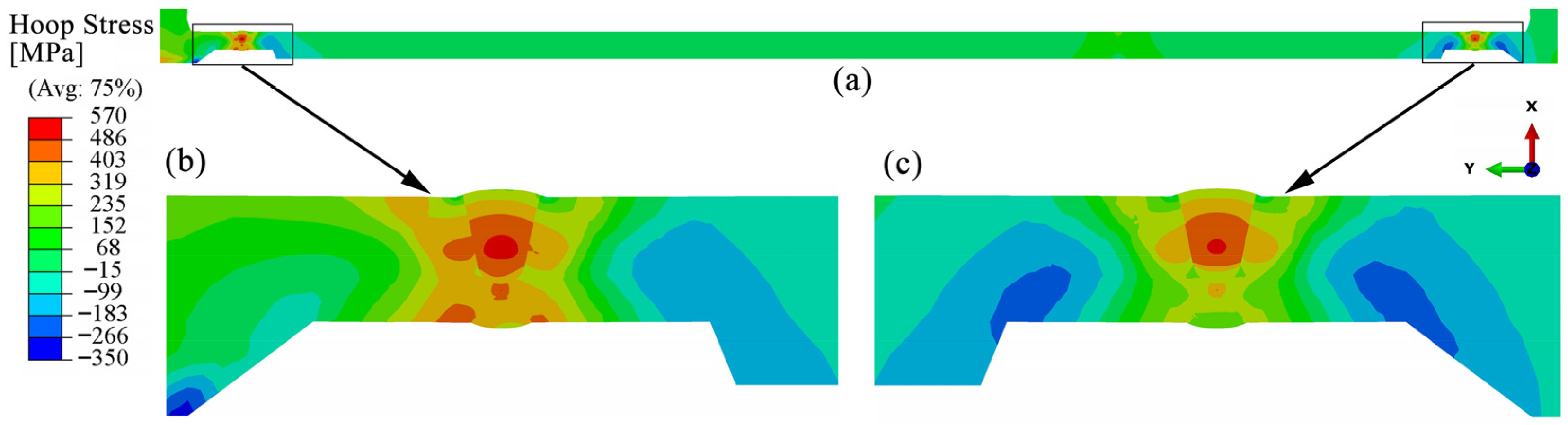

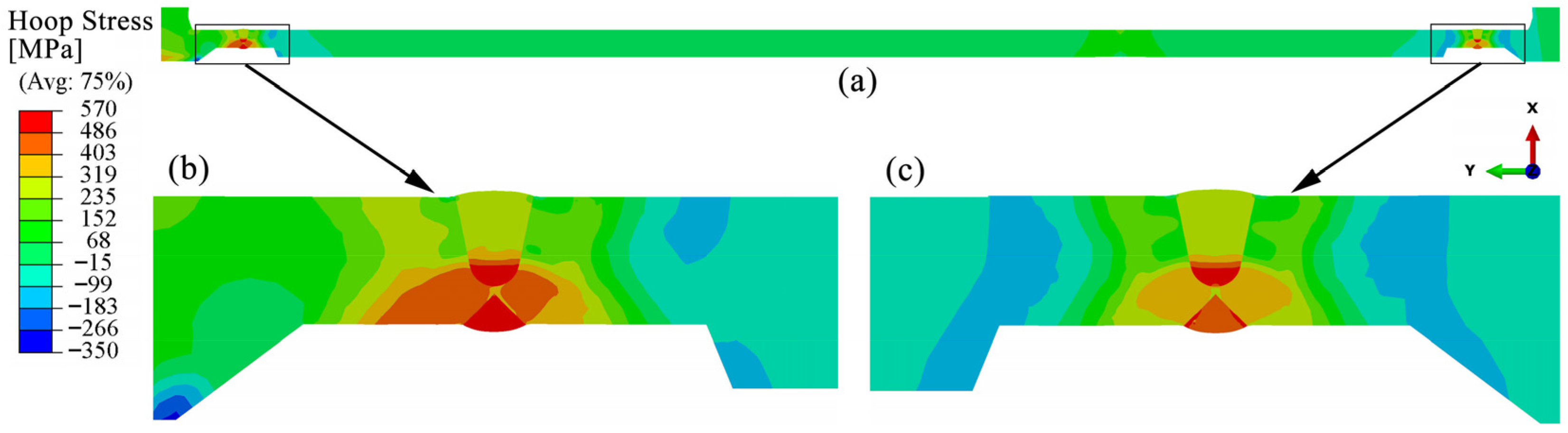

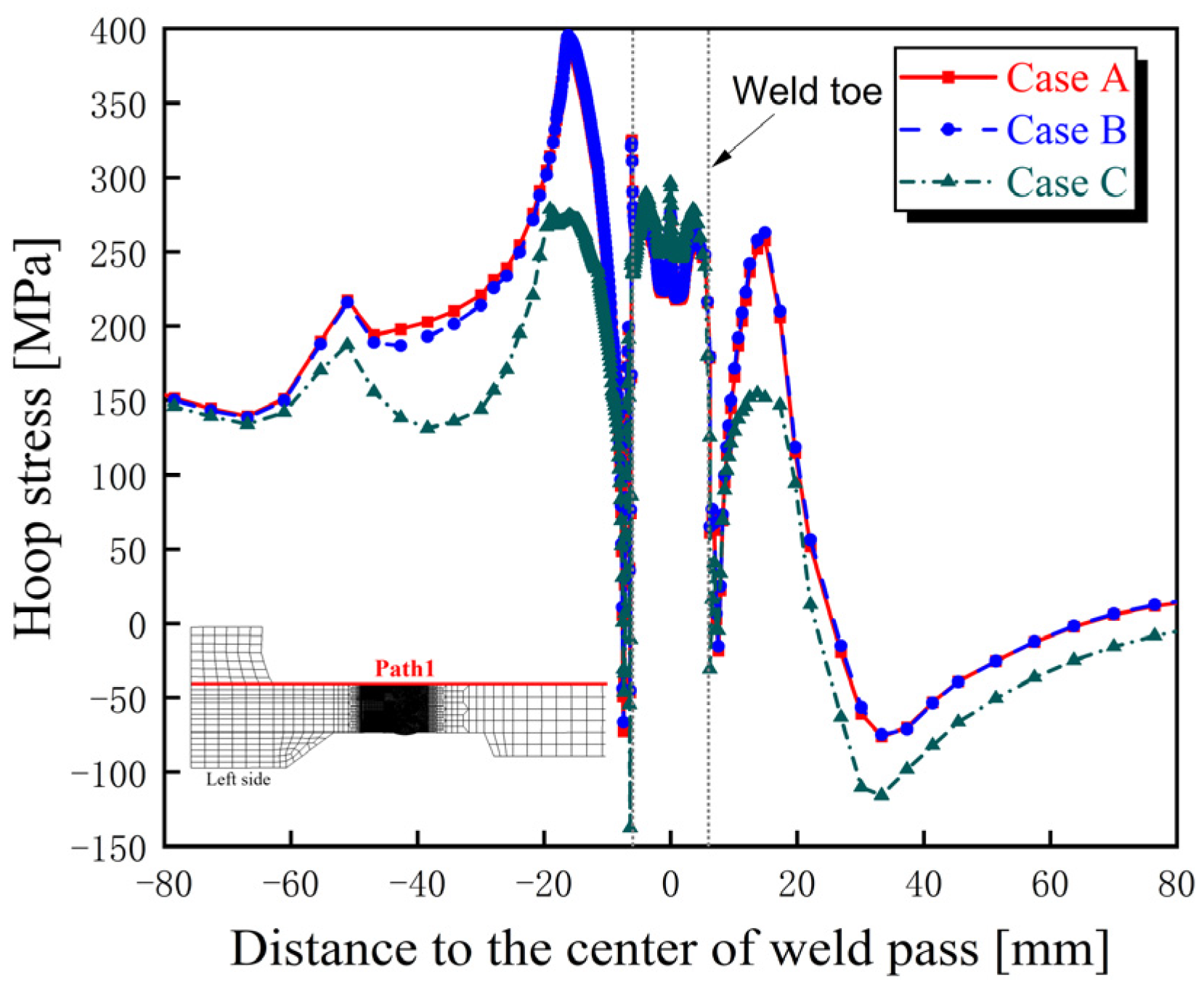

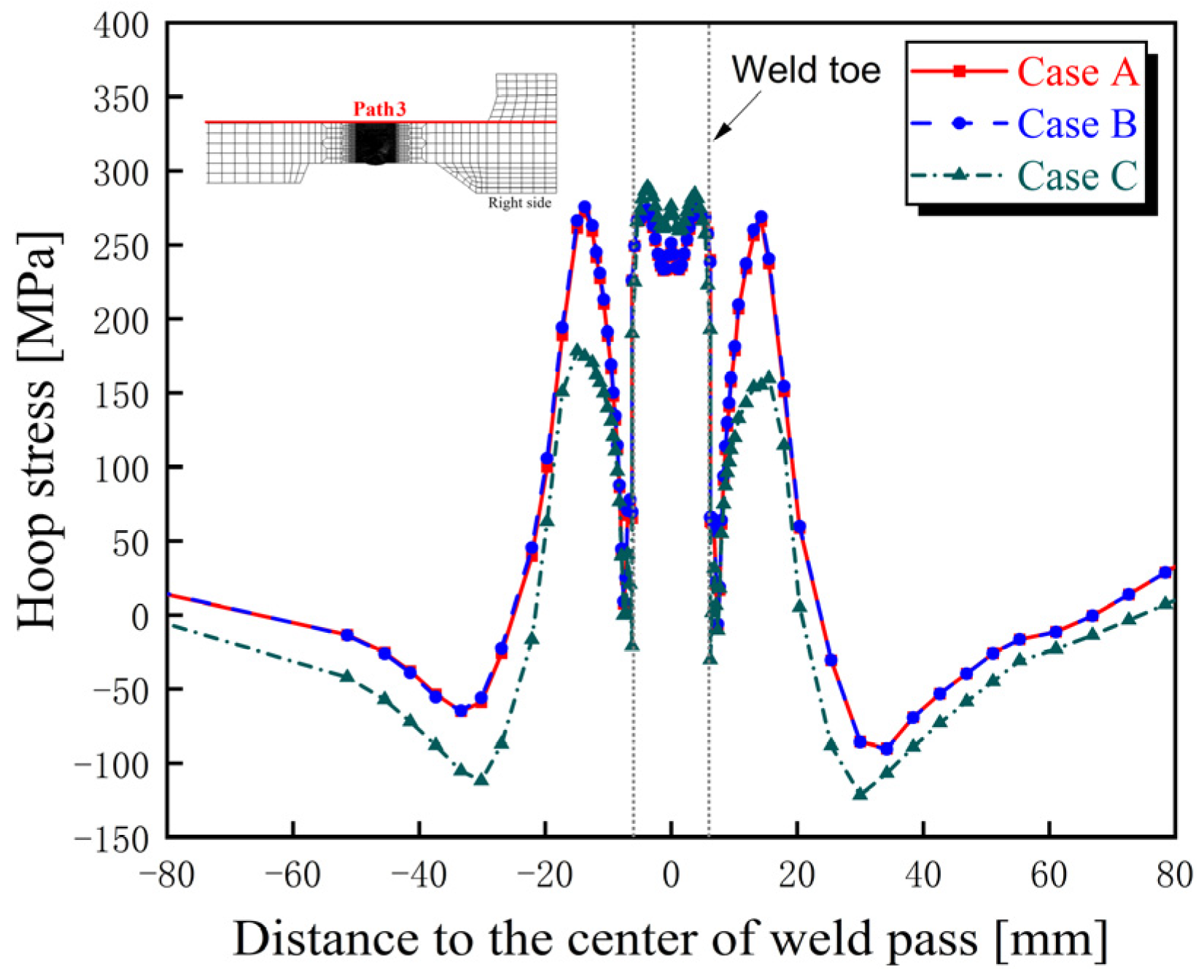

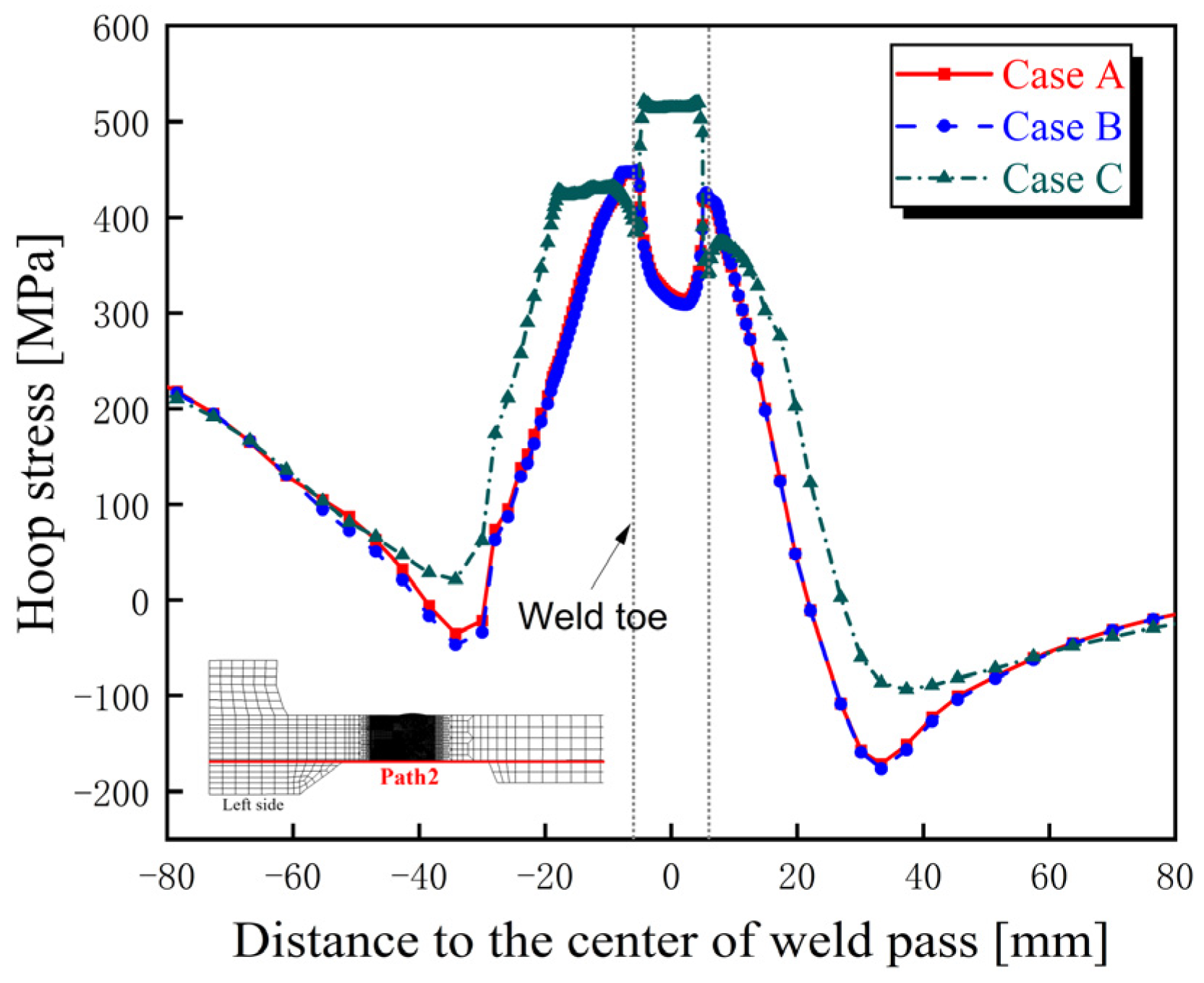

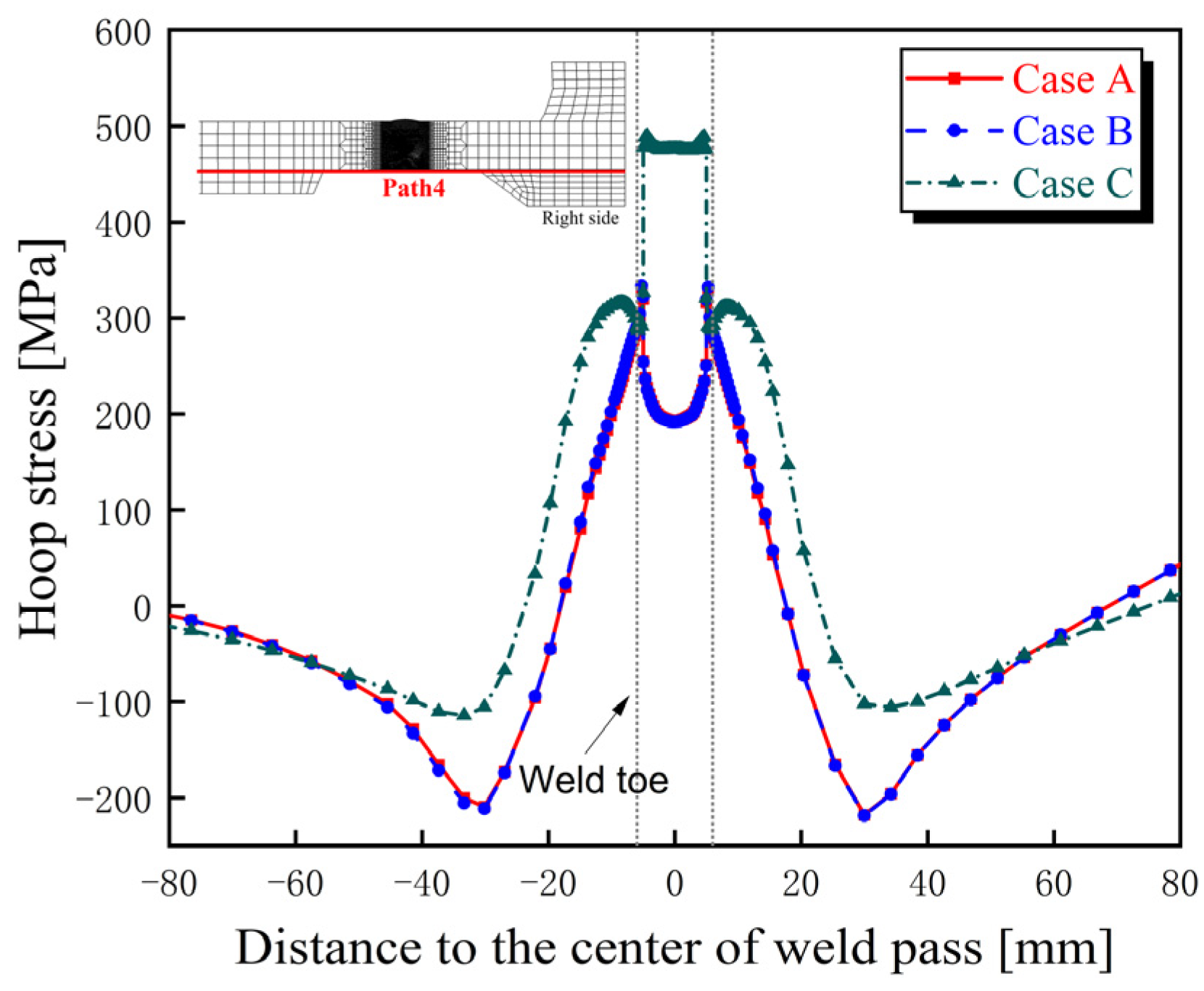

4.3.1. Hoop Residual Stress

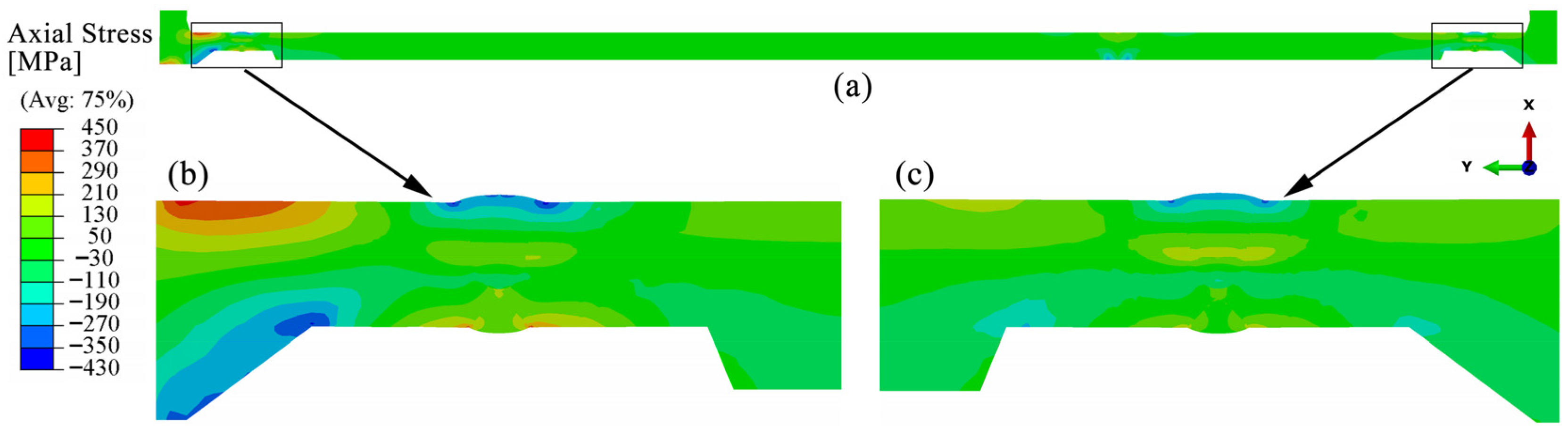

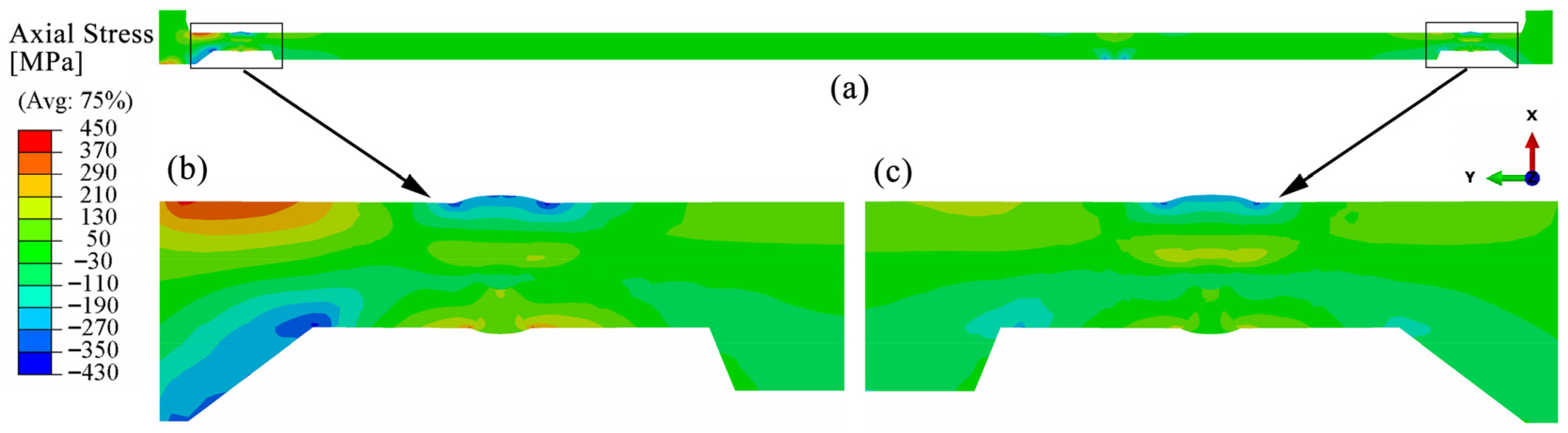

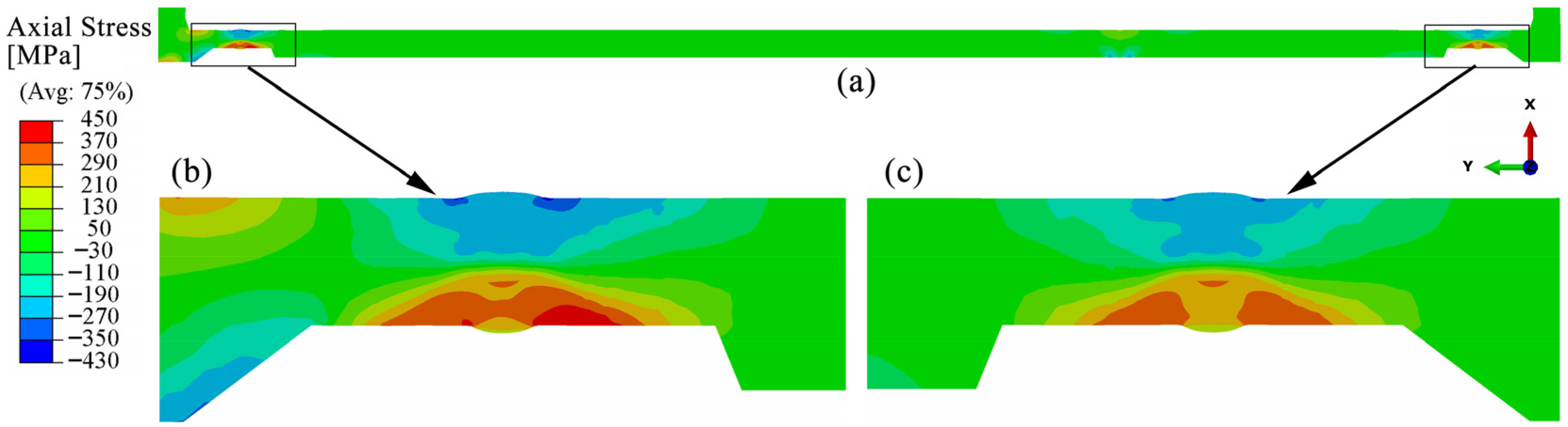

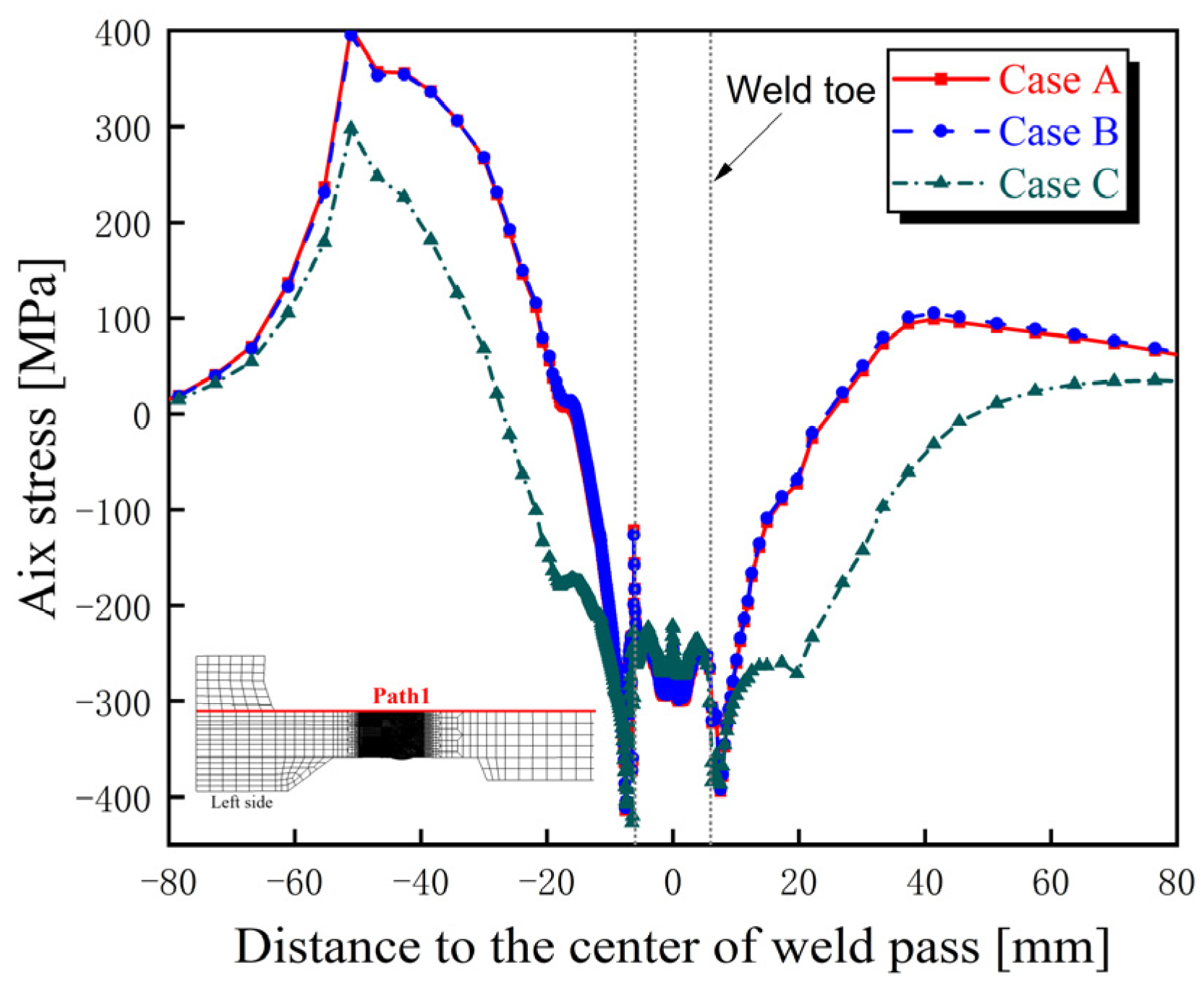

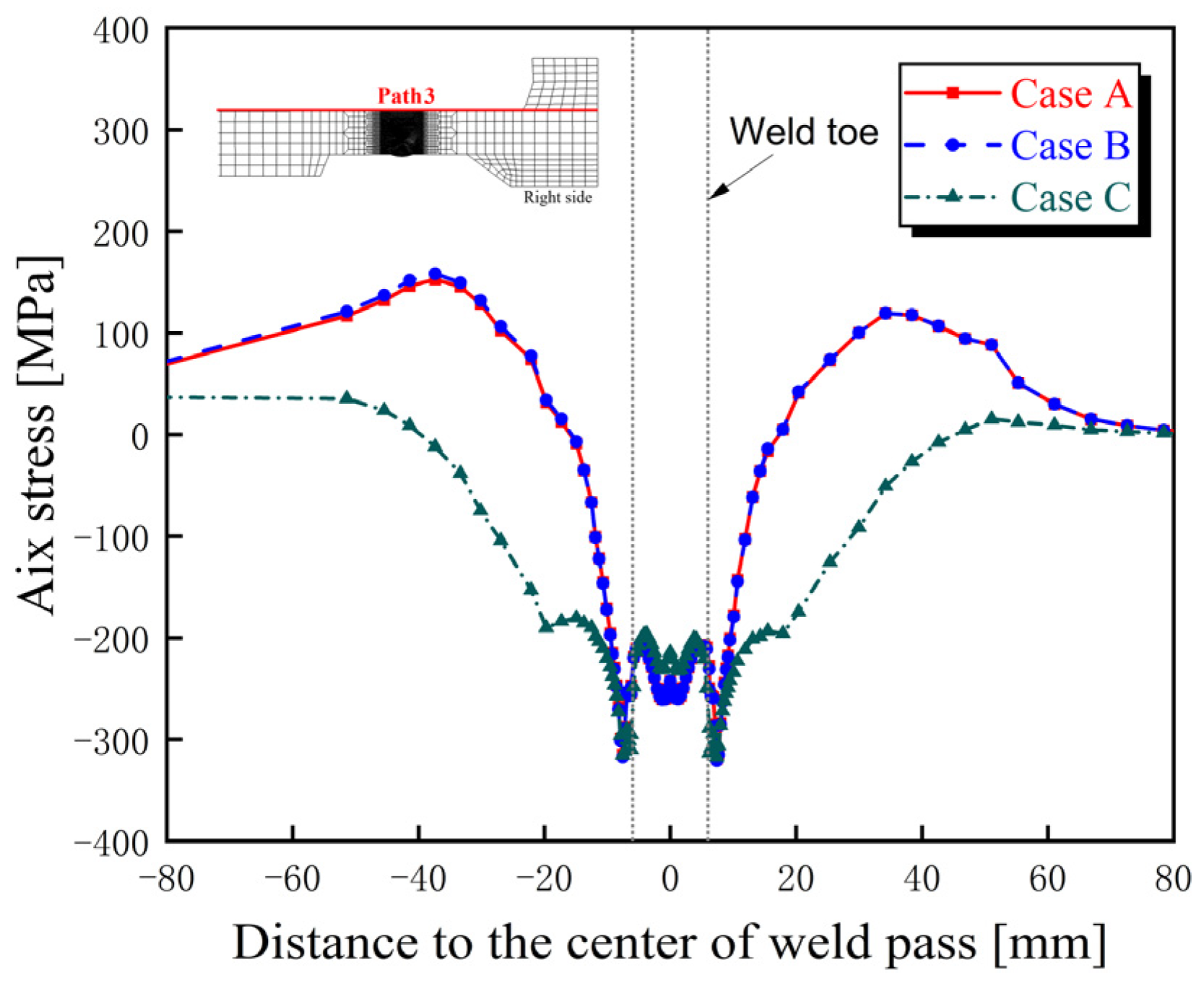

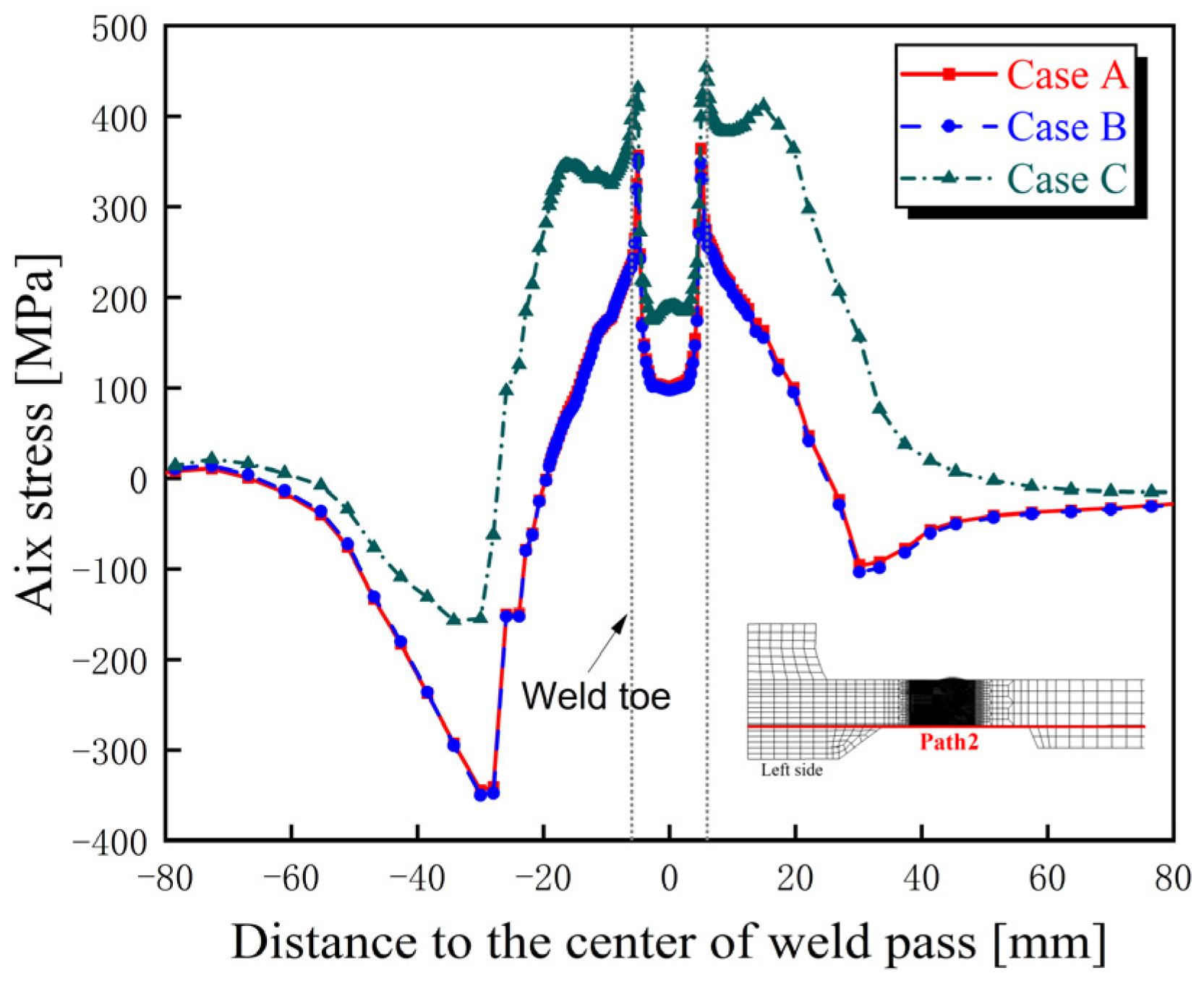

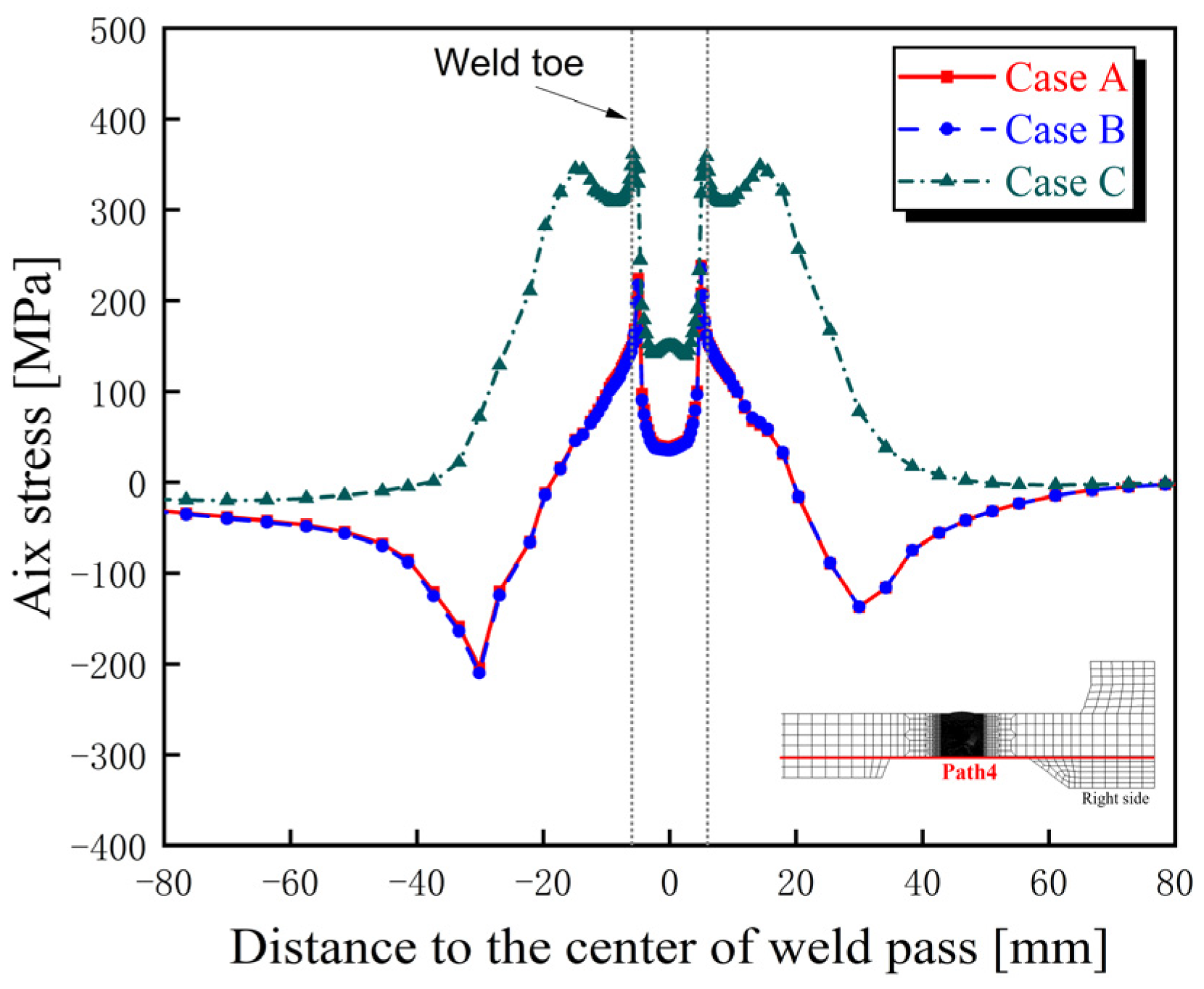

4.3.2. Axial Residual Stress

4.3.3. Discussion

5. Conclusions

- (1)

- Compared with the moving heat source model, the two-dimensional plane strain model demonstrates superior capability in simulating welding residual stresses in the weathering steel butt-welded joint, while significantly reducing computing time. A comparison between numerical simulation results and experimental measurements confirms that the computational method based on the two-dimensional plane strain model proposed in this study is suitable for the numerical simulation of welding residual stresses in large-scale welded structures, such as high-speed train bogies.

- (2)

- The distribution characteristics of residual stress in the bogie beam welds obtained through numerical simulation are as follows: (1) Hoop residual stresses in the weld zones of both inner and outer surfaces and their adjacent regions are predominantly tensile. (2) The peak tensile stress on the outer surface occurs at the weld toe and exceeds the yield strength of the material at room temperature. (3) On the inner surface, axial tensile stress near the weld toe is present but remains below the yield strength, whereas the corresponding axial stress on the outer surface is compressive, indicating a significant contribution of bending-induced stress to the overall axial residual stress distribution.

- (3)

- The sequence of weld beads has a notable influence on the magnitude and distribution of welding residual stresses within the beam, particularly on the inner surface. Specifically, when the inner surface weld is performed later (Case C), the hoop and axial tensile residual stresses at the weld toes on the inner surface of the beam are higher than those observed when the inner weld is completed first (Case A), with a difference of approximately 150 MPa.

- (4)

- From the perspective of fatigue performance, the welding sequence involving the prior completion of weld passes near the inner surface, followed by the remaining welds, proves more effective in optimizing the distribution and magnitude of residual stresses. Therefore, this sequence of weld beads is recommended as the preferred strategy for controlling residual stress in the beam structure and enhancing its fatigue resistance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| density | |

| specific heat | |

| thermal conductivity | |

| heat generation rate of the internal heat source | |

| convective heat loss | |

| convective heat transfer coefficient | |

| ambient temperature | |

| initial temperature of the workpiece | |

| radiative heat loss | |

| emissivity coefficient | |

| Stefan–Boltzmann constant | |

| heat flux densities of the front portions | |

| heat flux densities of the rear portions | |

| , | distribution coefficients |

| v | welding speed |

| t | welding start time |

| arc voltage | |

| welding current | |

| , , b, c | shape parameters of the heat source |

| heat flux density per unit volume and per unit time | |

| assumed heating duration | |

| η | arc efficiency coefficient |

| L | total length of the welding line |

| V | total volume of the weld metal |

| total strain | |

| elastic strain | |

| plastic strain | |

| thermal strain |

References

- Wang, B. Overall Design and Bogie of High-Speed EMU, 2nd ed.; Southwest Jiaotong University Press: Chengdu, China, 2014; p. 143. (In Chinese) [Google Scholar]

- Gao, Y. Research on Load Characteristics of Bogie Frame of High-Speed EMU in Severe Cold Conditions. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2017. (In Chinese). [Google Scholar]

- Webster, G.A.; Ezeilo, A.N. Residual stress distributions and their influence on fatigue lifetimes. Int. J. Fatigue 2001, 23, 375–383. [Google Scholar] [CrossRef]

- Fang, X.Y.; Zhang, H.N.; Ma, D.W.; Wu, Z.J.; Huang, W. Influence of welding residual stress on subsurface fatigue crack propagation of rail. Eng. Fract. Mech. 2022, 271, 108642. [Google Scholar] [CrossRef]

- Hu, W.; Lu, F.; Zhang, X. Research on Residual Stress of Welding for High-Speed EMU Bogie Frame (Part I). Weld. Technol. 2018, 47, 71–74. (In Chinese) [Google Scholar]

- Yu, Z.; Hu, W.; Liu, Y.; Yang, X. Optimization of Welding Sequence for the Beam Tube of EMU Based on Numerical Simulation. Weld. Technol. 2018, 47, 42–46. (In Chinese) [Google Scholar]

- Kendall, O.; Paradowska, A.; Abrahams, R.; Reid, M.; Qiu, C.; Mutton, P.; Yan, W. Residual stress measurement techniques for metal joints, metallic coatings and components in the railway industry: A review. Materials 2022, 16, 232. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Liu, Q.; Hu, M.; Li, K.; Cai, Z. Effect of welding sequence and the transverse geometry of the weld overlay on the distribution of residual stress in the weld overlay repair of T23 tubes. Metals 2021, 11, 568. [Google Scholar] [CrossRef]

- Deng, D.; Kiyokuni, S. Influence of welding sequence on residual stress distribution in thick plate welding. Trans. China Weld. Inst. 2011, 32, 55–58. (In Chinese) [Google Scholar]

- Deng, D. Influence of deposition sequence on welding residual stress and deformation in an austenitic stainless steel J-groove welded joint. Mater. Des. 2013, 49, 1022–1033. [Google Scholar] [CrossRef]

- Zheng, X.; Li, D.; Liao, W.; Zhang, H. Residual Stress and Fatigue Strength Analysis of Stiffener Welds of Steel-Plate Composite Girder Bridge Considering Welding Sequence. Buildings 2024, 14, 1801. [Google Scholar] [CrossRef]

- Radaj, D. Heat Effects of Welding; Springer: New York, NY, USA, 1992; pp. 23–26. [Google Scholar]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Pu, X.; Zhang, C.; Li, S.; Deng, D. Simulating welding residual stress and deformation in a multi-pass butt-welded joint considering balance between computing time and prediction accuracy. Int. J. Adv. Manuf. Technol. 2017, 93, 2215–2226. [Google Scholar] [CrossRef]

- Deng, D. FEM prediction of welding residual stress and distortion in carbon steel considering phase transformation effects. Mater. Des. 2009, 30, 359–366. [Google Scholar] [CrossRef]

- LU, S.; Wang, H.; Dai, P.; Deng, D. Effect of creep on prediction accuracy and calculating efficiency of residual stress in post weld heat treatment. Acta Met. Sin 2019, 55, 1581–1592. Available online: https://www.ams.org.cn/EN/10.11900/0412.1961.2019.00208 (accessed on 10 August 2025).

- ISO 16834:2025; Welding Consumables—Wire Electrodes, Wires, Rods and Deposits for Gas Shielded Arc Welding of High Strength Steels—Classification. International Organization for Standardization: Geneva, Switzerland, 2025.

- ISO 5178:2019; Destructive Tests on Welds in Metallic Materials—Longitudinal Tensile Test on Weld Metal in Fusion Welded Joints. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 6892-2:2018; Metallic Materials—Tensile Testing—Part 2: Method of Test at Elevated Temperature. International Organization for Standardization: Geneva, Switzerland, 2018.

- da Silva, L.O.P.; Lima, T.N.; Júnior, F.M.d.S.; Callegari, B.; Folle, L.F.; Coelho, R.S. Heat-Affected Zone Microstructural Study via Coupled Numerical/Physical Simulation in Welded Superduplex Stainless Steels. Crystals 2024, 14, 204. [Google Scholar] [CrossRef]

- Deng, D.; Kiyoshima, S. FEM prediction of welding residual stresses in a SUS304 girth-welded pipe with emphasis on stress distribution near weld start/end location. Comput. Mater. Sci. 2010, 50, 612–621. [Google Scholar] [CrossRef]

- Coules, H.E. Contemporary approaches to reducing weld induced residual stress. Mater. Sci. Technol. 2013, 29, 4–18. [Google Scholar] [CrossRef]

- McClung, R.C. A literature survey on the stability and significance of residual stresses during fatigue. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 173–205. [Google Scholar] [CrossRef]

- Macdonald, K. Fracture and Fatigue of Welded Joints and Structures; Elsevier: Leiden, The Netherlands, 2011; pp. 124–128. [Google Scholar]

- Gkatzogiannis, S. Finite Element Simulation of Residual Stresses from Welding and High Frequency Hammer Peening; KIT Scientific Publishing: Karlsruhe, Germany, 2022; pp. 15–20. [Google Scholar]

| Materials | C | Si | Mn | Cr | Ni | Cu | Ti |

|---|---|---|---|---|---|---|---|

| SMA490BW | 0.080 | 0.22 | 1.35 | 0.51 | 0.13 | 0.32 | |

| Weld metal | 0.056 | 0.39 | 1.03 | 0.80 | 0.35 | 0.028 |

| Weld Pass | Welding Current [A] | Voltage [V] | Welding Speed [cm·min−1] | Heat Input [kJ·cm−1] |

|---|---|---|---|---|

| 1 | 170 | 22 | 37 | 6.1 |

| 2 | 200 | 24 | 30 | 9.6 |

| 3 | 240 | 26 | 24 | 15.6 |

| 4 | 240 | 26 | 21.6 | 17.3 |

| Case | Mesh Model | Heat Source Model |

|---|---|---|

| CASE1 | 3D | Moving Heat Source |

| CASE2 | 2D Plane Strain | Instantaneous Heat Source |

| Pass | CASE1 | CASE2 | ||||

|---|---|---|---|---|---|---|

| [W/mm3] | [s] | |||||

| 1 | 1.3 | 1.3 | 1.6 | 1.6 | 5.81 | 1 |

| 2 | 4.0 | 4.5 | 4.3 | 5.8 | 18.1 | 2 |

| 3 | 5.0 | 6.0 | 6.5 | 6.8 | 10.65 | 2 |

| 4 | 5.0 | 6.0 | 8.0 | 5.3 | 11.65 | 2 |

| Case | Mesh Model | Heat Source Model | Calculation Time | Stress Field Accuracy | |

|---|---|---|---|---|---|

| Transverse | Longitudinal | ||||

| CASE1 | 3D | Moving Heat Source | 14 h 40 min | Moderate | Better |

| CASE2 | 2D Plane Strain | Instantaneous Heat Source | 21 min | Acceptable | Good |

| Weld Pass | Welding Current [A] | Voltage [V] | Welding Speed [cm·min−1] | Heat Input [kJ·cm−1] |

|---|---|---|---|---|

| B1 | 220 | 22 | 36 | 8.1 |

| B2 | 250 | 25 | 33 | 11.4 |

| F1 | 270 | 27 | 54 | 8.1 |

| F2 | 290 | 29 | 42 | 12.0 |

| F3 | 290 | 29 | 39 | 12.9 |

| F4 | 250 | 25 | 30 | 12.5 |

| Case | Welding Sequence | Description |

|---|---|---|

| Case A | B1L→B2L→F1L→F2L→F3L→F4L→ B1R→B2R→F1R→F2R→F3R→F4R | Welding on each side, first the inner weld bead then the outer weld bead |

| Case B | B1L→B2L→B1R→B2R→F1L→F2L→ F3L→F4L→F1R→F2R→F3R→F4R | Alternating welding on both sides, first the inner weld bead then the outer weld bead |

| Case C | F1L→F2L→F3L→F4L→B1L→B2L→ F1R→F2R→F3R→F4R→B1R→B2R | Welding on each side, first the outer weld bead then the inner weld bead |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Mao, Z.; Zhou, C.; Yang, Z.; Wang, Y.; Deng, D. An Investigation into the Influence of Weld Bead Sequence on Residual Stress Distribution in a High-Speed Train Bogie Beam Using Thermo-Elastic–Plastic Finite Element Analysis. Metals 2025, 15, 1225. https://doi.org/10.3390/met15111225

Wang G, Mao Z, Zhou C, Yang Z, Wang Y, Deng D. An Investigation into the Influence of Weld Bead Sequence on Residual Stress Distribution in a High-Speed Train Bogie Beam Using Thermo-Elastic–Plastic Finite Element Analysis. Metals. 2025; 15(11):1225. https://doi.org/10.3390/met15111225

Chicago/Turabian StyleWang, Gaojian, Zhixu Mao, Chenyang Zhou, Zuoshi Yang, Yifeng Wang, and Dean Deng. 2025. "An Investigation into the Influence of Weld Bead Sequence on Residual Stress Distribution in a High-Speed Train Bogie Beam Using Thermo-Elastic–Plastic Finite Element Analysis" Metals 15, no. 11: 1225. https://doi.org/10.3390/met15111225

APA StyleWang, G., Mao, Z., Zhou, C., Yang, Z., Wang, Y., & Deng, D. (2025). An Investigation into the Influence of Weld Bead Sequence on Residual Stress Distribution in a High-Speed Train Bogie Beam Using Thermo-Elastic–Plastic Finite Element Analysis. Metals, 15(11), 1225. https://doi.org/10.3390/met15111225