- Article

Pattern Recognition of Hazardous Gas Leak Monitoring Data Based on Field Sensors

- Jian Xi,

- Lei Guan and

- Xiaoguang Zhu

- + 2 authors

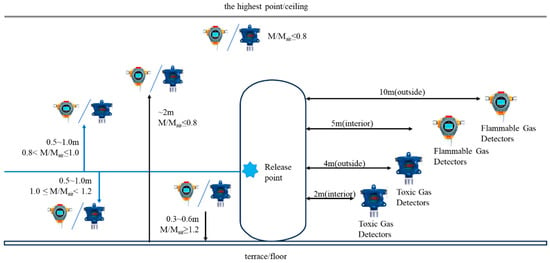

Hazardous gas leaks are a major trigger of chemical incidents. If not handled in time, they can easily lead to secondary disasters such as fires and explosions. In recent years, with the construction of hazardous chemical monitoring and early-warning systems in China, large volumes of field operating data from flammable and toxic gas sensors have been accumulated, providing a data foundation for leak-pattern studies grounded in real-world scenarios. In this study, 56 leak samples verified by site feedback were selected. Time-aware interpolation and Z-score normalization were used for preprocessing, and time-series features—including standard deviation of first differences, autocorrelation coefficients, and frequency-domain energy—were extracted. Leak patterns were then identified using two unsupervised approaches: K-Means clustering and a 1D-CNN autoencoder. Results show that K-Means effectively distinguishes macro-patterns such as sustained leaks, instantaneous leaks, fluctuating leaks, and interrupted leaks, while the autoencoder demonstrates stronger capability in extracting temporal features, revealing leak evolution and transition characteristics. The two methods are complementary and together provide a viable route to developing an end-to-end model for leak scenario identification and risk discrimination. This work not only verifies the feasibility of conducting leak-pattern recognition using real GDS data but also offers technical guidance for the intelligent upgrading of hazardous chemical monitoring and early-warning systems.

28 December 2025