- Article

Distinguishing Process Faults from Model Drift Through Variable Contribution Analysis: A Novel Perspective on Anomaly Diagnosis

- Thiago K. Anzai and

- José Carlos Costa da Silva Pinto

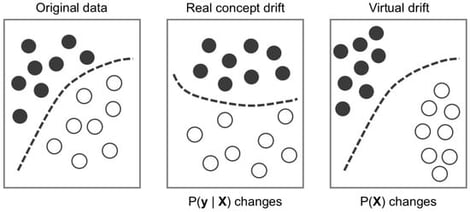

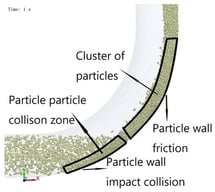

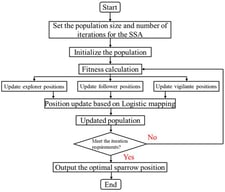

Conventional anomaly diagnosis methods often treat process faults and model drift as distinct, independent issues: anomalous behavior is attributed to process problems, whereas drift is seen as a secondary concern. This traditional perspective neglects the fact that, when a fault is detected, the first diagnosis that must be provided regards the source of the observed deviation: a process fault or a model malfunction. In this context, the present study tackles this fundamental diagnosis problem, proposing that effective anomaly diagnosis should distinguish process faults from model inadequacies originating from operational changes. To address this challenge, the Nearest Normal Value (NNV) contribution analysis technique was developed to quantify individual variable contributions through counterfactual analysis. Unlike conventional diagnostic methods that rely on static references, the NNV technique provides contribution profiles that characterize the operational state dynamically. The methodology was validated using three distinct datasets, including actual operational data from an oil production system. On real data, the normalized dispersion index decreased from 0.92 to 0.58 during a documented fault (37% change), whereas it changed from 0.76 to 0.63 during an operating mode shift (17% change), showing, thus, distinct contribution signatures for faults versus drift-related regime changes. The findings suggest that incorporating the proposed approach into anomaly diagnosis systems could reduce false alarms and improve diagnostic accuracy in dynamic industrial environments where operating conditions evolve over time.

7 March 2026