Journal Description

Journal of Composites Science

Journal of Composites Science

is an international, peer-reviewed, open access journal on the science and technology of composites, published monthly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, ESCI (Web of Science), Inspec, CAPlus / SciFinder, and other databases.

- Journal Rank: JCR - Q2 (Materials Science, Composites) / CiteScore - Q1 (Engineering (miscellaneous))

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 15.9 days after submission; acceptance to publication is undertaken in 3.9 days (median values for papers published in this journal in the second half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

Impact Factor:

3.7 (2024);

5-Year Impact Factor:

3.9 (2024)

Latest Articles

Microbial Adhesion on 3D-Printed Composite Polymers Used for Orthodontic Clear Aligners: A Systematic Review and Meta-Analysis of In Vitro Evidence

J. Compos. Sci. 2026, 10(1), 26; https://doi.org/10.3390/jcs10010026 - 6 Jan 2026

Abstract

Objectives: This systematic review and meta-analysis aimed to evaluate microbial adhesion and biofilm formation on additively manufactured composite-based orthodontic clear aligners compared with thermoformed aligners and other conventional polymeric materials. The influence of material composition, surface roughness, post-processing parameters, and cleaning protocols on

[...] Read more.

Objectives: This systematic review and meta-analysis aimed to evaluate microbial adhesion and biofilm formation on additively manufactured composite-based orthodontic clear aligners compared with thermoformed aligners and other conventional polymeric materials. The influence of material composition, surface roughness, post-processing parameters, and cleaning protocols on microbial colonization was also assessed. Methods: A comprehensive search of PubMed, EMBASE, Scopus, Web of Science, and the Cochrane Library was conducted up to September 2025. Only in vitro studies investigating microbial adhesion, biofilm biomass, or microbiome changes on three-dimensional (3D)-printed aligner composites were included. Primary outcomes consisted of colony-forming units (CFU), optical density (OD) from crystal violet assays, viable microbial counts, and surface roughness. Risk of bias was assessed using the RoBDEMAT tool. Data were narratively synthesized, and a random-effects meta-analysis was performed for comparable datasets. Results: Five studies fulfilled the inclusion criteria, of which two in vitro studies were eligible for meta-analysis. Microbial adhesion and biofilm accumulation were influenced by the manufacturing technique, composite resin formulation, and surface characteristics. Certain additively manufactured aligners exhibited smoother surfaces and reduced bacterial adhesion compared with thermoformed controls, whereas others with increased surface roughness showed higher biofilm accumulation. Incorporating bioactive additives such as chitosan nanoparticles reduced Streptococcus mutans biofilm formation without compromising material properties. The meta-analysis, based on two in vitro studies, demonstrated higher OD values for bacterial biofilm on 3D-printed aligners compared with thermoformed aligners, indicating increased biofilm biomass (p < 0.05), but not necessarily viable bacterial load. Conclusions: Microbial adhesion and biofilm formation on 3D-printed composite clear aligners are governed by resin composition, additive manufacturing parameters, post-curing processes, and surface finishing. Although certain 3D-printed materials display antibacterial potential, the limited number of studies restricts the generalizability of these findings. Clinical Significance: Optimizing composite formulations for 3D printing, alongside careful post-curing and surface finishing, may help reduce microbial colonization. Further research is required before translating these findings into definitive clinical recommendations for clear aligner therapy.

Full article

(This article belongs to the Special Issue Additive Manufacturing of Advanced Composites, 2nd Edition)

Open AccessReview

Challenges in Tensile Testing of Fibre-Reinforced Polymer Composites at Room and Cryogenic Temperatures: A Review

by

Jared J. Ng, John E. Cater and Mark P. Staiger

J. Compos. Sci. 2026, 10(1), 25; https://doi.org/10.3390/jcs10010025 - 6 Jan 2026

Abstract

Fibre-reinforced polymer (FRP) composites are key materials used in the fabrication of lightweight and high-performance structures. Thus, a comprehensive understanding of material performance is required to ensure the safe and reliable operation of FRPs across a broad range of temperatures. For example, the

[...] Read more.

Fibre-reinforced polymer (FRP) composites are key materials used in the fabrication of lightweight and high-performance structures. Thus, a comprehensive understanding of material performance is required to ensure the safe and reliable operation of FRPs across a broad range of temperatures. For example, the application of FRPs in cryogenic environments, especially for lightweight cryogenic fuel storage, is gaining considerable attention. However, obtaining accurate tensile property measurements for FRPs can be challenging, as failure of the test specimen near the grips is common, even at room temperature. Under cryogenic conditions, the increased complexity of the experimental setup further reduces the accuracy and reproducibility of the tensile properties. This paper reviews standard test methods for tensile testing of FRPs and discusses the challenges of performing tensile tests in both room and cryogenic environments. Key experimental design considerations and directions for future research are identified to support the development of reliable tensile test methods that yield accurate and consistent measurements of FRP material properties.

Full article

(This article belongs to the Collection Editorial Board Members’ Collection Series: Fibre Composite Materials)

Open AccessArticle

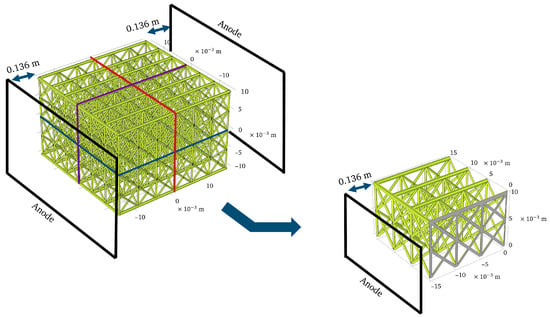

Finite Element Simulation and Experimental Validation of Nickel Coating Thickness Distribution in Electroplated FCCZ Lattice Structures

by

Marco Noack, Robert Maier and Eckhard Kirchner

J. Compos. Sci. 2026, 10(1), 24; https://doi.org/10.3390/jcs10010024 - 6 Jan 2026

Abstract

Metal electrodeposition on additively manufactured lattice structures enables the creation of functionally graded hybrid components with enhanced mechanical properties. However, predicting coating thickness distribution remains challenging due to complex current density fields in intricate geometries. This study develops and validates a finite element

[...] Read more.

Metal electrodeposition on additively manufactured lattice structures enables the creation of functionally graded hybrid components with enhanced mechanical properties. However, predicting coating thickness distribution remains challenging due to complex current density fields in intricate geometries. This study develops and validates a finite element electrochemical simulation model for predicting coating thickness distribution in lattice structures using COMSOL Multiphysics 6.1. The model incorporates Butler–Volmer electrode kinetics, mass transport limitations, and the Laplace equation for current distribution. Experimental validation was performed using FCCZ lattice structures electrochemically coated with nickel for 24 h at 200 A/m2. CT scanning analysis revealed mean absolute errors of 5.25% between simulation and experiment after model calibration. The validated model successfully captures the exponential coating gradient from exposed edges to internal regions and provides a robust predictive tool for coating thickness distribution, which is essential for the effective design and optimization of electrochemically metallized lattice structures.

Full article

(This article belongs to the Special Issue Lattice Structures)

►▼

Show Figures

Figure 1

Open AccessArticle

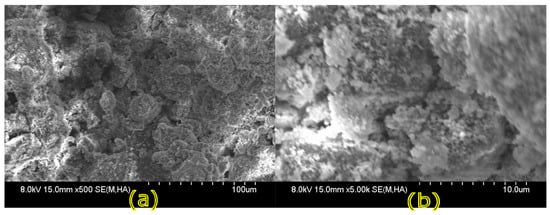

Development of Nanostructured Composite Coating with Antibacterial Properties on Anodized Stainless Steel

by

Cristiana Alexandra Crãciun, Camelia Ungureanu, Oana Brîncoveanu, Elena Iuliana Bîru, Cristian Pîrvu and Cristina Dumitriu

J. Compos. Sci. 2026, 10(1), 23; https://doi.org/10.3390/jcs10010023 - 5 Jan 2026

Abstract

Copper has become more important owing to its eco-friendliness and persistent efficacy against infections. Furthermore, copper has benefits such as safety in use and durability. This study aimed to develop and assess the antibacterial efficacy of stainless steel coated with a composite layer,

[...] Read more.

Copper has become more important owing to its eco-friendliness and persistent efficacy against infections. Furthermore, copper has benefits such as safety in use and durability. This study aimed to develop and assess the antibacterial efficacy of stainless steel coated with a composite layer, which is nanostructured and incorporates copper, to create antibacterial surfaces with good adherence and good corrosion resistance. The composite coating was produced using anodic oxidation, with an external copper layer applied via pulse electroplating. The homogenous cauliflower-like covering showed important characteristics, like increased surface roughness, boosted surface free energy, reduced contact angle, and higher hardness. Additionally, the adherence between the composite covering and the substrate was exceptional. Electrochemical experiments indicated aggressive corrosion behavior in chloride-containing settings. Antibacterial tests were conducted on four prevalent bacterial strains: Staphylococcus aureus, Escherichia coli, Pseudomonas aeruginosa, and Salmonella typhimurium—microorganisms often linked to healthcare and environmental pollution. The coating exhibited enhanced antibacterial efficacy relative to untreated steel and anodized steel. Results indicated that the composite coating is an effective and possibly cost-efficient method for controlling the surface proliferation of the mentioned pathogens.

Full article

(This article belongs to the Special Issue Metal Composites, Volume II)

►▼

Show Figures

Figure 1

Open AccessArticle

Mechanical and Microstructural Performance of Fly Ash-Based Geopolymer Mortar Activated by Silica Fume-Derived Sodium Silicate

by

Navid Pourdolat, Prakriti Raizada and Rishi Gupta

J. Compos. Sci. 2026, 10(1), 22; https://doi.org/10.3390/jcs10010022 - 5 Jan 2026

Abstract

The construction industry faces growing pressure to adopt sustainable materials due to the high CO2 emissions associated with ordinary Portland cement (OPC) production. Geopolymers synthesized from industrial by-products such as fly ash offer a promising low-carbon alternative. However, the extensive use of

[...] Read more.

The construction industry faces growing pressure to adopt sustainable materials due to the high CO2 emissions associated with ordinary Portland cement (OPC) production. Geopolymers synthesized from industrial by-products such as fly ash offer a promising low-carbon alternative. However, the extensive use of commercial sodium silicate (SSC) as an activator remains constrained by its high cost and energy-intensive manufacturing. This study investigates a silica fume-derived sodium silicate alternative (SSA) combined with NaOH as a more sustainable activator for fly ash-based geopolymer mortar. Mortars were prepared with alkali activator-to-precursor (AA/P) ratios of 0.7 and 0.5 and cured at 65 °C and 80 °C. SSA-based mixes exhibited comparable flowability to SSC-based mortars, with slightly longer setting times making them favorable for placement. Mechanical tests showed the superior performance of SSA systems, with AS0.7-65 achieving the highest compressive strength and AS0.7-80 demonstrating greater flexural and tensile strength. Microstructural analyses (SEM, EDX, ATR-FTIR) revealed denser matrices and enhanced sodium aluminosilicate hydrate (N-A-S-H) and calcium-rich N(C)-A-S-H gel formation. Economic assessment indicated approximately 30% cost reduction and a modest (~2%) decrease in CO2 emissions. These findings highlight SSA as a technically viable and sustainable activator for next-generation geopolymer construction.

Full article

(This article belongs to the Special Issue Composite Materials for Civil Engineering Applications)

►▼

Show Figures

Figure 1

Open AccessArticle

Monitoring Microcracking and Leakage of a Hydrogen Tank Using Fiber Optics and the Thermal Expansion

by

Miguel González del Val, Jose Manuel Martinez Olmo, Ángela Salazar Castaman, Fernando Cabrerizo and Malte Frovel

J. Compos. Sci. 2026, 10(1), 21; https://doi.org/10.3390/jcs10010021 - 5 Jan 2026

Abstract

The structural health monitoring (SHM) of microcracking in cryogenic hydrogen storage tanks is a critical aspect for ensuring long-term safety and operational reliability. Early detection of such damage can prevent leaks and structural failure, making the development of sensitive, non-intrusive diagnostic techniques essential.

[...] Read more.

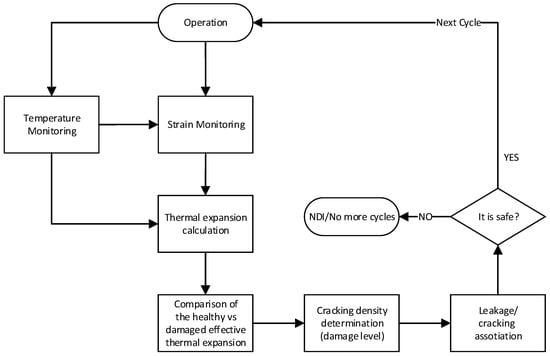

The structural health monitoring (SHM) of microcracking in cryogenic hydrogen storage tanks is a critical aspect for ensuring long-term safety and operational reliability. Early detection of such damage can prevent leaks and structural failure, making the development of sensitive, non-intrusive diagnostic techniques essential. In this study, a series of experimental tests were conducted to evaluate the feasibility of using thermal expansion behavior as a potential SHM indicator. The material under investigation was a carbon–epoxy composite laminate (M21/IMA) with a [0/90]2s layup, representative of those used in cryogenic aerospace applications. Artificial microcracks were introduced at cryogenic temperatures (approximately 20 K), followed by thermal expansion and gas permeability measurements. The objective was to explore the correlation between induced damage and measurable physical changes, with the aim of assessing the viability of this approach for future SHM strategies in liquid hydrogen tank systems.

Full article

(This article belongs to the Topic Advanced Carbon Fiber Reinforced Composite Materials, Volume II)

►▼

Show Figures

Figure 1

Open AccessArticle

Properties of Composite Magnetic Filaments for 3D Printing, Produced Using SmCo5/Fe Exchange-Coupled Nanocomposites

by

Razvan Hirian, Roxana Dudric, Rares Bortnic, Florin Popa, Sergiu Macavei, Cristian Leostean and Viorel Pop

J. Compos. Sci. 2026, 10(1), 20; https://doi.org/10.3390/jcs10010020 - 5 Jan 2026

Abstract

Magnetic filaments for fused deposition modeling, 3D printing, were produced by depositing polyamide 11 (PA11), by liquid–liquid phase separation and precipitation, onto exchange-coupled nanocomposite magnetic powders, SmCo5 + 20 wt% Fe produced by mechanical milling and subsequent annealing. The produced filaments have

[...] Read more.

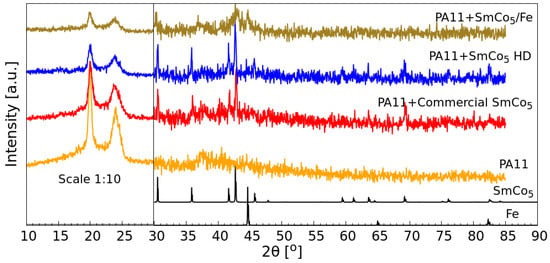

Magnetic filaments for fused deposition modeling, 3D printing, were produced by depositing polyamide 11 (PA11), by liquid–liquid phase separation and precipitation, onto exchange-coupled nanocomposite magnetic powders, SmCo5 + 20 wt% Fe produced by mechanical milling and subsequent annealing. The produced filaments have good mechanical properties, a tensile strength of 32 MPa and a maximum elongation of slightly over 40%. The filaments also present good magnetic properties: a high coercive field of 1 T at 300 K and nearly double the saturation magnetization and remanence, compared to filaments made by depositing PA11 on commercial SmCo5 and recycled SmCo5 powders and four times the energy product. This work shows that magnetic filaments made by encapsulating exchange-coupled magnetic nanocomposite powders in PA11 may be a viable option for the production of 3D-printed isotropic bonded magnets, as the high energy product and remanence especially can lead to a reduction in both magnetic powder quantity and rare earth elements required for high performance magnetic filaments. This in turn may reduce costs and improve sustainability.

Full article

(This article belongs to the Special Issue Recent Progress in Hybrid Composites)

►▼

Show Figures

Figure 1

Open AccessArticle

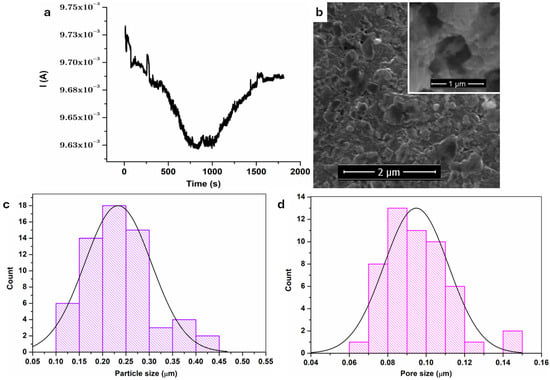

Functional Nanocomposites with a Positive Temperature Coefficient of Resistance Based on Carbon Nanotubes Synthesized by Laser Ablation

by

Alexandr V. Shchegolkov, Aleksei V. Shchegolkov, Ivan D. Parfimovich, Vladimir V. Kaminskii and Mariya Y. Putyrskaya

J. Compos. Sci. 2026, 10(1), 19; https://doi.org/10.3390/jcs10010019 - 4 Jan 2026

Abstract

This study presents the development of high-performance polymer composites designed for operation under extreme conditions. The research aimed to investigate the influence of laser ablation parameters on the synthesis of carbon nanotubes (CNTs) and to evaluate their efficacy as electrically conductive fillers. CNTs

[...] Read more.

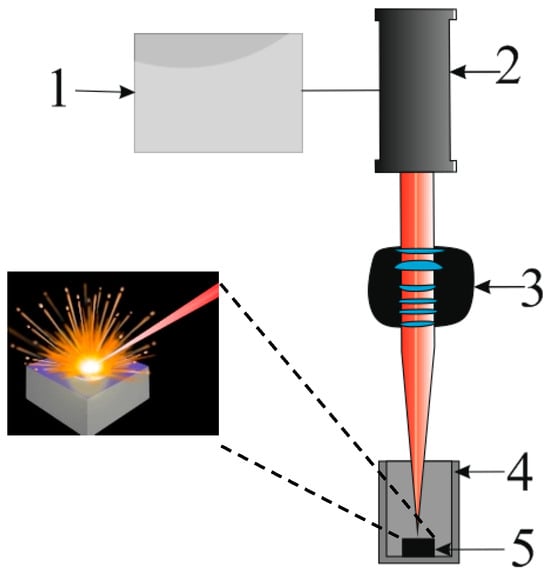

This study presents the development of high-performance polymer composites designed for operation under extreme conditions. The research aimed to investigate the influence of laser ablation parameters on the synthesis of carbon nanotubes (CNTs) and to evaluate their efficacy as electrically conductive fillers. CNTs were synthesized using a 200 W laser ablation setup, with the graphite-to-ferrocene ratio in the target varied from 3:1 to 8:1 at a constant pulse duration of 0.1 s. Comprehensive analysis by Raman spectroscopy and scanning electron microscopy (SEM) demonstrated that this method enables the production of nanotubes with controlled morphology and diameters ranging from 20 to 70 nm. It was established that varying the target composition serves as an effective tool for managing the specific surface area and structure of the synthesized CNTs. The obtained nanotubes exhibited high efficiency in forming conductive networks within polymer matrices (exemplified by silicone), thereby imparting the composites with tailored electrophysical properties. A key finding of the work is the identified dependence of the positive temperature coefficient of resistance (PTCR) of the composites on the morphology and composition of the carbon filler. This property opens prospects for creating “smart” self-regulating heating elements based on the developed materials, including for anti-icing systems. Thus, the study results confirm that the targeted synthesis of CNTs via laser ablation and their subsequent incorporation into polymer matrices constitutes an effective strategy for expanding the functional capabilities of composite materials in modern technical applications.

Full article

(This article belongs to the Section Nanocomposites)

►▼

Show Figures

Figure 1

Open AccessArticle

Eco-Friendly Synthesis of ZnO-Based Nanocomposites Using Haloxylon and Calligonum Extracts for Enhanced Photocatalytic Degradation of Methylene Blue

by

Elham A. Alzahrani, Sabri Ouni, Mohamed Bouzidi, Abdullah S. Alshammari, Ahlam F. Alshammari, Rizwan Ali, Odeh A. O. Alshammari, Naim Belhaj Mohamed and Noureddine Chaaben

J. Compos. Sci. 2026, 10(1), 18; https://doi.org/10.3390/jcs10010018 - 4 Jan 2026

Abstract

This study presents a green synthesis of zinc oxide (ZnO) nanoparticles (NPs) capped with Haloxylon (P1) and Calligonum (P2) extracts. The use of plant-derived biomolecules as natural capping agents offers an environmentally friendly strategy to tune surface chemistry and to enhance the photocatalytic

[...] Read more.

This study presents a green synthesis of zinc oxide (ZnO) nanoparticles (NPs) capped with Haloxylon (P1) and Calligonum (P2) extracts. The use of plant-derived biomolecules as natural capping agents offers an environmentally friendly strategy to tune surface chemistry and to enhance the photocatalytic behavior of ZnO NPs. ZnO/plant extracts nanocomposites were prepared via a hydrothermal route and systematically characterized using transmission electron microscopy (TEM), X-ray diffraction (XRD), UV–Vis spectroscopy, and photoluminescence (PL), followed by evaluation of their photocatalytic performance against methylene blue (MB) under UV irradiation. XRD confirmed a wurtzite structure with crystallite sizes ranging from 8.95 to 10.93 nm, while PL spectra indicated an improved charge carrier separation in extract-capped ZnO. The characteristics and pollutant removal performance of the greenly synthesized ZnO composites were compared with those of a chemically synthesized ZnO nanoparticles reference sample. Adsorption tests under dark conditions revealed a strong difference between the materials: ZnO-P1 removed 48% of MB, whereas ZnO-P2 adsorbed only 7%, demonstrating a much higher affinity of the Haloxylon-derived surface groups toward MB. In comparison, the chemically synthesized ZnO exhibited an adsorption capacity of 54%, confirming that the Haloxylon-mediated surface provides a comparable efficient dye uptake prior to irradiation. After UV irradiation, all samples exhibited a photocatalytic activity with a total MB removal reached ~59% for the reference ZnO sample and ~53% for ZnO-P1 compared to about 13% for the ZnO-P2. Kinetic analysis also confirmed that ZnO-P1 possessed a high degradation rate constant, indicating a better intrinsic photocatalytic efficiency in addition to the strong adsorption contribution. The enhanced performance of plant-capped ZnO is attributed to phytochemical-induced surface defects, which facilitated charge separation and boosted the generation of reactive oxygen species (ROS). Overall, these results demonstrate that Haloxylon and Calligonum extracts are effective and sustainable capping agents, providing a low-cost, eco-friendly approach for designing ZnO nanocatalysts composites with promising applications in wastewater treatment and environmental remediation.

Full article

(This article belongs to the Special Issue Composites: A Sustainable Material Solution, 2nd Edition)

►▼

Show Figures

Graphical abstract

Open AccessArticle

Finite Element-Based Methodology for the Evaluation of the Flexural Properties of Cement-Based Nanocomposites

by

Stylianos Anastopoulos, Faidra Givannaki, Paraskevas Papanikos, Zoi S. Metaxa and Nikolaos D. Alexopoulos

J. Compos. Sci. 2026, 10(1), 17; https://doi.org/10.3390/jcs10010017 - 2 Jan 2026

Abstract

The main goal of the present article was to develop a methodology for the calculation of the flexural properties of a cement-based matrix with different multi-walled carbon nanotubes’ (CNTs) volume fraction as a reinforcement at early age. The homogenization tool of the ANSA

[...] Read more.

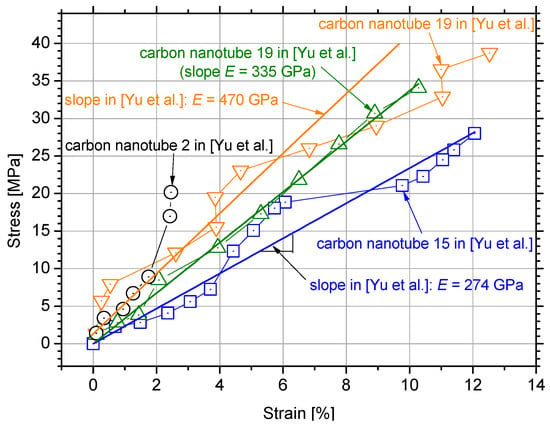

The main goal of the present article was to develop a methodology for the calculation of the flexural properties of a cement-based matrix with different multi-walled carbon nanotubes’ (CNTs) volume fraction as a reinforcement at early age. The homogenization tool of the ANSA® software package was exploited for the modelling of the inclusion geometries in a cubic matrix and for mesh generation. A Representative Volume Element (RVE) was constructed with either random orientation tensor algorithm or periodic geometry algorithm tools and for different concentrations of the nano-reinforcement. Finite element modelling (FEM) of the pre-cracked specimens for flexural tests followed, and the numerical results were compared against the experimental ones. Different input parameters were considered, including the reinforcement Poisson’s ratio (νCNT) as well as the effective elastic modulus (ECNT) to predict the flexural behaviour of the nano-reinforced matrices. It was found that both parameters play a pivotal role for the numerical simulation and the best simulation results were obtained for CNTs’ effective elastic modulus ECNT = 470 GPa and Poisson’s ratio of νCNT = 0.10 values for the two (2) different investigated concentrations of carbon nanotubes (0.6 and 1.2%, respectively) in the cementitious matrix.

Full article

(This article belongs to the Section Nanocomposites)

►▼

Show Figures

Figure 1

Open AccessArticle

Degradation of Tensile Properties in CFRCM Composites Under Anodic Polarization: Role of Standardized Electrolyte Solutions

by

Miaochang Zhu, Yawen Zhang, Haorui Chen, Jun Deng and Chaoqun Zeng

J. Compos. Sci. 2026, 10(1), 16; https://doi.org/10.3390/jcs10010016 - 2 Jan 2026

Abstract

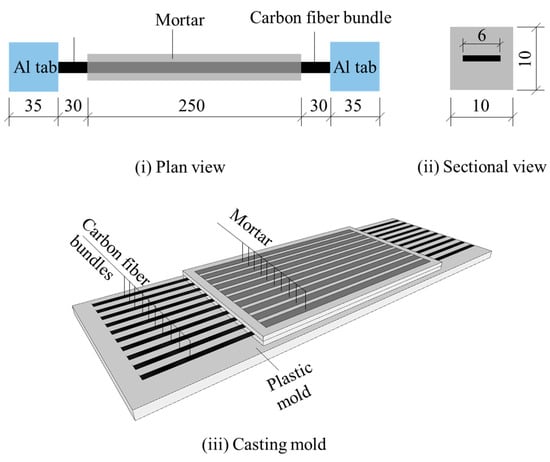

This study systematically investigates the tensile property degradation of Carbon Fabric-Reinforced Cementitious Matrix (CFRCM) composites under anodic polarization, explicitly comparing the effects of three standard-required electrolyte environments (NACE/ISO). CFRCM specimens were polarized for 20 days at current densities of 200 and 400 mA/m

[...] Read more.

This study systematically investigates the tensile property degradation of Carbon Fabric-Reinforced Cementitious Matrix (CFRCM) composites under anodic polarization, explicitly comparing the effects of three standard-required electrolyte environments (NACE/ISO). CFRCM specimens were polarized for 20 days at current densities of 200 and 400 mA/m2 in NaCl, NaOH, and simulated concrete pore solutions. Results reveal that anodic polarization significantly reduces peak tensile strength and post-cracking stiffness, with degradation severity dependent on the electrolyte type (NaCl > NaOH > Pore Solution). Crucially, comparative analysis demonstrates that the strength degradation of carbon fiber bundles embedded in the mortar matrix is more pronounced than that of bare bundles. This work provides essential durability data for CFRCM composites for integrated ICCP-Structural Strengthening systems.

Full article

(This article belongs to the Special Issue Composite Materials for Civil Engineering Applications)

►▼

Show Figures

Figure 1

Open AccessArticle

Cross-Property Relations for Continuous Fiber-Reinforced Ceramic Matrix Composites

by

Pu Li, Shouyi Wang, Wei Li, Chunling Zhao, Zhenhua Chen, Jinxin Dai, Shifeng Yuan, Haifeng Zhao and Jian Jiao

J. Compos. Sci. 2026, 10(1), 15; https://doi.org/10.3390/jcs10010015 - 2 Jan 2026

Abstract

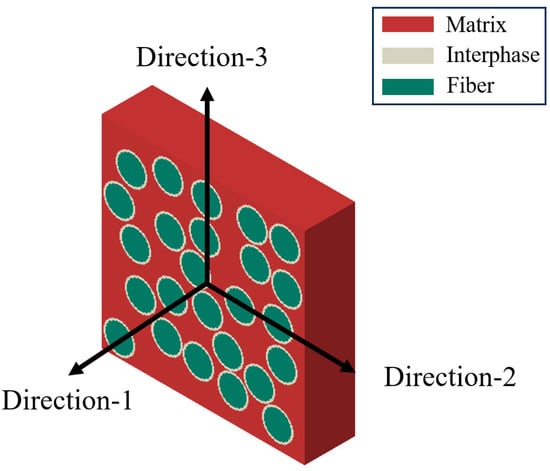

Continuous fiber-reinforced ceramic matrix composites (CFRCMCs) are extensively applied in high-temperature fields such as aerospace, energy, and transportation due to their superior mechanical and thermal properties. The explicit and numerical cross-property relations of CFRCMCs are established by integrating a generalized self-consistent scheme, effective-medium

[...] Read more.

Continuous fiber-reinforced ceramic matrix composites (CFRCMCs) are extensively applied in high-temperature fields such as aerospace, energy, and transportation due to their superior mechanical and thermal properties. The explicit and numerical cross-property relations of CFRCMCs are established by integrating a generalized self-consistent scheme, effective-medium conduction models, and finite element analysis. The results reveal that CFRCMCs with a fixed fiber–interphase volume ratio exhibit nearly linear cross-property relations. While the random distribution and diameter of fibers have minimal effects on these relations, a decrease in interphase properties causes the cross-property curves to shift downward. The cross-property relation surfaces for CFRCMCs with varying fiber–interphase volume ratios are validated through finite element analysis. In summary, cross-property relations in CFRCMCs facilitate the prediction of challenging-to-measure physical properties from more readily accessible parameters, substantially simplifying material characterization. This methodology not only optimizes experimental workflows but also delivers a rigorous theoretical framework for multiphysics applications, particularly in extreme thermo-mechanical environments where coupled properties are critical to performance.

Full article

(This article belongs to the Special Issue Editorial Board Members’ Collection Series: Modeling and Simulation of Composite Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Production and Remanufacturing of Vitrimer Matrix Composite Tubes

by

Alison Kennedy, Carineh Ghafafian and Steven Nutt

J. Compos. Sci. 2026, 10(1), 14; https://doi.org/10.3390/jcs10010014 - 2 Jan 2026

Abstract

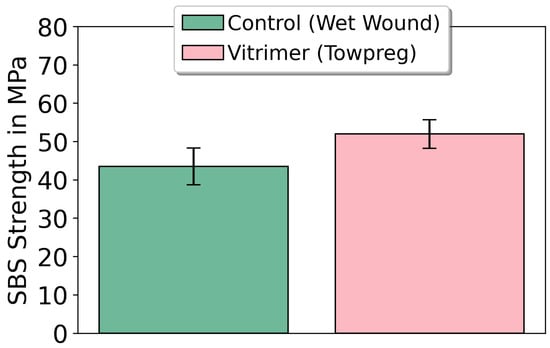

Composite tubes were filament-wound and cured using a vitrimer epoxy resin and carbon fiber (CF). The matrix was dissolved under mild conditions, and recovered continuous fiber tows were used to rewind a second-generation tube. Property retention and microstructural quality were evaluated by mechanical

[...] Read more.

Composite tubes were filament-wound and cured using a vitrimer epoxy resin and carbon fiber (CF). The matrix was dissolved under mild conditions, and recovered continuous fiber tows were used to rewind a second-generation tube. Property retention and microstructural quality were evaluated by mechanical tests and examination of polished sections. The vitrimer–matrix composite exhibited a higher short-beam shear strength compared to specimens wound with a traditional epoxy, typical of hydrogen tanks. Single-fiber testing revealed that CFs were not degraded by the recycling process. The remanufactured composite exhibited mechanical properties comparable to those of the first-generation material when normalized to the fiber volume fraction. This work demonstrates a circular manufacturing process that includes full fiber recovery and re-use for producing a second-generation filament-wound article.

Full article

(This article belongs to the Special Issue Composite Materials for Hydrogen Storage)

►▼

Show Figures

Figure 1

Open AccessArticle

A Temperature-Dependent Visco-Hyperelastic Constitutive Model for Carbon Fiber/Polypropylene Prepreg

by

Haochen Zhu and Mingrui Liu

J. Compos. Sci. 2026, 10(1), 12; https://doi.org/10.3390/jcs10010012 - 1 Jan 2026

Abstract

This study first heat-treats the surface of plain-woven carbon fibers to remove the surface sizing. The treated carbon fibers were then hot-pressed with polypropylene films to produce a carbon fiber/polypropylene prepreg. The resulting prepreg was subjected to uniaxial and off-axis tensile tests, providing

[...] Read more.

This study first heat-treats the surface of plain-woven carbon fibers to remove the surface sizing. The treated carbon fibers were then hot-pressed with polypropylene films to produce a carbon fiber/polypropylene prepreg. The resulting prepreg was subjected to uniaxial and off-axis tensile tests, providing fundamental data for constructing a constitute model for the carbon fiber/polypropylene prepreg. The relative error between the model predictions and experimental data is maintained within ±10%. Based on the experimental results, a temperature-dependent viscoelastic–hyperelastic constitutive model for carbon fiber/polypropylene is proposed. This model decomposes the unit volume strain energy function into four components: matrix isochoric deformation energy, fiber tensile strain energy, fiber–fiber shear strain energy, and fiber-matrix shear strain energy. The matrix energy is strain rate-dependent, exhibiting viscoelastic mechanical behavior. The material parameters of the constitutive model were identified by fitting the experimental data. The model was implemented in MATLABR2024a, and off-axis tensile tests were performed at temperatures ranging from 423 K to 453 K. Numerical simulations were compared with experimental results to validate the model. This work provides guidance for the development and validation of constitutive models for thermoplastic polypropylene prepregs.

Full article

(This article belongs to the Topic Advanced Composites Manufacturing and Plastics Processing, 2nd Volume)

►▼

Show Figures

Figure 1

Open AccessArticle

Improvement of Cyclic Stability of High-Capacity Lithium-Ion Battery Si/C Composite Anode Through Cu Current Collector Perforation

by

Shakhboz Sh. Isokjanov, Ainur B. Gilmanov, Yulia S. Vlasova, Alena I. Komayko, Olesia M. Karakulina and Valeriy V. Krivetskiy

J. Compos. Sci. 2026, 10(1), 11; https://doi.org/10.3390/jcs10010011 - 1 Jan 2026

Abstract

The adoption of silicon-graphite composites as anode materials for the next generation of lithium-ion batteries with enhanced specific capacity requires complex technological efforts in order to mitigate the problem of the quick performance fading of electrodes due to the mechanical degradation of materials.

[...] Read more.

The adoption of silicon-graphite composites as anode materials for the next generation of lithium-ion batteries with enhanced specific capacity requires complex technological efforts in order to mitigate the problem of the quick performance fading of electrodes due to the mechanical degradation of materials. The matter is currently being addressed in terms of electrolyte components, polymer binders, materials structure and morphology itself, as well as current collector design, which differ greatly in cost and scalability. The present work describes the efficacy of Cu foil perforation—a simple, low-cost, and easily scalable approach—as a means of Si/C composite anode performance stabilization during extensive charge-discharge cycling. The NMC||Si/C pouch-type full cells demonstrated over 90% of initial capacity retention after 100 charge-discharge cycles in the case of a 250 µm perforated Cu foil used as a current collector, compared to only 60% capacity left in the same conditions for plain Cu foil as an anode. The obtained result is related to the prevention of anode material delamination off the foil surface as a result of silicon expansion and contraction, which is achieved through the formation inter-penetrating metal-composite structure and the presence of “stitches”, connecting and holding both sides of the electrode tightly attached to the current collector.

Full article

(This article belongs to the Section Composites Applications)

►▼

Show Figures

Figure 1

Open AccessArticle

Effect of Paraffin Microcapsule and Carbon Nanotube Content on the Thermal Behavior of Thermoplastic Polyurethane Nanocomposites with Thermal Energy Storage Capability

by

Daniele Rigotti, Andrea Dorigato and Alessandro Pegoretti

J. Compos. Sci. 2026, 10(1), 10; https://doi.org/10.3390/jcs10010010 - 1 Jan 2026

Abstract

The development of multifunctional polymer composites capable of both heat conduction and latent heat storage is of great interest for advanced thermal management applications. In this work, thermoplastic polyurethane (TPU) nanocomposites containing microencapsulated paraffin-based phase change materials (PCMs) and multi-walled carbon nanotubes (MWCNTs)

[...] Read more.

The development of multifunctional polymer composites capable of both heat conduction and latent heat storage is of great interest for advanced thermal management applications. In this work, thermoplastic polyurethane (TPU) nanocomposites containing microencapsulated paraffin-based phase change materials (PCMs) and multi-walled carbon nanotubes (MWCNTs) were systematically investigated. The microstructure, thermal stability, specific heat capacity, thermal diffusivity and conductivity of these composites were analyzed as a function of the PCM and MWCNTs content. SEM observations revealed the homogeneous dispersion of PCM microcapsules and the presence of localized MWCNT aggregates in PCM-rich domains. Thermal diffusivity measurements indicated a monotonic decrease with increasing temperature for all compositions, from 0.097 mm2·s−1 at 5 °C to 0.091 mm2·s−1 at 25 °C for neat TPU, and from 0.186 mm2·s−1 to 0.173 mm2·s−1 for TPU with 5 vol.% MWCNTs. Distinct non-linear behavior was observed around 25 °C, i.e., in correspondence to the paraffin melting, where the apparent diffusivity temporarily decreased due to latent heat absorption. The trend of the thermal conductivity (λ) was determined by the competing effects of PCM and MWCNTs: PCM addition reduced λ at 25 °C from 0.162 W·m−1·K−1 (neat TPU) to 0.128 W·m−1·K−1 at 30 vol.% PCM, whereas the incorporation of 5 vol.% of MWCNTs increased λ up to 0.309 W·m−1·K−1. In PCM-containing nanocomposites, MWCNT networks efficiently bridged the polymer–microcapsule interfaces, creating continuous conductive pathways that mitigated the insulating effect of the encapsulated paraffin and ensured stable heat transfer even across the solid–liquid transition. A one-dimensional transient heat-transfer model confirmed that increasing the matrix thermal conductivity accelerates the melting of the PCM, improving the dynamic thermal buffering capacity of these materials. Therefore, these results underlined the potential of TPU/MWCNT/PCM composites as versatile materials for applications requiring both rapid heat dissipation and effective thermal management.

Full article

(This article belongs to the Special Issue Feature Papers in Journal of Composites Science in 2025)

►▼

Show Figures

Figure 1

Open AccessArticle

Interactive Influence of Recycled Concrete Aggregate and Recycled Steel Fibers on the Fresh and Hardened Performance of Eco-Efficient Fiber-Reinforced Self-Compacting Concrete

by

Ahmed Redha Abdul-Rahman, Khaleel Hasan Younis and Bahman Omar Taha

J. Compos. Sci. 2026, 10(1), 9; https://doi.org/10.3390/jcs10010009 - 1 Jan 2026

Abstract

This study investigates the synergistic influence of recycled concrete aggregate (RCA) and recycled steel fibers (RSF) on the fresh and hardened performance of eco-efficient fiber-reinforced self-compacting concrete (SCC). Twelve C30/37.5 mixtures were produced using demolition waste as coarse RCA at replacement levels of

[...] Read more.

This study investigates the synergistic influence of recycled concrete aggregate (RCA) and recycled steel fibers (RSF) on the fresh and hardened performance of eco-efficient fiber-reinforced self-compacting concrete (SCC). Twelve C30/37.5 mixtures were produced using demolition waste as coarse RCA at replacement levels of 25, 50, 75, and 100% by mass, combined with RSF recovered from scrap tires at volume fractions of 0.25, 0.50, and 0.75%. Fresh properties were assessed in accordance with EFNARC guidelines using slump-flow (T500), V-funnel, L-box, and J-ring tests, while hardened performance was evaluated through compressive, splitting tensile, and flexural strengths at 28 days, together with density and ultrasonic pulse velocity (UPV). Increasing RCA and RSF contents reduced workability, reflected in lower slump-flow diameters and higher T500 and V-funnel times, although most mixtures maintained satisfactory self-compacting behaviour. Compressive strength decreased with RCA content and, to a lesser extent, with higher RSF, with a maximum reduction of about 39% at 100% RCA relative to the control mix, yet values remained structurally acceptable. In contrast, RSF markedly enhanced tensile and flexural responses: at 25% RCA, 0.75% RSF increased splitting tensile and flexural strengths by approximately 41% and 29%, respectively, compared with the corresponding fiber-free mix. RCA reduced density and UPV by about 10–14%, but these reductions were partially mitigated by RSF addition. Overall, the results demonstrate that SCC with moderate RCA (25–50%) and RSF (0.50–0.75%) can achieve a favourable balance between rheological performance and enhanced tensile and flexural behaviour, offering a viable composite solution for sustainable structural applications.

Full article

(This article belongs to the Section Composites Applications)

►▼

Show Figures

Figure 1

Open AccessArticle

Design of an Additively Manufactured Torsion Bushing with a Gyroid Core Topology

by

Dragoş Alexandru Apostol, Dan Mihai Constantinescu, Ștefan Sorohan and Alexandru Vasile

J. Compos. Sci. 2026, 10(1), 8; https://doi.org/10.3390/jcs10010008 - 1 Jan 2026

Abstract

This study examines the torsional behavior of an additively manufactured bushing featuring a unique topology, which includes a flexible gyroid core and rigid inner and outer sleeves. The bushing is designed and fabricated using two materials: thermoplastic polyurethane (TPU) and polylactic acid (PLA),

[...] Read more.

This study examines the torsional behavior of an additively manufactured bushing featuring a unique topology, which includes a flexible gyroid core and rigid inner and outer sleeves. The bushing is designed and fabricated using two materials: thermoplastic polyurethane (TPU) and polylactic acid (PLA), which are interpenetrated in successive layers throughout the bushing’s thickness. First, tensile mechanical tests are conducted on both materials with different infill patterns. The 45/135 infill proves to be the most suitable, providing good stiffness, strength, ductility, and data reproducibility. Additionally, the effectiveness of the interlocking created between the two materials through the printing process is evaluated by testing different overlap lengths. With an overlap of 2 mm, the extrusion process remains unaffected, minimizing voids and defects while ensuring strong interlayer bonding. Next, the designed bushing is subjected to torsional loading under both single and repetitive angular rotations, and its response is measured in terms of torque. The aim of this study is to evaluate the suitability of TPU and PLA materials for developing a design intended for dynamic mechanical environments, serving as a proof of concept. The quasi-static results indicate the presence of local damages and a viscoelastic response of the bushing during twisting, while also demonstrating its strong ability to withstand significant angles of rotation. Quasi-static results indicate local damage and the bushing’s viscoelastic response during twisting, as well as its ability to withstand significant angles of rotation.

Full article

(This article belongs to the Topic Advances in Rubbers, Elastomers and Resins for Leading Edge Technologies)

►▼

Show Figures

Figure 1

Open AccessArticle

An Energetic Analysis of Apparent Hardening and Ductility in FRP Plate Debonding

by

Nefeli Mitsopoulou and Marinos Kattis

J. Compos. Sci. 2026, 10(1), 7; https://doi.org/10.3390/jcs10010007 - 1 Jan 2026

Abstract

We investigate the progressive debonding of FRP reinforcements using an analytical framework based on fracture mechanics and a bilinear softening cohesive law. This study focuses on the energetic analysis of the “apparent hardening” phase observed in the force–slip (

We investigate the progressive debonding of FRP reinforcements using an analytical framework based on fracture mechanics and a bilinear softening cohesive law. This study focuses on the energetic analysis of the “apparent hardening” phase observed in the force–slip (

(This article belongs to the Special Issue Polymer Composites and Fibers, 3rd Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

Structural Adhesive Bonding of Vacuum-Infused Acrylic-Based Thermoplastic Fibre-Reinforced Laminates

by

Nils Xavier Bohlmann, Pedro Henrique Evangelista Fernandes, Morten Voß, Sebastian Veller, Christof Nagel, Katharina Arnaut and Vinicius Carrillo Beber

J. Compos. Sci. 2026, 10(1), 6; https://doi.org/10.3390/jcs10010006 - 1 Jan 2026

Abstract

Driven by regulatory and environmental demands, composite structures must combine high structural performance, recyclability, and resource efficiency. Here, an investigation on the structural adhesive bonding of glass-fibre-reinforced thermoplastic Elium© composite laminates is undertaken. Substrates are manufactured using vacuum infusion. Evaluation is performed on

[...] Read more.

Driven by regulatory and environmental demands, composite structures must combine high structural performance, recyclability, and resource efficiency. Here, an investigation on the structural adhesive bonding of glass-fibre-reinforced thermoplastic Elium© composite laminates is undertaken. Substrates are manufactured using vacuum infusion. Evaluation is performed on the following three commercial two-component adhesives cured at RT: an epoxy (EP), a polyurethane (PU), and an acrylate system (AC). Based on Dynamic Mechanical Analysis, the glass transition temperatures of the EP, PU, and AC adhesives are 56.5, 102.9, and 111.9 °C, respectively. The AC adhesive exhibits the highest shear strength and displacement at failure, reflecting a superior load-bearing capacity. Fractographic analysis further supports these findings: AC joints show a mixed substrate/cohesive failure mode, while EP samples fail exclusively by adhesion failure and PU samples predominantly by a mixture of special cohesion, adhesion and substrate failure. Regarding processing, the EP samples show the highest pot life, followed by PU and then AC. Nonetheless, the pot life of the AC adhesive does not limit its range of application.. The results highlight the advantages of adhesive bonding of Elium© in enabling lightweight and more circular composites. RT-cured adhesives eliminate the need for drilling and energy-intensive thermal curing, allowing design flexibility and reductions in CO2 footprint within composite production.

Full article

(This article belongs to the Special Issue Composites: A Sustainable Material Solution, 2nd Edition)

►▼

Show Figures

Graphical abstract

Journal Menu

► ▼ Journal Menu-

- J. Compos. Sci. Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Instructions for Authors

- Special Issues

- Topics

- Sections & Collections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Fibers, J. Compos. Sci., Materials, Polymers, Applied Mechanics

Advances in Fiber–Matrix Interface: Cohesion Enhancement, Characterization and Modeling of Interfacial Debonding

Topic Editors: Quentin Bourgogne, Hamid Zahrouni, Hubert ChapuisDeadline: 28 February 2026

Topic in

Materials, Ceramics, J. Compos. Sci.

New Advances in High-Performance Structural Ceramics and Their Composites

Topic Editors: Amparo Borrell, Rut Benavente, Rujie HeDeadline: 31 March 2026

Topic in

Alloys, Applied Mechanics, Crystals, J. Compos. Sci., Powders, Nanomaterials

Multiscale Characterization, Mechanical Behavior and Computational Simulation of Bulk Materials, Metallic Powders and/or Nanoparticles

Topic Editors: Xiangnan Pan, Qing Peng, Hui Qi, Raj DasDeadline: 30 June 2026

Topic in

Fibers, J. Compos. Sci., JMMP, Materials, Polymers, Recycling

Advanced Composites Manufacturing and Plastics Processing, 2nd Volume

Topic Editors: Patricia Krawczak, Ludwig Cardon, Frederik DesplentereDeadline: 1 September 2026

Conferences

Special Issues

Special Issue in

J. Compos. Sci.

Trends and Challenges in Developing and Processing Composite Materials

Guest Editor: Heitor Luiz Ornaghi JúniorDeadline: 15 January 2026

Special Issue in

J. Compos. Sci.

Composite Materials for Civil Engineering Applications

Guest Editors: Yanshuai Wang, Dong Guo, Jun He, Bai ZhangDeadline: 20 January 2026

Special Issue in

J. Compos. Sci.

Innovations of Composite Materials in Prosthetic Dentistry

Guest Editors: Rodolfo Reda, Dario Di NardoDeadline: 30 January 2026

Special Issue in

J. Compos. Sci.

Polymer Composites: Fiber Architecture, Interfacial Engineering, and Processing

Guest Editors: Kristofer Paso, Patrycja Bazan, P. M. VisakhDeadline: 31 January 2026

Topical Collections

Topical Collection in

J. Compos. Sci.

Editorial Board Members’ Collection Series: Fibre Composite Materials

Collection Editors: Hom Nath Dhakal, Mazeyar Parvinzadeh Gashti, Esfandiar Pakdel