- Communication

A Creep Model with a Real Structural Parameter for Deformable Solids

- Rafael Shaikhutdinov

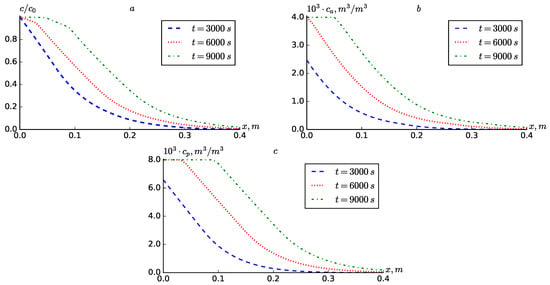

Creep in metals as a phenomenon has been comprehensively studied in solid mechanics as well as in materials science. This interest stems from two key motivations: assessing the strength characteristics of components subjected to prolonged exposure at high temperatures and enhancing our understanding of plastic deformation mechanisms. As it is known, the mechanics of deformable solids employ constitutive equations when describing creep behavior, whereas strength physics utilize models aimed at quantifying a particular creep deformation mechanism or mechanisms in novel materials and to predict the performance of the parts manufactured from them. However, such models are rarely encountered within traditional mechanics problem-solving frameworks. To bridge this gap, this study demonstrates how some classic boundary value problems can incorporate the kinetic equation of a metal creep model with a real structural parameter derived from the theory of irreversible deformations. The main derivation steps and numerical solutions are provided for steady and transient creep conditions, along with visualizations illustrating the distribution of actual structural parameters. This research outlines promising pathways for incorporating diverse structural creep models—typically associated with materials science—into solid mechanics. These findings lay the groundwork for more accurate predictions of evolving material properties in applications where creep deformations play a critical role.

17 December 2025

![Creep curves for nickel alloy at a constant temperature

T

=

1023

[K] under stresses

σ

: bottom line—180 [MPa]; middle line—200 [MPa]; top line—250 [MPa]; circles—experimental points [15].](https://mdpi-res.com/applmech/applmech-06-00091/article_deploy/html/images/applmech-06-00091-g001-550.jpg)