- Article

Structural Characterization and Photocatalytic Performance of PDMS/TiO2 Nanocomposites Prepared via Ex Situ Dispersion Route

- Abdelkader Hassein-Bey,

- Nadir Belgroune and

- Amel Boudjemaa

- + 4 authors

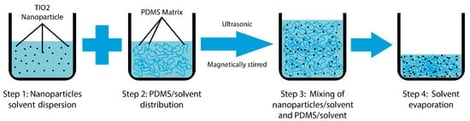

This work reports the elaboration and testing of polydimethylsiloxane/titanium dioxide (PDMS/TiO2) polymer nanocomposites, focusing on producing and combining TiO2 nanoparticles with a polymer matrix through an ex situ route. By mixing the inherent flexibility of PDMS with the unique properties of nanoparticles, the nanocomposites aim to enhance mechanical stability, optical response, and photocatalytic activity. X-ray diffraction (XRD) confirmed the successful incorporation of TiO2 into the PDMS matrix. UV–visible spectroscopy monitored photocatalytic performance using metronidazole as a model pollutant under 365 nm irradiation. Kinetic analysis revealed degradation and showed that the reaction rate constant (k) increased with TiO2 loading, reaching a maximum of 0.0019 min−1 for the 6 wt.% composite. These findings indicate that while the reaction kinetics are slower than those of free powders, the PDMS/TiO2 nanocomposites provide a viable, recoverable, and flexible solution for environmental remediation applications. Future efforts will target improved durability, broadened visible light absorption, and process optimization for scalable fabrication.

14 February 2026