Crashworthiness of Additively Manufactured Crash Boxes: A Comparative Analysis of Fused Deposition Modeling (FDM) Materials and Structural Configurations

Abstract

1. Introduction

2. Experimental Procedure

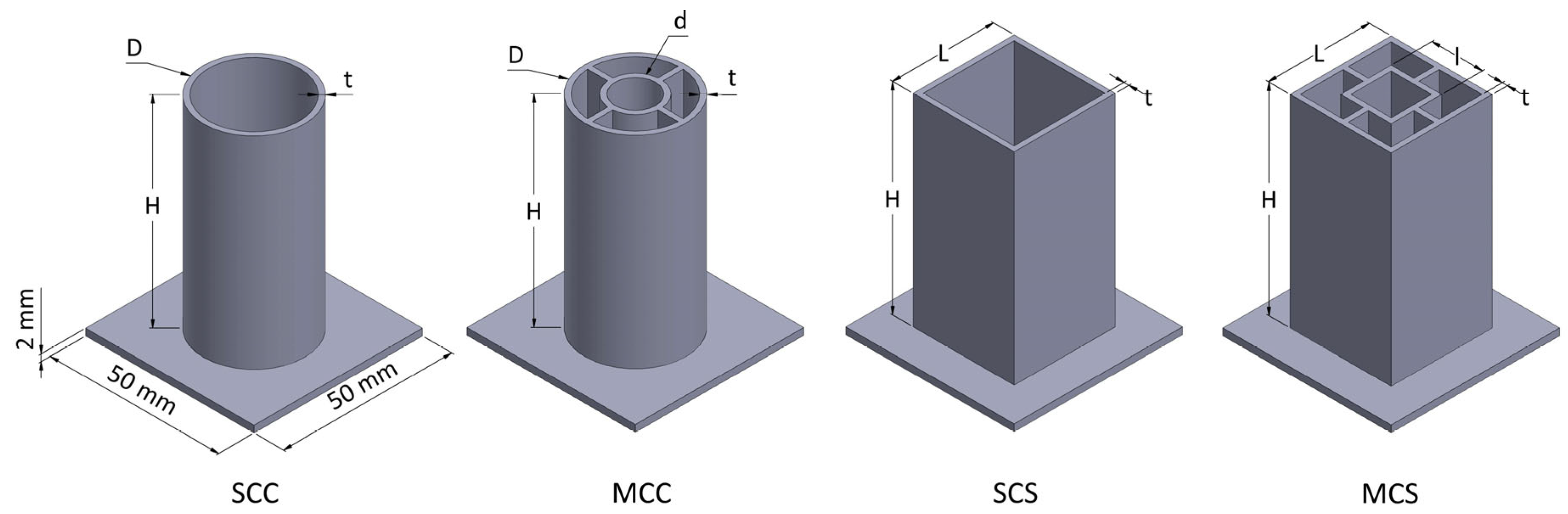

2.1. Geometrical Design

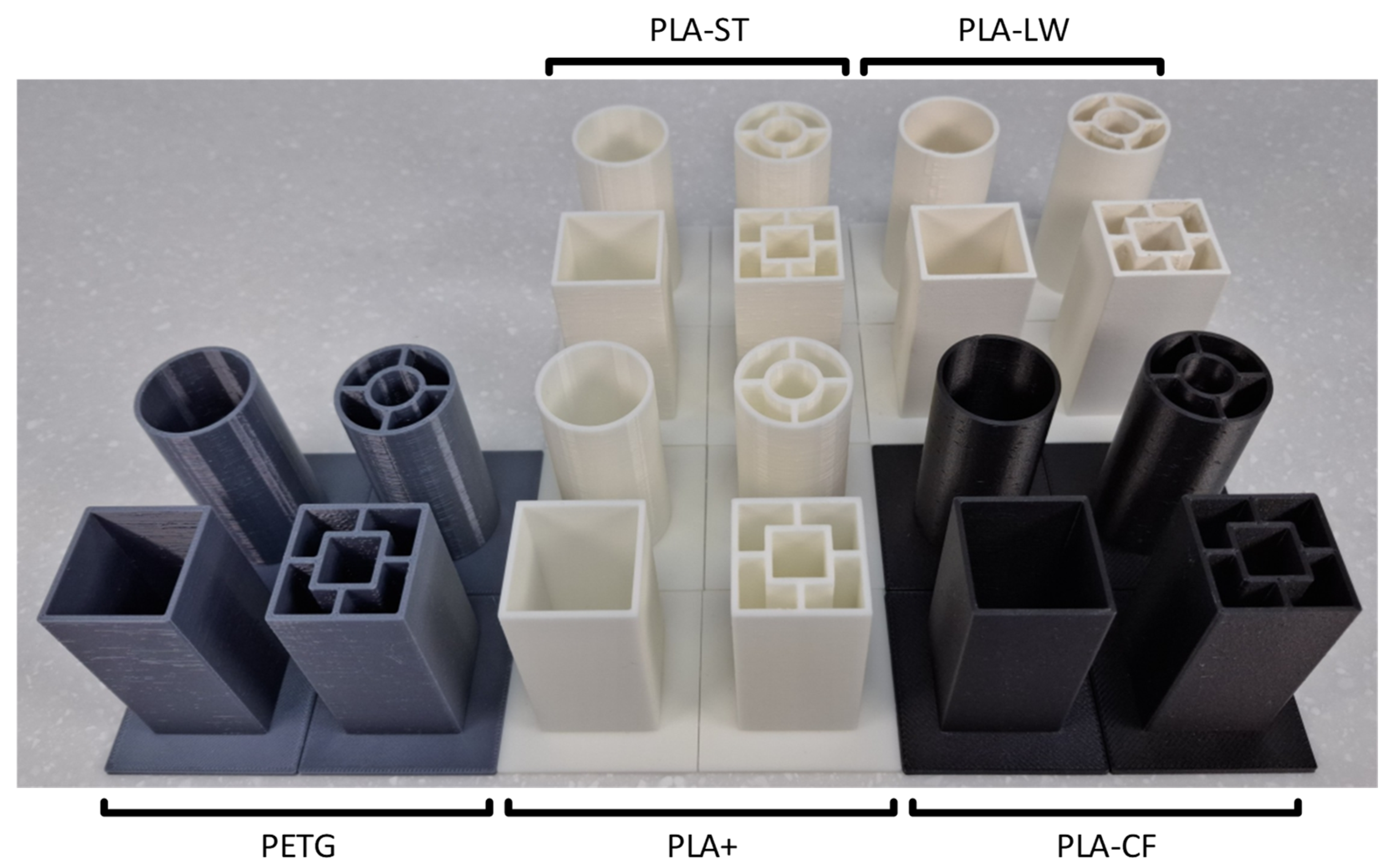

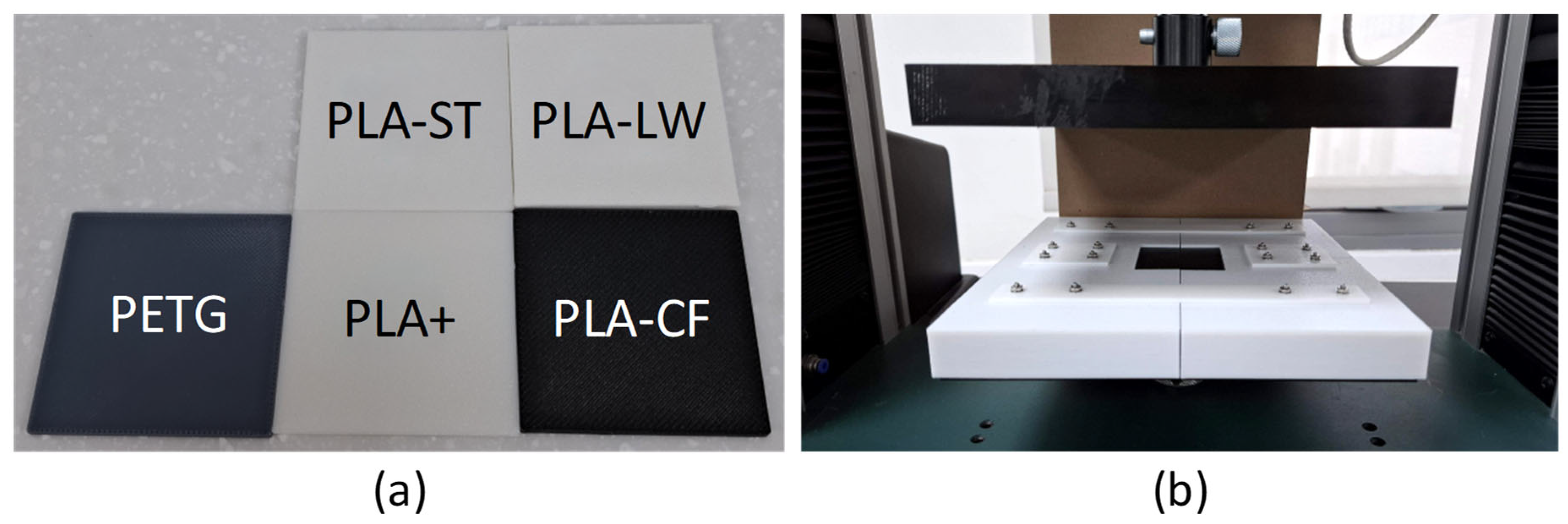

2.2. Materials and Processing Parameters

2.3. Experimental Method

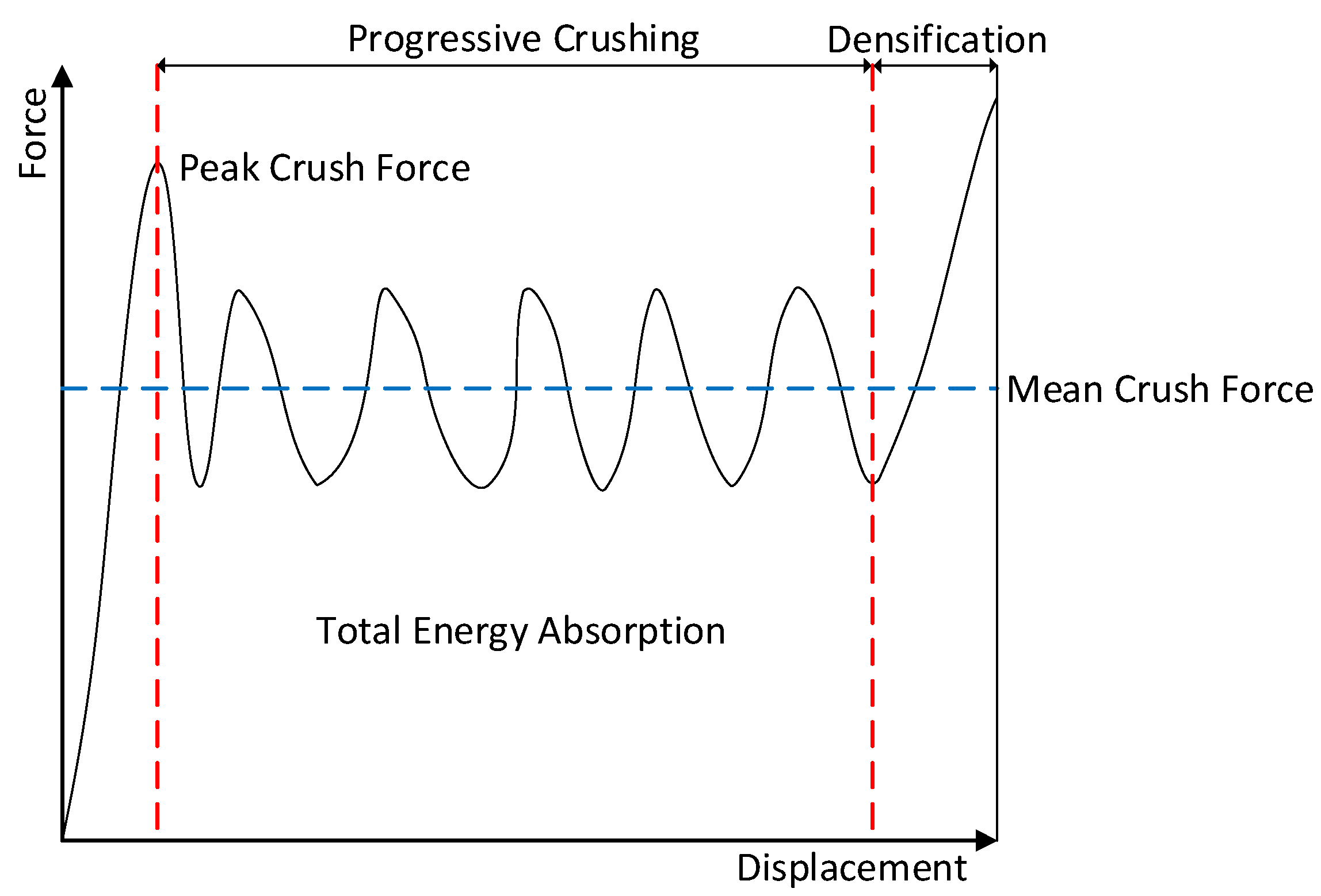

2.4. Definition of Crashworthiness Indicators

2.4.1. Total Energy Absorption,

2.4.2. Peak Crush Force,

2.4.3. Mean Crush Force,

2.4.4. Specific Energy Absorption,

2.4.5. Crush Force Efficiency,

2.4.6. Composite Objective Function,

3. Results and Discussion

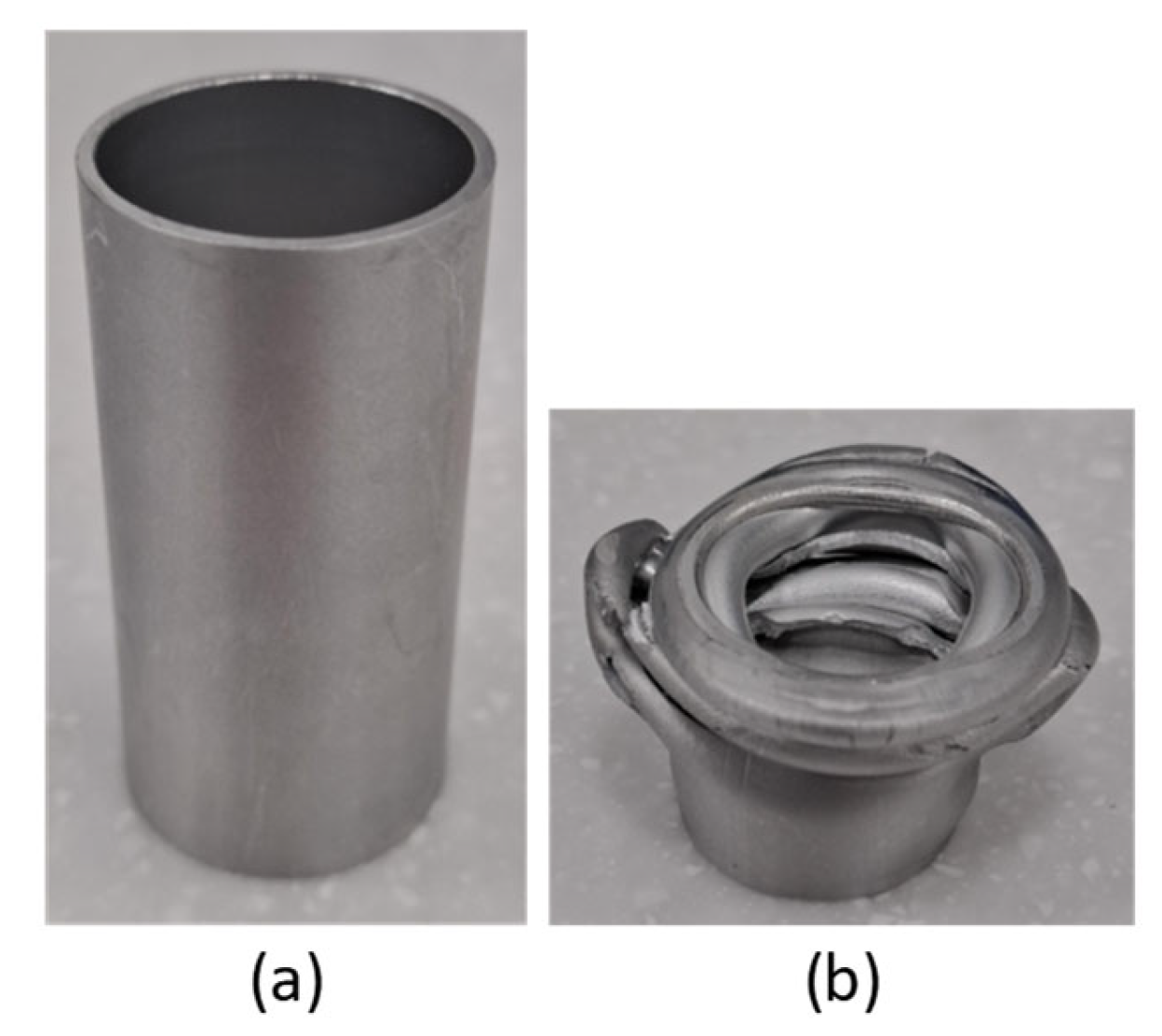

3.1. Deformation Patterns

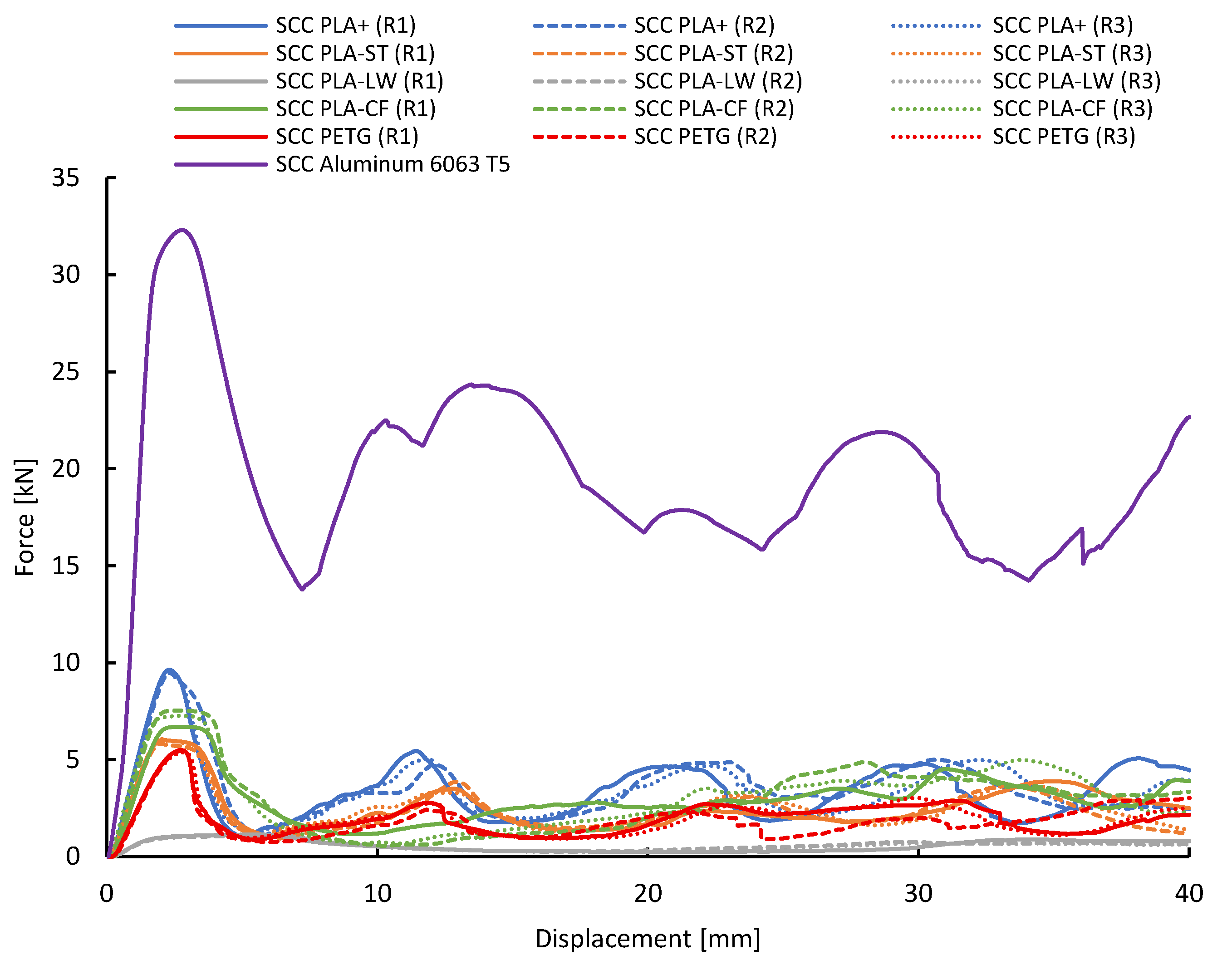

3.2. Force–Displacement Relationship

3.3. Energy–Displacement Relationship

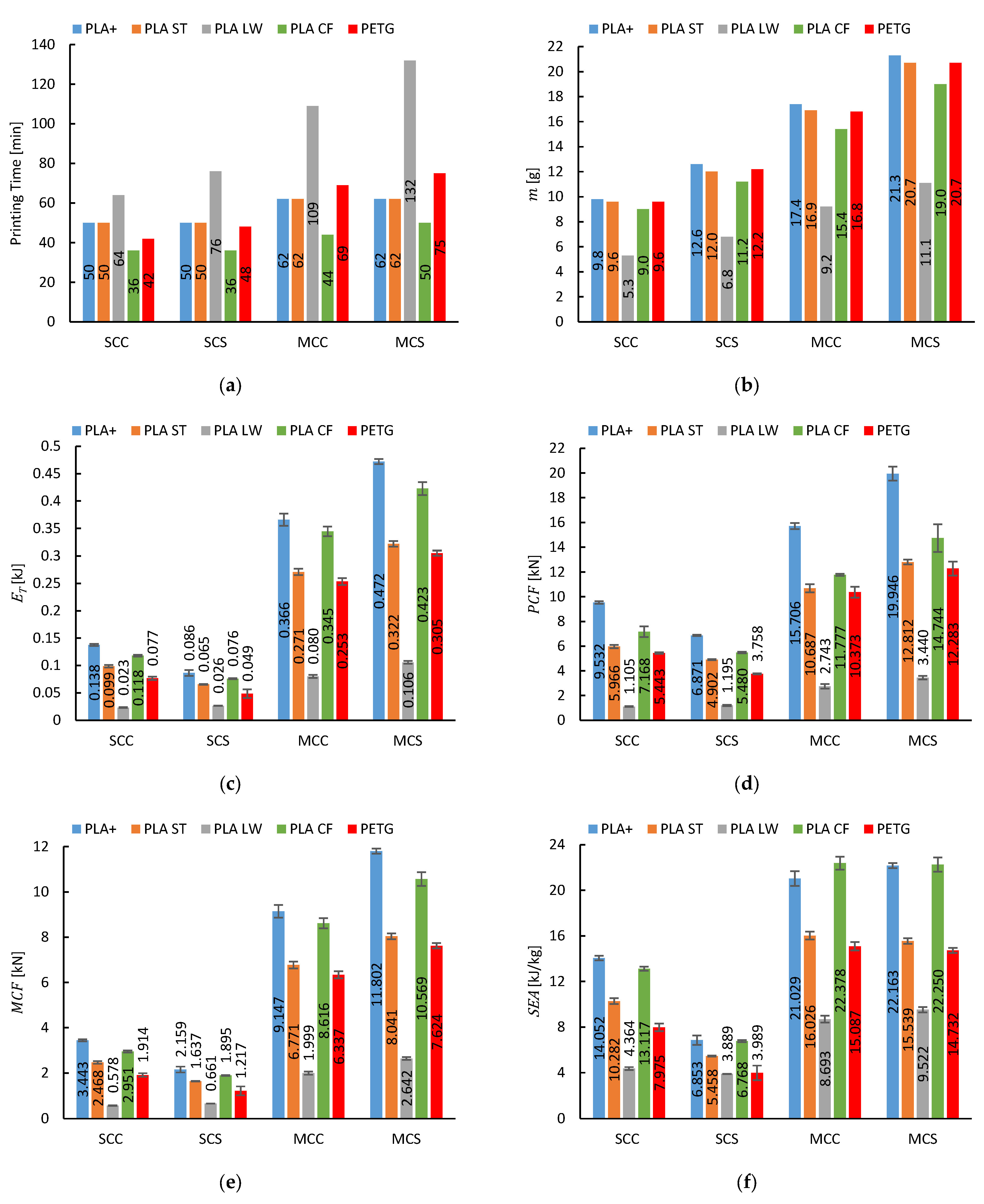

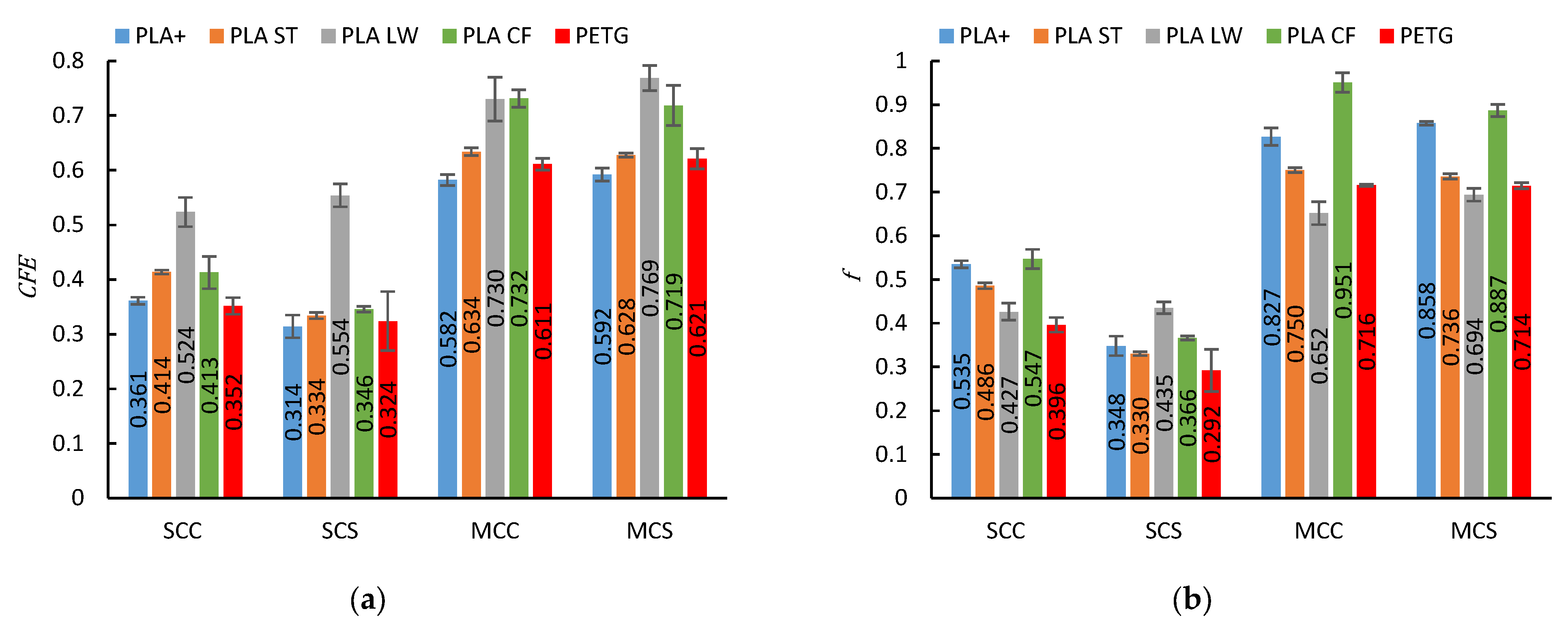

3.4. Crashworthiness Indicators

4. ANOVA of Crashworthiness Indicators

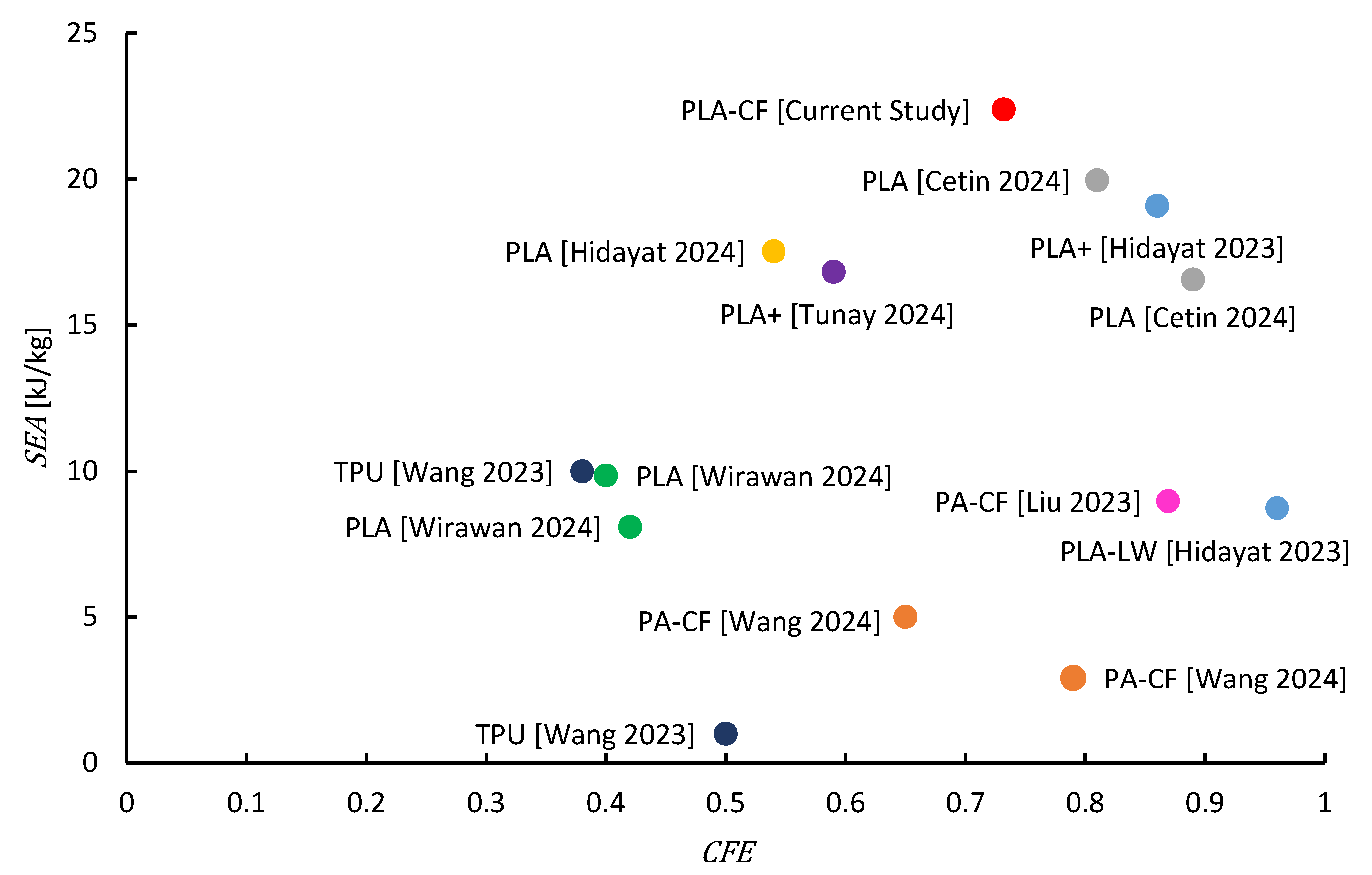

5. Crashworthiness Comparison Between Additively and Traditionally Manufactured Materials

6. Limitations, Practical Implications, and Future Work

7. Conclusions

- PLA-CF achieved the best performance, with the MCC design configuration achieving an of 22.378 ± 0.570 J/g and a of 0.732 ± 0.016. The MCS design configuration achieved an of 21.167 ± 0.308 J/g and a of 0.672 ± 0.011.

- PETG and PLA-LW demonstrated the lowest crashworthiness performance, primarily due to the low structural stiffness of PLA-LW and the brittle fracture characteristics of PETG.

- Multi-cell configurations (MCC and MCS) outperformed single-cell configurations (SCC and SCS) across all tested materials.

- ANOVA results revealed that geometry was the dominant factor influencing crash performance, accounting for 60.47%, 77.19%, and 85.59% of the variance in , , and , respectively. Both material type and geometry, as well as their interaction, showed statistically significant effects (p < 0.05), reinforcing their importance in determining crashworthiness.

- To evaluate the crashworthiness of additively manufactured materials relative to traditional ones, a compression test was performed on aluminum 6063-T5. While aluminum 6063-T5 possesses superior material properties, PLA-CF demonstrated an adequate level of crashworthiness. It also offers distinct advantages, including reduced mass, lower and enhanced design flexibility inherent to additive manufacturing. These attributes make PLA-CF a promising alternative for efficient crash box designs, particularly in the development of advanced geometric architectures such as bio-inspired, lattice, and multi-cellular structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Omar, M.A. The Automotive Body Manufacturing Systems and Processes; John Wiley and Sons: Hoboken, NJ, USA, 2011; ISBN 9780470976333. [Google Scholar]

- Ma, J.; Dai, H.; Shi, M.; Yuan, L.; Chen, Y.; You, Z. Quasi-Static Axial Crushing of Hexagonal Origami Crash Boxes as Energy Absorption Devices. Mech. Sci. 2019, 10, 133–143. [Google Scholar] [CrossRef]

- Yuan, L.; Shi, H.; Ma, J.; You, Z. Quasi-Static Impact of Origami Crash Boxes with Various Profiles. Thin-Walled Struct. 2019, 141, 435–446. [Google Scholar] [CrossRef]

- Wesselmecking, S.; Kreins, M.; Dahmen, M.; Bleck, W. Material Oriented Crash-Box Design—Combining Structural and Material Design to Improve Specific Energy Absorption. Mater. Des. 2022, 213, 110357. [Google Scholar] [CrossRef]

- Kaczyński, P.; Makuła, P. Constitutive Strength Model for Spot Joints of Thin-Walled Energy-Absorbing Elements. Eng. Struct. 2023, 292, 116592. [Google Scholar] [CrossRef]

- Hanssen, A.G.; Langseth, M.; Hopperstad, O.S. Static and Dynamic Crushing of Circular Aluminum Extrusions with Aluminum Foam Filler. Int. J. Impact Eng. 2000, 24, 475–507. [Google Scholar] [CrossRef]

- Hanssen, A.G.; Langseth, M.; Hopperstad, O.S. Static and Dynamic Crushing of Square Aluminum Extrusions with Aluminum Foam Filler. Int. J. Impact Eng. 2000, 24, 347–383. [Google Scholar] [CrossRef]

- Acar, E.; Altin, M.; Güler, M.A. Evaluation of Various Multi-Cell Design Concepts for Crashworthiness Design of Thin-Walled Aluminum Tubes. Thin-Walled Struct. 2019, 142, 227–235. [Google Scholar] [CrossRef]

- Aktaş, C.; Acar, E.; Güler, M.A.; Altın, M. An Investigation of the Crashworthiness Performance and Optimization of Tetra-Chiral and Reentrant Crash Boxes. Mech. Based Des. Struct. Mach. 2023, 51, 6881–6904. [Google Scholar] [CrossRef]

- Mert, S.K.; Demiral, M.; Altin, M.; Acar, E.; Güler, M.A. Experimental and Numerical Investigation on the Crashworthiness Optimization of Thin-Walled Aluminum Tubes Considering Damage Criteria. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 113. [Google Scholar] [CrossRef]

- Güler, M.A.; Mert, S.K.; Altin, M.; Acar, E. An Investigation on the Energy Absorption Capability of Aluminum Foam-Filled Multi-Cell Tubes. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 541. [Google Scholar] [CrossRef]

- Chen, J.; Li, E.; Liu, W.; Mao, Y.; Hou, S. Crashworthiness Analysis of Novel Cactus-Inspired Multi-Cell Structures under Axial Crushing. Int. J. Mech. Sci. 2024, 268, 109053. [Google Scholar] [CrossRef]

- Kathiresan, M.; Manisekar, K.; Rajamohan, V.; Güler, M.A. Investigations on Crush Behavior and Energy Absorption Characteristics of GFRP Composite Conical Frusta with a Cutout under Axial Compression Loading. Mech. Adv. Mater. Struct. 2022, 29, 5360–5377. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three Dimensional Objects by Stereolithography. US4575330A, 11 March 1986. [Google Scholar]

- Saber, A.; Amer, A.M.; Shehata, A.I.; El-Gamal, H.A.; Abd_Elsalam, A. Recent Developments in Additively Manufactured Crash Boxes: Geometric Design Innovations, Material Behavior, and Manufacturing Techniques. Appl. Sci. 2025, 15, 7080. [Google Scholar] [CrossRef]

- Li, Q.; Wang, W.; Tan, H.; Long, X.; Wang, F.; Hu, L. Energy Absorption Characteristics of Modular Assembly Structures under Quasi-Static Compression Load. Compos. Struct. 2024, 342, 118260. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Xue, X.; Zhou, J.; Song, Z. Axial and Lateral Crushing Performance of Plate-Lattice Filled Square Sandwich Tubes. Compos. Struct. 2021, 274, 114404. [Google Scholar] [CrossRef]

- Tao, Y.; Li, W.; Wei, K.; Duan, S.; Wen, W.; Chen, L.; Pei, Y.; Fang, D. Mechanical Properties and Energy Absorption of 3D Printed Square Hierarchical Honeycombs under In-Plane Axial Compression. Compos. Part B Eng. 2019, 176, 107219. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, J.; Chen, J.; Okabe, Y.; Pan, L.; Xu, M. The Beetle Elytron Plate: A Lightweight, High-Strength and Buffering Functional-Structural Bionic Material. Sci. Rep. 2017, 7, 4440. [Google Scholar] [CrossRef] [PubMed]

- Alkhatib, S.E.; Matar, M.S.; Tarlochan, F.; Laban, O.; Mohamed, A.S.; Alqwasmi, N. Deformation Modes and Crashworthiness Energy Absorption of Sinusoidally Corrugated Tubes Manufactured by Direct Metal Laser Sintering. Eng. Struct. 2019, 201, 109838. [Google Scholar] [CrossRef]

- Stanczak, M.; Fras, T.; Blanc, L.; Pawlowski, P.; Rusinek, A. Numerical and Experimental Study on Mechanical Behaviour of the AlSi10Mg Aluminium Structures Manufactured Additively and Subjected to a Blast Wave. In Proceedings of the EPJ Web of Conferences, Madrid, Spain, 20–24 September 2021; EDP Sciences: Les Ulis, France, 2021; Volume 250, p. 02017. [Google Scholar]

- Tang, Y.; Li, Q.; Miao, X.; Chen, B.; Yin, L.; Liu, X.; Gu, C. Design Novel Origami Structures for Energy Absorption under Compressive Load. Acta Mech. Sin. 2024, 40, 423271. [Google Scholar] [CrossRef]

- Zeng, Y.; Du, X.; Yao, H.; Li, P.; Dong, P.; Chen, J. An Nylon Lattice Structure with Improved Mechanical Property and Energy Absorption Capability. Compos. Part C Open Access 2022, 8, 100285. [Google Scholar] [CrossRef]

- Peng, X.; Liu, G.; Li, J.; Wu, H.; Jia, W.; Jiang, S. Compression Property and Energy Absorption Capacity of 4D-Printed Deformable Honeycomb Structure. Compos. Struct. 2023, 325, 117591. [Google Scholar] [CrossRef]

- Raj, R.; Jiyalal Prajapati, M.; Tsai, J.T.; Kumar, A.; Jeng, J.Y. Design and Additive Manufacturing of Novel Hybrid Lattice Metamaterial for Enhanced Energy Absorption and Structural Stability. Mater. Des. 2024, 245, 113268. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, Z.; Okudan Kremer, G.E.; Qin, H. Origami-Inspired Infill Pattern for Additive Manufacturing. Manuf. Lett. 2022, 33, 516–520. [Google Scholar] [CrossRef]

- Saber, A.; Güler, M.A.; Acar, E.; ElSayed, O.S.; Aldallal, H.; Alsadi, A.; Aldousari, Y. Crash Performance of Additively Manufactured Tapered Tube Crash Boxes: Influence of Material and Geometric Parameters. Designs 2025, 9, 72. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, X.; Huang, Z. Axial Crushing of Nylon and Al/Nylon Hybrid Tubes by FDM 3D Printing. Compos. Struct. 2021, 256, 113055. [Google Scholar] [CrossRef]

- Luo, G.; Liu, J.; Li, L.; Xue, P.; Zhao, J.; Chen, Y. Crashworthiness Analysis and Multi-Objective Optimization Design for Foam-Filled Spiral Tube. Int. J. Mech. Sci. 2024, 282, 109588. [Google Scholar] [CrossRef]

- Capasso, I.; Andreacola, F.R.; Brando, G. Additive Manufacturing of Metal Materials for Construction Engineering: An Overview on Technologies and Applications. Metals 2024, 14, 1033. [Google Scholar] [CrossRef]

- Wu, Y.; Fang, J.; Wu, C.; Li, C.; Sun, G.; Li, Q. Additively Manufactured Materials and Structures: A State-of-the-Art Review on Their Mechanical Characteristics and Energy Absorption. Int. J. Mech. Sci. 2023, 246, 108102. [Google Scholar] [CrossRef]

- Chen, W.; Guo, C.; Zuo, X.; Zhao, J.; Peng, Y.; Wang, Y. Experimental and Numerical Investigation of 3D Printing PLA Origami Tubes under Quasi-Static Uniaxial Compression. Polymers 2022, 14, 4135. [Google Scholar] [CrossRef]

- Khoa, N.D.; Bohara, R.P.; Ghazlan, A.; Thai, T.; Ngo, T. Novel Hierarchical Bioinspired Cellular Structures with Enhanced Energy Absorption under Uniaxial Compression. Aerosp. Sci. Technol. 2024, 147, 108995. [Google Scholar] [CrossRef]

- Efstathiadis, A.; Symeonidou, I.; Tsongas, K.; Tzimtzimis, E.K.; Tzetzis, D. 3D Printed Voronoi Structures Inspired by Paracentrotus Lividus Shells. Designs 2023, 7, 113. [Google Scholar] [CrossRef]

- Sun, G.; Wang, J.; Wang, K.; Baghani, M.; Peng, Y.; Rao, Y. Repeatable Compressive Functionality of 3D Printed Shape-Memory Thin-Walled Corrugated Structures. Int. J. Mech. Sci. 2023, 257, 108552. [Google Scholar] [CrossRef]

- Ha, N.S.; Pham, T.M.; Tran, T.T.; Hao, H.; Lu, G. Mechanical Properties and Energy Absorption of Bio-Inspired Hierarchical Circular Honeycomb. Compos. Part B Eng. 2022, 236, 109818. [Google Scholar] [CrossRef]

- Awd Allah, M.M.; Abdel-Aziem, W.; Abd El-baky, M.A. Collapse Behavior and Energy Absorbing Characteristics of 3D-Printed Tubes with Different Infill Pattern Structures: An Experimental Study. Fibers Polym. 2023, 24, 2609–2622. [Google Scholar] [CrossRef]

- Zhang, D.; Li, M.; Qiu, N.; Yang, J.; Wu, C.; Steven, G.; Li, Q.; Fang, J. 4D-Printed Reusable Metamaterial via Shape Memory Effect for Energy Dissipation. Int. J. Mech. Sci. 2024, 275, 109309. [Google Scholar] [CrossRef]

- Bintara, R.D.; Choiron, M.A. Deformation Pattern and Energy Absorption of Polylactic Acid (PLA) Carbon Crash Box under Quasi Static Loading. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Malang, Indonesia, 1 February 2021; IOP Publishing: Bristol, UK, 2021; Volume 1034, p. 012011. [Google Scholar]

- Liu, Y.; Tan, Q.; Lin, H.; Wang, J.; Wang, K.; Peng, Y.; Yao, S. Integrated Design and Additive Manufacturing of Lattice-Filled Multi-Cell Tubes. Compos. Sci. Technol. 2023, 243, 110252. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Cai, R.; Xiang, J.; Wang, K.; Yao, S.; Peng, Y. Effects of Loading Rate and Temperature on Crushing Behaviors of 3D Printed Multi-Cell Composite Tubes. Thin-Walled Struct. 2023, 182, 110311. [Google Scholar] [CrossRef]

- Wang, K.; Liu, Y.; Wang, J.; Xiang, J.; Yao, S.; Peng, Y. On Crashworthiness Behaviors of 3D Printed Multi-Cell Filled Thin-Walled Structures. Eng. Struct. 2022, 254, 113907. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Tan, Q.; Gao, H.; Wang, K.; Yao, S.; Peng, Y. On Multi-Stage Deformation and Gradual Energy Absorption of 3D Printed Multi-Cell Tubes with Varying Cross-Section. Eng. Struct. 2024, 319, 118839. [Google Scholar] [CrossRef]

- Li, J.; Qu, M.; Jiang, Z. Multi-Objective Optimization for 3D Printed Origami Crash Box Cell Based on Artificial Neural Networks and NSGA-II. J. Mater. Process. Des. 2023, 7, 1–13. [Google Scholar] [CrossRef]

- Xing, S.; Jiang, Z.; Zhao, J.; Sun, X.; Wang, Y. Failure Mechanism and Crashworthiness Optimization of Variable Stiffness Nested Origami Crash Box. Eng. Fail. Anal. 2025, 167, 108953. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Wang, K.; Yao, S.; Peng, Y.; Rao, Y.; Ahzi, S. Progressive Collapse Behaviors and Mechanisms of 3D Printed Thin-Walled Composite Structures under Multi-Conditional Loading. Thin-Walled Struct. 2022, 171, 108810. [Google Scholar] [CrossRef]

- Yao, R.; Pang, T.; Zhang, B.; Fang, J.; Li, Q.; Sun, G. On the Crashworthiness of Thin-Walled Multi-Cell Structures and Materials: State of the Art and Prospects. Thin-Walled Struct. 2023, 189, 110734. [Google Scholar] [CrossRef]

- Tunay, M.; Bardakci, A. A Study of Crashworthiness Performance in Thin-Walled Multi-Cell Tubes 3D-Printed from Different Polymers. J. Appl. Polym. Sci. 2024, 141, e56287. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Nikkhah, H. Crashworthiness Investigation of Bitubal Columns Reinforced with Several inside Ribs under Axial and Oblique Impact Loads. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 367–383. [Google Scholar] [CrossRef]

- Özen, İ.; Gedikli, H.; Aslan, M. Experimental and Numerical Investigation on Energy Absorbing Characteristics of Empty and Cellular Filled Composite Crash Boxes. Eng. Struct. 2023, 289, 116315. [Google Scholar] [CrossRef]

- Wang, K.; Sun, G.; Wang, J.; Yao, S.; Baghani, M.; Peng, Y. Reversible Energy Absorbing Behaviors of Shape-Memory Thin-Walled Structures. Eng. Struct. 2023, 279, 115626. [Google Scholar] [CrossRef]

- Hidayat, D.; Istiyanto, J.; Sumarsono, D.A.; Kurniawan, F.; Ardiansyah, R.; Wandono, F.A.; Nugroho, A. Investigation on the Crashworthiness Performance of Thin-Walled Multi-Cell PLA 3D-Printed Tubes: A Multi-Parameter Analysis. Designs 2023, 7, 108. [Google Scholar] [CrossRef]

- Hidayat, D.; Istiyanto, J.; Sumarsono, D.A.; Kurniawan, F.; Abdurohman, K. Crashworthiness Characteristics of Thin-Walled Multi-Cell Structures via the Application of Annealing Process: An Experimental Investigation. Evergreen 2024, 11, 1892–1900. [Google Scholar] [CrossRef]

- Saber, A.; Güler, M.A.; Altin, M.; Acar, E. Bio-Inspired Thin-Walled Energy Absorber Adapted from the Xylem Structure for Enhanced Vehicle Safety. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 613. [Google Scholar] [CrossRef]

- Altin, M.; Acar, E.; Güler, M.A. Foam Filling Options for Crashworthiness Optimization of Thin-Walled Multi-Tubular Circular Columns. Thin-Walled Struct. 2018, 131, 309–323. [Google Scholar] [CrossRef]

- Cetin, E. Energy Absorption of Thin-Walled Multi-Cell Tubes with DNA-Inspired Helical Ribs under Quasi-Static Axial Loading. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 607. [Google Scholar] [CrossRef]

- Wirawan, W.A.; Junipitoyo, B.; Putro, S.H.S.; Sabitah, A.; Suudy, A.H.; Ridwan, R.; Choiron, M.A. Collapse Behavior and Energy Absorption Characteristics of Design Multi-Cell Thin Wall Structure 3D-Printed Under Quasi Statistic Loads. Automot. Exp. 2024, 7, 149–160. [Google Scholar] [CrossRef]

- Wang, K.; Tan, Q.; Wang, J.; Liu, Y.; Zhai, Z.; Yao, S.; Peng, Y. A Low-Cost Granular-Medium Hot Quasi-Isostatic Pressing Method for Enhancing Compressive Properties of 3D Printed Structures. J. Manuf. Process. 2024, 115, 441–451. [Google Scholar] [CrossRef]

- Wu, S.; Zheng, G.; Sun, G.; Liu, Q.; Li, G.; Li, Q. On Design of Multi-Cell Thin-Wall Structures for Crashworthiness. Int. J. Impact Eng. 2016, 88, 102–117. [Google Scholar] [CrossRef]

| Property | PLA+ | PLA-ST | PLA-LW | PLA-CF | PETG |

|---|---|---|---|---|---|

| Density (g/cm3) | 1.23 | 1.25 | 1.2 | 1.21 | 1.27 |

| Tensile Strength (MPa) | 63 | 34.3 | 32.2 | 39 | 52.2 |

| Elongation at Break (%) | 20 | 90 | 68.9 | 4.27 | 83 |

| Flexural Strength (MPa) | 74 | 43 | 41.31 | 103 | 58.1 |

| Flexural Modulus (MPa) | 1973 | 1477 | 1701 | 5003 | 1073 |

| IZOD Impact Strength (kJ/m2) | 9 | 63 | 8.58 | 5.08 | 4.7 |

| Parameter | PLA+ | PLA-ST | PLA-LW | PLA-CF | PETG |

|---|---|---|---|---|---|

| Printing temperature (°C) | 220 | 220 | 245 | 220 | 255 |

| Bed temperature (°C) | 65 | 65 | 55 | 65 | 80 |

| Diameter of nozzle (mm) | 0.4 | 0.4 | 0.4 | 0.6 | 0.4 |

| Layer height (mm) | 0.2 | 0.2 | 0.2 | 0.3 | 0.2 |

| Infill density (%) | 100 | 100 | 100 | 100 | 100 |

| Outer wall print speed (mm/s) | 200 | 200 | 50 | 120 | 80 |

| Inner wall print speed (mm/s) | 300 | 300 | 50 | 150 | 120 |

| Case | Printing Time [min] | [g] | [kJ] | [kN] | [kN] | [kJ/kg] | ||

|---|---|---|---|---|---|---|---|---|

| SCC PLA+ | 50 | 9.8 | 0.138 ± 0.002 | 9.532 ± 0.094 | 3.443 ± 0.048 | 14.052 ± 0.195 | 0.361 ± 0.007 | 0.535 ± 0.008 |

| SCS PLA+ | 50 | 12.6 | 0.086 ± 0.005 | 6.871 ± 0.044 | 2.159 ± 0.129 | 6.853 ± 0.410 | 0.314 ± 0.021 | 0.348 ± 0.022 |

| MCC PLA+ | 62 | 17.4 | 0.366 ± 0.011 | 15.706 ± 0.251 | 9.147 ± 0.281 | 21.029 ± 0.645 | 0.582 ± 0.010 | 0.827 ± 0.020 |

| MCS PLA+ | 62 | 21.3 | 0.472 ± 0.005 | 19.946 ± 0.567 | 11.802 ± 0.116 | 22.163 ± 0.217 | 0.592 ± 0.012 | 0.858 ± 0.004 |

| SCC PLA ST | 50 | 9.6 | 0.099 ± 0.002 | 5.966 ± 0.134 | 2.468 ± 0.060 | 10.282 ± 0.249 | 0.414 ± 0.004 | 0.486 ± 0.007 |

| SCS PLA ST | 50 | 12.0 | 0.065 ± 0.001 | 4.902 ± 0.044 | 1.637 ± 0.013 | 5.458 ± 0.044 | 0.334 ± 0.006 | 0.330 ± 0.005 |

| MCC PLA ST | 62 | 16.9 | 0.271 ± 0.006 | 10.687 ± 0.322 | 6.771 ± 0.146 | 16.026 ± 0.346 | 0.634 ± 0.007 | 0.750 ± 0.006 |

| MCS PLA ST | 62 | 20.7 | 0.322 ± 0.005 | 12.812 ± 0.192 | 8.041 ± 0.127 | 15.539 ± 0.246 | 0.628 ± 0.003 | 0.736 ± 0.006 |

| SCC PLA LW | 64 | 5.3 | 0.023 ± 0.001 | 1.105 ± 0.032 | 0.578 ± 0.017 | 4.364 ± 0.130 | 0.524 ± 0.027 | 0.427 ± 0.019 |

| SCS PLA LW | 76 | 6.8 | 0.026 ± 0.000 | 1.195 ± 0.042 | 0.661 ± 0.003 | 3.889 ± 0.015 | 0.554 ± 0.021 | 0.435 ± 0.013 |

| MCC PLA LW | 109 | 9.2 | 0.080 ± 0.003 | 2.743 ± 0.183 | 1.999 ± 0.069 | 8.693 ± 0.300 | 0.730 ± 0.040 | 0.652 ± 0.026 |

| MCS PLA LW | 132 | 11.1 | 0.106 ± 0.003 | 3.440 ± 0.141 | 2.642 ± 0.063 | 9.522 ± 0.226 | 0.769 ± 0.023 | 0.694 ± 0.014 |

| SCC PLA CF | 36 | 9.0 | 0.118 ± 0.002 | 7.168 ± 0.427 | 2.951 ± 0.042 | 13.117 ± 0.185 | 0.413 ± 0.029 | 0.547 ± 0.022 |

| SCS PLA CF | 36 | 11.2 | 0.076 ± 0.001 | 5.480 ± 0.054 | 1.895 ± 0.024 | 6.768 ± 0.085 | 0.346 ± 0.005 | 0.366 ± 0.005 |

| MCC PLA CF | 44 | 15.4 | 0.345 ± 0.009 | 11.777 ± 0.082 | 8.616 ± 0.220 | 22.378 ± 0.570 | 0.732 ± 0.016 | 0.951 ± 0.022 |

| MCS PLA CF | 50 | 19.0 | 0.402 ± 0.006 | 14.953 ± 0.031 | 10.054 ± 0.146 | 21.167 ± 0.308 | 0.672 ± 0.011 | 0.887 ± 0.014 |

| SCC PETG | 42 | 9.6 | 0.077 ± 0.003 | 5.443 ± 0.060 | 1.914 ± 0.078 | 7.975 ± 0.327 | 0.352 ± 0.015 | 0.396 ± 0.017 |

| SCS PETG | 48 | 12.2 | 0.049 ± 0.008 | 3.758 ± 0.044 | 1.217 ± 0.196 | 3.989 ± 0.642 | 0.324 ± 0.054 | 0.292 ± 0.048 |

| MCC PETG | 69 | 16.8 | 0.253 ± 0.006 | 10.373 ± 0.439 | 6.337 ± 0.155 | 15.087 ± 0.368 | 0.611 ± 0.011 | 0.716 ± 0.002 |

| MCS PETG | 75 | 20.7 | 0.305 ± 0.005 | 12.283 ± 0.562 | 7.624 ± 0.115 | 14.732 ± 0.222 | 0.621 ± 0.019 | 0.714 ± 0.007 |

| Source of Variation | DF | Contribution | Adj SS | Adj MS | p-Value |

|---|---|---|---|---|---|

| Material | 4 | 33.27% | 748.5399 | 187.1350 | 6.26 × 10−44 |

| Geometry | 3 | 60.47% | 1360.3018 | 453.4339 | 1.05 × 10−49 |

| Material × Geometry | 12 | 6.06% | 136.3953 | 11.3663 | 4.95 × 10−26 |

| Error | 40 | 0.20% | 4.4994 | 0.1118 | |

| Total | 59 | 100% |

| Source of Variation | DF | Contribution | Adj SS | Adj MS | p-Value |

|---|---|---|---|---|---|

| Material | 4 | 18.62% | 0.2540 | 0.0635 | 5.21 × 10−23 |

| Geometry | 3 | 77.19% | 1.0531 | 0.3510 | 1.69 × 10−35 |

| Material × Geometry | 12 | 2.87% | 0.0392 | 0.0033 | 8.39 × 10−7 |

| Error | 40 | 1.32% | 0.0180 | 0.0005 | |

| Total | 59 | 100% |

| Source of Variation | DF | Contribution | Adj SS | Adj MS | p-Value |

|---|---|---|---|---|---|

| Material | 4 | 8.53% | 0.2075 | 0.0519 | 3.96 × 10−24 |

| Geometry | 3 | 85.59% | 2.0811 | 0.6937 | 2.83 × 10−44 |

| Material × Geometry | 12 | 5.34% | 0.1299 | 0.0108 | 3.98 × 10−17 |

| Error | 40 | 0.53% | 0.0128 | 0.0003 | |

| Total | 59 | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saber, A.; Amer, A.M.; Shehata, A.I.; El-Gamal, H.A.; Abd_Elsalam, A. Crashworthiness of Additively Manufactured Crash Boxes: A Comparative Analysis of Fused Deposition Modeling (FDM) Materials and Structural Configurations. Appl. Mech. 2025, 6, 52. https://doi.org/10.3390/applmech6030052

Saber A, Amer AM, Shehata AI, El-Gamal HA, Abd_Elsalam A. Crashworthiness of Additively Manufactured Crash Boxes: A Comparative Analysis of Fused Deposition Modeling (FDM) Materials and Structural Configurations. Applied Mechanics. 2025; 6(3):52. https://doi.org/10.3390/applmech6030052

Chicago/Turabian StyleSaber, Ahmed, A. M. Amer, A. I. Shehata, H. A. El-Gamal, and A. Abd_Elsalam. 2025. "Crashworthiness of Additively Manufactured Crash Boxes: A Comparative Analysis of Fused Deposition Modeling (FDM) Materials and Structural Configurations" Applied Mechanics 6, no. 3: 52. https://doi.org/10.3390/applmech6030052

APA StyleSaber, A., Amer, A. M., Shehata, A. I., El-Gamal, H. A., & Abd_Elsalam, A. (2025). Crashworthiness of Additively Manufactured Crash Boxes: A Comparative Analysis of Fused Deposition Modeling (FDM) Materials and Structural Configurations. Applied Mechanics, 6(3), 52. https://doi.org/10.3390/applmech6030052