Modeling of Nomex Honeycomb Structure Milling Assisted by Longitudinal–Torsional Vibrations with a CZ10 Combined Tool: Optimization of Tool Wear and Surface Integrity

Abstract

1. Introduction

2. Design of the Cutting Tool and the Part

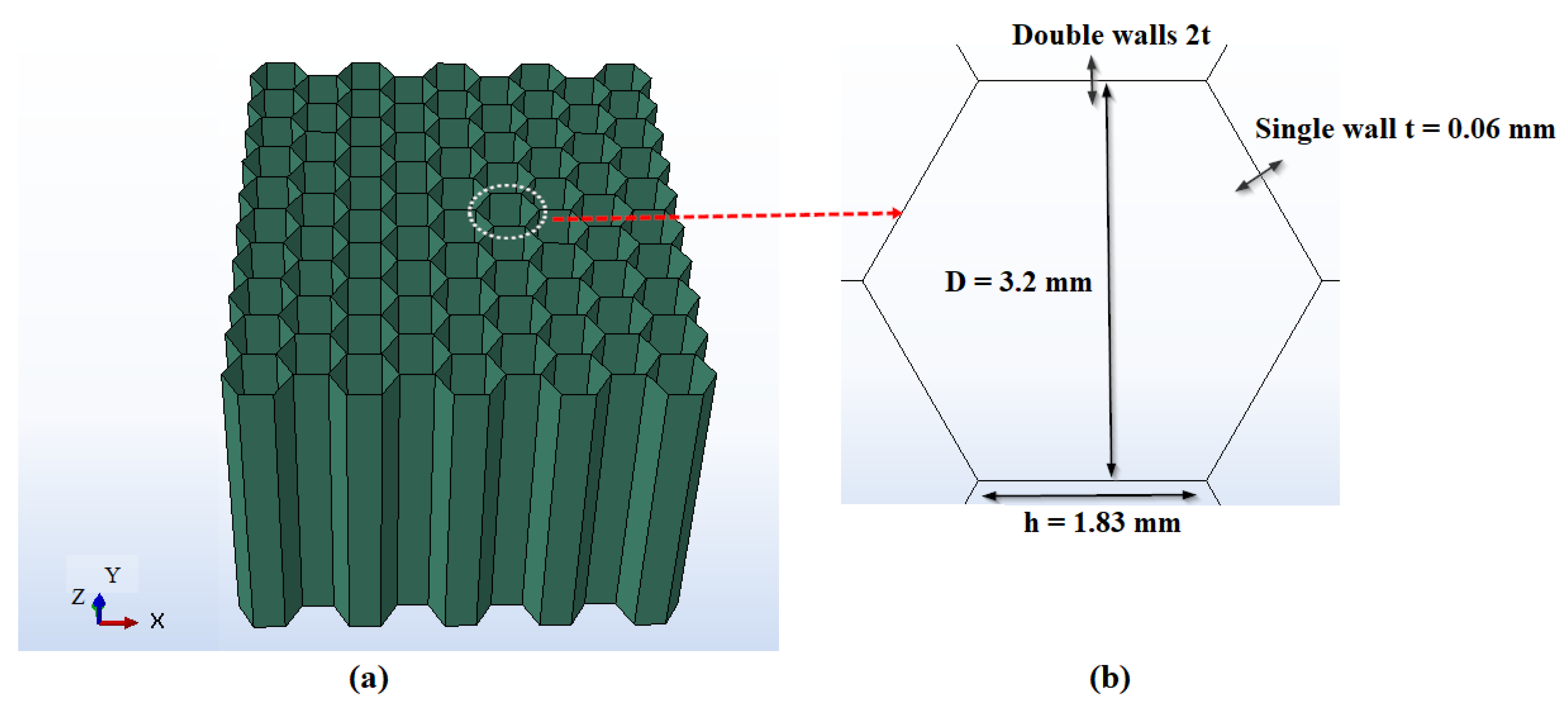

2.1. Dimensions of the Honeycomb Structure

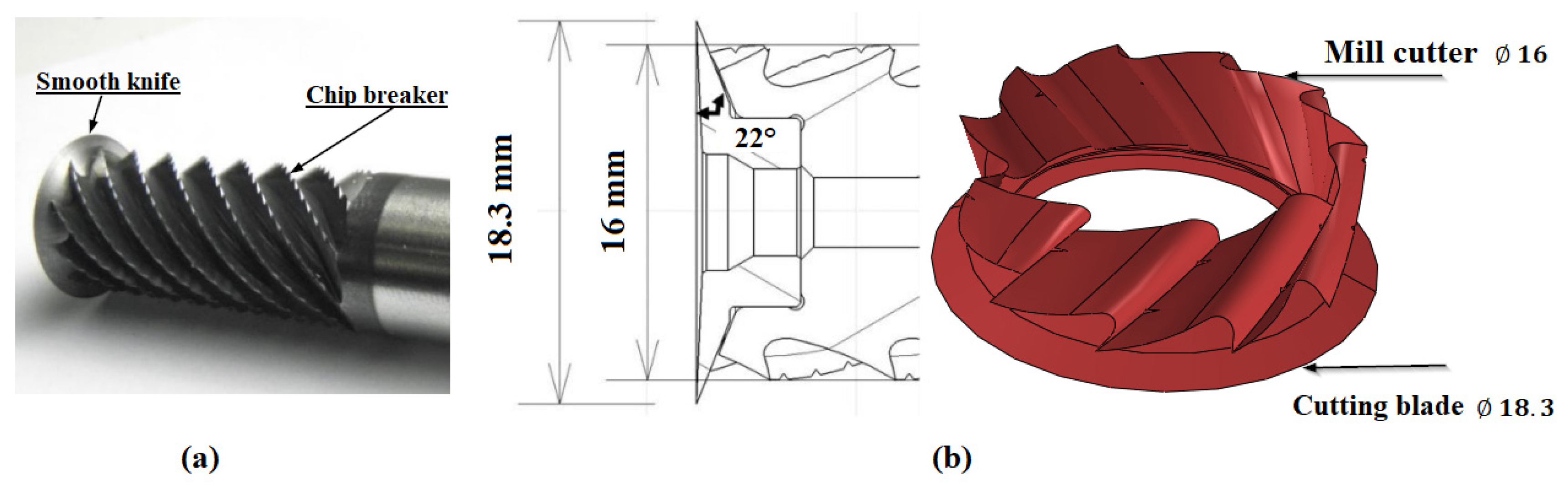

2.2. Dimension and Characteristics of the Cutting Tool

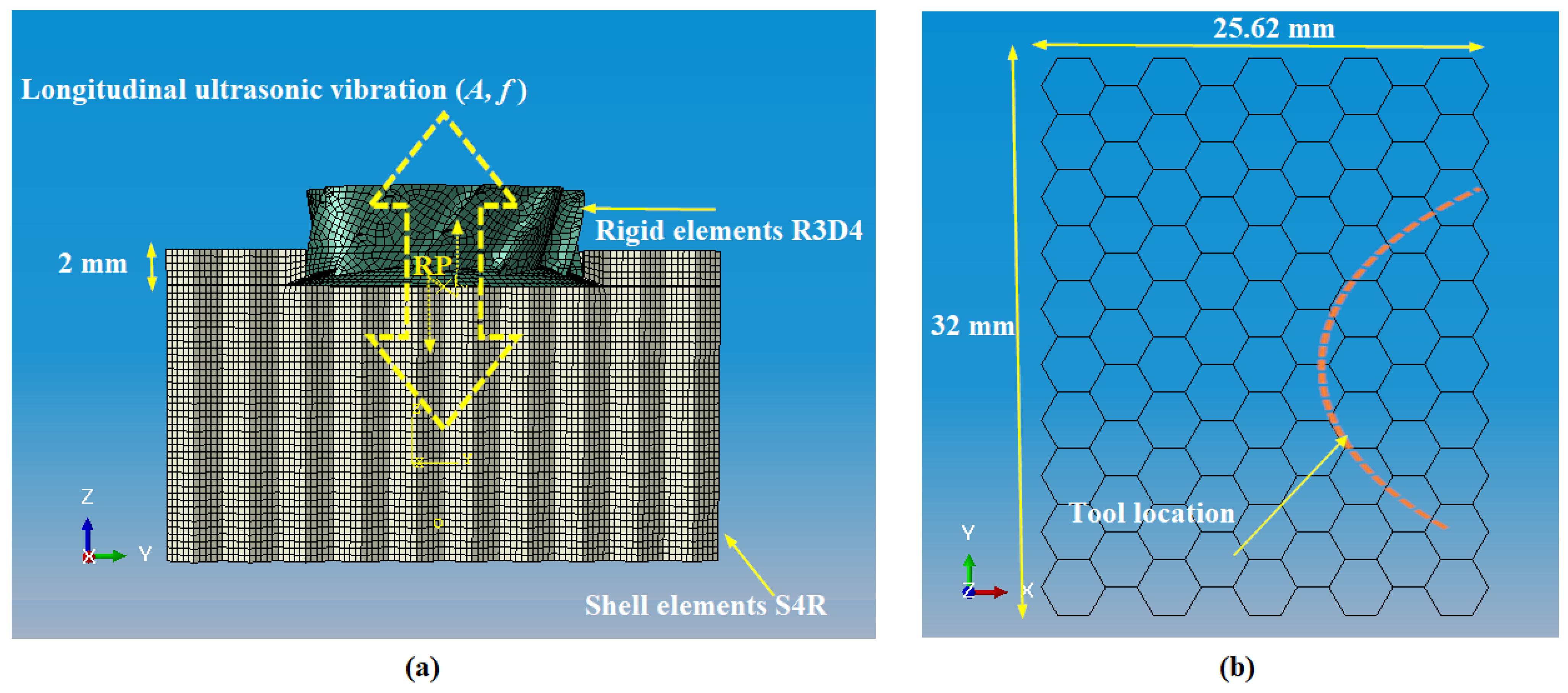

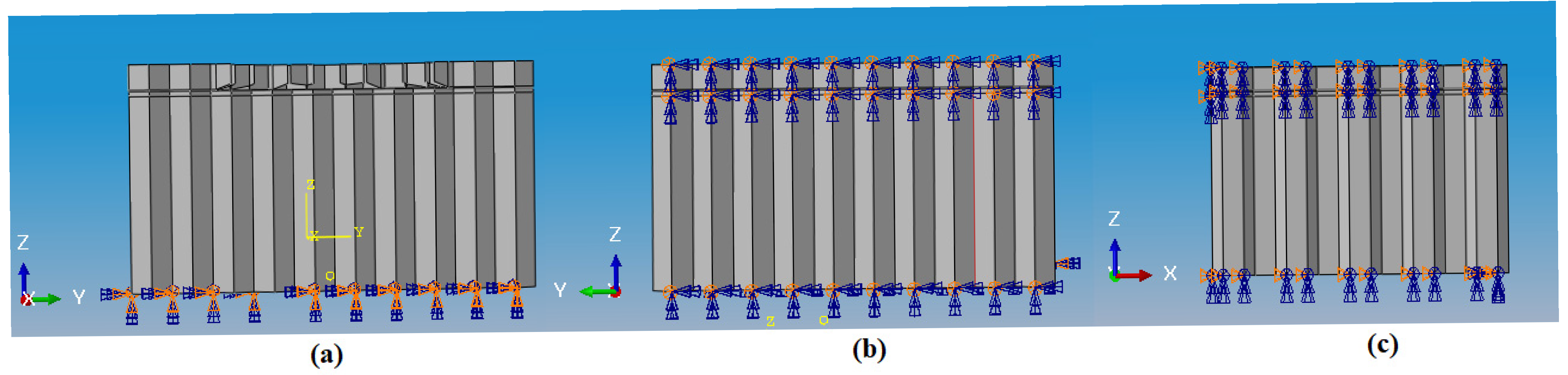

3. Finite Element Modelling

4. Material Characteristics, Degradation Mechanisms and Failure Criteria

5. Results and Discussions

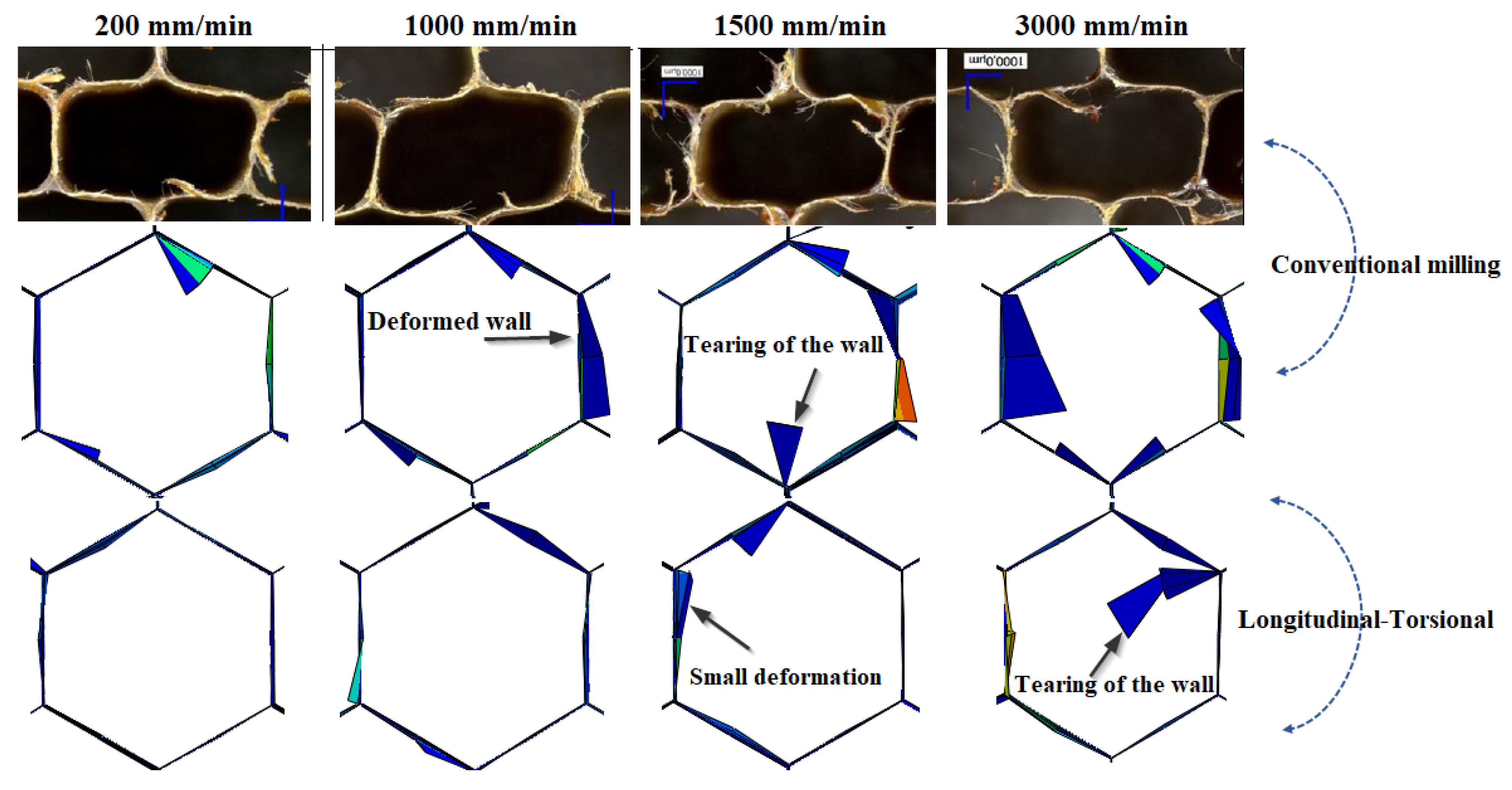

5.1. Analysis of Surface Defects as a Function of Feed Rate

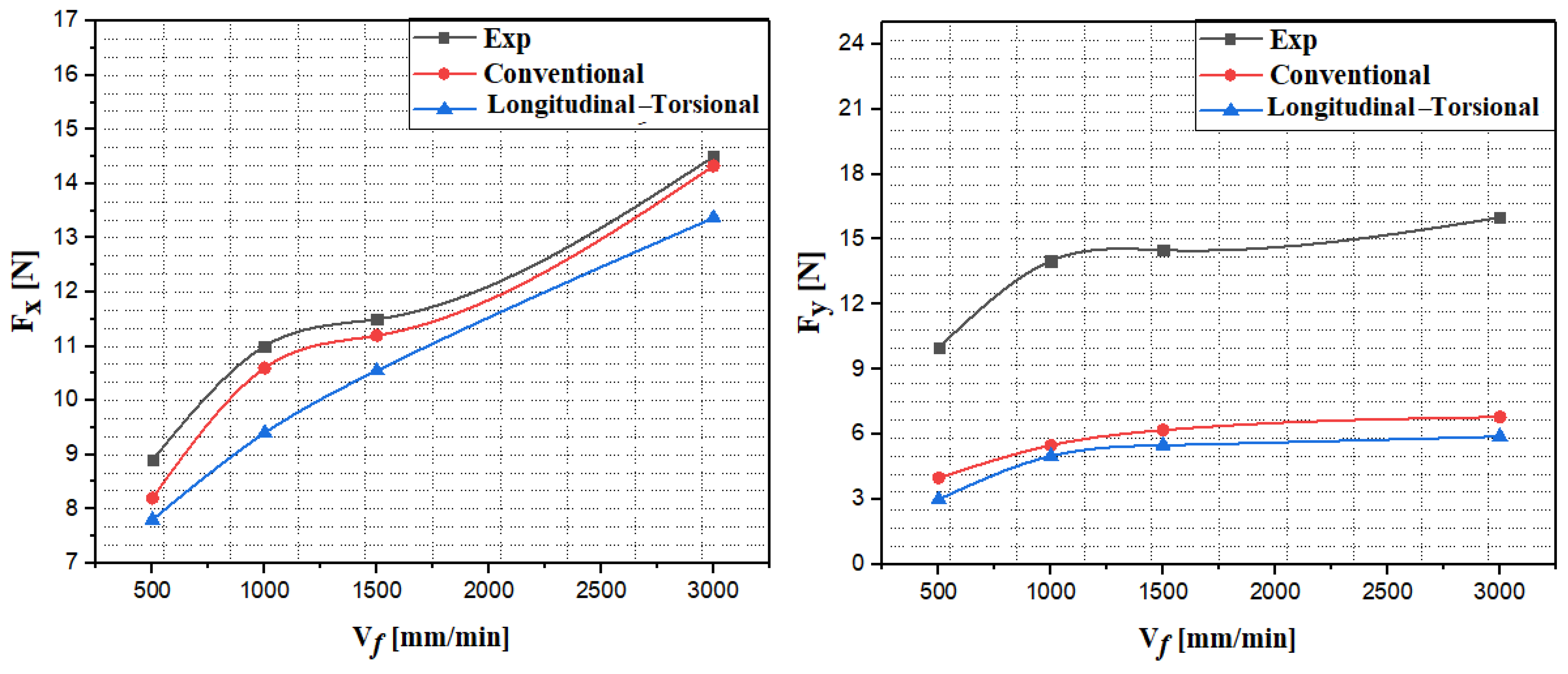

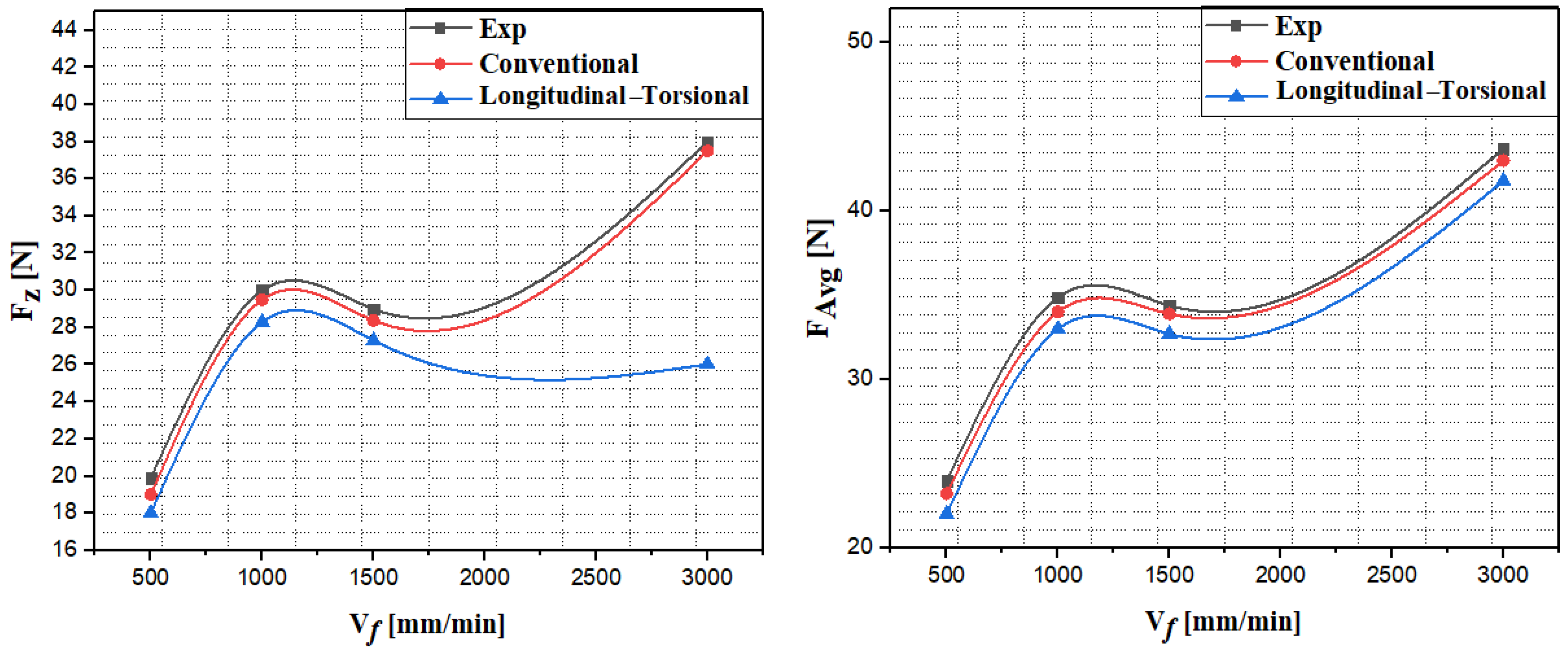

5.2. Comparative Analysis of Conventional and Longitudinal–Torsional Machining: Impact of Feed Rate on Cutting Force and Its Components

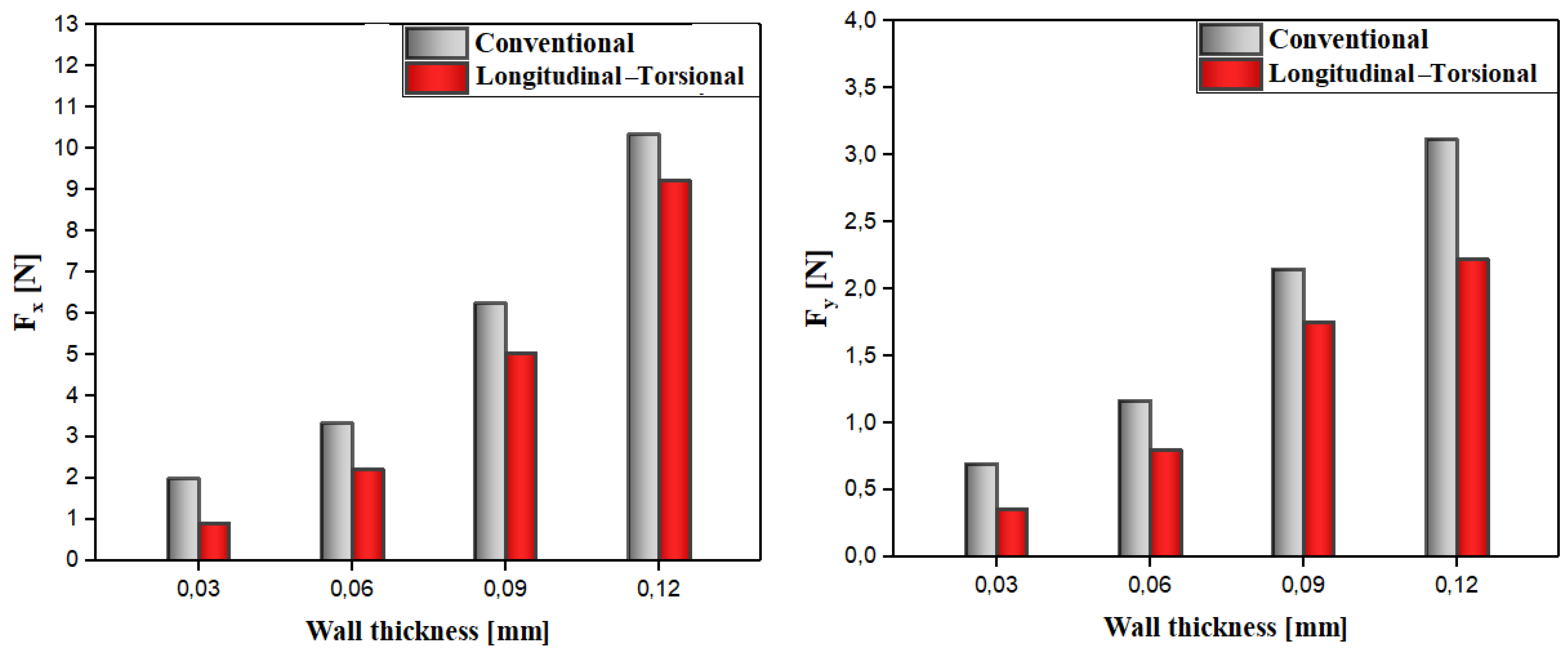

5.3. Comparative Analysis of Conventional and Longitudinal–Torsional Machining: Impact of Wall Thickness on Cutting Force and Its Components

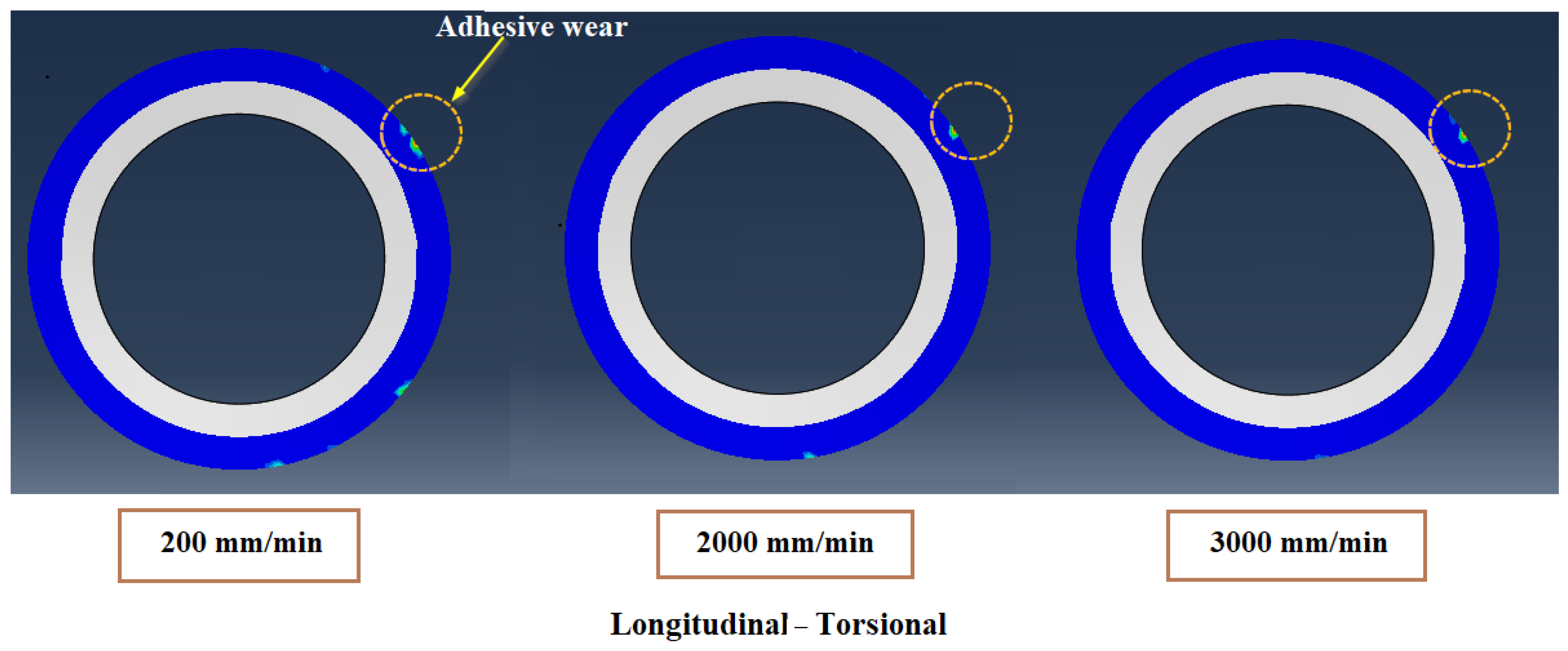

5.4. Comparative Analysis of Conventional and Longitudinal–Torsional Machining: Impact of Feed Rate on Cutting Tool Wear

6. Conclusions

- The integration of longitudinal torsional vibrations made it possible to reduce cutting force in all directions, with reductions ranging from 20% to 40%, particularly for the Fz and Fx components.

- At high feed rates, the ultrasonic vibration-assisted longitudinal–torsional milling process reduces adhesive wear, thus enabling a cleaner cut and increased tool durability, unlike conventional milling, which promotes adhesive wear, especially at low feed rates.

- The integration of the new longitudinal–torsional milling technology into the CZ10 combined cutting tool significantly improves the efficiency of the milling process, thus providing a more robust, precise and efficient solution, meeting the demanding standards of the industrial sectors.

- Surface defects, such as tears and deformations, are significantly reduced with ultrasonic vibration-assisted machining. This method maintains superior surface quality even at high feed rates (3000 mm/min), unlike conventional machining, where surface quality deteriorates rapidly under similar conditions.

- In order to improve the simulation of the interaction between the cutting tool and the structure, it would be necessary to replace the S4R shell elements with solid elements in the cutting zone, thus allowing a more accurate simulation of the burrs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Foo, C.C.; Chai, G.B.; Seah, L.K. Propriétés mécaniques du matériau Nomex et de la structure alvéolaire Nomex. Compos. Struct. 2007, 80, 588–594. [Google Scholar] [CrossRef]

- Ahmad, S.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z.; Ma, K. Technologies de traitement des composites alvéolaires Nomex (NHC): Revue critique. Compos. Struct. 2020, 250, 112545. [Google Scholar] [CrossRef]

- Roy, R.; Park, S.-J.; Kweon, J.-H.; Choi, J.-H. Caractérisation des propriétés mécaniques des matériaux constitutifs de l’âme alvéolaire Nomex. Compos. Struct. 2014, 117, 255–266. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Gao, W. Out-of-plane shear property analysis of Nomex honeycomb sandwich structure. J. Reinf. Plast. Compos. 2021, 40, 165–175. [Google Scholar] [CrossRef]

- Li, W.; Qiu, C.; Li, Z.; Nie, H. Un critère de rupture pour les structures en nid d’abeilles prenant en compte l’apparition d’instabilité sous charges hors plan. J. Sandw. Struct. Mater. 2020, 425586206. [Google Scholar]

- Zarrouk, T.; Salhi, J.E.; Nouari, M.; Bouali, A. Enhancing the Machining Performance of Nomex Honeycomb Composites Using Rotary Ultrasonic Machining: A Finite Element Analysis Approach. Materials 2024, 17, 2044. [Google Scholar] [CrossRef]

- Mughal, K.H.; Qureshi, M.A.M.; Jamil, M.F.; Ahmad, S.; Khalid, F.A.; Qaiser, A.A.; Maqbool, A.; Raza, S.F.; Zhang, J. Investigation of hybrid ultrasonic machining process of Nomex honeycomb composite using a toothed disc cutter. Ultrasonics 2024, 141, 107343. [Google Scholar] [CrossRef]

- Zarrouk, T.; Nouari, M.; Salhi, J.E.; Essaouini, H.; Abbadi, M.; Abbadi, A.; Lahlaouti, M.L. In-Depth Analysis of the Processing of Nomex Honeycomb Composites: Problems, Techniques and Perspectives. Machines 2024, 12, 561. [Google Scholar] [CrossRef]

- Ahmad, S.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z. Experimental study on rotary ultrasonic machining (RUM) characteristics of Nomex honeycomb composites (NHCs) by circular knife cutting tools. J. Manuf. Process. 2020, 58, 524–535. [Google Scholar] [CrossRef]

- Daud, S.Z.M.; Lim, J.; Amir, M.; Kim, S.W. Enhancing impact energy absorption in composite sandwich structures through synergistic smart material integration. Results Eng. 2024, 21, 101902. [Google Scholar] [CrossRef]

- Yang, C.; Huo, Y.; Meng, K.; Zhou, W.; Yang, J.; Nan, Z. Fatigue failure analysis of platform screen doors under subway aerodynamic loads using finite element modeling. Eng. Fail. Anal. 2025, 174, 109502. [Google Scholar] [CrossRef]

- Xu, P.; Guo, W.; Yang, L.; Yang, C.; Zhou, S. Crashworthiness analysis and multi-objective optimization of a novel metal/CFRP hybrid friction structures. Struct. Multidiscip. Optim. 2024, 67, 97. [Google Scholar] [CrossRef]

- Jiang, E.; Yue, Q.; Xu, J.; Fan, C.; Song, G.; Yuan, X.; Ma, Y.; Yu, X.; Yang, P.; Feng, P.; et al. A wear testing method of straight blade tools for Nomex honeycomb composites machining. Wear 2024, 546, 205325. [Google Scholar] [CrossRef]

- Xu, J.; Yue, Q.; Zha, H.; Yuan, X.; Cai, X.; Xu, C.; Ma, Y.; Feng, P.; Feng, F. Wear reduction by toughness enhancement of disc tool in Nomex honeycomb composites machining. Tribol. Int. 2023, 185, 108475. [Google Scholar] [CrossRef]

- Zarrouk, T.; Nouari, M.; Salhi, J.E. Numerical study on rotary ultrasonic machining (RUM) characteristics of Nomex honeycomb composites (NHCs) by UCSB cutting tool. Int. J. Adv. Manuf. Technol. 2024, 132, 5351–5366. [Google Scholar] [CrossRef]

- Zarrouk, T.; Salhi, J.E.; Atlati, S.; Nouari, M.; Salhi, M.; Salhi, N. Study on the behavior law when milling the material of the Nomex honeycomb core. Mater. Today Proc. 2021, 45, 7477–7485. [Google Scholar] [CrossRef]

- Zarrouk, T.; Nouari, M.; Makich, H. Simulated Study of the Machinability of the Nomex Honeycomb Structure. J. Manuf. Mater. Process. 2023, 7, 28. [Google Scholar] [CrossRef]

- Zarrouk, T.; Nouari, M.; Salhi, J.E.; Abbadi, M.; Abbadi, A. Three-Dimensional Finite Element Modeling of Ultrasonic Vibration-Assisted Milling of the Nomex Honeycomb Structure. Algorithms 2024, 17, 204. [Google Scholar] [CrossRef]

- Liang, Y.; Feng, P.; Song, Z.; Zhu, S.; Wang, T.; Xu, J.; Yue, Q.; Jiang, E.; Ma, Y.; Song, G.; et al. Wear Mechanisms of Straight Blade Tool by Dual-Periodic Impact Platform. Int. J. Mech. Sci. 2025, 288, 110031. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Kang, R.; Sun, J.; Jia, Z.; Dong, Z. Analysis of influence on ultrasonic-assisted cutting force of Nomex honeycomb core material with straight knife. Chin. J. Mech. Eng. 2017, 53, 73–82. [Google Scholar] [CrossRef]

- Cao, W.; Zha, J.; Chen, Y. Cutting force prediction and experiment verification of paper honeycomb materials by ultrasonic vibration-assisted machining. Appl. Sci. 2020, 10, 4676. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, Z.; Wang, Y.; Xu, Z.; Song, H.; Kang, R. Charization of surface microscopic of Nomex honeycomb after ultrasonic assisted cutting. J. Mech. Eng. 2007, 53, 90–99. [Google Scholar] [CrossRef]

- Xiang, D.; Wu, B.; Yao, Y.; Liu, Z.; Feng, H. Ultrasonic longitudinal-torsional vibration-assisted cutting of Nomex® honey-comb-core composites. Int. J. Adv. Manuf. Technol. 2019, 100, 1521–1530. [Google Scholar] [CrossRef]

- Jaafar, M. Étude Expérimentale et Simulation Numérique de L’usinage des Matériaux en Nids D’abeilles: Application au Fraisage des Structures Nomex® et Aluminium. Ph.D. Thesis, Université de Lorraine, Nancy, France, 2018. [Google Scholar]

- Fischer, S.; Drechsler, K.; Kilchert, S.; Johnson, A. Mechanical tests for foldcore base material properties. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1941–1952. [Google Scholar] [CrossRef]

- Nasir, M.A.; Khan, Z.; Farooqi, I.; Nauman, S.; Anas, S.; Khalil, S.; Pasha, A.; Shah, M.; Qaiser, H.; Ata, R. Transverse shear behavior of a Nomex core for sandwich panels. Mech. Compos. Mater. 2015, 50, 733–738. [Google Scholar] [CrossRef]

- Jenarthanan, M.P.; Jeyapaul, R. Optimisation of machining parameters on milling of GFRP composites by desirability function analysis using Taguchi method. Int. J. Eng. Sci. Technol. 2013, 5, 22–36. [Google Scholar] [CrossRef]

- Keshavanarayana, S.; Thotakuri, M.V. Off-axis compression behaviour of honeycomb core in WT-plane. Int. J. Crashworthiness 2009, 14, 173–181. [Google Scholar] [CrossRef]

- Haddad, M. Étude de L’impact des Défauts D’usinage des Structures Composites par Détourage sur leur Comportement Mécanique. Ph.D. Thesis, Université Toulouse III—Paul Sabatier, Toulouse, France, 2013. [Google Scholar]

| Density [g/cm3] | Young’s Modulus [MPa] | Poisson’s Radio |

|---|---|---|

| 1.4 | 3400 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zarrouk, T.; Salhi, J.-E.; Nouari, M.; Barboucha, M. Modeling of Nomex Honeycomb Structure Milling Assisted by Longitudinal–Torsional Vibrations with a CZ10 Combined Tool: Optimization of Tool Wear and Surface Integrity. Appl. Mech. 2025, 6, 47. https://doi.org/10.3390/applmech6030047

Zarrouk T, Salhi J-E, Nouari M, Barboucha M. Modeling of Nomex Honeycomb Structure Milling Assisted by Longitudinal–Torsional Vibrations with a CZ10 Combined Tool: Optimization of Tool Wear and Surface Integrity. Applied Mechanics. 2025; 6(3):47. https://doi.org/10.3390/applmech6030047

Chicago/Turabian StyleZarrouk, Tarik, Jamal-Eddine Salhi, Mohammed Nouari, and Mohammed Barboucha. 2025. "Modeling of Nomex Honeycomb Structure Milling Assisted by Longitudinal–Torsional Vibrations with a CZ10 Combined Tool: Optimization of Tool Wear and Surface Integrity" Applied Mechanics 6, no. 3: 47. https://doi.org/10.3390/applmech6030047

APA StyleZarrouk, T., Salhi, J.-E., Nouari, M., & Barboucha, M. (2025). Modeling of Nomex Honeycomb Structure Milling Assisted by Longitudinal–Torsional Vibrations with a CZ10 Combined Tool: Optimization of Tool Wear and Surface Integrity. Applied Mechanics, 6(3), 47. https://doi.org/10.3390/applmech6030047