Metallography Specimen Mounting Device Suitable for Industrial or Educational Purposes

Abstract

1. Introduction

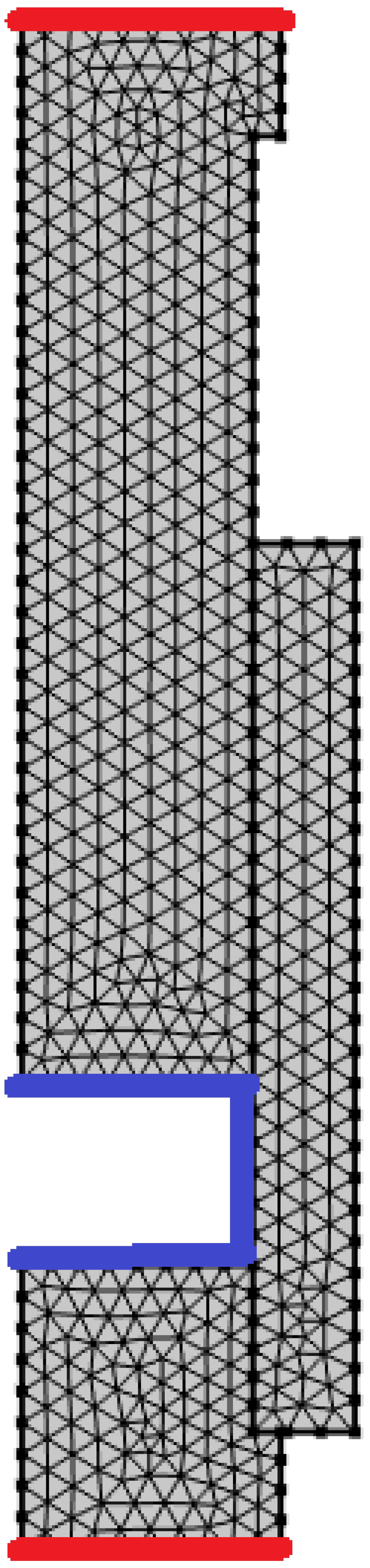

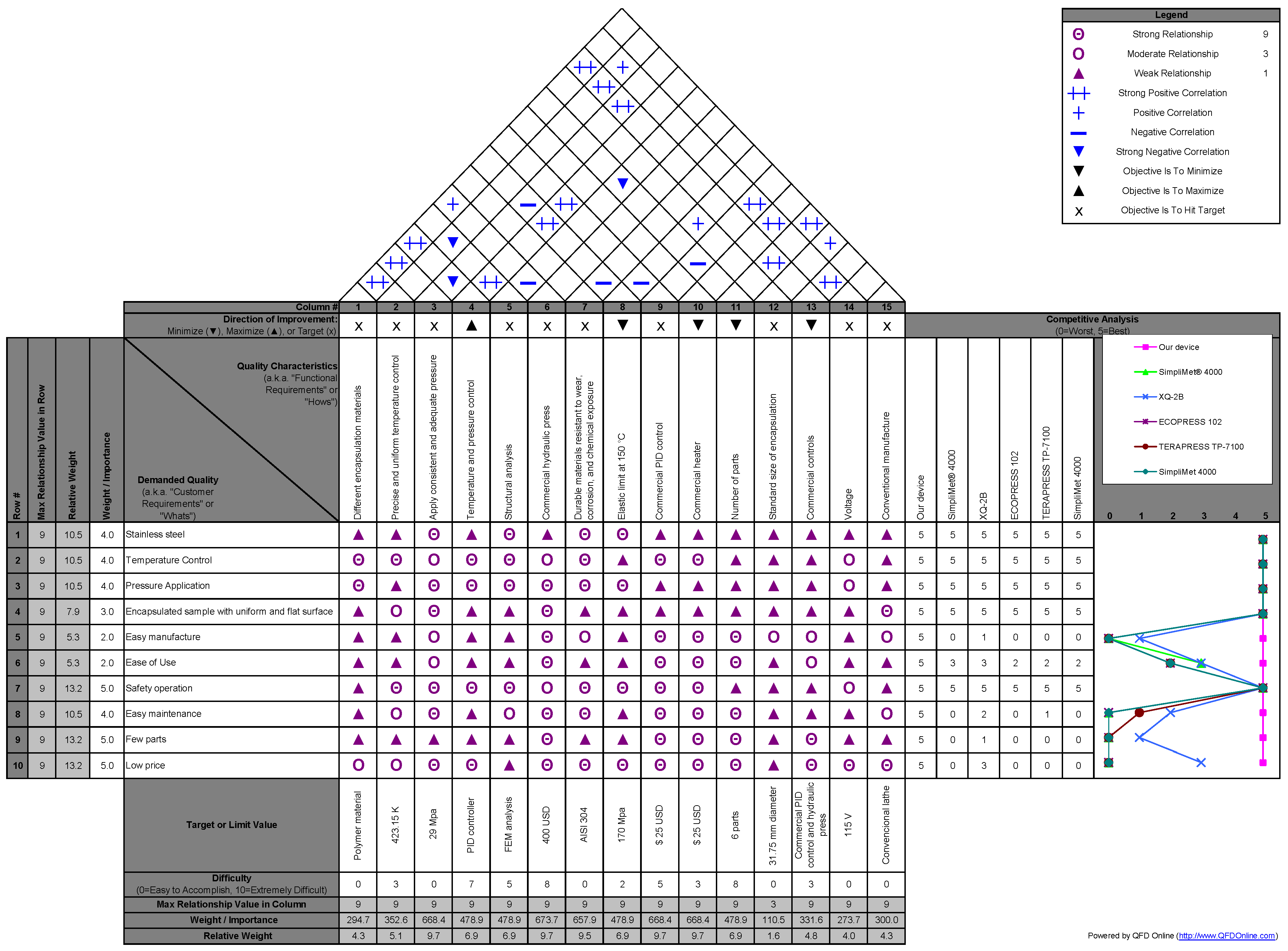

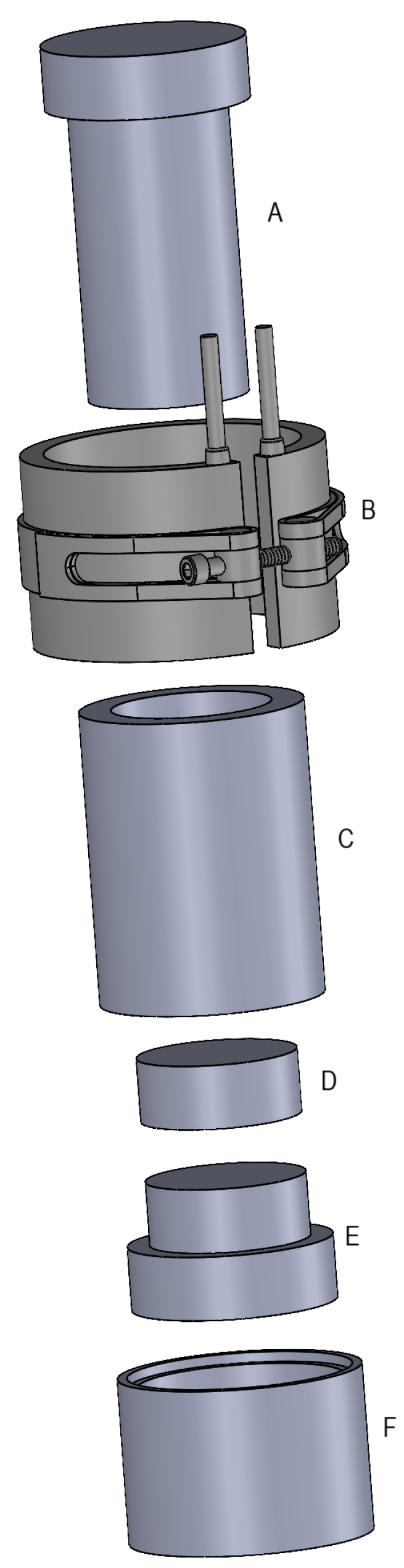

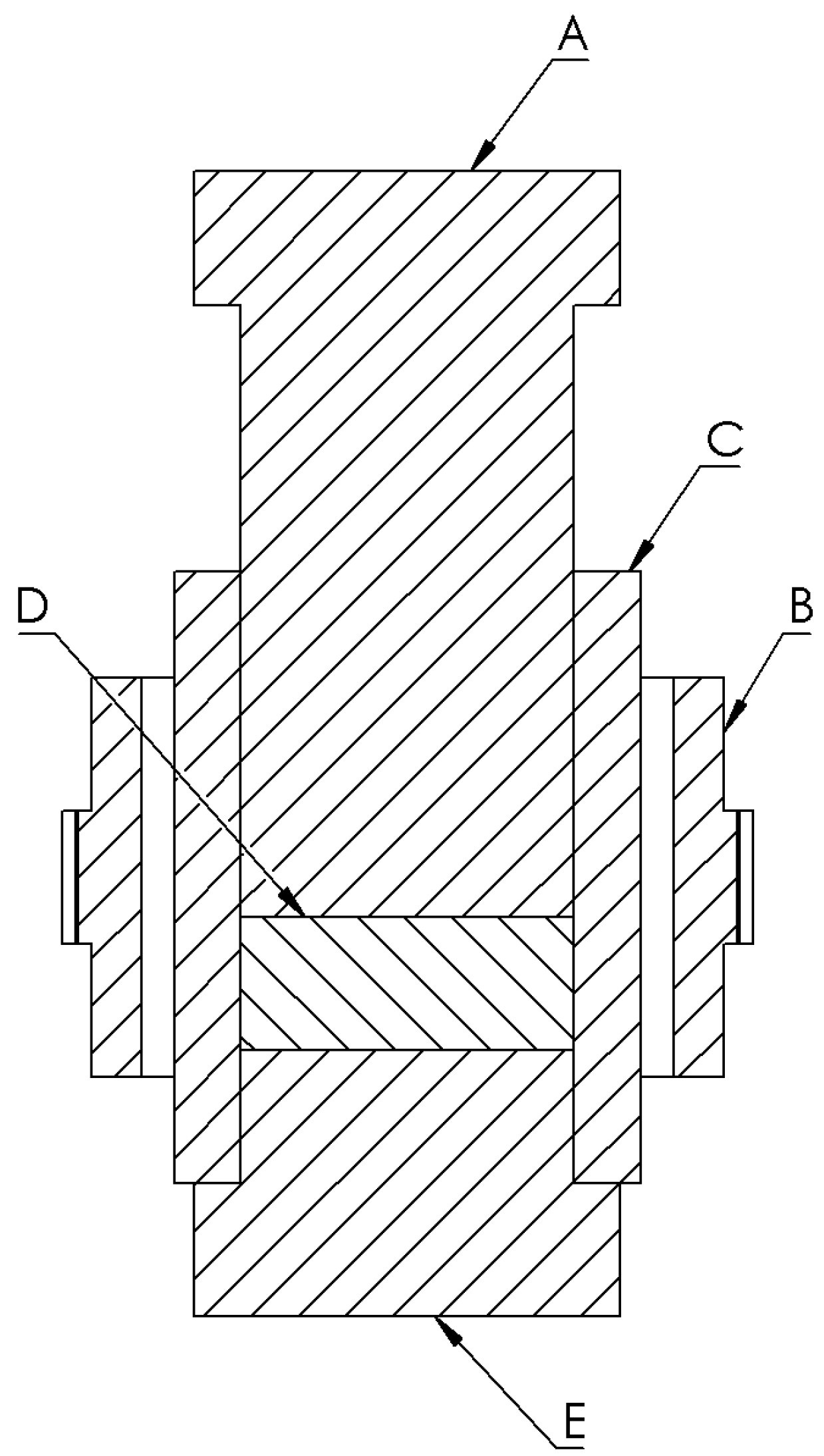

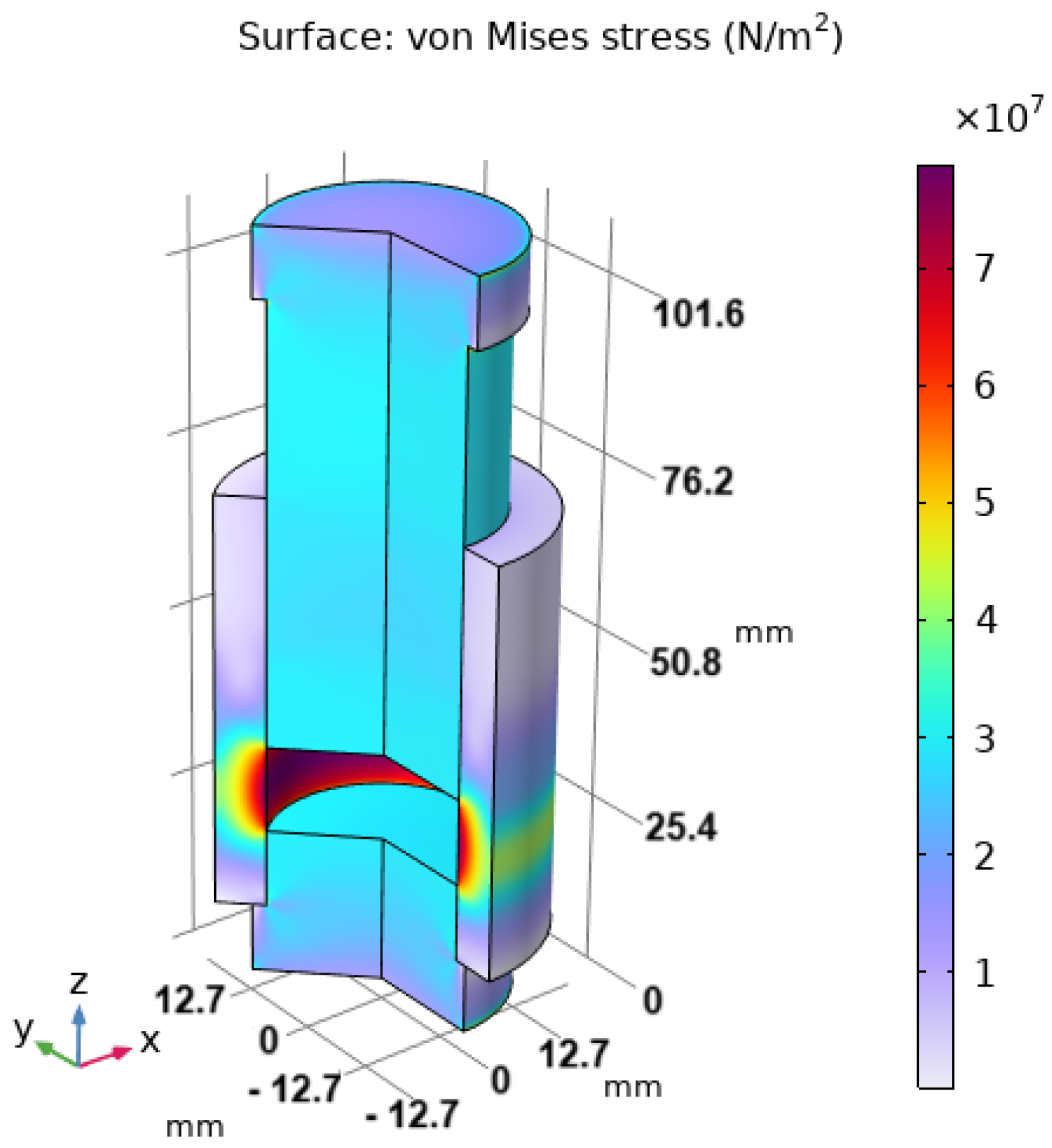

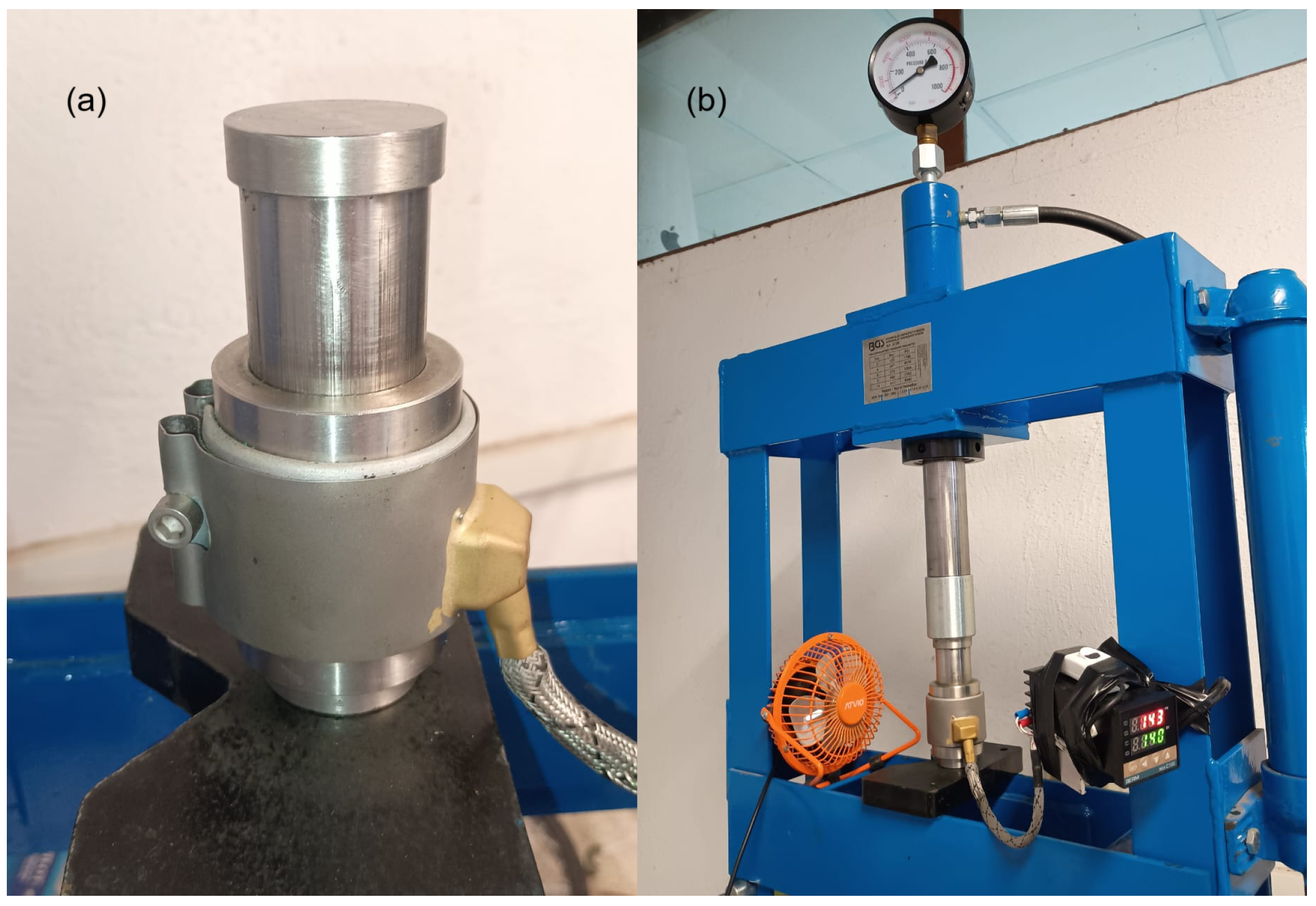

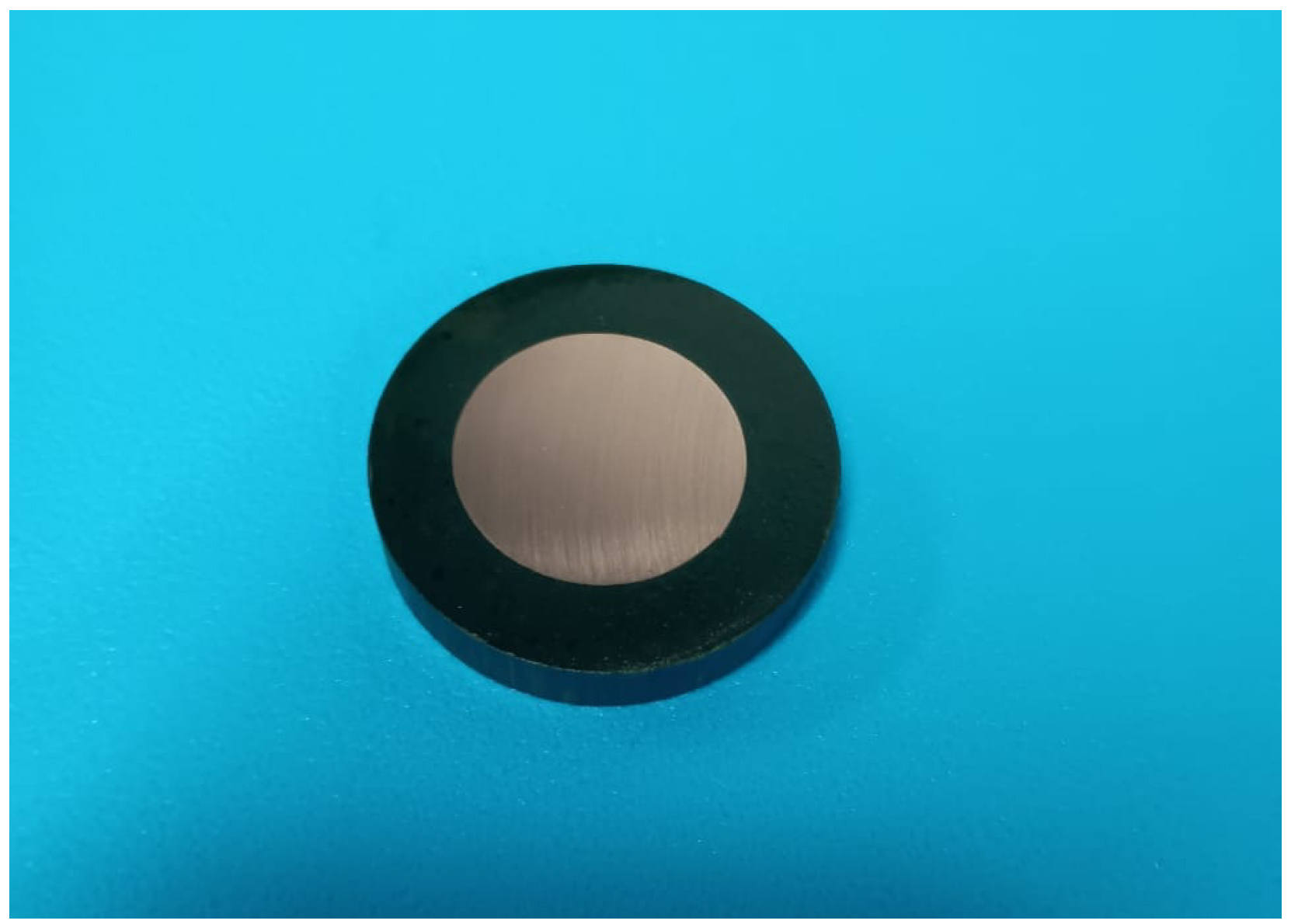

2. Materials and Methods

3. Design and Modeling

4. Results and Discussions

5. Conclusions

6. Patents

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HoQ | House of Quality |

| QFD | Quality Function Deployment |

| FEM | Finite Element Method |

| FoS | Factor of Security |

References

- Saha, S.; Wiese, G. Grain size characterization of nickel alloy 718 with optimized metallographic sample preparation route followed by a novel etching technique. Pract. Metallogr. 2025, 62, 97–120. [Google Scholar] [CrossRef]

- Peñuela-Cruz, C.; Márquez-Herrera, A.; Aguilera-Gómez, E.; Saldaña-Robles, A.; Mis-Fernández, R.; Peña, J.; Caballero-Briones, F.; Loeza-Poot, M.; Hernández-Rodríguez, E. The effects of sandblasting on the surface properties of magnesium sheets: A statistical study. J. Mater. Res. Technol. 2023, 23, 1321–1331. [Google Scholar] [CrossRef]

- Salazar-Peralta, A.; Bernal-Martínez, L.A.; Sánchez-Orozco, R. Application of the Metallographic Method in Steels with Low Carbon Content; ECORFAN: Mexico City, Mexico, 2024. [Google Scholar] [CrossRef]

- Vander Voort, G.F. Metallographic Techniques in Failure Analysis; ASM International: Almere, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Perez, N. Metallography and Microscopy. In Materials Science: Theory and Engineering; Springer: Berlin/Heidelberg, Germany, 2024; pp. 139–180. [Google Scholar]

- Ravikumar, S.; Surekha, R.; Thavarajah, R. Mounting media: An overview. J. Dr. Ysr Univ. Health Sci. 2014, 3, S1–S8. [Google Scholar] [CrossRef]

- Azmi, M.N.B.N.; Suhaimi, K.B. Design and fabrication of JIG to hold metallographic specimen. Int. J. Res. Innov. Manag. 2022, 8, 21–34. [Google Scholar]

- Warren, D.F.; Tate, R.S.; Cox, M.D. Sample Mounting Press. U.S. Patent 7,404,707, 29 July 2008. [Google Scholar]

- Akinlabi, O.; Adeiza, B.; Emmanuel, O. Development of laboratory hot compression mounting press machine. J. Sci. Res. Rep. 2018, 18, 1–12. [Google Scholar] [CrossRef]

- Florin-Timotei, A.; Flaviu-Ionuţ, B. Automation of a Metallographic Sample Preparation Station. J. Electr. Electron. Eng. 2019, 12, 23–26. [Google Scholar]

- Keith, M.W., Jr. Mounting Press. U.S. Patent 4,131,403, 26 December 1978. [Google Scholar]

- Almazán-Gómez, M.Á.; El Khatabi, F.; Llano, C.; Pérez, J. Modelling regional exposure to new trade wars. J. Policy Model. 2025, in press. [Google Scholar] [CrossRef]

- Mundial, F.E. Bridging the Skills and Innovation Gap to Boost Productivity in Latin America; World Economic Forum: Geneva, Switzerland, 2015. [Google Scholar]

- Tiwari, A.; Vasnani, H.; Jain, R.; Swarnkar, H.; Tanwar, H.; Srivastava, S. Fabrication of low-cost metal polishing machine for preparation of microstructure samples of lightweight alloy and composite material. Glob. J. Eng. Technol. Adv. 2024, 19, 112–123. [Google Scholar] [CrossRef]

- Akinlabi, O.; Abel, B.; Emmanuel, O.O. Development of a Laboratory Metallographic Grinding/Polishing Machine. Adv. Res. 2019, 17, 1–13. [Google Scholar] [CrossRef]

- Rimantho, D.; Pratomo, V.A.; Pane, E.A.; Noywuli, N. Quality Function Deployment Method for Cooking Stove Design Using Hermetia Illucens Oil. Math. Model. Eng. Probl. 2025, 12, 103–114. [Google Scholar] [CrossRef]

- Akao, Y. Quality Function Deployment: Integrating Customer Requirements into Product Design; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar]

- Muñoz, E. Diseño de Autoclave Para Materiales Compuestos. Ph.D. Thesis, Universidad Nacional de Mar del Plata. Facultad de Ingeniería, Mar del Plata, Argentina, 2025. [Google Scholar]

- Xiong, L.; Lan, S.; Wang, J.; Ding, X.; Yuan, Y. Numerical simulation analysis of discharge in water under different pressures. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 2461–2468. [Google Scholar] [CrossRef]

- Goyal, R.K. Simulation and design of hybrid hydrogen storage tanks: Aluminium liner with glass fiber overwrap. Int. J. Hydrogen Energy 2025, 106, 969–972. [Google Scholar] [CrossRef]

- Vignesh, R.V.; Gunasekaran, S.; Padmanaban, R.; Thirumalini, S. Numerical Simulation of Wear in Wind Turbine Brake Pads. In Advances in Solid-State Welding and Processing of Metallic Materials; CRC Press: Boca Raton, FL, USA, 2025; pp. 233–256. [Google Scholar]

- Pedrero Moya, J.I. Tecnología de Máquinas. Tomo i. Fundamentos. Ejes, Acoplamientos y Apoyos; Editorial UNED: Madrid, Spain, 2023; Volume 1. [Google Scholar]

- Dowling, N.E.; Kampe, S.L.; Kral, M.V. Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture, and Fatigue, 5th ed.; Pearson: Harlow, UK, 2020. [Google Scholar]

- Committee, A.I.H. ASM Handbook: Fatigue and Fracture; ASM International: Almere, The Netherlands, 1990; Volume 19. [Google Scholar]

- Guthrie, R.; Jonas, J.; ASM, M.H.V. 1: Properties and Selection: Irons Steels and High Performance Alloys; ASM International: Almere, The Netherlands, 1990; Volume 2, p. 329. [Google Scholar]

- Carrizo, P.S. Application of Metallographic Techniques to Studies in Ancient Metals. In Reverse Engineering of Ancient Metals; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; pp. 93–122. [Google Scholar] [CrossRef]

| Parameter | Proposed Device | Commercial Systems |

|---|---|---|

| Cost | <$500 USD | $5000–$10,000 USD |

| Component Count | 6 | ~100 |

| Safety Factor (FoS) | 2.1 | 1.5–2.0 (industry standard) |

| Heating System | Commercial | Proprietary, integrated |

| Compatibility | Standard hydraulic press | Specialized equipment |

| Heat up and cooling time | ≥6 min | ≥2 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Márquez-Herrera, A. Metallography Specimen Mounting Device Suitable for Industrial or Educational Purposes. Appl. Mech. 2025, 6, 36. https://doi.org/10.3390/applmech6020036

Márquez-Herrera A. Metallography Specimen Mounting Device Suitable for Industrial or Educational Purposes. Applied Mechanics. 2025; 6(2):36. https://doi.org/10.3390/applmech6020036

Chicago/Turabian StyleMárquez-Herrera, Alfredo. 2025. "Metallography Specimen Mounting Device Suitable for Industrial or Educational Purposes" Applied Mechanics 6, no. 2: 36. https://doi.org/10.3390/applmech6020036

APA StyleMárquez-Herrera, A. (2025). Metallography Specimen Mounting Device Suitable for Industrial or Educational Purposes. Applied Mechanics, 6(2), 36. https://doi.org/10.3390/applmech6020036