-

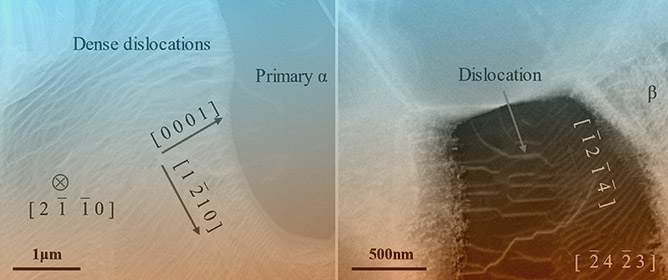

The Effect of Microstructure on the Very High Cycle Fatigue Behavior of Ti-6Al-4V Alloy

The Effect of Microstructure on the Very High Cycle Fatigue Behavior of Ti-6Al-4V Alloy -

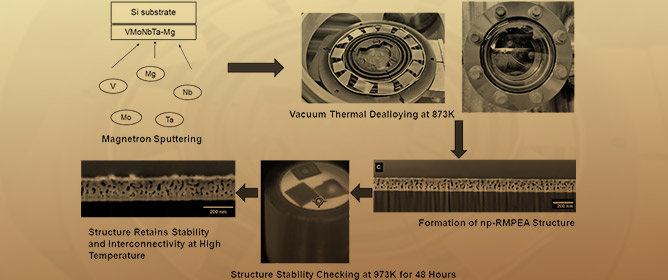

Inhibited Surface Diffusion in Nanoporous Multi-Principal Element Alloy Thin Films Prepared by Vacuum Thermal Dealloying

Inhibited Surface Diffusion in Nanoporous Multi-Principal Element Alloy Thin Films Prepared by Vacuum Thermal Dealloying -

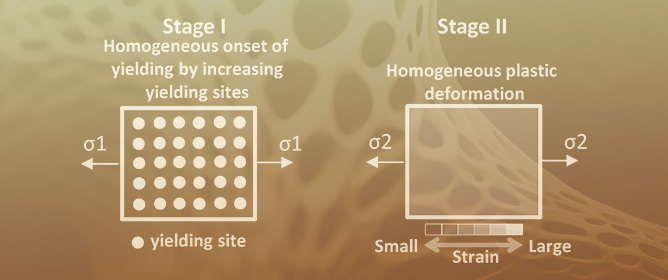

Suppression of Inhomogeneous Plastic Deformation in Medium-Carbon Tempered Martensite Steel

Suppression of Inhomogeneous Plastic Deformation in Medium-Carbon Tempered Martensite Steel -

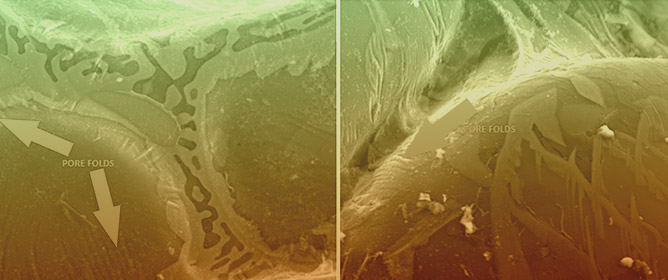

Effect of Gating System Design on the Quality of Aluminum Alloy Castings

Effect of Gating System Design on the Quality of Aluminum Alloy Castings -

A Study of a Cryogenic CuAlMn Shape Memory Alloy

A Study of a Cryogenic CuAlMn Shape Memory Alloy

Journal Description

Metals

Metals

is an international, peer-reviewed, open access journal published monthly online by MDPI. The Portuguese Society of Materials (SPM), and the Spanish Materials Society (SOCIEMAT) are affiliated with Metals and their members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), Inspec, CAPlus / SciFinder, and other databases.

- Journal Rank: JCR - Q2 (Metallurgy & Metallurgical Engineering) / CiteScore - Q1 (Metals and Alloys)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 15 days after submission; acceptance to publication is undertaken in 2.7 days (median values for papers published in this journal in the second half of 2023).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Companion journals for Metals include: Compounds and Alloys.

Impact Factor:

2.9 (2022);

5-Year Impact Factor:

2.9 (2022)

Latest Articles

Modelling and Prediction of Process Parameters with Low Energy Consumption in Wire Arc Additive Manufacturing Based on Machine Learning

Metals 2024, 14(5), 567; https://doi.org/10.3390/met14050567 (registering DOI) - 11 May 2024

Abstract

Wire arc additive manufacturing (WAAM) has attracted increasing interest in industry and academia due to its capability to produce large and complex metallic components at a high deposition rate. One of the basic tasks in WAAM is to determine appropriate process parameters, which

[...] Read more.

Wire arc additive manufacturing (WAAM) has attracted increasing interest in industry and academia due to its capability to produce large and complex metallic components at a high deposition rate. One of the basic tasks in WAAM is to determine appropriate process parameters, which will directly affect the morphology and quality of the weld bead. However, the selection of process parameters relies heavily on empirical data from trial-and-error experiments, which results in significant time and cost expenditures. This paper employed different machine learning models, including SVR, BPNN, and XGBoost, to predict process parameters for WAAM. Furthermore, the SVR model was optimized by the Genetic Algorithm (GA) and Particle Swarm Optimization (PSO) algorithms. A 3D laser scanner was employed to obtain the weld bead’s point cloud, and the weld bead size was extracted using the point cloud processing algorithm as the training data. The K-fold cross-validation strategy was applied to train and validate machine learning models. The comparison results showed that PSO–SVR predicted process parameters with the highest precision, with the RMSE, R2, and MAE being 1.1670, 0.9879, and 0.8310, respectively. Based on the process parameters produced by PSO–SVR, an optimal process parameter combination was chosen by taking into comprehensive consideration the impacts of power consumption and efficiency. The effectiveness of the process parameter optimization method was proved through three groups of validation experiments, with the energy consumption of the first two groups decreasing by 10.68% and 11.47%, respectively.

Full article

(This article belongs to the Special Issue Advances in Additive Manufacturing and Their Applications (2nd Edition))

►

Show Figures

Open AccessArticle

Non-Contact Evaluation of Deformation Characteristics on Automotive Steel Sheets

by

Ľubomír Ambriško and Ladislav Pešek

Metals 2024, 14(5), 566; https://doi.org/10.3390/met14050566 (registering DOI) - 11 May 2024

Abstract

►▼

Show Figures

The work is focused on experimental research of deformation characteristics on three grades of hot-dip galvanized steels for the automotive industry. Deformation maps were obtained using the DIC (Digital Image Correlation) method. The map documents the development of longitudinal and transverse deformations under

[...] Read more.

The work is focused on experimental research of deformation characteristics on three grades of hot-dip galvanized steels for the automotive industry. Deformation maps were obtained using the DIC (Digital Image Correlation) method. The map documents the development of longitudinal and transverse deformations under tensile stress. In addition to uniaxial tension, the investigated specimens were subjected to eccentric tension. The stable crack growth (SCG) was evaluated using a non-contact measurement technique on CT (compact tension) specimens. The deformation of steels, which affects the resistance to stable crack growth (confirmed by the Design of Experiments—DOE method), was manifested in the first stages of eccentric loading of specimens. The notch root radius varies considerably due to the blunting of the starting fatigue crack. The resistance to stable crack growth, which represents a safety reserve during a vehicle crash, was obtained.

Full article

Figure 1

Open AccessArticle

Microwave Treatment of Copper–Nickel Sulfide Ore for Promotion of Grinding and Flotation

by

Xiaolei Fang, Zhiwei Peng, Tianle Yin, Mingjun Rao and Guanghui Li

Metals 2024, 14(5), 565; https://doi.org/10.3390/met14050565 (registering DOI) - 11 May 2024

Abstract

The effect of microwave treatment on the grinding and flotation performance of a typical copper–nickel sulfide ore was evaluated, based on the determination of its microwave absorption capability, grinding and flotation indexes such as crack percentage, mineral liberation degree, particle size distribution, relative

[...] Read more.

The effect of microwave treatment on the grinding and flotation performance of a typical copper–nickel sulfide ore was evaluated, based on the determination of its microwave absorption capability, grinding and flotation indexes such as crack percentage, mineral liberation degree, particle size distribution, relative work index (RWI), metal enrichment ratio, and recovery. There were obvious differences between the microwave absorption capabilities of the main minerals in the ore, as demonstrated by their different microwave penetration depths. They also induced temperature differences between sulfide minerals and gangue minerals which could reach 418 °C after microwave treatment for 20 s. It was shown that microwave treatment could effectively improve the grindability of the ore, as proven by the increase in fine particles smaller than 0.074 mm and a decrease in RWI after grinding due to the higher crack percentage and mineral liberation degree. Moreover, microwave treatment affected the ore floatability because of the generation of cuprite, retgersite, and rozenite with poor floatability when the treatment time was extended. By microwave treatment for a proper time, 20 s, an optimal balance between the grindability and flotation performance could be achieved. Compared with the untreated ore, the RWI of the ore decreased by 11.5%. After flotation, the Cu and Ni enrichment ratios of the flotation concentrate increased by 0.3 and 0.2, respectively. Meanwhile, their corresponding recoveries increased by 4.2% and 3.1%. This study provides new insights for the treatment of copper–nickel sulfide ore to enhance the grinding and flotation process.

Full article

(This article belongs to the Special Issue Toward Achieving a Carbon-Neutral Society: Beneficiation and Extractive Metallurgy for Producing Critical Metals from Ores/Wastes)

Open AccessArticle

Niobium’s Effect on the Properties of a Quasi-High-Entropy Alloy of the CoCrFeMnNi System

by

Svetlana Kvon, Aristotel Issagulov, Vitaliy Kulikov and Saniya Arinova

Metals 2024, 14(5), 564; https://doi.org/10.3390/met14050564 (registering DOI) - 10 May 2024

Abstract

This paper deals with the possibility of smelting quasi-high-entropy alloys (QHEAs) with the partial use of ferroalloys in the charge instead of pure metals. The Cantor alloy (CoCrFeMnNi) was used as the base alloy and the comparison sample, into which niobium was introduced

[...] Read more.

This paper deals with the possibility of smelting quasi-high-entropy alloys (QHEAs) with the partial use of ferroalloys in the charge instead of pure metals. The Cantor alloy (CoCrFeMnNi) was used as the base alloy and the comparison sample, into which niobium was introduced in the amount of 14 to 18% by weight. The structure, hardness, strength, and tribological properties of prototypes were studied. The results obtained showed, on the one hand, the possibility of using ferroalloys as charge components in the smelting of QHEAs and, on the other hand, the positive effect of niobium in the amount of 14–17% on the strength and wear resistance of the alloy. Increasing the niobium content above 18% leads to its uneven distribution in the structure, consequently decreasing the strength and wear resistance of the alloy. The structure of the studied alloys is represented by a solid solution of FCC, which includes all metals, and the niobium content varies widely. In addition, the structure is represented by the phases of implementation: niobium carbide NbC 0.76–1.0, manganese carbide Mn7C3, and a CrNi intermetallic compound with a cubic lattice.

Full article

Open AccessArticle

Theoretical Energy Consumption Analysis for Sustainable Practices in Iron and Steel Industry

by

Hongming Na, Jingchao Sun, Yuxing Yuan, Ziyang Qiu, Lei Zhang and Tao Du

Metals 2024, 14(5), 563; https://doi.org/10.3390/met14050563 (registering DOI) - 10 May 2024

Abstract

Exploring theoretical energy consumption introduces a fresh perspective for energy-saving research within the iron and steel industry, with a primary focus on the energy expended during material transformation. Building upon the theory of theoretical energy consumption, this study meticulously investigates the theoretical energy

[...] Read more.

Exploring theoretical energy consumption introduces a fresh perspective for energy-saving research within the iron and steel industry, with a primary focus on the energy expended during material transformation. Building upon the theory of theoretical energy consumption, this study meticulously investigates the theoretical energy consumption associated with each stage of the iron and steel making process, including coking, sintering, pelletizing, ironmaking, steelmaking, and hot rolling. The findings reveal that, under specific conditions, the theoretical energy consumption for each process is as follows: coking (2.59 GJ), sintering (1.36 GJ), pelletizing (1.02 GJ), ironmaking (8.81 GJ), steelmaking (−0.16 GJ), and hot rolling (0.76 GJ). Additionally, this study delves into the analysis of influencing factors on theoretical energy consumption. Using the coking process as an illustrative example, it is observed that the theoretical energy consumption in coking decreases with a reduction in both moisture and volatile content in coal. Under the specified conditions, the minimum theoretical energy consumption for each process is as follows: coking (2.51 GJ), sintering (0.98 GJ), pelletizing (0.67 GJ), ironmaking (8.38 GJ), steelmaking (−0.58 GJ), and hot rolling (0.07 GJ), respectively. This comprehensive analysis serves as a valuable resource for advancing sustainable practices in the iron and steel industry.

Full article

Open AccessArticle

Phase Formation and Magnetic Properties of (Y1−xSmx)Co5 Melt-Spun Ribbons

by

Xiang Liu, Siyue Yang, Xingping Zheng, Feilong Dai, Qingrong Yao and Jiang Wang

Metals 2024, 14(5), 562; https://doi.org/10.3390/met14050562 - 10 May 2024

Abstract

Using X-ray diffraction (XRD) and a vibrating sample magnetometer (VSM), the effects of Sm substitution, wheel speed, and annealing temperature on the phase formation and magnetic properties of (Y1−xSmx)Co5 (x = 0.2, 0.3, 0.4, 0.5) melt-spun ribbons were

[...] Read more.

Using X-ray diffraction (XRD) and a vibrating sample magnetometer (VSM), the effects of Sm substitution, wheel speed, and annealing temperature on the phase formation and magnetic properties of (Y1−xSmx)Co5 (x = 0.2, 0.3, 0.4, 0.5) melt-spun ribbons were investigated. The results indicate the following: (1) With the increase in Sm substitution, it was found that (Y1−xSmx)Co5 ribbons are entirely composed of the (Y-Sm)Co5 phase with a CaCu5-type structure. Additionally, the coercivity gradually increases, while the remanence and saturation magnetization gradually decrease. (2) As the wheel speed increases, the (Y1−xSmx)Co5 ribbons exhibit an increasing proportion of (Y-Sm)Co5 phase until reaching a speed of 40 m/s, where they are entirely composed of the (Y-Sm)Co5 phase. Magnetic measurements show that the coercivity (Hcj) and remanence (Br) of (Y0.5Sm0.5)Co5 ribbons increase gradually with increasing wheel speed, while saturation magnetization decreases. The variation in magnetic properties is mainly attributed to the formation of nucleation centers for reversed magnetic domain (2:7 and 2:17 phases); (3) (Y0.5Sm0.5)Co5 ribbons are composed of the (Y-Sm)Co5 phase and a small amount of the Sm2Co7 phase after annealing at 550 °C, 600 °C, and 650 °C. Temperature elevation promotes crystallization of the amorphous phase, resulting in a gradual decrease in coercivity, while the remanence and saturation magnetization exhibit an overall increasing trend. Through continuous optimization of the process, favorable magnetic properties were achieved under the conditions of a 0.5 Sm substitution level, a wheel speed of 40 m/s, and an annealing temperature of 550 °C, with a coercivity of 7.98 kOe, remanence of 444 kA/m, and saturation magnetization of 508 kA/m.

Full article

(This article belongs to the Section Metallic Functional Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Investigation into the Hot-Forming Limit for 22MnB5 Hot-Forming Steel under a Stamping Process

by

Wenwu He, Bin Yang, Xuezhong Zhang, Min Li, Shuli Sun, Bao Wang and Qingxian Ma

Metals 2024, 14(5), 561; https://doi.org/10.3390/met14050561 - 10 May 2024

Abstract

Hot-forming technology for 22MnB5 hot-forming steel (22MnB5 HF steel) plates has been widely used in the automobile manufacturing industry in recent years. Physical simulation and numerical modeling were carried out in order to determine the forming limit of a 22MnB5 steel plate for

[...] Read more.

Hot-forming technology for 22MnB5 hot-forming steel (22MnB5 HF steel) plates has been widely used in the automobile manufacturing industry in recent years. Physical simulation and numerical modeling were carried out in order to determine the forming limit of a 22MnB5 steel plate for the stamping process. The deformation experiments were performed in a temperature range of 600~900 °C and a strain rate range of 0.1~10 s−1. In the uniaxial tensile tests, it was found that at the forming temperature of 600 °C, the condition of dynamic recrystallization was not fully reached, and thus the corresponding tensile strength was much larger than that at other deformation temperatures. In the numerical simulation of bulging experiments, it was found that 22MnB5 steel had good formability when the initial deformation temperature was high and the forming speed was low by using the instability criterion, combining the maximum punch force and strain path transition. The forming limit diagram of 22MnB5 steel at a temperature of 700 °C and tool speed of 25 mm/s was obtained by means of simulation and a hot stamping experiment. The establishment of the forming limit of the 22MnB5 steel plate can provide theoretical and technical guidance for the hot-forming process.

Full article

(This article belongs to the Special Issue Simulation and Optimization Methods in Machining and Structure/Material Design)

►▼

Show Figures

Figure 1

Open AccessArticle

Long-Range Influence of Cr on the Stacking Fault Energy of Cr-Containing Concentrated Solid-Solution Alloys

by

Hao Xiao, Qingyuan Liu, Shijun Zhao, Songqin Xia, Yugang Wang and Chenxu Wang

Metals 2024, 14(5), 560; https://doi.org/10.3390/met14050560 - 10 May 2024

Abstract

Single-phase concentrated solid-solution alloys (CSAs) have exhibited excellent mechanical and radiation tolerance properties, making them potential candidate materials for nuclear applications. These excellent properties are closely related to dislocation movements, which depend on the stacking fault energies (SFEs). In CSAs, SFEs show large

[...] Read more.

Single-phase concentrated solid-solution alloys (CSAs) have exhibited excellent mechanical and radiation tolerance properties, making them potential candidate materials for nuclear applications. These excellent properties are closely related to dislocation movements, which depend on the stacking fault energies (SFEs). In CSAs, SFEs show large fluctuations due to variations in the local atomic environments in the vicinity of the stacking faults. In this work, first-principle calculations were performed to investigate the origin of the fluctuations in the SFEs of the widely studied CSA, NiCoCr, which show a very wide distribution from about −200 mJ/m2 to 60 mJ/m2. Compared to the common understanding that only atoms in close proximity to the stacking fault influence the SFEs in pure metals and dilute alloys, charge redistribution can be observed in several nearby planes of the stacking fault in NiCoCr, indicating that atoms several atomic layers away from stacking fault also contribute to the SFEs. Our analysis shows that Cr plays a major role in the large fluctuation in the SFEs of NiCoCr based on both electronic and magnetic responses. The flexible electronic structure of Cr facilitates easier charge transfer with Cr in several nearby atomic planes near the stacking fault, leading to significant changes in the d-electron number, orbital occupation number, and magnetic moments of Cr.

Full article

(This article belongs to the Special Issue Study of Microstructure and Irradiation Damages in Metals and Alloys—2nd Edition)

►▼

Show Figures

Figure 1

Open AccessReview

Some Recent Advances in Germanium Recovery from Various Resources

by

Francisco Jose Alguacil and Jose Ignacio Robla

Metals 2024, 14(5), 559; https://doi.org/10.3390/met14050559 - 9 May 2024

Abstract

Though nowadays germanium does not reach the range of popularity of other metals, i.e., rare earth elements, its utility in target industries makes it a strategic metal. Though germanium can be found in a series of raw materials, the principal source for its

[...] Read more.

Though nowadays germanium does not reach the range of popularity of other metals, i.e., rare earth elements, its utility in target industries makes it a strategic metal. Though germanium can be found in a series of raw materials, the principal source for its recovery is from secondary wastes of the zinc industry; also, the recyclability of germanium-bearing waste materials is becoming of interest. In this recovery and due to the size of the target materials, because the diffusion and reaction are to be considered, hydrometallurgy performs a key role in achieving this goal. The present work reviews the most recent applications (2023 and 2024 years) of hydrometallurgical operations on the recovery of germanium from different solid and liquid sources.

Full article

(This article belongs to the Special Issue Advances in Sustainable Hydrometallurgy)

►▼

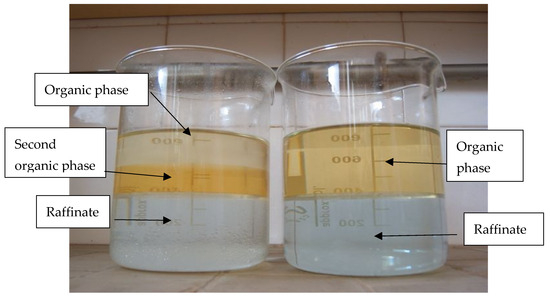

Show Figures

Figure 1

Open AccessArticle

High-Throughput Multi-Principal Element Alloy Exploration Using a Novel Composition Gradient Sintering Technique

by

Brady L. Bresnahan and David L. Poerschke

Metals 2024, 14(5), 558; https://doi.org/10.3390/met14050558 - 9 May 2024

Abstract

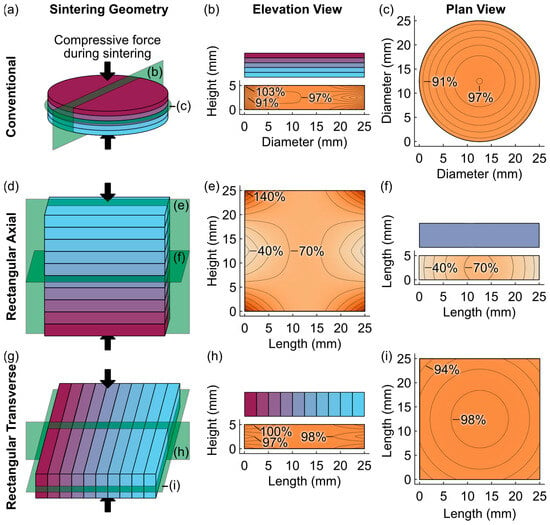

This work demonstrates the capabilities and advantages of a novel sintering technique to fabricate bulk composition gradient materials. Pressure distribution calculations were used to compare several tooling geometries for use with current-activated, pressure-assisted densification or spark plasma sintering to densify a gradient along

[...] Read more.

This work demonstrates the capabilities and advantages of a novel sintering technique to fabricate bulk composition gradient materials. Pressure distribution calculations were used to compare several tooling geometries for use with current-activated, pressure-assisted densification or spark plasma sintering to densify a gradient along the long dimension of the specimen. The selected rectangular tooling design retains a low aspect ratio to ensure a uniform pressure distribution during consolidation by using a side loading configuration to form the gradient along the longest dimension. Composition gradients of NixCu1−x, MoxNb1−x, and MoNbTaWHfx (x from 0 to 1) were fabricated with the tooling. The microstructure, composition, and crystal structure were characterized along the gradient in the as-sintered condition and after annealing to partially homogenize the layers. The successful fabrication of a composition gradient in a difficult-to-process material like the refractory multi-principal element alloy system MoNbTaWHfx shows the utility of this approach for high-throughput screening of large material composition spaces.

Full article

(This article belongs to the Special Issue Advances in Field-Assisted Processing of Metallic Materials: Experiments and Simulations)

►▼

Show Figures

Figure 1

Open AccessArticle

Influence of Various Processing Routes in Additive Manufacturing on Microstructure and Monotonic Properties of Pure Iron—A Review-like Study

by

Christof J. J. Torrent, Seyed Vahid Sajadifar, Gregory Gerstein, Julia Richter and Thomas Niendorf

Metals 2024, 14(5), 557; https://doi.org/10.3390/met14050557 - 8 May 2024

Abstract

Additive manufacturing processes have attracted broad attention in the last decades since the related freedom of design allows the manufacturing of parts with unique microstructures and unprecedented complexity in shape. Focusing on the properties of additively manufactured parts, major efforts are made to

[...] Read more.

Additive manufacturing processes have attracted broad attention in the last decades since the related freedom of design allows the manufacturing of parts with unique microstructures and unprecedented complexity in shape. Focusing on the properties of additively manufactured parts, major efforts are made to elaborate process-microstructure relationships. For instance, the inevitable thermal cycling within the process plays a significant role in microstructural evolution. Various driving forces contribute to the final grain size, boundary character, residual stress state, etc. In the present study, the properties of commercially pure iron processed on three different routes, i.e., hot rolling as a reference, electron powder bed fusion, and laser powder bed fusion, using different raw materials as well as process conditions, are compared. The manufacturing of the specimens led to five distinct microstructures, which differ significantly in terms of microstructural features and mechanical responses. Using optical and electron microscopy as well as transmission electron microscopy, the built specimens were explored in various states of a tensile test in order to reveal the microstructural evolution in the course of quasistatic loading. The grain size is found to be most influential in enhancing the material’s strength. Furthermore, substructures, i.e., low-angle grain boundaries, within the grains play an important role in terms of the homogeneity of strain distribution. On the contrary, high-angle grain boundaries are found to be regions of strain localization. In summary, a holistic macro-meso-micro-nano investigation is performed to evaluate the behavior of these specific microstructures.

Full article

(This article belongs to the Section Additive Manufacturing)

►▼

Show Figures

Figure 1

Open AccessArticle

An ANN Hardness Prediction Tool Based on a Finite Element Implementation of a Thermal–Metallurgical Model for Mild Steel Produced by WAAM

by

Jun Cheng, Yong Ling and Wim De Waele

Metals 2024, 14(5), 556; https://doi.org/10.3390/met14050556 - 8 May 2024

Abstract

WAAM has emerged as a promising technique for manufacturing medium- and large-scale metal parts due to its high material deposition efficiency and automation level. However, its high heat accumulation and complex thermal evolution strongly affect the resulting microstructures and mechanical properties. The heterogeneous

[...] Read more.

WAAM has emerged as a promising technique for manufacturing medium- and large-scale metal parts due to its high material deposition efficiency and automation level. However, its high heat accumulation and complex thermal evolution strongly affect the resulting microstructures and mechanical properties. The heterogeneous and unpredictable nature of these properties hinder the widespread application of WAAM in the steel construction industry. In this study, an artificial neural network (ANN) hardness model is developed, based on a thermal–metallurgical model for mild steel. The objective is to establish non-linear relationships between the input process parameters and the desired output, i.e., hardness. The thermal–metallurgical model utilizes a well-distributed heat source model, a death-and-birth algorithm, and a metallurgical model to simulate the temperature field and to calculate the microstructure phase fraction. The temperature prediction errors at four thermocouple positions are mostly below 20%. Because of the limited experimental data, twenty-five simulation experiments are performed using the L25 orthogonal array based on the Taguchi method. The analysis of variance (ANOVA) reveals that the travel speed has the greatest impact on hardness. With the dataset from the thermal–metallurgical model, an ANN model to predict hardness is developed. A comparison to experimental data shows excellent performance and accuracy, with the Mean Absolute Percentage Error (MAPE) of ANN predictions within 10% of the targeted hardness.

Full article

(This article belongs to the Section Additive Manufacturing)

►▼

Show Figures

Figure 1

Open AccessArticle

Finite Element Analysis and Experimental Verification of Thermal Fatigue of W-PFM with Stacked Structure

by

Chao Qi, Yanfei Qi, Hanfeng Song, Xiao Wang, Shanqu Xiao and Bo Wang

Metals 2024, 14(5), 555; https://doi.org/10.3390/met14050555 - 8 May 2024

Abstract

►▼

Show Figures

As the prime candidate for plasma-facing materials (PFM), the response of tungsten (W) to thermal shock loads is an important research topic for future fusion devices. Under heat loads, the surface of tungsten plasma-facing materials (W-PFM) can experience thermal damage, including brittle cracking

[...] Read more.

As the prime candidate for plasma-facing materials (PFM), the response of tungsten (W) to thermal shock loads is an important research topic for future fusion devices. Under heat loads, the surface of tungsten plasma-facing materials (W-PFM) can experience thermal damage, including brittle cracking and fatigue cracks. Therefore, exploring solutions for thermal damage of W-PFM remains one of the current research focuses. We propose a novel approach to mitigate thermal radiation damage in PFM, namely, the stacked structure W-PFM. The surface thermal stress distribution of the stacked structure W-PFM under heat loads was simulated and analyzed by the finite element method. As the foil thickness decreases, both the peak thermal stresses in the normal direction (ND) and rolling direction (RD) decrease. When the thickness decreases to a certain value, the peak thermal stress in the RD decreases to about 1384 MPa and no longer decreases; while the peak thermal stress in the ND approaches 0 MPa and can be neglected. In the range of approximately 5–100 mm, the accumulated equivalent plastic strain decreases sharply as the thickness decreases; in other thickness ranges, it decreases slowly. Thermal fatigue experiments were conducted on the stacked structure W composed of W foils with different thicknesses and bulk W using an electron beam facility. The samples were applied with a power density of 30 MW/m2 for 10,000 and 20,000 pulses. The cracks on the surface of the stacked structure W extended along the ND direction, while on the surface of bulk W, besides the main crack in the ND direction, a crack network also formed. The experimental results were consistent with finite element simulations. When the pulse number was 10,000, as the thickness of the W foil decreased, the number and width of the cracks on the surface of the stacked structure W decreased. Only four small cracks were present on the surface of stacked structure W (0.05 mm). When the pulse number increased to 20,000, the plastic deformation and number of cracks on the surface of all samples increased. However, the stacked structure W (0.05 mm) only added one small crack and had the smallest surface roughness (Ra = 1.536 μm). Quantitative analysis of the fatigue cracks showed that the stacked structure W-PFM (0.05 mm) exhibited superior thermal fatigue performance.

Full article

Figure 1

Open AccessArticle

Development of Neural Networks to Study Flow Behavior of Medium Carbon Microalloyed Steel during Hot Forming

by

Anas Al Omar, Pau Català, Jose Ignacio Alcelay and Esteban Peña

Metals 2024, 14(5), 554; https://doi.org/10.3390/met14050554 - 8 May 2024

Abstract

In the present article, the application of an artificial neural network (ANN) model whose function is the development of plastic instability maps of a medium carbon microalloyed steel during the hot forming process is studied. Secondly, we proceed to create another ANN capable

[...] Read more.

In the present article, the application of an artificial neural network (ANN) model whose function is the development of plastic instability maps of a medium carbon microalloyed steel during the hot forming process is studied. Secondly, we proceed to create another ANN capable of providing the recrystallized grain size in the steady state resulting from forming deformation. We start from the experimental data of a medium carbon microalloyed steel obtained by hot compression tests with strain rates that vary between 10−4 s−1 and 3 s−1 and in a range of temperatures between 900 °C and 1150 °C. These experimental data are used to train the proposed ANN and obtain flow curves. Finally, the processing maps are developed by applying the dynamic materials model (DMM), according to which the safe hot forming domains and the plastic instability domains of the studied material are delineated. The comparison between the ANN and the experimental maps is carried out. It is ascertained that the optimal regions of forging in the ANN maps coincide with those obtained in the experimental maps. In addition, a study of the influence of the microstructure on the behavior of the studied steel during hot forming is carried out.

Full article

(This article belongs to the Section Metal Casting, Forming and Heat Treatment)

►▼

Show Figures

Figure 1

Open AccessReview

Overview: Machine Learning for Segmentation and Classification of Complex Steel Microstructures

by

Martin Müller, Marie Stiefel, Björn-Ivo Bachmann, Dominik Britz and Frank Mücklich

Metals 2024, 14(5), 553; https://doi.org/10.3390/met14050553 - 7 May 2024

Abstract

►▼

Show Figures

The foundation of materials science and engineering is the establishment of process–microstructure–property links, which in turn form the basis for materials and process development and optimization. At the heart of this is the characterization and quantification of the material’s microstructure. To date, microstructure

[...] Read more.

The foundation of materials science and engineering is the establishment of process–microstructure–property links, which in turn form the basis for materials and process development and optimization. At the heart of this is the characterization and quantification of the material’s microstructure. To date, microstructure quantification has traditionally involved a human deciding what to measure and included labor-intensive manual evaluation. Recent advancements in artificial intelligence (AI) and machine learning (ML) offer exciting new approaches to microstructural quantification, especially classification and semantic segmentation. This promises many benefits, most notably objective, reproducible, and automated analysis, but also quantification of complex microstructures that has not been possible with prior approaches. This review provides an overview of ML applications for microstructure analysis, using complex steel microstructures as examples. Special emphasis is placed on the quantity, quality, and variance of training data, as well as where the ground truth needed for ML comes from, which is usually not sufficiently discussed in the literature. In this context, correlative microscopy plays a key role, as it enables a comprehensive and scale-bridging characterization of complex microstructures, which is necessary to provide an objective and well-founded ground truth and ultimately to implement ML-based approaches.

Full article

Figure 1

Open AccessArticle

Investigation of the Influence of Alloy Atomic Doping on the Properties of Cu-Sn Alloys Based on First Principles

by

Zongfan Wei, Jiaying Chen, Jingteng Xue, Nan Qu, Yong Liu, Ling Sun, Yuchen Xiao, Baoan Wu, Jingchuan Zhu and Huiyi Tang

Metals 2024, 14(5), 552; https://doi.org/10.3390/met14050552 - 7 May 2024

Abstract

In order to design Cu-Sn alloys with excellent overall performance, the structural stability, mechanical properties, and electronic structure of X-doped Cu-Sn alloys were systematically calculated using first-principles calculations. The calculation results of the cohesive energy indicate that the Cu-Sn-X structures formed by X

[...] Read more.

In order to design Cu-Sn alloys with excellent overall performance, the structural stability, mechanical properties, and electronic structure of X-doped Cu-Sn alloys were systematically calculated using first-principles calculations. The calculation results of the cohesive energy indicate that the Cu-Sn-X structures formed by X atoms (X = Ag, Ca, Cd, Mg, Ni, Zr) doping into Cu-Sn can stably exist. The Cu-Sn-Ni structure is the most stable, with a cohesive energy value of −3.84 eV. Doping of X atoms leads to a decrease in the bulk modulus, Possion’s ratio and B/G ratio. However, doping Ag and Ni atoms can improve the shear modulus, Young’s modulus, and strain energy of the dislocation. The doping of Ni has the highest enhancement on shear modulus, Young’s modulus, and strain energy of the dislocation, with respective values as follows: 63.085 GPa, 163.593 GPa, and 1.689 W/J·

(This article belongs to the Section Computation and Simulation on Metals)

►▼

Show Figures

Figure 1

Open AccessArticle

Numerical Simulation and Experimental Verification of Hot Roll Bonding of 7000 Series Aluminum Alloy Laminated Materials

by

Wei Xu, Chengdong Xia and Chengyuan Ni

Metals 2024, 14(5), 551; https://doi.org/10.3390/met14050551 - 7 May 2024

Abstract

In the present study, the hot roll bonding process of 7000 series aluminum alloy laminated materials was numerically simulated and investigated using the finite element method, and the process parameters were experimentally verified by properties testing and microstructure analysis after hot roll bonding.

[...] Read more.

In the present study, the hot roll bonding process of 7000 series aluminum alloy laminated materials was numerically simulated and investigated using the finite element method, and the process parameters were experimentally verified by properties testing and microstructure analysis after hot roll bonding. In the roll bonding process of aluminum alloy laminated materials, the effects of the intermediate layer, pass reduction ratio, rolling speed and thickness ratio of component layers were studied. The results of finite element simulations showed that the addition of a 701 intermediate layer in the hot roll bonding process could effectively coordinate the deformation of the 705 layer and 706 layer and prevented the warping of the laminated material during hot rolling. It is recommended to use a multi-pass rolling process with small deformation and high speed, and the recommended rolling reduction ratio is 20%~30%, the hot rolling speed is 1.5~2.5 m/s and the thickness ratio of the 705 layer and 706 layer is about 1:5. Based on the above numerical results, five-layer and seven-layer 7000 series aluminum alloy laminated materials were prepared by the hot roll bonding process. The results showed that metallurgical bonding was realized between each component layer, and no delamination was observed from the tensile fracture between the interfaces of component layers. The tensile strength of the prepared laminated materials decreased with the increase in the thickness ratio of the 705 layer, and the bonding strengths of the laminated materials were in the range of 88–99 MPa. The experimental results verified the rationality of the process parameters recommended by the numerical simulations in terms of warping and delamination prevention.

Full article

(This article belongs to the Special Issue Numerical Simulation and Experimental Research of Metal Rolling)

►▼

Show Figures

Figure 1

Open AccessArticle

Role of Semiconductive Property on Selective Cementation Mechanism of Iron Oxides to Gold in Galvanic Interaction with Zero-Valent Aluminum from Gold–Copper Ammoniacal Thiosulfate Solutions

by

Joshua Zoleta, Kosei Aikawa, Nako Okada, Ilhwan Park, Mayumi Ito, Yogarajah Elakneswaran and Naoki Hiroyoshi

Metals 2024, 14(5), 550; https://doi.org/10.3390/met14050550 - 7 May 2024

Abstract

Iron oxides (hematite, Fe2O3, and magnetite, Fe3O4), previously used as electron mediators in the galvanic system with zero-valent aluminum (ZVAl), have been shown to recover Au upon cementation in Au–Cu ammoniacal thiosulfate media selectively, and

[...] Read more.

Iron oxides (hematite, Fe2O3, and magnetite, Fe3O4), previously used as electron mediators in the galvanic system with zero-valent aluminum (ZVAl), have been shown to recover Au upon cementation in Au–Cu ammoniacal thiosulfate media selectively, and this warrants further investigation. This research is focused on investigating the role of the semiconductive properties of metal oxides by performing a cementation experiment by mixing 0.15 g of electron mediators (Fe3O4, Fe2O3, TiO2 (anatase and rutile)) and 0.15 g of zero-valent aluminum powder as an electron donor in various electrochemical experiments. The results revealed that upon the cementation experiment, synthetic Fe2O3 and Fe3O4 were consistently able to selectively recover Au at around 90% and Cu at around 20%. Compared to activated carbon (AC), TiO2, in anatase and rutile forms, obtained selective recovery of gold, but the recovery was utterly insignificant compared to that of iron oxides, obtaining an average of 93% Au and 63% Cu recovery. The electrochemical and surface analysis supports the results obtained upon the cementation process, where TiO2, upon cyclic voltammetry (CV), obtained two reduction peaks centered at −1.0 V and −0.5 V assigned to reducing Au and Cu ions, respectively. Furthermore, various electrochemical impedance spectroscopic analyses revealed that the flat band potential obtained in the Mott–Schottky plot is around −1.0 V and −0.2 V for iron oxides and titanium oxides, respectively, suggesting that the electrons travel from semiconductor interface to electrolyte interface, and electrons are accessible only to Au ions in the electrolyte interface (reduction band edge around −1.0 V). The determination of this selective cementation mechanism is one of a kind. It has been proposed that the semiconductive properties of Fe2O3, Fe3O4, and, by configuring their relative energy band diagram, the travel of electrons from the iron oxide–electrolyte interface facilitate the selective cementation towards Au(S2O3)23+ ions in gold–copper ammoniacal thiosulfate solutions.

Full article

(This article belongs to the Section Extractive Metallurgy)

►▼

Show Figures

Figure 1

Open AccessArticle

Comparison of STP and TP Modes of Wire and Arc Additive Manufacturing of Aluminum–Magnesium Alloys: Forming, Microstructures and Mechanical Properties

by

Qiang Zhu, Ping Yao and Huan Li

Metals 2024, 14(5), 549; https://doi.org/10.3390/met14050549 - 7 May 2024

Abstract

Aluminum–magnesium (Al–Mg) alloys, known for their lightweight properties, are extensively utilized and crucial in the advancement of wire and arc additive manufacturing (WAAM) for direct high-quality printing—a focal point in additive manufacturing research. This study employed 1.2 mm ER5356 welding wire as the

[...] Read more.

Aluminum–magnesium (Al–Mg) alloys, known for their lightweight properties, are extensively utilized and crucial in the advancement of wire and arc additive manufacturing (WAAM) for direct high-quality printing—a focal point in additive manufacturing research. This study employed 1.2 mm ER5356 welding wire as the raw material to fabricate two sets of 30-layer thin-walled structures. These sets were manufactured using two distinct welding modes, speed-twin pulse (STP) and twin pulse (TP). Comparative evaluations of the surface quality, microstructures, and mechanical properties of the two sets of samples indicated that both the STP and TP modes were suitable for the WAAM of Al–Mg alloys. Analyses of grain growth in the melt pools of both sample sets revealed a non-preferential grain orientation, with a mixed arrangement of equiaxed and columnar grains. The STP mode notably achieved a refined surface finish, a reduced grain size, and a slight increase in tensile strength compared to the TP mode. From the comparison of the tensile data at the bottom, middle, and top of the two groups of samples, the additive manufacturing process in the STP mode was more stable.

Full article

(This article belongs to the Special Issue Additive Manufacturing of Light Metal Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Analysis of the Influence of Contact Stress on the Fatigue of AD180 High-Carbon Semi-Steel Roll

by

Yaxing Liu, Lixin Liu, Qian Cheng, Haipeng Hou, Zehua Zhang and Zhongkai Ren

Metals 2024, 14(5), 548; https://doi.org/10.3390/met14050548 - 6 May 2024

Abstract

In this study, to investigate the problem of contact fatigue and the damage mechanism of an AD180 high-carbon semi-steel roll, rolling contact fatigue tests were conducted using specimens cut from the periphery of a roll ring. These specimens were characterized under different contact

[...] Read more.

In this study, to investigate the problem of contact fatigue and the damage mechanism of an AD180 high-carbon semi-steel roll, rolling contact fatigue tests were conducted using specimens cut from the periphery of a roll ring. These specimens were characterized under different contact stresses using SEM, a profile system, an optical microscope, and a Vickers hardness tester. The results indicates that the main forms of fatigue damage of an AD180 high-carbon semi-steel roll are peeling, pitting corrosion, and plowing. Moreover, the surface of the roll exhibits delamination and plastic deformation characteristics under high contact stress. Meanwhile, the size and depth of peeling, as well as the amount of pitting corrosion, increase with the contact stress. Peeling is mainly caused by a crack that originates at the edge of the specimen surface and propagates along the pearlite structure and the interface between pearlite and cementite. High contact stress can lead to an increase in the crack propagation depth and angle, resulting in the formation of larger peeling. Under cyclic loading, the near-surface microstructure of the specimen hardens due to grain refinement and dislocation strengthening, and the depth of the hardened layer increases with the increase in contact stress. When the contact stress reaches 1400 MPa, the near surface structure of the specimen changes from pearlite to troostite.

Full article

(This article belongs to the Special Issue Numerical Simulation of Metal Forming Process)

►▼

Show Figures

Figure 1

Journal Menu

► ▼ Journal Menu-

- Metals Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Photography Exhibition

- Instructions for Authors

- Special Issues

- Topics

- Sections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Society Collaborations

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Coatings, Materials, Metals, JMMP, Machines

Development of Friction Stir Welding and Processing

Topic Editors: Yongxian Huang, Li Zhou, Xiangchen Meng, Yuming XieDeadline: 31 May 2024

Topic in

Applied Sciences, Crystals, J. Compos. Sci., Materials, Metals

Modern Material Technologies Intended for Industrial Applications

Topic Editors: Tomasz Tański, Andrzej N. Wieczorek, Marcin StaszukDeadline: 30 June 2024

Topic in

Coatings, CMD, Materials, Metals, Molecules

Corrosion and Protection of Metallic Materials, 2nd Edition

Topic Editors: Sebastian Feliú, Jr., Federico R. García-Galván, Lucien VelevaDeadline: 31 July 2024

Topic in

Energies, Materials, Catalysts, Metals, Hydrogen

Hydrogen—The New Energy Vector for the Transition of Industries "Hard to Abate"

Topic Editors: Pasquale Cavaliere, Geoffrey BrooksDeadline: 31 August 2024

Conferences

Special Issues

Special Issue in

Metals

Creep and Fatigue Behavior of Alloys

Guest Editor: A. Toshimitsu Yokobori, Jr.Deadline: 15 May 2024

Special Issue in

Metals

Mesoscopic Changes in Conventional and Innovative Processing Technologies

Guest Editor: Jurij J. SidorDeadline: 31 May 2024

Special Issue in

Metals

Advances in Preparation Methods and Numerical Simulation of Composites: Formation and Properties

Guest Editors: Zhengyi Jiang, Hongmei ZhangDeadline: 10 June 2024

Special Issue in

Metals

Advances in Lightweight Metal Matrix Composites

Guest Editors: Pilar Rey, Gaspar González-DoncelDeadline: 30 June 2024