A Study of a Cryogenic CuAlMn Shape Memory Alloy

Abstract

1. Introduction

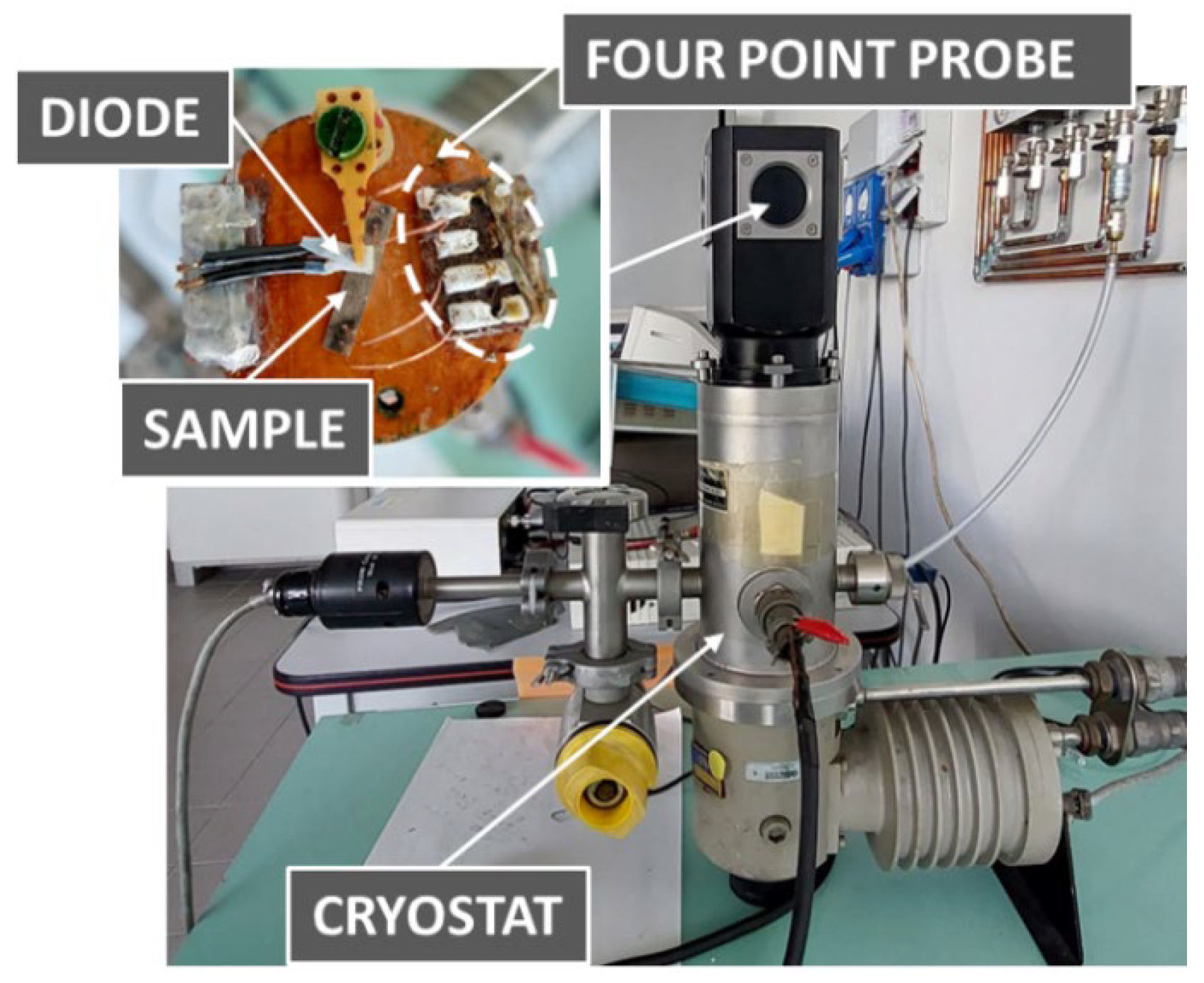

2. Materials and Methods

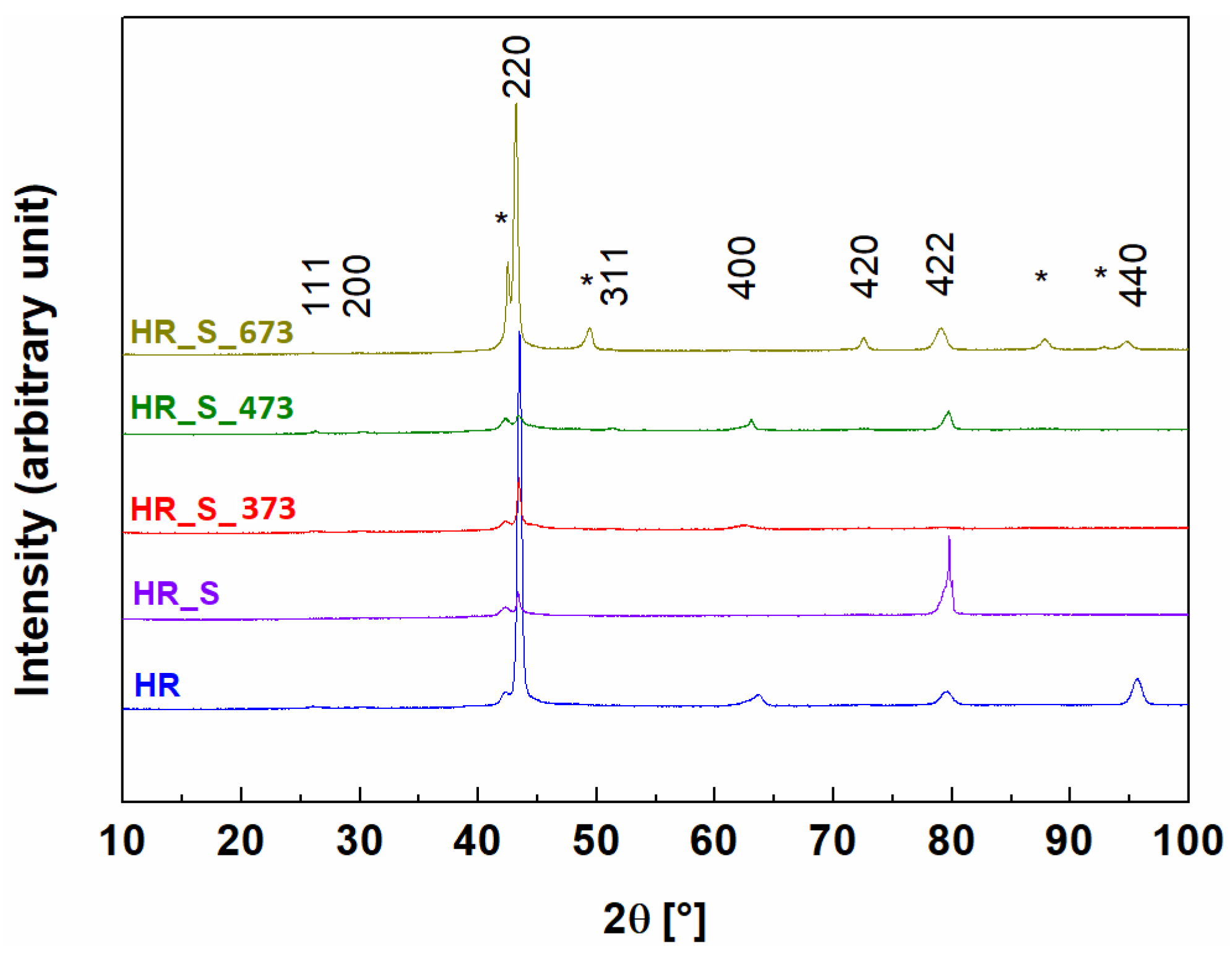

3. Results

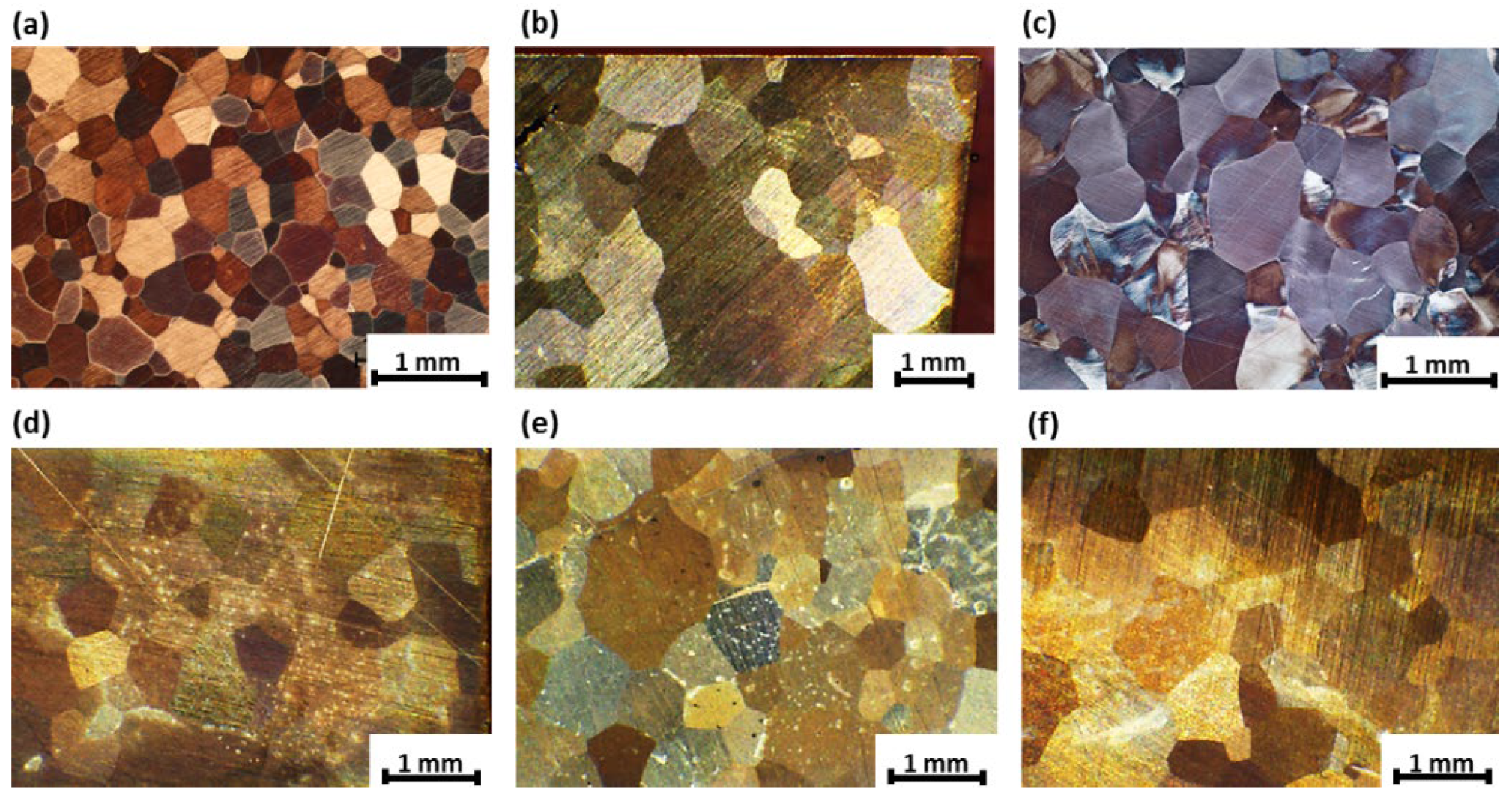

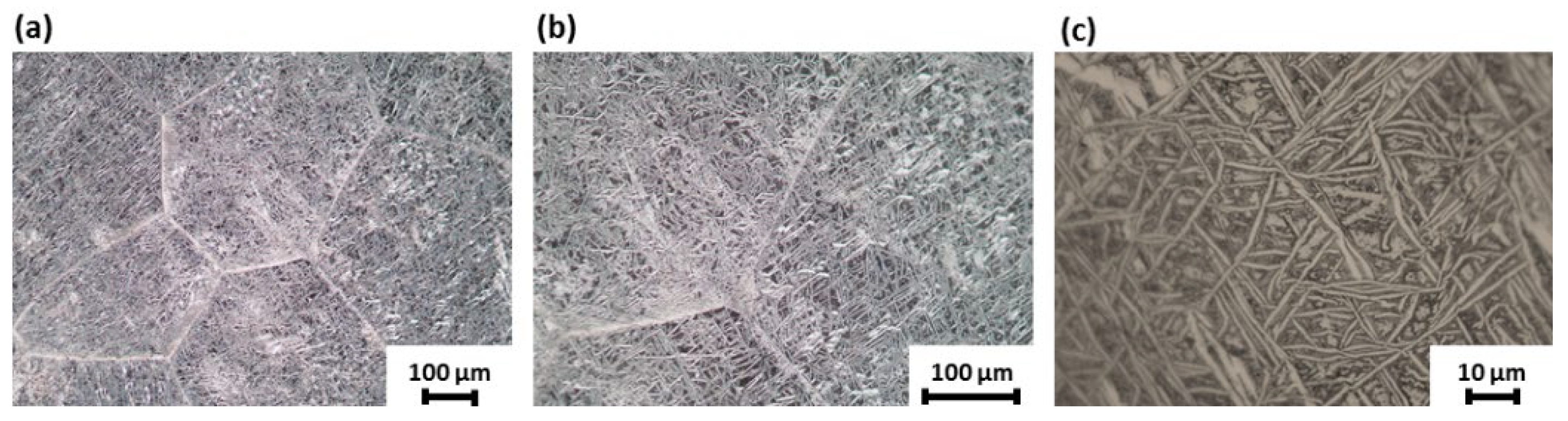

3.1. Microstructure

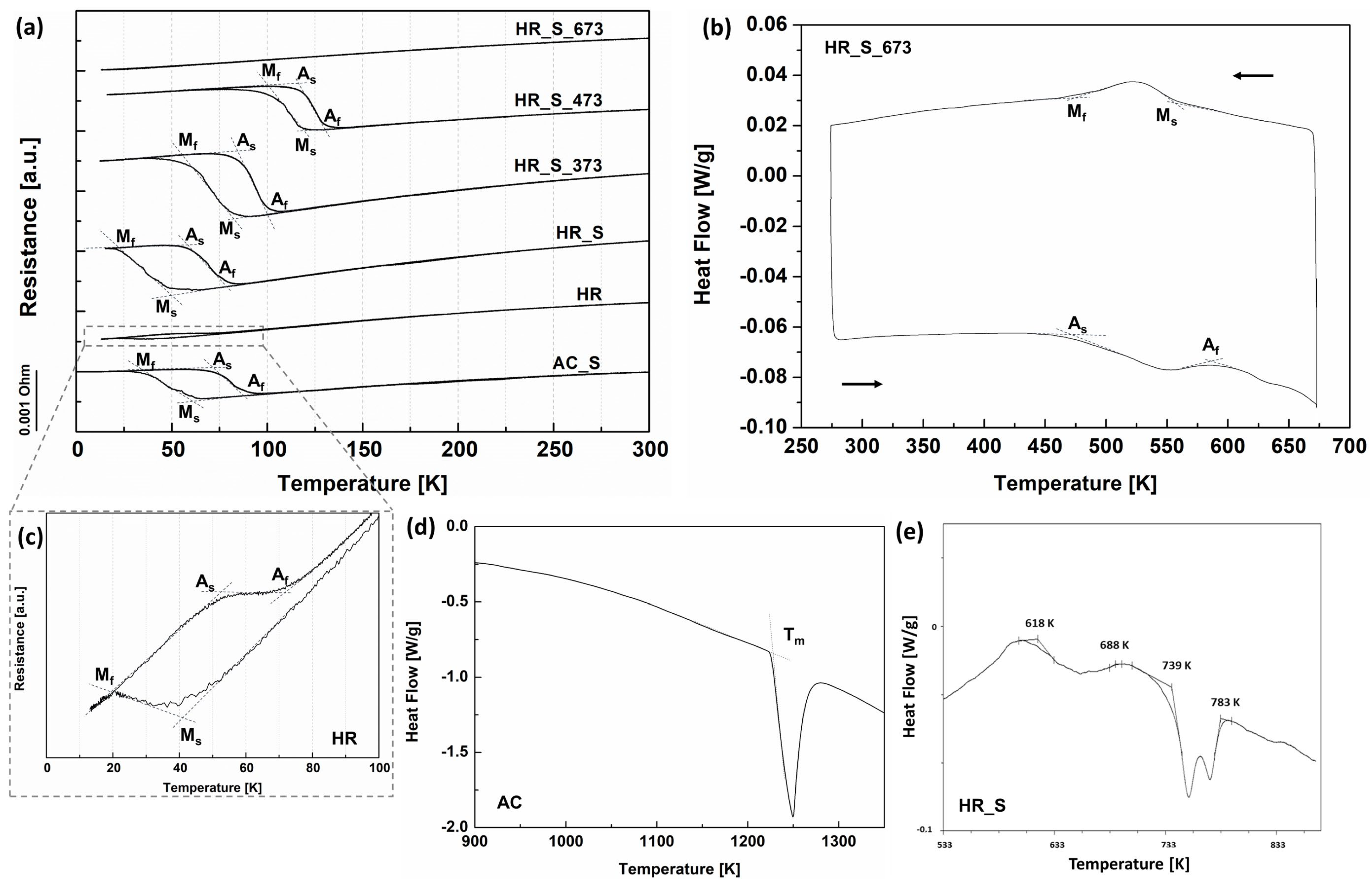

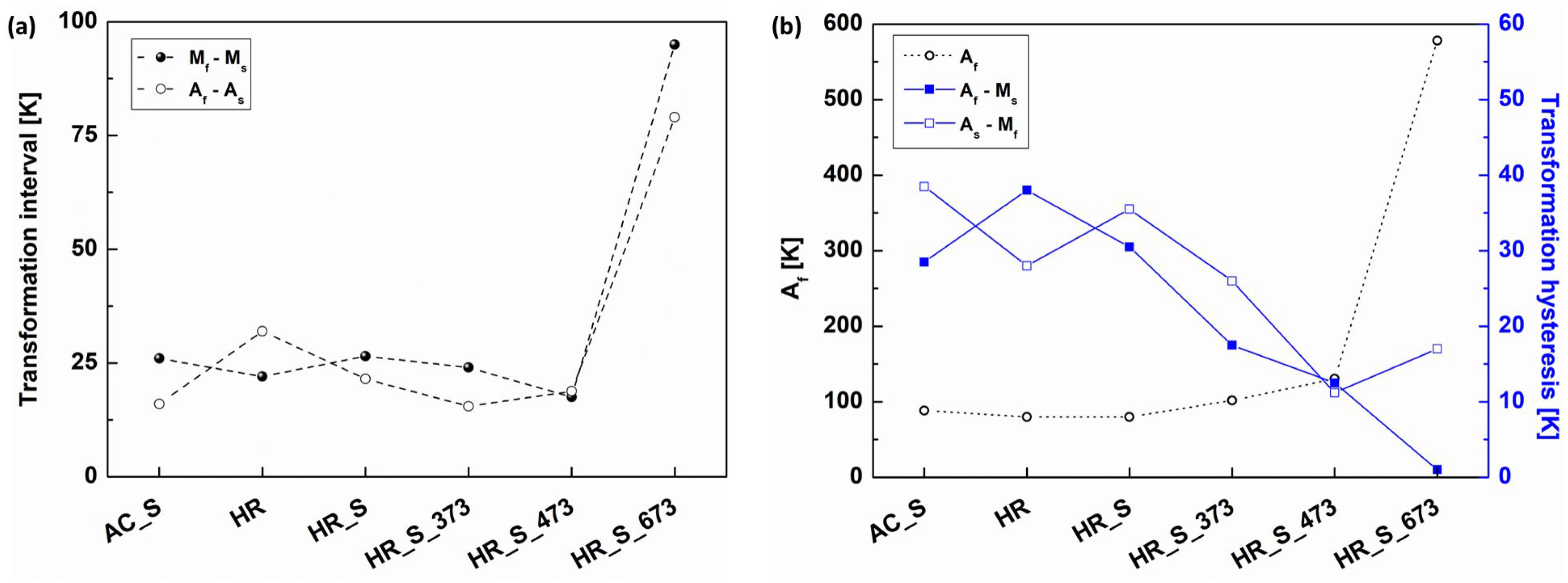

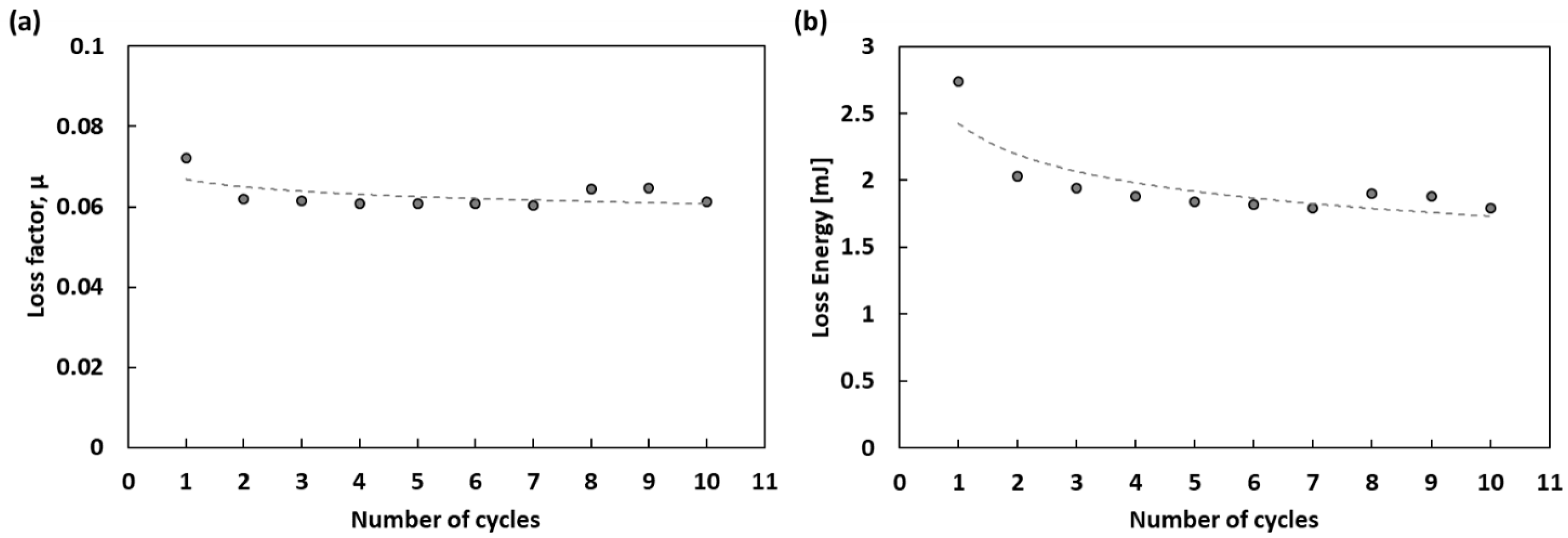

3.2. Thermal and Mechanical Analysis

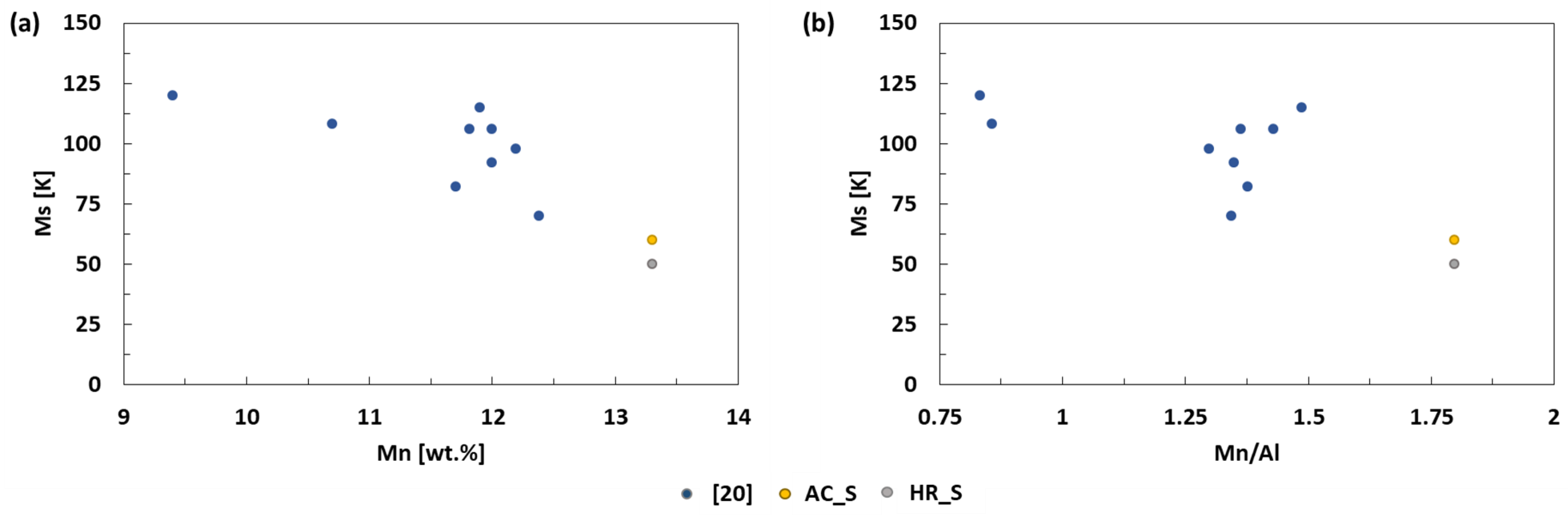

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duerig, T.W.; Melton, K.N.; Stockel, D.; Wayman, C.M. Engineering Aspects of Shape Memory Alloys; Elsevier Ltd.: Amsterdam, The Netherlands; Butterworth–Heinemann: Oxford, UK, 1990. [Google Scholar] [CrossRef]

- Concilio, A.; Antonucci, V.; Auricchio, F.; Lecce, L.; Sacco, E. Shape Memory Alloy Engineering for Aerospace, Structural and Biomedical Applications; Elsevier Ltd.: Amsterdam, The Netherlands; Butterworth–Heinemann: Oxford, UK, 2021. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Patel, S.K.; Behera, B.; Swain, B.; Roshan, R.; Sahoo, D.; Behera, A. A review on NiTi alloys for biomedical applications and their biocompatibility. Mater. Today Proc. 2020, 33, 5548–5551. [Google Scholar] [CrossRef]

- Nespoli, A.; Dallolio, V.; Villa, E.; Passaretti, F. A new design of a Nitinol ring-like wire for suturing in deep surgical field. Mater. Sci. Eng. C 2015, 56, 30–36. [Google Scholar] [CrossRef]

- Kim, M.S.; Heo, J.K.; Rodrigue, H.; Lee, H.T.; Pané, S.; Han, M.W.; Ahn, S.H. Shape Memory Alloy (SMA) Actuators: The Role of Material, Form, and Scaling Effects. Adv. Mater. 2023, 35, 2208517. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Reconciling viability and cost-effective shape memory alloy options—A review of copper and iron based shape memory metallic systems. Eng. Sci. Technol. Int. J. 2016, 19, 1582–1592. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Kainuma, R.; Ishida, K. Ductile Cu–Al–Mn based shape memory alloys: General properties and applications. Mater. Sci. Technol. 2008, 24, 896–901. [Google Scholar] [CrossRef]

- Liu, J.-L.; Chen, Z.H.; Huang, H.-Y.; Xie, J.-X. Microstructure and superelasticity control by rolling and heat treatment in columnar-grained Cu-Al-Mn shape memory alloy. Mater. Sci. Eng. A 2017, 696, 315–322. [Google Scholar] [CrossRef]

- Sasmaz, M.; Bayri, A.; Aydogdu, Y. The Magnetic Behavior and Physical Characterization of Cu–Mn–Al Ferromagnetic Shape Memory Alloy. J. Supercond. Nov. Magn. 2011, 24, 757–762. [Google Scholar] [CrossRef]

- Prado, M.O.; Lovey, F.C.; Civale, L. Magnetic properties of Cu-Mn-Al alloys with shape memory effect. Acta Mater. 1998, 46, 137–147. [Google Scholar] [CrossRef]

- Cesari, E.; Pons, J.; Santamarta, R.; Segui, C.; Chernenko, V.A. Ferromagnetic shape memory alloys: An overview. Arch. Metall. Mater. 2004, 49, 779–789. [Google Scholar]

- Lázpita, P.; Villa, E.; Villa, F.; Chernenko, V.A. Temperature Dependent Stress-Strain behavior and Martensite Stabilization in Magnetic Shape Memory Ni51.1Fe16.4Ga26.3Co6.2. Metals 2021, 11, 920. [Google Scholar] [CrossRef]

- Villa, E.; Villa, F.; Rodriguez Crespo, B.; Lazpita, P.; Salazar, D.; Chernenko, V.A.; Hosoda, H. Shape memory and elastocaloric properties of melt-spun NiMn-based Heusler alloys. J. Alloys Compd. 2023, 965, 171437. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Anaele, J.U.; Okotete, E.A. Martensite aging phenomena in Cu-based alloys: Effects on structural transformation, mechanical and shape memory properties: A critical review. Sci. Afr. 2021, 12, e00760. [Google Scholar] [CrossRef]

- Mallik, U.S.; Sampath, V. Effect of composition and ageing on damping characteristics of Cu–Al–Mn shape memory alloys. Mater. Sci. Eng. A 2008, 478, 48–55. [Google Scholar] [CrossRef]

- Kozubuski, R.; Soltys, J. Precipitation from metastable β-phase in the Heusler alloy Cu2.00Al1.00Mn1.00. J. Mater. Sci. 1983, 18, 1689–1697. [Google Scholar] [CrossRef]

- Gordo, P.; Frederico, T.; Melicio, R.; Amorim, A. Implementation of a Cryogenic Facility for Space Debris Analysis. Appl. Sci. 2021, 11, 948. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, A. Cryogenic technology for infrared detection in space. Sci. Rep. 2022, 12, 2349. [Google Scholar] [CrossRef]

- Nespoli, A.; Ninarello, D.; Fanciulli, C. A Review on Shape Memory Alloys with Martensitic Transition at Cryogenic Temperatures. Metals 2023, 13, 1311. [Google Scholar] [CrossRef]

- Umale, T.; Salas, D.; Tomes, B.; Arroyave, R.; Karaman, I. The effects of wide range of compositional changes on the martensitic transformation characteristics of NiTiHf shape memory alloys. Scr. Mater. 2019, 161, 78–83. [Google Scholar] [CrossRef]

- Zak, G.; Kneissl, A.C.; Zatulskij, G. Shape memory effect in cryogenic Cu-Al-Mn alloys. Scripta Mater. 1996, 34, 363–367. [Google Scholar] [CrossRef]

- Wang, H.; Huang, H.Y.; Su, Y.J. Tuning the operation temperature window of the elastocaloric effect in Cu-Al-Mn shape memory alloys by composition design. J. Alloys Compd. 2020, 828, 154265. [Google Scholar] [CrossRef]

- Lei, Y.; Qin, X.; Wan, F.; Liu, P.; Chen, L.; Wang, J. In-situ observation of martensitic transformation in Cu-Al-Mn cryogenic shape memory alloys. Fusion Eng. Des. 2017, 125, 603–607. [Google Scholar] [CrossRef]

- Bian, Z.; Song, J.; Liu, P.; Wan, F.; Lei, Y.; Wang, Q.; Yang, S.; Zhan, Q.; Chen, L.; Wang, J. In Situ Observation of Thermoelastic Martensitic Transformation of Cu-Al-Mn Cryogenic Shape Memory Alloy with Compressive Stress. Materials 2022, 15, 3794. [Google Scholar] [CrossRef] [PubMed]

- Trehern, W.; Ozcan, H.; Franco, B.; Hite, N.; Malone, N.; Loveall, B.; Morrison, T.D.; Benafan, O.; Karaman, I. Exploring thermomechanical functionality of CuAlMn as an extreme low temperature shape memory alloys. Mater. Lett. 2022, 308, 131246. [Google Scholar] [CrossRef]

- Nespoli, A.; Bassani, E.; Della Torre, D.; Donnini, R.; Villa, E.; Passaretti, F. An experimental study on pseudoelasticity of a NiTi-based damper for civil applications. Smart Mater. Struct. 2017, 26, 105041. [Google Scholar] [CrossRef]

- Sutou, Y.; Koeda, N.; Omori, T.; Kainuma, R.; Ishida, K. Effects of ageing on bainitic and thermally induced martensitic transformations in ductile Cu–Al–Mn-based shape memory alloys. Acta Mater. 2009, 57, 5748–5758. [Google Scholar] [CrossRef]

- Villars, P.; Cenzual, K. Pearson’s Crystal Data: Crystal Structure Database for Inorganic Compounds; ASM International: Materials Park, OH, USA, 2007. [Google Scholar]

- Chatterjee, S.; Chattopadhyay, S.; Giri, S.; Majumdar, S. Nature of the glassy magnetic state in the Cu2.84Mn0.44Al0.72 shape memory alloy. Europhys. Lett. 2013, 104, 47014. [Google Scholar] [CrossRef][Green Version]

- Niitsu, K.; Kimura, Y.; Omori, T.; Kainuma, R. Cryogenic superelasticity with large elastocaloric effect. NPG Asia Mater. 2018, 10, e457. [Google Scholar] [CrossRef]

- Liu, J.-L.; Huang, H.-Y.; Xie, J.-X. Effects of aging treatment on the microstructure and superelasticity of columnar-grained Cu71Al18Mn11 shape memory alloy. Int. J. Miner. Metal. Mater. 2016, 23, 1157. [Google Scholar] [CrossRef]

- Kožuh, S.; Gojić, M.; Ivanić, I.; Holjevac Grgurić, T.; Kosec, B.; Anžel, I. The Effect of Heat Treatment on the Microstructure and Mechanical Properties of Cu-Al-Mn Shape Memory Alloy. Kem. Ind. 2018, 67, 11–17. [Google Scholar] [CrossRef]

- Aksu Canbay, C.; Karagoz, Z.; Yakuphanoglua, F. Controlling of Transformation Temperatures of Cu-Al-Mn Shape Memory Alloys by Chemical Composition. Acta Phys. Pol. A 2014, 125, 1163–1166. [Google Scholar] [CrossRef]

- Nespoli, A.; Bettini, P.; Villa, E.; Sala, G.; Passaretti, F.; Grande, A.M. A study on damping property of NiTi elements produced by selective laser-beam melting. Adv. Eng. Mater. 2021, 23, 2001246. [Google Scholar] [CrossRef]

| Reference | Cu [wt.%] | Al [wt.%] | Mn [wt.%] | Ms [K] | Af [K] | Mn/Al | Tech. |

|---|---|---|---|---|---|---|---|

| [24] | 79.3 | 11.3 | 9.4 | 120 | ND | 0.832 | ND |

| [22] | 80.1 | 8 | 11.9 | 115 | 143 | 1.488 | AAS |

| [25] | 76.8 | 12.5 | 10.7 | 108 | 145 | 0.856 | ND |

| [22] | 79.6 | 8.4 | 12 | 106 | 137 | 1.429 | AAS |

| [26] | 79.5 | 8.7 | 11.8 | 106 | 122 | 1.363 | WDS |

| [26] | 78.4 | 9.4 | 12.2 | 98 | 116 | 1.299 | WDS |

| [22] | 79.1 | 8.9 | 12 | 92 | 123 | 1.348 | AAS |

| [11] | 79.8 | 8.5 | 11.7 | 82 | ND | 1.376 | ND |

| [26] | 78.4 | 9.2 | 12.4 | 70 | 91 | 1.345 | WDS |

| Sample | Post Processing Route |

|---|---|

| AC_S | As-cast and Solubilized at 1173 K for 1 h (wq) |

| HR | Hot-Rolled |

| HR_S | Hot-Rolled + Solubilized at 1173 K for 1 h (wq) |

| HR_S_373 | Hot-Rolled + Solubilized + Heat treated at 373 K for 30 min (wq) |

| HR_S_473 | Hot-Rolled + Solubilized + Heat treated at 473 K for 30 min (wq) |

| HR_S_673 | Hot-Rolled + Solubilized + Heat treated at 673 K for 30 min (wq) |

| wt.% | Cu | Al | Mn |

|---|---|---|---|

| nominal | 79 | 7.5 | 13.5 |

| measured | 79.3 (0.4) | 7.4 (0.3) | 13.3 (0.5) |

| Sample | Ms [K] | Mf [K] | As [K] | Af [K] |

|---|---|---|---|---|

| AC_S | 60 | 34 | 73 | 89 |

| HR | 42 | 20 | 48 | 80 |

| HR_S | 50 | 23 | 59 | 80 |

| HR_S_373 | 84 | 60 | 86 | 102 |

| HR_S_473 | 118 | 101 | 112 | 131 |

| HR_S_673 | 577 | 482 | 499 | 578 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nespoli, A.; Passaretti, F.; Ninarello, D.; Pani, M.; Artini, C.; Ferro, F.; Fanciulli, C. A Study of a Cryogenic CuAlMn Shape Memory Alloy. Metals 2024, 14, 323. https://doi.org/10.3390/met14030323

Nespoli A, Passaretti F, Ninarello D, Pani M, Artini C, Ferro F, Fanciulli C. A Study of a Cryogenic CuAlMn Shape Memory Alloy. Metals. 2024; 14(3):323. https://doi.org/10.3390/met14030323

Chicago/Turabian StyleNespoli, Adelaide, Francesca Passaretti, Davide Ninarello, Marcella Pani, Cristina Artini, Francesca Ferro, and Carlo Fanciulli. 2024. "A Study of a Cryogenic CuAlMn Shape Memory Alloy" Metals 14, no. 3: 323. https://doi.org/10.3390/met14030323

APA StyleNespoli, A., Passaretti, F., Ninarello, D., Pani, M., Artini, C., Ferro, F., & Fanciulli, C. (2024). A Study of a Cryogenic CuAlMn Shape Memory Alloy. Metals, 14(3), 323. https://doi.org/10.3390/met14030323