Journal Description

Fibers

Fibers

is an international, peer-reviewed, open access journal on fiber science, published monthly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, ESCI (Web of Science), Ei Compendex, PubAg, CAPlus / SciFinder, Inspec, and other databases.

- Journal Rank: JCR - Q2 (Materials Science, Multidisciplinary) / CiteScore - Q1 (Civil and Structural Engineering)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 23.3 days after submission; acceptance to publication is undertaken in 5.8 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

Impact Factor:

3.9 (2024);

5-Year Impact Factor:

4.1 (2024)

Latest Articles

The Science of Laundering and Wear: Understanding Fiber Fragmentation from Secondhand Cotton Denim

Fibers 2025, 13(12), 166; https://doi.org/10.3390/fib13120166 - 11 Dec 2025

Abstract

►

Show Figures

Demand for clothing is estimated to increase globally by 4.5% per year, and secondhand clothing is often used to fill that demand. A clear understanding of the environmental impact of secondhand items would support transparency around sustainability, which is a rising consumer concern.

[...] Read more.

Demand for clothing is estimated to increase globally by 4.5% per year, and secondhand clothing is often used to fill that demand. A clear understanding of the environmental impact of secondhand items would support transparency around sustainability, which is a rising consumer concern. This study focuses on the characteristics of the fiber fragment material released during the laundering of secondhand, 100% cotton denim clothing, and the implications of secondhand clothing’s contribution of fiber fragments to the environment. The test method used was AATCC TM212-2021, with detergent, conditioned specimens, and filters. The specimens included thirteen pairs of secondhand men’s 100% cotton jeans (SHS) and two pairs of new jeans (CN controls). This study concluded that the amount of fiber fragmentation material shed by SHS was 23.2% of that shed by CN. While this is less than is shed by new clothing, there is still shed material to consider, including dyes and processing chemicals that can contribute to anthropogenic contamination of the environment. The fiber fragment size and frequency were found to have statistically significant differences between SHS (length 370.5 µm, diameter 16.9 µm, 3093 fiber fragments per filter) and CN (320.7 µm, 13.8 µm, and 5962 fiber fragments per filter).

Full article

Open AccessArticle

Assessing the Role of Recycled Tyre Polymer Fibres (RTPFs) on the Key Hydration Processes Governing Autogenous Shrinkage

by

Katarina Didulica, Ana Baričević and Vesna Zalar Serjun

Fibers 2025, 13(12), 165; https://doi.org/10.3390/fib13120165 - 10 Dec 2025

Abstract

The incorporation of recycled tyre polymer fibres (RTPF) in cementitious composites provides an effective and sustainable approach in tyre waste management while offering potential benefits in mitigating early-age volume deformations. This study evaluates the influence of RTPFs, used in dry (RTPFd)

[...] Read more.

The incorporation of recycled tyre polymer fibres (RTPF) in cementitious composites provides an effective and sustainable approach in tyre waste management while offering potential benefits in mitigating early-age volume deformations. This study evaluates the influence of RTPFs, used in dry (RTPFd) and pre-wetted (RTPFw) states, on key hydration processes governing autogenous shrinkage in cement pastes with w/c of 0.4 and 0.22. The results show that RTPF reduced workability and altered the setting process due to the fibre–matrix mechanical interactions. Incorporation of RTPFs induced changes in water distribution at the fibre surface, delaying self-desiccation and maintaining higher internal relative humidity. While RTPFs offer a beneficial reduction in autogenous shrinkage by 12–41% in mixtures with w/c of 0.4 and by 15–34% in mixtures with w/c of 0.22, RTPFs also increased porosity, which contributed to a reduction in 28-day compressive strength of up to 16%. These findings highlight the dual effect of RTPF on early-age performance and provide insight into their potential application in sustainable cementitious composites.

Full article

(This article belongs to the Special Issue Fiber-Reinforced Concrete and Fiber-Reinforced Polymer Materials: Innovative Solutions in Construction Engineering)

►▼

Show Figures

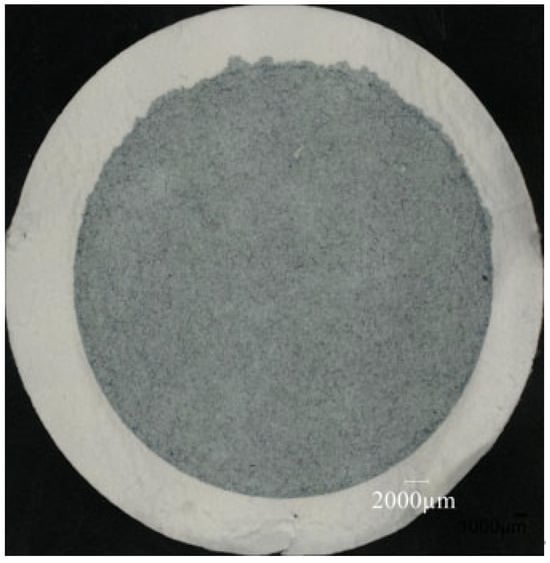

Figure 1

Open AccessArticle

Bond Stress Analysis Between High-Performance Steel Fiber Reinforced Mortar and Deformed Steel Bars Under Pull-Out Test

by

Ramdane Sidali Amrouche, Samira Djaknoun, Messaoud Saidani, Zineb Abeoub and Giangiacomo Minak

Fibers 2025, 13(12), 164; https://doi.org/10.3390/fib13120164 - 5 Dec 2025

Abstract

►▼

Show Figures

Despite increased utilization of high-performance mortars in construction, there remains a paucity of research concerning the bond performance of steel reinforcement, particularly within masonry structures. This study characterizes the bond stress behavior in high-performance steel fiber mortar (HPSFRM) to define critical design bond

[...] Read more.

Despite increased utilization of high-performance mortars in construction, there remains a paucity of research concerning the bond performance of steel reinforcement, particularly within masonry structures. This study characterizes the bond stress behavior in high-performance steel fiber mortar (HPSFRM) to define critical design bond stress parameters. Pull-out tests were performed, incorporating three primary variables: compressive resistance, steel fiber volume, and steel rebars diameter. To support safe and reliable bond design in HPSFRM precast members, various methods for analyzing bond strength, alongside empirical predictive equations, were evaluated. The results revealed that although the rate of increase in bond strength was impacted by the incorporation of steel fibers, the bond strength demonstrated significant improvement in the mortar compressive strength. Introducing steel fibers at a volumetric content of 1% doubled the bond strength. The optimum fiber content was found at 1%, where bond strength increased by 6% and slip by 102% due to effective fiber bridging. Increasing the dosage to 2% yielded only a marginal 2–5% gain, hindered by clustering and poor dispersion. Variations in steel bar diameter had a more pronounced effect on bond stress behavior. The proposed model addresses the underestimation of bond strength and ductility by existing empirical models and code provisions.

Full article

Figure 1

Open AccessArticle

Recycling of Glass Fibers from Wind Turbine Blade Wastes via Chemical-Assisted Solvolysis

by

Maria Modestou, Dionisis Semitekolos, Tao Liu, Christina Podara, Savvas Orfanidis, Ana Teresa Lima and Costas Charitidis

Fibers 2025, 13(12), 163; https://doi.org/10.3390/fib13120163 - 5 Dec 2025

Abstract

►▼

Show Figures

Wind turbine blades (WTBs) have always been considered one of the greatest engineering achievements. They primarily use glass fiber-reinforced polymers (GFRPs) because of their lightweight nature, impressive strength-to-weight ratio, and durability. Until now, typical disposal methods of End-of-Life (EoL) WTBs are landfill or

[...] Read more.

Wind turbine blades (WTBs) have always been considered one of the greatest engineering achievements. They primarily use glass fiber-reinforced polymers (GFRPs) because of their lightweight nature, impressive strength-to-weight ratio, and durability. Until now, typical disposal methods of End-of-Life (EoL) WTBs are landfill or incineration. However, such practices are neither environmentally sustainable nor compliant with current regulations. This study investigates a low-temperature solvolysis process using a poly(ethylene glycol)/NaOH system under ambient pressure for efficient decomposition of the polyester matrix, promoting the potential of chemical recycling as an alternative to landfilling and incineration by offering a viable method for recovering glass fibers from WTB waste. A parametric study evaluated the influence of reaction time (4–5.5 h) and catalyst-to-resin ratio (0.1–2.0 g NaOH per g resin) on solvolysis efficiency. Optimal conditions (200 g PEG200, 12.5 g NaOH, 10 g GFRP, 5.5 h) achieved an ~80% decomposition efficiency and fibers exhibiting minimal surface degradation. SEM and EDX analyses confirmed limited morphological damage, while excessive NaOH (>15 g) caused notable etching of the glass fibers. ICP-OES of liquid residues detected high Na (780 mg/L) and Si (139 mg/L) concentrations, verifying partial dissolution of the fiber structure under strongly alkaline conditions. After applying a commercial sizing agent (Hydrosize HP2-06), TGA confirmed ~1.2% sizing mass, and nanoindentation analysis showed the interfacial modulus and hardness of re-sized fibers improved by over 70% compared to unsized recycled fibers, approaching the performance of virgin fibers.

Full article

Graphical abstract

Open AccessArticle

Electrospun Carbon Fibers from Green Solvent-Fractionated Kraft Lignin

by

Marta Goliszek-Chabros and Omid Hosseinaei

Fibers 2025, 13(12), 162; https://doi.org/10.3390/fib13120162 - 4 Dec 2025

Abstract

►▼

Show Figures

High production costs and sustainability issues are the main factors limiting the widespread application of carbon fibers in various industrial sectors. Lignin, a by-product from the paper and pulping industry, due to its high carbon content of up to 60%, can be considered

[...] Read more.

High production costs and sustainability issues are the main factors limiting the widespread application of carbon fibers in various industrial sectors. Lignin, a by-product from the paper and pulping industry, due to its high carbon content of up to 60%, can be considered a potential replacement for polyacrylonitrile in carbon fiber production. The production of lignins with distinct molecular weight distributions as well as group functionalities is essential to enhance high-value applications of lignin. In this study, we present a simple, green solvent-based fractionation method for LignoBoost softwood kraft lignin to obtain a lignin fraction with tailored physicochemical properties for electrospun carbon fiber production without polymeric spinning additives. Sequential solvent extraction was used to produce two fractions with distinct molecular weights: low-molecular-weight softwood kraft lignin (LMW-SKL) and high-molecular-weight softwood kraft lignin (HMW-SKL). The lignin fractions were characterized using size exclusion chromatography (SEC) for the molar mass distribution. The thermal properties of lignins were studied using thermogravimetry (TGA) and differential scanning calorimetry (DSC). Hydroxyl group content was quantified using quantitative 31P NMR spectroscopy. We successfully demonstrated the electrospinning of a high-molecular-weight lignin fraction—obtained in high yield from the fractionation process—without the use of any additives, followed by thermal conversion to produce electrospun carbon fibers. The presented results contribute to the valorization of lignin as well as to the development of green and sustainable technologies.

Full article

Figure 1

Open AccessArticle

Multilayer Electrospun Nanofibrous Membranes for Enhanced Heavy Metal Remediation

by

Magaly Granda, Ezequiel Zamora-Ledezma, Michael Macías Pro, Joseph Guamán, Alexis Debut, Frank Alexis, Frederico B. De Sousa and Christian Narváez-Muñoz

Fibers 2025, 13(12), 161; https://doi.org/10.3390/fib13120161 - 2 Dec 2025

Abstract

►▼

Show Figures

This study presents the fabrication and performance analysis of multilayer membranes produced by electrospinning using polyacrylonitrile (PAN), chitosan (CS), and Nylon 6 (N6) for the removal of chromium (Cr) and cadmium (Cd) from water. The electrospun membranes were configured in six different multilayer

[...] Read more.

This study presents the fabrication and performance analysis of multilayer membranes produced by electrospinning using polyacrylonitrile (PAN), chitosan (CS), and Nylon 6 (N6) for the removal of chromium (Cr) and cadmium (Cd) from water. The electrospun membranes were configured in six different multilayer structures. The morphological and mechanical properties of the membranes were evaluated using SEM and tensile testing. Adsorption experiments were performed using synthetic and real water samples from the Cutuchi River. The multilayer membranes demonstrated metal ion removal efficiencies up to 80.81% for

Figure 1

Open AccessArticle

Finite Element Models on Shear Behavior of Deep Beams Prepared Using Steel Fiber-Reinforced Recycled Coarse Aggregate Concrete

by

Said Elkholy, Mohamed Salem and Ahmed Godat

Fibers 2025, 13(12), 160; https://doi.org/10.3390/fib13120160 - 26 Nov 2025

Abstract

Numerous experimental and numerical studies have extensively investigated the performance of reinforced deep beams made with natural coarse aggregate concrete. However, limited research has been carried out on reinforced deep beams made of concrete with coarse aggregate from recycled materials and steel fibers.

[...] Read more.

Numerous experimental and numerical studies have extensively investigated the performance of reinforced deep beams made with natural coarse aggregate concrete. However, limited research has been carried out on reinforced deep beams made of concrete with coarse aggregate from recycled materials and steel fibers. The main goal of this research is to create an accurate finite element model that can mimic the behavior of deep beams using concrete with recycled coarse aggregate and different ratios of steel fibers. The suggested model represents the pre-peak, post-peak, confinement, and concrete-to-steel fiber bond behavior of steel fiber concrete, reinforcing steel, and loading plates by incorporating the proper structural components and constitutive laws. The deep beams’ nonlinear load–deformation behavior is simulated in displacement-controlled settings. In order to verify the model’s correctness, the ultimate loading capacity, load–deflection relationships, and failure mechanisms are compared between numerical predictions and experimental findings. The comparison outcomes of the performance of the beams demonstrate that the numerical model effectively predicts the behavior of deep beams constructed with recycled coarse aggregate concrete. The findings of the experiment and the numerical analysis exhibit a high degree of convergence, affirming the model’s capability to accurately simulate the performance of such beams. In light of how accurately the numerical predictions match the experimental results, an extensive parametric study is conducted to examine the impact of parameters on the performance of deep beams with different ratios of steel fibers, concrete compressive strength, type of steel fibers (short or long), and effective span-to-effective depth ratio. The effect of each parameter is examined relative to its effect on the fracture energy.

Full article

(This article belongs to the Special Issue Fiber-Reinforced Concrete and Fiber-Reinforced Polymer Materials: Innovative Solutions in Construction Engineering)

►▼

Show Figures

Figure 1

Open AccessBrief Report

Natural Fiber Composites for Sustainable Model Rocketry: Bamboo and Jute as Alternatives to Fiberglass

by

Lais Alves, Tabata Barreto, Nordine Leklou and Silvio de Barros

Fibers 2025, 13(12), 159; https://doi.org/10.3390/fib13120159 - 26 Nov 2025

Abstract

►▼

Show Figures

The search for sustainable alternatives to synthetic composites has become increasingly relevant in aerospace engineering education and student rocketry. Fiberglass is widely used for rocket fuselages due to its favorable balance of performance and cost, but it is energy-intensive, non-biodegradable, and environmentally burdensome.

[...] Read more.

The search for sustainable alternatives to synthetic composites has become increasingly relevant in aerospace engineering education and student rocketry. Fiberglass is widely used for rocket fuselages due to its favorable balance of performance and cost, but it is energy-intensive, non-biodegradable, and environmentally burdensome. This study provides the first demonstration of natural fiber composites applied to student rocket fuselages, evaluating bamboo and jute as sustainable alternatives to fiberglass. Fiberglass, bamboo, and jute laminates were fabricated following the procedures of the RocketWolf team at CEFET/RJ. The fuselages were characterized by parachute ejection tests, surface roughness analysis, and flight simulations using OpenRocket software. Additional data such as laminate mass, wall thickness, fiber–resin ratio, and cost analysis were incorporated to provide a comprehensive assessment. Results revealed contrasting behaviors: untreated bamboo composites showed poor resin impregnation, brittle behavior, and lack of structural stability, confirming their unsuitability without chemical treatment. Jute composites, in contrast, achieved adequate impregnation, cylindrical geometry, and superior surface roughness (Ra = 37 µm) compared to fiberglass with paint (62 µm) or envelopes (52 µm). Both fiberglass and jute fuselages successfully passed parachute ejection tests, while simulations indicated apogees close to 1 km, fulfilling competition requirements. The jute fuselage also presented slightly improved stability margins. Economically, jute was ~492% cheaper than fiberglass in fiber-only comparison but absorbed more resin; nevertheless, real purchase prices favored jute. These findings confirm that jute composites are a technically feasible, cost-effective, and sustainable substitute for fiberglass in student rocket fuselages. Beyond technical validation, this work demonstrates the educational and environmental benefits of integrating natural fibers into academic rocketry, bridging sustainability, performance, and innovation.

Full article

Figure 1

Open AccessArticle

Mechanical Characterization of Carbon Fibers and Their Interfaces Recycled Through Plasma-Assisted Solvolysis Under Different Processing Conditions

by

Ilektra Tourkantoni, Konstantinos Tserpes, Dimitrios Marinis, Ergina Farsari and Eleftherios Amanatides

Fibers 2025, 13(12), 158; https://doi.org/10.3390/fib13120158 - 24 Nov 2025

Abstract

The rapid expansion of carbon-fiber-reinforced polymer (CFRP) applications in aerospace, automotive, and energy sectors has intensified concerns over end-of-life waste and the absence of efficient recycling solutions. Plasma-assisted solvolysis has emerged as a promising hybrid approach, combining oxidative chemical treatment with plasma activation

[...] Read more.

The rapid expansion of carbon-fiber-reinforced polymer (CFRP) applications in aerospace, automotive, and energy sectors has intensified concerns over end-of-life waste and the absence of efficient recycling solutions. Plasma-assisted solvolysis has emerged as a promising hybrid approach, combining oxidative chemical treatment with plasma activation to accelerate matrix degradation. In this study, CFRP cylinders (6.4 cm height, 5.5 cm internal, and 6.0 cm external diameter) were processed in a closed-loop plasma solvolysis system under varied operational parameters, including plasma power, plasma gas composition, and nitric acid concentration. The mechanical performance of the recovered carbon fibers was assessed through single-fiber tensile and microbond tests, evaluating both tensile and interfacial properties. In most cases, the recycled fibers retained—or even exceeded—the tensile strength of their virgin counterparts, reaching up to 1.49 times that of the virgin fibers. Young’s modulus, though more variable, ranged from 0.48 to 1.67 times the reference value depending on treatment conditions. Elongation at break generally increased, particularly in the 24K (24,000-filaments) fiber sets, suggesting improved surface ductility. Weibull statistical analysis indicated higher consistency in 3K (3000-filaments) fiber batches compared to 24K, whereas interfacial shear strength was moderately retained across conditions. Overall, balanced plasma and acid conditions enabled efficient fiber recovery with high strength and interfacial performance, validating plasma-assisted solvolysis as a viable route for recovering high-performance fibers suitable for structural reuse, in alignment with circular economy principles.

Full article

(This article belongs to the Topic Advanced Carbon Fiber Reinforced Composite Materials, Volume II)

►▼

Show Figures

Figure 1

Open AccessReview

Valorization of Natural Byproducts Through Additive Manufacturing for Ecologically Sustainable Composite Materials: A Literature Review

by

Ioannis Filippos Kyriakidis, Anargiros Karelis, Nikolaos Kladovasilakis, Eleftheria Maria Pechlivani and Konstantinos Tsongas

Fibers 2025, 13(12), 157; https://doi.org/10.3390/fib13120157 - 24 Nov 2025

Abstract

►▼

Show Figures

This review paper explores the influence of natural byproducts on polymer matrices via additive manufacturing (AM), focusing specifically on the development of eco-friendly composite materials. A broad range of lignocellulosic residues—such as sawdust, wood chips, bark, and other related byproducts—are evaluated for their

[...] Read more.

This review paper explores the influence of natural byproducts on polymer matrices via additive manufacturing (AM), focusing specifically on the development of eco-friendly composite materials. A broad range of lignocellulosic residues—such as sawdust, wood chips, bark, and other related byproducts—are evaluated for their potential incorporation into polymer matrices to create filaments and pastes appropriate for AM techniques. The paper initially examines the features of natural byproducts and their typical uses, then evaluates the benefits that AM presents in comparison to conventional manufacturing techniques. Special emphasis is placed on the physicochemical and mechanical properties of the developed composites, encompassing their thermal characteristics (glass transition temperature, melting point, and stability), density, and mechanical behavior under both static and dynamic loading. Furthermore, the environmental effects of these composites are thoroughly assessed through Life Cycle Assessment (LCA), highlighting their contribution to minimizing ecological footprints and promoting circular economy initiatives. Collectively, the findings indicate that the additive manufacturing of composites derived from natural byproducts represent a promising pathway toward sustainable industrial production.

Full article

Figure 1

Open AccessArticle

Structural Performance of Columns with Glass Fiber-Reinforced Polymer Bars Under Axial Compression

by

Trupti Amit Kinjawadekar, Shantharam Patil and Gopinatha Nayak

Fibers 2025, 13(11), 156; https://doi.org/10.3390/fib13110156 - 20 Nov 2025

Abstract

►▼

Show Figures

Corrosion continues to be a major challenge affecting the service life, safety and durability of steel-reinforced concrete (RC) structures. The deterioration of steel not only reduces structural capacity but also increases long-term maintenance costs. To address this limitation, glass fiber-reinforced polymer (GFRP) is

[...] Read more.

Corrosion continues to be a major challenge affecting the service life, safety and durability of steel-reinforced concrete (RC) structures. The deterioration of steel not only reduces structural capacity but also increases long-term maintenance costs. To address this limitation, glass fiber-reinforced polymer (GFRP) is being investigated as an alternative to conventional steel reinforcement, particularly in aggressive environments. This work examines the behavior of composite columns reinforced with GFRP bars with steel stirrups. Sixteen square columns of 150 × 150 × 850 mm dimensions, cast with M30 grade concrete, were reinforced using either GFRP or steel, while varying stirrup spacing and bar diameters. Experimental observations showed that GFRP reinforcement contributed about 10–12% of the ultimate capacity of the columns. A marked enhancement in load carrying capacity of GFRP-RC columns was obtained with closer stirrup spacing. The axial strength of GFRP-reinforced columns was comparable to steel-reinforced ones with the same main reinforcement ratio. Ductility increased by 12% when stirrup spacing was reduced. The difference between analytical and experimental values ranged between 12% and 15%, whereas experimental and numerical results differed by 10–12%. Based on these results, a modification factor derived from IS 456:2000 is proposed for predicting the capacity of ‘GFRP-reinforced’ columns. The outcomes clearly highlight the potential of GFRP reinforcement as a durable, sustainable and practical substitute for conventional steel reinforcement.

Full article

Figure 1

Open AccessReview

Industrial Hemp as Precursor for Sustainable Bioproducts: Recent Trends and Prospects

by

Sodiq Babatunde Yusuf, Nnaemeka Ewurum, Harrison Appiah and Jovale Vincent Tongco

Fibers 2025, 13(11), 155; https://doi.org/10.3390/fib13110155 - 20 Nov 2025

Abstract

►▼

Show Figures

The generation of over 150 million tons of hemp waste annually is as much of a sustainability challenge as it is an opportunity for the circular bioeconomy. This review provides a critical analysis of the recent trends in the use of industrial hemp

[...] Read more.

The generation of over 150 million tons of hemp waste annually is as much of a sustainability challenge as it is an opportunity for the circular bioeconomy. This review provides a critical analysis of the recent trends in the use of industrial hemp waste as a precursor to producing sustainable bioproducts. The objective is to synthesize the current state of knowledge and to identify the various pathways for valorizing hemp waste beyond the traditional applications. The methodology involved the systematic assessment of the recent literature to identify the applications in textiles, biocomposites, packaging, and, most importantly, advanced areas such as hemp-based carbon materials for storing energy, biomedical materials, and smart biomaterials. Findings showed that hemp waste is a versatile material for creating high-value products, as it shows promise in carbon electrodes for supercapacitors as well as reinforcement for 3D-printed biocomposites. However, there are some limitations in terms of standardization and scalability. The review concludes that future progress depends on multidisciplinary research to optimize conversion and utilization processes, including the development of comprehensive life-cycle assessments and reliable supply chains.

Full article

Graphical abstract

Open AccessArticle

Experimental Evaluation of RC Structures with Brick Infills for Vertical Forest Adaptation in Seismic Regions

by

Theodoros Rousakis, Vachan Vanian, Martha Lappa, Adamantis G. Zapris, Ioannis P. Xynopoulos, Maristella Voutetaki, Stefanos Kellis, George Sapidis, Maria Naoum, Nikos Papadopoulos, Violetta K. Kytinou, Martha Karabini, Constantin E. Chalioris, Athanasia K. Thomoglou and Emmanouil Golias

Fibers 2025, 13(11), 154; https://doi.org/10.3390/fib13110154 - 17 Nov 2025

Cited by 1

Abstract

►▼

Show Figures

Existing Mediterranean reinforced concrete buildings with masonry infills exhibit critical seismic vulnerabilities, yet real-time damage detection capabilities remain limited. This study validates a novel dense piezoelectric transducer (PZT) network concept for early damage detection in deficient RC structures under progressive seismic loading. A

[...] Read more.

Existing Mediterranean reinforced concrete buildings with masonry infills exhibit critical seismic vulnerabilities, yet real-time damage detection capabilities remain limited. This study validates a novel dense piezoelectric transducer (PZT) network concept for early damage detection in deficient RC structures under progressive seismic loading. A three-dimensional single-story RC frame with brick infills, representative of pre-Eurocode Mediterranean construction (non-ductile detailing, inadequate transverse reinforcement), was tested at serviceability limit states (SLSs) (Phase A) using a dynamic pushover approach with the 1978 Thessaloniki earthquake record, progressively scaled from EQ0.1g to EQ1.1g within the GREENERGY vertical forest renovation project. The specimen featured 48 PZTs using electromechanical impedance (EMI) methodology, 12 accelerometers, 8 displacement sensors, and 20 strain gauges. Progressive infill deterioration initiated at EQ0.5g while steel reinforcement remained elastic (max 2350 μstrain < 2890 μstrain yield). Maximum inter-story drift reached 11.37‰ with negligible residual drift (0.204‰). The PZT network, analyzed through Root Mean Square Deviation (RMSD), successfully detected internal cracking and infill-frame debonding before visible manifestation, validating its early warning capability. Floor acceleration amplification increased from 1.26 to 1.57, quantifying structural stiffness degradation. These SLS results provide critical baseline data enabling the Phase B implementation of sustainable vertical forest retrofitting strategies for aging Mediterranean building stock.

Full article

Figure 1

Open AccessArticle

Study of the Physical and Chemical Properties of Banana Peduncle Fibers of the Cultivar “William Cavendish”: Influence of Extraction Techniques

by

Solange Mélanie Anafack, Paul William Mejouyo Huisken, Jean-Yves Drean, Omar Harzallah, Rodrigue Nicodème Sikame Tagne, Hermann Tamaguelon Dzoujo, Murugesh Babu and Ebenezer Njeugna

Fibers 2025, 13(11), 153; https://doi.org/10.3390/fib13110153 - 17 Nov 2025

Abstract

►▼

Show Figures

This study deals with the physical, chemical, and thermal properties of William banana peduncle fibers in order to consider the possibility of using these new fibers in textile applications. The samples were collected in Cameroon, in the Littoral region, Njombe Penja district (agri-food

[...] Read more.

This study deals with the physical, chemical, and thermal properties of William banana peduncle fibers in order to consider the possibility of using these new fibers in textile applications. The samples were collected in Cameroon, in the Littoral region, Njombe Penja district (agri-food industry). The fibers were extracted by three methods, including Water Retting (WR), Dew Retting (DR), and Mechanical Extraction (ME). The various resulting fibers were characterized by X-ray Diffraction (XRD), Thermogravimetric Analysis (TGA), Fourier-Transform Infrared Spectroscopy (FT-IR) and Scanning Electron Microscopy (SEM), respectively. The FTIR analysis confirmed the lignocellulosic structure of the fibers and revealed that the three extraction methods had not affected the chemical nature of the fibers. The extraction methods also had no significant impact on density and moisture content. Scanning electron microscopy showed bands of fibers bundles on all samples. Thermogravimetric analysis (TGA) showed that the fibers extracted were thermally stable at 82 °C. X-ray diffraction (XRD) analysis showed crystallinity levels ranging from 58.24% for (WR), 54.83% for (DR), and 69.53% for (ME). The results obtained on the chemical composition show that the extracted fibers consist mainly of 71.8%, 73.6%, and 74.8% cellulose for WR, DR, and ME, respectively, making them suitable for textile applications.

Full article

Figure 1

Open AccessArticle

FRESCO: An Open Database for Fiber and Polymer Strengthening of Infilled RC Frame Systems

by

Vachan Vanian and Theodoros Rousakis

Fibers 2025, 13(11), 152; https://doi.org/10.3390/fib13110152 - 10 Nov 2025

Abstract

►▼

Show Figures

This paper presents FRESCO (Fiber REinforced Strengthening COmposite Database), a comprehensive open-source database designed to systematically organize experimental data on infilled RC frame systems that can be strengthened with advanced composite materials, such as Fiber-Reinforced Polymers (FRP), Textile-Reinforced Mortars (TRM), and other fiber-based

[...] Read more.

This paper presents FRESCO (Fiber REinforced Strengthening COmposite Database), a comprehensive open-source database designed to systematically organize experimental data on infilled RC frame systems that can be strengthened with advanced composite materials, such as Fiber-Reinforced Polymers (FRP), Textile-Reinforced Mortars (TRM), and other fiber-based solutions. The database employs open source practices while providing high-quality output that is fully compatible with leading commercial software packages such as ANSYS 2022R2. It uses Python3 as the main programming language and FreeCAD v1.0 as the model generation engine, with a systematic 13-section structure that ensures complete documentation of all parameters necessary for numerical modeling and validation of analytical methods. Two types of databases are provided: in comma-separated format (.csv) for common everyday interaction and in JSON format (.json) for easy programmatic access. The database features automated 3D modeling capabilities, converting experimental data into detailed finite element models with solid RC frame geometry, reinforcement details, and infill configurations. Validation through three comprehensive examples demonstrates that numerical models generated from the database closely match experimental results, with response curves that closely match the initial stiffness, the peak loading and the post-peak stiffness degradation phase across different loading conditions. The database focuses on RC frame systems with unreinforced brick infill. Reflecting the term FRESCO, which in Greek (φρέσκο) means “fresh”, the database is designed as a dynamic, evolving resource, with future versions planned to include RC walls and full buildings.

Full article

Figure 1

Open AccessArticle

Finite Element Modelling of Pultruded FRP Beam-to-Column Joints

by

Jawed Qureshi and Karthick Murugan Mahendran

Fibers 2025, 13(11), 151; https://doi.org/10.3390/fib13110151 - 7 Nov 2025

Abstract

►▼

Show Figures

This research addresses the critical gap in accurately modelling pultruded fibre-reinforced polymer (FRP) beam-to-column joints, where previous studies largely ignored progressive damage mechanisms. A novel finite element framework is developed in ABAQUS, integrating Hashin’s failure criterion with fracture energy-based damage evolution to simulate

[...] Read more.

This research addresses the critical gap in accurately modelling pultruded fibre-reinforced polymer (FRP) beam-to-column joints, where previous studies largely ignored progressive damage mechanisms. A novel finite element framework is developed in ABAQUS, integrating Hashin’s failure criterion with fracture energy-based damage evolution to simulate delamination and brittle failure in FRP cleats. The model is rigorously validated against full-scale experimental data, achieving close agreement in moment–rotation response, initial stiffness (within 5%), and ultimate moment capacity (variation < 10%). Quantitative results confirm that delamination at the fillet radius governs failure, while qualitative analysis reveals the sensitivity of stiffness to cleat geometry and bolt characteristics. A parametric study demonstrates that increasing cleat thickness and bolt diameter enhances stiffness up to 15%, whereas bolt–hole clearance introduces slip without significantly affecting strength. The validated FEM reduces reliance on costly physical testing and provides a robust tool for optimising FRP joint design, supporting the future development of design guidelines for pultruded FRP structures.

Full article

Figure 1

Open AccessArticle

Effect of Electron Radiation and Triallyl Isocyanurate on the Structure, Thermal, and Mechanical Properties of Epoxy Resin Filled with Dusty Fiber Fraction Derived from Recycled Wind Turbine Blades

by

Rafał Malinowski, Danuta Matykiewicz, Volodymyr Krasinskyi, Urszula Gryczka and Daniel Kaczor

Fibers 2025, 13(11), 150; https://doi.org/10.3390/fib13110150 - 4 Nov 2025

Abstract

►▼

Show Figures

This paper presents the investigation of the effect of electron radiation or the combined action of this radiation and triallyl isocyanurate (TAIC) on the structural, thermal, and mechanical properties of epoxy resin filled with a fraction of dust fibers (DFs) from recycled wind

[...] Read more.

This paper presents the investigation of the effect of electron radiation or the combined action of this radiation and triallyl isocyanurate (TAIC) on the structural, thermal, and mechanical properties of epoxy resin filled with a fraction of dust fibers (DFs) from recycled wind turbine blades. The resin containing 20 wt% of DF was irradiated with doses of 40, 80, 120, and 160 kGy. The results showed that electron radiation had only a slight effect on the properties of the studied composite, mainly on its glass transition temperature. More significant changes were observed with the combined action of radiation and TAIC. The main effect that occurred after the TAIC addition was the plasticization of the polymer matrix. With its participation, the glass transition temperature, thermal stability, and the hardness of the material and its flexural modulus were significantly reduced. The degree of change in these properties was regulated by the radiation dose. Furthermore, no significant changes in the composite structure were observed after radiation treatment, while the introduction of TAIC into the polymer matrix caused the formation of gas cells, probably due to the partial decomposition of TAIC.

Full article

Figure 1

Open AccessReview

Molecular Self-Reassembled Regenerated Fibres and Their Significance in Tissue Engineering Bio-Composites

by

Kristiyan Stiliyanov-Atanasov and Probal Basu

Fibers 2025, 13(11), 149; https://doi.org/10.3390/fib13110149 - 4 Nov 2025

Abstract

►▼

Show Figures

Due to their interesting physicochemical and bioactive properties, regenerated fibres (including cellulose and collagen regenerated fibres) have been considered attractive biomaterials for biomedical applications. These regenerated fibres have an altered molecular arrangement compared to the native fibres and exhibit unique properties. Despite their

[...] Read more.

Due to their interesting physicochemical and bioactive properties, regenerated fibres (including cellulose and collagen regenerated fibres) have been considered attractive biomaterials for biomedical applications. These regenerated fibres have an altered molecular arrangement compared to the native fibres and exhibit unique properties. Despite their distinctive structural characteristics, a meagre amount of research explores their potential for the development of tissue-engineering bio-composites. This work focuses on exploring the promise of cellulose and collagen-based regenerated fibres in tissue-regeneration bio-composite development. Initially, the work investigates the similarities and dissimilarities between the collagen and cellulose structures, which are linked to their specific properties, such as crystallinity, chemical characteristics, and mechanical properties. It then delves deeper into their molecular structural reassembly and various aspects of the already reported bio-composites developed using them. Finally, their promise in the development of tissue-engineering bio-composites is explored through a meticulous comparative analysis of their advantages and challenges. It was found that efficient biodegradability is one of the key advantages of regenerated fibres, whereas difficulty in processing presents a significant disadvantage. Despite these facts, regenerated fibres can incorporate enhanced and desired properties into the bio-composite matrix, which could lead to tissue-specific bio-regenerative applications.

Full article

Figure 1

Open AccessArticle

Mechanical Performances of Natural Textiles for Eco-Friendly Composite Materials: A Comparative Assessment

by

Gianfranco Stipo, Valerio Alecci, Mario De Stefano, Stefano Galassi, Maria Cristina Salvatici and Maria Luisa Satta

Fibers 2025, 13(11), 148; https://doi.org/10.3390/fib13110148 - 4 Nov 2025

Abstract

►▼

Show Figures

In the last decades, composite materials made of synthetic fibers embedded in organic or inorganic matrices have been successfully used for strengthening reinforced-concrete and masonry buildings. The scientific community is currently discussing the low sustainability of these materials and their environmental impact due

[...] Read more.

In the last decades, composite materials made of synthetic fibers embedded in organic or inorganic matrices have been successfully used for strengthening reinforced-concrete and masonry buildings. The scientific community is currently discussing the low sustainability of these materials and their environmental impact due to the production process, the life cycle, and the generation of potentially harmful waste. In this context, the use of natural textiles represents a promising solution, alternative to conventional synthetic fibers, aimed at designing an innovative composite material obtained from renewable resources with no energy consumption and greatly reducing the impact of building activities on the environment. In this paper, an experimental assessment of ten different natural textiles is presented in order to compare their mechanical properties for possible use in innovative, eco-friendly composite materials. Mechanical tensile tests were performed on the ten different textiles before and after an all-natural protective treatment referred to as the “hornification” process. Treatment-induced changes in the fiber morphology were also analyzed using a scanning electron microscope (SEM), which provided high-resolution images of the surface and cross-sectional area of the fibers. Considering that the current demand for sustainable building materials capable of ensuring a greener future for the construction industry is on the rise, the promising results obtained in this study could be useful to the academic community and building industry.

Full article

Figure 1

Open AccessArticle

Numerical Evaluation of the Effective Thermo-Mechanical Properties of a Large-Scale Additively Manufactured Short Fiber-Reinforced Polymer Composite

by

Aigbe E. Awenlimobor and Douglas E. Smith

Fibers 2025, 13(11), 147; https://doi.org/10.3390/fib13110147 - 30 Oct 2025

Abstract

►▼

Show Figures

This study presents a finite element analysis (FEA)-based numerical homogenization method for evaluating the effective thermo-mechanical properties of a large-area additively manufactured particulate-filled composite using realistic periodic representative volume elements (RVEs) generated from reconstructed X-ray µ-CT image scans of a 3D-printed bead. The

[...] Read more.

This study presents a finite element analysis (FEA)-based numerical homogenization method for evaluating the effective thermo-mechanical properties of a large-area additively manufactured particulate-filled composite using realistic periodic representative volume elements (RVEs) generated from reconstructed X-ray µ-CT image scans of a 3D-printed bead. The numerical results of the predicted effective properties, including the elastic stiffness, coefficient of thermal expansion (CTE) and thermal conductivity, were benchmarked with the Mori–Tanaka–Benveniste analytical estimates, which were found to be comparable. Initial sensitivity analysis using a single region of interest (ROI) extracted from the bead’s volume was performed to determine a suitable RVE size. The impact of inherent micro-porosities on the resulting composite material’s behavior was also quantified in the current investigation and was shown to reduce the composite’s effective properties. Using a suitable RVE size, the effect of anisotropy due to spatial variation in the microstructure across the bead specimen on the computed composite’s effective properties was also assessed. The results show that the regions closer to the exposed surface of the print bead with highly aligned and densely packed fiber particulates have superior properties as compared to inner regions with a more randomly oriented and less densely packed fibrous microstructure.

Full article

Graphical abstract

Journal Menu

► ▼ Journal Menu-

- Fibers Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Instructions for Authors

- Special Issues

- Topics

- Topical Collections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Energies, Fibers, Micromachines, Molecules, Nanoenergy Advances

Advances on the Application of Nanomaterials and 2D Materials for Sensors, Solar Cells, Microelectronics, and Optoelectronics

Topic Editors: Alessia Irrera, Antonio Alessio LeonardiDeadline: 31 December 2025

Topic in

Fibers, J. Compos. Sci., Materials, Polymers, Applied Mechanics

Advances in Fiber–Matrix Interface: Cohesion Enhancement, Characterization and Modeling of Interfacial Debonding

Topic Editors: Quentin Bourgogne, Hamid Zahrouni, Hubert ChapuisDeadline: 28 February 2026

Topic in

Applied Sciences, Optics, Sensors, Materials, Fibers, Photonics, Micromachines

Distributed Optical Fiber Sensors

Topic Editors: Jian Li, Hao Wu, Giancarlo C. Righini, Zhe Ma, Yahui WangDeadline: 30 June 2026

Topic in

Fibers, J. Compos. Sci., JMMP, Materials, Polymers, Recycling

Advanced Composites Manufacturing and Plastics Processing, 2nd Volume

Topic Editors: Patricia Krawczak, Ludwig Cardon, Frederik DesplentereDeadline: 1 September 2026

Conferences

Special Issues

Special Issue in

Fibers

Fiber-Reinforced Cement Composites and Geopolymers: Mechanics and Durability

Guest Editors: Maciej Kaźmierowski, Roman JaskulskiDeadline: 15 March 2026

Special Issue in

Fibers

Recent Developments in Structural Applications of Fiber-Reinforced Concrete

Guest Editors: Maria C. C. Naoum, Nikos Papadopoulos, George SapidisDeadline: 15 April 2026

Special Issue in

Fibers

Fiber-Reinforced Concrete and Fiber-Reinforced Polymer Materials: Innovative Solutions in Construction Engineering

Guest Editors: Theodoros Rousakis, Ioannis E. Kavvadias, Maria C. C. Naoum, Kosmas E. Bantilas, Emmanouil GoliasDeadline: 31 May 2026

Topical Collections

Topical Collection in

Fibers

Feature Papers in FibersCollection Editors: Ionela Andreea Neacsu, Alexandru Grumezescu