Highlights

What are the main findings?

- Agro-industrial byproducts have gained attention as components in filament production for fused deposition modeling 3D printing.

- Most reviewed studies focus on the physical, mechanical, and barrier properties of filaments, and recent research highlights the incorporation of modified cellulose or lignin.

What is the implication of the main finding?

- Despite the novelty of incorporating agro-industrial byproducts, there are still scaling challenges and there are few products on the market.

- There is more focus on analysing the materials and final properties of 3D printing filaments. However, the environmental and regulatory aspects of filament production are less studied.

Abstract

Three-dimensional (3D) printing based on polymers reinforced with lignocellulosic components is an accessible and sustainable technology. Cellulose-based byproducts from industry, as well as crops, food, and forestry wastes, represent potential resources for additive manufacturing and have been evaluated in recent years, primarily in combination with polymers such as PLA or ABS. During fused deposition modeling (FDM), several parameters must be considered during raw material conditioning, blending, extrusion, and 3D printing. It is essential to understand how these parameters influence the final properties and their impact on the final application. This review focuses on the latest studies of lignocellulosic byproducts for 3D printing filaments and how the parameters involved during filament production and 3D printing influence the properties of the final product. Recent studies concerning applications, technical issues, and environmental and regulatory aspects were also analyzed.

1. Introduction

In the 1980s, stereolithography emerged as a pioneering form of 3D printing technology, which later evolved into what is now known as additive manufacturing (AM) [1]. AM, widely known as 3D printing, is a process that fabricates physical objects layer by layer from a computer-aided design model. AM provides exceptional precision in controlling geometry, material distribution, and structural integrity, establishing itself as a critical technology across diverse industries ranging from rapid prototyping to high-performance manufacturing, reducing material wastes and total costs [2,3,4]. AM-based technologies are classified into seven categories: binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination, and vat photopolymerization [5]. Material extrusion is widely used due to its simplicity and affordability [6] and encompasses fused deposition modeling (FDM or FFF), also referred to as fused filament fabrication [7], direct ink writing [8], and liquid deposition modeling [9]. Unlike FDM/FFF, where the printing material consists of a solid filament, direct ink writing utilizes viscoelastic inks [10], whereas liquid deposition modeling employs pasty materials [11]. FDM remains one of the most widely adopted printing techniques, especially for creating 3D objects from thermoplastic resins [12].

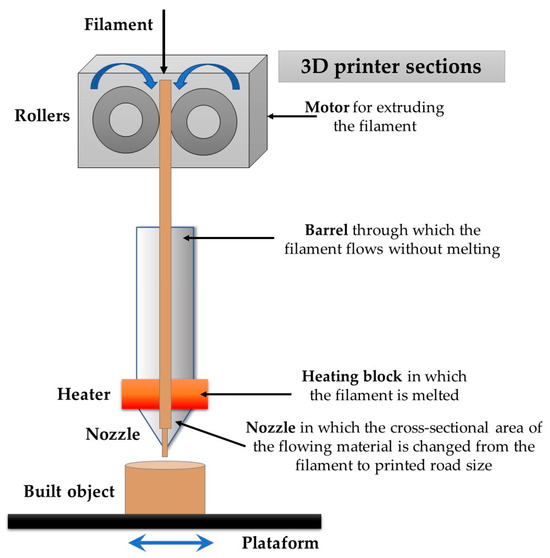

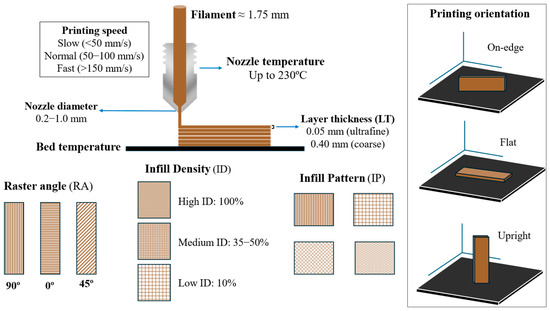

During the FDM process (Figure 1), a thermoplastic polymer filament is continuously fed into the extruder, where it is heated beyond its glass transition or melting temperature, allowing for controlled layer-by-layer deposition to form the desired structure [13].

Figure 1.

Schematic representation of the FDM process.

Then, the material is extruded through a nozzle onto the build platform horizontally in an x-y plane following the designated pattern [8]. The structure is completed layer by layer, and the build platform moves in the z plane, allowing the next layer to be deposited. In some cases, heating the build platform may be required to enhance the adhesion of the first printed layer [14]. Some FDM printers also possess multiple extrusion nozzles, allowing the simultaneous use of different printing and support materials [13]. Several parameters, including filament material and operational and environmental conditions, affect the FDM process [13,15,16]. These parameters then influence the final properties of the 3D-printed structures.

Most FDM prints occur at temperatures below 300 °C [2]. Considering the plastic pyramid, standard and engineering plastics used in 3D printing include acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polyamide (Nylon), and polyethylene terephthalate glycol (PETG) [8]. One of the most used is ABS, offering good impact strength and toughness [17]. PLA offers high tensile strength and biodegradability [16,18]. Polyamide/Nylon filaments offer high toughness, impact, and abrasion strength (printing of durable and flexible 3D objects) [16,19]. Some advanced engineering plastics used in 3D printing, such as polyether ketone and polyetherimide, require higher processing temperatures, which can pose challenges to conventional FDM printers [16,20]. Plastics can also be blended with other materials to enhance specific properties (mechanical, thermal), reduce water uptake, or increase sustainability in filaments when using non-biodegradable plastics. Lignocellulosic fibers have been used as a reinforcing agent in the production of 3D printing filaments [21,22,23,24,25]. The addition can reduce polymer filament costs and improve their mechanical performance (tensile and impact strength) [26,27]. For example, previous studies demonstrated that incorporating sugarcane bagasse fibers (20–40 wt% load) into biopolyethylene filaments [28] or wood fibers (20 wt%) into polyhydroxyalkanoate (PHA) systems [25] enhances tensile strength compared to filaments made from pure plastics.

There are numerous opportunities to utilize lignocellulosic components as fillers in filaments, including lignin and cellulose fibers. The forestry and agricultural sectors generate vast amounts of biomass waste, such as cereal straws, wheat and rice husks, pine and eucalyptus sawdust, and sugarcane bagasse. Each year, approximately 1300 million tons of agricultural waste are produced [29]. That of biomass, often deemed worthless [30], is frequently discarded or incinerated, exacerbating environmental pollution [31]. Moreover, lignin is generally burned for energy generation; however, its utilization could be more valuable in filament production owing to its special properties, such as antioxidant and antimicrobial activity. Nevertheless, integrating lignocellulosic biomass into 3D printing filament production demands a comprehensive analysis of the key parameters and the effects of incorporating lignocellulosic components. Although several authors have explored this topic previously, the surge in research on 3D printing with lignocellulosic fiber-based fillers, particularly over the past 5 years, requires an updated review of the latest advancements.

This review presents an updated overview of current literature on lignocellulosic waste as reinforcement in FDM printing filaments. It examines the types of available byproducts, their processing routes, and the resulting filament properties, with particular focus on emerging applications in the biomedical and construction sectors. The analysis also addresses key challenges related to technical feasibility, economic viability, and environmental impact.

In contrast to previous reviews that primarily emphasize resource availability or the broad use of natural fibers, this work offers a comprehensive and integrative perspective on the role of lignocellulosic byproducts in 3D printing. It underscores the critical interplay between process parameters and final product performance, while also examining recent advancements, persistent technical challenges, and key environmental and regulatory considerations.

2. Materials and Methods

The methodology consisted of five steps: question definition, search, initial selection (inclusion and exclusion of articles), secondary selection (after reading the abstracts), and data compilation and synthesis.

The studies were collected from Science Direct and Google Scholar databases and were selected considering their contribution to one or more of these overall questions:

- Which lignocellulosic residues are generated, and in what amounts?

- What type of treatment is performed on byproducts to make them suitable for 3D printing?

- What parameters should be considered during the manufacturing of the filament and the 3D structure?

- How do these parameters influence filament production or 3D printing, and what properties are relevant?

- What applications have been studied in recent years?

- What are the technical, environmental, and regulatory considerations for 3D printing based on lignocellulosic waste?

The search strategy focused on identifying studies related to raw material sources, filament production, and performance optimization for FDM 3D printing. The following keywords were used in various combinations, applying Boolean operators: 3D printing, additive manufacturing, fused deposition modeling, FDM, agricultural waste, agro-industrial waste, forestry industrial waste, wood processing byproducts, filament production, extrusion, printing parameters, compatibilizers, biodegradation, 3D-printed materials, life cycle assessment, and industrial scale. The compilation included reviews and original articles published between 2020 and 2025 in English, whereas editorial notes, book chapters, and conference proceedings were excluded.

Only fused deposition manufacturing was considered, along with reviews evaluating lignocellulosic-based filaments. Articles mentioning 4D printing were not considered.

3. Results

A total of 132 studies were evaluated, including original articles and reviews. Information on the amounts of lignocellulosic waste was obtained from statistical reports, data on current applications were gathered from webpages, and further articles were included following the recommendations of peer reviewers.

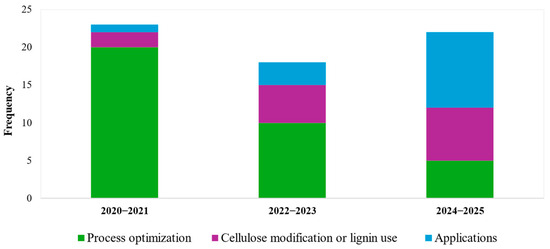

Earlier research emphasized fillers, printing conditions, and the nature of lignocellulosic fibers. In contrast, recent studies increasingly targeted end-use applications, with growing interest in fiber modification and lignin integration strategies (Figure 2).

Figure 2.

Estimated evolution of the approach in FDM 3D printing over recent years.

Most of the original studies employed lignocellulosic residues in combination with PLA, highlighting its prevalence as a biopolymer matrix. In contrast, ABS and other polymers were explored in only a limited number of cases, suggesting a narrower scope of material diversity. Wood derivatives are the most frequently studied materials for 3D printing filaments, although some research has also examined agricultural waste.

3.1. Agro/Forest Industrial Wastes as a Feedstock

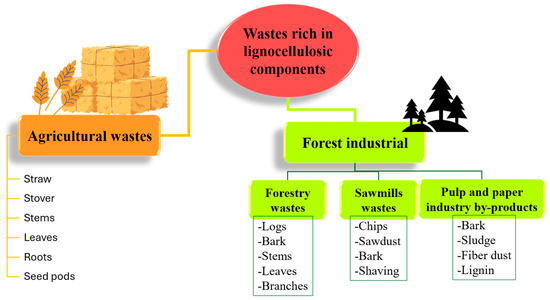

Gross classification of agro/forest industrial byproducts is shown in Figure 3. The classification is quite broad and includes byproducts rich in lignocellulosic components, proteins, lipids, or bioactive components. The categories labeled “Agricultural Wastes” and “Forest Industry” predominantly comprise lignocellulosic byproducts. These materials, which include straw, stover, stems, and leaves generated during harvesting and subsequent handling processes, represent significant sources of structural biopolymers such as cellulose, hemicellulose, and lignin.

Figure 3.

Summary classification of agro-forestry industrial byproducts rich in lignocellulosic components.

Similarly, the forest industry yields substantial lignocellulosic resources through various stages of biomass utilization. Residues obtained from tree harvest, along with byproducts from primary wood processing, as well as the pulp and paper manufacturing sectors, offer considerable potential for the recovery and application of these valuable lignocellulosic components.

3.1.1. Agricultural Wastes

Changes in lifestyle and population growth have significantly increased food production and consumption, resulting in substantial food waste and large volumes of crop residues. Crops (straw, leaves, seed pods, and shells) are the most common type of residue in the classification of agricultural waste, generated during the harvest of rice, corn, wheat, triticale, sorghum, soybeans, and other crops (Table 1) [32]. However, there are some exceptions, such as integrated management strategies that involve government policies, technological innovations, and farmer education [33].

Sugarcane is a major and the primary agricultural output in several countries, with Brazil and India accounting for approximately 60% of global production for sugar, rum, molasses, and biofuel [34,35]. The sugar and ethanol industry generates >279 million tons of solid and liquid waste annually [36]. Four types of waste are produced throughout the sugarcane processing chain: dry leaves and sugarcane tops, sugarcane bagasse, sugarcane press mud (a residue from filtering sugarcane juice), vinasse (a liquid byproduct from biomass distillation in ethanol production), and molasses (a viscous, dark, sugar-rich byproduct of sugarcane processing) [37,38]. Most of these wastes (except for molasses and vinasse) are primarily composed of cellulose, hemicelluloses, lignin, waxes, protein, and ashes (mainly SiO2) [36]. Sugarcane bagasse can contain up to 40% cellulose, while sugarcane press mud contains about 10% [37].

Corn stover wastes (stalks, leaves, husks, and cobs remaining after corn grain harvest) are a common source of first-generation ethanol, particularly in Brazil and the United States [39]. Rice harvesting and processing generate straws and husks as byproducts. Approximately 1140 million tons of rice straw waste are generated each year [40]. Its high ash content makes it a valuable resource for silica recovery, while its lignocellulosic fraction can be used for ethanol production [41].

Table 1.

Estimated global production of agricultural wastes. Data compiled and organized from [34,35,36,42,43,44].

Table 1.

Estimated global production of agricultural wastes. Data compiled and organized from [34,35,36,42,43,44].

| Product | Estimated Global Production (Mmt) | Major Producers (%) | Wastes Generated | Ref. | |

|---|---|---|---|---|---|

| Sugarcane | 2000 (2022/2023) | Brazil | 38 | Straw (harvesting). Bagasse, molasses, press mud (sugar elaboration). >279 million tons generated in sugar and ethanol production | [34,35,36] |

| India | 23 | ||||

| China | 5 | ||||

| Thailand | 5 | ||||

| Pakistan | 4 | ||||

| Corn | 1220 (2024) | USA | 31 | Corn stover. 47–50% of the total produced | [42] |

| China | 24 | ||||

| Brazil | 11 | ||||

| EU | 5 | ||||

| Argentina | 4 | ||||

| Wheat | 800 (2024) | China | 18 | Straw. 50% of straw per harvested wheat | |

| EU | 15 | ||||

| India | 14 | ||||

| Russia | 10 | ||||

| USA | 7 | ||||

| Rice | 538 (2024) | India | 27 | Straw (harvesting) and husks. Rice husk is 22% of the total rice produced | [42,43] |

| China | 27 | ||||

| Bangladesh | 7 | ||||

| Indonesia | 6 | ||||

| Vietnam | 5 | ||||

| Soybean | 421 (2024) | Brazil | 40 | Straw and okara. Up to 1.2 kg of okara per kg of soybean processed | [42,44] |

| USA | 28 | ||||

| Argentina | 12 | ||||

| China | 5 | ||||

| India | 3 | ||||

Mmt: million metric tons. USA: United States, EU: European Union.

Wheat straw is another widely generated grain crop residue, and its composition consists of cellulose, hemicellulose, lignin, proteins, minerals (calcium and phosphorus), silica, acid detergent, ash, bioactive compounds, and vitamins [45]. Soybean harvesting and the production of soy milk, tofu, and other products generate considerable waste. The three largest producers are in the American continent, accounting for 80% of the total production [42].

3.1.2. Waste Generated in the Wood Processing, Pulp, and Paper Industry

From log extraction to end products, various stages of wood processing generate valuable byproducts. The chief sources include forest operations, sawmills, plywood and particleboard manufacturing, and the pulp and paper industry. The highest estimated availability of wood residues is in East Asia and North America (approx. 500 million m3/year), followed by South America and Europe (around 150 million m3/year). Sources vary by region: logging residues dominate in Central and East Africa, while post-consumer waste prevails in areas with limited forest production, such as North Africa and Central Asia. In South America, Northern Europe, and Oceania, industrial processing residues account for over 30% of the theoretical potential [46].

Forest operations generate significant residues (25–45% of the harvested wood), including leaves, stumps, branches, needles, roots, sawdust, stems, and small logs [47]. In recent years, forest management efforts have increased the utilization of these residues for composting and energy production [48,49].

Wood operations such as sawing, planing, sanding, and milling also generate wood waste. Sawdust, bark, trimmings, split wood, planer shavings, and sander dust are some examples. Offcuts and chips are often used to generate steam for drying and as fuel [47,50]. The bark and shavings are primarily utilized as bedding in farms and animal facilities [51]. Sawdust usually accounts for 12–25% of wood treated in sawmills. Its shape, size, and quantity are influenced by the physical and chemical properties of the used timber (for example, softwood produces less sawdust than hardwood) as well as by the cutting instruments (shape, size, sharpness) or circumstances of the technological operations [51]. The bark is generated by debarking in barking drums in sawmills, plywood, and particle wood production, or at the beginning of pulping processes [47].

The pulp and paper industry generates sawdust and bark, black liquor, rejects from screening, pulping, or paper stock preparation, sludge from water treatment or the papermaking machine, and combustion ashes [52,53]. Kraft pulping generates approximately 100 kg of waste per ton of pulp produced, whereas semichemical and mechanical pulping produce around 60 kg per ton [54]. Debarking, chipping, chip screening, chip handling, and storage wood operations generate mainly bark and sawdust. Fine sawdust can serve as a raw material for filaments without the necessity of reducing the size. Black pine sawdust (particle size < 250 μm) has been incorporated into PLA filament production using a twin-screw extruder, improving thermal properties and flexural strength [55]. Wood sawdust has also been combined with wood combustion ashes and cellulose pulp to produce PLA-reinforced filaments [56].

In chemical pulping mills, black liquor (lignin-rich byproduct) is generated during the washing stage following pulping. Lignin plays a crucial role in the overall recovery process as a source of fuel. However, in some cases, a portion can be separated and used as technical lignin. It can be utilized in the development of thermoplastics, thermosets, fillers, composites, and blends or as a precursor for 3D printing filaments [57]. Good printability and enhanced mechanical properties were obtained when unmodified technical kraft and phenolated organosolv lignins were incorporated into PLA matrices [58]. Lignin offers numerous possibilities for filament production due to its thermoplastic behavior and the improvement it produces in the thermal and mechanical properties of the filaments [59].

3.2. Processing Agro/Forest Industrial Waste into Filaments

The production of 3D printing structures includes raw material conditioning, polymer blending, filament fabrication, and final printing. Parameters must be controlled in each step to optimize the processes.

It is essential to consider control parameters, as their selection directly impacts the final properties of printed structures. In FDM, printing speed affects interlayer adhesion and porosity, while the bed temperature influences raster bonding. Additionally, the raster angle plays a critical role in determining the mechanical properties of the final product. A precise calibration of these parameters is fundamental to optimizing structural integrity and performance [60]. Table 1 summarizes some studies performed and the parameters involved.

3.2.1. Raw Material Conditioning

Regardless of the intended application of lignocellulosic byproducts in 3D printing filament production, the processing steps outlined by most researchers follow a consistent pattern, typically involving pretreatment, drying, and grinding. The removal of moisture from wood fibers is essential to prevent bubble formation and ensure proper adhesion when blended with polymers.

Likewise, PLA and thermoplastic starch (TPS) are highly susceptible to moisture absorption from the surrounding environment, as evidenced by filament degradation under sustained relative humidity conditions [61,62]. Proper drying protocols and storage strategies are crucial for maintaining material integrity and optimizing composite performance [62]. The authors observed that elevated humidity levels resulted in higher melt flow indexes and greater porosity while maintaining molecular integrity and crystalline structure. However, mechanical properties exhibited a decline as humidity increased, highlighting the significant impact of moisture on material performance [62].

Particle sizes are usually divided into ultrafine (<20 µm), fine (50–500 µm), intermediate (1000–10,000 µm), and coarse (>10,000 µm) [63]. However, the lignocellulosic particle sizes chosen by different authors can reach up to approximately 250 µm (Table 2). It is recommended that the particle size in the filaments be one-fifth to one-half the size of the nozzle [64]. Most studies performed particle size reduction by milling, followed by sieving to obtain fractions ≤ 250 µm [55,65,66,67,68,69]. Huang et al. [69] analyzed the influence of particle sizes of red gum sawdust on mechanical properties when added to PLA for filament production. The results showed that particle sizes between 90 and 150 µm maximized the tensile strength, but the elongation reached the highest values when using particles with sizes < 9 µm [69]. It has been previously reported that an increase in particle size generates a less uniform structure and poorer dispersion. However, if the particle size is too small, particle aggregation occurs, reducing dispersion [70].

The production of filaments reinforced with lignocellulosic byproducts has been carried out using the milling residue as it was or, in some cases, after chemical pretreatment. Acid or alkaline treatments are the most common, allowing the purification of the cellulose fraction of the material through the elimination of other components such as extractives, some lignin, and hemicelluloses [70,71]. These treatments have improved mechanical properties (increased tensile strength and elongation) and thermal behavior while reducing water absorption and wettability, as in the case of Yu et al. [70]. The authors found that alkaline pretreatment and ultrasound enhanced the properties of rice husk powder. This improvement was attributed to a lower proportion of amorphous components and better interfacial adhesion with the polymer [70].

The primary challenge in lignocellulosic-based filaments lies in the poor adhesion between fibers and polymer matrix, which hinders effective stress transfer from the matrix to the reinforcement [72], compromising the mechanical properties of the composite. Some strategies to improve the adhesion between polymer and filler are mentioned in the following sections.

Table 2.

Three-dimensional (3D) printing studies using lignocellulosic byproducts as a reinforcement.

Table 2.

Three-dimensional (3D) printing studies using lignocellulosic byproducts as a reinforcement.

| Filament Components | Lignocellulosic Fiber | Filament Production Conditions | 3D Printing Parameters | Ref. | ||

|---|---|---|---|---|---|---|

| Conditioning or Pretreatment | Particle Size (µm) | Filler Load (wt%) | ||||

| Japanese cedar sapwood + PLA | Milled, sieved, and treated with temperature (180 °C for 2–6 h). Then dried at 105 °C, 24 h | <149 | 0, 20 | Single-screw extruder, 16 rpm, 70–210 °C | RA: 0°, Nozzle T: 210 °C, Bed T: 60 °C, FFS: 30 mm/s, ID: 100%, IP: n.i., LT: 0.30 mm | [65] |

| Black pine (Pinus nigra) timber sawdust + PLA | Sieved, dried at 103 °C | 177–250 | 0–20 | Twin-screw extruder, 100–180 °C, 50 rpm | RA: 45°, Nozzle T: 180 °C, Bed T: 50 °C, FFS: 50 mm/s, ID: 100%, IP: n.i., LT: 0.30 mm | [55] |

| Wood powder + silane + PLA + acrylic ester resin | Acetylation | <48 | 0, 5 | Twin-screw extruder, 170–190 °C | RA: 0°, Nozzle T: 220 °C, Bed T: 55 °C, FFS: 40 mm/s, ID: n.i., IP: n.i., LT: 0.20 mm | [73] |

| Poplar fiber + PLA + silane + tributyl citrate | Milled, coupled, and dried | <117 | 5 | Single-screw extruder 45 rpm, 170 °C | RA: n.i., Nozzle T: 200–240 °C, Bed T: 80 °C, FFS: 20–100 mm/s, ID: 100%, IP: n.i., LT: 0.10–0.50 mm | [74] |

| Recycled woodblock fibers + PLA | Grinding, sieving, dried at 80 °C | <250 | 0–15 | Single-screw extruder, 165 °C | RA: 0°, 90°, Nozzle T: 180–210 °C, Bed T: 45 °C, FFS: 35 mm/s, ID: 100%, IP: Linear, LT: 0.20 mm | [68] |

| Wood ashes + PLA | Dried at 80 °C for 24 h | n.i. | 0–20 | Single-screw extruder, 170–180 °C, 4 rpm | RA: 45°, Nozzle T: 200 °C, Bed T: 60 °C, FFS: 30 mm/s, ID: 100%, IP: n.i., LT: 0.40 mm | [56] |

| Jack pine sawdust + PLA | Milled, sieved, and dried at 80 °C for 24 h | <150 | ||||

| Red Gum sawdust + ABS + maleic anhydride | Milled, sieved, and dried at 105 °C for 24 h | 150–212, 90–150, <90 | 0–20 | n.i. | RA: 45°, Nozzle T: 245–250 °C, Bed T: 100 °C, FFS: 15 mm/s, ID: 100%, IP: n.i., LT: 0.30 mm | [69] |

| Grey Box sawdust + ABS + maleic anhydride | ||||||

| Printed office paper + silane + PLA | Coupled and dried at 103 °C to a constant weight | n.i. | 5–15 | Single-screw extruder, 175–180 °C | Printing parameters n.i. | [75] |

| Organosolv lignin hardwood + PLA | Dried at 60 °C for 72 h | n.i. | 0, 10 | Single-screw extruder, 170–195 °C, 12.2–14.5 rpm | RA: n.i., Nozzle T: 200 °C, Bed T: n.i., FFS: 40 mm/s, ID: 100%, IP: Rectilinear, LT: 0.40 mm | [76] |

| Organosolv lignin hardwood + TPU | Single-screw extruder, 195–200 °C, 9.7–10.4 rpm | RA: n.i., Nozzle T: 210 °C, Bed T: n.i., FFS: 40 mm/s. ID: 100%, IP: Rectilinear, LT: 0.40 mm | ||||

| Organosolv lignin + PLA | Dried at 70 °C overnight | n.i. | 0, 30, 50, 70 | Single-screw extruder, 180 °C | RA: 0°, 90°, Nozzle T: 215 °C, Bed T: 60 °C, FFS: 50 mm/s, ID: 15% inside (100% Top-bottom), IP: n.i., LT: 0.15 mm | [58] |

| Kraft lignin + PLA | ||||||

| Kenaf cellulose fibers + silane + PLA | Alkaline treatment, then coupled, and dried at 110 °C for 24 h | n.i. | 0, 12.5 | Twin-screw extruder, 190–210 °C, 25–29 rpm | RA: n.i., Nozzle T: 210 °C, Bed T: 60 °C, FFS: 60 mm/s, ID: 100%, IP: linear, LT: 0.18–0.27 mm | [77] |

| Kenaf powder + ABS | n.i. | 120 | 0–10 | Twin-screw extruder, 160–260 °C | RA: n.i., Nozzle T: 230 °C, Bed T: 105 °C, FFS: 40–80 mm/s, ID: 100%, IP: linear, LT: 0.18–0.27 mm. | [78] |

| Kenaf cellulose fibers + PLA | Alkaline and bleaching treatment, then coupled, and dried at 50 °C for 24 h | n.i. | 0, 10 | Conical twin-screw microcompounding, 180 °C, 40 rpm | RA: n.i., Nozzle T: 190 °C, Bed T: 60 °C, FFS: 20 mm/s, ID: 300%, IP: n.i., LT: 0.20 mm. | [79] |

| Flour waste (Wheat middling) + PLA | Milled, sieved, and dried at 75 °C for 1 h | n.i. | 0, 10, 20 | Single-screw extruder, 165–175 °C, 5 rpm | RA: n.i., Nozzle T: 230 °C, Bed T: 60 °C, FFS: 20 mm/s. ID: 100%, IP: linear, LT: 0.20 mm. | [80] |

| Rice husks + PLA | ||||||

| Rice straw powder + PLA | Alkaline and ultrasound treatments, dried at 105 °C for 10 h, and milled | <250, <115, <106, <75 | 0, 1 | Twin-screw extruder, 170–190 °C | RA: n.i., Nozzle T: 205 °C, Bed T: 45 °C, FFS: 55 mm/s, ID: 100%, IP: n.i., LT: 0.20 mm | [70] |

| Rice husks + TPC | Acid hydrolysis, methanesulfonic acid, and alkaline treatments, dried at 50 °C for 2 h | <200 | 10 | Single-screw extruder, 160 °C, 0.05 mm/s | RA: n.i., Nozzle T: 210–220–230 °C, Bed T: 80 °C, FFS: 15–20–25 mm/s, ID: 100%, IP: n.i., LT: 0.20–0.30 mm | [71] |

| Rice husks + PLA | Milled, dried, and sieved | n.i. | 0–2 | Single-screw extruder, 177–197 °C, 5–8 rpm | RA: n.i., Nozzle T: 200 °C, Bed T: 60 °C, FFS: 60 mm/s, ID: n.i., IP: n.i., LT: 0.20 mm | [81] |

| Hedysarum coronarium stems + PLA | Milled, sieved, and dried at 40 °C for 72 h | <106 | 0–20 | Single-screw extruder, 160–190 °C, 20 rpm | RA: 45°, Nozzle T: 230 °C, Bed T: 60 °C, FFS: 20 mm/s, ID: 100%, IP: rectilinear, LT: 0.10–0.20 mm | [82] |

| Corn stalk powder + PLA + silanes + additives | Coupled and dried at 105 °C | n.i. | 1–20 | Single-screw extruder, 195–215 °C, 60–80 rpm | RA: n.i., Nozzle T: 195 °C, Bed T: n.i., FFS: 50 mm/s, ID: 100%, IP: n.i., LT: 0.15 mm | [83] |

| Soybean hulls + rHDPE + rPP + maleic anhydride | Pyrolysis, milled, and dried at 85 °C | 0, 20 | Twin-screw extruder, 180 °C, 100 rpm | RA: 0–45–90°, Nozzle T: 200–235 °C, Bed T: 80–100 °C, FFS: 35 mm/s, ID: 100%, IP: n.i., LT: 0.30 mm | [84] | |

| Soybean hulls + PLA/PBAT | Milled, and dried at 80 °C for 3 h | 125 | 0, 5, 10 | Twin-screw extruder, 170–180 °C, 4.3 rpm | RA: 0–45–90°, Nozzle T: 185–215 °C, Bed T: n.i., FFS: n.i., ID: 50–75–100%, IP: n.i., LT: 0.20–0.40 mm | [85] |

| Soybean hulls + TPS | Acid hydrolysis | n.i. | 0, 10 | Single-screw extruder, 165 °C, 0.15 mm/s | RA: 45°, Nozzle T: 220 °C, Bed T: 65 °C, FFS: 30 mm/s, ID: 100%, IP: n.i., LT: 0.20 mm | [86] |

| Oil palm fiber + ABS | Alkaline treatment, mixing, hot press molding, and crushing | n.i. | 0–7 | Single-screw extruder, 160–240 °C, 30 rpm | RA: 0°, Nozzle T: 240 °C, Bed T: 80 °C, FFS: 10 mm/s, ID: 100%, IP: Rectilinear, LT: 0.20 mm | [87] |

| Henequen fibers flour + PLA | Drying and milling (milling in two steps) | 90–250 | 1–5 | Single-screw extruder, 175–185 °C, 15 rpm | RA: 0–45–90°, Nozzle T: 215 °C, Bed T: 60 °C, FFS: 30 mm/s ID: 100%, IP: Lineal, LT: 0.15 mm | [66] |

| Agave tequilana fibers + PLA | Dephited, milled, and sieved | 106–150 | 0–10 | Twin-screw extruder, 160–175 °C, 65 rpm | RA: 0–45–90°, Nozzle T: 190 °C, Bed T: 70 °C, FFS: 50 mm/s. ID: 100%, IP: Crosshatch, LT: n.i. | [88] |

| Pistachio seed husks + PLA | Alkaline treatment, washed, dried at 100 °C for 4 h, and milled | 0.049–0.162 | 0, 5–15 | n.i. | RA: 90°, Nozzle T: 215 °C, Bed T: 60 °C, FFS: 50 mm/s. ID: n.i., IP: n.i., LT: 0.10 mm | [89] |

| Coffee seed husks + PLA | ||||||

| Chestnut seed husks + PLA | ||||||

| Walnut seed husks +PLA | ||||||

| Peanuts shells + PBAT | Milled, sieved, and dried at 60 °C for 24 h | <149 | 0–5 | Single-screw extruder, 150–154 °C, 40 rpm | RA: n.i., Nozzle T: 175 °C, Bed T: n.i., FFS: 30 mm/s, ID:100%, IP: n.i., LT: 0.20 mm | [90] |

| Soybean shells + PBAT | ||||||

| Weed hemp powder + PLA | Dried at 90 °C for 10 h | 150 | 0, 10-15 | Twin-screw extruder, 160–170 °C, 300 rpm | RA: n.i., Nozzle T: 200 °C, Bed T: n.i., FFS: 60 mm/s ID: 50%, IP: n.i., LT: 0.25 mm | [91] |

| Sicilian cherry tomato scraps + PLA | 100 | 0, 15–25 | ||||

| Discarded carob flour + PLA | 130 | 0, 10–20 | ||||

| Orange pruning waste + PLA | 100 | 0, 10–20 | ||||

| Kern hazelnut Shell powder + PLA | Dried at 100 °C for 24 h | 25.8 | 0, 10–30 | Twin-screw extruder, 170–190 °C, 250 rpm | RA: n.i., Nozzle T: 200–220 °C, Bed T: 55 °C, FFS: 25–50 mm/s, ID:100%, IP: Rectilinear, LT: 0.20 mm | [92] |

| Macadamia Nutshells + PLA | Milled, sieved, alkaline treatment, and dried at 85 °C for 48 h | ≈50 | 0, 10 | Single-screw extruder, 160–170 °C, 20–25 rpm | RA: n.i., Nozzle T: 210 °C, Bed T: n.i., FFS: 75 mm/s, ID: 100%, IP: n.i., LT: 0.06 mm | [93] |

n.i.: not informed, T: temperature, RA: raster angle, FFS: Printing speed, ID: Infill density, IP: infill pattern, LT: layer thickness.

3.2.2. Polymer Matrix Selection and Blending

Shapes, sizes, rheology, and operational parameters for 3D printing processes (temperature, heating rate, and cooling rate) can influence the material microstructures and properties of the printed objects. The selection of polymer depends on the 3D printing technology used and the required mechanical properties of the final product [8].

Biodegradable polymers can be degraded by fungi, bacteria, and enzymes, which can fragment them, and they are compostable when this process occurs in a compost medium. Biobased polymers are derived from renewable resources (plants, animals, or microorganisms) as a sustainable alternative to petroleum-based polymers. Biobased polymers cannot be biodegradable, and similarly, biodegradable polymers cannot be biobased.

Table 3 compares the main characteristics of the biodegradable and non-biodegradable matrices used in lignocellulosic fiber–polymer composites. ABS is an amorphous thermoplastic widely used in 3D printing due to its excellent impact resistance, toughness, dimensional and thermal stability, and strong chemical resistance [94]. Its relatively low glass transition temperature (around 102–115 °C) and high printing temperature (ranging from 220 to 260 °C) make it suitable for a variety of applications. However, the polymer requires an efficient ventilation system, since volatile organic compounds (VOCs) could be emitted at extrusion temperatures [95]. PETG (Tg: 75–85 °C) and Nylon have mechanical properties similar to those of ABS but with lower emissions. PETG is also more recyclable and versatile, with processing temperatures similar to those of ABS [96]. Conventional polymer recycling remains limited due to challenges such as collection inefficiencies, high levels of contamination, heterogeneity of components in the mixture, and reduced mechanical properties. Nonetheless, waste and recycled thermoplastics are increasingly recognized as valuable emerging raw materials for the development of 3D-printed products [97]. In parallel, bio-based polymers derived from renewable biomass, such as biopolyethylene, polypropylene, Bio-Nylon, and Bio-PC, are developed as sustainable alternatives to petroleum-based counterparts [98].

Table 3.

Comparison between biodegradable and non-biodegradable matrices used in lignocellulosic fiber–polymer composites.

Biodegradable options include plastics derived from natural resources, microorganisms, and synthesized polymers. The cost is higher for PHAs, which are produced in low volume, while TPS is cheaper. PHAs are produced by bacterial fermentation and are usually applied to biomedical solutions due to their high biocompatibility. However, in recent years, the trend has also included packaging solutions [72]. PLA, polycaprolactone (PCL), and polyvinyl alcohol (PVA) are synthetic polymers. PLA is widely applied in 3D printing (printing temperature range 190–230 °C) as a sustainable alternative to ABS (higher biodegradability, less VOC emissions, and lower extrusion temperatures) [95]. PCL also presents good biodegradability and biocompatibility, making it suitable for applications such as tissue engineering [99].

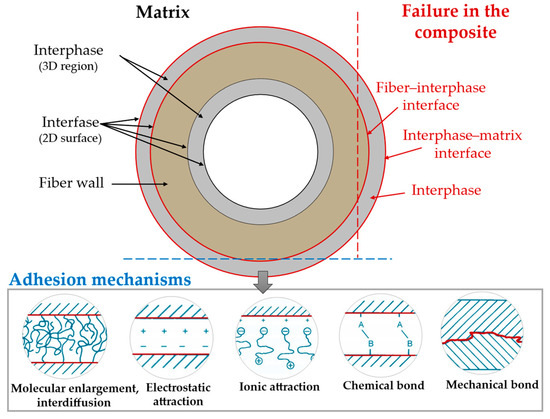

3.2.3. Compatibility of Lignocellulosic Fiber/Filler with Thermoplastics

The interactions between lignocellulosic materials and polymeric matrices determine the strength, toughness, creep, and moisture stability of the composite, but to a lesser extent, its stiffness [100]. The surface between lignocellulosic fiber–polymer phases forms an interface, whereas the regions where both phases coexist define the interphase [101,102]. Although the cause of failure in the composite material is complex to establish, it can occur due to a failure at the fiber–interphase interface, the interphase–matrix interface, or the interphase itself. The most significant interfacial interactions involve intermolecular forces (hydrogen bonds and covalent bonds) [103]. Covalent chemical bonds provide a strong link between phases, ensuring interfacial performance (Figure 4) [104]. Generally, the developed strategies to enhance these interactions are based on matrices or lignocellulosic fibers/fillers [100,104]. The ones based on matrices utilize grafting to the backbone of the polymer with specific chemical compounds as compatibilizers. In this form, the compatibilizer presents a backbone like that of the matrix, along with functional groups that can bond with the hydroxyl groups on the lignocellulosic surface [104,105]. Then, compatibility is the result of physical or chemical interactions and, to a lesser extent, mechanical or electrostatic bonds, which depend on the type and chemical structure of the compatibilizers [105,106].

Figure 4.

Schematic cross-sectional view of the lignocellulosic fiber–matrix interface in the composite, illustrating adhesion mechanisms and representative failure modes.

Some strategies involve the use of coupling agents (Table 4) or surface modification of fibers. Coupling agents include silanes, maleic anhydrides, isocyanates, and phthalates [106]. For example, the addition of maleic anhydride maximized the tensile strength (up to 6.5% higher) and elongation (up to 17% higher) in systems with PLA and henequen fibers [66]. Silane coupling agents (able to bridge natural fiber and polymers) are compounds like 3-aminopropyltriethoxysilane or γ-methacryloxypropyl trimethoxysilane that usually react with cellulose fibers. The coupling agent was applied to the fibers before mixing with PLA, using ultrasonic treatment in ethanol as a solvent, followed by solvent evaporation [75,83,107]. Aumnate et al. [79] added polyethylene glycol to mixtures of kenaf fibers coupled with PLA, finding an increase in tensile strength, elongation, and Young’s modulus. In some cases, a toughening agent like tributyl citrate is also added to maximize mechanical properties and toughness [74].

Table 4.

Changes in properties with the use of compatibilizers.

The use of compatibilizers allows covalent bonds or specific interactions between the functional groups in the polymer and the OH groups in cellulose, significantly improving interfacial adhesion [108]. Maleic anhydride can react with the hydroxyl groups of cellulose through an esterification reaction, forming covalent bonds that strengthen the fiber–matrix interface. This chemical interaction reduces interfacial energy, improves fiber dispersion in the matrix, and increases the mechanical strength of the biocomposite [109].

Also, the chemical modifications of cellulose (e.g., acetylation) reduce its hydrophilic character by replacing -OH groups with acetyl groups (-COCH3), which favors its dispersion in nonpolar matrices. Mercerization and silanization of the lignocellulosic material surface are the most widely applied methods [100,110]. Mercerization is an alkaline treatment that removes non-structural compounds (pectins, waxes, and other extractable substances) from the lignocellulosic surface, producing a rough topography to improve fiber–matrix interaction. Native hydroxide treatment, one of the most common alkalization methods, produces an increase in the amount of amorphous cellulose, which is, in effect, a change in the structure from native cellulose I to native cellulose II. This treatment depolymerizes the molecular structure of native cellulose I, promoting shorter chain lengths [111]. Silanization treatment reduces the hydrophilicity of lignocellulosic materials by using organosilanes with bifunctional groups, thereby providing an interaction between fibers and the polymer matrix through the formation of bridges between them. They are formed by a functional group that is chemically compatible with the polymer and another functional group that can react with the hydroxyl groups of the lignocellulosic material and other silicon compounds. The adhesion characteristics depend on the chemical groups comprising the organosilane compound, the additives and solvents, as well as the type of reinforcement [106,112]. Acetylation treatment involves the esterification reaction of the hydroxyl groups of the fibers using acetic acid and acetic anhydride. It produces an increase in acetyl groups on the fiber surface, which are less polar than hydroxyl groups, thereby increasing its hydrophobicity [113]. This treatment reduces the moisture adsorption and increases the surface roughness [113].

The degree to which the molecular chains of the polymer contact a surface (wetting), fiber dispersion, and adhesion at the interfacial level are critical for good transmission stress in the composites. The degree of fiber dispersion would correspond to a high number of individual fibers (good) or fiber agglomeration (poor) within the matrix [50,100].

3.2.4. Compounding Methods (Single-Screw vs. Twin-Screw Extrusion)

Additive manufacturing technologies produce 3D structures by laying 2D polymer or composite layers sequentially along the vertical axis. In FDM, 3D structures are generated by melting a thermoplastic polymer, which is extruded through a nozzle and deposited layer by layer onto a build plate, forming a physical replica of the digital model. The extrusion system in the 3D printer consists of four sections, as shown in Figure 1 [114].

The first sections should ensure a good grip on the filament, thereby ensuring its continuous flow without grinding. In these sections, the filament should have high buckling pressure and stiffness. The heating block should limit any heat loss to the other parts of the extrusion system. In this section, melt rheology during extrusion requires a shear-thinning behavior with an appropriate melt viscosity. The nozzle should provide sufficient heat to melt the extruded material at various extrusion speeds. In the last section, the properties of the extrudate require a rapid increase in viscosity and good layer bonding [114].

In the extrusion, a thermoplastic polymer is fed as a filament into the extruder, which acts as a piston to ensure a continuous flow. The polymer is heated above its melting point, avoiding overheating, which may cause unwanted discharge during non-printing movements. Melt polymer exits from the nozzle into a smaller cross-sectional area [114,115].

An ideal polymer should have high stiffness for optimum feeding. Subsequently, the polymer undergoes rapid changes in its viscosity with heating and during extrusion, and finally, its viscosity increases to ensure the geometry of the 3D-printed object. Thermoplastic polymers have optimal viscoelastic behavior upon heating and cooling [114,116].

The single-screw extruder is widely used due to its ease of operation in polymer and composite production. It consists of a single screw inside a static, cylindrical barrel, divided into compression, feed, and metering zones. Polymers are melted and homogenized in the compression zone for a suitable distribution in the metering zone. The polymer is fed into the barrel by gravity force, and the speed of the screw controls the output rate. Its advantages are low cost, single design, and low maintenance costs, whereas its disadvantages are poor mixing and being unsuitable for low-heat-resistant materials [117,118].

The twin-screw extruder provides high shear forces between the screws and the barrel, as well as between the rotating screws. It favors a suitable mixing of polymers and their composites. The twin-screw extruder generates a broad range of mixing operations and heat transfers. Compared to a single-screw extruder, it has a high dispersion capacity, which results in better mixing, better process parameter control, easier material feed, and better productivity. On the other hand, it is expensive, requires more energy input, and does not apply to polymers that are shear-sensitive [118,119].

During the extrusion of lignocellulosic-based filaments, temperature plays a critical role, as lignocellulosic components undergo thermal degradation that triggers hydrolysis and oxidation reactions in the raw material. These processes primarily result in material darkening [120]. At extrusion temperatures, the degradation of hemicelluloses leads to the release of volatile compounds, notably acetic and formic acids [121].

3.2.5. Parameters in 3D Printing

Figure 5 shows some parameters involved in the 3D printing operation. Process parameters during FDM 3D printing, such as print orientation, layer thickness, infill density and pattern, print speed, and extrusion temperature, significantly affect the quality and mechanical properties of printed parts.

Figure 5.

Parameters involved in 3D printing: printing orientation, printing speed, filament nozzle diameter and temperature, bed temperature, layer thickness, raster angle, and infill density.

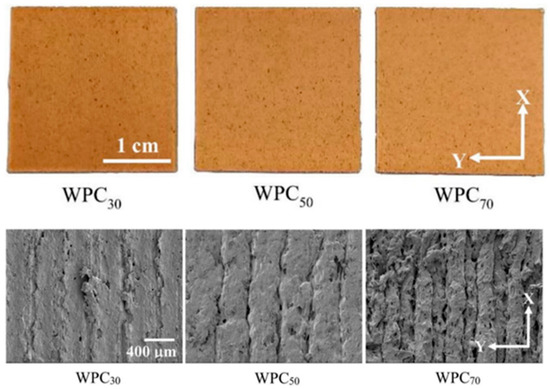

The printing speed (FFS), usually expressed in mm/s, refers to the rate at which the print head moves while depositing filament layer by layer. It depends on several factors, including printer specifications, nozzle diameter, filament type, and layer thickness (LT). Printing speed affects the quality of the 3D-printed structure. For instance, excessively high speeds can produce poor material deposition and surface finish. On the contrary, very low speeds, particularly when using wood-based filaments, can lead to thermal degradation of the wood components [122]. When using composite filaments of polymers and lignocellulosic fibers, some interactive effect is evidenced between temperature and printing speed. Yang and Yeh [123] studied how three different printing speeds (30, 50, and 70 mm/s) affected the morphology and mechanical properties of the printed structures. Printing speed mainly affected density; differences were observed in morphology, color of structures, and mechanical compression (Figure 6). Significant differences in tensile and flexural strength were not observed. However, the compression test results were maximal at the lowest printing speed. The highest printing speed generated a low bonding strength between layer interfaces due to minimal bonding between adjacent layers. Also, the printed structures presented a darker brown color as the printer speed decreased. The authors attributed this to lower speeds, explaining that the lignocellulosic fiber spends more time at high temperatures, degrading polysaccharides and extractives [123]. Later, Yang et al. found that the printing speed (20, 40, 60, 80, and 100 mm/s) of filaments with 5 wt% of poplar fibers coupled with silanes influences the density and flexural strength [74].

Figure 6.

From left to right, the increase in printing speed: WPC30 (30 mm/s), WPC50 (50 mm/s), and WPC70 (70 mm/s). Some 3D structures and their color changes (top). Morphology from SEM microphotographs (bottom). Extracted from Yang and Yeh [124] (License CC BY 4.0 (http://creativecommons.org/licenses/by/4.0/)).

Within the printer head, the nozzle melts the filament and deposits it onto the build platform (Figure 5). The nozzle temperature plays a key role during 3D printing. Yang et al. [74] studied the effect of nozzle temperature (200–240 °C) in 3D printing by FDM from 5 wt% of poplar fibers coupled with silanes and PLA. The results showed that flexural properties initially increased with temperature, reaching an optimum at 220 °C, before declining thereafter. The authors attributed this behavior to the fact that the composite (PLA + fiber) completely melted at 220 °C, which is not observed at lower temperatures (where probably voids are formed in the 3D structure). Above 220 °C, lignocellulosic components degrade, resulting in lower mechanical properties [74].

The temperature of the printer bed also plays a crucial role in ensuring proper adhesion of the printed structure. If the bed temperature is too low, the material may fail to adhere adequately, leading to detachment during printing. Conversely, if the temperature is excessively high, the material can over-melt and bond too strongly with the bed surface, making removal of the printed object difficult and potentially damaging [122]. The bed temperatures in PLA-based filaments are usually around 60 °C [58,73,75], and increase with the use of ABS-based filaments [69].

LT refers to the height of each 3D-printed layer and depends on the printer capacity and the diameter of the nozzle. Usually, the maximum LT is limited to 80% of the nozzle diameter. For example, if the nozzle diameter is 0.40 mm, the maximum LT to reach is 0.32 mm. Thinner layers increase the frequency of reheating in previously deposited layers, reduce porosity and surface roughness, and enhance interlayer diffusion. As layer thickness decreases, both flexural and tensile strength have been shown to improve [124]. Yang et al. [74] found that the increase in LT from 0.1 to 0.5 mm decreased the flexural strength by up to 42%, and the authors attributed this to the increased voids between printed filaments, which led to inefficient adhesion between the printed filaments and weak bonding in the layers [74].

Raster angle (RA) refers to the orientation between the deposited filament layer and the bed axis, typically the X-axis. RA could be used individually or in combination with other angles to create various configurations, such as grid or criss-cross patterns. A study performed by Ulkir et al. [125] using Taguchi’s L27 orthogonal array demonstrated that RA and printing speed were the most influential parameters in tensile and compressive properties (contributing around 40% each in a five-parameter system) [125]. Algarni [126] studied the effect of three raster angles (0°, 45°, 90°) on the tensile properties of 3D-printed specimens. The authors found an increase of 36%, 28%, and 18% in tensile strength, elongation, and Young’s modulus, respectively, when reorienting the RA from 0° to 90 °C [126]. Ramirez-Prieto also demonstrated that a specimen printed at 0°/0° RA exhibited the highest flexural strength compared to 0°/90° (grid) orientation and 45°/−45° (criss-cross) orientation (lowest) [127]. PLA/silanized poplar fiber filaments were also printed in four raster angles (transversal stripe, longitudinal stripe, 90° cross, and 45° cross) at 220 °C, LT of 0.2 mm, and 40 mm/s. The results showed that the tensile (and elongation) and flexural (except modulus) properties were highest with longitudinal stripes. The mechanical properties of 3D structures at a 45° cross were higher than those with a 90° cross, except for a similar flexural modulus [74].

Infill pattern (IP) is the internal structure of a 3D-printed component. The configurations could be linear, layered, honeycomb, triangular, grid, gyroid, cubic, or concentric. IP affects the mechanical properties of 3D-printed structures. Yeoh et al. [128] studied the effect of three IP configurations on tensile strength, elongation, Young’s modulus, and microhardness. The results showed that the grid IP maximized the tensile strength and elongation compared to zigzag and concentric IP, but the concentric IP allowed them to reach the highest microhardness [128]. Infill density (ID) is the internal density of the printed structure, expressed as a percentage. An ID of 100% is practically a solid structure, and as it decreases, the more holes the printed structure contains. Ali et al. [85] evaluated the effect of ID on tensile strength under different RAs for PLA/polybutylene adipate terephthalate (PBAT)/soy hull filaments. The authors determined an optimal ID of 75% [85].

Finally, printing orientation (build orientation) refers to the position of the 3D structure on the print bed during fabrication. Three configurations are possible: flat, upright, and on-edge [122].

3.2.6. Properties Evaluated in Filaments and 3D Printing

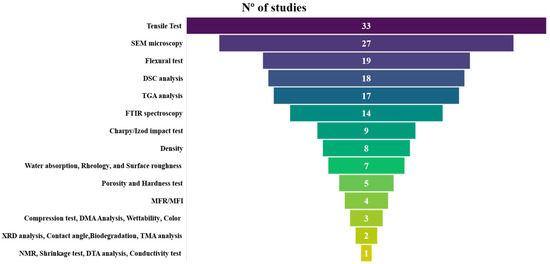

All the original articles analyzed in this review included characterization, either of the filaments or the resulting 3D-printed structures [55,56,58,62,64,65,66,67,68,69,70,71,73,74,75,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,107,123,125,129,130,131,132,133,134]. The most common tests included tensile strength, morphology analysis by scanning electron microscopy (SEM), thermal characterization (TGA/DSC), and flexural testing (three-point bending) (Figure 7).

Figure 7.

Demonstrative graph of the frequencies of properties studied in the analyzed studies.

Mechanical testing of the filaments and the printed dogbones were carried out according to ISO (527, 178, 179, 604) [67,90,91,92,131,135], ASTM (D638, D790, D256, D2240, D995, D3039, D695) [56,66,68,69,75,78,79,81,84,85,86,87,88,90,91,92,131], GB/T (10402, 1449) [83] or CNS (5846-1) [65] standards. Other evaluation parameters included factors such as fiber type, size, or load [55,56,64,69,80,81,84,87,90,92], chemical modification/coupling agents [66,77,79,86], and the influence of printing parameters [85,92] on mechanical properties. Tensile strength was the most evaluated property in all analyzed studies, followed by flexural and impact tests.

SEM analysis is often used to examine the surface of the filament or 3D structure [55,56,62,64,66,67,68,69,70,71,74,75,77,78,79,81,82,84,86,87,88,90,92,93,107,123,125,129,131,132,133,134], usually at the fracture point after tensile testing. Secondary electron detectors in SEM analysis were also applied in wood/PLA filaments to evaluate the PLA thermal degradation during the extrusion process [64].

Thermal behavior was evaluated through differential scanning calorimetry (DSC), thermogravimetric analysis (TGA) [55,56,58,66,67,77,84,87,88,129,131], thermomechanical analysis (TMA) [80,84], and differential thermal analysis (DTA) [55]. Through TGA/DSC, the authors were able to evaluate the melting point of the mixtures, the crystallinity, and the thermal degradation of the components. Differential thermal analysis (DTA) helps to determine the compatibilizers and TMA dimensional changes (thermal expansion). Glass transition temperatures, as well as storage modulus, damping, and loss modulus, were determined by dynamic mechanical analysis (DMA) [67,80].

Studies on coupling agents or chemical modifications often incorporate Fourier Transform Infrared (FTIR) [55,58,67,70,73,75,77,79,80,87,93,107,129,131,134] and Nuclear Magnetic Resonance (NMR) spectroscopy [58] to analyze structural and chemical changes. FTIR spectra reveal differences between silane-treated and untreated samples [77].

Rheometers and melt flow rate tests (MFR/MFI) helped the authors understand the viscoelastic behavior of the samples [56,62,71,73,74,75,79,84,93,129]. Rheological characterization was performed with parallel plate rheometers [56,75,79,84]. Rheology provides insights into the behavior of molten material under shear stress, which is essential for ensuring continuous extrusion without jamming and for achieving proper interlayer adhesion. Furthermore, the MFI provides a rapid measurement of the fluidity, a critical parameter for adjusting the formulation and avoiding mechanical failures during printing. The shear rate for the melt extrusion-based FDM system ranges between 100 and 200 s−1 [79]. The addition of raw material treatments and compatibilizers allowed for lower viscosities at all shear rates. Untreated or mildly treated lignocellulosic fibers produce high-viscosity filaments that cause nozzle clogging and insufficient material flow [71].

Density was determined using the weight-to-volume ratio [66,69,88,92,129] and a pycnometer [86,130]. In some cases, these data were used to calculate porosity [66,88,92]. Visual inspection was also employed to assess porosity in forest waste-based filaments [69].

For surface roughness analysis, atomic force microscopy [89] and a profilometer [92] were used.

The CIE L*a*b* color system was also applied to 3D samples, specifically to visualize the effect of thermal degradation of lignocellulosic fillers in the printed structures [65].

The influence of fiber incorporation on the water retention of filaments and printed structures was evaluated through water absorption (specimens immersed in water) [56,65,87,88,128,130], swelling [56,65,87], wettability [65], and contact angle [79,133].

According to the application, specific parameters, such as antibacterial activity [89], biodegradation [88,89], thermal conductivity [68], crystallinity [79,93], and biocompatibility [133], were evaluated. One of the studies performed a wire pull test (ISO 3341) to determine the mechanical strength of the filament [128].

3.3. Recent Studies of Applications

Filaments derived from agricultural and forest byproducts are promising for numerous applications. These materials are attractive in contexts that prioritize the circular economy, environmental sustainability, or cost-effective production.

Recent studies assessed the incorporation of agricultural and forest byproducts in the production of polymeric filaments for FDM printing [56,68,80,81,85,92,130]. The primary objective of most studies was to develop sustainable composite materials without specific applications. However, these materials exhibit broad potential across a wide range of sectors, including construction, packaging, automotive, and medicine, among others. For example, the addition of soybean hulls in PLA/PBAT blends results in composites suitable for biomedical and rigid packaging purposes [85]. Specific applications of composite materials were evaluated in the biomedical industry. For instance, scaffolds manufactured from filaments based on 1 wt% palm residue fibers and poly(hydroxybutyrate-co-hydroxyvalerate) (PHBV) showed potential for bone tissue engineering [133]. Moreover, biomedical prototypes, such as neck orthosis and laryngoscope devices, were successfully manufactured from hemp/PLA filaments (Figure 8) [91]. Hemp incorporation in PLA provided a superior elastic modulus compared to pure PLA [91].

Figure 8.

Neck orthosis 3D-printed with hemp/PLA filament using FDM. Reprinted from Cali et al. [91] (License CC BY 4.0 (http://creativecommons.org/licenses/by/4.0/ accessed on 2 September 2025)).

Additionally, waste powders from pistachio, coffee, chestnut, and walnut seed husks were coated onto PLA surgical threads, leading to improved hardness performance [89]. Food waste has also been incorporated into PLA for the manufacture of capsules intended for drug release [131].

The development of sustainable materials was also investigated using forestry waste. For instance, waste wood fibers were compounded with PLA and used to manufacture cellular structures with engineered flexural properties. These composite materials may be an asset for applications in aerospace, automotive, and construction [68]. Similarly, filaments of recycled pine wood (15 wt%) and PLA/PHA were used to obtain sandwich panels of different configurations [135]. Moreover, wood residues, such as sawdust or ashes, incorporated into PLA can be potentially used for biodegradable container applications [56].

Some research reported the printing of different objects using composite filaments, for example, agricultural tube prototypes from peanut or soybean shells/PBAT filaments [90]. Moreover, ornamental and design objects, including jewelry and pots, were obtained from filaments based on hazelnut shells and PLA [92]. Other examples include the production of elliptical gears with shafts and spectacle frames from pyrolyzed soy-hulls incorporated into recycled high-density polyethylene/polypropylene blends [84].

The industry has also embraced the use of natural fiber-filled filaments in 3D printing. For example, Ford Motor Company developed dashboard panel prototypes using PLA filaments filled with flax and hemp fibers, which were 25% lighter than those made with ABS [136]. Conversely, composite filaments have also entered the market. Unkarbon™, an Indian company, offers filaments made from hemp/PLA and wood/PLA [137]. Moreover, UPM developed a biocomposite material (UPM Formi EcoAce) of wood, cellulose fibers, and bio-PP, for injection molding and extrusion, and suitable for end-use applications in food contact, personal care, and consumer goods [138].

Future research is expected to broaden the application of these composite filaments into new sectors and deepen their exploration within existing fields.

3.4. Scaling-Up

Most studies conducted have evaluated the production of filaments and 3D structures at a laboratory scale. However, it is essential to understand the current challenges related not only to scaling up (from lab to large scale), but also to regulatory and environmental aspects.

Just as in a laboratory, technical challenges of filaments and 3D structures at an industrial scale include ensuring compatibility between the matrix and reinforcement to achieve optimal homogeneity, maintaining thermal stability and humidity control, minimizing nozzle clogging, ensuring constant quality, and managing controlled degradation. At a large scale, challenges include inefficient solidification, imprecise nozzle temperature, long build time, and dimensional limitations. For example, current large-scale 3D printers from BLB Industries, Tractus 3D, BigRep, CreatBot, and 3D Platform reach dimensions up to 2 m [139].

In the construction sector, analyses of large-scale prototypes focus on material exposure to environmental conditions and their impact on mechanical properties [135,140,141]. Additionally, 3D printing construction has higher building and assembly costs compared to those of conventional printers. However, a sensitivity analysis revealed the potential to reduce transportation costs for small-scale projects involving low volume [142].

Also, 3D printing with lignocellulosic byproducts shows potential in the manufacture of automotive and aircraft parts. Currently, companies such as Formula 1 teams, Koenigsegg, Ford, Bugatti, and BMW, among others, have implemented lightweight parts, prototypes, panels, and advanced components printed in 3D [143]. The ability to produce customized parts on demand avoids overproduction, while the use of bio-based filaments enables more sustainable production processes, generating a circular economy [144].

3.5. Environmental and Regulatory Aspects: Life Cycle Assessment and Sustainability Benefits

Life cycle assessment (LCA) (ISO 14040 and ISO 14044 standards) is a tool to evaluate the potential environmental impacts associated with a product or service throughout its entire life [145], where “entire life” involves raw material sources, manufacturing, distribution, use, and end-of-life treatments [146]. Although additive manufacturing is often considered more sustainable than subtractive manufacturing due to its efficient materials use [147], its rapid expansion and widespread adoption in recent years underscore the need for a comprehensive assessment of its overall sustainability. The simplest way to apply LCA to additive manufacturing is to print an object, collect lifecycle data through experiments, and calculate the environmental impact [148].

Several aspects can compromise the sustainability of FDM technology, such as energy consumption during printing, waste generated due to failed prints or support materials, and emission of ultrafine particles and volatile organic compounds [147]. Among them, energy consumption has been identified as the foremost contributor to the environmental impact. FDM machines require energy to feed the filament into the printer, melt it, move the nozzle, operate the cooling fans, and, when necessary, heat the bed [149]. Other factors influencing energy consumption include the processing speed, type of thermoplastic material used, layer thickness, and build volume [147]. Additionally, higher energy consumption leads to increased carbon dioxide (CO2) emissions. A study found that ABS and PP had the highest energy consumption during printing, ranging from 60,000 to 63,000 J, and CO2 emissions exceeding 10 kg CO2 equivalent. In comparison, energy consumption and emissions of PLA, PETG, and TPU were lower, all below 40,000 J and 6.8 kg CO2 equivalent, respectively [150]. One approach to reducing energy consumption is to increase printing speed [151].

The sourcing of materials also influences the environmental impact of FDM. For instance, ABS exhibits the highest environmental impact compared with PLA and PETG. Its life cycle is associated with higher fossil resource depletion, ozone depletion, and contributions to climate change. However, PLA exhibits higher freshwater ecotoxicity and water depletion. Aside from that, PETG has the lowest environmental impact [148]. Moreover, composite filaments can offer reduced environmental impact. For example, 5–20 wt% of palm fibers incorporated into ABS resulted in significant reductions in agricultural land use and ozone depletion, decreasing approximately from 0.35 to as low as 0.125 m2a, and from 3.0 × 10−5 to as low as 7.5 × 10−6 kg CFC-11 (trichlorofluoromethane) equivalent, respectively [152]. Moreover, the addition of sugarcane bagasse pulp to BioPE matrices reduced the global warming impact, without considering CO2 capture, from 2.01 kg CO2-eq (fossil PE filament) and 1.38 kg CO2-eq (BioPE filament) to as low as 1.02 kg CO2-eq [28]. Similarly, the use of recycled materials may also contribute to lower environmental impacts. For instance, filaments from recycled PP filled with wood dust reduced energy consumption and CO2 emissions by 56% and 37%, respectively [153]. However, due to the specific nature of LCA, further analysis is needed to fully comprehend the environmental implications of different novel and composite materials.

At a larger scale, lignocellulosic fiber preparation, extrusion, and 3D printing operations can generate emissions of ultrafine particles and volatile compounds [154]. During PLA/wood filament production and 3D printing, the VOCs emitted from pure PLA were lactide, ethanol, 2-methyl-2-propanol, acetone, and formaldehyde. Meanwhile, biocomposite filaments emitted d-limonene, 3-carene, α-pinene, isoprene, and p-cymene. Compared to ABS, PLA emitted up to 7 times fewer VOCs [95]. However, emissions can be reduced below the recommended exposure work limits (OSHA, NIOSH, EU regulations) with appropriate emissions management in the workplace [154]. One of the key advantages of FDM printing with biodegradable composite filaments is that the printed parts can degrade at the end of their life cycle. Biodegradable thermoplastics can break down into simple compounds, such as CO2 and water, decreasing plastic waste and pollution. Among these thermoplastics are PLA, which can be degraded by industrial composting, and PCL, which can also be managed through home composting or directly in the soil environment [155]. There are multiple standard test methods for assessing the biodegradation of plastics, which can be grouped according to the environment in which biodegradation occurs [156].

ASTM D5338 [157] and its equivalent ISO 14855 [158] are used to evaluate biodegradation under composting conditions. Similarly, ASTM 5988 [159] and ISO 17556 [160] assess biodegradation in aerobic soil environments. In addition, ASTM D5526 [161], ASTM D5511 [162], ISO 15985 [163], and ISO 11734 [164] are used to evaluate biodegradation under anaerobic conditions (landfills and anaerobic digestion plants). Finally, marine biodegradation is assessed using standards such as ASTM D6691 [165], ISO 19679 (seawater/sediment interface) [166], and ISO 22404 (marine sediment) [167]. The addition of lignocellulosic byproducts to plastic filaments may accelerate their biodegradation rate. The reason is that lignocellulosic fillers degrade rapidly, leaving behind the plastic matrix with increased surface area, thereby enhancing further biodegradation [168,169]. For instance, the addition of 20 wt% wood fibers to PHA increased its biodegradation in the soil environment, resulting in a 34.3% increase in weight loss. Similarly, the addition of 3 and 5 wt% of walnut shells and carrot pomace to PLA filament increased biodegradability up to 7.6% [170].

Despite the environmental benefits that lignocellulosic byproducts could offer (i.e., reduced emissions, enhanced biodegradation), there is currently no regulatory framework for their use [171].

4. Discussion and Future Perspectives

4.1. Current State

The studies reviewed have demonstrated the potential for using lignocellulosic byproducts as reinforcing agents in 3D printing filaments. Lignocellulosic byproducts have demonstrated versatility in particle size, high cellulosic content, high availability, and low cost. Harvest residues after size reduction or mild chemical treatment also demonstrate great potential as reinforcing agents. The addition of coupling agents, such as silanes or maleic anhydride, or surface modification of the fibers enhances compatibility with the polymer matrix, allowing for a reduction in water absorption and improved mechanical properties. The increase in fiber loading has also improved tensile, impact, and flexural strength, enhancing applications in areas such as construction and automotive parts.

Occasionally, the presence of untreated and modified lignocellulosic byproducts influenced thermal and rheological properties. Several of the studies reviewed placed particular emphasis on the rheological behavior of the components, highlighting that it is associated with optimal processability during extrusion and 3D printing, preventing equipment failures by adding lignocellulosic fibers. However, despite the importance of rheological behavior, studies are generally focused on mechanical properties without a complete evaluation of sample processability.

The LCA-analyzed studies indicated that FDM printing presents significant environmental challenges, mainly due to its high energy consumption and CO2 emissions. They are a consequence of the process parameters and the type of polymer used. The choice of material impacts the environmental footprint. For example, PLA and PETG offer more sustainable alternatives to ABS, although with limitations. The use of biocomposites and recycled materials, such as lignocellulosic fibers and recycled polymers, notably reduces impacts like resource depletion and global warming. However, LCA requires more complex models that consider variability, scalability, and multidimensional aspects to assess the sustainability of the processes involved.

The use of lignocellulosic fibers has demonstrated potential for a wide range of applications, such as medical orthoses, packaging, automotive parts, and construction, among others. However, there are still challenges to be solved for successful scaling.

Table 5 shows the main stages involved in the production of 3D printing structures.

Table 5.

Challenges in scaling up.

Some of the challenges during raw materials conditioning involve the variable composition of raw materials and high costs concerning investment, energy, and water consumption. Furthermore, the materials used are generally roughly characterized, primarily indicating major components such as cellulose, hemicelluloses, and lignin. In the case of a complete characterization, it is observed that only the total extractives and ash are indicated, without specifying, for example, the presence of trace metals in the fibrous composition, like the silica content in rice straw.

Standardization and raw material pretreatment are strategies to solve variable composition problems, while improving the energy efficiency of the overall process, recirculating water, and evaluating simpler alternative routes for chemical modification of raw materials are strategic options to mitigate the other challenges of raw material processing.

Limitations in filament production are generally operational and are often associated with raw material and process characteristics, which are often easily resolved. For example, the thermal degradation of materials can be mitigated by incorporating thermal protection additives into the mixture, while viscosity control can be enhanced by adding an MFI modifier.

The main bottleneck in process scaling is likely the 3D printing stage, as the technology is not yet fully developed, and large-scale systems still require considerable time to print a structure. In most cases, manufacturers invest in injection molding technology, which is a more versatile system.

Regarding current regulations, there is still no specific regulatory framework that supports the use of these lignocellulosic additives in commercial filaments, which limits their industrial adoption and raises the urgent need for regulations that validate their safety, efficacy, and environmental traceability.

4.2. Future Perspectives

Future perspectives in 3D printing include process optimization, improvements in the compatibility of the components involved, and exploring alternative, more environmentally friendly routes for cellulose modification, the development of new compatibilizers, and the design of products for new applications or the optimization of designs to achieve greater market share, particularly in key sectors such as medical and automotive. The technological development of more efficient 3D printing systems at an industrial scale offers greater market competitiveness. Progress in the development of international standards for lignocellulosic filaments will be key to their industrial adoption, in combination with biodegradability or compostability certification schemes.

5. Conclusions

The integration of lignocellulosic byproducts into FDM 3D printing represents a promising strategy for moving toward more sustainable, functional, and circular manufacturing. Lignocellulosic byproducts not only offer a renewable source of materials but also enable the development of filaments with tunable mechanical, thermal, and optical properties. The printing parameters are critical for optimizing the structural and functional quality of 3D structures, especially in biocomposites.

Despite numerous application studies, scaling up 3D printing from lignocellulosic biomass still presents numerous challenges. The advancement of these technologies should be accompanied by clear regulatory frameworks and environmental evaluations, including LCA and assessments of biodegradability and potential toxicity.

Author Contributions

Conceptualization, N.E., A.P.d.L., M.E.V. and M.C.A.; methodology, N.E.; validation, N.E., A.P.d.L. and M.C.A.; formal analysis, N.E.; investigation, N.E., A.P.d.L., M.E.V. and I.N.Q.T.; data curation, N.E., A.P.d.L., M.E.V. and I.N.Q.T.; writing—original draft preparation, N.E., A.P.d.L., M.E.V. and I.N.Q.T.; writing—review and editing, N.E., A.P.d.L., M.E.V. and M.C.A.; visualization, N.E., A.P.d.L. and M.E.V.; supervision, M.C.A.; project administration, M.C.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing does not apply to this article.

Acknowledgments

The authors thank the Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), Argentina.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Abbreviations

The following abbreviations are used in this manuscript:

| ABS | Acrylonitrile Butadiene Styrene |

| AM | Additive manufacturing |

| DMA | Dynamic mechanical analysis |

| DSC | Differential scanning calorimetry |

| EU | European Union |

| FDM/FFF | Fused deposition modeling |

| FTIR | Fourier Transform Infrared |

| ID | Infill density |

| IP | Infill pattern |

| LCA | Life cycle assessment |

| LT | Layer thickness |

| MFI | Melt flow index |

| MFR | Melt flow rate |

| Mmt | Million metric tons |

| PHA | Polyhydroxyalkanoates |

| PHB | Poly(3-hydroxybutyrate) |

| PBAT | Poly(butylene adipate-co-terephthalate) |

| PLA | Polylactic acid |

| TGA | Thermogravimetric analysis |

| TMA | Thermomechanical analysis |

| TPC | Thermoplastic copolyester |

| TPS | Thermoplastic starch |

| TPU | Thermoplastic polyurethane |

| SEM | Scanning electron microscopy |

| RA | Raster angle |

References

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive Manufacturing of Structural Materials. Mater. Sci. Eng. R Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of Additive Manufacturing Applications towards Environmental Sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Rasiya, G.; Shukla, A.; Saran, K. Additive Manufacturing—A Review. Mater. Today Proc. 2021, 47, 6896–6901. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 21 May 2025).

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef]

- Doshi, M.; Mahale, A.; Kumar Singh, S.; Deshmukh, S. Printing Parameters and Materials Affecting Mechanical Properties of FDM-3D Printed Parts: Perspective and Prospects. Mater. Today Proc. 2022, 50, 2269–2275. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K.K. 3D Printing of Polymer Composites: Materials, Processes, and Applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Jiang, L.; Peng, X.; Walczyk, D. 3D Printing of Biofiber-Reinforced Composites and Their Mechanical Properties: A Review. Rapid Prototyp. J. 2020, 26, 1113–1129. [Google Scholar] [CrossRef]

- Karakurt, I.; Lin, L. 3D Printing Technologies: Techniques, Materials, and Post-Processing. Curr. Opin. Chem. Eng. 2020, 28, 134–143. [Google Scholar] [CrossRef]

- Bodenschatz, U.; Rosenthal, M. 3D Printing of a Wood-Based Furniture Element with Liquid Deposition Modeling. Eur. J. Wood Wood Prod. 2024, 82, 241–244. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of Polymer Composites: A Short Review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef]