Abstract

The urgent need to decarbonize the construction sector has prompted research into sustainable alternatives to conventional concrete. This study compares two industrially produced pulps with contrasting lignin contents: a bleached kraft cellulose pulp with near-zero lignin used in paper production and a thermo-mechanical lignocellulose pulp with high lignin content used in MDF production. Fiber-reinforced composites were produced by partially replacing mineral aggregates with fibers at dosages from 0.1% to 3% by mass and air-curing to simulate practical curing conditions. The specimens were evaluated for density, water absorption, and compressive strength, with compressive strength measured at 7, 28, and 60 days. Results showed a reduction in density for both fiber types, along with increased water absorption and decreased compressive strength at higher fiber contents. Cellulose composites achieved a more favorable mechanical performance than lignocellulose composites but showed markedly higher water absorption, raising concerns about long-term durability. By testing two pulps that differ primarily in lignin content across multiple replacement ratios, the study provides a systematic comparison of their effects on composite properties. The comparison explicitly contrasts the lignin contents of the two industrial pulps—bleached kraft (~0.1%) versus thermo-mechanical (27.4%)—to isolate lignin-driven effects on hydration and property development. A practical air-curing protocol was adopted, leveraging fiber-bound/process water, thereby reflecting use cases where external water curing is constrained.

1. Introduction

Cement production is a major source of global CO2 emissions, contributing approximately 7–8% of total anthropogenic emissions due to the energy-intensive process of clinker formation and the calcination of limestone [1]. Each ton of Portland cement generates roughly 0.6–0.8 tons of CO2, making the sector a critical target for decarbonization efforts [2]. As infrastructure demand continues to grow, particularly in developing regions, the need for low-emission alternatives within the construction industry becomes increasingly urgent [3]. International roadmaps, such as those of the Global Cement and Concrete Association (GCCA), highlight the development of low-carbon cement composites as a crucial strategy for achieving the cement industry’s net-zero targets by 2050 [4].

The incorporation of Supplementary Cementitious Materials (SCMs) offers a practical and scalable solution to reducing CO2 emissions from cement production [5]. SCMs such as fly ash [6], ground granulated blast furnace slag [7], and calcined clays [8] are used to partially replace clinker, the most carbon-intensive component of cement. This substitution can reduce the carbon footprint of concrete by up to 44% [9], while maintaining durability and long-term strength [10]. Given that clinker production accounts for most of the cement industry’s emissions, SCMs play a vital role in achieving global decarbonization objectives within the construction sector.

Besides SCMs, various bio-based and mineral waste materials have been studied as low-carbon additives in cement composites. Agricultural residues such as rice husk ash [11], wheat straw [12], and corn stalks [13], along with wood-processing by-products like sawdust [14] and wood chips [15], offer renewable and regionally abundant alternatives to conventional aggregates. Their integration reduces reliance on high-emission raw materials and contributes to lower embodied carbon. Moreover, the incorporation of such residues into cement composites aligns with circular economic principles by diverting waste streams into valuable construction uses. While their mechanical contribution depends on treatment and mix design, these materials offer a viable pathway for reducing environmental impact without fundamentally altering cement processing technologies.

Among various strategies, the incorporation of natural and waste-derived fibers into cementitious composites has gained increasing attention [16]. Wood-based fibers offer a renewable and biodegradable alternative that can reduce the overall environmental burden of construction materials. Studies have demonstrated that fibers from hemp [17], flax [18], jute [19], and wood pulp [20] can improve composite behavior by enhancing crack resistance and toughness, while simultaneously reducing density [21,22]. When added in small proportions, these fibers have a minimal negative impact on mechanical strength, making them attractive for sustainable construction applications.

The wood and paper industries generate substantial volumes of waste, much of which is underutilized or incinerated [23,24]. Europe generates millions of tons of paper sludge and low-grade cellulose materials annually, much of which cannot be recycled because of contamination or fiber degradation. Lignocellulose residues from wood processing industries also constitute a notable source of waste [25]. The use of these materials as additives in cement composites supports circular economy principles by converting low-value biomass into functional components that enhance the performance of cement composites.

Incorporating low amounts of wood-derived fiber into cement matrices has been shown to provide notable benefits, including improved durability, reduced thermal conductivity, and better post-cracking behavior [26]. These enhancements are achieved without the need for synthetic polymers or high-cost additives, making fiber-reinforced cement composites a promising solution for affordable and eco-conscious construction. The fibrous inclusions can also decrease composite density, which is beneficial for prefabrication and transport efficiency.

Despite these advantages, achieving homogeneous fiber dispersion and consistent mechanical performance remains challenging. Improper mixing can lead to fiber agglomeration [27], increased porosity, and reduced compressive strength. Additionally, variability in fiber morphology, water absorption, and chemical composition can interfere with cement hydration and matrix bonding, complicating formulation optimization [28]. These technical barriers have limited the widespread adoption of such composites in structural applications.

This study investigates the incorporation of two types of fiber pulps that are already produced at an industrial scale: bleached kraft pulp used in paper manufacturing (~0.1% lignin) and thermo-mechanical pulp used in Medium-Density Fiberboard (MDF) production (~27.4% lignin). These materials offer consistent quality and established production methods. The research is based on the hypothesis that introducing small amounts of such pulps into the cement matrix can reduce the environmental impact of the composite without causing significant loss of mechanical performance. To evaluate this, a portion of the mineral aggregates was replaced with fiber at ratios ranging from 0.1% to 3% by mass, and the produced composites were assessed for density, water absorption, and compressive strength. By holding mix proportions and curing conditions constant and varying only pulp type and dosage, the study isolates lignin-driven effects on composite behavior. The direct, side-by-side comparison of cellulose and lignocellulose pulps under a single air-curing regime reflects practical precast and cast-in-place conditions and clarifies how lignin content governs trade-offs between sustainability gains and mechanical performance.

2. Materials and Methods

2.1. Materials

The binder used in all mixes was Portland slag cement CEM II/A-S 42.5 N, produced by Cementownia Warta S.A. (Trębaczew, Poland). This cement was made in accordance with PN-EN 197-1 [29] and contains a proportion of ground granulated blast furnace slag. The physical and environmental performance of this binder is detailed in Environmental Product Declaration No 09-09/24 [30].

Tap water was used in all mixtures.

The mineral aggregates used in the study were sourced from a local paving stone manufacturer, Zakład Betoniarski Kazimierz Mordaka (Wąwał, Poland). Both sand and coarse aggregates were additionally sieved using vibrating screen LPzE-3e Morek (Marcyporęba, Poland). The aggregate fraction consisted of particles ranging from 2 to 4 mm, while the sand fraction included particles smaller than 2 mm. Prior to mixing, both fractions were oven-dried to a constant mass to eliminate the influence of moisture on the mix proportions.

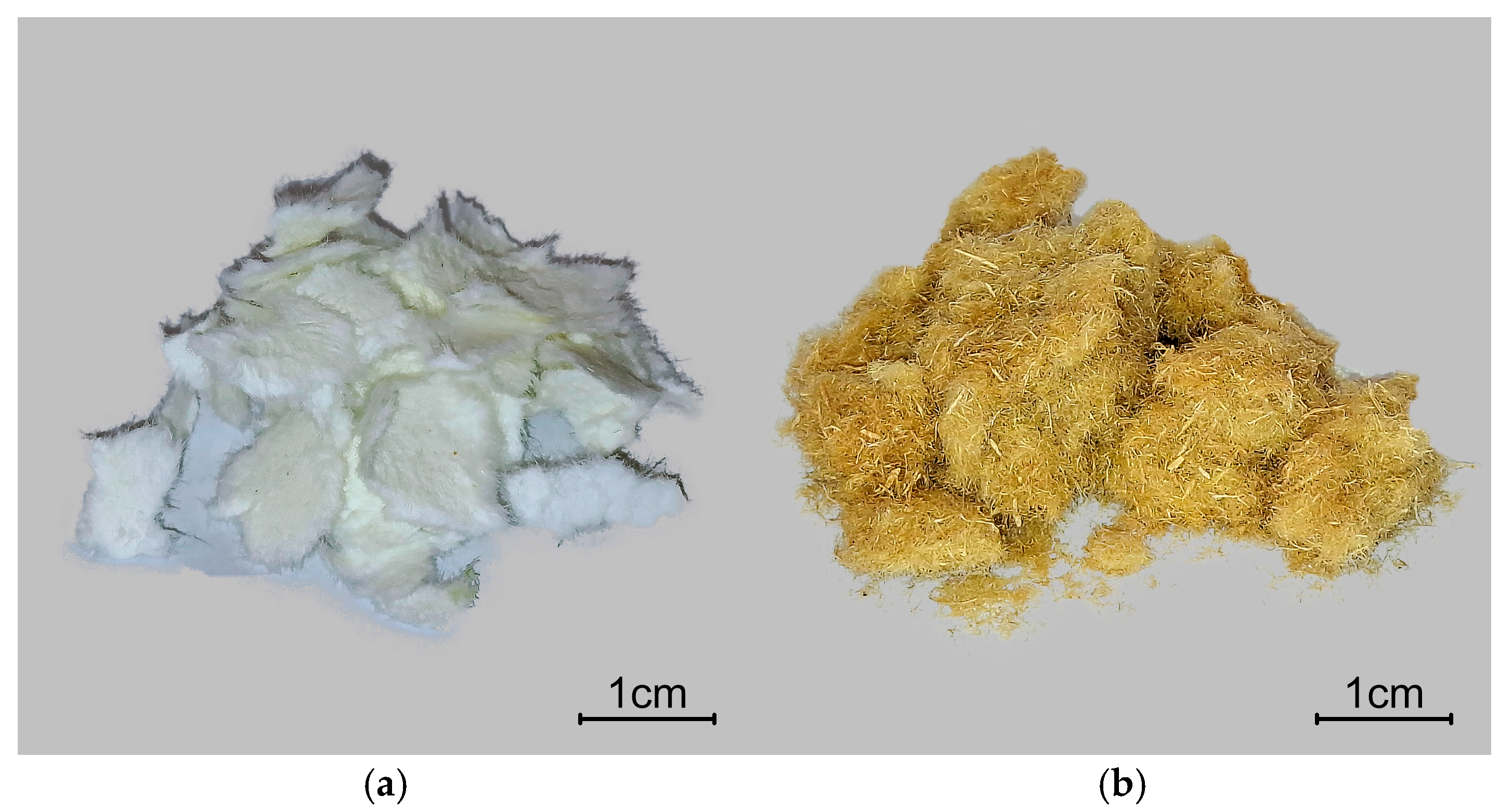

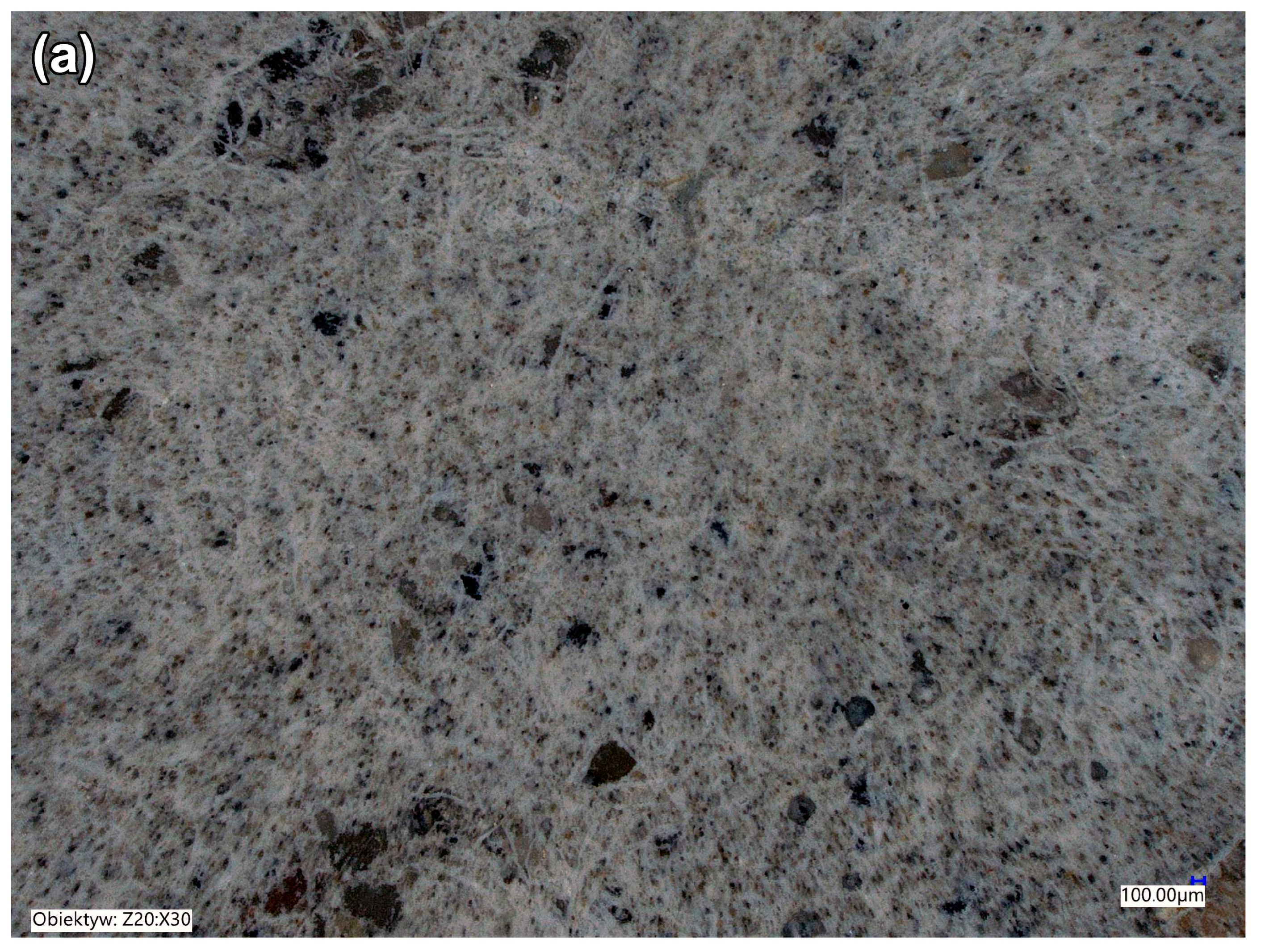

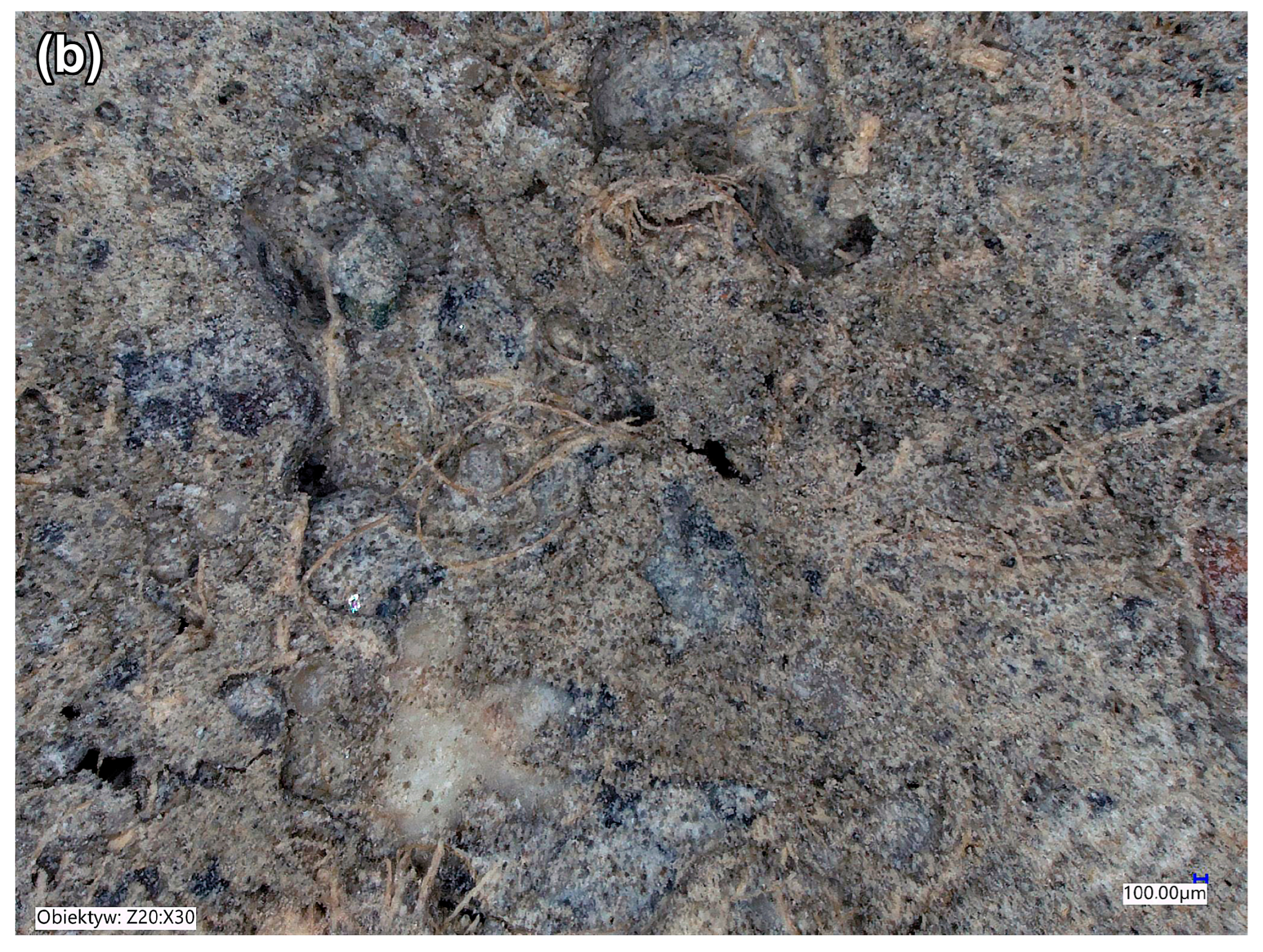

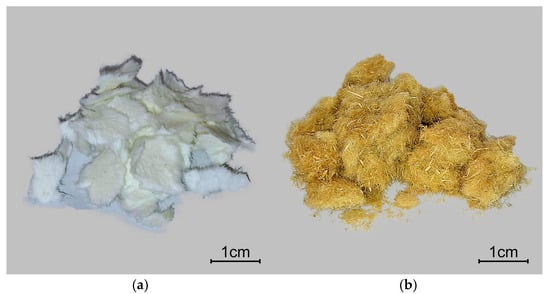

Two types of industrial fiber pulps with contrasting lignin contents were used. Bleached kraft pulp (Standal), produced from pine wood, was used as a source of cellulose fibers. The pulp was supplied by a Polish paper mill and delivered in the form of dry sheets. Thermo-mechanical pulp used in the production of MDF was used as a source of lignocellulose fibers. The pulp was supplied by a Polish MDF manufacturer. The material was delivered as dry, dispersed fibers and was packed in a big bag. Figure 1 shows microscopic images of both pulps, highlighting the morphological differences between cellulose and lignocellulose fibers.

Figure 1.

Images of industrial pulps used in the study: (a) cellulose fibers from bleached kraft pulp; (b) lignocellulose fibers from thermo-mechanical pulp.

Dry matter content was determined in accordance with ISO 638-1 [31]. The weighted average fiber length was measured using a Morfi Compact Black Edition analyser (Techpap, Grenoble, France), following the ISO 16065 standard [32]. The degree of polymerization was assessed according to ISO 5351 [33].

The contents of cellulose, lignin, extractives, and ash were determined using TAPPI standard methods T 203, T 222, T 204, and T 211 [34,35,36,37], respectively. Hemicellulose content was calculated as the difference between the total mass of the sample and the sum of the analytically determined contents of cellulose, lignin, extractives, and ash.

The detailed characteristics of both pulps are presented in Table 1.

Table 1.

Characteristics of cellulose and lignocellulose pulps.

2.2. Mix Design

All composite mixtures were designed with constant cement and total aggregate mass. In both series, lignocellulose and cellulose fibers replaced a portion of the mineral aggregate by mass at the following replacement ratios: 0.1%, 0.25%, 0.5%, 0.75%, 1.0%, 1.5%, 2.0%, and 3.0%. The reference mix corresponds to an air-cured concrete aligned with the B-15 strength class. The detailed mix proportions used in the study are presented in Table 2.

Table 2.

Proportions of concrete mixes.

The water-to-cement ratio used in the formulation of the reference mix was set at 0.5. Due to the hydrophilic nature of cellulose and lignocellulose fibers, part of the mixed water was absorbed by the fibers, reducing the amount available for cement hydration and affecting the workability of the mix. To compensate for this effect, the water content in the fiber-reinforced mixtures was adjusted accordingly. For lignocellulose fibers, which were supplied in the form of dispersed fibers, supplementary water was added during mixing at a 1:1 mass ratio relative to the fiber content. Cellulose fibers were supplied in the form of dry sheets, which were manually broken down and mixed with supplementary water to prepare a slurry with a fiber concentration of 10% by mass. The slurry was prepared 24 h prior to mixing to allow fiber hydration.

2.3. Mixing, Casting, and Curing

Mixing was performed manually using a hand-held electric mixer (Dual Handle Paddle Mixer DWD241, Stanley Black & Decker, Baltimore, MD, USA). The formulation and mixing procedures varied depending on the fibers used, with mix proportions detailed in Table 2. For reference and lignocellulose fiber mixes, the dry contents (cement, aggregates, and fiber) were blended first for approximately 1 min. Water was then gradually added. The full mix was blended for an additional 3–4 min until a uniform and workable consistency was obtained. For cellulose fiber mixes, cement and sand were blended for approximately 1 min. Next, the slurry and coarse aggregates were mixed in a separate container to facilitate further disintegration of the pulp. The wet mixture was then gradually added to the dry components, along with water. Mixes were blended for an additional 3–4 min until a uniform consistency was achieved. At all tested dosages (0.1–3% replacement by mass), and with supplementary water added to offset fiber uptake, no significant changes in workability were observed under the manual compaction protocol, and superplasticizers were not required.

The fresh concrete was poured into 150 mm × 150 mm × 150 mm cubic molds. Each specimen was compacted on a vibrating table with an amplitude of 3 mm and a frequency of 48 Hz. The compaction time was set to approximately 15 s to eliminate entrapped air. The compaction time was kept consistent for all specimens. A total of 87 specimens were cast, 7 for the reference mix and 5 for each fiber content level in both cellulose and lignocellulose fiber-reinforced mixes.

After casting, the molds were placed in an indoor environment with good ventilation. The specimens were typically demolded after 24 h. However, for mixtures with higher fiber content, demolding was delayed to prevent damage to early-age specimens, as these exhibited slower setting times. This behavior was evaluated through qualitative observations of surface hardness and needle penetration. In such cases, demolding was performed after 48 or 72 h, with 72 h being the maximum duration any specimen remained in the mold. All specimens were air cured under identical indoor ambient conditions for a duration of 7, 28, and 60 days without additional moisture control. This approach was chosen to simulate real-world conditions and assess the performance of the composites in environments where standard water curing is not feasible. The adopted curing schedule made it possible to evaluate early, standard, and long-term strength development in the composites.

2.4. Testing

2.4.1. Density

Samples were tested after a 28-day air-curing period. The weight and volume of each specimen were recorded. Density was calculated by dividing the mass by the volume and reported in kg/m3. Mass measurements were carried out using a Steinberg Systems SBS-PT-3000 digital scale (Berlin, Germany) with an accuracy of 1 g. The density of each specimen was determined individually, and the average value was reported for each mix.

2.4.2. Water Absorption

The water absorption of the concrete was measured using an immersion method on one specimen from each mix. Prior to testing, all specimens were oven-dried at a temperature of 70 °C until a constant mass was achieved. Dry specimens’ weights were then recorded. Once weighed, the specimens were then fully submerged in water for a period of 24 h. After immersion, excess surface water was removed using a damp cloth. Water absorption was calculated as the percentage increase in mass relative to dry mass.

2.4.3. Compressive Strength Testing

Compressive strength was measured using an OTIS HS WWr-15T press following PN-EN 13791:2019-07 [38]. In addition to the primary 60-day age (long-term performance under air curing), specimens were also tested at 7 and 28 days to capture early and standard strength development.

2.4.4. Microscopic Surface Analysis

Microscopic observations were carried out using a VHX-7000 digital microscope (Osaka, Japan) equipped with a VH-Z20R lens (magnification 20–200×) and a VH-Z100UR lens (magnification 100–1000×). Surface smoothness was assessed using the integrated surface profiling software provided with the microscope.

3. Results

The results of the experimental study are summarized in Table 3 for cement composites reinforced with cellulose fiber originating from the paper industry, and in Table 4 for composites containing lignocellulose fibers sourced from an MDF factory. These tables present the average values for density and compressive strength measured at 60 days, and reported values for water absorption of composites at varying mineral aggregates replacement ratio (0.1–3%). To complement these results, the development of compressive strength over time was also evaluated at 7, 28, and 60 days, as shown in Table 5. The obtained results indicate that the addition of both cellulose pulp used in paper production and lignocellulose pulp used in MDF manufacturing leads to a reduction in composite properties compared to conventional concrete. The reference mix, corresponding to the B-15 strength class, provides the baseline against which these reductions are evaluated. The differences in performance can be attributed to lignin content, with low-lignin cellulose pulp producing more moderate effects and high-lignin lignocellulose pulp resulting in greater property losses.

Table 3.

Physical and mechanical properties of cement composites reinforced with cellulose fibers: density, compressive strength, and water absorption.

Table 4.

Physical and mechanical properties of cement composites reinforced with lignocellulose fibers: density, compressive strength, and water absorption.

Table 5.

Compressive strength development of cement composites reinforced with cellulose and lignocellulose fibers measured at 7, 28, and 60 days for different fiber dosages (0.1% and 3% replacement of mineral aggregates).

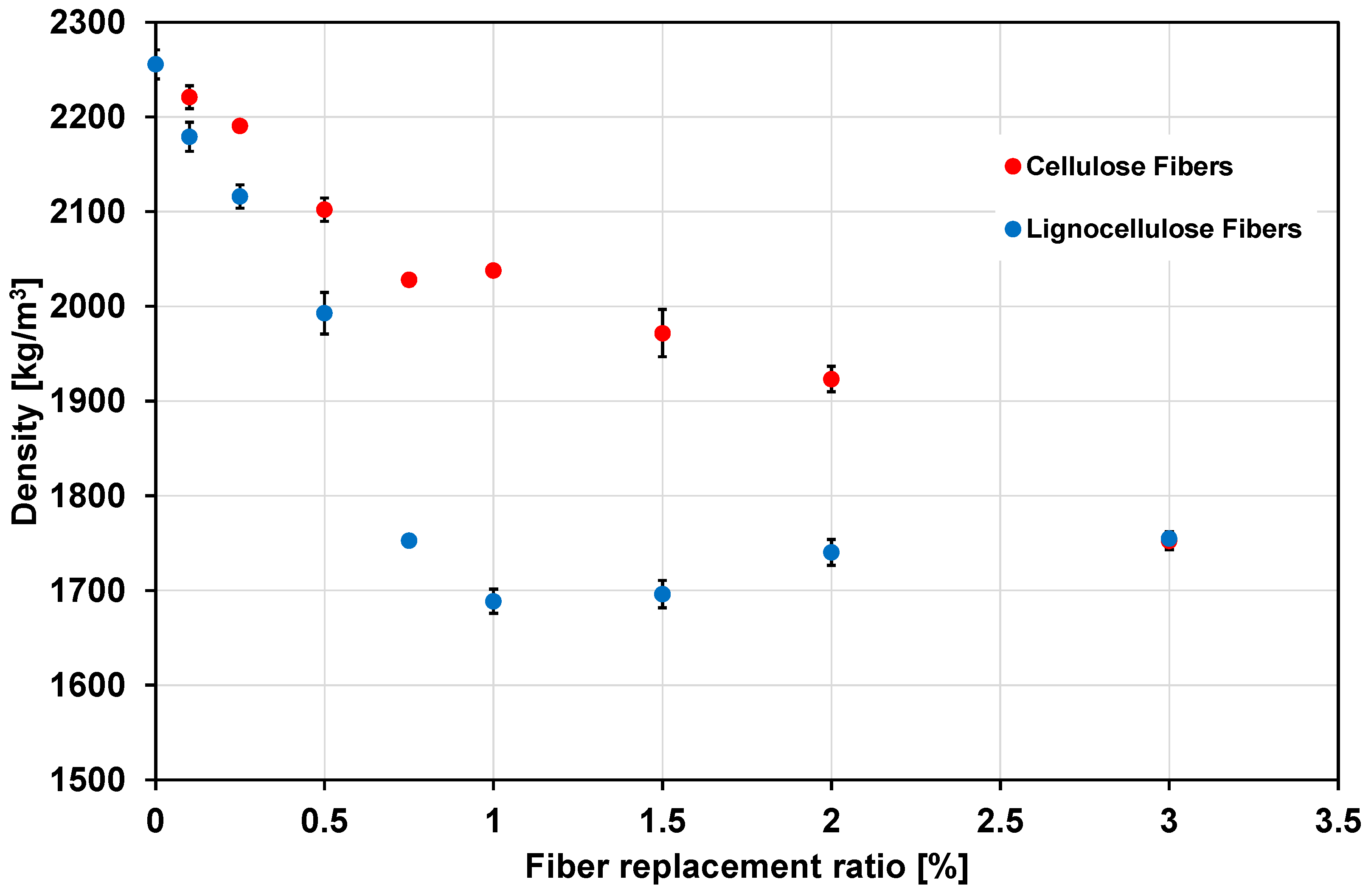

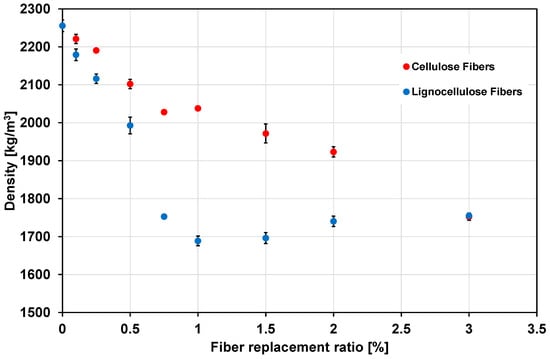

3.1. Density

The reference mix exhibited the highest density, being measured at 2255.5 kg/m3. In both cellulose and lignocellulose series, a clear decrease in density was observed with increasing fiber content. For cellulose fiber-reinforced composites, the density decreased progressively from 2220.9 kg/m3 at 0.1% fiber content to 1752.5 kg/m3 at 3%, representing a 22% reduction relative to the reference. In the lignocellulose series, the minimum density of 1688.6 kg/m3 was recorded at 1.5% fiber content, which is equivalent to a 25% decrease compared to the reference mix. Notably, a slight increase in density was observed beyond this point, with a final value of 1754.8 kg/m3 at 3% fiber content. This trend may reflect retained internal moisture at higher fiber contents under air curing, which could elevate bulk density despite the overall downward trend. Further targeted conditioning measurements would be required to confirm the mechanism. At this stage, the exact mechanism cannot be isolated. The relationship between fiber dosage and composite density for both series is illustrated in Figure 2.

Figure 2.

Effect of fiber replacement on the density of cellulose- and lignocellulose-reinforced composites.

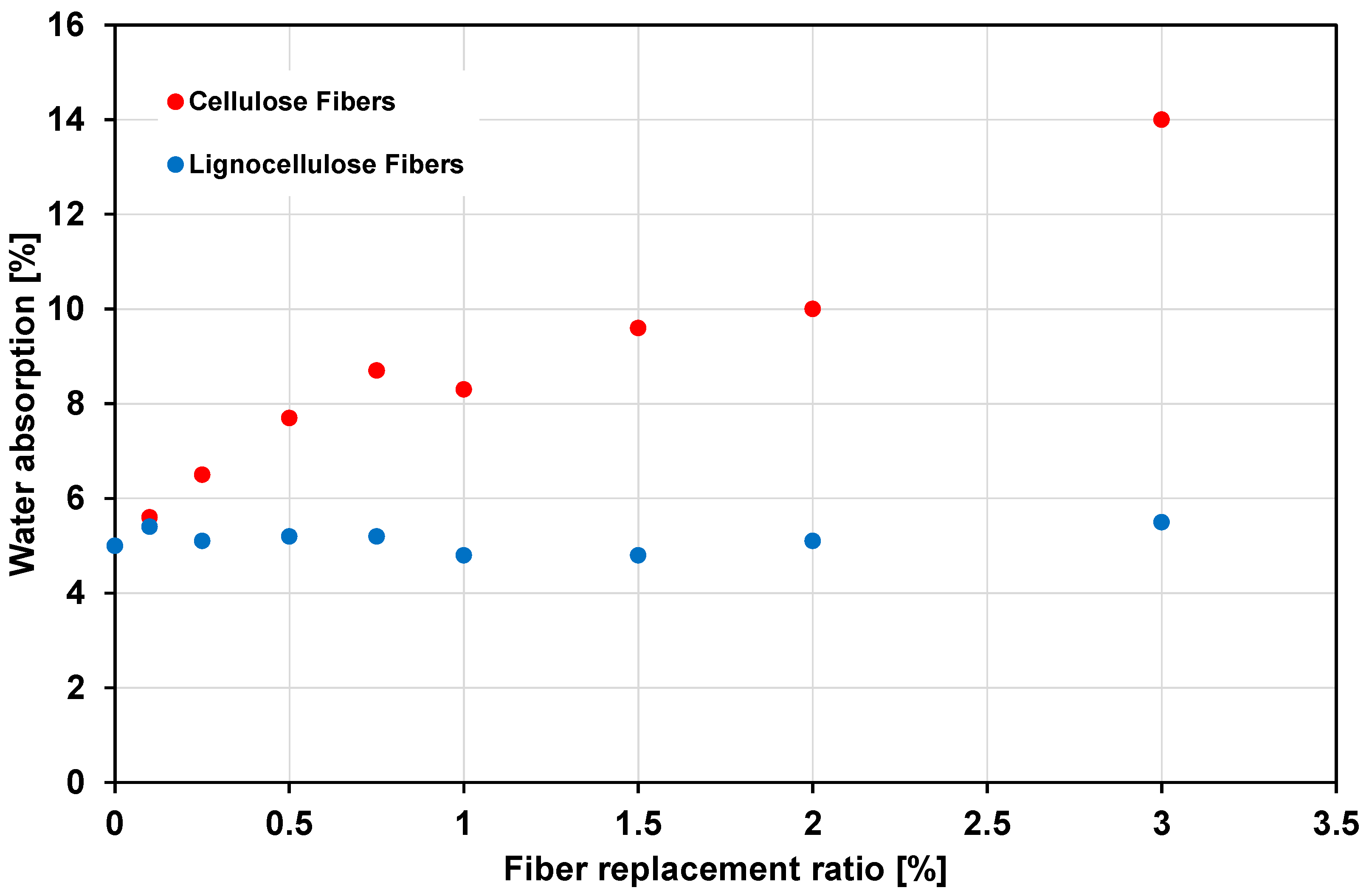

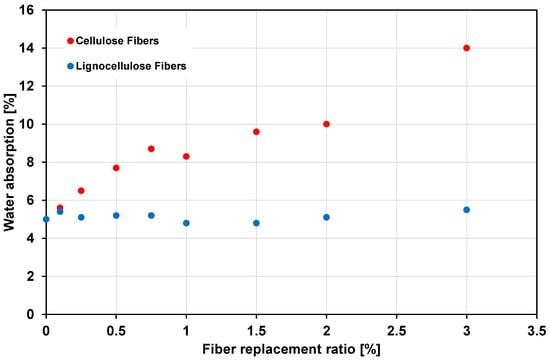

3.2. Water Absorption

Water absorption values increased in all fiber-reinforced composites relative to the reference concrete, which exhibited a baseline absorption of 5.0%. In the cellulose series, water absorption increased with fiber content, reaching a maximum of 14.0% at 3%, equivalent to an 180% increase. In the lignocellulose series, water absorption remained relatively stable, fluctuating between 4.8% and 5.5% across all replacement levels. The highest value of 5.5% was recorded at 3% fiber content, representing only a 10% increase compared to the reference mix. The relationship between fiber dosage and water absorption in both series is illustrated in Figure 3.

Figure 3.

Effect of fiber content on water absorption of cellulose- and lignocellulose-reinforced composites.

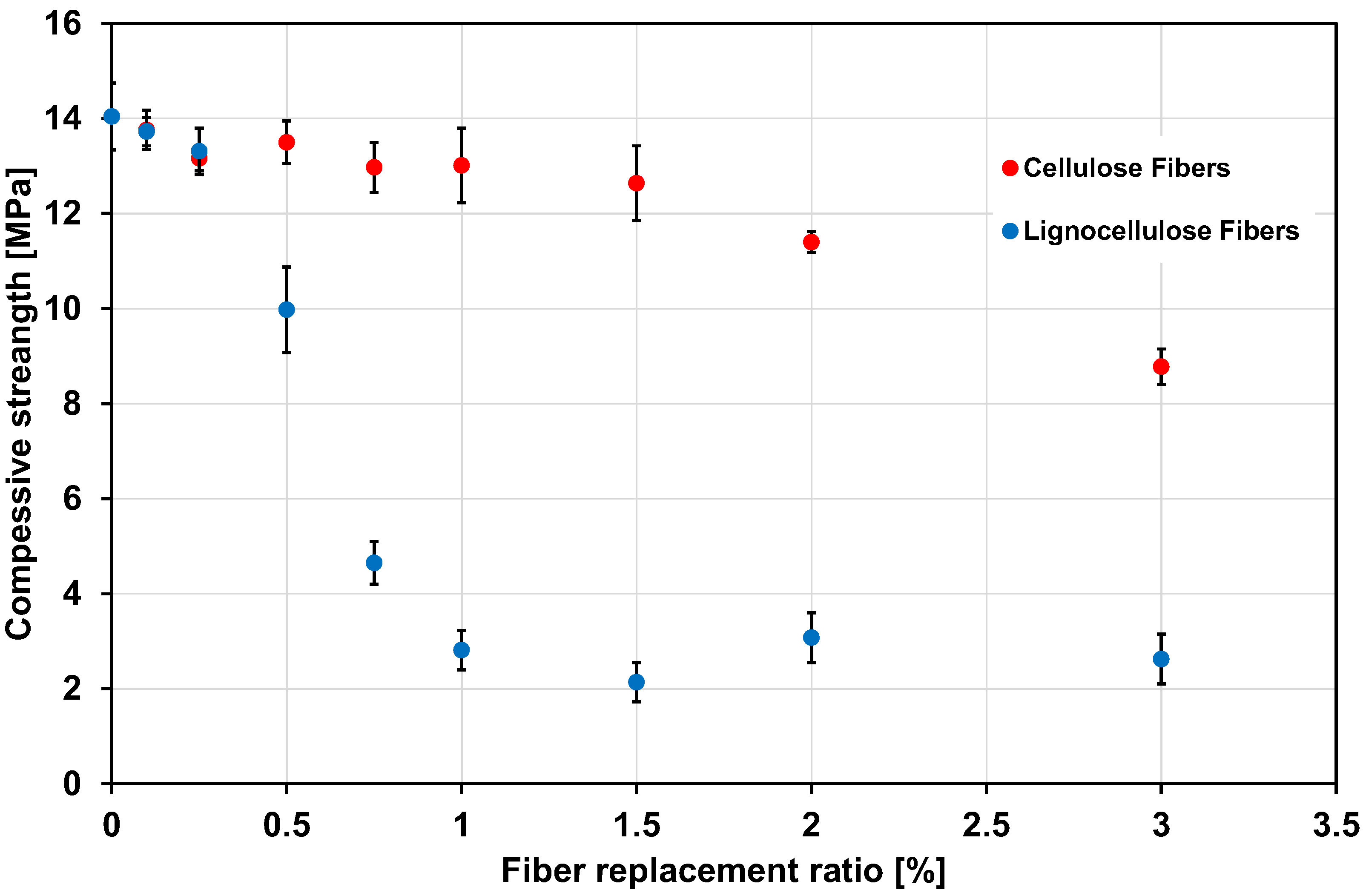

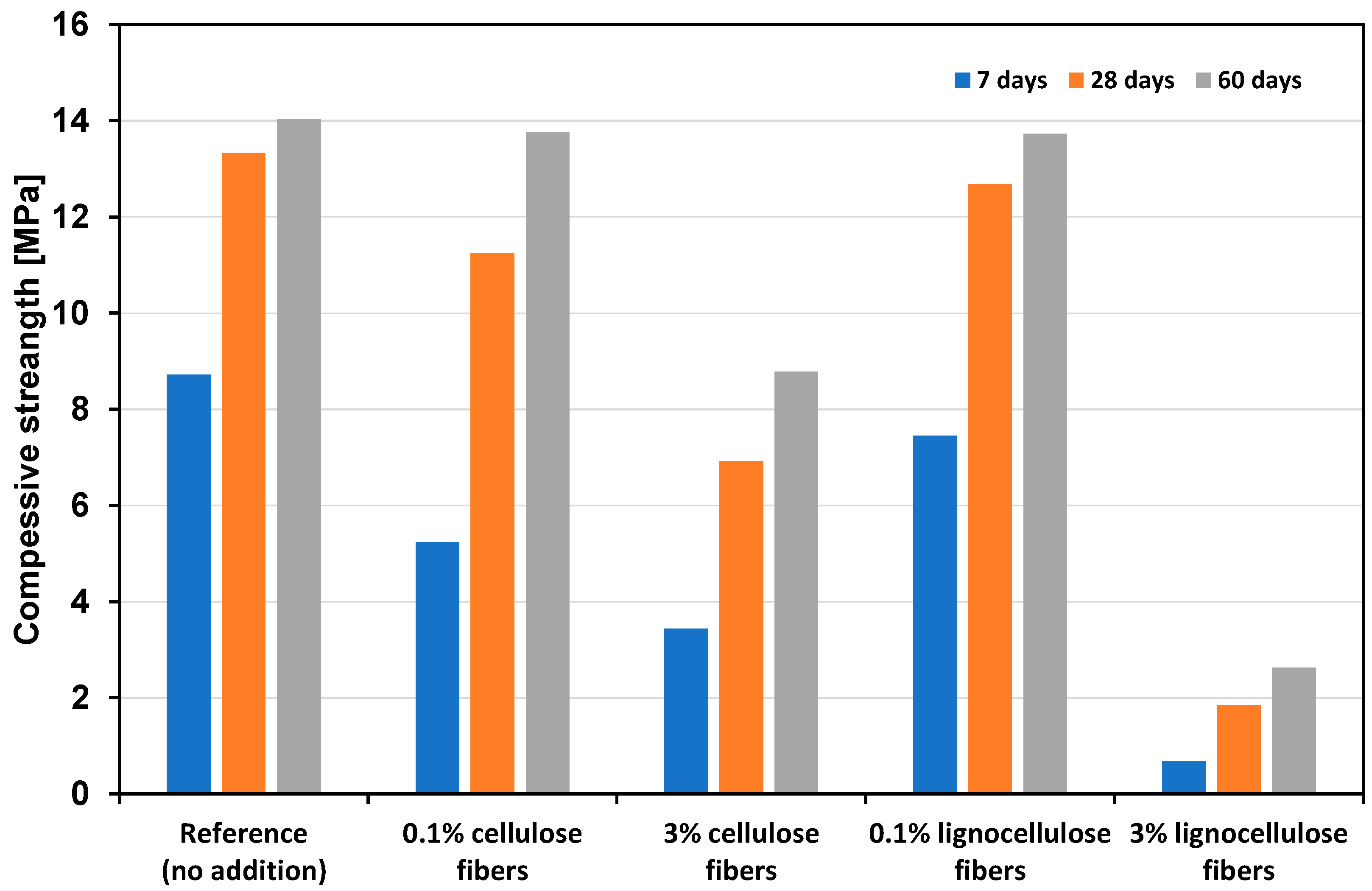

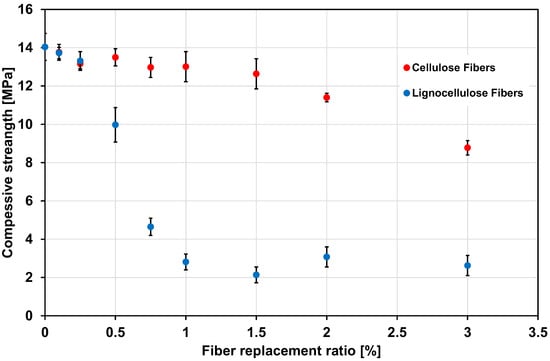

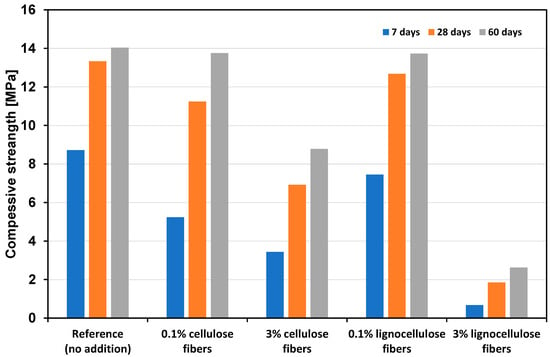

3.3. Compressive Strength

The reference mix achieved a compressive strength of 14.04 MPa after 60 days, which is consistent with B-15 strength class. In the composites reinforced with cellulose fibers, a gradual reduction in 60-day compressive strength was observed with increasing fiber content. The lowest value of 8.78 MPa was recorded at 3% cellulose content, corresponding to a 38% decrease compared to the reference. Composites incorporating lignocellulose fibers showed more significant strength reductions, with 60-day compressive strength values ranging from 13.73 MPa at 0.1% fiber content to a minimum of 2.14 MPa at 1.5%, followed by a slight recovery to 2.63 MPa at 3%. The maximum strength loss in this series reached ~85% (at 1.5% lignocellulose). These results reflect the role of lignin: cellulose pulp with near-zero lignin content retained higher mechanical performance, while lignocellulose pulp with high lignin content interfered more strongly with strength development, particularly at higher dosages. Overall, cellulose fibers retained more favorable compressive performance than lignocellulose fibers at comparable dosages; in line with the broader results of this study, both series are best positioned for non-structural applications unless further treatments are applied.

Figure 4 summarizes the effect of dosage on 60-day compressive strength, while Figure 5 shows time development (7/28/60 days) for the lignocellulose series at representative dosages; Table 5 reports the corresponding time-series data for both series.

Figure 4.

Effect of fiber content on compressive strength of composites reinforced with cellulose and lignocellulose fibers.

Figure 5.

Compressive strength development of composites reinforced with lignocellulose fibers at 7, 28, and 60 days.

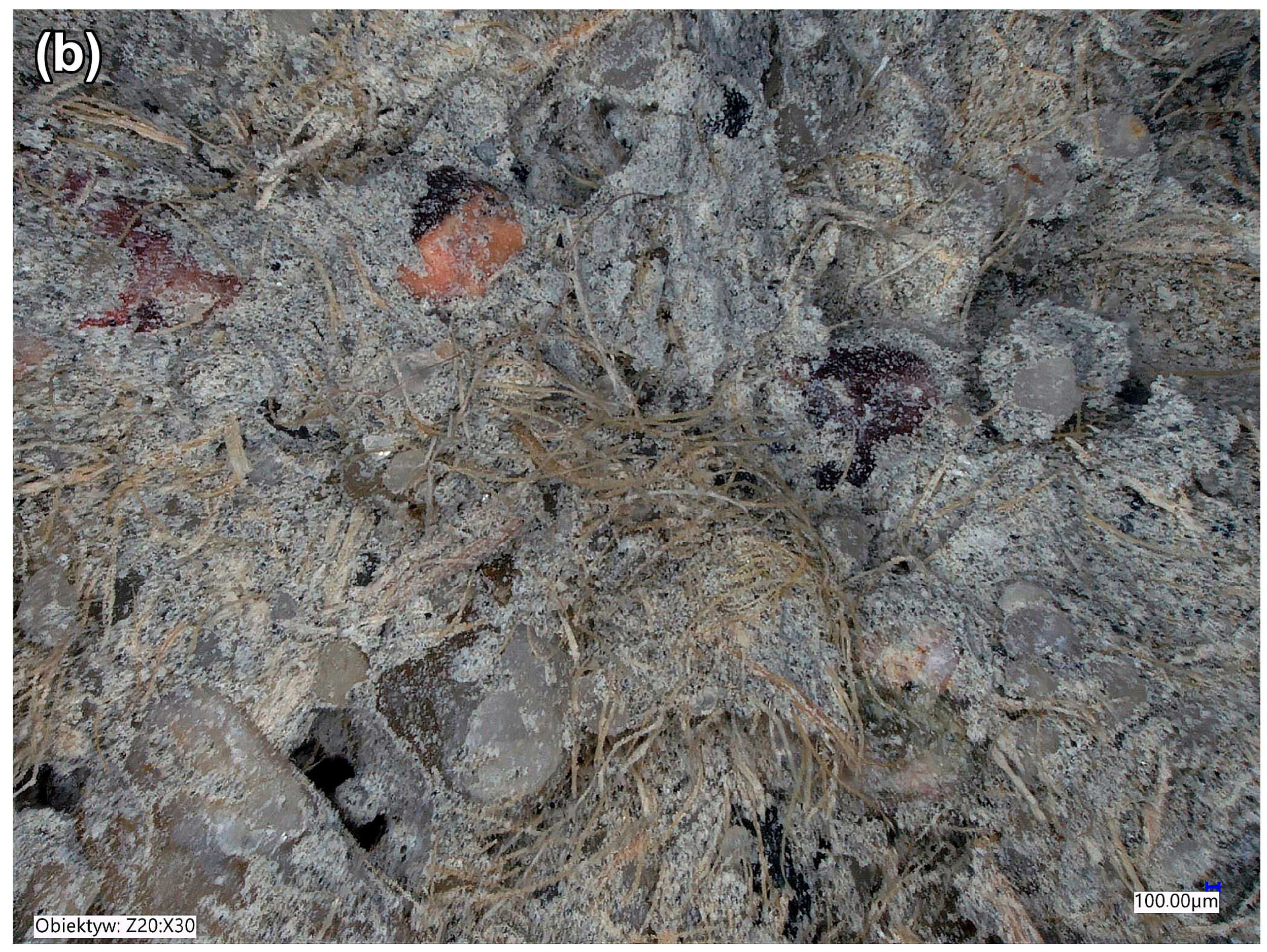

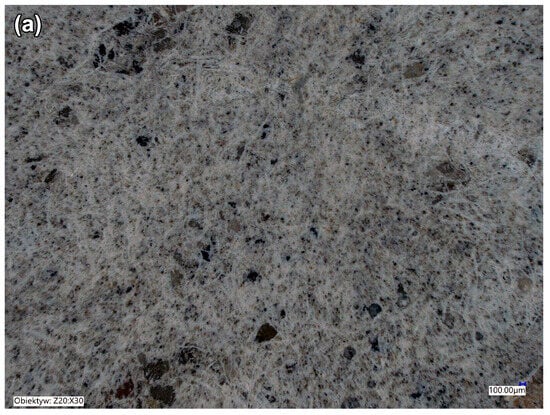

3.4. Auxiliary Methods

To complement the mechanical and physical testing, microscopic examination was conducted to observe the surface and internal structure of the fiber-reinforced composites. Figure 6 shows a comparison of the composite surfaces with cellulose and lignocellulose pulp, while Figure 7 presents the internal structure of the specimens following compressive strength testing.

Figure 6.

Comparison of the surface of the composite with the addition of: (a) cellulose pulp; (b) lignocellulose pulp. Visible features include fiber dispersion quality, local fiber bundles, and surface voids.

Figure 7.

Internal structure after compression: (a) cellulose pulp; (b) lignocellulose pulp. Visible features include fiber pull-out, crack paths, and debonding at the interfacial zone.

As shown in Figure 6, the surface of specimens with bleached kraft cellulose pulp exhibits a markedly more uniform fiber dispersion, forming a comparatively smooth and continuous surface with few discernible voids at the magnifications used. In contrast, specimens with lignocellulose pulp display spatially heterogeneous dispersion with localized fiber bundles (rope-/braid-like agglomerates) and visible surface voids. These surface-level differences are mirrored at the fracture plane in Figure 7: cellulose–pulp composites show widespread fiber pull-out indicative of distributed crack-bridging by multi-directionally oriented fibers, whereas lignocellulose–pulp composites tend to crack along or across larger agglomerates (‘fiber bundles’), creating preferential planes of weakness. The resulting microstructural non-uniformity in the lignocellulose series is consistent with the more pronounced reductions in compressive strength observed at higher dosages.

4. Discussion

The experimental results confirm that the inclusion of both cellulose and lignocellulose fibers in cement composites results in a measurable reduction in density and compressive strength and an increase in water absorption relative to conventional concrete. These findings align with the observations reported by Raabe et al. [39], who investigated cement composites reinforced with cellulose fibers, and Lin et al. [40], who examined composites containing lignocellulose fibers. Both studies also documented performance trade-offs associated with wood-derived fibers reinforcements in cement composites.

In terms of mechanical behavior, composites reinforced with cellulose fibers exhibited a more moderate decline in compressive strength compared to those incorporating lignocellulose fibers. At 3% fiber content, strength in the cellulose series dropped by approximately 38%, while lignocellulose mixes exhibited a reduction of up to 85%. This difference is attributable to several factors, including fiber morphology, chemical composition, water retention capacity, and increased porosity. Another important factor is lignin content: cellulose fibers with low lignin showed better compatibility with the cement matrix, while high-lignin lignocellulose fibers intensified hydration interference and weakened interfacial bonding. Additionally, water-soluble compounds such as sugars and hemicelluloses present in untreated wood fibers can inhibit cement hydration by interfering with the formation of hydration products, as reported by Yang et al. [41]. Another critical factor is the swelling behavior of natural fibers when exposed to water. As shown by Mohammed et al. [42], fiber swelling can disrupt the microstructure of the cement matrix, creating internal stresses and weak interfacial zones, which further compromise mechanical performance. The same study also reported that the incorporation of natural fibers can interfere with the compaction process, leading to the formation of voids that negatively impact the overall strength of the composite. The results of this study showed that cellulose fiber-reinforced composites, which contained finer fibers and a lower lignin content, performed better in terms of mechanical strength. This supports the findings of Hamada et al. [43], who observed that fibers with a lower lignin content and finer texture tend to disperse more uniformly and interfere less with cement bonding. These findings highlight the importance of carefully balancing the mechanical drawbacks associated with natural fiber reinforcement by optimizing fiber type, treatment, and dosage to ensure performance is not compromised.

Water absorption was also found to increase with fiber content, especially in composites with cellulose fibers, where values reached 14%, representing a 180% increase compared to the reference mix. Composites containing lignocellulose fibers exhibited only a minor increase, with absorption peaking at just 5.5%. This disparity may be attributed to the higher surface area and hydrophilicity of cellulose pulp, which increases porosity and water retention. According to Golewski et al. [44], typical water absorption for conventional concrete ranges between 4 and 6%. The cellulose composites tested in this study exhibited significantly higher values, raising concerns about long-term durability. Elevated water absorption can compromise freeze–thaw resistance, accelerate carbonation, and lead to chemical degradation over time, as discussed by Merta et al. [45]. Therefore, while the use of fibers may reduce the carbon footprint and material weight of composites, the significantly increased water absorption observed in some formulations must be addressed to ensure long-term durability. Accordingly, interior/dry-service conditions are preferable for the cellulose series at higher dosages unless sorptivity is mitigated via treatments or mix design.

This study was a screening-level comparison restricted to density, water absorption, and compressive strength under air curing, which were chosen to simulate practical real-world curing conditions. Other important aspects, including tensile and flexural strength, setting behavior, microstructural interactions, and durability, were beyond the present scope. Future work will expand testing to these properties using standardized methods and advanced analyses (Vicat, SEM-EDS, XRD, FTIR, TGA), with particular focus on low-lignin pulps and treatments to enhance fiber–matrix compatibility. To overcome the challenges observed with both bleached kraft and thermo-mechanical pulps, future research should emphasize fiber surface modification and chemical treatments, which have already shown promise in improving mechanical performance, as demonstrated by Biskri et al. [46]. Another promising direction is the use of shorter fibers such as nanocellulose, which, due to its nanoscale dimensions and large surface area, can disperse uniformly within the cement matrix and form strong physical interactions. This has been confirmed by Santos et al. [47], who reported significant improvements in strength and durability in nanocellulose-reinforced cement composites.

When compared with recent literature, our results emphasize the importance of lignin content in fiber–cement compatibility. Sadrolodabaee et al. [48] reported that kraft pulp could serve as a suitable reinforcement in cement composites, showing stable mechanical performance when incorporated at moderate dosages. This observation aligns with the present findings for low-lignin cellulose pulp, which exhibited only moderate reductions in compressive strength. Although further research is needed to establish full engineering design parameters, the present results provide initial guidance on potential applications. The reduction in density, combined with compressive strengths between 8.8 and 14.0 MPa for cellulose composites (and lower values for lignocellulose at higher dosages), indicates that these materials are most appropriate for non-structural roles. Suitable uses include lightweight partitions, cladding panels, acoustic baffles, underlayments, and controlled low-strength fillers, where modest strength and ease of handling are more important than load-bearing capacity. Further work on mechanical, microstructural, and durability properties will be essential to validate and expand these potential applications.

5. Conclusions

This study assessed the influence of cellulose fibers sourced from paper manufacturing and lignocellulose fibers originating from MDF production on the physical and mechanical properties of cement composites, contributing to the growing body of research on sustainable reinforcement in cement composites. A key focus was the role of lignin, since cellulose pulp contained near-zero lignin while lignocellulose pulp retained a high lignin fraction. Based on the experimental outcomes, the following conclusions can be drawn:

- The use of both cellulose and lignocellulose fiber pulps in cement composites, when added at higher dosages, does not allow for producing materials with properties comparable to conventional concrete of equivalent composition, with the high lignin content of lignocellulose further amplifying these limitations.

- Replacing ≥1.5% of mineral aggregates with cellulose pulp led to a ~10–20% reduction in compressive strength (depending on dosage), whereas for lignocellulose pulp the reduction already exceeded ~25% at ≥0.5%. At 3% lignocellulose, the maximum strength loss reached ~80%.

- In terms of water absorption, both fiber types caused a marked increase relative to the reference mix, reaching up to 14% for cellulose fibers and 5.5% for lignocellulose fibers. This significantly elevated moisture uptake limits the potential use of these composites in applications where low water absorption and long-term durability are essential.

- The reduction in mechanical properties can be attributed to the disruption of matrix cohesion caused by the presence of long, unmodified fibers. An interesting avenue for future research involves the use of shorter fibers such as those derived from recycled paper or subjecting the raw pulp to additional processing in order to reduce fiber length. This could result in improved dispersion, better bonding, and a more uniform internal structure of the composite;

- The findings of this study indicate that, while industrially sourced fiber pulps can be incorporated into cement composites, their use, particularly without treatment, introduces significant performance limitations, with high lignin content in lignocellulose pulp further intensifying these effects, highlighting the need for material processing and design optimization.

Author Contributions

Conceptualization, P.T. and P.P.; methodology, P.P.; software, P.T. and P.P.; validation, P.P.; formal analysis, P.T.; investigation, P.T. and P.P.; resources, P.T. and P.P.; data curation, P.T. and P.P.; writing—original draft preparation, P.T.; writing—review and editing, P.T. and P.P.; visualization, P.T. and P.P.; supervision, P.P.; project administration, P.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| SCMs | Supplementary Cementitious Materials |

| MDF | Medium-Density Fiberboard |

References

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising Cement and Concrete Production: Strategies, Challenges and Pathways for Sustainable Development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Bhusan Das, B.; Adak, D. Roadmap to a Net-Zero Carbon Cement Sector: Strategies, Innovations and Policy Imperatives. J. Environ. Manag. 2024, 359, 121052. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting Future Carbon Emissions from Cement Production in Developing Countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef]

- GCCA (Global Cement and Concrete Association). Concrete Future. The GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete. Available online: https://gccassociation.org/concretefuture/ (accessed on 5 July 2025).

- Samad, S.; Shah, A. Role of Binary Cement Including Supplementary Cementitious Material (SCM), in Production of Environmentally Sustainable Concrete: A Critical Review. Int. J. Sustain. Built Environ. 2017, 6, 663–674. [Google Scholar] [CrossRef]

- Ho, L.S.; Van Quang, L.; Van-Pham, D.-T.; Huynh, T.-P. Strength Development and Microstructural Characterization of Eco-Cement Paste with High-Volume Fly Ash. Results Eng. 2025, 26, 105013. [Google Scholar] [CrossRef]

- Zhang, R.; Scott, A.N.; Panesar, D.K. Carbonation and CO2 Reabsorption of Cement-Based Materials: Influence of Limestone Filler and Ground-Granulated Blast-Furnace Slag. Constr. Build. Mater. 2024, 416, 135166. [Google Scholar] [CrossRef]

- Chen, J.; Plank, J. Calcined Clays for Climate Neutral (“Net Zero”) Cements: Shear-Dependent Rheological Behavior and Application Performance. Cem. Concr. Compos. 2025, 162, 106145. [Google Scholar] [CrossRef]

- Shah, I.H.; Miller, S.A.; Jiang, D.; Myers, R.J. Cement Substitution with Secondary Materials Can Reduce Annual Global CO2 Emissions by up to 1.3 Gigatons. Nat. Commun. 2022, 13, 5758. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Hu, H.; Luo, Y.; Yao, W.; Wei, Y.; She, A. A Carbon Footprint Assessment for Usage of Recycled Aggregate and Supplementary Cementitious Materials for Sustainable Concrete: A Life-Cycle Perspective in China. J. Clean. Prod. 2025, 490, 144772. [Google Scholar] [CrossRef]

- Khankhaje, E.; Jang, H.; Kim, J.; Rafieizonooz, M. Utilizing Rice Husk Ash as Cement Replacement in Pervious Concrete: A Review. Dev. Built Environ. 2025, 22, 100675. [Google Scholar] [CrossRef]

- Farooqi, M.U.; Ali, M. Durability Evaluation of Wheat Straw Reinforced Concrete for Sustainable Structures. J. Build. Eng. 2024, 82, 108400. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Haque, M.A.; Kazmi, S.M.S.; Munir, M.J. Development of Plant-Concrete Composites Containing Pretreated Corn Stalk Bio-Aggregates and Different Type of Binders. Cem. Concr. Compos. 2021, 121, 104054. [Google Scholar] [CrossRef]

- Özkan, İ.G.M.; Aldemir, K.; Alhasan, O.; Benli, A.; Bayraktar, O.Y.; Yılmazoğlu, M.U.; Kaplan, G. Investigation on the Sustainable Use of Different Sizes of Sawdust Aggregates in Eco-Friendly Foam Concretes: Physico-Mechanical, Thermal Insulation and Durability Characteristics. Constr. Build. Mater. 2024, 438, 137100. [Google Scholar] [CrossRef]

- Dias, S.; Tadeu, A.; Almeida, J.; Humbert, P.; António, J.; de Brito, J.; Pinhão, P. Physical, Mechanical, and Durability Properties of Concrete Containing Wood Chips and Sawdust: An Experimental Approach. Buildings 2022, 12, 1277. [Google Scholar] [CrossRef]

- Maier, D.; Manea, D.L.; Tămaș-Gavrea, D.-R.; Țiriac, A.; Costin, P. Wood–Cement Composites: A Sustainable Approach for Mitigating Environmental Impact in Construction. J. Compos. Sci. 2024, 8, 474. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A. Use of Hemp, Kenaf and Bamboo Natural Fiber in Cement-Based Concrete. Int. Conf. Adv. Constr. Mater. Struct. 2022, 65, 2070–2072. [Google Scholar] [CrossRef]

- Rahimi, M.; Omran, A.; Tagnit-Hamou, A. Role of Homogenization and Surface Treatment of Flax Fiber on Performance of Cement-Based Composites. Clean. Mater. 2022, 3, 100037. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Yang, W.; Wang, J.; Jin, L. Preparation and Properties of Pretreated Jute Fiber Cement-Based Composites. Ind. Crops Prod. 2024, 210, 118090. [Google Scholar] [CrossRef]

- Xu, R.; He, T.; Da, Y.; Liu, Y.; Li, J.; Chen, C. Utilizing Wood Fiber Produced with Wood Waste to Reinforce Autoclaved Aerated Concrete. Constr. Build. Mater. 2019, 208, 242–249. [Google Scholar] [CrossRef]

- Zaid, O.; Al-Dala’ien, R.N.; Arbili, M.M.; Alashker, Y. Optimizing Natural Fiber Content and Types for Enhanced Strength and Long-Term Durability in High-Performance Concrete. Clean. Eng. Technol. 2025, 26, 100983. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z. Mechanical Properties of Natural as Well as Synthetic Fiber Reinforced Concrete: A Review. Constr. Build. Mater. 2022, 333, 127353. [Google Scholar] [CrossRef]

- Haile, A.; Gelebo, G.G.; Tesfaye, T.; Mengie, W.; Mebrate, M.A.; Abuhay, A.; Limeneh, D.Y. Pulp and Paper Mill Wastes: Utilizations and Prospects for High Value-Added Biomaterials. Bioresour. Bioprocess. 2021, 8, 35. [Google Scholar] [CrossRef]

- Kircher, M.; Aranda, E.; Athanasios, P.; Radojcic-Rednovnikov, I.; Romantschuk, M.; Ryberg, M.; Schock, G.; Shilev, S.; Stanescu, M.D.; Stankeviciute, J.; et al. Treatment and Valorization of Bio-Waste in the EU. EFB Bioecon. J. 2023, 3, 100051. [Google Scholar] [CrossRef]

- Zbieć, M.; Franc-Dąbrowska, J.; Drejerska, N. Wood Waste Management in Europe through the Lens of the Circular Bioeconomy. Energies 2022, 15, 4352. [Google Scholar] [CrossRef]

- Bittner, C.M.; Oettel, V. Fiber Reinforced Concrete with Natural Plant Fibers—Investigations on the Application of Bamboo Fibers in Ultra-High Performance Concrete. Sustainability 2022, 14, 12011. [Google Scholar] [CrossRef]

- Xu, N.; Qian, Y. Effects of Fiber Volume Fraction, Fiber Length, Water-Binder Ratio, and Nanoclay Addition on the 3D Printability of Strain-Hardening Cementitious Composites (SHCC). Cem. Concr. Compos. 2023, 139, 105066. [Google Scholar] [CrossRef]

- Choi, Y.C. Hydration and Internal Curing Properties of Plant-Based Natural Fiber-Reinforced Cement Composites. Case Stud. Constr. Mater. 2022, 17, e01690. [Google Scholar]

- PN-EN 197-1:2012; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Polish Committee for Standardization (PKN): Warsaw, Poland, 2012.

- Portland slag cement. Cementownia Warta, S.A. Available online: https://www.wartasa.com.pl/products/cement-portlandzki-zuzlowy-en-197-1-cem-ii-a-s-425-n-2/ (accessed on 5 July 2025).

- ISO 638-1:2004; Paper, Board and Pulps—Determination of Dry Matter Content—Part 1: Oven-Drying Method (Laboratory Procedure). International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 16065-2:2014; Pulps—Determination of Fibre Length by Automated Optical Analysis—Part 2: Automated Optical Method. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 5351:2010; Pulps—Determination of Limiting Viscosity Number in Cupri-Ethylenediamine (CED) Solution. International Organization for Standardization: Geneva, Switzerland, 2010.

- TAPPI T 203 cm-99; Alpha-, Beta- and Gamma-Cellulose in Pulp. Technical Association of the Pulp and Paper Industry (TAPPI): Peachtree Corners, GA, USA, 1999.

- TAPPI T 222 om-02; Acid-Insoluble Lignin in Wood and Pulp. Technical Association of the Pulp and Paper Industry (TAPPI): Peachtree Corners, GA, USA, 2002.

- TAPPI T 204 cm-97; Solvent Extractives of Wood and Pulp. Technical Association of the Pulp and Paper Industry (TAPPI): Peachtree Corners, GA, USA, 1997.

- TAPPI T 211 om-02; Ash in Wood, Pulp, Paper and Paperboard: Combustion at 525 °C. Technical Association of the Pulp and Paper Industry (TAPPI): Peachtree Corners, GA, USA, 2002.

- PN-EN 13791:2019-07; Assessment of In-situ Compressive Strength in Structures and Precast Concrete Components. Polish Committee for Standardization (PKN): Warsaw, Poland, 2019.

- Raabe, J.; Wisky Silva, D.; Del Menezzi, C.H.S.; Tonoli, G.H.D. Impact of Nanosilica Deposited on Cellulose Pulp Fibers Surface on Hydration and Fiber-Cement Compressive Strength. Constr. Build. Mater. 2022, 326, 126847. [Google Scholar] [CrossRef]

- Lin, C.; Luo, Q.; Kanstad, T.; Grammatikos, S.; Ji, G. A Comprehensive Study on the Physico-Mechanical Properties of a Sustainable Mortar Reinforced by Waste Wood Fiber. Constr. Build. Mater. 2025, 461, 139928. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X. Study on Compatibility of Poplar Wood and Portland Cement. Constr. Build. Mater. 2022, 314, 125586. [Google Scholar] [CrossRef]

- Mohammed, M.; Oleiwi, J.K.; Mohammed, A.M.; Jawad, A.J.M.; Osman, A.F.; Adam, T.; Betar, B.O.; Gopinath, S.C.B. A Review on the Advancement of Renewable Natural Fiber Hybrid Composites: Prospects, Challenges, and Industrial Applications. J. Renew. Mater. 2024, 12, 1237–1290. [Google Scholar] [CrossRef]

- Hamada, H.M.; Shi, J.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Kaplan, G. Application of Natural Fibres in Cement Concrete: A Critical Review. Mater. Today Commun. 2023, 35, 105833. [Google Scholar] [CrossRef]

- Golewski, G.L. Assessing of Water Absorption on Concrete Composites Containing Fly Ash up to 30 % in Regards to Structures Completely Immersed in Water. Case Stud. Constr. Mater. 2023, 19, e02337. [Google Scholar] [CrossRef]

- Merta, I.; Serjun, V.Z.; Pranjić, A.M.; Šajna, A.; Štefančič, M.; Poletanović, B.; Ameri, F.; Mladenović, A. Investigating the Synergistic Impact of Freeze-Thaw Cycles and Deicing Salts on the Properties of Cementitious Composites Incorporating Natural Fibers and Fly Ash. Clean. Eng. Technol. 2025, 24, 100853. [Google Scholar] [CrossRef]

- Biskri, Y.; Babouri, L.; Boukhelf, F.; Charradi, K.; Annaba, K.; El Mendili, Y. On the Physical-Mechanical Behavior of Fiber Cement Composite: Effect of Chemical Treatment of Sisal Fibers. J. Build. Eng. 2025, 101, 111978. [Google Scholar] [CrossRef]

- Santos, R.F.; Ribeiro, J.C.L.; de Carvalho, J.M.F.; Magalhães, W.L.E.; Pedroti, L.G.; Nalon, G.H.; Lima, G.E.S.d. Nanofibrillated Cellulose and Its Applications in Cement-Based Composites: A Review. Constr. Build. Mater. 2021, 288, 123122. [Google Scholar] [CrossRef]

- Sadrolodabaee, P.; Claramunt, J.; Ardanuy, M.; de la Fuente, A. Mechanical and Durability Characterization of a New Textile Waste Micro-Fiber Reinforced Cement Composite for Building Applications. Case Stud. Constr. Mater. 2021, 14, e00492. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).