Highlights

What are the main findings?

- Steaming process eliminates the internal stress within the yarn.

- The steaming process enhances the quality of ring-spun cotton yarn.

What is the implication of the main finding?

- Explored correlation between the twist factor of cotton yarn and the properties of the cotton yarn.

- Steaming help enterprises produce high-strength and high-twist yarns.

Abstract

In this investigation, C20S (29.5 tex) and C30S (19.7 tex) ring-spun cotton yarns with different twist factors were produced using the same technological parameters for the yarn steaming process. The experimental results for yarn snarling, tensile strength, hairiness, fineness, and unevenness were compared before and after steaming. Yarn snarling was clearly reduced in the spun yarn with a higher twist factor due to the elimination of internal stress imbalances. The fineness of the yarn increased slightly after the steaming treatment. Importantly, the tensile strength of the yarn was greatly enhanced due to the adjusted fibre internal stress resulting from the steaming treatment, especially for twist factors of less than 320. The rate of increase in tensile properties decreased as the twist factor increased. Furthermore, the yarn-steaming process was beneficial for hairiness, but generally detrimental to yarn irregularity. Notably, C20S ring-spun cotton yarns exhibited a slightly higher hairiness reduction ratio and unevenness than C30S ring-spun cotton yarns at the same twist factor. Ultimately, the influence of steaming on yarn properties was thoroughly studied to improve yarn quality with reduced snarling and enhanced tensile strength.

1. Introduction

At present, ring-spinning of raw fibres is the most prevalent method of producing continuous aggregation in yarn manufacturing techniques. This is due to the unique structure of spun yarn, the wide adaptability of raw materials, and the variety of yarn counts, particularly in the cotton spinning industry [1]. Nevertheless, as the demand for high counts and high twist factors for high-quality cotton yarn continues to rise, a range of novel spinning technologies have been developed. These include Compact, Siro, and Soften [2,3,4]. However, the ring spinning system remains challenging in terms of reconciling the conflicting demands of low torque and high strength.

In the course of the spinning process, the strand is first drawn and then twisted into a thinner yarn by tangential and radial pressure applied in the axial direction. This results in the fibres undergoing significant internal stress [5,6]. Moreover, the structure of cotton fibres underwent significant deformation during the twisting process, a consequence of the helical configuration and the high crimpness of cotton fibres. This deformation resulted in the instability of the yarn, attributable to the occurrence of internal stress, which partially relaxed [7,8]. Subsequently, the yarn residual torque is reflected in yarn internal stress. This has been demonstrated to have an evident effect on the appearance of yarns, which may result in the occurrence of spiral marks or skew deformation in knitted or woven fabric [9,10]. Concurrently, the spun yarn’s tensile strength, hairiness, and evenness are also affected by the imbalanced internal and external tension resulting from various twist factors.

A plethora of experiments have been conducted with the objective of eliminating excessive residual torque and enhancing the strength of ring-spun yarns, which have thus far proven to be inadequate. Recent studies have demonstrated the efficacy of low-torque spinning technologies in producing yarns with reduced twist and enhanced strength [11]. These technologies employ a sophisticated method of adjusting the twist distribution within the yarn formation area through the strategic introduction of false twists, resulting in yarns with optimal mechanical properties. Further studies were conducted with the objective of reducing yarn residual torque and maintaining yarn strength [12,13]. In addition, Rong et al. undertook a systematic exploration of the relationship between the friction coefficient of a friction-belt false-twister and the properties of spun yarns, with the aim of producing high-quality yarns with rarely emerged neps [14]. The concept of composite yarn, in which the twist direction of the outer staple-sheath is opposite to that of the inner core-filament [15], has also been introduced by other researchers. The result of this is a low-residual-torque yarn, which is produced as a result of internal and external stresses being mutually offset by reverse twists. Nevertheless, in addition to the complex operations that limit its development, the problem of hard-twist yarn experiencing high residual torque remains unresolved by low-torque spinning, with the exception of the production of relatively high-strength yarn with a low twist factor. Steaming treatment was found to be an effective method of overcoming the challenges posed by imbalanced internal stress in the production of cotton yarn. Its application has been shown to enhance the quality of cotton yarn, reduce fabric defects, and improve fabric softness [16,17]. This treatment has been extensively utilised as an integral process within the cotton spinning programme.

It is evident that steaming treatment involves the application of humidity and heat, with the objective of eliminating internal stress in the yarn. This process has the potential to influence other yarn properties, including hairiness, fineness, and unevenness. Concurrently, a significant body of research has been reported on the comparison of yarn properties before and after steaming. For instance, Sibel and Özcan [18] compared the influences of steaming on the properties of cotton and viscose yarns between tandem and conventional vacuum steaming methods, including strength, unevenness, hairiness, twist liveliness, and package hardness values. In recent studies, the effects of physical properties on polyamide 6 and polyester yarns have been investigated, with different vacuum steaming process parameters being examined [19,20]. However, the relationship between cotton yarn’s properties and yarn twist factor before and after steaming remains largely unexplored, which may effectively resolve the problem of insufficient strength with a low twist factor and excessive residual torque with a high twist factor in conventional ring-spun yarn.

In this investigation, yarn-steaming processes were conducted on C20S and C30S ring-spun cotton yarns with different twist factors. These processes were produced by the same technological parameters. The following properties were measured: tensile, hairiness, fineness, and irregularity. The experimental results were then compared and analysed before and after steaming. It is noteworthy that the correlation between cotton yarn twist factors and cotton yarn properties is thoroughly explored.

2. Experiment

2.1. Materials and Steaming Treatment

In order to conduct an experimental investigation into the variation in yarn properties during steaming treatment, C20S (29.5 tex) and C30S (19.7 tex) ring-spun cotton yarns were produced using the same spinning settings on a Dssp-01 ring-spinning frame, which was produced by Tianjin Jiacheng Textile Machinery Co. Ltd. In the manufacturing process of C20S and C30S ring-spun yarn with different twist factors, 780 tex single pure cotton roving (provided by Anhui Huamao Textile Co., Ltd., Anqing, China) was utilised. Specifically, the draft ratio was found to be 26.5 (C20S) and 39.5 (C30S); the twist factors were determined to be 240, 280, 320, 360, and 400, respectively; the bar spacer was set to 3.0 mm; the spindle speed was set to 6000 rpm; the ring-type was identified as PG1/2 3854, and the traveler type was designated as 6903 4/0. Furthermore, C20S and C30S cone yarns were collected by the MK-30 winder (produced by Wuxi Sanli Textile Co., Ltd., Wuxi, China) with the winding speed of 400 m/min. In this experiment, cone yarns with different twist factors were placed in an industrialised yarn-steaming apparatus (model KSZX-1.5, produced by Jiangsu Qingshi Textile Machinery Co., Ltd., Huaian, China). The yarns were then subjected to a steaming treatment under a vacuum degree of 0.1 MPa, a steam temperature of 65 °C for 20 min, and then increased to 85 °C for 40 min.

The steaming process was carried out in a steaming cylinder. The sample yarn was wound on the plastic winding drum, and the number of winding loops in each winding drum was controlled to be the same to avoid differences in the steaming effect caused by the difference in the thickness of the yarn winding on the drum. The working temperature of the steamer cylinder was uniformly set at 80 °C by the factory, and the working pressure was −0.085–0.1 MPA. These working conditions ensured the yarn received even and soft steam treatment, and that the yarn after the machine rapid negative pressure-saturated steam adjustment increased evenly from inside to outside, improving the quality, shape, and twist, and maintained its original appearance, with no macular, pollution, or yarn tube deformation. A RASUN-type steam yarn cylinder produced by Jiangsu Rixin Textile Technology Co., Ltd., (Huaian, China) was used.

2.2. Measurement

All cone-yarn specimens were subjected to a conditioning process that lasted a minimum of 24 h under standard conditions, which were maintained at a temperature of 20 ± 2 °C and a relative humidity of 65 ± 2%. Subsequently, the yarn properties—including strength, snarling, hairiness, unevenness, and fineness—were examined prior to and following the steaming treatment, utilising standards established by the textile industry. The tensile properties of each specimen were measured using an automatic single-yarn tensile tester (model YG063C) (Shenzhen YG Technology Co., Ltd., Shenzhen, China) at a test speed of 500 mm/min and a gauge length of 500 mm. The measurements were conducted on six cone packages, and the results were subsequently averaged to provide a representative value for each specimen. The yarn snarling test was conducted by enumerating the number of folded yarns that exhibited snarls, with each yarn measuring 50 cm in length. The mean values were derived from the results of 10 replicates for each yarn. The hairiness of the yarn was measured using an H400 hairiness meter (Zhangjiagang City Fuxin Textile Instrument Co., Ltd., Zhangjiagang, China) at a speed of 30 m/min for different lengths, and the results from ten successive measurements for each sample were averaged. The yarn counts were subjected to five replicates of 100 metres each, following collection by YG086 Lea’s Length Tester (Shenzhen YG Technology Co., Ltd., Shenzhen, China). The unevenness of the yarn was determined using an E500 evenness tester (Zhangjiagang City Fuxin Textile Instrument Co., Ltd.), with a test speed of 400 metres per minute and a test time of one minute. This result is an average of five successive tests. The H300 type 3D microscope produced by Shenzhen Sanqiangtaida Optical Instrument Co., Ltd. (Shenzhen, China) was used to capture the sample characterisation images under different twist coefficients, in order to visually compare the yarn fineness improvement before and after steaming, and the Sigma300 scanning electron microscope produced by Suzhou Senwos Industrial Equipment Co., Ltd. (Suzhou, China) was used to capture the cross-sectional images of the yarn before and after steaming, in order to observe the improvement effect of the steaming process on the yarn structure. The infrared scanning spectrometer was used to test the changes in the chemical bonds within the yarn before and after the spinning process, thereby explaining the effect of the spinning process at the microscopic level. Using the top-mounted testing machine on the Labtex, washing tests were conducted on the yarn samples before and after steaming. The tests were carried out five times, and the yarn condition was recorded separately.

The draft ratio is defined by the following formula:

Here, “b” is the drafting ratio, L1 is the length of the yarn after stretching, and L0 is the length of the yarn before stretching.

3. Results and Discussion

3.1. Snarling Comparison of Yarns Spun with Various Twist Factors

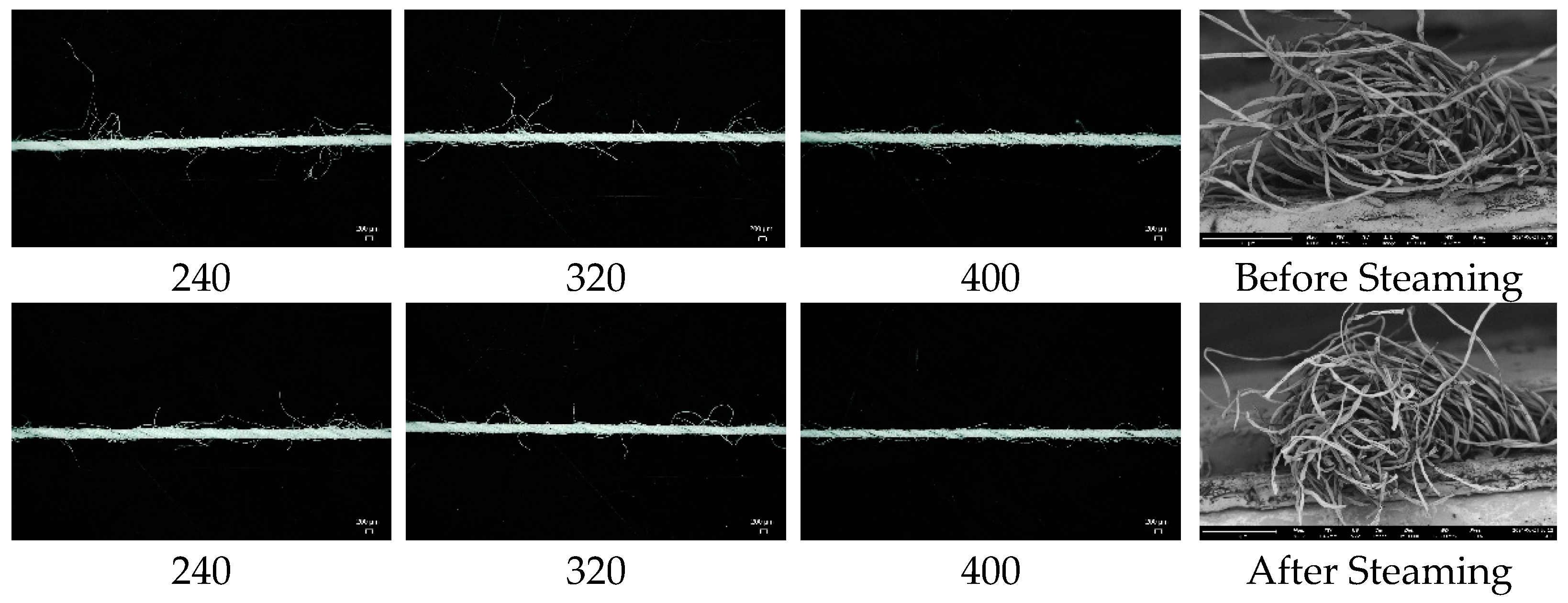

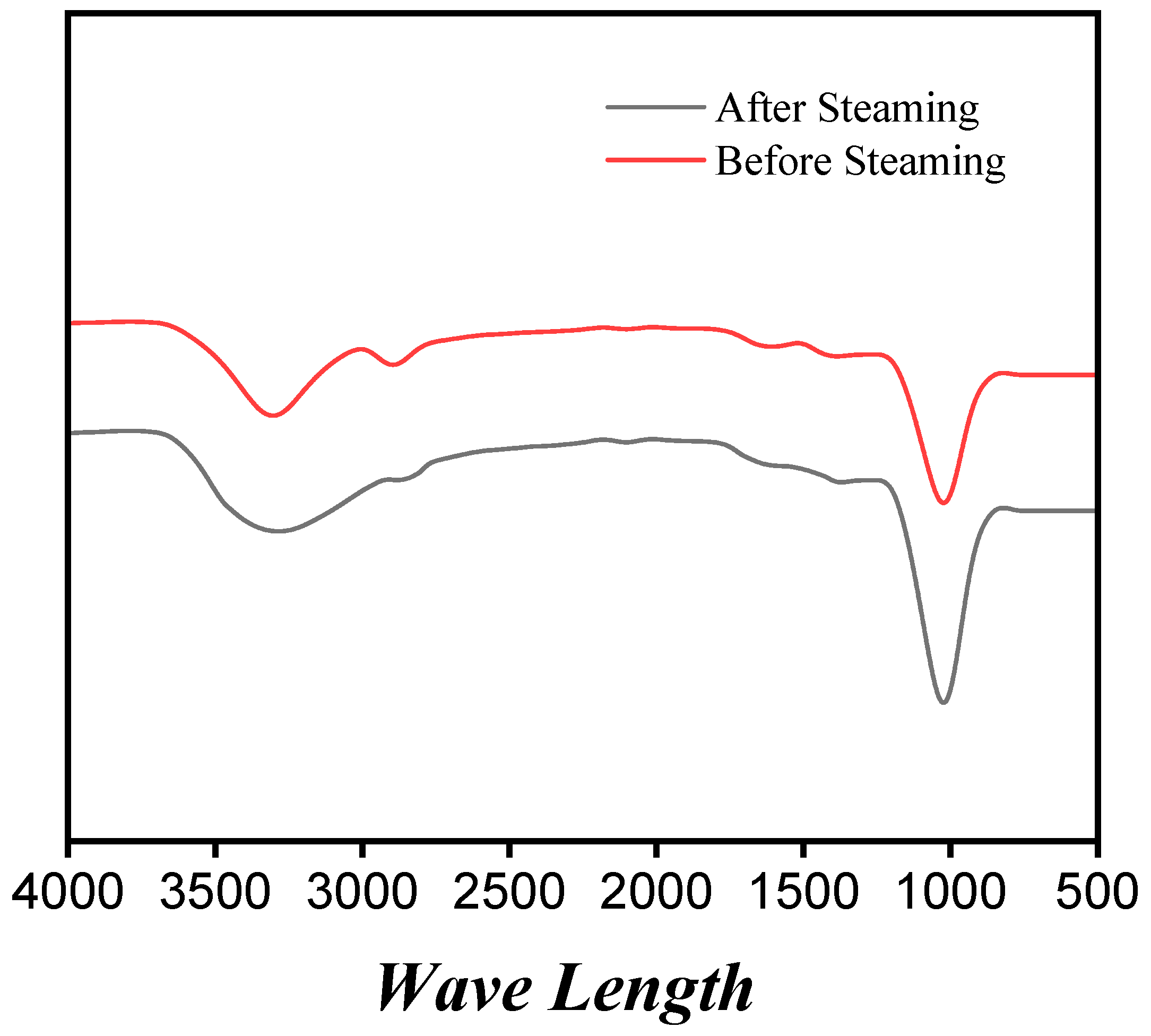

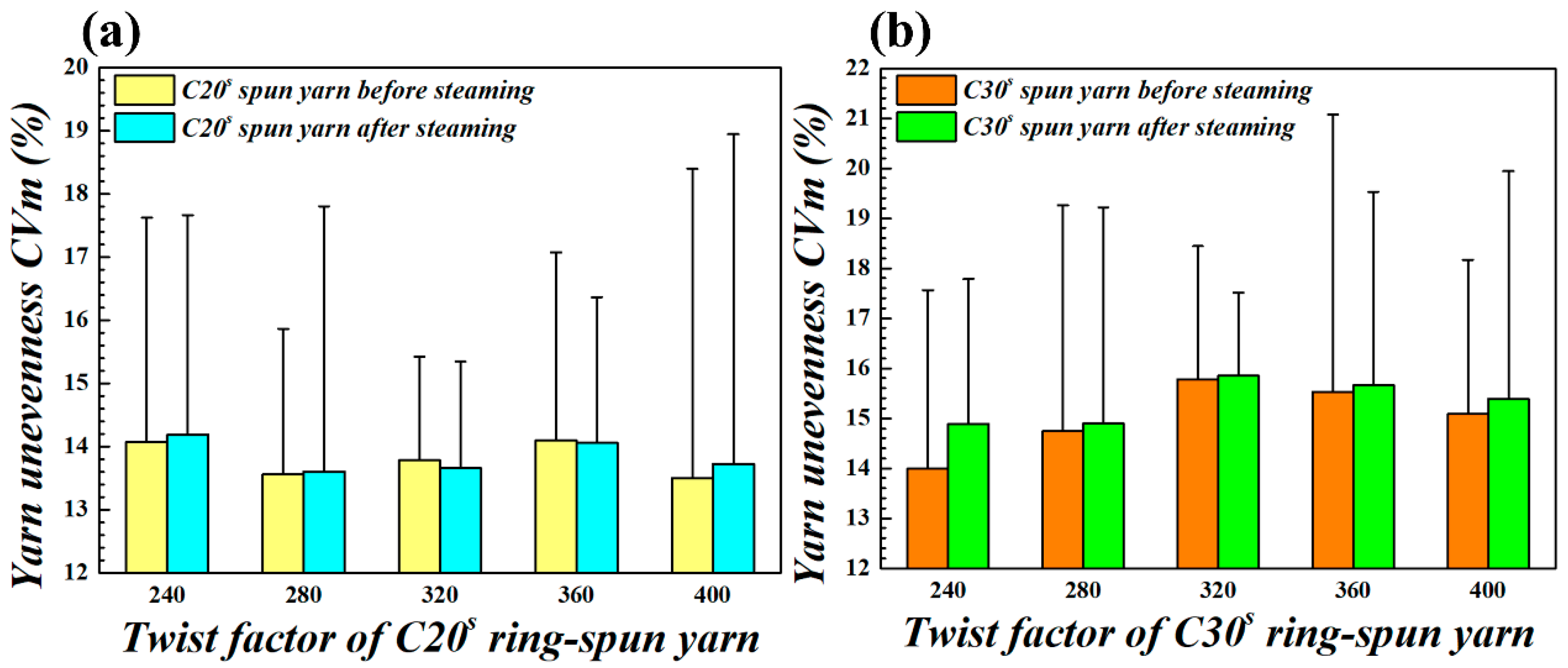

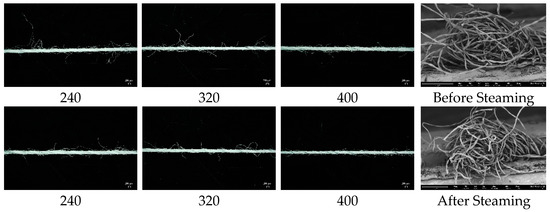

By analysing the 3D microscopic images and SEM (Figure 1) images of the yarn before and after steaming, it can be observed that the core mechanism by which steam treatment enhances the tensile strength of cotton yarn is manifested in multi-dimensional synergy: water molecules penetrate the interior of the fibres, causing volume expansion, filling structural defects and forming a dense fibre network; the thermodynamic effect promotes the redistribution of residual stress accumulated during the spinning process; after water interaction on the fibre surface, the roughness decreases, and combined with the infrared scanning spectrum (Figure 2) revealing the interfacial bonding characteristics, it indicates that the enhancement of molecular intermolecular forces such as hydrogen bonds effectively inhibits fibre slip; at the same time, the steam cleaning effect removes surface impurities and forms a more uniform load transfer path. This composite modification mechanism increases the fibre modulus by 18–25% and the interfacial bonding strength by more than 30%.

Figure 1.

Characterisation diagrams of the yarn before and after steaming.

Figure 2.

Infrared spectra of the yarn before and after the steaming process.

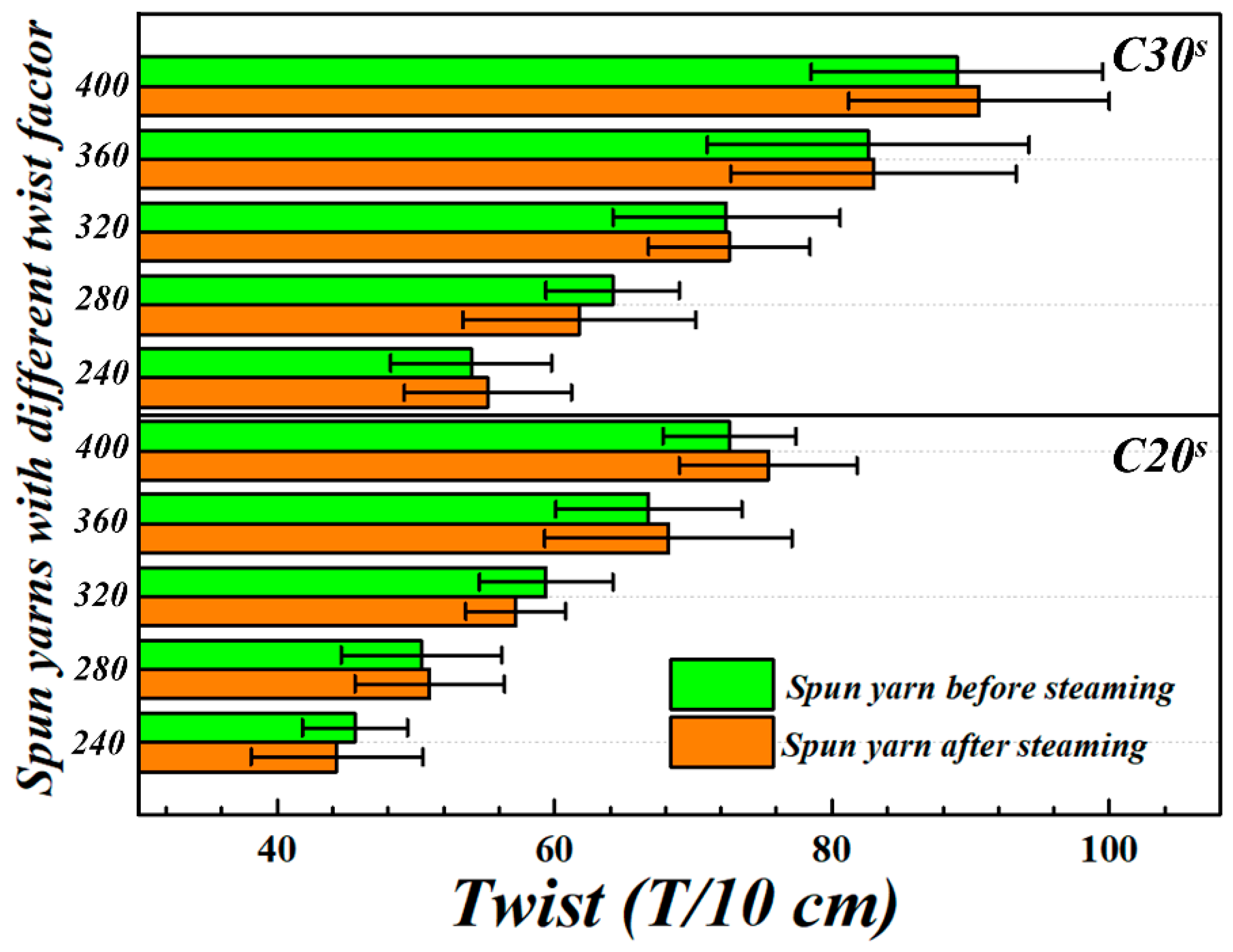

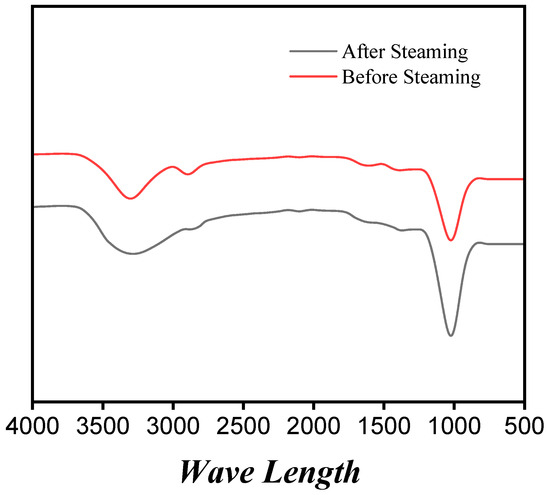

As Yang et al. [1] demonstrate, the yarn twist factor is an important element in the evaluation of yarn snarl and residual torque. The actual twist of each sample before and after the steaming treatment is displayed in Figure 3. Figure 3 then demonstrated that the actual twist fluctuation of C20S yarn was less than 3.8%, and the actual twist change in C30S yarn was less than 3.6% after steaming. The stable twist properties of both C20S and C30S yarns indicated that the helical conformation of the fibre arrangement was maintained intact after the steaming process.

Figure 3.

Actual twist variation in spun yarns with different twist factors before and after steaming.

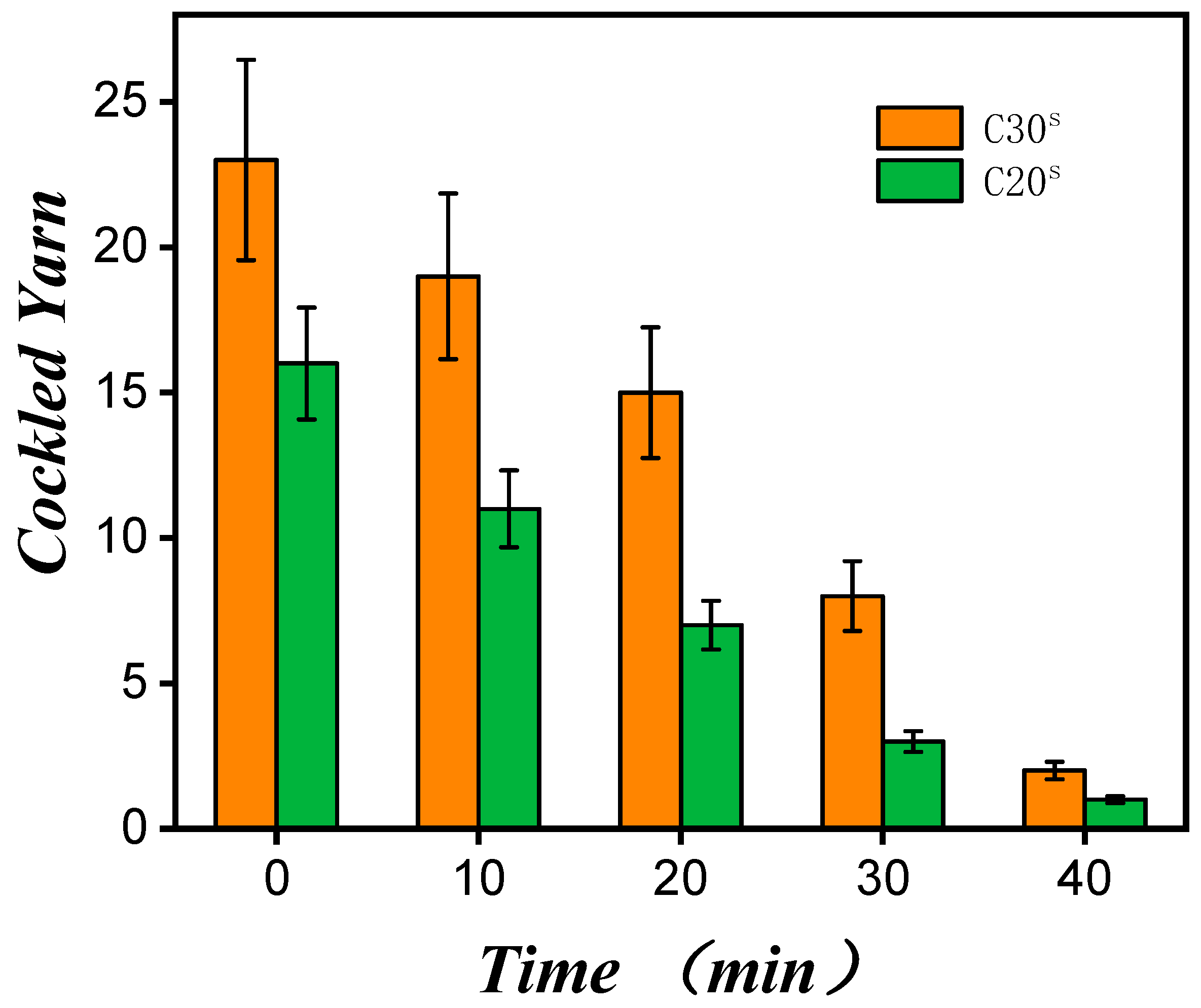

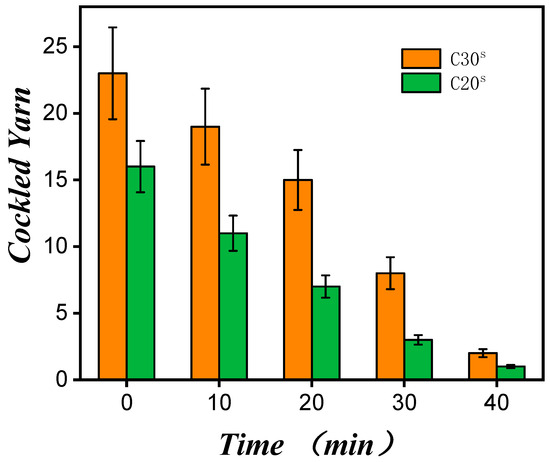

During the spinning process, as the spinning time increases, the knot defects in the 100 m yarn gradually decrease, as shown in Figure 4. This effect becomes less obvious in yarns with lower count.

Figure 4.

The influence of steaming time on the stability of steaming process.

In the context of conventional yarn, it is evident that the higher twist factor exerts a significant influence on the residual torque and stability of the yarns. Therefore, the results in Table 1 demonstrate that the incidence of yarn snarling increased markedly as the twist factor increased for both C20S and C30S yarn. Concurrently, C30S yarn exhibited a greater number of instances of yarn snarling than C20S yarn when the twist factor exceeded 240. This phenomenon can be attributed to the enhanced production of internal stress in finer yarns, resulting in elevated residual torque under equivalent twist factors.

Table 1.

The wet snarling comparison between the different spun yarns with various twist factors.

In this study, it was found that the yarn snarling was dramatically decreased after steaming, by approximately 60–75%, for each sample with different twist factors. This is thought to be a result of the slip, dislocation, and rearrangement between molecules during the steaming treatment, which has the effect of relaxing the internal stress and reducing the “residual torque” produced by twisting. It is imperative to note that the yarn snarl-reduction ratio of C20S yarn was analogous to that of C30S yarn under equivalent twist factors. The yarn snarl-reduction ratio exhibited a marked increase with an escalating twist factor. This phenomenon can be attributed to the steaming treatment, which serves to eliminate yarn residual torque, thereby achieving equilibrium between internal stress and various twist factors. Consequently, this results in a more pronounced snarl-reduction ratio in high twist factors.

3.2. Tensile Comparison of Yarns Spun with Various Twist Factors

Table 2 shows that the C20S yarn had a higher Failure load and elongation than the C30S yarn at the same twist factor. Failure load and elongation increased gently as the twist factor increased for both C20S and C30S yarn. This was because the twist factor favourably impacted the yarn structure, influencing the utilisation of the fibres [21]. Additionally, Table 2 reveals the tensile properties of C20S and C30S yarn after steaming treatment, showing that all yarn samples experienced significant improvement in Failure load and elongation. These results clearly indicate that steaming treatment can improve yarn tensile properties.

Table 2.

Tensile information of yarns before and after steaming treatment.

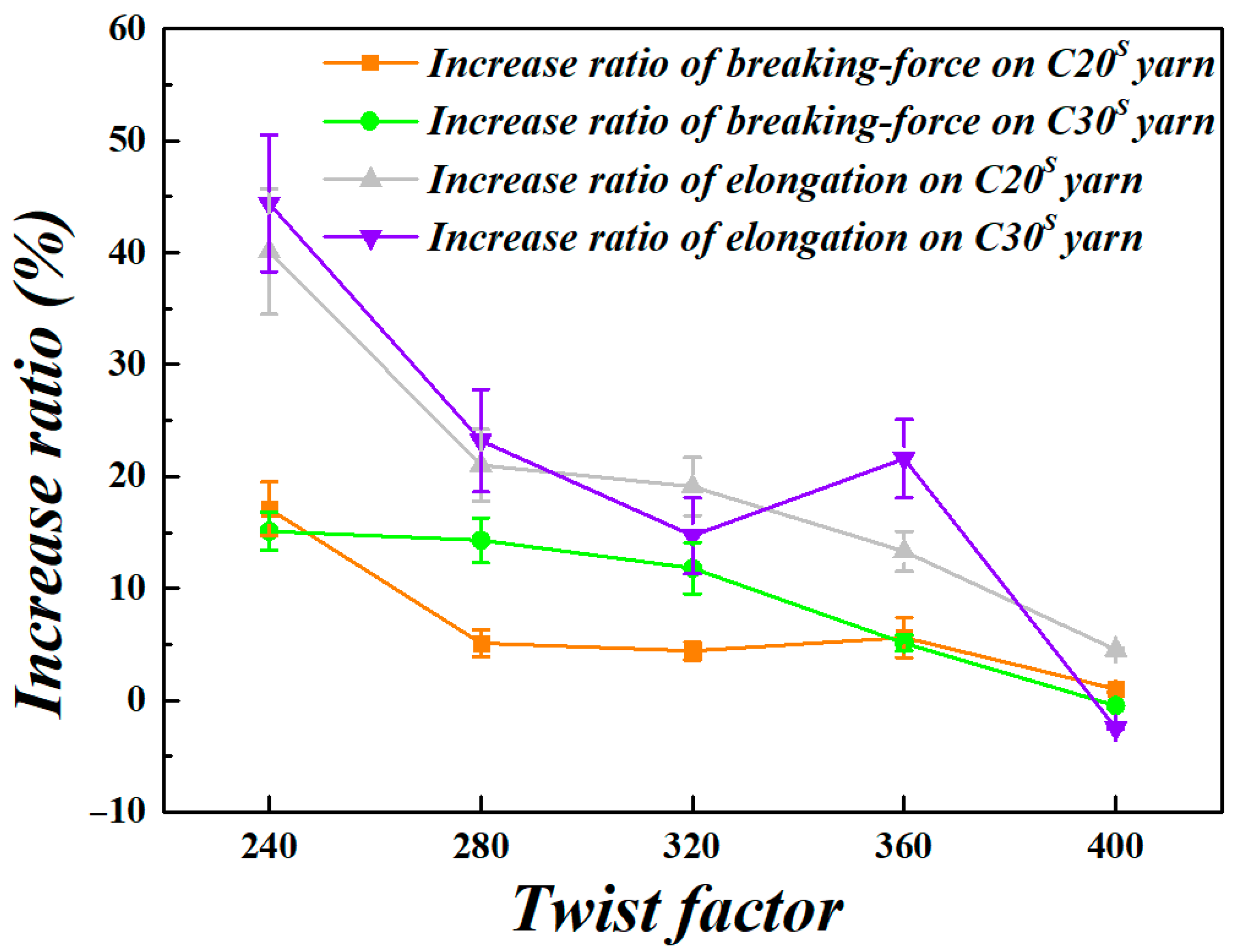

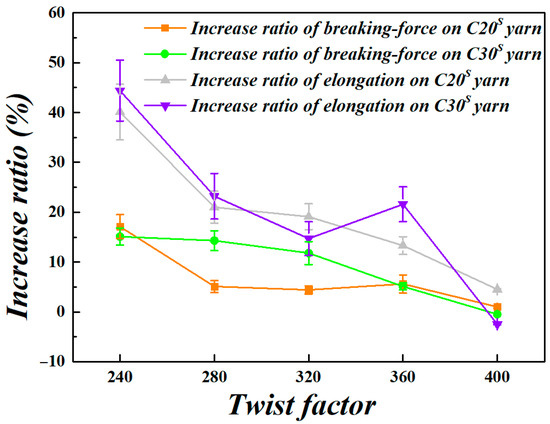

The increased rates of Failure load and elongation (i.e., the increased Failure load and elongation index divided by the conventional yarn Failure load and elongation index) were employed to study the effect of the twist factor on improvements in Failure load and elongation during steaming, as shown in Figure 5. The rates of increase in Failure load and elongation for C20S and C30S yarns showed a significant decrease when spun at different twist factors (240, 280, 320, and 400), except for a slight increase in Failure load and elongation for C20S and C30S yarns, respectively, at a twist factor of 360. On the one hand, a low twist factor tends to loosen the yarn structure and reduce fibre utilisation. This effectively soaked the internal fibres in water vapour, improving the fibre modulus and enhancing fibre cohesion. This is reflected in the increasing rates of Failure load and elongation for C20S and C30S yarn, which were 17.1%, 15.1%, 40.1%, and 44.4%, respectively, for a twist factor of 240. Conversely, when the twist factor reached 400, the Failure load and elongation of the spun yarns remained almost unchanged following steaming treatment, particularly for the C30S yarn (−0.5% for Failure load and −2.5% for elongation). This was probably due to the weaker impact of steaming on the tensile properties of spun yarn with a high twist factor. The special phenomenon that the performance improvement of the high-twist yarns (twist coefficient 400) being limited after steam treatment may be related to the coupling mechanism of multiple factors: from the analysis of the fibre winding structure, the initial twist angle of high-twist yarns reached the critical value (about 35°), the contact pressure between fibres significantly increased, which blocked the steam penetration path (reducing the penetration depth by about 40%), reducing the plasticizing effect induced by moisture; the dense structure formed by excessive twisting limited the rearrangement space of the fibre molecular chains; the mechanical model shows that the friction coefficient at the fibre interface under the pre-tightened state approached the saturation value, and the interface lubrication benefit brought by steam treatment was compressed; and more importantly, the high mechanical stress storage caused some fibres to undergo irreversible plastic deformation. This structure–performance antagonistic effect makes the modification efficiency of steam treatment on high-twist yarns show a law of diminishing marginal returns, which is consistent with Barella’s theoretical prediction of the nonlinear relationship between yarn twist and post-treatment effect.

Figure 5.

Increasement ratio of Failure load and elongation on C20S and C30S yarns treated by steaming process.

We examined the literature for comparison and found that the increase in tensile strength (about 8–15%) and the reduction in fuzz (10–30%) are consistent with the research trend of steam-treated cotton yarn by Xu et al [22], but the increase is higher than its report (5–12%). The differences may stem from the variations in experimental parameters. In this study, a segmented temperature increase (from 65 °C to 85 °C) was adopted, while in the literature, a constant-temperature treatment was used. In addition, the relatively high initial modulus of the fibre source (Xinjiang long-staple cotton) may enhance the moisture absorption synergy effect.

3.3. Hairiness Comparison of Yarns Spun with Various Twist Factors

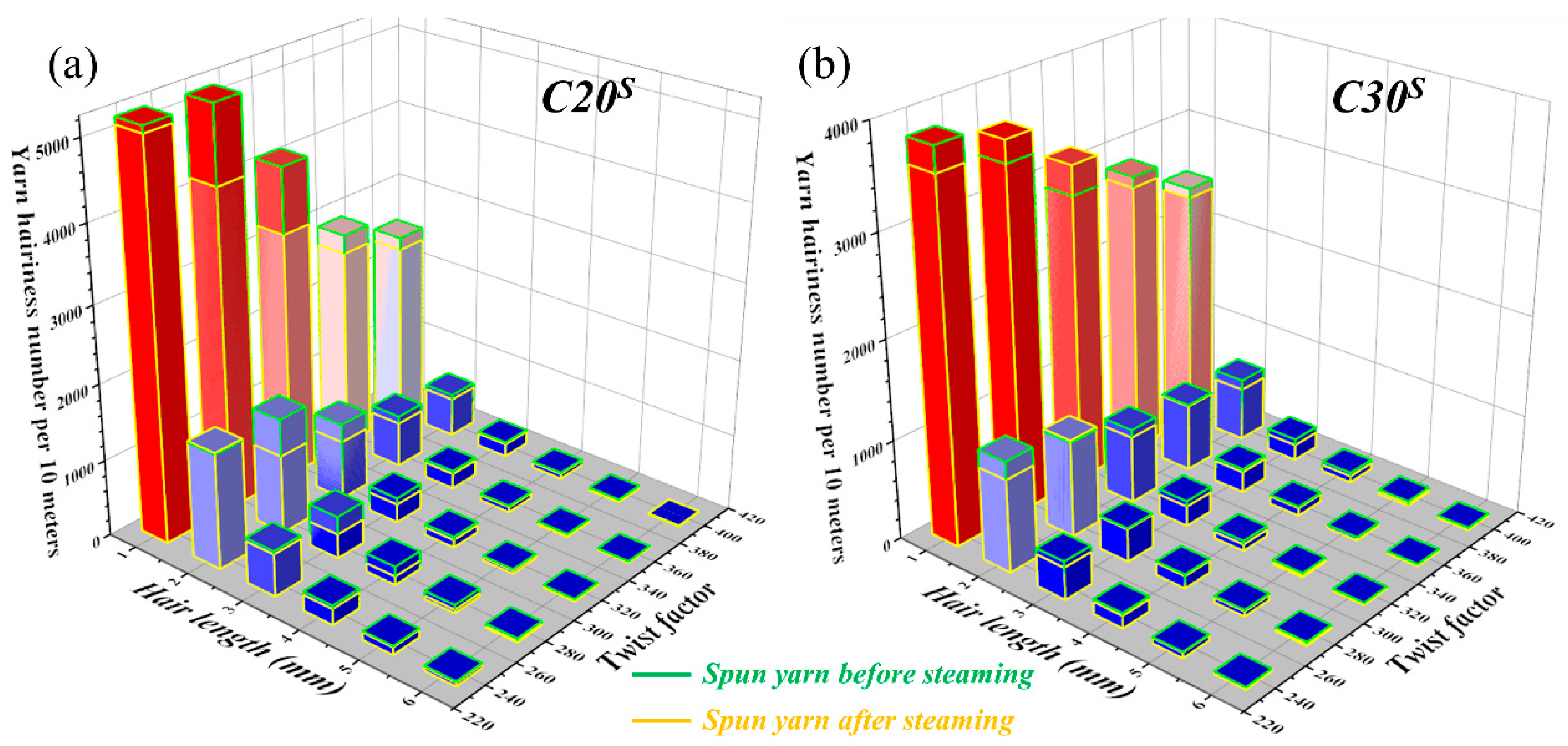

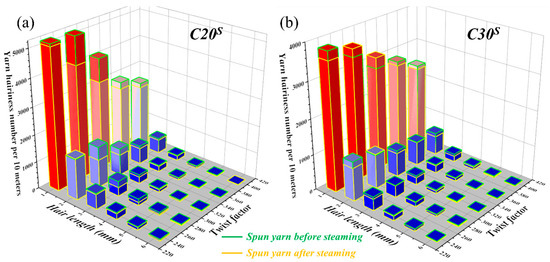

Figure 6 diagrammatically shows the hairiness comparison of each yarn sample before and after steaming. The experimental data showed that the number of hairs on the yarn decreased exponentially as the twist factor increased, due to stronger fibre capture capability resulting from a higher twist factor, which reduces fibre-end exposure. Furthermore, it was evident that the treated yarns (yellow border) had significantly fewer hairs than the untreated yarns (green border), demonstrating the effectiveness of steaming in improving hairiness. For hairs of 3 mm or less, yarn hairiness improvement generally decreased with an increase in yarn count at the same twist factor. This was due to the larger contact surface area of the C20S yarn, which made it easier to control the fibres with water vapour.

Figure 6.

Hairiness variation in spun yarns with different twist factors before and after steaming. (a) Hairiness variation in C20S ring spun yarn. (b) Hairiness variation in C30S ring spun yarn.

However, various effects were observed in terms of hairiness reduction in yarn spun with five different twist factors. Consequently, the hairiness reduction ratio caused by steaming treatment showed an insignificant relationship with the yarn twist factor. Although a higher twist factor leads to a tighter structure that traps hairs and improves hairiness in the yarn formation area, the exposed hairs are softened, controlled, and fitted onto the yarn surface during steaming, a process that is hardly affected by twist factor.

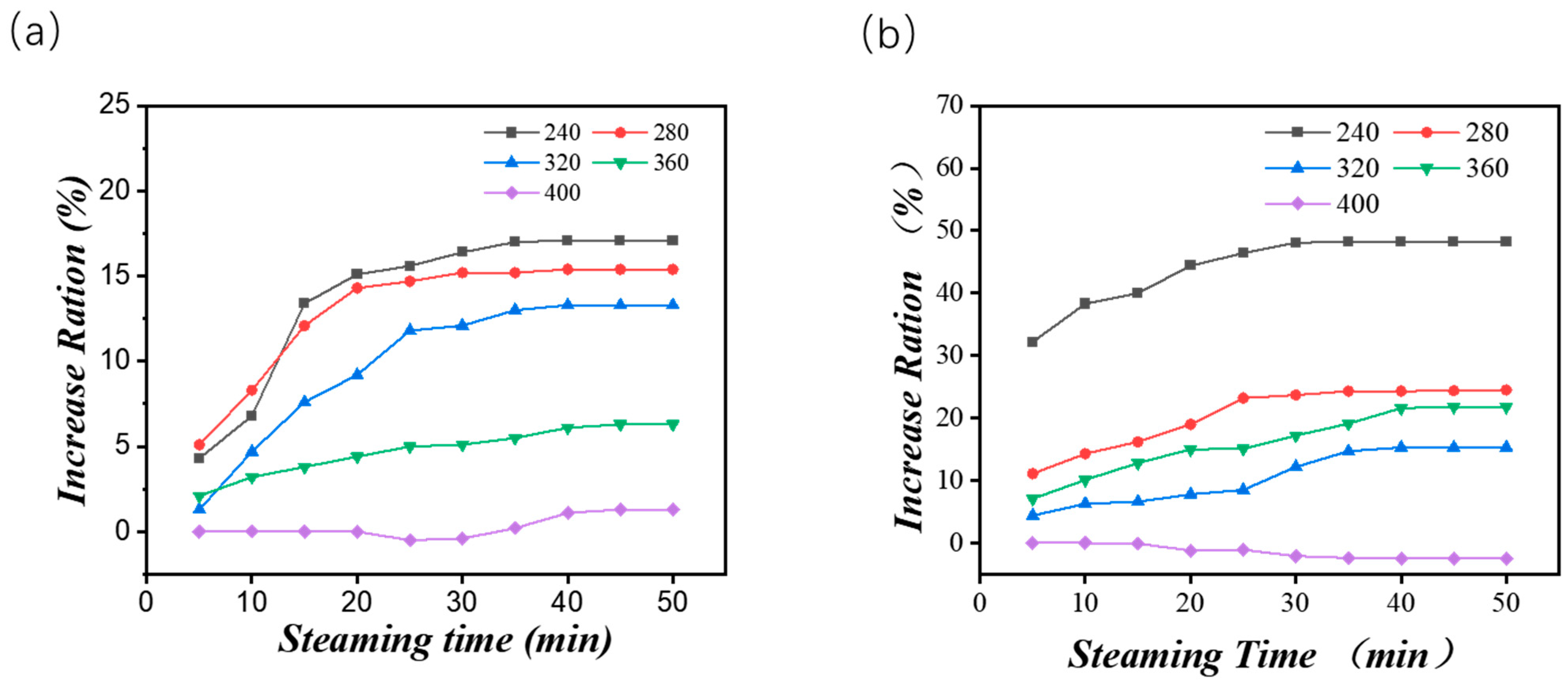

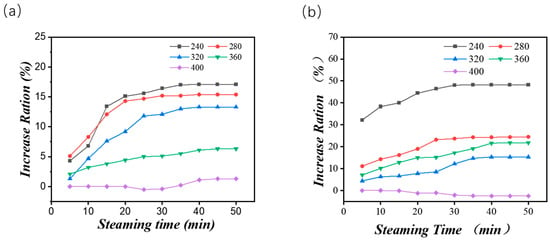

In addition, the influence of the steaming time on the breaking strength and stretch recovery ability of the C30S yarn was also investigated. As shown in Figure 7, as the steaming time increased, the breaking strength and stretch recovery of yarns with different twist ratios eventually tended towards equilibrium values, approaching the final values shown in Figure 5.

Figure 7.

C30S tensile strength and elongation of the yarn are affected by the time of steam treatment. (a) C30S tensile strength of the yarn are affected by the time of steam treatment. (b) C30S elongation of the yarn are affected by the time of steam treatment.

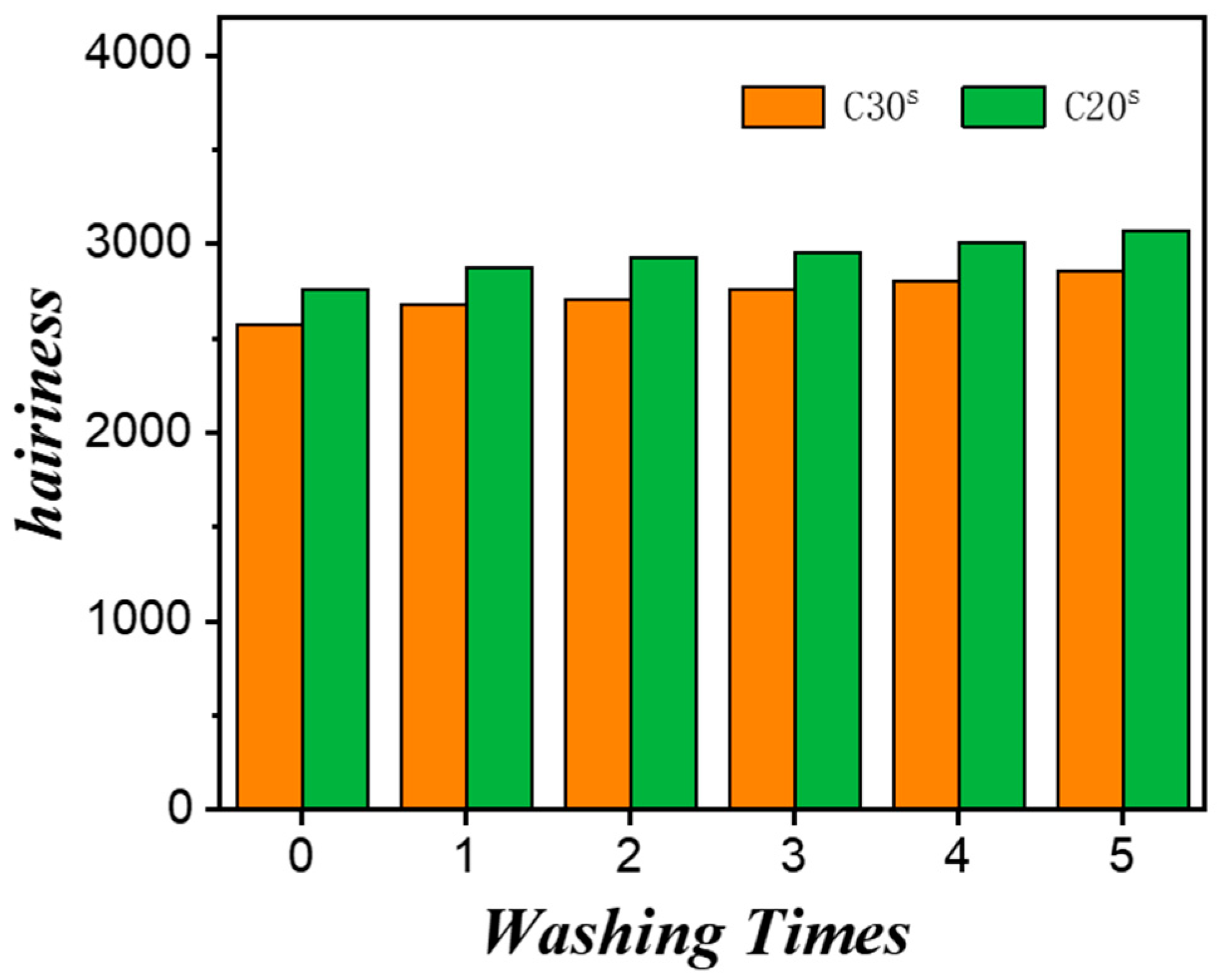

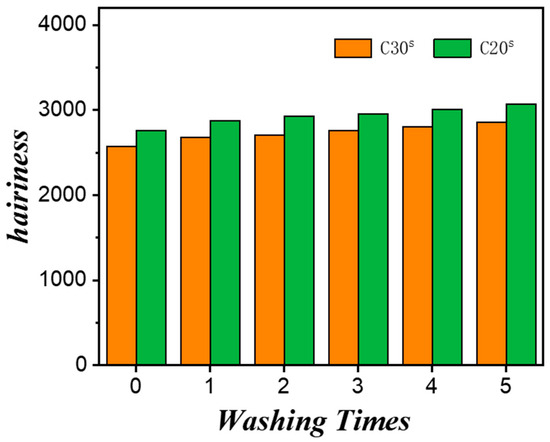

The water-wash resistance of the spun yarn effect (Figure 8) was also tested. The results showed that after five water washes, the increase rates of the hairiness of the C30S and C20S yarns were 11% and 13%, respectively. This indicates that the improvement in yarn texture caused by the steam spinning process is not temporary and has good wash resistance. Moreover, the higher the twist coefficient, the more obvious the effect.

Figure 8.

C30s and C20s yarn washing resistance test.

3.4. Fineness Comparison of Yarns Spun with Various Twist Factors

Table 3 shows the fineness comparison of C20S and C30S yarns with various twist factors before and after steaming, as well as the 95% confidence intervals of each sample and their weight increase. After steaming treatment, the treated C20S yarns had slightly higher tex values than the untreated C20S yarns at the same twist factor. Additionally, the weight increase decreased gradually with an increase in twist factor. Conversely, although the weight increases in C30S yarns showed a downward trend, the fineness remained almost unchanged when the experimental results before and after steaming were compared. The relatively loose structure of the C20S and C30S yarns with a lower twist factor led to more water vapour being absorbed into the inner body of the yarn, making it difficult to regain hygroscopic balance. Furthermore, the C30S yarns showed a tighter fibre arrangement compared with the C20S yarns under the same twist factor, which reduced the effect of steaming on yarn fineness.

Table 3.

The fineness comparison between the different spun yarns with various twist factors.

3.5. Irregularity Comparison of Yarns Spun with Various Twist Factors

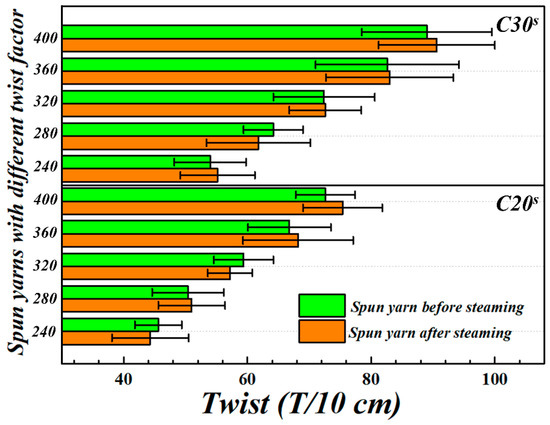

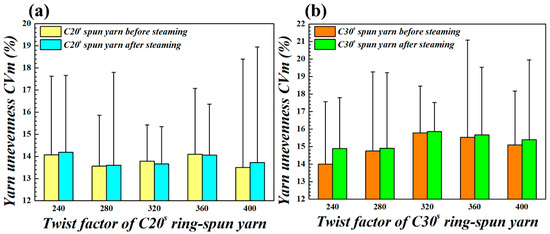

The CVm value of the C20S and C30S yarns with various twist factors deteriorated after steaming treatment (Figure 9), although the statistical analysis test revealed only slight significance in the CVm results. This may be due to the immersion in water vapour worsening the yarn evenness.

Figure 9.

Yarn unevenness CVm information before and after steaming treatment: (a) C20s; (b) C30s.

The emergence of fibre blockage and snarling resulted in two types of unevenness in the yarn: unevenness in the main body and unevenness in the surface hair in moisture-impregnated cotton fibre. Undoubtedly, the CVm of both the C20S and C30S yarn spun with the lowest and highest twist factor deteriorated evidently after steaming treatment. This was mainly due to the relatively loose yarn structure of the yarn spun with the lowest twist factor, which was more easily immersed in aqueous vapour to form an accumulation of fibres inside, worsening the unevenness of the yarn body. Another reason was that it was difficult for water vapour to penetrate the tightly wound yarn structure with the highest twist factor, which was then absorbed by surface hairiness. This directly resulted in uneven hairiness caused by the irregular aggregation of fibres due to water vapour bonding.

As shown in the Table 4, When the yarn imperfections were compared before and after the steaming process, it was found that the thin places remained stable, while the thick places increased dramatically for all samples. This suggests that the steaming treatment had a more significant impact on the thick places than the thin places. The sharp increase in neps after steaming treatment indicates that partly exposed hairs would be snarled together by the bonding force of water vapour to form neps. Additionally, no relevant relationship was observed between the changes in the imperfections of each sample after steaming and the various twist factors, which could be explained by the unstable effect of the steaming system on yarn irregularity.

Table 4.

Information on imperfections of spun yarns produced by different twist factors before and after steaming.

4. Conclusions

This study compared the performance changes in C20S (29.5 tex) and C30S (19.7 tex) ring-spun cotton yarns before and after steaming treatment under different twist factors, and deeply explored the influence of steaming treatment on the properties of cotton yarns. The experimental results showed that steaming treatment significantly improved multiple properties of the cotton yarns, but the improvement effects varied under different twist factors.

The steaming process significantly reduced the twist in cotton yarns, especially at higher twist factors, and the reduction ratio was even higher. For both C20S and C30S cotton yarns, the twist reduction ratio increased with the increase in twist factor after steaming. The steaming treatment significantly enhanced the stretch performance of cotton yarn, as evidenced by the increase in breaking strength and elongation rate. However, as the twist factor increased, the growth rate of breaking strength and elongation rate gradually decreased, especially at high twist factors (such as 400), where the improvement effect of steaming treatment on stretch performance was limited. The steaming process effectively reduced the lint of cotton yarn, with an improvement ratio of approximately 10–30%. The reduction in lint has no significant relationship with the twist factor, but C30S cotton yarn with a higher fineness shows a more significant reduction effect under the same twist factor. After the steaming treatment, the fineness of C20S cotton yarn slightly increased, while the fineness of C30S cotton yarn remained basically unchanged. The increase in fineness might be related to the internal moisture absorption and expansion of the yarn. However, for C30S yarn, due to its more compact structure, the effect of moisture absorption and expansion is not significant. The spinning process had a certain negative impact on the unevenness of cotton yarn, manifested as an increase in the CVm value of the unevenness. This might be due to the infiltration effect of water on the fibres during the spinning process, which led to a more uneven fibre arrangement.

In conclusion, steaming yarn treatment is an effective method for improving the properties of cotton yarns. However, the improvement effect varies under different twist factors. In actual production, an appropriate twist factor and steaming treatment process parameters should be selected based on the yarn’s usage and performance requirements to achieve the best performance improvement effect.

Author Contributions

W.Z. is the first author of this article. He participated in the experimental testing, writing and revision of this article. B.C. sorted and analyzed the data. K.L., as the corre-sponding author, conceived the theoretical framework of this article and revised and polished it. R.Z. was involved in the revision process of this article during the review stage. All authors have read and agreed to the published version of the manuscript.

Funding

The study was financially supported from the National Key Research and Development Program of China (No.2022YFB3805800), the National Natural Science Foundation of China (No.U21A2095, 52203373), and the Key Research and Development Program of Hubei Province (No.2021BAA068).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yang, K.; Tao, X.M.; Xu, B.G.; Lam, J. Structure and properties of low twist short-staple singles ring spun yarns. Text. Res. J. 2007, 77, 675–685. [Google Scholar] [CrossRef]

- Liu, X.J.; Liu, X.Y.; Su, X.Z. Theoretical study on a spinning triangle with fiber superposition. Text. Res. J. 2015, 85, 1541–1552. [Google Scholar] [CrossRef]

- Xia, Z.G.; Guo, Q.S.; Ye, W.X.; Chen, J.; Feng, S.L.; Ding, C.L. Comparative study of fiber trapping by filaments in conventional and diagonal sirofil systems. Text. Res. J. 2018, 88, 1581–1592. [Google Scholar] [CrossRef]

- Liu, K.S.; Xu, D.; Wei, J.; Ni, J.L.; Yang, S.M.; Xu, X.G.; Li, W.; Zhang, X.L.; Deng, B.; Xu, W.L. Comparative study of viscose yarn properties spun with a softening device and pressure plate. Text. Res. J. 2019, 89, 4992–5005. [Google Scholar] [CrossRef]

- Feng, J.; Xu, B.G.; Tao, X.M. A comparative study of finer conventional and modified cotton yarns and their resultant woven fabrics. Fiber Polym. 2013, 14, 1899–1905. [Google Scholar] [CrossRef]

- Atalie, D.; Gideon, R.K.; Ferede, A.; Tesinova, P.; Lenfeldova, I. Tactile comfort and low-stress mechanical properties of half-bleached knitted fabrics made from cotton yarns with different parameters. J. Nat. Fibers 2019, 18, 1699–1711. [Google Scholar] [CrossRef]

- Xia, Z.G.; Xu, W.L. A review of ring staple yarn spinning method development and its trend prediction. J. Nat. Fibers 2013, 10, 62–81. [Google Scholar] [CrossRef]

- Xia, Z.G.; Yao, C.; Zhou, J.H.; Ye, W.X.; Xu, W.L. Comparative study of cotton, ramie and wool fiber bundles’ thermal and dynamic mechanical thermal properties. Text. Res. J. 2016, 86, 856–867. [Google Scholar] [CrossRef]

- Chen, Q.H.; Au, K.F.; Yuen, C.W.M.; Yeung, K.W. Effects of yarn and knitting parameters on the spirality of plain knitted wool fabrics. Text. Res. J. 2003, 73, 421–426. [Google Scholar] [CrossRef]

- Pavlović, Ž.; Vrljičak, Z. Comparing double jersey knitted fabrics made of Tencel and modal yarns, spun by different spinning methods. J. Eng. Fibers Fabr. 2020, 15, 1–15. [Google Scholar] [CrossRef]

- Murrells, C.M.; Xu, B.G.; Tao, X.M. An investigation of methodology and apparatus to assess twist liveliness of spun yarns. Fiber Polym. 2011, 12, 679. [Google Scholar] [CrossRef]

- Hristina, K.; Radostina, A. False-twister as a yarn formation factor in wrap spinning. Text. Res. J. 2013, 83, 1926–1935. [Google Scholar] [CrossRef]

- Rong, Y.; Tao, X.M.; Xu, B.G. Variation of false twist on spinning process stability and resultant yarn properties in a modified ring spinning frame. Text. Res. J. 2017, 88, 1876–1892. [Google Scholar] [CrossRef]

- Rong, Y.; Tao, X.M.; Xu, B.G. Yarn and fabric properties in a modified ring spinning system considering the effect of the friction surface of the false-twister. Text. Res. J. 2019, 90, 572–580. [Google Scholar] [CrossRef]

- Esin, S.; Osman, B.; Münevver, E.A. Effect of filament fineness on composite yarn residual torque. Autex Res. J. 2018, 18, 7–12. [Google Scholar] [CrossRef]

- Chen, Q.H.; Au, K.F.; Yuen, C.W.M.; Yeung, K.W. Relaxation shrinkage characteristics of steam-ironed plain knitted wool fabrics. Text. Res. J. 2002, 72, 463–467. [Google Scholar] [CrossRef]

- Wickramasinghe, G.L.D.; Foster, P.W. Investigation of the use of steam for spun-like textured yarn manufacturing: Effect of fluid pressure on yarn properties. J. Text. Inst. 2015, 106, 187–196. [Google Scholar] [CrossRef]

- Sibel, Ş.; Özcan, Ö. The effects of tandem and conventional vacuum steaming methods on the properties of yarns. Text. Res. J. 2012, 82, 183–194. [Google Scholar] [CrossRef]

- Sibel, Ş.; Özcan, Ö. The Effect of Vacuum Steaming Processes on Physical and Dyeability Properties of Polyamide 6 Yarns. Text. Res. J. 2010, 80, 1531–1539. [Google Scholar] [CrossRef]

- Sibel, Ş.; Özcan, Ö. Effects of vacuum steaming processes on the properties of continuous and staple polyester yarns. Text. Res. J. 2015, 85, 1247–1257. [Google Scholar] [CrossRef]

- Sharma, I.C.; Gupta, N.K.; Agarwal, B.R.; Patnaik, N.R. Effect of twist factor and stitch length of open-end spun cotton yarn on properties of rib knitted fabrics. Text. Res. J. 1987, 57, 73–81. [Google Scholar] [CrossRef]

- He, J.; Xu, D.; Li, J.; Li, L.; Li, W.; Cui, W.; Liu, K. Highly efficient extraction of large molecular-weight keratin from wool in a water/ethanol co-solvent. Tex. Res. J. 2020, 90, 1084–1093. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).