Abstract

Due to the large amount of plastic waste that is currently produced, the demand for ecological solutions to this situation has been growing. Many research studies in recent years have focused on polylactic acid (PLA) as a biodegradable material made from renewable resources. The individual components of biodegradable materials should comply with the EN 13432 standard, which defines the properties of a “compostable” material. Careful selection of dyes and pigments is therefore important in terms of maintaining the biodegradability of the finished products. In this article, we focus on evaluating the flow properties of color masterbatches modified with inorganic biodegradable pigments. Two types of PLA were used as polymer pigment carriers, and titanium dioxide, carbon black, and two iron oxides were used as inorganic pigments. We monitored the effect of the type and concentration of pigments on the processability and rheological properties of the prepared color PLA masterbatches. The capillary viscometer and rotary rheoviscometer were used to determine rheological properties. The flow properties of color masterbatches containing 1 and 3 wt.% inorganic pigments with two types of pure polymers, PLA6100 and PLA175, were compared. We found that the color PLA masterbatches had good processability and satisfactory rheological properties, and therefore they are usable for further processing.

1. Introduction

Polymers, due to their diversity of structure and molecular weight, including their distribution, different polarity, and existence of intra- and intermolecular interactions, represent materials with great variability of properties from the point of view of rheology. The rheological characterization of polymer melts is of great importance in polymer processing for several reasons. Rheological measurements are excellent tools for process optimization and process troubleshooting. They are usually more sensitive and easier than other methods of characterization, and they provide significant insight into polymer behavior. Rheological measurements can be used to identify or differentiate various polymer grades [1,2].

The basic physical quantity is viscosity, which represents the material’s internal resistance to flow caused by external forces. The viscosity η we can define by Newton’s Law of viscosity (1) as the ratio of shear stress τ and the shear rate .

Polymers have, as a rule, a visco-elastic character, which means that the action of external forces causes permanent deformation (where the viscosity component is applied) and reversible deformation (where the elastic component is applied) [3]. Shear stress and shear rate are the main factors that determine the viscosity of the polymer melt. Other factors affecting the viscosity of polymers are temperature, pressure, molecular weight and its distribution, the structure of the polymer, and the presence of additives in the polymer (fillers, plasticizers, and modifiers).

From the point of view of the needs of individual polymer processing technologies, the flow curve (the dependence of the shear stress on the shear rate) represents complex information about the behavior of the polymer during its processing.

The response of a material to an imposed sinusoidal stress or strain can be evaluated by dynamic measurements using a parallel plate or cone-and-plate instrument. A perfectly elastic material would develop stress that would be in-phase with the strain because stress τ = modulus G × strain γ. For polymeric liquids whose behavior is partly viscous and partly elastic (viscoelastic), we can define G′ as the storage modulus (elastic part) and G″ as the loss modulus (viscous part). Further, we can define the dynamic viscosity η′ and the complex viscosity η* [1].

Most polymer materials used in practice are not pure polymers; they contain various additives, e.g., pigments, fillers, stabilizers, and plasticizers, or they are formed by a mixture of several polymers. Additives, which are in the form of solid particles, are dispersed in the polymer matrix during the mixing process, creating a polymer–solid dispersion system. These additives affect the rheological parameters of the polymers during mixing and processing as well as the properties of the final product [4,5,6,7].

Polylactic acid (PLA) is considered a suitable substitute for nonbiodegradable petroleum-based polymers. PLA exhibits several disadvantages that reduce its applicability and widespread commercialization [8,9]. The major shortcomings of PLA that negatively influence its other properties are slow crystallization kinetics, low melt strength, and brittleness and low toughness, which originate from its higher glass transition temperature [10]. The improvement of rheological and viscoelastic properties of PLA is of great importance as it enhances melt strength.

In the 1990s, more detailed research on PLA, especially its rheology, began. Numerous works on the study of PLA and its rheological behavior were published by Dorgan and colleagues [11,12,13,14,15,16,17]. Numerous experiments were focused to modify the rheological and viscoelastic properties of PLA, for example, by increasing the molecular weight of PLA [18], changing the content of D-lactide in PLA molecules [13,16,19,20], chain branching [11,16,21], controlling PLA crystallization [22], blending with other polymers [23,24,25,26,27,28,29,30], or incorporating micro-/nano-size particles and fillers [31,32,33,34,35,36,37,38,39]. Othman et al. [40,41] demonstrated the linear relationship between viscosity and molecular weight. Chile et al. [42] focused their study on the PLA with various tacticities and evaluated their thermal and rheological behaviors. The thermorheological and mechanical properties of PLAs and their blends and copolymers were investigated in the work of Othman, Xu et al. [43]. The study of Yang and Du [44] investigated the rheological, thermal, and mechanical properties of low- and high-molecular-weight polylactic acids. The rheological properties of semicrystalline and amorphous forms of PLA influence its processability. Fang and Hanna [22] analyzed PLA resins at various temperatures and shear rates. The semicrystalline PLA has a higher viscosity than amorphous PLA, under the same processing conditions, due to the difference in micromolecular structure of PLA.

Besides the advantages, PLA also shows drawbacks that limit its production and application [45,46]. The low glass transition temperature Tg (50–60 °C) and slow crystallization rate limit the usage of PLA only at relatively low service temperatures [47]. The researchers have sought to improve the negative properties of PLA in several ways. One of the methods is to develop copolymers or blends of PLA with other polymers such as poly(butylene adipate-co-terephthalate) PBAT [23], polycaprolactone PCL [24], polyhydroxybutyrate-co-valerate PHBV [25], acrylonitrile-butadiene-styrene ABS [26,27], polypropylene PP [28], polystyrene PS [29,30], etc.

The binary blends of PLA with synthetic/noncompostable polymers have also been explored because the development of such partial bioblends could be environmentally beneficial. The PLA/LDPE (low-density polyethylene) blends exhibited shear-thinning behavior at melt rheology measurements [48,49]. The various screw configurations of a twin-screw extruder can influence the rheological properties of PLA/LDPE blends [50,51].

The incorporation of nanoparticles, such as clay, TiO2, ZnO, SiO2, carbon black (CB), carbon nanotubes (CNTs), cellulose nanocrystals (CNCs), graphene or graphite, etc. [31,32,33,34,35,36,37,38,39], to the PLA matrix is a significant solution for the various problems of PLA because these agents can support the nucleation or increase the growth rate of spherical crystals [52,53]. The effects of nanoclay, its concentration, and localization on the rheology and properties of PLA blends were explored [54,55,56,57,58,59]. The positive effect of CB and CNT on viscosity, melt thermal stability, increasing crystallization rate, and electrical conductivity has been confirmed in several works [60,61,62,63,64,65,66,67,68,69].

Biodegradable plastics are increasingly used as daily consumption products in a broad range of applications, so the visual aspect of these objects, specifically their color, also needs to be addressed. Colorants for plastics include dyes, organic pigments, and inorganic pigments. Dyes are organic chemicals that are soluble in polymers and provide strong and transparent color. Pigments can be organic or inorganic particles that are insoluble in polymers [70]. The dyeing of polylactic acid has not yet been explored in detail, although it is similar, in many aspects, to conventional polyesters.

The water-soluble dyes, which can fix themselves to the fiber structure, are usually used for the dyeing of produced fibers, yarns, and textiles. This process is called dyeing from the bath. Since PLA is a polyester, the disperse dyes are suitable candidates for dyeing from the bath. Due to possible thermal degradation of PLA, the dyeing process takes place at lower temperatures, which results in poor exhaustion of disperse dyes, low egalization, and inefficiency of the process [71,72,73].

In addition, the biodegradability of PLA-based products is also important, which needs to be preserved and given due attention. Therefore, it is necessary to search for ecological alternatives for dyeing and to investigate dyeing with various types of natural dyes. Several works have investigated the possibilities of applying various natural dyes, derived, for example, from turmeric rhizomes, garcinia barks, rhubarb rhizomessappan and catechu barks, marigold petals or indigo, to PLA fabrics [74,75]. Dyeing PLA with natural dyes has shown partial success in terms of available color range and colorfastness [76].

Coloring in the mass is the more advantageous procedure from a technological, ecological, and economic point of view. In this process, the dyes are used in the form of powders, pastes or most often as color concentrates-masterbatches. Masterbatches are usually composed of the following components: polymer carrier, pigment, and compatibilizer dispersant. The carrier of the pigment in masterbatch is a polymer identical to the polymer for which the concentrate is assigned.

It should be mentioned that incorporating additives into PLA can compromise its biodegradability. For this reason, to preserve the biodegradability of the final PLA products, it is necessary to use additives that are also biodegradable. In addition to a biodegradable polymer carrier, it also requires a careful selection of pigments that comply with the European standard EN 13432 [77]. This standard defines the properties of material to be considered biodegradable, meaning that it can be processed through organic recovery (composting and anaerobic digestion). Inorganic pigments like TiO2, carbon black, or iron oxides meet these conditions. However, coloring in the mass, using biodegradable pigments, is still an underexplored area in PLA research [78], and the problem remains the small color range of such products. Natural organic pigments, prepared from plant and animal dyes, have a broad range of colors, but they have low thermo- and photostability [79,80].

In this work, the processing and rheological properties of biodegradable color masterbatches based on PLA were investigated. The influence of inorganic pigments and their concentration on the flow properties of color masterbatches was evaluated. Inorganic pigments were selected to maintain the biodegradability of the resulting products made from PLA and PLA color masterbatches. The rheological properties of the prepared PLA color masterbatches need to be known from the point of view of their further technological processing.

2. Materials and Methods

2.1. Materials

2.1.1. Polymers

Two types of polymers were used for preparation of color masterbatches: polylactic acid Ingeo I6100D (PLA6100) and polylactic acid LUMINY L175 (PLA175).

PLA6100 is a bio-based thermoplastic fiber-grade resin available in pellet form and designed for a broad range of fiber products. It has the following characteristics: melt flow index MFI = 24 g/10 min at 210 °C, glass transition temperature Tg = 55–60 °C, and melt temperature Tm = 165–180 °C (produced by NatureWork, Plymouth, MN, USA).

PLA175 is a high heat and high viscosity biobased homopolymer suitable for film extrusion, thermoforming or fiber spinning. It has the following characteristics: melt flow index MFI = 8 g/10 min at 210 °C, glass transition temperature Tg = 55–60 °C and melt temperature Tm = 175 °C (produced by Total Corbion, Gorinchem, The Netherlands).

2.1.2. Inorganic Pigments

White, black, and two types of red pigments were used for the addition of color PLA masterbatches.

Titanium dioxide PRETIOX AV01SF (Ti) is a universal, ultra-fine milled anatase TiO2, without surface treatment, possessing a high degree of whiteness and dispersibility. Its primary particle size (TEM) is 21 nm, Tm = 1850 °C, CAS 13463-67-7 (produced by Precheza a.s., Prerov, Czech Republic).

Carbon black Printex Alpha (PXA) is fine black powder with a high specific area and the following characteristics: average primary particle size 20 nm, Tm > 3000 °C, CAS 1333-86-4, (produced by Orion Engineered Carbons GmbH, Frankfurt, Germany).

Iron oxide Fepren TP 303 (Fe303) and Fepren TP 200 (Fe200) are fine dry-milled pigments with very high tinting strength, hiding power, and good particle size distribution. Particle size < 50 nm (BET), Tm > 1565 °C (both produced by Precheza a.s., Prerov, Czech Republic).

2.1.3. Dispersing Agent

Silicone oil V350 (produced by Azelis Slovakia, s.r.o., Bratislava, Slovakia) was used to ensure higher adhesion of pigments to the polymer carrier and better disintegration of pigment aggregates during dispersion.

2.2. Preparation of Color PLA Masterbatches

Before processing, the granules of PLA were dried in a laboratory oven at 60 °C for 3 h. The laboratory twin-screw extruder WP ZDSK (ø 28 mm) was used for the preparation of color PLA masterbatches in the temperature range of 180–210 °C. The prepared color masterbatches contained 1 or 3 wt.% of inorganic pigments. The materials’ composition and ingredients’ content of color masterbatches are presented in Table 1.

Table 1.

Composition of the color PLA masterbatches.

2.3. Methods

2.3.1. Processability Properties

The Dynisco Kayness capillary rheoviscometer was used for evaluation of the mass flow rate (MFR) and viscosity (η) of PLA pure polymers and color PLA masterbatches according to Standard STN EN ISO 1133. The conditions of measurements were as follows: temperature 210 °C and load 2.16 kg. The samples were dried at 70 °C for 2 h. The values of MFR, viscosity, and their coefficients of variation (cv) were determined from 10 measurements.

2.3.2. Rheological Properties

The rheological behaviors of the PLA polymers, as well as color PLA masterbatches, were measured using two types of viscosimeters:

- Rotary rheoviscosimeter Physica MCR 101 (Anton Paar, Graz, Austria) with parallel plate geometry (diameter of 25 mm and gap of 1 mm). The conditions of measurement: temperature 190 °C, air atmosphere, at 1% strain from 0.1 to 100 rad/s.

- Capillary viscosimeter GÖTTFERT RG20 with a circular diameter (L/D = 30/1; diameter of piston 15 mm). The conditions of measurement: temperature 190 °C, air atmosphere, shear speeds in the range of 90–4500 s−1 with preheating for 5 min.

3. Results and Discussion

In the experimental work, samples of PLA masterbatches containing four types of inorganic pigments (Ti, PXA, Fe303, and Fe200) were prepared with concentrations of each pigment of 1 and 3 wt.%. At the same time, to prevent agglomeration of pigment particles, dispersant V350 was used in the preparation of color masterbatches. For the color masterbatches with pigment content of 1 wt.%, dispersant was used in an amount of 0.3 wt.%, and for color masterbatches with pigment content of 3 wt.%, dispersant was used in an amount of 0.6 wt.% (Table 1). The dispersant forms the smallest proportion in color masterbatches but has a significant impact on the pigment dispersion process. It acts primarily as a surface-active substance in a non-aqueous environment, thereby ensuring the wettability of the pigment surface and higher adhesion of the pigments to the polymer carrier. In addition, it helps disintegration of aggregates during dispersion and stabilizes the degree of pigment dispersion. Dispersants affect the structure of pigment dispersions and also the rheological properties of the dispersions.

Two types of commercially available polymers were selected as polymer carriers (polymer matrix) in the preparation of biodegradable inorganic pigments’ masterbatches: PLA6100 and PLA175. These two types of PLA have different crystalline and amorphous proportions, based on which they also differ in flow properties (flow index, viscosity), which were studied using rheological measurements.

Rheological measurements of polymer melts allow obtaining important information about their behavior under conditions of shear and elongational flow, from which their processing conditions can be derived.

By analyzing the rheological properties of multicomponent systems, it is possible to obtain information about the mutual interactions of the components, agglomeration and disintegration of solid particles in the system, as well as the orientation of asymmetric particles during melt flow. The structure and properties of such polymer systems are determined by the properties of the individual components, the composition of the mixture, the size and orientation of the particles of the dispersed phase, and their mutual interactions. From the above, it follows that the study of the rheological properties of color dispersions of solid particles in polymers provides information about the flow properties of polymer melts, which are related to their processability.

The flow of a polymer melt is characterized mainly by viscosity η. Given that polymer melts are non-Newtonian viscoelastic fluids, viscosity characterizes only the plastic component of melt flow. The elasticity of melts is expressed exactly by the value of the first difference in normal stresses or deformation of the melt after extrusion. Another important parameter is the power law exponent n, which characterizes the deviation of the polymer melt from the Newtonian flow. Fiber-forming polymers are predominantly characterized as non-Newtonian viscoelastic fluids with an exponent value n ≤ 1.0.

First, melt flow index measurements of polymers and color masterbatches were performed. Melt flow index (MFI) is a standardized test method (STN EN ISO 1133) that indicates the rate of extrusion of a molten resin through a die of specified length and diameter under prescribed conditions of temperature, load and piston position in the barrel of an extrusion plastometer, the rate being determined as the mass (melt mass flow rate MFR in g/10 min) or volume (melt volume-flow rate MVR in cm3/10 min) extruded over a specified time.

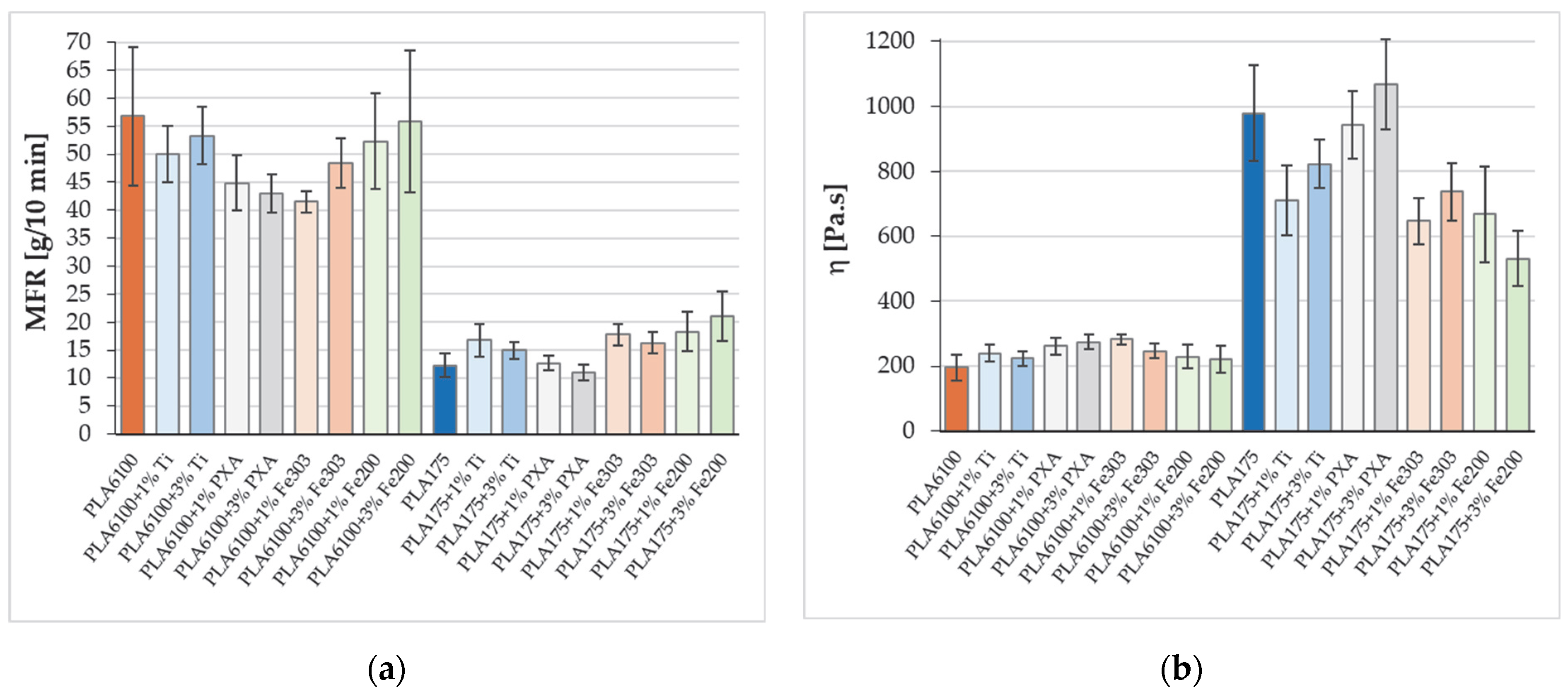

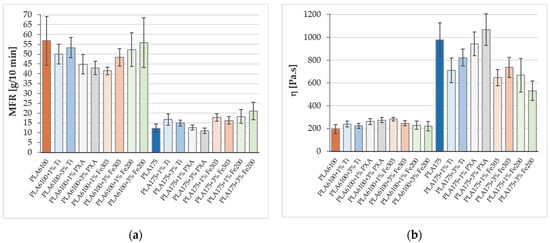

Based on the determination of the mass flow rate (MFR) of pure polymers and color masterbatches, it was found that all four inorganic pigments influenced the MFR value of PLA6100 masterbatches minimally compared to the MFR value of pure PLA6100 polymer (Figure 1a). Only for PLA6100 masterbatches containing 3 wt.% PXA and 1wt.% Fe303, the decrease in MFR was observed in comparison to pure PLA6100. Simultaneously, the viscosity of these color masterbatches increased compared to pure PLA6100 (Figure 1b).

Figure 1.

The dependence of (a) mass flow rate and (b) viscosity on the composition of the samples.

Color masterbatches based on PLA175 containing Ti and PXA pigments showed comparable MFR values compared to pure PLA175 (Figure 1a). The MFR values for PLA175 masterbatches containing Fe303 and Fe200 pigments were higher in comparison to pure PLA175 (Figure 1a). At the same time, these masterbatches showed a lower viscosity compared to pure PLA175 as well as the other color masterbatches (Figure 1b).

The influence of the four types of inorganic pigments (Ti, PXA, Fe303 and Fe200) and their concentration (1 and 3 wt.%) on the rheological properties of color PLA masterbatches was also evaluated based on flow curves constructed from the viscosity on shear rate dependences.

The rheological properties (viscosity, shear stress and power law exponent) of polymers as well as color concentrates were determined using a GÖTTFERT RG20 capillary viscometer and a Physica MCR 101 rotational rheoviscosimeter with plate/plate geometry.

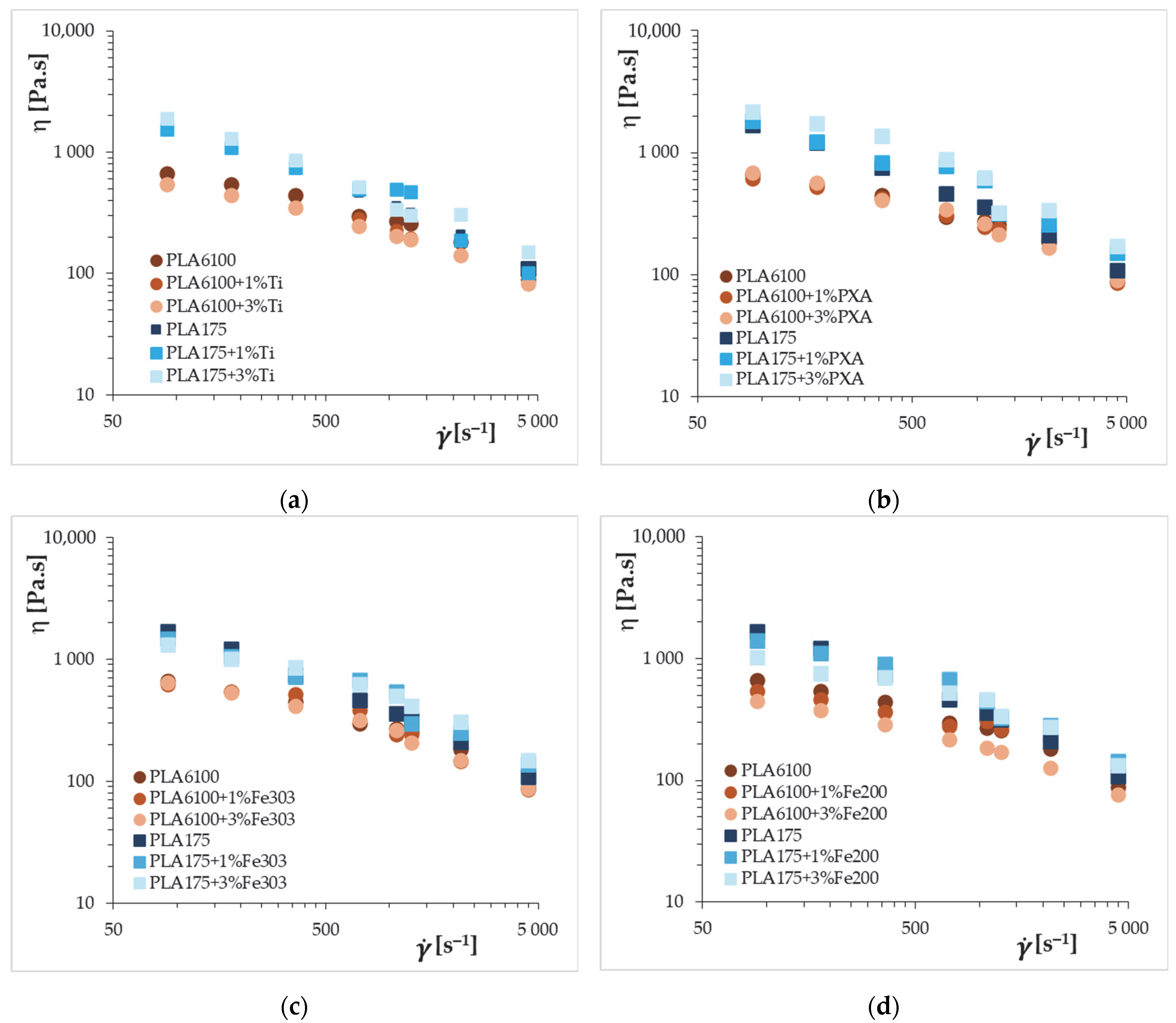

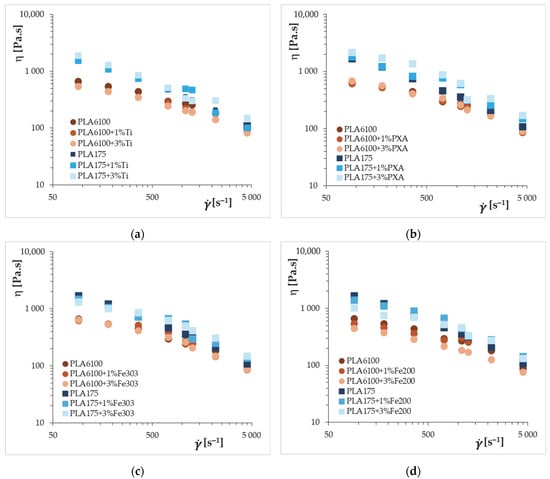

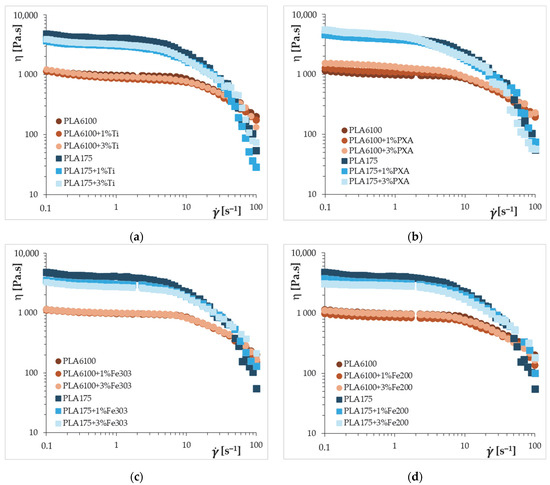

The dependences of viscosity on shear rate (in logarithmic scale) obtained from a capillary viscometer for individual types of PLA, as well as color PLA masterbatches, are shown in Figure 2a–d.

Figure 2.

Dependence of viscosity η on shear rate (in logarithmic scale) for PLA and color PLA masterbatches with 1 and 3 wt.% content of inorganic pigments: (a) Ti, (b) PXA, (c) Fe303 and (d) Fe200. Data obtained from the capillary viscosimeter.

The flow curves in Figure 2a–d show differences in the rheological behavior of color masterbatches depending on the polymer carrier used.

Color masterbatches based on PLA175 achieved higher values of viscosity compared to masterbatches based on PLA6100 polymer carrier. This results from the nature of the specific type of PLA, which differs in flow index values and the proportion of crystalline and amorphous phases. The MFI value declared by the producer for PLA175 is 8 g/10 min, and for PLA6100 is MFI = 24 g/10 min. It is known that the higher the MFI value, the lower the melt viscosity.

The difference in values of viscosity for an individual type of polymer was more pronounced at lower shear rates.

Each type of inorganic pigment affected the flow properties of color PLA masterbatches slightly differently, also depending on the type of polymer carrier.

In masterbatches based on PLA6100 polymer carrier, the effect of Ti pigment was manifested by a decrease in viscosity (~20%) across the entire shear rate range (Figure 2a).

The influence of both pigments, PXA and Fe303 (1 and 3 wt.%), results in only minimal deviations (<10%) from the viscosity of pure PLA6100 (Figure 2b,c).

The Fe200 pigment, at a concentration of 1wt.%, caused a decrease (<20%) in the viscosity of the color masterbatches (at shear rate range 4500–1080 s−1), compared to pure PLA6100. At a pigment content of 3 wt.% Fe200, there is an increase (~30%) in the viscosity of the color PLA masterbatch compared to pure PLA6100 (Figure 2d), throughout the shear rate range.

Pure PLA175, as well as color masterbatches based on PLA175, had higher viscosity than pure PLA6100 and color masterbatches based on PLA6100, mainly as a result of the lower MFI value of PLA175 (8 g/10 min) compared to PLA6100 (24 g/10 min).

The influence of pigments and their concentration on the rheological behavior of color masterbatches based on PLA175 was manifested individually.

The values of viscosity of color PLA masterbatches containing Ti pigment were very similar to the viscosity values of pure PLA175. At medium shear rate values (around 1000 s−1), there was an increase in the viscosity (>30%) of the color PLA masterbatch containing 1 wt.% Ti pigment (Figure 2a).

The PXA pigment caused an increase in the viscosity (20–80%) of color masterbatches based on PLA175 throughout the shear rate range, regardless of the pigment concentration in the masterbatch (Figure 2b).

The inorganic pigments based on iron oxides Fe303 and Fe200 increased the viscosity (~30%) of color PLA175 masterbatches, especially at higher shear rates (above 500 s−1), regardless of the pigment concentration (Figure 2c,d).

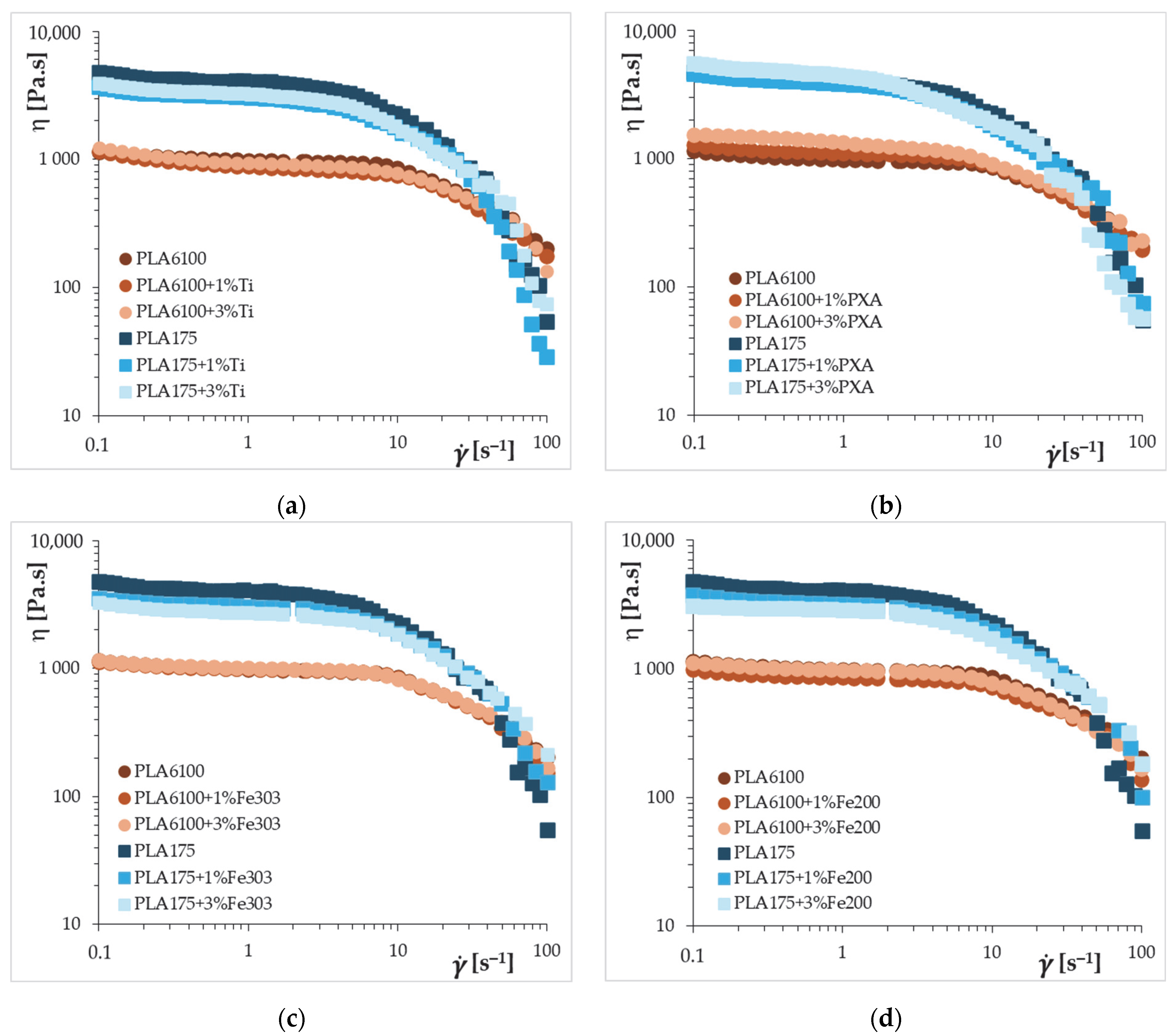

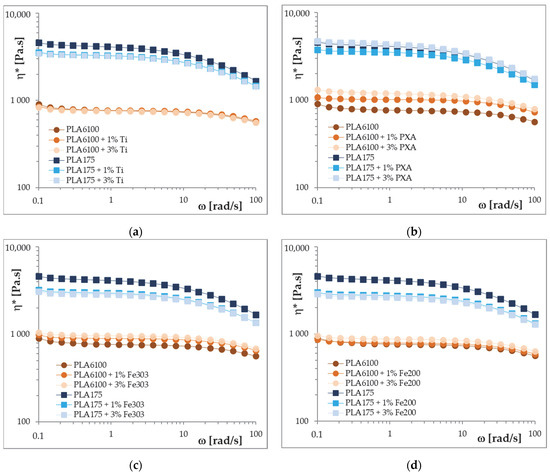

Figure 3 shows the dependencies of viscosity on shear rate (in logarithmic scale) of color PLA masterbatches with content of 1 and 3 wt.% of inorganic pigments (Ti, PXA, Fe303 and Fe200), which were measured on a rotary rheoviscometer with plate/plate geometry at a temperature of 190 °C. These measurements also showed a difference in the viscosity of individual masterbatches depending on the type of polymer carrier due to the different MFI of PLA6100 and PLA175 polymers.

Figure 3.

Dependence of viscosity η on shear rate (in logarithmic scale) for PLA and color PLA masterbatches with 1 and 3 wt.% content of inorganic pigments: (a) Ti, (b) PXA, (c) Fe303 and (d) Fe200. Data obtained from the rotary viscosimeter.

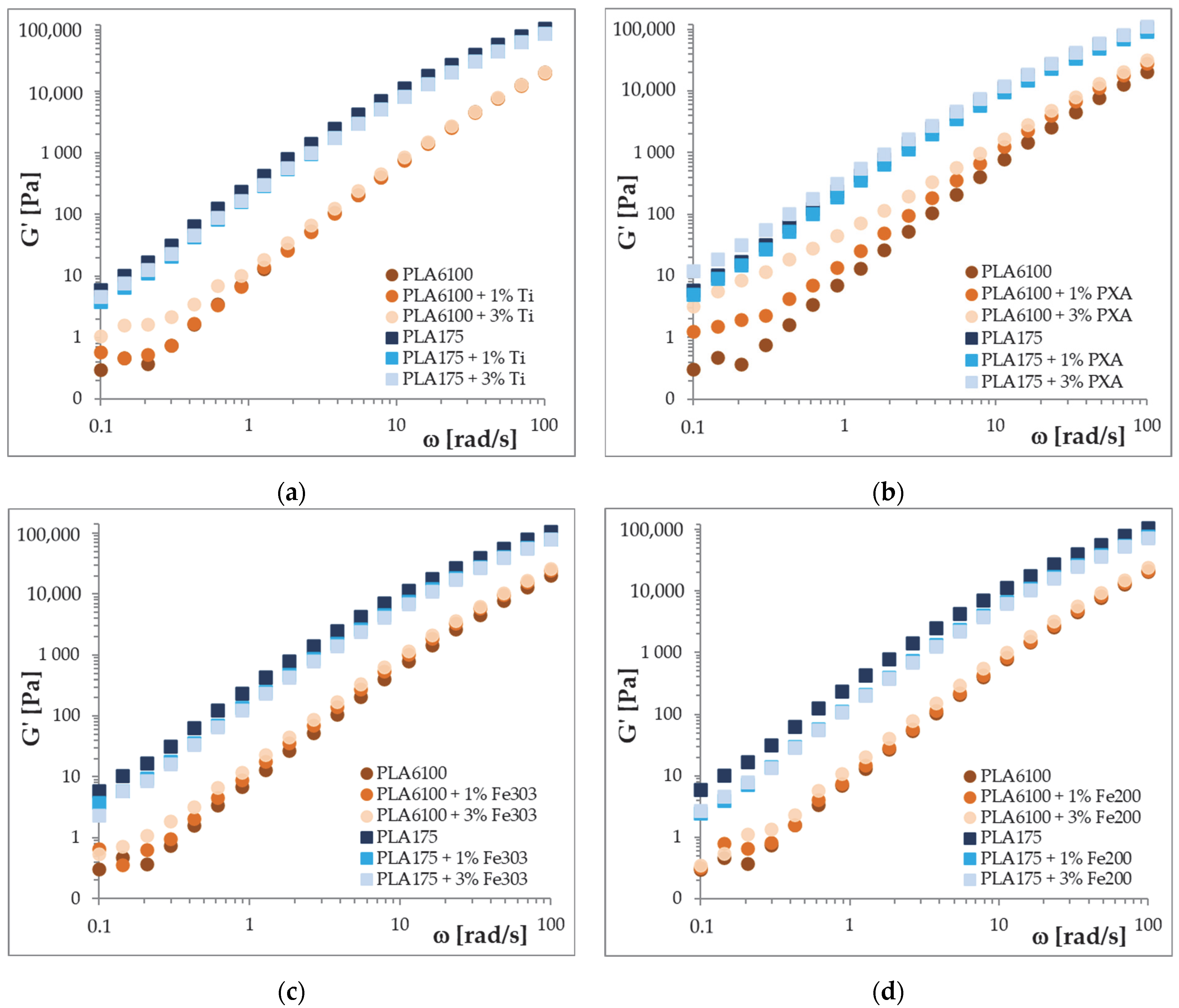

By comparing color PLA6100 masterbatches and color PLA175 masterbatches with the content of inorganic pigment Ti (Figure 3a), it was observed different rheological behavior of these melts. The viscosity of color PLA6100 masterbatches with pigment Ti (for both concentrations of pigment, 1 and 3 wt.%) changed only minimally (<10%) compared to the pure polymer carrier PLA6100. For masterbatches based on PLA175, we observed a decrease in viscosity (~20%) in color masterbatches with Ti pigment content of 1 wt.%, as well as for masterbatches with a Ti pigment content of 3 wt.% (Figure 3a).

When comparing pure PLA6100 with color PLA6100 masterbatches with 1 and 3 wt.% inorganic pigment PXA content, we observed an increase in viscosity by adding the inorganic pigment PXA (Figure 3b). In this case, the influence of the higher concentration of PXA pigment (3 wt.%) on the increased viscosity values (30–40%) was evident. Masterbatch with content of PXA pigment of 1 wt.% showed an increase in viscosity only about 10%.

In Figure 3b, we saw, at shear rates up to 1 s−1, an increase in the viscosity (~15%) of the color PLA175 masterbatch with a content of inorganic pigment PXA of 3 wt.%. While the viscosity of the color PLA175 masterbatch with a content of 1 wt.% PXA is comparable to the viscosity of pure PLA175 (Δη < 5%). At shear rates 1–10 s−1, the viscosities of color PLA175/PXA masterbatches decrease (~20%) compared to pure PLA175.

Addition of Fe303 and Fe200 pigments, with both concentrations of pigment, 1 and 3 wt.%, caused a minimal difference in the viscosity (~2%) when comparing the color PLA6100 masterbatches and pure PLA6100 (Figure 3c).

In the masterbatches based on PLA175, the addition of 1 and 3 wt.% of Fe303 and Fe200 pigments resulted in a decrease in viscosity (30–80%) compared to pure PLA175 (Figure 3c,d).

Several factors (e.g., size and shape of pigment particles, different chemical structure of pigments, or intermolecular interactions between pigment particles) could influence the increase in viscosity of colored PLA masterbatches containing inorganic pigment PXA in comparison to other pigments (Ti, Fe). We can assume that with increased content of PXA pigment, its dispersibility in the PLA polymer matrix worsens, also depending on the type of polymer carrier. The inorganic pigment particles of PXA remain aggregated, which can lead to an increase in the viscosity of the color PLA masterbatches.

The rheological properties of color PLA masterbatches were determined using a capillary viscometer and a rotational rheoviscometer with plate/plate geometry. The measurement results from both types of viscometers are comparable and give us reliable information about the rheological behavior of pure polymers as well as color PLA masterbatches. Results from the dependences in Figure 2a–d as well as Figure 3a–d, the viscosity decreases with increasing shear rate, regardless of the type of polymer carrier as well as the type of inorganic pigment.

Viscosity varied with shear rate, which is characteristic of non-Newtonian materials. The decrease in viscosity as the shear rate increases is also known as shear-thinning behavior (or pseudo-plastic behavior). The power law is the most frequently used model to express the shear-thinning behavior of polymers. From this model, the power law exponent n can be obtained [1,81], where τ is the shear stress, is the shear rate, and K is the consistency index.

The power law exponent n characterizes the deviation of the polymer melt from Newtonian flow. Many commercial polymers exhibit the values of n in the range 0.2–0.8, depending on molecular weight and chain branching of the polymer [1,82]. Fiber-forming polymers are predominantly characterized as non-Newtonian viscoelastic fluids with the exponent value n ≤ 1.0 [81].

The values of power law exponent n for pure PLA and color PLA masterbatches are listed in Table 2. All examined samples reached n values less than 1, which confirmed the pseudoplastic behavior of color PLA masterbatches.

Table 2.

The power law exponent n (on the base of values obtained) from capillary and rotary viscosimeter.

For all samples, the viscoelastic properties were also evaluated based on the evaluation of shear moduli.

The complex shear modulus consists of its real (G′) and imaginary (G″) components. The elastic modulus (storage modulus) G′ represents that part of the energy supplied during shear stress of the material, which is accumulated (stored) in the polymer material. After the removal of the external force that caused the shear deformation, this energy is quantitatively released back (elastically reversible deformation. Therefore, G′ represents the elastic component of the deformation of the tested material.

The loss modulus G″ represents that part of the energy supplied during shear stress of the material, which is consumed for its irreversible deformation, or is dissipated in the form of heat to the surroundings. This part largely represents the plastic component of the deformation of the tested material [3].

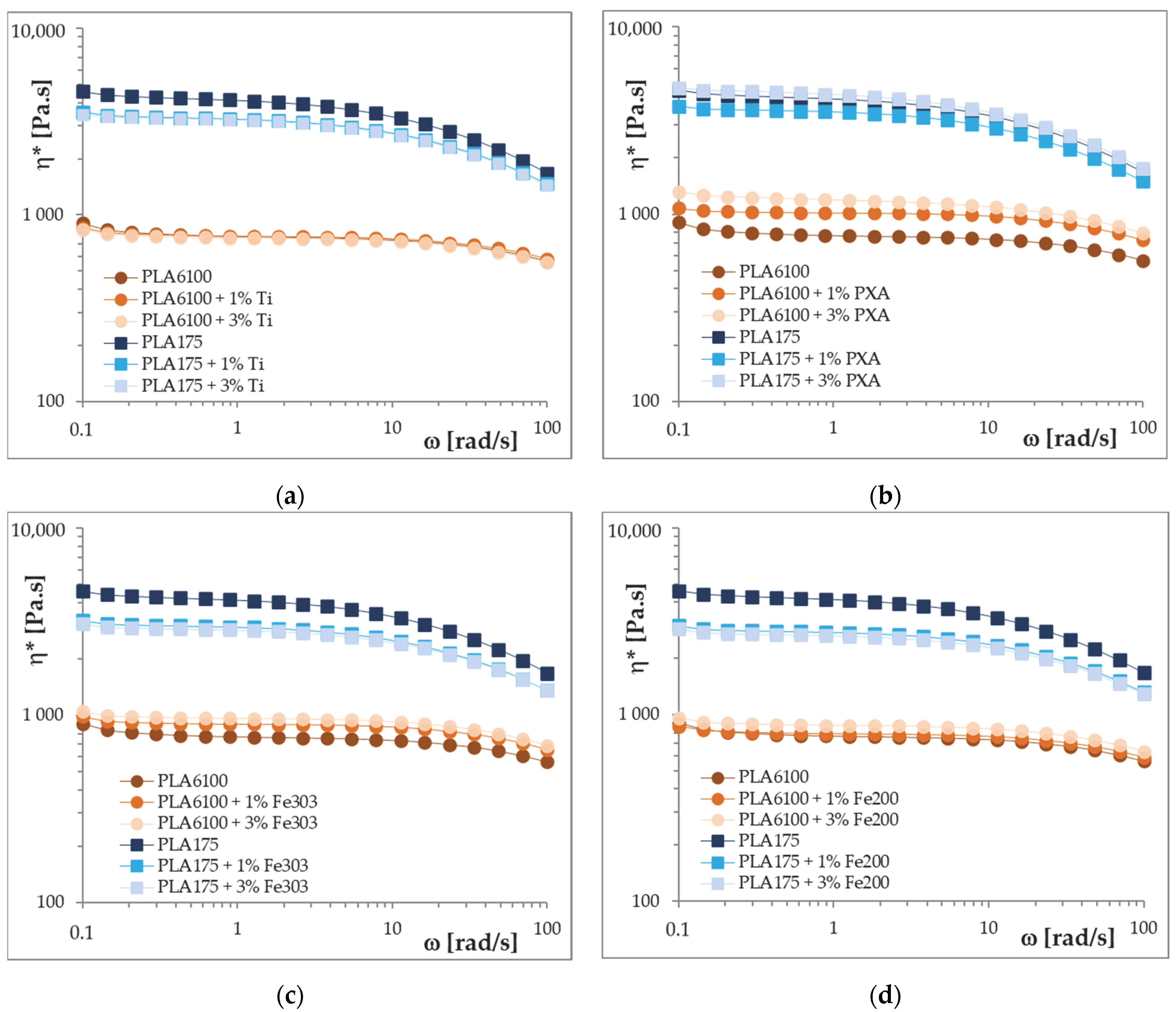

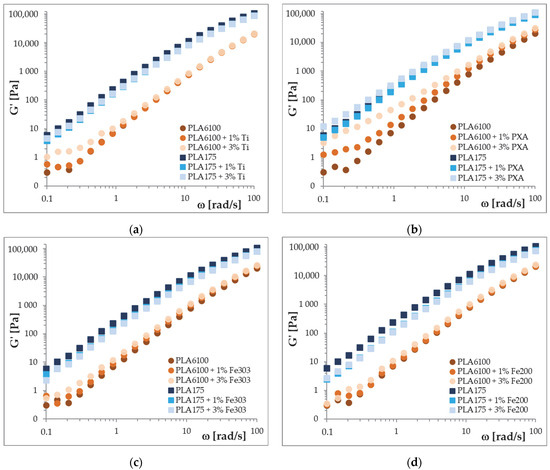

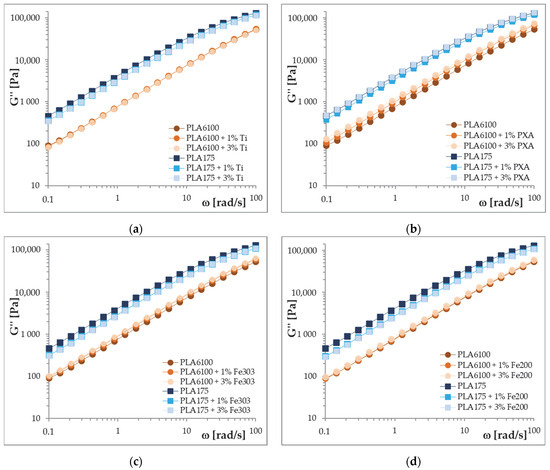

A rotary viscometer with a plate-plate measuring module was used to analyze the visco-elastic properties at 1% strain and an angular frequency of 1–100 rad/s. The dependences of the complex viscosity, elastic modulus, and loss modulus on the angular velocity of pure PLA and prepared color PLA masterbatches were obtained (Figure 4, Figure 5 and Figure 6).

Figure 4.

Dependence of complex viscosity η* on angular frequency ω (in logarithmic scale) for PLA and color PLA masterbatches with 1 and 3 wt.% content of inorganic pigments: (a) Ti, (b) PXA, (c) Fe303 and (d) Fe200.

Figure 5.

Dependence of storage modulus G′ on angular frequency ω (in logarithmic scale) for PLA and color PLA masterbatches with 1 and 3 wt.% content of inorganic pigments: (a) Ti, (b) PXA, (c) Fe303 and (d) Fe200.

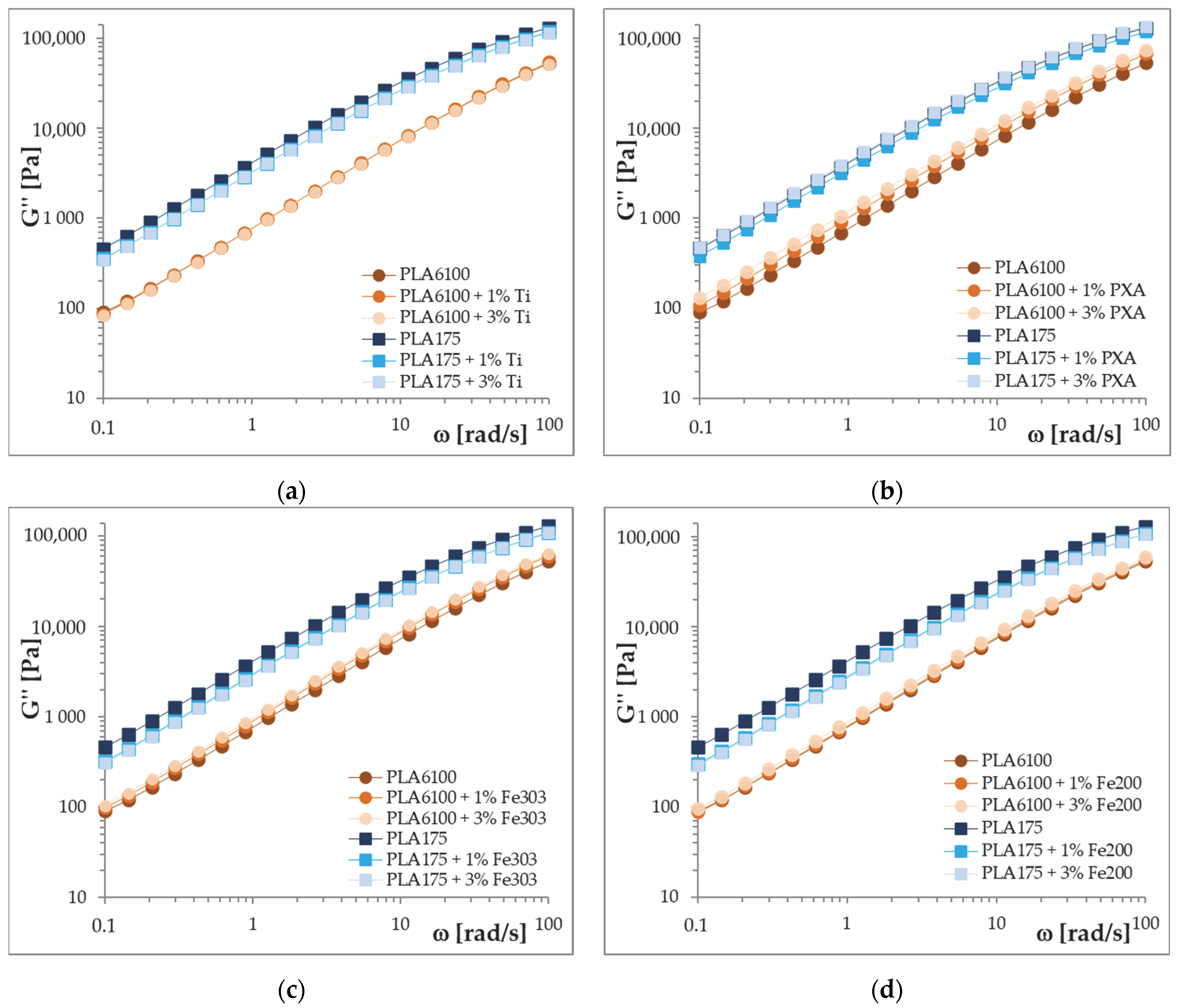

Figure 6.

Dependence of loss modulus G″ on angular frequency ω (in logarithmic scale) for PLA and color PLA masterbatches with 1 and 3 wt.% content of inorganic pigments: (a) Ti, (b) PXA, (c) Fe303 and (d) Fe200.

Figure 4 shows the complex viscosity of pure types of PLA as well as color PLA masterbatches with content of inorganic pigments.

From the dependencies, we can state an increase in complex viscosity, especially for color PLA6100 masterbatches containing PXA and Fe303 pigments compared to pure PLA6100 (Figure 4b,c). A slight increase in complex viscosity was also recorded in color PLA6100 masterbatches containing Fe200 pigment (Figure 4d). Color masterbatches based on PLA6100 with the content of pigment Ti showed no differences in complex viscosity compared to pure PLA6100 (Figure 4a).

In color masterbatches prepared from PLA175 polymer carrier, the opposite effect of the inorganic pigments content was observed. Pigments Ti, Fe303 and Fe200 caused a decrease in complex viscosity in the entire range, and the higher the pigment concentration in the masterbatch, the greater the decrease in complex viscosity (Figure 4a,c,d). In color PLA175 masterbatches containing PXA pigment, a decrease in viscosity was found at a 1 wt.% pigment concentration, and at a 3 wt.% pigment content, on the contrary, an increase in the viscosity of the concentrate compared to pure PLA175 (Figure 4b). This may be because at a higher concentration of PXA pigment, the pigment agglomerates are formed. Pigment agglomerates can worsen the dispersibility and thus negatively affect the rheological properties of the melt of the color masterbatches, especially based on a polymer carrier with higher crystallinity (PLA175).

Figure 5 and Figure 6 visualize the dynamic storage (G′) and loss (G″) moduli of pure PLA and color PLA masterbatches as a function of angular frequency. From the figures, it is concluded that these dependences are very similar to the dependences of complex viscosity shown in Figure 4a–d.

Inorganic pigments slightly increase the storage (G′) and loss (G″) moduli of color PLA6100 masterbatches compared to pure PLA6100 polymer carriers. On the contrary, in color masterbatches based on PLA175, the effect of inorganic pigments leads to a slight decrease in the storage (G′) and loss (G″) moduli compared to pure PLA175. The exception was color PLA175/PXA masterbatches. A slight increase in the storage (G′) and loss (G″) moduli was noticed for the color PLA175 masterbatch containing 3 wt.% PXA. A slight decrease in the storage (G′) and loss (G″) moduli was noticed for the color PLA175 masterbatch containing 1 wt.% PXA (Figure 5b and Figure 6b).

The incorporation of inorganic pigments into the PLA matrix did not cause significant changes in the PLA/inorganic pigment/dispersant system, as can be seen in Figure 4, Figure 5 and Figure 6. The shape of the curves and the flow characteristics of the color PLA masterbatches follow those of pure PLA6100 and PLA175. This means that pigment particles could not significantly modify the PLA macromolecules’ dynamics, and the level of polymer–pigment interactions was low. Since the dispersed pigment particles did not induce significant rheological changes in the system, it can therefore be assumed that the polymer matrix PLA determines the rheological behavior of color PLA masterbatches [32,83,84].

4. Conclusions

This work aimed to evaluate the possibilities of using inorganic pigments for the preparation of biodegradable color PLA masterbatches. We monitored the influence of two types of polymer carriers—PLA6100 and PLA175—as well as the effect of the type and concentration of inorganic pigments on the rheological properties of the prepared color PLA masterbatches. Four types of inorganic pigments were used—titanium dioxide, carbon black, and two types of iron oxides. Rheological properties were determined using a capillary viscometer and a rotational rheoviscometer with plate/plate geometry. Based on the rheological properties, we can subsequently assess the processability of the prepared color PLA masterbatches during their further technological processing, e.g., in the preparation of fibers or films.

Based on the data obtained, we can draw the following conclusions:

- From the evaluation of the processing and flow properties of the prepared color PLA masterbatches, we can see differences in the rheological behavior of the color masterbatches depending on the polymer carrier used.

- All four inorganic pigments influenced the MFR values of color PLA masterbatches minimally compared to the MFR values of pure PLA6100 and PLA175.

- The results of rheological properties measurements using a capillary viscometer and a rotary rheoviscometer with plate/plate geometry were comparable and gave us reliable information about the rheological behavior of pure PLA as well as color PLA masterbatches.

- From the obtained flow curves (dependence of viscosity on shear rate) as well as the dependencies of complex viscosity on angular frequency (in oscillatory measurements), we found that in color masterbatches based on PLA6100, the influence of inorganic pigments led to a certain increase in viscosity. This increase in viscosity was (more or less) significant with respect to the type and concentration of a particular inorganic pigment.

- On the contrary, in masterbatches based on PLA175, the specific type and concentration of the given pigment caused a greater or lesser decrease in viscosity compared to pure PLA175.

- A slightly different behavior was recorded only for color PLA masterbatches containing the inorganic pigment PXA, regardless of the type of polymer carrier.

- The results obtained from the evaluation of storage and loss modules confirm the previous conclusions of the influence of the polymer carrier, type, and concentration of the inorganic pigment on the rheological properties of color PLA masterbatches.

Based on the above, we can conclude that the observed changes in the rheological behavior of the prepared color PLA masterbatches compared to the rheological behavior of pure PLA (I6100 and L175) are not significant. It can therefore be assumed that the processability of the prepared color PLA masterbatches during their further technological processing will be sufficient and satisfactory. The individual components of the color masterbatches prepared in this way (polymer carrier and pigment) meet the requirements of valid ISO standards, and future products made from such concentrates will retain the status of biodegradable materials. The color PLA masterbatches prepared in this way can be subsequently used in further technological processing, e.g., in the preparation of fibers, foils, or monofilaments for 3D printers.

Author Contributions

Conceptualization, M.H. and A.U.; methodology, M.H., M.P. and Z.T.; validation, A.U., M.P. and Z.T.; formal analysis, M.H.; investigation, M.H.; resources, M.H.; data curation, M.H.; writing—original draft preparation, M.H.; writing—review and editing, A.U.; visualization, M.H.; supervision, A.U. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Slovak Research and Development Agency under contract No. APVV-21-0172.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This work was supported by the Slovak Research and Development Agency under contract No. APVV-21-0172.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vlachopoulos, J.; Polychronopoulos, N. Chapter 1 Basic Concepts in Polymer Melt Rheology and Their Importance in Processing. In Applied Polymer Rheology: Polymeric Fluids with Industrial Applications, 1st ed.; Kontopoulou, M., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 1–26. [Google Scholar] [CrossRef]

- Sangroniz, L.; Fernández, M.; Santamaria, A. Polymers and rheology: A tale of give and take. Polymer 2023, 271, 125811. [Google Scholar] [CrossRef]

- Alexy, P. Processes of Polymer Processing, (in Slovak: Procesy Spracovania Polymérov), 1st ed.; STU: Bratislava, Slovakia, 2010; pp. 5–14. [Google Scholar]

- Jain, S.; Misra, M.; Mohanty, A.K.; Ghosh, A.K. Thermal, Mechanical and Rheological Behavior of Poly(lactic acid)/Talc Composites. J. Polym. Environ. 2012, 20, 1027–1037. [Google Scholar] [CrossRef]

- Unal, H. Morphology and mechanical properties of composites based on polyamide 6 and mineral additives. Mater. Des. 2004, 25, 483–487. [Google Scholar] [CrossRef]

- Surendren, A.; Pal, A.K.; Rodriguez-Uribe, A.; Shankar, S.; Lim, L.T.; Mohanty, A.K.; Misra, M. Upcycling of post-industrial starch-based thermoplastics and their talc-filled sustainable biocomposites for single-use plastic alternative. Int. J. Biol. Macromol. 2023, 253, 126751. [Google Scholar] [CrossRef]

- Helanto, K.; Talja, R.; Rojas, O.J. Effects of talc, kaolin and calcium carbonate as fillers in biopolymer packaging materials. J. Polym. Eng. 2021, 41, 746–758. [Google Scholar] [CrossRef]

- Samantaray, P.K.; Little, A.; Haddleton, D.M.; McNally, T.; Tan, B.; Sun, Z.; Huang, W.; Ji, Y.; Wan, C. Poly(glycolic acid) (PGA): A versatile building block expanding high performance and sustainable bioplastic applications. Green Chem. 2020, 22, 4055–4081. [Google Scholar] [CrossRef]

- Samantaray, P.K.; Little, A.; Wemyss, A.M.; Iacovidou, E.; Wan, C. Design and Control of Composability in Synthetic Biopolyesters. ACS Sustain. Chem. Eng. 2021, 9, 9151–9164. [Google Scholar] [CrossRef]

- Nofar, M.; Salehiyan, R.; Ray, S.S. Rheology of poly (lactic acid)-based systems. Polym. Rev. 2019, 59, 465–509. [Google Scholar] [CrossRef]

- Dorgan, J.R.; Williams, J.S. Melt rheology of poly(lactic acid): Entanglement and chain architecture effects. J. Rheol. 1999, 43, 1141–1155. [Google Scholar] [CrossRef]

- Dorgan, J.R.; Lehermeier, H.; Mang, M. Thermal and rheological properties of commercial-grade poly (lactic acid)s. J. Polym. Environ. 2000, 8, 1–9. [Google Scholar] [CrossRef]

- Palade, L.I.; Lehermeier, H.J.; Dorgan, J.R. Melt rheology of high L-content polylactic acid. Macromolecules 2001, 34, 1384–1390. [Google Scholar] [CrossRef]

- Dorgan, J.R.; Lehermeier, H.J.; Palade, L.I.; Cicero, J. Polylactides: Properties and prospects of an environmentally benign plastic from renewable resources. Macromol. Symp. 2001, 175, 55–66. [Google Scholar] [CrossRef]

- Lehermeier, H.J.; Dorgan, J.R. Melt rheology of poly (lactic acid): Consequences of blending chain architectures. Polym. Eng. Sci. 2001, 41, 2172–2184. [Google Scholar] [CrossRef]

- Dorgan, J.R.; Janzen, J.; Clayton, M.P.; Hait, S.B.; Knauss, D.M. Melt rheology of variable L-content poly(lactic acid). J. Rheol. 2005, 49, 607–619. [Google Scholar] [CrossRef]

- Dorgan, J.R. Rheology of Poly(Lactic Acid). In Poly (Lactic Acid) Synthesis, Structures, Properties, Processing, Applications, and End of Life, 2nd ed.; Auras, R.A., Lim, L.T., Selke, S.E.M., Tsuji, H., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022; pp. 153–167. [Google Scholar] [CrossRef]

- Cooper-White, J.J.; Mackay, M.E. Rheological properties of poly(lactides). Effect of molecular weight and temperature on the viscoelasticity of poly(L-lactic acid). J. Polym. Sci. Part B Polym. Phys. 1999, 37, 1803–1814. [Google Scholar] [CrossRef]

- Hirata, M.; Kimura, Y. Thermomechanical properties of stereoblock poly(lactic acid)s with different PLLA/PDLA block compositions. Polymer 2008, 49, 2656–2661. [Google Scholar] [CrossRef]

- Rahaman, M.H.; Tsuji, H. Synthesis and Characterization of Stereo Multiblock Poly(lactic acid)s with Different Block Lengths by Melt Polycondensation of Poly(L-lactic acid)/Poly(D-lactic acid) Blends. Macromol. React. Eng. 2012, 6, 446–457. [Google Scholar] [CrossRef]

- Dealy, J.M.; Wissbrun, K.F. Melt Rheology and Its Role in Plastics Processing—Theory and Applications, 1st ed.; Van Nostrand Reinhold: New York, NY, USA, 1990; 665p. [Google Scholar] [CrossRef]

- Fang, Q.; Hanna, M.A. Rheological properties of amorphous and semicrystalline polylactic acid polymers. Ind. Crops Prod. 1999, 10, 47–53. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

- Matta, A.K.; Rao, R.U.; Suman, K.N.S.; Rambabu, V. Preparation and characterization of biodegradable PLA/PCL polymeric blends. Procedia Mater. Sci. 2014, 6, 1266–1270. [Google Scholar] [CrossRef]

- Muniyasamy, S.; Ofosu, O.; John, M.J.; Anandjiwala, R.D. Mineralization of poly(lactic acid)(PLA), poly(3-hydroxybutyrate-covalerate) (PHBV) and PLA/PHBV blend in compost and soil environments. J. Renew. Mater. 2016, 4, 133–145. [Google Scholar] [CrossRef]

- Li, Y.; Shimizu, H. Improvement in toughness of poly(L-lactide) (PLLA) through reactive blending with acrylonitrile–butadiene–styrene copolymer (ABS): Morphology and properties. Eur. Polym. J. 2009, 45, 738–746. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and PP composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. Part A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Preparation and characterization of binary and ternary blends with poly(lactic acid), polystyrene, and acrylonitrile-butadiene-styrene. J. Biomater. Nanobiotechnology 2012, 3, 405–412. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Effect of recycling on the rheological and mechanical properties of poly(lactic acid)/polystyrene polymer blend. J. Mater. Sci. 2011, 46, 3013–3019. [Google Scholar] [CrossRef]

- Keshtkar, M.; Nofar, M.; Park, C.B.; Carreau, P.J. Extruded PLA/clay nanocomposite foams blown with supercritical CO2. Polymer 2014, 55, 4077–4090. [Google Scholar] [CrossRef]

- Morici, E.; Pecoraro, G.; Carroccio, S.C.; Bruno, E.; Scarfato, P.; Filippone, G.; Dintcheva, N.T. Understanding the Effects of Adding Metal Oxides to Polylactic Acid and Polylactic Acid Blends on Mechanical and Rheological Behaviour, Wettability, and Photo-Oxidation Resistance. Polymers 2024, 16, 922. [Google Scholar] [CrossRef]

- Sánchez-Rodríguez, C.; Pamies, R.; Sanes, J.; Carrión-Vilches, F.J.; Bermúdez, M.D. Bio-based materials in tribology: New salicylate ionic liquid+ZnO nanolubricant of PLA and PLA nanocomposite. Tribol. Int. 2024, 198, 109868. [Google Scholar] [CrossRef]

- Stratiotou Efstratiadis, V.; Argyros, A.; Efthymiopoulos, P.; Maliaris, G.; Nasikas, N.K.; Michailidis, N. Utilization of Silica Filler as Reinforcement Material of Polylactic Acid (PLA) in 3D Printing Applications: Thermal, Rheological, and Mechanical Performance. Polymers 2024, 16, 1326. [Google Scholar] [CrossRef]

- Kuan, C.F.; Kuan, H.C.; Ma, C.C.M.; Chen, C.H. Mechanical and electrical properties of multi-wall carbon nanotube/poly(lactic acid) composites. J. Phys. Chem. Solids 2008, 69, 1395–1398. [Google Scholar] [CrossRef]

- Dhar, P.; Bhasney, S.M.; Kumar, A.; Katiyar, V. Acid functionalized cellulose nanocrystals and its effect on mechanical, thermal, crystallization and surfaces properties of poly (lactic acid) bionanocomposites films: A comprehensive study. Polymer 2016, 101, 75–92. [Google Scholar] [CrossRef]

- Sabzi, M.; Jiang, L.; Liu, F.; Ghasemi, I.; Atai, M. Graphene nanoplatelets as poly(lactic acid) modifier: Linear rheological behavior and electrical conductivity. J. Mater. Chem. A 2013, 1, 8253–8261. [Google Scholar] [CrossRef]

- Xu, P.; Tian, H.; Han, L.; Yang, H.; Bian, J.; Pan, H.; Zhang, H. Improved heat resistance in poly (lactic acid)/ethylene butyl methacrylate glycidyl methacrylate terpolymer blends by controlling highly filled talc particles. J. Therm. Anal. Calorim. 2022, 147, 5719–5732. [Google Scholar] [CrossRef]

- Przekop, R.E.; Kujawa, M.; Pawlak, W.; Dobrosielska, M.; Wieleba, W. Graphite modified polylactide (PLA) for 3D printed (FDM/FFF) sliding elements. Polymers 2020, 12, 1250. [Google Scholar] [CrossRef] [PubMed]

- Othman, N.; Ramírez, J.A.A.; Mehrkhodavandi, P.; Dorgan, J.R.; Hatzikiriakos, S.G. Solution and melt viscoelastic properties of controlled microstructure poly(lactide). J. Rheol. 2011, 55, 987–1005. [Google Scholar] [CrossRef]

- Othman, N.; Jazrawi, B.; Mehrkhodavandi, P.; Hatzikiriakos, S.G. Wall slip and melt rheology of poly(lactides). Rheol. Acta 2012, 51, 357–369. [Google Scholar] [CrossRef]

- Chile, L.E.; Mehrkhodavandi, P.; Hatzikiriakos, S.G. A Comparison of the Rheological and Mechanical Properties of Isotactic, Syndiotactic, and Heterotactic Poly(lactide). Macromolecules 2016, 49, 909–919. [Google Scholar] [CrossRef]

- Othman, N.; Xu, C.; Mehrkhodavandi, P.; Hatzikiriakos, S.G. Thermorheological and mechanical behavior of polylactide and its enantiomeric diblock copolymers and blends. Polymer 2012, 53, 2443–2452. [Google Scholar] [CrossRef]

- Yang, H.; Du, J. Crystallinity, Rheology, and Mechanical Properties of Low-/High-Molecular-Weight PLA Blended Systems. Molecules 2024, 29, 15. [Google Scholar] [CrossRef]

- Gupta, B.; Revagade, N.; Hilborn, J. Poly(lactic acid) fiber: An overview. Prog. Polym. Sci. 2007, 32, 455–482. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly (lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Melt rheology of poly(lactic acid)/low density polyethylene polymer blends. Adv. Chem. Eng. Sci. 2011, 1, 208–214. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Poly(lactic acid)/low density polyethylene polymer blends: Preparation and characterization. Asia-Pac. J. Chem. Eng. 2012, 7, S310–S316. [Google Scholar] [CrossRef]

- Jiang, G.; Huang, H.X.; Chen, Z.K. Rheological responses and morphology of polylactide/linear low density polyethylene blends produced by different mixing type. Polym.-Plast. Technol. Eng. 2011, 50, 1035–1039. [Google Scholar] [CrossRef]

- Balakrishnan, H.; Hassan, A.; Wahit, M.U. Mechanical, thermal, and morphological properties of polylactic acid/linear low density polyethylene blends. J. Elastomers Plast. 2010, 42, 223–239. [Google Scholar] [CrossRef]

- Huang, T.; Yang, J.; Zhang, N.; Zhang, J.; Wang, Y. Crystallization of poly(l-lactide) in the miscible poly(l-lactide)/poly(vinyl acetate) blend induced by carbon nanotubes. Polym. Bull. 2018, 75, 2641–2655. [Google Scholar] [CrossRef]

- Wang, L.; Yu, G.; Zhu, Y.; Li, C.; Li, J.; Guo, S. Fabrication of polylactide with high-content, ordered, and continuous transcrystallinity via multilayered two-dimensional interface. Mater. Des. 2021, 204, 109687–109695. [Google Scholar] [CrossRef]

- Nofar, M.; Heuzey, M.C.; Carreau, P.; Kamal, M. Effects of nanoclay and its localization on the morphology stabilization of PLA/PBAT blends under shear flow. Polymer 2016, 98, 353–364. [Google Scholar] [CrossRef]

- Eslami, H.; Kamal, M.R. Elongational rheology of biodegradable poly(lactic acid)/poly[(butylene succinate)-co-adipate] binary blends and poly(lactic acid)/poly[(butylene succinate)-co-adipate]/clay ternary nanocomposites. J. Appl. Polym. Sci. 2012, 127, 2290–2306. [Google Scholar] [CrossRef]

- D’Anna, A.; Arrigo, R.; Frache, A. Rheology, Morphology and thermal properties of a PLA/PHB/clay blend nanocomposite: The influence of process parameters. J. Polym. Environ. 2022, 30, 102–113. [Google Scholar] [CrossRef]

- Ebadi-Dehaghani, H.; Khonakdar, H.A.; Barikani, M.; Jafari, S.H.; Wagenknecht, U.; Heinrich, G. On localization of clay nanoparticles in polypropylene/poly(lactic acid) blend nanocomposites: Correlation with mechanical properties. J. Macromol. Sci. Part B Phys. 2016, 55, 344–360. [Google Scholar] [CrossRef]

- Nuñez, K.; Rosales, C.; Perera, R.; Villarreal, N.; Pastor, J.M. Poly(lactic acid)/low-density polyethylene blends and its nanocomposites based on sepiolite. Polym. Eng. Sci. 2011, 52, 988–1004. [Google Scholar] [CrossRef]

- Bitinis, N.; Verdejo, R.; Maya, E.M.; Espuche, E.; Cassagnau, P.; Lopez-Manchado, M.A. Physicochemical properties of organoclay filled polylactic acid/natural rubber blend bionanocomposites. Composites. Sci. Technol. 2012, 72, 305–313. [Google Scholar] [CrossRef]

- D’Urso, L.; Acocella, M.R.; Guerra, G.; Iozzino, V.; De Santis, F.; Pantani, R. PLA Melt Stabilization by High-Surface-Area Graphite and Carbon Black. Polymers 2018, 10, 139. [Google Scholar] [CrossRef]

- D’Urso, L.; Acocella, M.R.; De Santis, F.; Guerra, G.; Pantani, R. Poly(l-lactic acid) nucleation by alkylated carbon black. Polymer 2022, 256, 125237. [Google Scholar] [CrossRef]

- Abdalla, A.; Hamzah, H.H.; Keattch, O.; Covill, D.; Patel, B.A. Augmentation of conductive pathways in carbon black/PLA 3D-printed electrodes achieved through varying printing parameters. Electrochim. Acta 2020, 354, 136618. [Google Scholar] [CrossRef]

- Seetala, K.; Clower, W.; Wilson, C.G. Electrochemical enhancement of carbon black-infused poly(lactic acid) filament for additive manufactured electronic applications. Addit. Manuf. 2023, 61, 103283. [Google Scholar] [CrossRef]

- Fernandes-Junior, W.S.; Orzari, L.O.; Kalinke, C.; Bonacin, J.A.; Janegitz, B.C. A miniaturized additive-manufactured carbon black/PLA electrochemical sensor for pharmaceuticals detection. Talanta 2024, 275, 126154. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, S.T.; Zhou, Y.G.; Zou, J. Conductivity of PLA/PBAT blends with carbon black as a conductive filler. Mater. Lett. 2025, 378, 137592. [Google Scholar] [CrossRef]

- Silva, L.R.G.; Bertolim, L.V.; Stefano, J.S.; Bonacin, J.A.; Richter, E.M.; Munoz, R.A.A.; Janegitz, B.C. New route for the production of lab-made composite filaments based on soybean oil, polylactic acid and carbon black nanoparticles, and its application in the additive manufacturing of electrochemical sensors. Electrochim. Acta 2025, 513, 145566. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, Y.; Zhang, M.; Yu, W. Selective localization of multiwalled carbon nanotubes in poly(ε-caprolactone)/polylactide blend. Biomacromolecules 2009, 10, 417–424. [Google Scholar] [CrossRef]

- Park, D.H.; Kan, T.G.; Lee, Y.K.; Kim, W.N. Effect of multi-walled carbon nanotube dispersion on the electrical and rheological properties of poly(propylene carbonate)/poly(lactic acid)/multi-walled carbon nanotube composites. J. Mater. Sci. 2012, 48, 481–488. [Google Scholar] [CrossRef]

- Jang, M.G.; Lee, Y.K.; Kim, W.N. Influence of lactic acid-grafted multi-walled carbon nanotube (LA-g-MWCNT) on the electrical and rheological properties of polycarbonate/poly(lactic acid)/LA-g-MWCNT composites. Macromol. Res. 2015, 23, 916–923. [Google Scholar] [CrossRef]

- Markarian, J. Back-to-basics: Adding colour to plastics. Plast. Addit. Compd. 2009, 11, 12–15. [Google Scholar] [CrossRef]

- Dawson, T. Progress towards a greener textile industry. Color. Technol. 2012, 128, 1–8. [Google Scholar] [CrossRef]

- Baig, G.A. Coloration of poly(lactic acid) based textiles—A review. Polimery 2020, 65, 417–429. [Google Scholar] [CrossRef]

- Avinc, O.; Bakan, E.; Demirçalı, A.; Gedik, G.; Karcı, F. Dyeing of poly(lactic acid) fibres with synthesised novel heterocyclic disazo disperse dyes. Color. Technol. 2020, 136, 356–369. [Google Scholar] [CrossRef]

- Ujjin, S.; Jantip, S. Study on the Dyeing Properties of Poly(Lactic Acid) and Silk Yarns with Natural Dyes. Adv. Mater. Res. 2012, 486, 384–387. [Google Scholar] [CrossRef]

- Burkinshaw, S.M.; Jeong, D.S.; Chun, T.I. The coloration of poly(lactic acid) fibres with indigoid dyes: Part 2: Wash fastness. Dye. Pigment. 2013, 97, 374–387. [Google Scholar] [CrossRef]

- Hussain, T.; Tausif, M.; Ashraf, M. A review of progress in the dyeing of eco-friendly aliphatic polyester-based polylactic acid fabrics. J. Clean. Prod. 2015, 108, 476–483. [Google Scholar] [CrossRef]

- EN 13432; Certified Bioplastics, Performance in Industrial Composting. European Bioplastics Association: Berlin, Germany, 2015.

- Parra-Campos, A.; Albán-Bolaños, P.; Villada-Castillo, H.S.; Portela-Guarín, H.; Palacios, L.M.; Arboleda-Muñoz, G.A. Evaluation of a biodegradable color concentrate in bags for coffee seedlings. DYNA 2020, 87, 16. Available online: https://www.redalyc.org/articulo.oa?id=49663642004 (accessed on 12 June 2023). [CrossRef]

- Pagnan, C.S.; Mottin, A.C.; Oréfice, R.L.; Ayres, E.; Câmara, J.J.D. Annatto-colored Poly(3-hydroxybutyrate): A Comprehensive Study on Photodegradation. J. Polym. Environ. 2018, 26, 1169–1178. [Google Scholar] [CrossRef]

- Moreira, J.B.; Terra, A.L.M.; Costa, J.A.V.; de Morais, M.G. Development of pH indicator from PLA/PEO ultrafine fibers containing pigment of microalgae origin. Int. J. Biol. Macromol. 2018, 118, 1855–1862. [Google Scholar] [CrossRef] [PubMed]

- Chhabra, R.P. Non-Newtonian fluids: An introduction. In Rheology of Complex Fluids, 1st ed.; Krishnan, J.M., Deshpande, A.P., Kumar, P.B.S., Eds.; Springer: New York, NY, USA, 2010; pp. 3–34. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, X.; Ma, X.; Fang, J. Influence of carbon black on the properties of plasticized poly(lactic acid) composites. Polym. Degrad. Stab. 2008, 93, 1044–1052. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly(lactic acid)–biochar biocomposites: Effect of processing and filler content on rheological, thermal, and mechanical properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [PubMed]

- Botta, L.; Scaffaro, R.; La Mantia, F.P.; Dintcheva, N.T. Effect of different matrices and nanofillers on the rheological behavior of polymer-clay nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2009, 48, 344–355. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).