Abstract

Basalt fiber-reinforced composites are increasingly utilized in sustainable construction due to their high strength, environmental benefits, and durability. However, the long-term tensile performance of these composites in alkaline environments remains a critical concern. This study investigates the degradation performance of basalt fibers exposed to different alkaline solutions (NaOH, KOH, and Ca(OH)2) with varying concentrations (5 g/L, 15 g/L, and 30 g/L) over various exposure periods (7, 14, and 28 days). The performance assessment is carried out by mechanical properties, including tensile strength and modulus of elasticity, using experimental techniques and Response Surface Methodology (RSM) to find influential factors on tensile performance. The findings indicate that tensile strength degradation is highly dependent on alkali type and concentration, with Ca(OH)2-treated fibers exhibiting superior mechanical retention (max tensile strength: 938.94 MPa) compared to NaOH-treated samples, which showed the highest degradation rate. Five machine learning (ML) models, including Tree Random Forest (TRF), Function Multilayer Perceptron (FMP), Lazy IBK, Meta Bagging, and Function SMOreg (FSMOreg), were also implemented to predict tensile strength based on exposure parameters. FSMOreg demonstrated the highest prediction accuracy with a correlation coefficient of 0.928 and the lowest error metrics (RMSE 181.94). The analysis boosts basalt fiber durability evaluations in cement-based composites.

1. Introduction

The construction sector occupies a prominent position in the world’s progress, playing a crucial role in shaping our urban landscapes, infrastructure, and habitats [1]. However, as urbanization and global development continue to advance rapidly, the challenges pertaining to sustainability and materials utilization in this industry have attracted considerable attention. Throughout history, the sector has heavily relied on non-renewable resources, often obtaining materials without considering their ecological impact or the long-term consequences for the environment. Consequently, there has been extensive mining, deforestation, and energy-intensive production methods, resulting in significant contributions to environmental degradation, climate change, and resource depletion [2].

Furthermore, the elimination of construction waste and the limited lifespan of certain construction materials contribute to a recurring need for new resources, which puts additional strain on our planet’s finite reserves and worsens issues associated with greenhouse gas emissions [3]. As the dangers of climate change become increasingly apparent and resources become scarcer and costlier, the importance of implementing sustainable construction practices has never been more crucial [4]. The current challenge lies in integrating sustainable, renewable, and low-impact materials and techniques into mainstream construction without compromising on safety, durability, and affordability [5]. The transition toward a more sustainable construction paradigm not only addresses environmental concerns but also offers economic benefits, resilience against resource scarcity, and improved societal well-being in the long term. Such optimization strategies have recently been extended through data-driven approaches, where machine learning models are applied to predict and optimize concrete properties using sustainable aggregates [6,7].

Tackling the sustainability challenges in the construction sector necessitates the development of inventive solutions that surpass conventional methods. One promising approach is the inclusion of fibers, particularly inorganic ones, into cement-based materials [8]. This strategy not only addresses environmental concerns but also enhances the structural characteristics of the constructions, presenting a harmonious fusion of eco-friendliness and advanced material science. Therefore, a growing interest in the incorporation of fibers into cementitious materials to enhance performance while mitigating certain environmental drawbacks has been increasing. Research has demonstrated that the inclusion of fibers in cement matrices enhances tensile strength, decreases crack propagation, and improves overall durability, resulting in structures that require less maintenance and repair throughout their lifespans [9,10]. Consequently, this not only diminishes the demand for new materials and subsequent waste production but also reduces energy consumption and emissions associated with repair activities.

In the domain of fiber reinforcement, inorganic fibers, specifically, are gaining prominence. Unlike their organic counterparts, which can deteriorate over time or in adverse conditions [11], inorganic fibers can perform better. Inorganic fibers are primarily derived from minerals or are man-made [12,13]. Popular examples include glass, basalt, and carbon fibers. These fibers are renowned for their high tensile strength, resistance to environmental degradation, and thermal stability [14]. When mixed with cement, they contribute significantly to the overall strength, durability, and fire resistance of the composite material [15]. The utilization of these inorganic fibers not only yields superior mechanical properties but also harmonizes with the transition towards more sustainable construction materials, bridging the gap between modern engineering demands and environmental accountability. Recent mix-design studies on alkali-activated binders demonstrate how targeted formulation (e.g., slag–metakaolin systems) can tune fresh and hardened properties for advanced applications, reinforcing the importance of combined experimental and optimization approaches [16].

Basalt fibers, derived from natural volcanic rock, offer thermal stability and resistance to corrosive chemicals and exhibit a more environmentally friendly production and extraction process compared to conventional reinforcement materials [17,18]. They ensure the long-term performance of the composite by maintaining their integrity over time. Moreover, their thermal stability and environmentally friendly nature, resulting from their natural origin and energy-efficient production process, make them an attractive option [19]. When incorporated into cementitious matrices, basalt fibers enhance the tensile strength and mitigate crack propagation, thereby contributing to the creation of durable structures with an extended lifespan [19]. In the broader context of sustainable construction, the utilization of basalt fiber-reinforced cementitious composites signifies a convergence of strength, durability, and environmental responsibility.

Basalt fibers have been the subject of research due to their behavior in alkaline environments such as in cementitious materials, where the pore solution is highly alkaline with pH typically more than 12 [20]. It has been determined that basalt fibers and products derived from them are most vulnerable to damage in alkaline environments [21,22]. The results that were documented indicate that the deterioration of Basalt Fibers (BF) was influenced by various factors, such as the types and concentrations of alkali solutions, immersion temperature and duration, and the chemical composition of the fiber [23]. The primary focus of the majority of studies conducted thus far has been on examining the changes in fiber performance when exposed to NaOH solution [24]. This variation is believed to be caused by the breakdown of -Si-O-Si- bonds within the fiber’s network structure when exposed to OH− ions [25]. Basalt fiber degradation in Ca(OH)2 solutions was also carried out in the past; for example, aging of basalt fiber in cement solution with aging intervals of 1 day to 15 days and at temperatures of 20–80 °C revealed that the degradation of basalt fiber was mainly linked with the inhibiting effect of Ca. The authors claimed that Ca in basalt fiber formed the Ca-Si, thus preserving the tensile strength of the fiber [23]. Ding and colleagues conducted a study on the resistance of basalt fiber to alkali in a cement solution with a pH of 12.0, under specific conditions of treatment time (ranging from 6 to 168 h) at a temperature of 80 °C. Their findings suggested that the interaction between hydrated Ca(OH)2 and -Si-O-Si- resulted in the formation of CaSiO3, which acted as a protective layer for the fiber, thus hindering further deterioration. The research also indicated that the newly created Ca-Si compound played a role in mitigating the degradation of basalt fiber within the Ca(OH)2 environment [26]. The inclusion of NaOH/KOH in concrete has become a common practice due to the growing demand for high compressive strength [27]. A single study has been documented on the degradation of basalt fiber in KOH, where the aging process was carried out in a 10% KOH solution for 90 days [28]. Results indicated that basalt fiber subjected to a mild alkaline environment remained stable, while those exposed to a strong alkaline solution exhibited poor weight retention. Ref. [29] conducted a study comparing the elemental composition of original basalt fiber, as well as the outer and inner layers of basalt fiber processed by immersion in a 2 mol/L NaOH solution at 100 °C for 6 h. The findings revealed a significant reduction in the concentrations of Na, K, and Al in the outer layer of basalt fibers following treatment with NaOH. However, the changes in Si content during the alkali immersion, which is crucial for evaluating the -Si-O-Si- structures in basalt fiber, remained unclear. A thorough understanding of the characteristics of alkali-treated basalt fiber could enhance the longevity of related composites. Therefore, conducting a comprehensive investigation into the degradation patterns of basalt fiber in various alkali conditions is essential. Machine-learning models have been successfully used to predict the mechanical behavior of alkali-activated systems, illustrating that data-driven methods can capture complex interactions in highly alkaline environments [30].

Basalt fiber reinforced polymer (BFRP) has exhibited commendable corrosion resistance in aggressive alkaline environments, suggesting its potential as a substitute for steel rebars in reinforced concrete structures [31]. Basalt fibers’ length, diameter, and volume fraction are important in determining the compressive strength of basalt fiber-reinforced cementitious composites. Basalt fibers prevent concrete shrinkage and also render the propagation of cracks, thus increasing the compressive strength of the composites [32,33]. The compressive strength of the basalt-reinforced concrete depends on the number of dispersed fibers and can be disturbed when the volume fraction of fibers in concrete is large [34]. Basalt fibers can significantly enhance the tensile strength, crack resistance, and ductility of the basalt-reinforced cementitious composites. However, with a significant increase in fiber volume fraction, the tensile strength of the composites is observed to decrease [35,36].

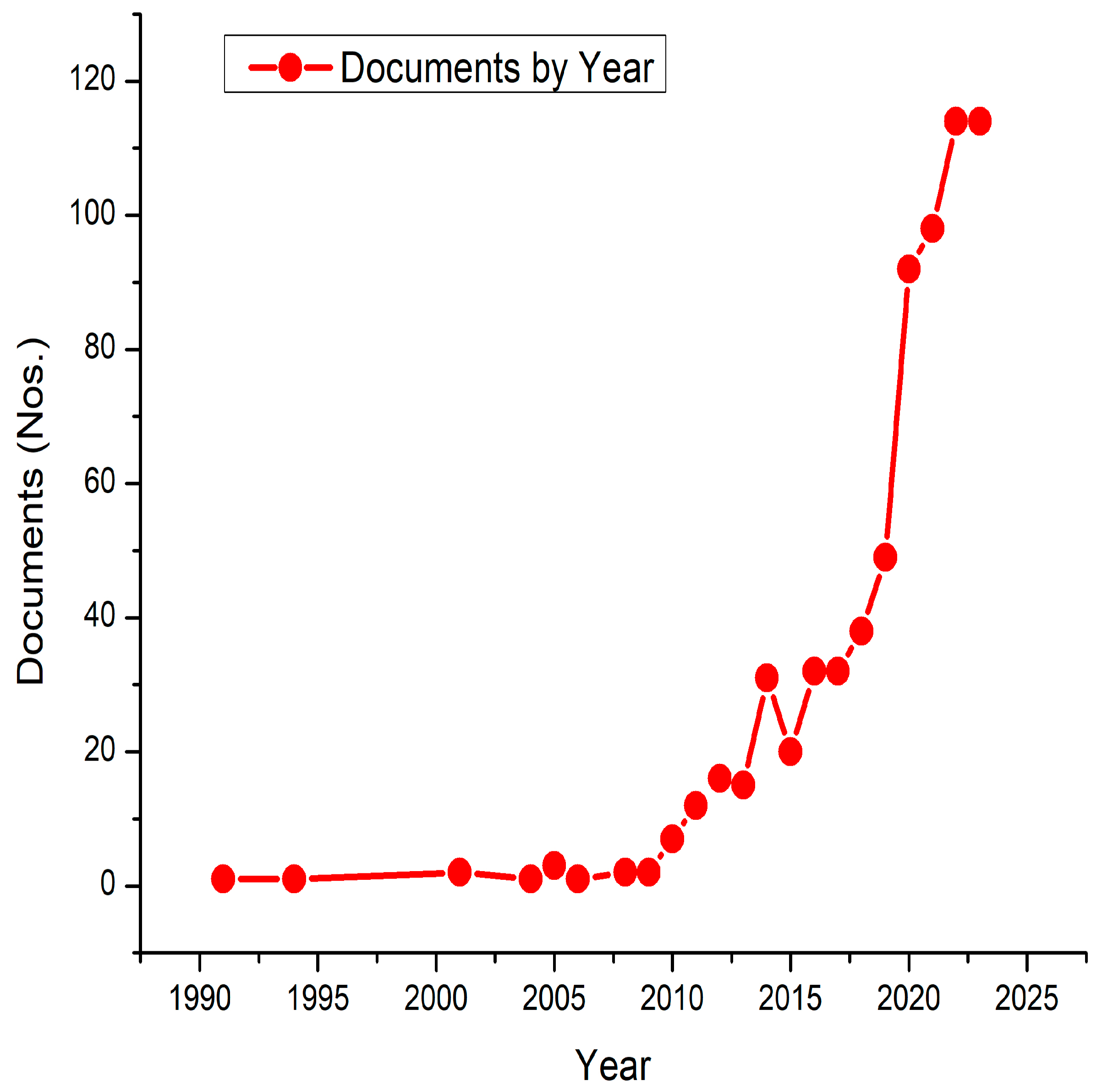

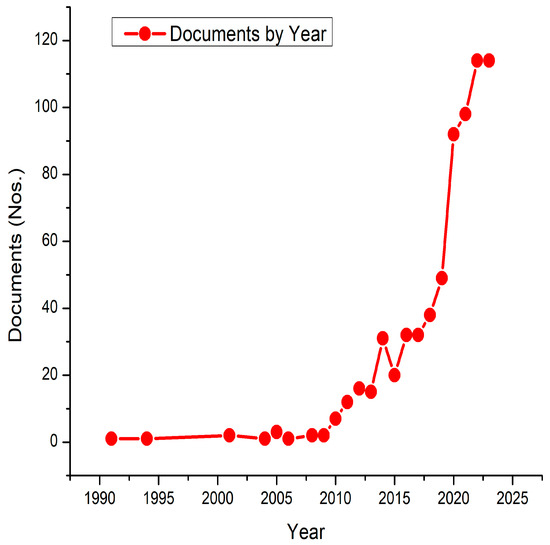

Figure 1, based on Scopus data, highlights the interest of the scientific community towards basalt fiber and its application in cement-based materials. Data are obtained from 1991 to date and represents an increased number of published data from 2010 and a sudden boost from 2016, indicating the growing interest and significance of basalt fibers in cement-based materials towards a sustainable green materials approach and an attractive alternative to the traditional materials.

Figure 1.

Publications on basalt fiber and its application in cementitious materials based on the Scopus database.

Recent research endeavors involving basalt fiber in cementitious materials are summarized in Table 1. This literature assessment is organized around the objectives and outcomes of various studies. The primary purpose of this section is to identify the latest advancements in this field of research.

Table 1.

Summary of the latest research works with basalt fiber in cementitious materials.

According to Table 1, it can be realized that literature in recent years underscores the transformative role of basalt fibers (BF) in improving cementitious materials. Lv et al. and Iftikhar et al. (2023) highlight BF’s enhancement of durability and strength and its synergy with recycled components. Challenges like BF’s corrosion, addressed by Wang et al., find solutions in innovations like basalt powder. Further, AI research by Najm, Mohamed, and Alzard (2023), along with Sun et al.’s findings, showcases BF’s potential in diverse applications, from electrical resistivity to eco-friendly geopolymer composites. Collectively, BF emerges as a pivotal component in advancing cementitious materials.

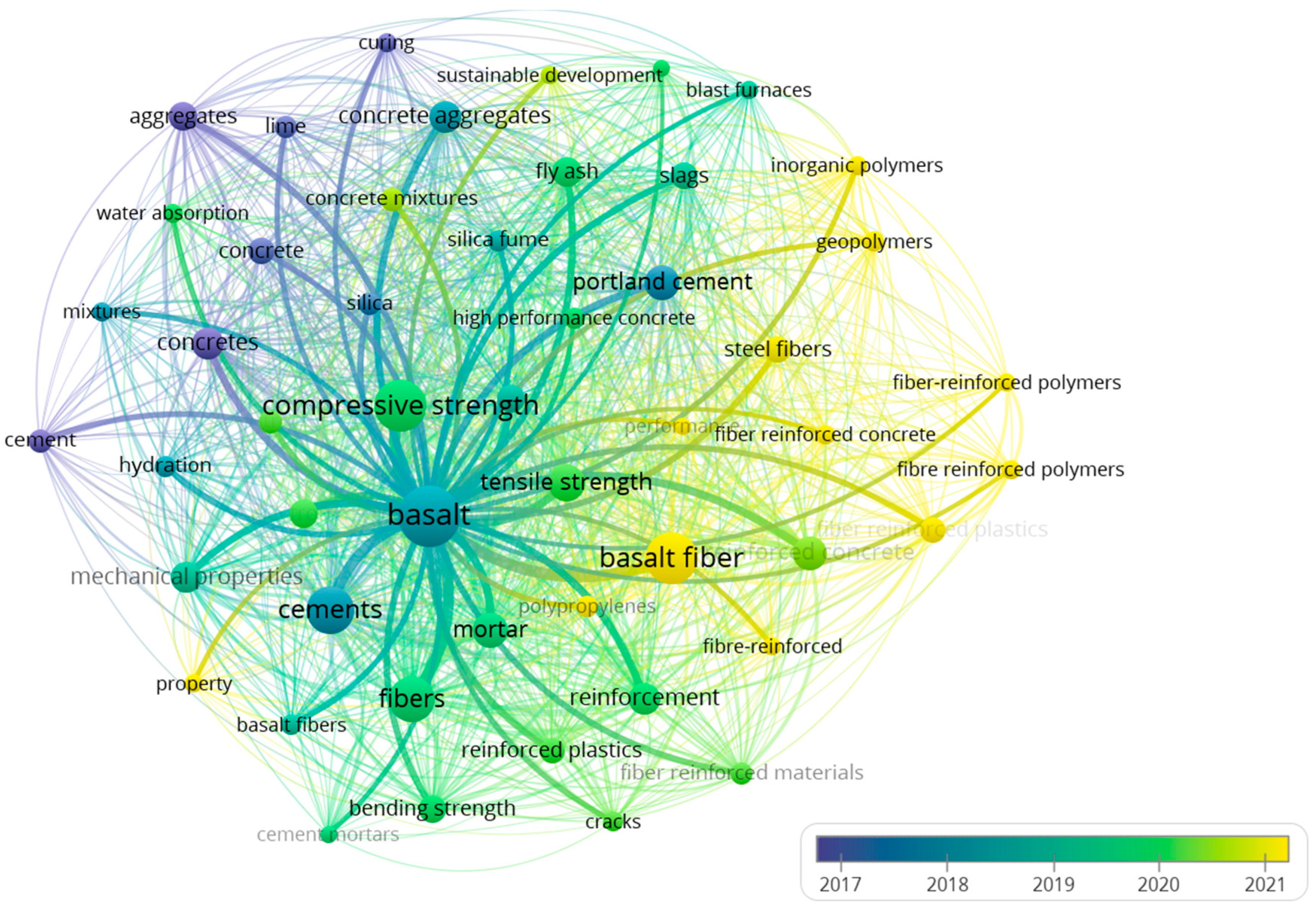

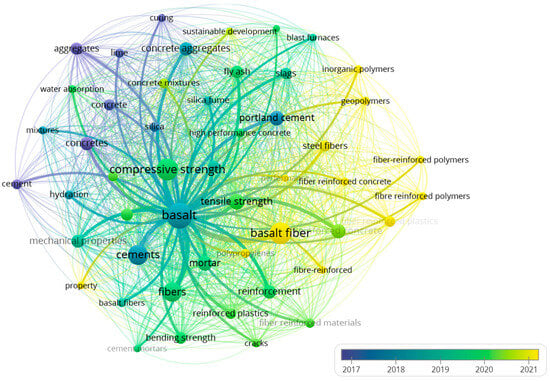

Figure 2, derived from a VOSviewer version 1.6.20 analysis of the Scopus database based on keyword frequency, reveals that prior studies have not extensively explored the use of basalt as a fiber in alkaline settings, an aspect this research aims to address. This study also seeks to measure the tensile resilience of each specimen, viewing it as the primary metric in the optimization process. During this optimization, several preparatory variables, such as the kind of alkali, its concentration, and the curing duration, will be examined. Hence, this research aims to bridge the knowledge gap regarding the impact of various alkalis on cement paste preparations enriched with eco-friendly fiber additives. Moreover, Figure 2 indicates a surge in research focusing on basalt fibers from 2005.

Figure 2.

The results of the bibliometric study on the use of basalt fiber in cement paste compositions, based on the Scopus database.

This study aims to develop lab-scale samples of various basalt-based fibers exposed to alkaline environments and evaluate their mechanical characteristics using the One-Factor-at-A-Time (OFAT) approach. It will involve a thorough characterization of the formulated samples through advanced techniques such as Differential Scanning Calorimetry (DSC), Thermo-Gravimetric Analysis (TGA), and Scanning Electron Microscope (SEM) to gain insights into the fibers’ thermal and structural properties. Additionally, the study will apply the Historical Data Analysis (HDA)-Response Surface Methodology (RSM) for optimization, conducting sensitivity assessments, and mathematically modeling the influential factors affecting the tensile performance of the fibers. Lastly, a Machine Learning (ML) model will be employed to predict the behavior of basalt fibers during alkaline treatment processes, enhancing the understanding of their performance under different treatment conditions.

Subsequently, Section 2 details the methodologies employed, emphasizing both experimental and computational strategies. Section 3 showcases the findings and insights from this investigation, emphasizing their implications. Lastly, Section 4 highlights the study’s primary contributions and proposes directions for forthcoming research.

2. Materials and Methods

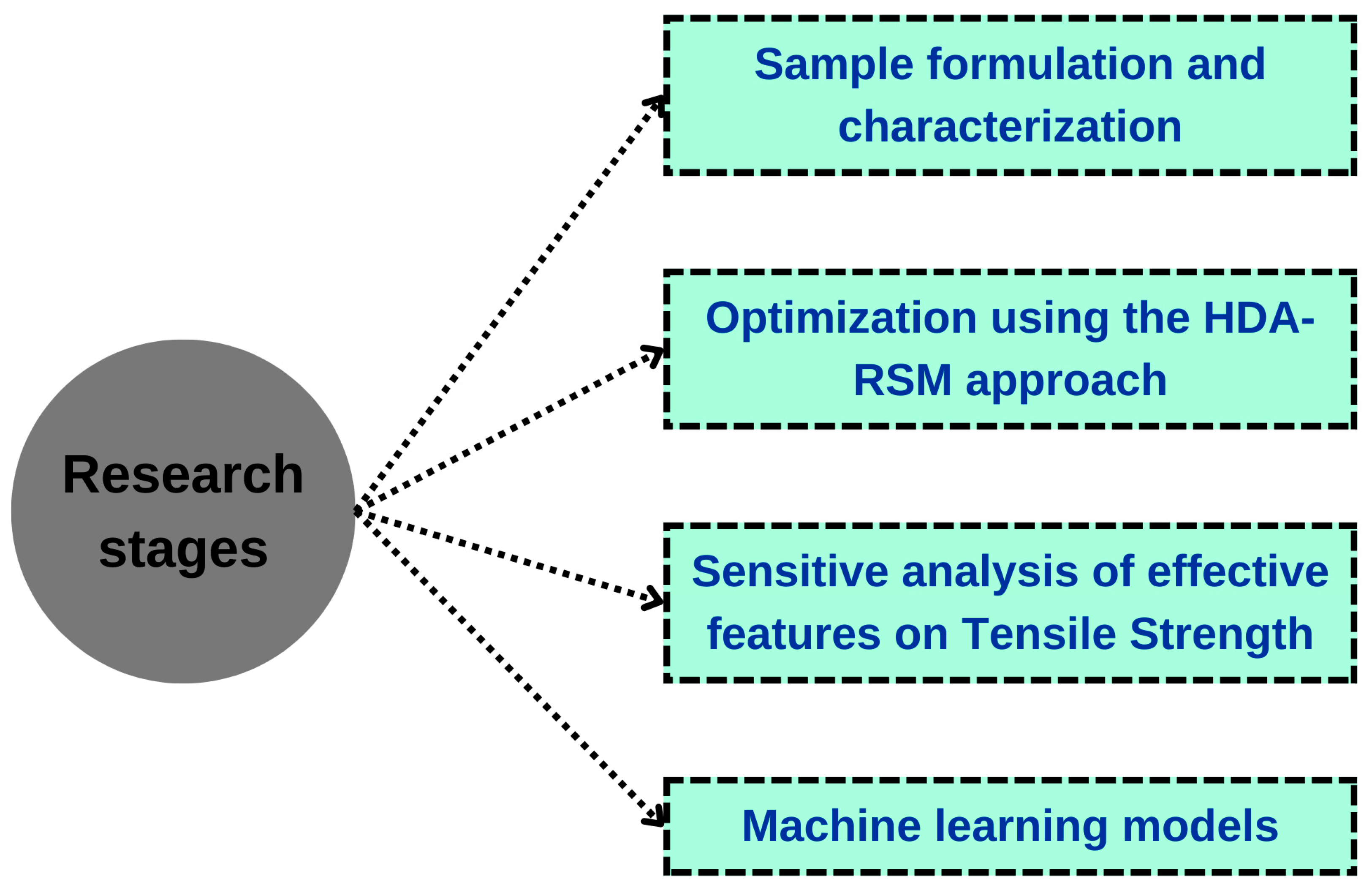

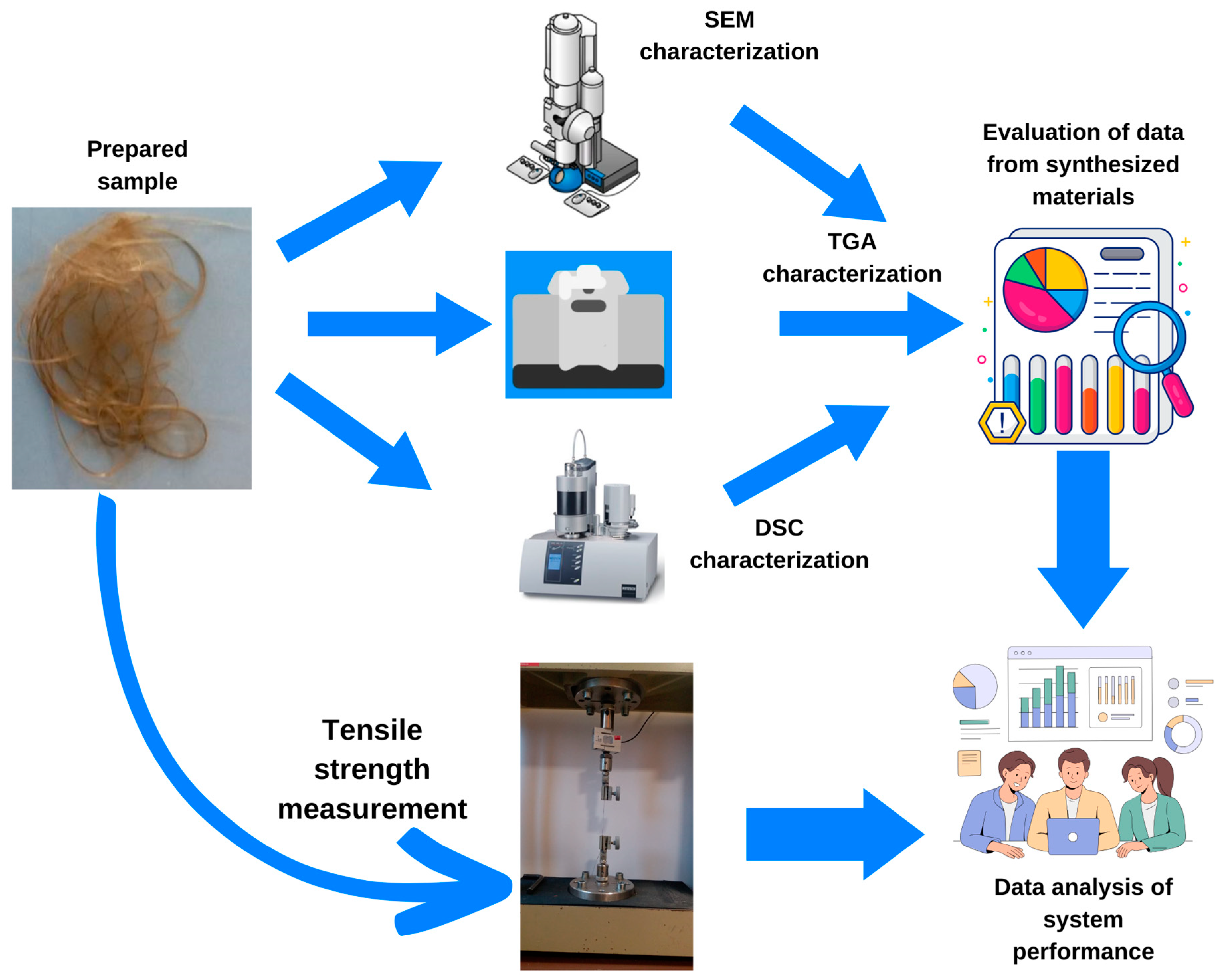

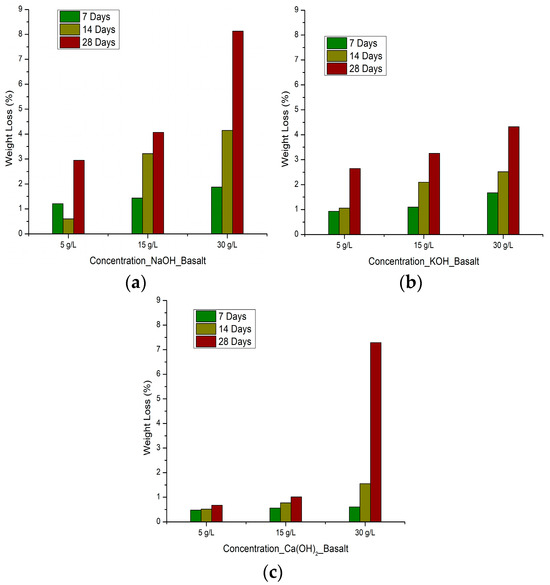

The research route for this investigation is illustrated in Figure 3. Based on the outlined framework, this study is segmented into four phases: (1) sample formulation and characterization, (2) optimization using the HDA-RSM approach based on second-order polynomial regression, (3) development of a prediction system, and (4) Machine Learning (ML) model development based on the historical databank. The experimental and computational evaluations proceed in a stepwise manner, encompassing data assembly, classification, and model formulation.

Figure 3.

Research roadmap of the present study.

2.1. Materials and Equipment

Materials and compounds used in this research, as well as the instruments employed, are listed in Table 2 and Table 3, respectively. The materials were sourced from various suppliers, while the instruments were accessed at the Technical University of Liberec.

Table 2.

Materials used in this study.

Table 3.

Instruments used in this study.

2.2. Procedures and Methods of Measurement

For preparing alkaline solutions, three alkalis, NaOH, KOH, and Ca(OH)2, with different concentrations were chosen. Samples were immersed in the prepared solutions for 7, 14, and 28 days at room temperature. For sample preparation, twenty basalt fiber threads, each measuring fifty centimeters, were used in each sample. Alkali solutions were prepared by dissolving 5 g, 15 g, and 30 g of each alkali in one liter of distilled water. The pH of the prepared alkaline solutions was measured prior to immersion, showing values of 13.59, 13.98, and 14.00 for NaOH; 13.70, 13.98, and 14.00 for KOH; and 13.38, 13.38, and 13.35 for Ca(OH)2 at concentrations of 5 g/L, 15 g/L, and 30 g/L, respectively, and are presented in Table 4.

Table 4.

Alkalis and pH-adjusting compounds used in this study.

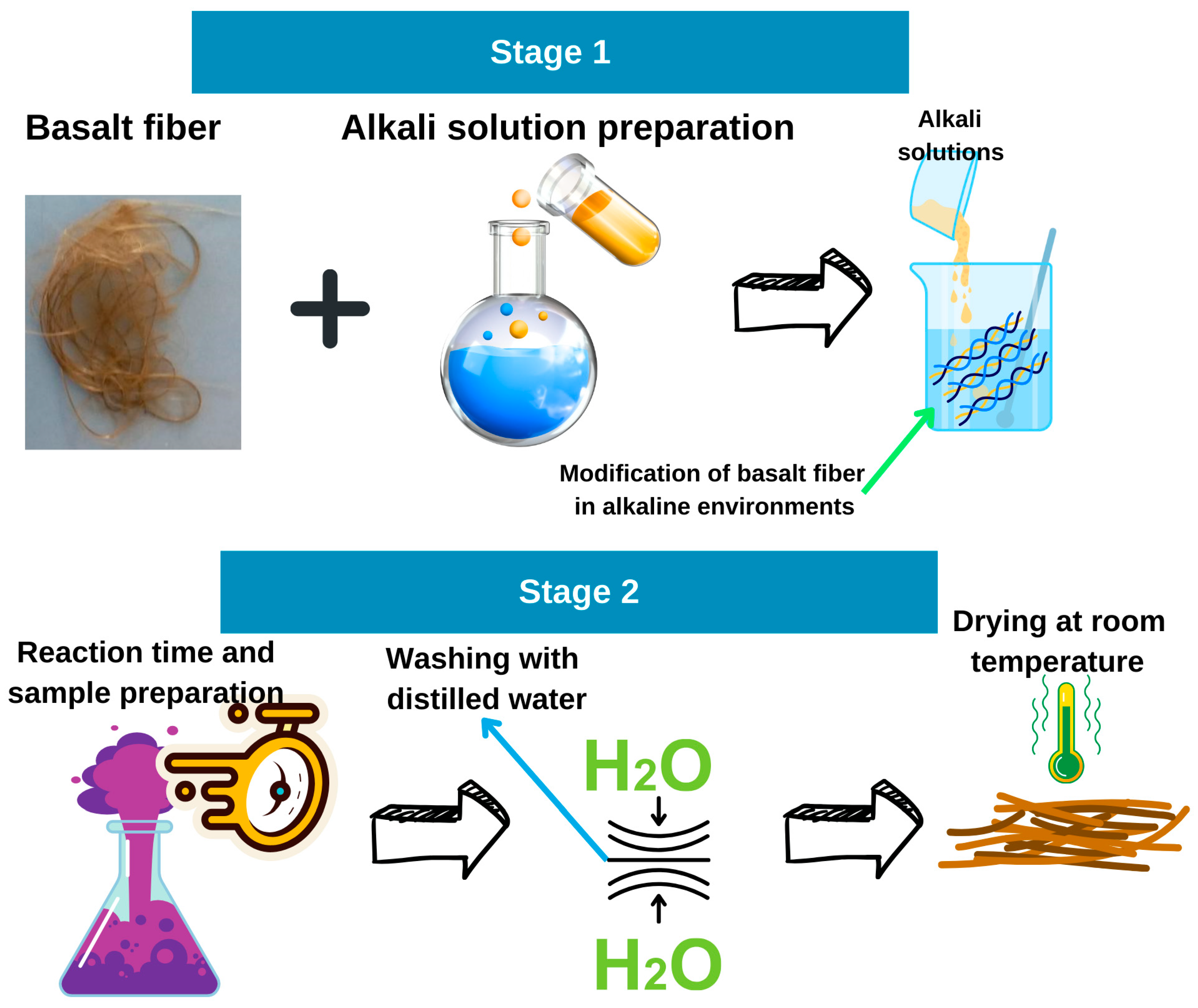

The solution was then transferred into a 200 mL container, where the basalt fibers were fully immersed. Samples were left in the solution for durations of 7, 14, and 28 days at room temperature. After the specified treatment period, the fibers were removed, thoroughly rinsed with distilled water, and allowed to air-dry at room temperature. Overall in this study, three types of alkalis (NaOH, KOH, and Ca(OH)2) were taken, each prepared at three concentrations (5 g/L, 15 g/L, and 30 g/L), and three immersion times (7, 14, and 28 days). This resulted in a total of 27 experimental runs, ensuring systematic evaluation of the combined effects of alkali type, concentration, and exposure duration on the performance of basalt fibers. The analyses included weight loss measurement to assess material degradation, tensile strength, and modulus of elasticity to evaluate mechanical stability, and DSC and TGA to investigate thermal properties. Together, these techniques provide a thorough understanding of how the treatment affects sample characteristics, allowing for a comprehensive evaluation of its impact.

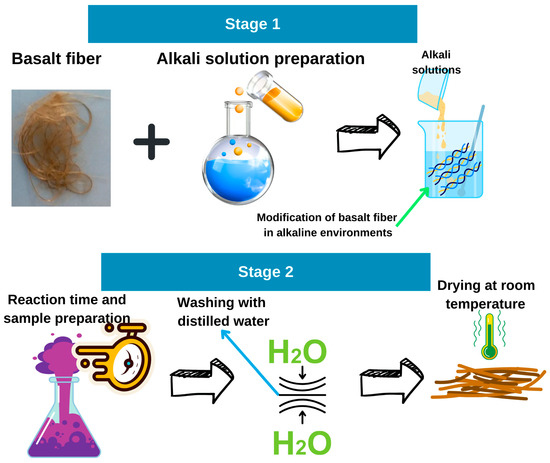

Figure 4 illustrates the sequential steps involved in experimental sample preparation and data collection.

Figure 4.

Sample preparation steps and material treatment procedure in an alkali environment through the present research.

Figure 5 depicts the subsequent steps undertaken after the samples were realized. Initially, the samples undergo three distinct characterization processes: TGA, SEM, and DSC. Following these characterizations, the tensile strength and modulus of elasticity of each sample are assessed using the Universal Testing Machine, TIRA TEST 2300 apparatus. The concluding step involves analyzing the accumulated data to determine the efficacy of the process in enhancing the quality of the samples. All experimental procedures in this research were conducted based on ČSN EN ISO 2062 [47], ČSN EN ISO 5079 [48], ČSN EN ISO 11358-1 [49], ČSN EN ISO 11357-1 [50], and ISO/TS 21383:2021 [51].

Figure 5.

The stages of material characterization and analysis after and before treatment by different instruments.

2.3. HDA-RSM Modelling

The effects of key process parameters on tensile strength are analyzed based on RSM modeling by using a historical data analysis framework. The research commenced with an extensive compilation of historical data, concentrating on three fundamental variables: exposure duration, type of alkali, and its concentration. These parameters were systematically recorded across diverse experimental conditions to capture their influence on material performance. The collected dataset served as the foundation for constructing an initial predictive model. Subsequently, RSM was employed to refine this model, providing deeper insights into the intricate interactions among the selected variables and their collective impact on tensile strength. Through this approach, the study aimed to determine optimal parameter ranges and forecast system behavior under new conditions. RSM also facilitated the identification of significant factors and their interdependence, enabling targeted adjustments to achieve desired tensile strength outcomes. All computations of the RSM model are implemented in Design Expert 7.0.0.

2.4. Machine Learning Model

This study also develops methods for prediction of tensile strength (TS) of basalt fibers based on alkali type, alkali concentration, and reaction time by using five different machine learning algorithms: (1) Tree Random Forest (TRF), (2) Function Multilayer Perceptron (FMP), (3) Lazy IBK, (4) Meta Bagging, and (5) Function SMOreg (FSMOreg). The machine learning models are trained and tested using a 70% training and 30% testing split. All computations are conducted in WEKA 3.9.

To predict tensile strength TS = f(A,C,T), where A is alkali type, C is concentration, and T is time, machine learning models were employed to capture complex, nonlinear mappings beyond the limits of traditional regressions. Unlike fixed-form models, ML learns patterns directly from data, offering a novel, adaptive methodology in fiber degradation analysis that improves predictive capability and generalization. This approach is novel in fiber durability analysis, as previous studies relied mostly on traditional regression, limiting prediction accuracy and adaptability to diverse scenarios.

3. Results

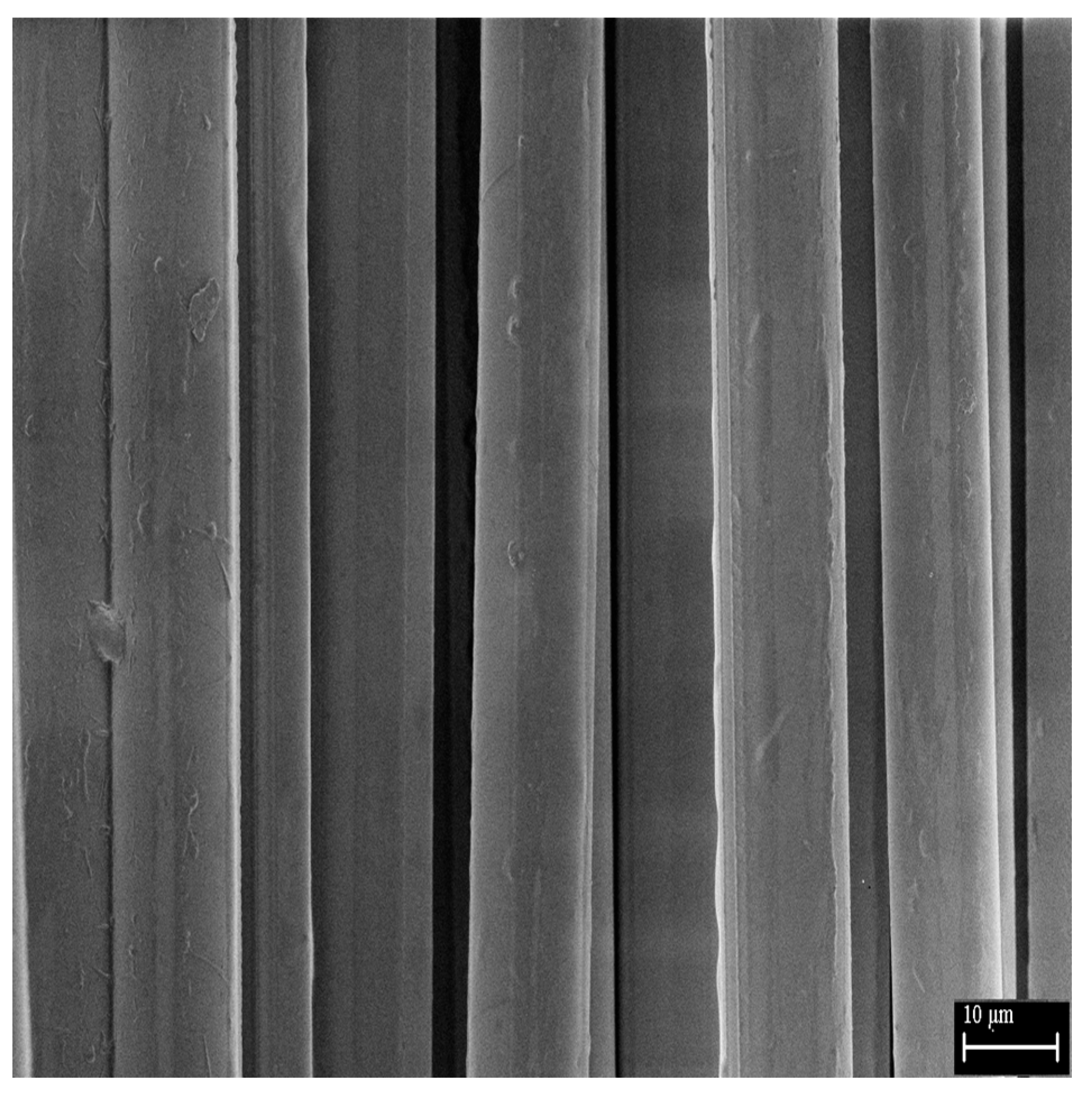

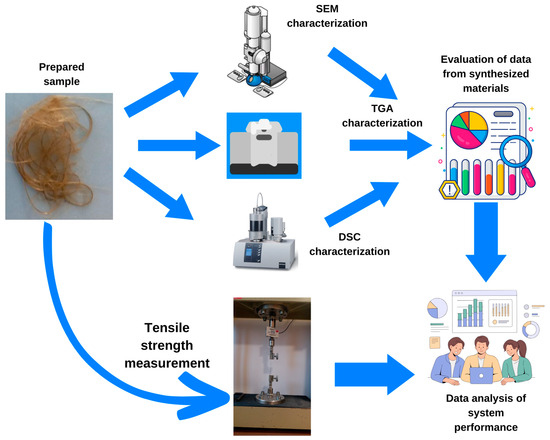

Prior to alkaline treatment, the as-received basalt fibers were characterized to establish baseline properties. The fibers had an average density of 2.74 g, a tensile strength of 860.11 MPa, and a modulus of elasticity of 69.46 GPa (see Table 5). SEM imaging captured at a magnification of 1.00 K X revealed smooth surfaces with no visible defects or microcracks (see Figure 6). These baseline measurements confirm the uniformity and integrity of the fibers, ensuring that the changes observed in treated fibers are solely due to the effects of alkaline exposure.

Table 5.

Properties of as-received basalt fiber.

Figure 6.

SEM image of as-received basalt fiber.

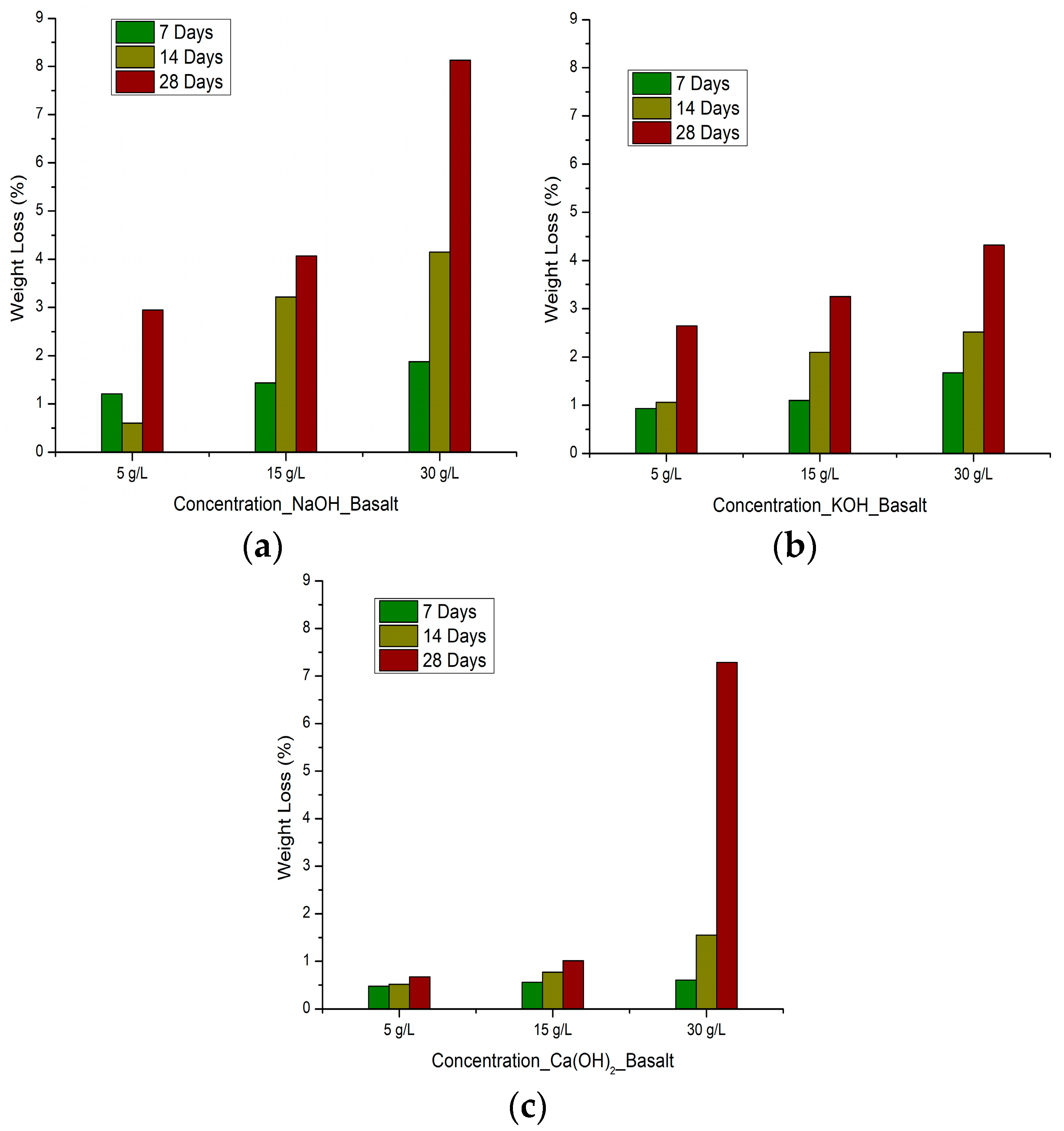

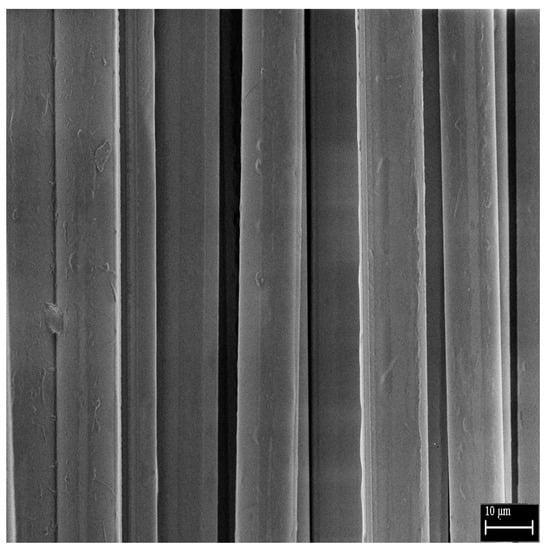

The alkalinity of the testing environment for basalt fibers was controlled by dissolving varying concentrations of NaOH, KOH, and Ca(OH)2 in distilled water, resulting in highly alkaline solutions with pH values ranging from 13.38 to 14. Figure 7 presents the weight loss (%) of basalt fibers following exposure to these alkalis over different durations. In Figure 7a, NaOH treatment shows a consistent increase in weight loss with both concentration and time, peaking at 8% after 28 days with a 30 g/L solution, indicating aggressive degradation. In contrast, Figure 7b shows KOH-induced degradation to be less severe, with a maximum of 4% weight loss under the same conditions, suggesting a comparatively milder reactivity. Figure 7c illustrates Ca(OH)2 exposure, where initial degradation was minimal, but a notable increase to 7% weight loss occurred only at 28 days with 30 g/L concentration, implying a delayed or threshold-dependent reaction.

Figure 7.

Weight loss (%) of the basalt fibers treated with various alkali solutions in this study (a–c).

These findings highlight the differential reactivity of alkalis with basalt fibers, reflecting not just the solution pH but also the chemical nature and interaction kinetics of each alkali. The degradation is attributed to physicochemical reactions in which alkalis disrupt the internal structure of the fibers, particularly the silica and alumina phases [26,52]. The variations in degradation intensity across alkalis underscore their differing affinities for these components, with NaOH being the most aggressive, followed by Ca(OH)2 under prolonged exposure. This differential behavior is critical for assessing the durability of basalt fibers in cementitious systems, where long-term alkaline exposure may significantly compromise their integrity [53].

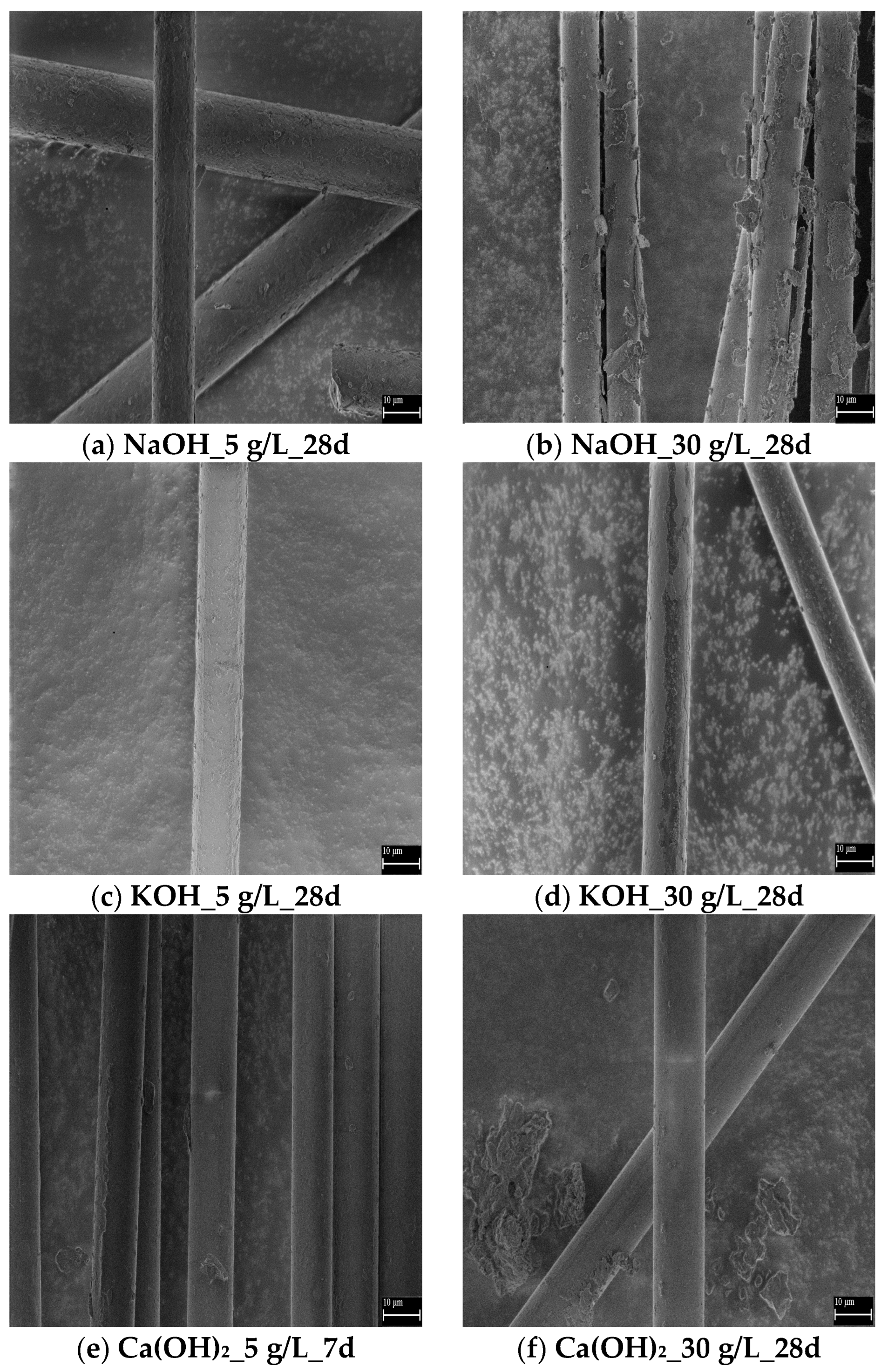

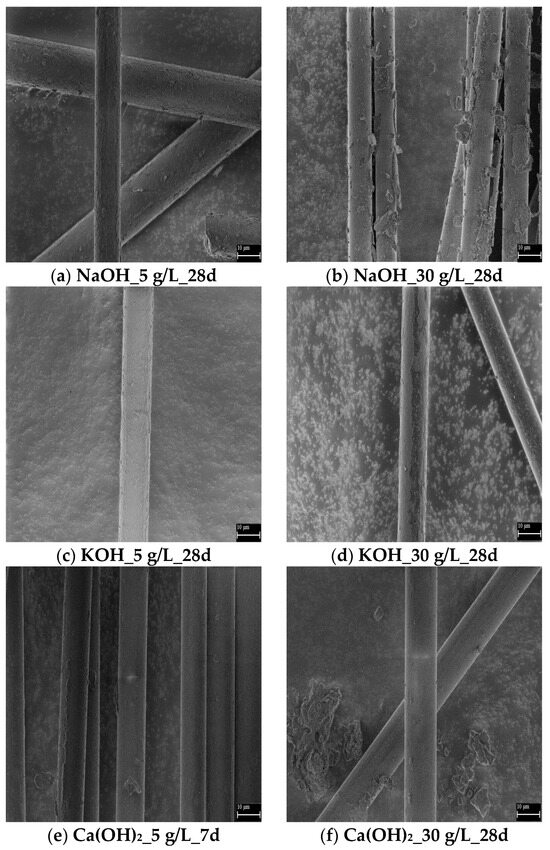

The SEM characterization results for basalt fibers, influenced by varying alkali solutions and their respective concentrations, are depicted in Figure 8. As outlined in Figure 7, all the SEM images were captured at a magnification of 1.00 K X.

Figure 8.

The SEM findings from the basalt fibers treated with various alkali solutions in this study (a–f).

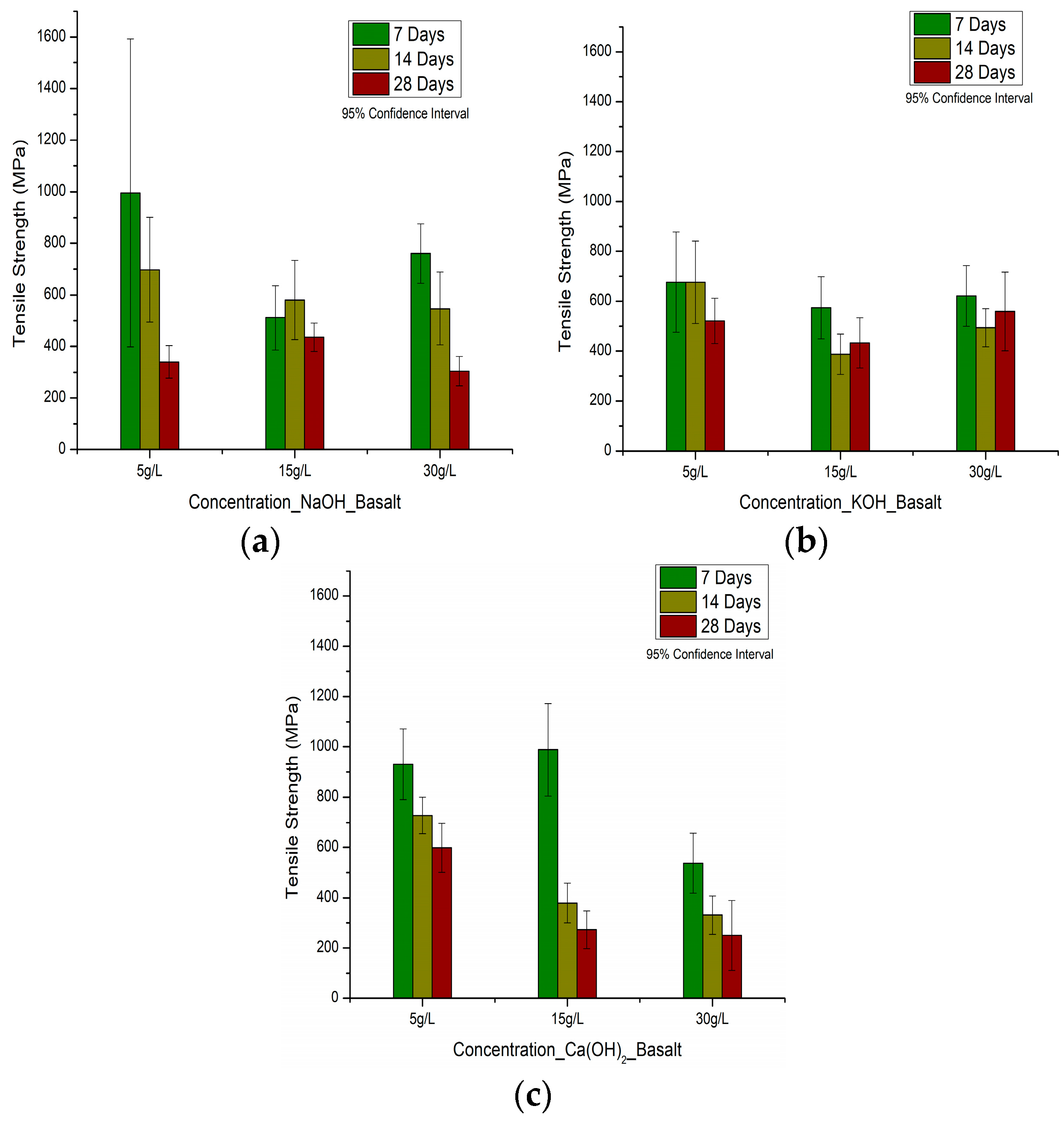

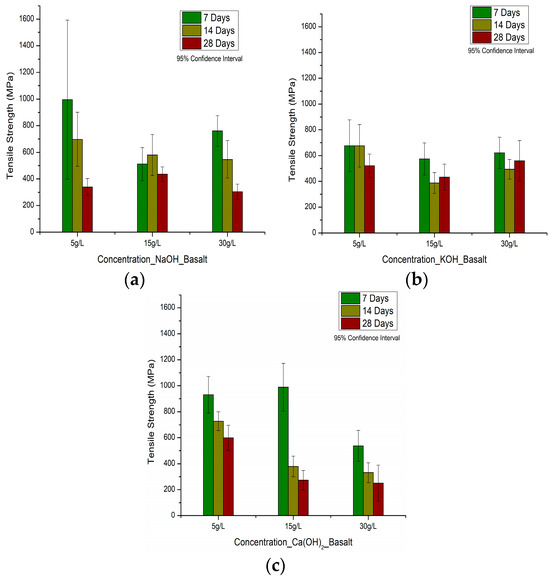

The tensile strength degradation of basalt fibers subjected to alkaline environments is illustrated in Figure 9. Under NaOH treatment (Figure 9a), tensile strength declined markedly over time across all concentrations. For instance, at 5 g/L, the strength dropped from 995.45 MPa (7 days) to 340.39 MPa (28 days), indicating that even low-concentration exposure results in substantial degradation over time. At 15 g/L, the strength initially decreased to 511.29 MPa at 7 days, then slightly increased to 580.14 MPa at 14 days, before declining again to 435.33 MPa at 28 days. For 30 g/L, a consistent drop was observed from 760.65 MPa (7 days) to 304.85 MPa (28 days). Despite the highest initial strength at 5 g/L for 7 days, a general trend of strength reduction with increasing concentration and exposure time was evident, underscoring the aggressive nature of NaOH on basalt fibers [54], as can be observed in Figure 8a,b. In contrast, KOH treatment (Figure 9b) exhibited a less predictable pattern. At 5 g/L, strength remained nearly unchanged from 676.39 MPa (7 days) to 676.16 MPa (14 days), followed by a drop to 520.93 MPa at 28 days. At 15 g/L, a significant reduction was seen after 7 days (573.5 MPa) to 387.31 MPa at 14 days, with a slight recovery to 433.19 MPa at 28 days. Interestingly, at 30 g/L, strength fell from 621.06 MPa (7 days) to 494.02 MPa (14 days), then increased to 559.21 MPa at 28 days. These fluctuations suggest complex fiber–alkali interactions, potentially involving short-term reorganization or restructuring of the fiber matrix that momentarily improves mechanical performance [22], as reflected in Figure 8c,d. For Ca(OH)2-treated fibers (Figure 9c), the 5 g/L concentration maintained relatively high tensile strength across all durations, starting at 931.17 MPa (7 days) and declining to 598.65 MPa by 28 days. A significant anomaly was observed at 15 g/L, where strength peaked at 988.33 MPa (7 days), then plummeted to 379.01 MPa at 14 days and 272.43 MPa at 28 days. The 30 g/L treatment followed a steady decrease from 537.31 MPa (7 days) to 250.22 MPa (28 days). The unexpected initial strength increase at 15 g/L may point to a transient stabilization effect or superficial mineral deposition, though this rapidly deteriorates, indicating a delayed but severe degradation mechanism [55] as shown in Figure 8f.

Figure 9.

The tensile strength of basalt fibers subjected to various alkalis, concentrations, and durations in this study: (a) NaOH, (b) KOH, and (c) Ca(OH)2 (a–c).

Building on the observations from Figure 9, the tensile strength trends align with broader insights on basalt fiber durability in alkaline environments. The consistent strength degradation under NaOH treatment reinforces its aggressive impact over time, as highlighted by [54]. In contrast, the fluctuating responses under KOH and Ca(OH)2 treatments reflect more complex and less predictable interactions, suggesting that both alkali type and exposure conditions critically influence performance. These findings support the view that while short-term exposure, particularly at lower NaOH concentrations, may offer transient benefits [56], extended or high-concentration treatments generally lead to mechanical deterioration—underlining the importance of tailoring alkali treatments to application-specific requirements [57,58,59].

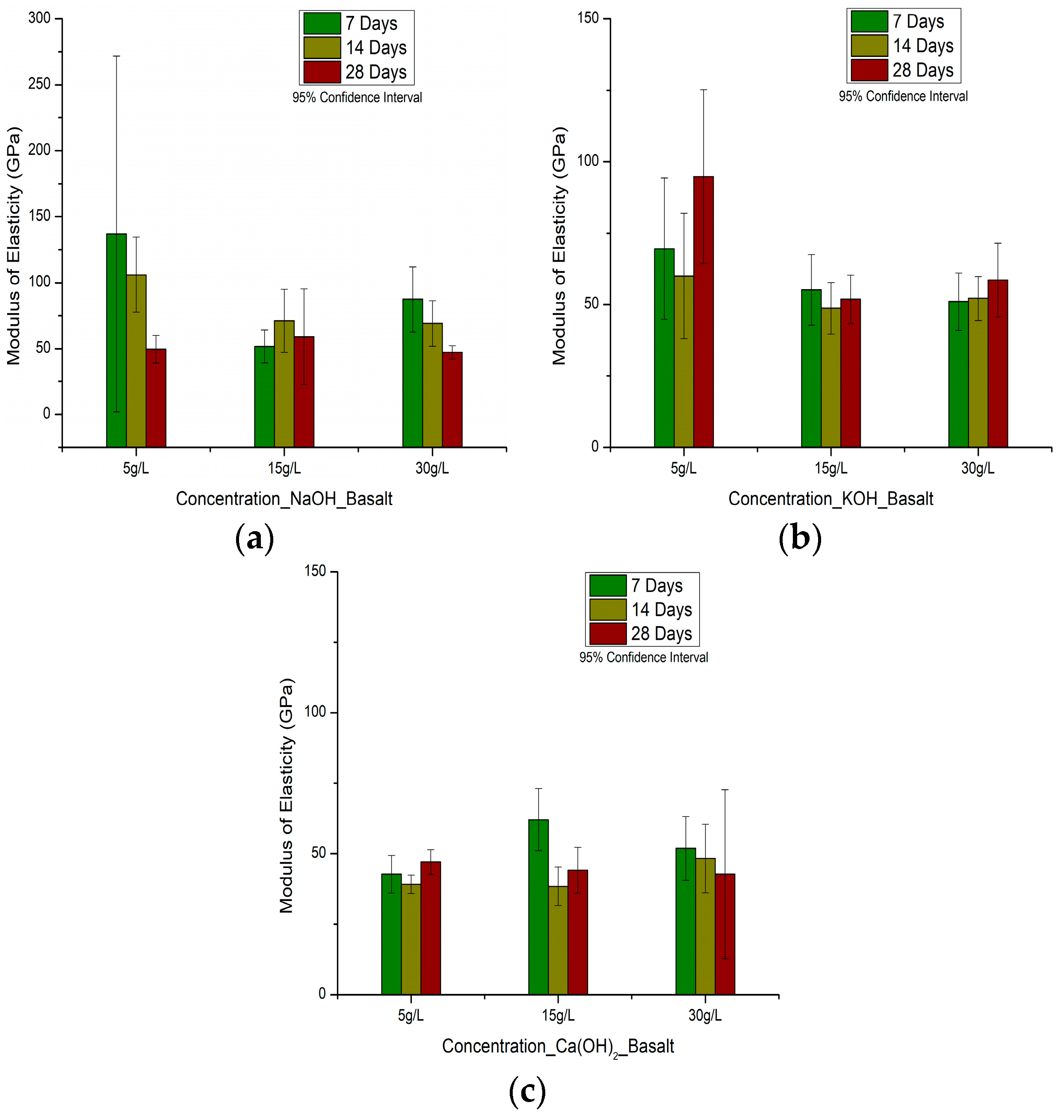

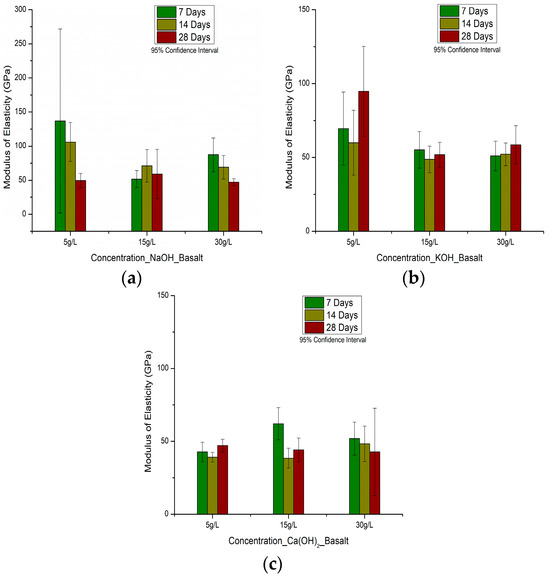

Figure 10 shows how the Modulus of Elasticity (MoE) of basalt fibers is affected by various alkali treatments over time, highlighting their potential for use in structural applications [60]. For NaOH treatment (Figure 10a), a pronounced decline in MoE is observed with increased exposure time, particularly at the 5 g/L concentration, which starts above 150 GPa at 7 days but drops significantly by 28 days. At 15 g/L, the modulus remains more stable across time, ranging between 40 and 70 GPa, though a mild downward trend is still evident. Interestingly, the 30 g/L treatment shows less variation across time, implying that beyond a certain concentration threshold, further NaOH exposure results in less pronounced stiffness loss. These patterns reflect the damaging effect of prolonged or aggressive NaOH treatment on fiber structure, which aligns with previous findings suggesting that while moderate alkali treatment can enhance interfacial bonding, overexposure leads to deterioration in mechanical properties [61,62]. In contrast, KOH-treated fibers (Figure 10b) exhibit a generally increasing trend in MoE over time, particularly at the 5 g/L concentration, where the modulus peaks at 28 days. At higher concentrations (15 g/L and 30 g/L), the increase in stiffness is less pronounced, indicating diminishing returns with excessive alkali dosage. This suggests that controlled KOH treatment may induce favorable structural rearrangements or improve interfacial bonding, as supported by [63], who noted enhanced fiber-matrix adhesion and improved composite performance after alkaline treatment. For Ca(OH)2 treatment (Figure 10c), the MoE remains relatively consistent at 5 g/L across all time intervals, with only slight reductions over time, indicating limited influence at lower concentrations. However, at 15 g/L and 30 g/L, a gradual but clear reduction in modulus occurs with increasing duration, most notably at 28 days. This trend implies that prolonged exposure to Ca(OH)2, particularly at higher concentrations, leads to progressive degradation in fiber stiffness—likely due to hydroxide ions reacting with silicate structures in the fibers, weakening the Si–O network [64].

Figure 10.

The modulus of elasticity of basalt fibers subjected to various alkalis, concentrations, and durations in this study (a–c).

The degradation of basalt fibers in alkaline environments can be explained by the disruption of their silicate network. The primary mechanism involves the progressive dissolution of Si–O–Si bonds, which weakens the integrity of the aluminosilicate structure [54]. As alkali concentration increases, the higher availability of hydroxyl ions (OH−) accelerates the bond cleavage and promotes leaching of network modifiers such as Na, K, and Al, thereby amplifying mass loss and mechanical deterioration [56]. This explains why concentration exerts a more dominant influence on degradation compared to immersion time or even alkali type, as the chemical driving force for dissolution is directly proportional to hydroxyl ion activity.

The role of alkali type is also significant. NaOH, due to its smaller hydrated ionic radius, penetrates more effectively into the fiber network, causing more aggressive dissolution relative to KOH [52]. By contrast, Ca(OH)2 behaves differently: although it maintains a highly alkaline pH, the presence of Ca2+ ions can lead to precipitation of secondary calcium-silicate-hydrate (C-S-H) phases on the fiber surface. This deposition may create a passivation layer that temporarily slows further attack, explaining the delayed but eventually pronounced degradation observed at longer durations with higher Ca(OH)2 concentrations. The lower OH− activity of Ca(OH)2 is consistent with the measured pH values of the prepared solutions (Table 4), highlighting that solution alkalinity directly influences the rate of silicate network dissolution and fiber degradation.

Together, these mechanisms highlight that alkali concentration governs the rate of silicate network dissolution, while the type of alkali influences the mode of degradation, either direct penetration (NaOH, KOH) or partial surface passivation (Ca(OH)2). These findings align with previous reports [52,54,56] and provide a mechanistic framework for interpreting the observed differences in weight loss, tensile strength, and modulus of elasticity among the tested solutions.

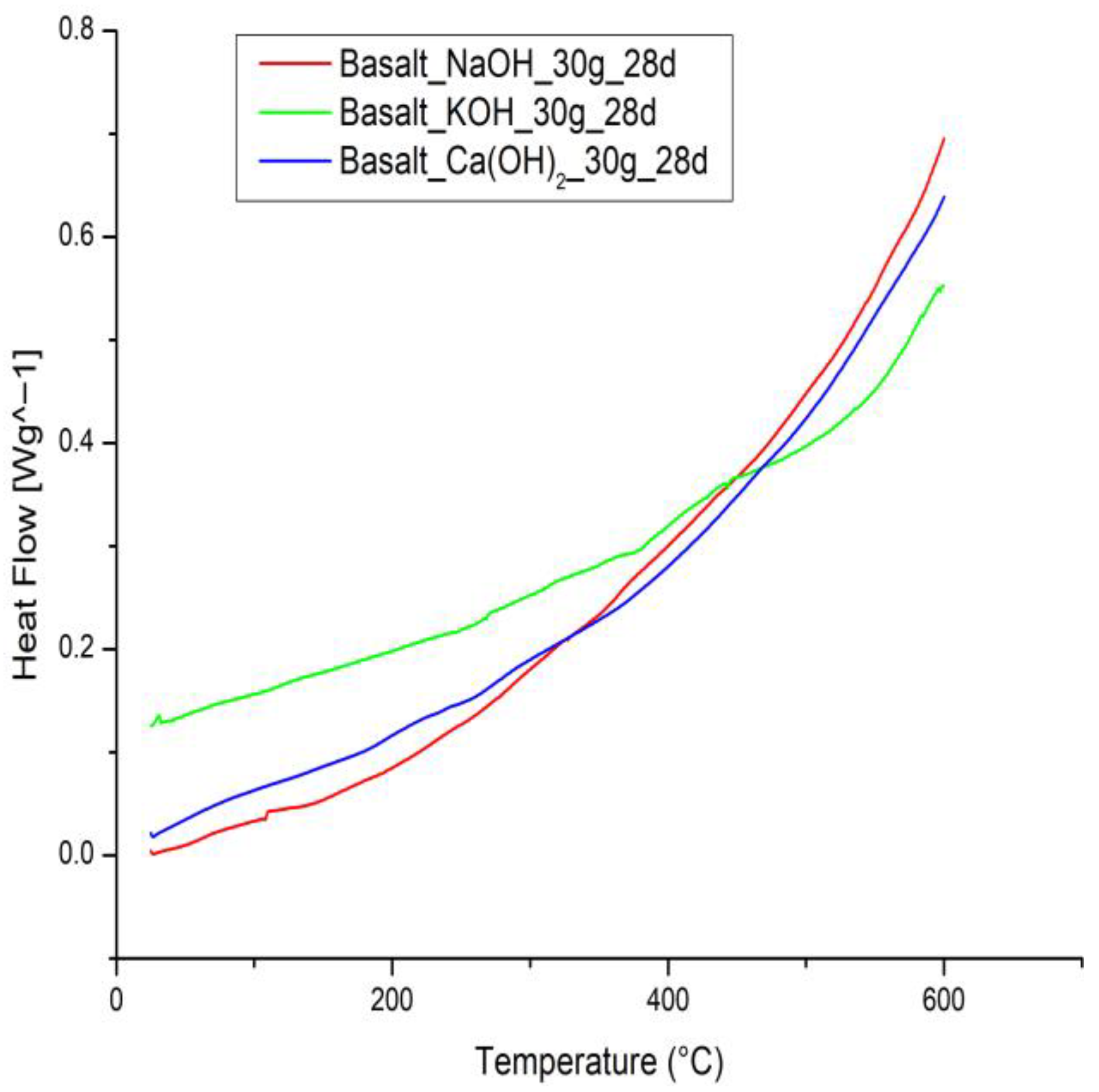

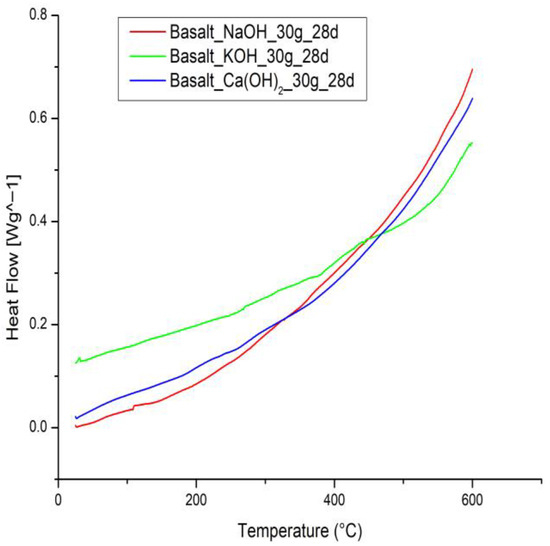

Figure 11 presents Differential Scanning Calorimetry (DSC) data for basalt fibers treated with 30 g/L NaOH, KOH, and Ca(OH)2 after 28 days, highlighting the thermal properties and phase transitions of these fibers. All treatments show endothermic reactions, with heat flow increasing as temperature rises. Basalt fibers treated with NaOH exhibit the lowest initial heat flow, but after 200 °C, heat flow increases sharply, surpassing the other treatments above 400 °C. This suggests more intense decomposition or structural changes at higher temperatures [65,66]. KOH-treated fibers show the highest initial heat flow, but the increase is more gradual, stabilizing after 400 °C, indicating fewer thermal changes and suggesting greater thermal stability. The NaOH and Ca(OH)2 treatments display similar thermal behavior, marked by substantial endothermic activity above 400 °C, pointing to significant structural alterations at high temperatures. In contrast, KOH-treated fibers show a more stable thermal response, indicating enhanced structural integrity during heating. These results indicate that NaOH and Ca(OH)2 are more aggressive in modifying the basalt fiber structure, while KOH treatment provides greater thermal stability [67]. This analysis is crucial for assessing the thermal stability and performance of alkaline-treated basalt fibers in various applications.

Figure 11.

The DSC analysis outputs of different basalt samples.

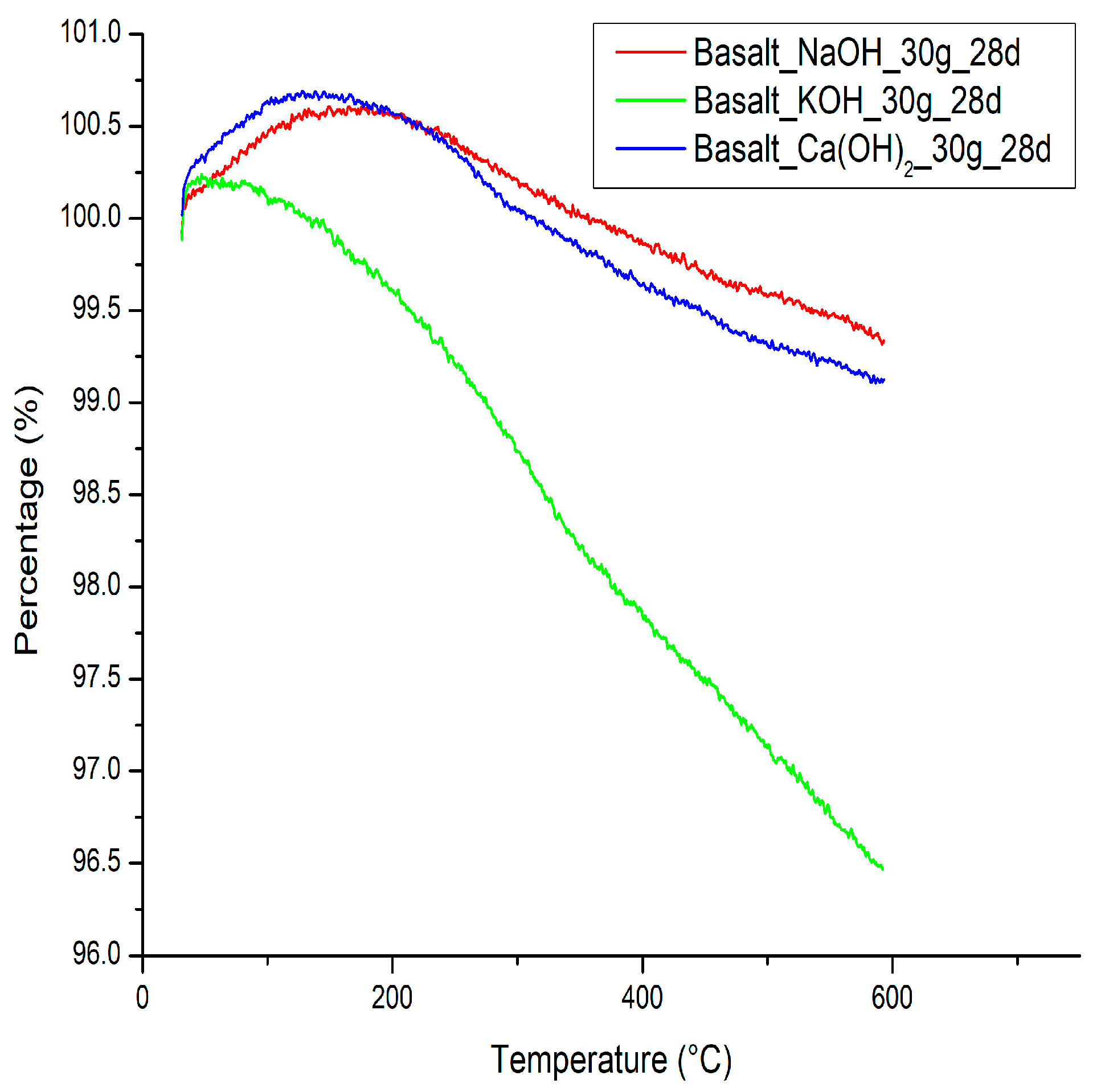

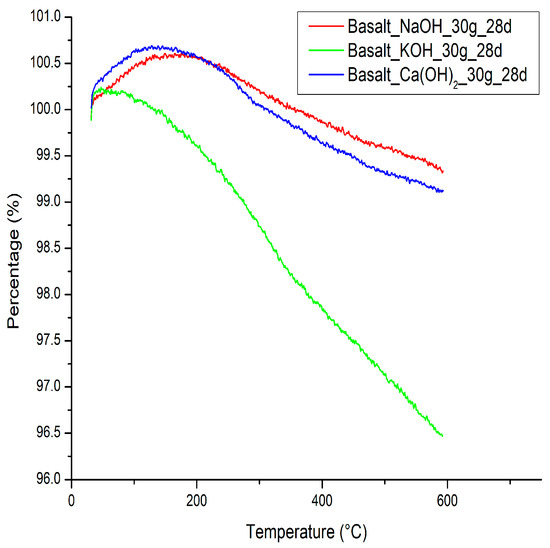

Figure 12 presents the thermogravimetric analysis (TGA) results for basalt fibers treated with NaOH, KOH, and Ca(OH)2, illustrating the weight change as a function of temperature. TGA is a key technique for evaluating the thermal stability and decomposition behavior of materials, as discussed by [68,69]. It provides valuable insights into how alkaline treatments influence the thermal properties of basalt fibers. The TGA curves start at nearly 100%, indicating minimal initial weight loss. Basalt fibers treated with NaOH show the least weight loss, stabilizing just above 99% at 650 °C, indicating high thermal stability. In contrast, KOH-treated fibers exhibit a more significant weight loss, dropping to 96.5% at 650 °C, suggesting greater thermal decomposition or volatilization [70]. Ca(OH)2-treated fibers experience intermediate weight loss, ending at about 98.5%, indicating moderate thermal stability. All samples display initial stability up to 100 °C, attributed to moisture removal, followed by weight loss due to decomposition or volatilization. These findings highlight the varying impacts of alkaline treatments on the thermal properties and decomposition behavior of basalt fibers, with NaOH providing the highest stability and KOH the least.

Figure 12.

The TGA results of different basalt samples.

Table 6 presents a comparative analysis of different regression models based on key statistical criteria, including standard deviation, R-Squared, adjusted R-Squared, predicted R-Squared, and the predicted residual sum of squares (PRESS). The table evaluates four models: Linear, Two-Factor Interaction (2FI), Quadratic, and Cubic, highlighting their performance in terms of fitness and predictive accuracy.

Table 6.

The outcomes of statistical indicators for curve-fitting analysis through the present study.

Among the models, the Quadratic model is selected as the most suitable choice due to its improved goodness of fit while maintaining a reasonable balance between adjusted and predicted R-Squared values. It achieves an R-Squared value of 0.68, which is higher than both the Linear (0.53) and 2FI (0.58) models, indicating better explanatory power. Although its predicted R-Squared (0.17) is lower than that of the Linear model (0.35), it is still within an acceptable range compared to the alternative models. The Quadratic model also maintains a relatively lower standard deviation (141.01) compared to the Linear (148.04) and 2FI (149.41) models, suggesting better precision. Furthermore, while its PRESS value (892,179.5) is higher than that of the Linear model, it remains considerably lower than that of the Cubic model (1,802,868), which is overfitted and aliased. Although the Linear model provides better predictive accuracy, it does not capture complex interactions in the data as effectively as the Quadratic model. The Cubic model, despite having the highest R-Squared (0.84), suffers from severe overfitting, as indicated by its negative predicted R-Squared (−0.67) and extremely high PRESS value. Therefore, the Quadratic model is chosen as the best compromise, balancing improved explanatory power with reasonable predictive capability. The selected quadratic model is demonstrated in Equation (1).

where TS = Tensile Strength, A = Alkali Type, C = Alkali Concentration, T = Time.

TS = +1245.72 + (10.63 × A) − (24.94882 × C) − (50.81 × T) − (4.94 × A × C) − (0.28 × A × T) + (0.22 × C × T) + 16.89 × A2 + (0.66 × C2) + 0.92 × T2

Figure S1 shows the contour plot from the RSM model, highlighting the interaction of alkali concentration, type, and exposure time on tensile strength. The central low-response region (0.497) reflects conditions of higher degradation, while the outer zones (up to 0.609) indicate improved strength retention. The smooth contours and symmetry confirm concentration and time as dominant factors, validating the quadratic model’s predictive accuracy and optimization reliability.

Table 7 presents the results of the Analysis of Variance (ANOVA) performed in this investigation, evaluating the significance of different factors affecting the model. The table provides values for the sum of squares, degrees of freedom (df), mean square, F-value, and p-value for each factor and interaction term.

Table 7.

The results of ANOVA analysis in this investigation.

The overall model is statistically significant, as indicated by its p-value of 0.0057, which is below the conventional threshold of 0.05. This suggests that the regression model adequately explains the variability in the response variable. Among the individual factors, B-Alkali Concentration (p = 0.011) and C-Time (p = 0.0002) are significant, meaning they have a strong influence on the response. The A-Alkali Type factor, however, is not significant (p = 0.69), indicating that its impact on the response variable is minimal.

Interaction terms such as AB, AC, and BC do not exhibit significant effects, as their p-values are well above 0.05, suggesting that interactions between these variables do not notably impact the response. Among the quadratic terms, B2 shows a marginal effect with a p-value of 0.102, while A2 and C2 are not statistically significant.

The residual sum of squares is 338,025.5, with 17 degrees of freedom, indicating the unexplained variation in the model. The total sum of squares is 1,078,498, representing the overall variability in the dataset. Overall, the ANOVA results suggest that the most influential factors in the model are B-Alkali Concentration and C-Time, while the interactions and quadratic terms have limited impact. The model itself is statistically significant, reinforcing its suitability for explaining the variability in the response variable.

Figure S2a illustrates the coefficient estimate analysis, where the relative influence of experimental factors on tensile strength is evaluated. The results clearly show that alkali concentration (B) and exposure time (C) are the most significant contributors, with negative coefficients of −94.41 and −158.02, respectively. These findings indicate that increasing either concentration or exposure duration reduces the tensile strength of basalt fibers. In contrast, the quadratic terms B2 (104.14) and C2 (102.01) exert a positive influence, suggesting non-linear effects where moderate levels of concentration and time may partially stabilize tensile properties. Figure S2b presents the Variance Inflation Factor (VIF) analysis to assess potential multicollinearity among predictors. All variables exhibit VIF values close to unity, ranging from 1.00 to 1.04, which are far below the threshold of 5, indicating negligible collinearity and ensuring model robustness. This result reinforces the reliability of the coefficient estimates, confirming that the observed effects stem from genuine relationships rather than redundancy among predictors. Collectively, the coefficient and VIF analyses validate the robustness of the RSM model, highlighting concentration and time as dominant parameters in driving the degradation behavior of basalt fibers under alkaline environments.

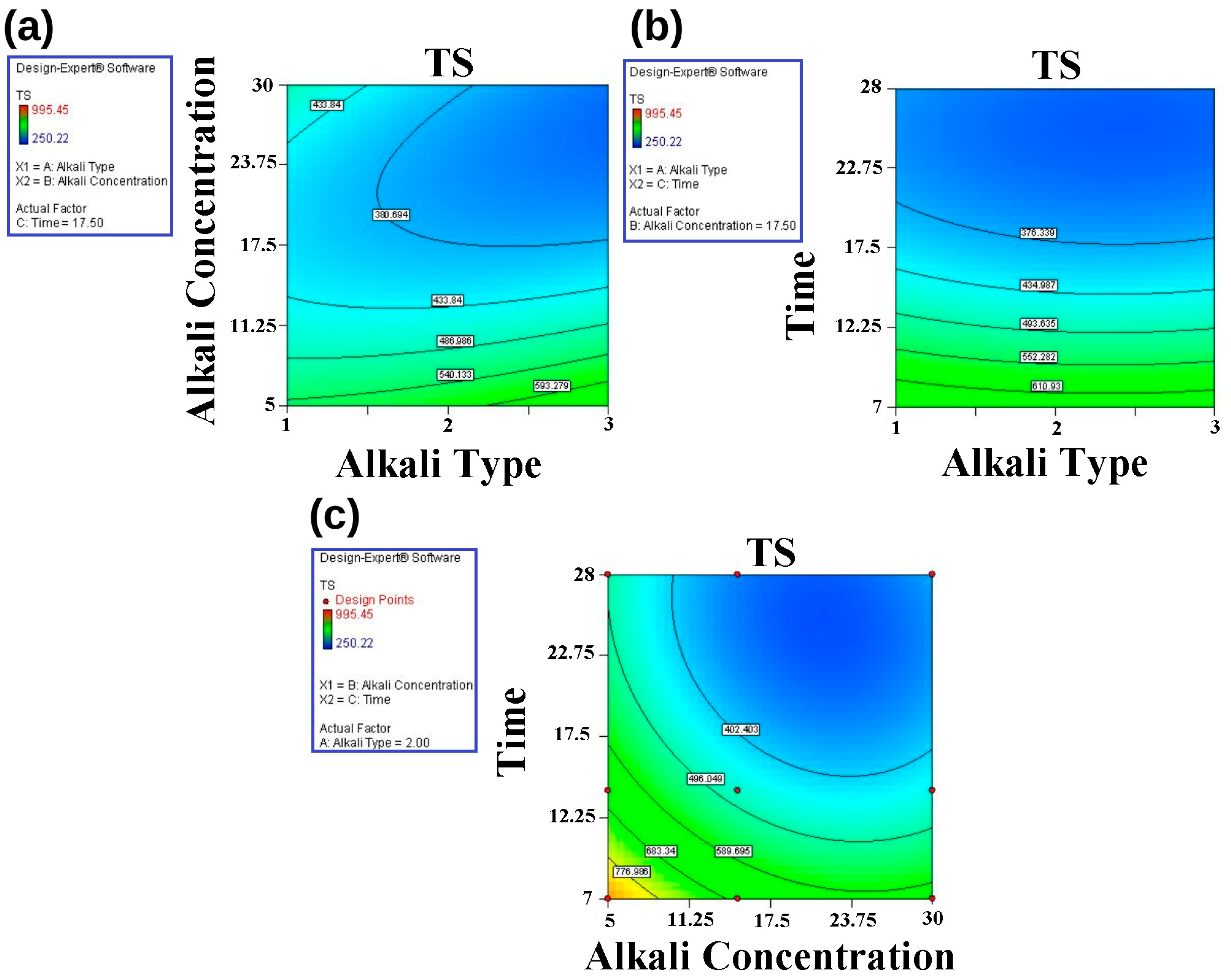

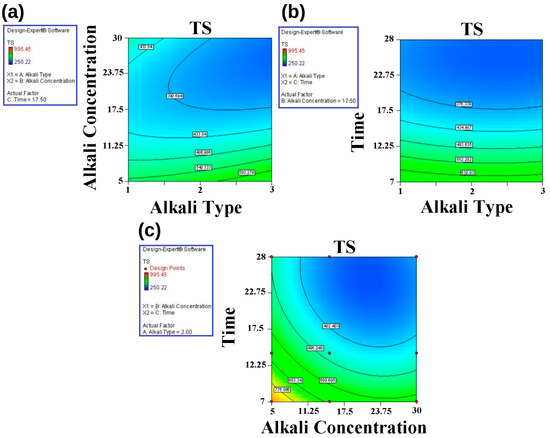

Following the ANOVA analysis, Figure 13a–c presents a sensitivity analysis of the interaction effects of different process parameters on the response variable (Tensile Strength: TS). These contour plots illustrate how changes in the selected parameters influence TS as a sensitive analysis. According to Figure 13a, the range of TS variations is more sensitive to alkali concentration than alkali type, as indicated by the steeper gradient of contour lines along the alkali concentration axis. This observation aligns with the results of the ANOVA analysis, confirming that alkali concentration plays a dominant role in influencing TS. Similarly, in Figure 13b, the effect of alkali type on TS appears to be less significant compared to time, as indicated by the relatively uniform contour distribution. This suggests that changes in the alkali type do not necessarily lead to substantial improvements in TS, reinforcing the statistical findings. Furthermore, Figure 13c highlights that TS is highly sensitive to alkali concentration, particularly at lower levels of reaction time. The observed nonlinear response suggests a potential synergistic effect between alkali concentration and time, where optimal conditions can significantly enhance TS. This behavior further validates the interaction effects identified through ANOVA.

Figure 13.

The sensitive analysis of the quadratic model is based on (a) Alkali Concentration-Alkali type vs. TS, (b) Time-Alkali type vs. TS, and (c) Alkali Concentration-Time vs. TS.

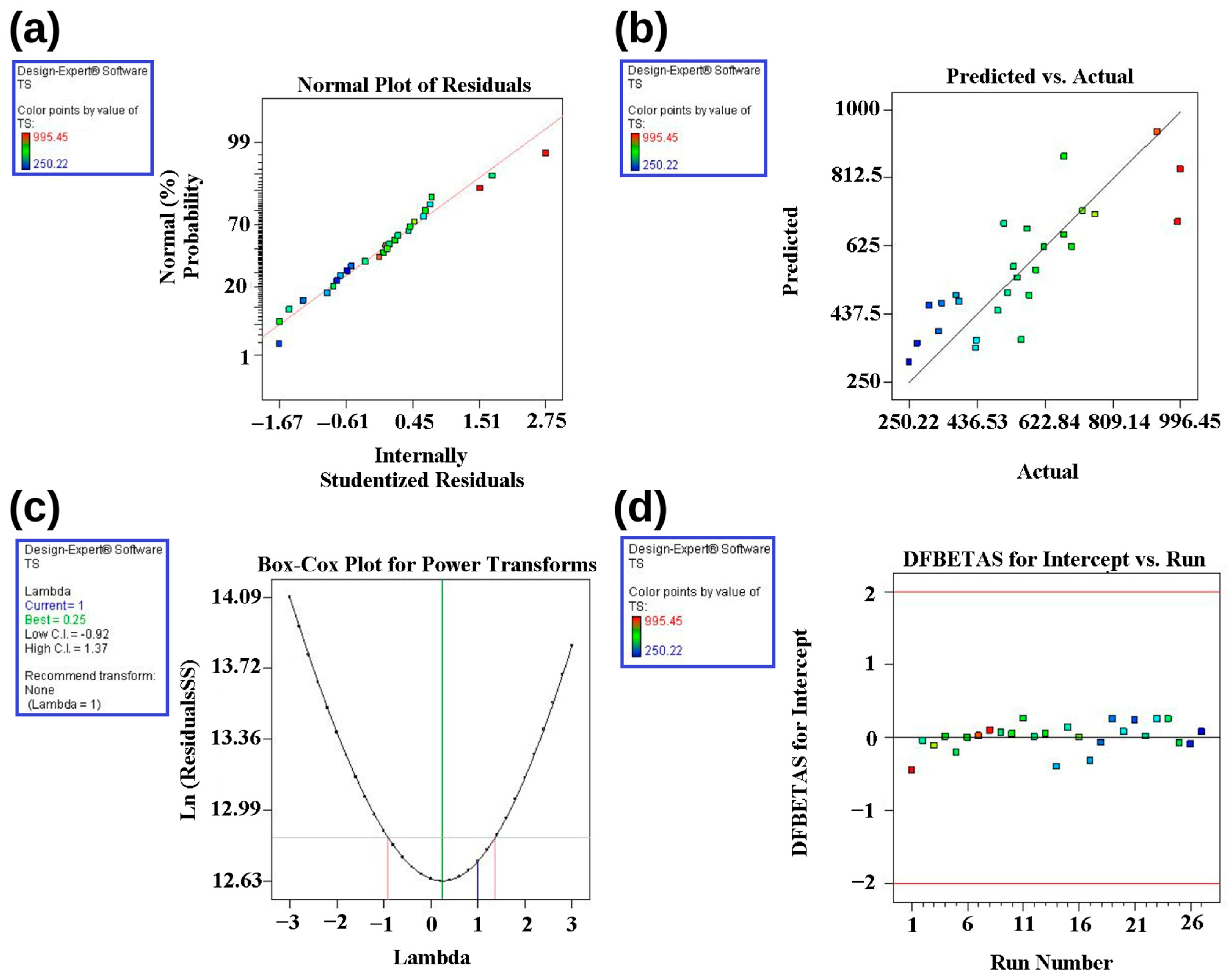

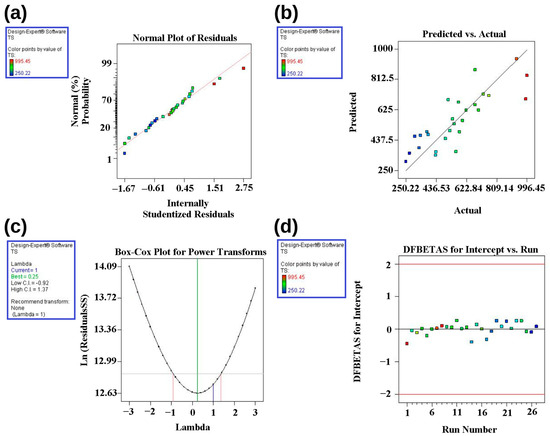

Figure 14a–d presents the residual and model validation plots derived from the RSM analysis for predicting TS based on the experimental factors: alkali type, alkali concentration, and time. According to Figure 14a, the normal probability plot of residuals indicates whether the model errors are normally distributed. The data points closely follow the diagonal reference line, suggesting that the residuals exhibit approximate normality. The presence of no significant deviations or outliers confirms that the assumption of normality is satisfied, ensuring the validity of the regression model. Figure 14b compares the predicted tensile strength values against the actual experimental results. The data points lie close to the 45-degree line, which indicates a strong agreement between predicted and actual values. Minor deviations suggest that while the model provides reliable predictions, there might be slight variations due to experimental noise or unaccounted factors.

Figure 14.

The statistical outputs of RSM analysis are based on (a) Normal Plot of Residuals, (b) Predicted vs. Actual Plot, (c) Box-Cox Plot for Power Transformations, and (d) DFBETAS for Intercept vs. Run Number.

The Box-Cox plot (Figure 14c) evaluates whether a transformation is necessary to improve model accuracy. The λ (lambda) value of 1 suggests that no transformation is required, as the model already satisfies the assumptions of normality and homoscedasticity. The confidence interval (CI) ranges from −0.92 to 1.37, confirming that the current model structure is appropriate for the given data.

Figure 14d assesses the influence of individual experimental runs on the regression model’s intercept. The DFBETAS values remain within the recommended threshold (±1), implying that no single experimental run excessively influences the model. This confirms the robustness of the regression model, suggesting that the tensile strength predictions remain stable across different experimental conditions. Overall, these diagnostic plots confirm that the RSM model effectively describes the relationship between tensile strength and experimental factors. The model assumptions are satisfied, and no significant transformations or adjustments are needed, ensuring reliable predictions within the studied parameter space.

The RSM diagnostics in Figure S3a–d confirm the adequacy of the fitted model for the response TS. In Figure S3a, externally studentized residuals plotted against run number are centered near zero, remain within the ±3 limits, and show no systematic trend across the sequence of runs; the color mapping of TS reveals no structure, consistent with homoscedasticity and independence. Figure S3b displays leverage by run number: a few design points have moderately higher leverage—as expected from the experimental results—but all stay below the customary cutoff (~0.75), indicating stable coefficient estimates. In Figure S3c, Cook’s distance values are well below the reference line (1.0), showing that removing any single run would not materially alter the fitted coefficients. Figure S3d plots DFFITS by run number; values cluster near zero and lie within the ±2 guideline, confirming the absence of influential runs and supporting robust predictions. Collectively, these diagnostics support key assumptions underlying RSM—linearity in coded factors and independent errors with approximately constant variance—and indicate that no individual experimental trial unduly drives the fit, allowing the response surface and effect estimates to be interpreted confidently for optimization and sensitivity analysis.

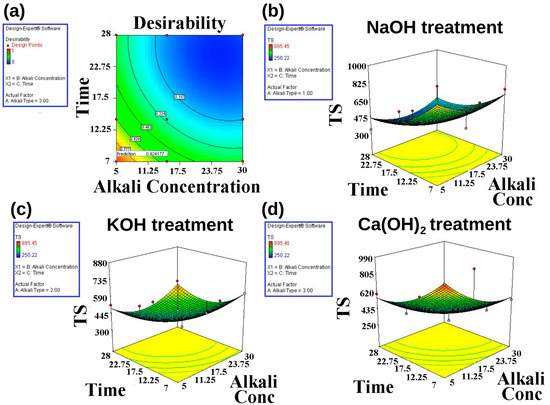

Table 8 presents the RSM-optimized TS values for different alkali types at a fixed concentration (5) and time (7). The highest TS (938.94 MPa) and desirability (0.92) are achieved with Ca(OH)2, followed by KOH (867.49 MPa, 0.828) and NaOH (834.64 MPa, 0.784), indicating Ca(OH)2 as the most effective for TS enhancement.

Table 8.

The outcomes of optimization through RSM analysis for three input parameters.

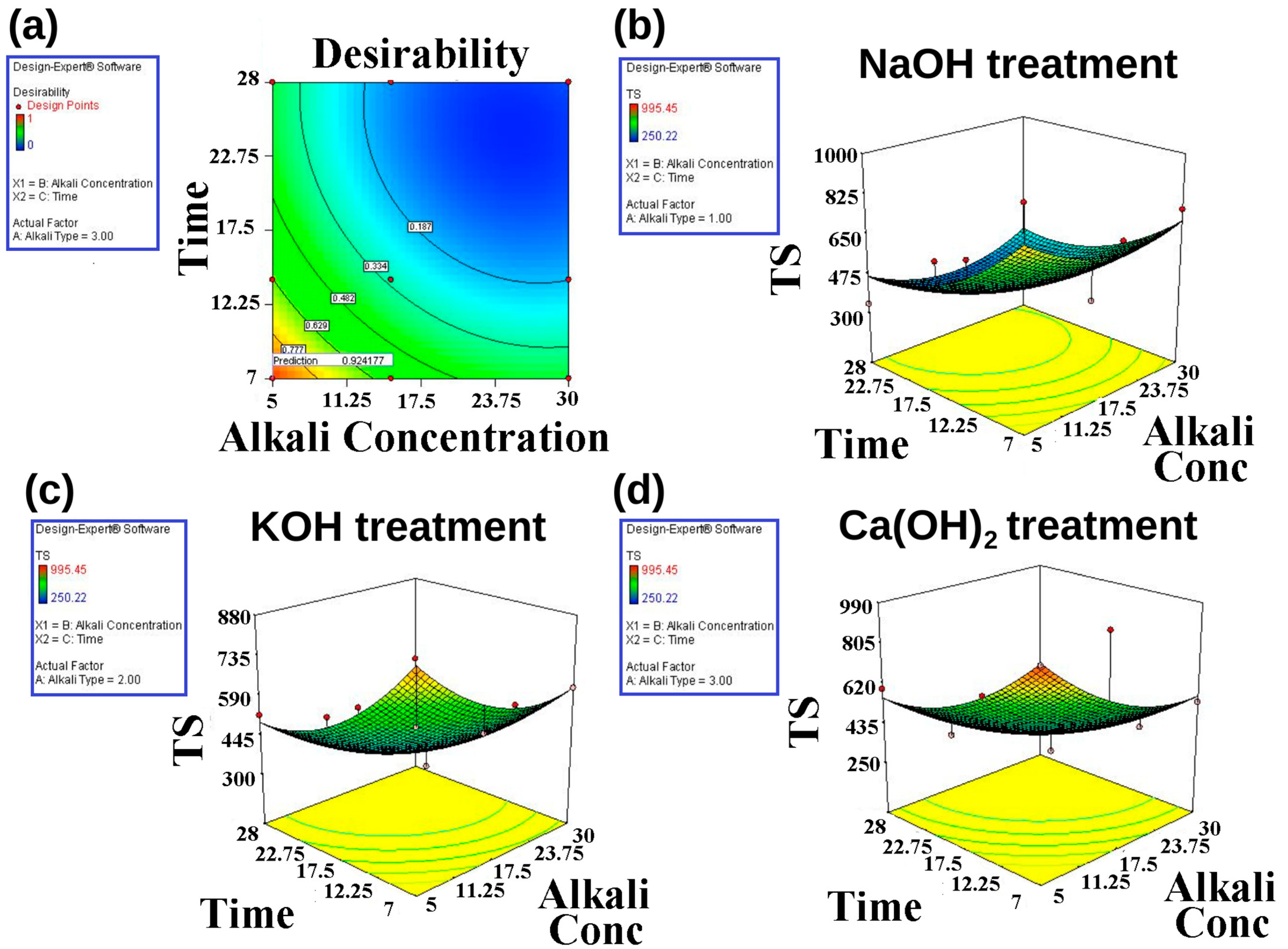

Figure 15a–d presents graphical representations derived from the RSM analysis, illustrating the desirability function (Figure 15a) and three-dimensional response surface plots for TS under different alkali treatments (Figure 15b–d). The analysis aims to determine the optimal conditions for maximizing TS based on alkali type, concentration, and treatment time.

Figure 15.

The outcomes of the optimization procedure are based on (a) a contour plot of desirability for tensile strength optimization, (b) NaOH, (c) KOH, and (d) Ca(OH)2 treatments.

Figure 15a visualizes the desirability function associated with the RSM model, reflecting how well the selected input variables optimize tensile strength. The desirability index ranges from 0 to 1, with higher values indicating more favorable conditions. This plot corresponds to Suggestion 1 in Table 7, where the highest desirability (0.92) was achieved using Ca(OH)2 at an alkali concentration of 5 and a treatment time of 7 h. The contour plot demonstrates that desirability increases at lower concentrations and moderate treatment times, confirming that excessive exposure to alkali may negatively impact TS. According to Figure 15b, the three-dimensional response surface plot for NaOH treatment shows a non-linear relationship between TS and the two factors (alkali concentration and time). The plot suggests that increasing both concentration and time initially enhances TS, but excessive treatment duration leads to a decline. The contour plot at the bottom indicates that optimal tensile strength is achieved at moderate alkali concentrations and a treatment time of around 7–10 h. However, the maximum TS observed with NaOH (as seen in Table 7) is lower than that of other alkali types, making it less effective for tensile strength improvement. Based on Figure 15c, for KOH treatment, the response surface plot exhibits a more pronounced peak, suggesting a stronger dependence on alkali concentration and treatment duration. The curvature indicates that TS increases significantly with moderate concentration and time but declines beyond a critical threshold. Compared to NaOH, KOH results in higher tensile strength values, but the peak is not as pronounced as that observed in the Ca(OH)2 treatment. This suggests that KOH provides better modification of material properties than NaOH but is still not the optimal choice.

The response surface plot for Ca(OH)2 reveals a relatively symmetrical curvature, indicating a stable and predictable relationship between tensile strength, alkali concentration, and treatment time (Figure 15d). The peak of the surface is noticeably higher than in the NaOH and KOH treatments, confirming that Ca(OH)2 achieves the highest TS values. The contour plot at the base further supports that optimal TS is achieved at moderate alkali concentrations and treatment times around 7–10 h. This aligns with the desirability function in Figure 15a and the optimal conditions suggested in Table 7.

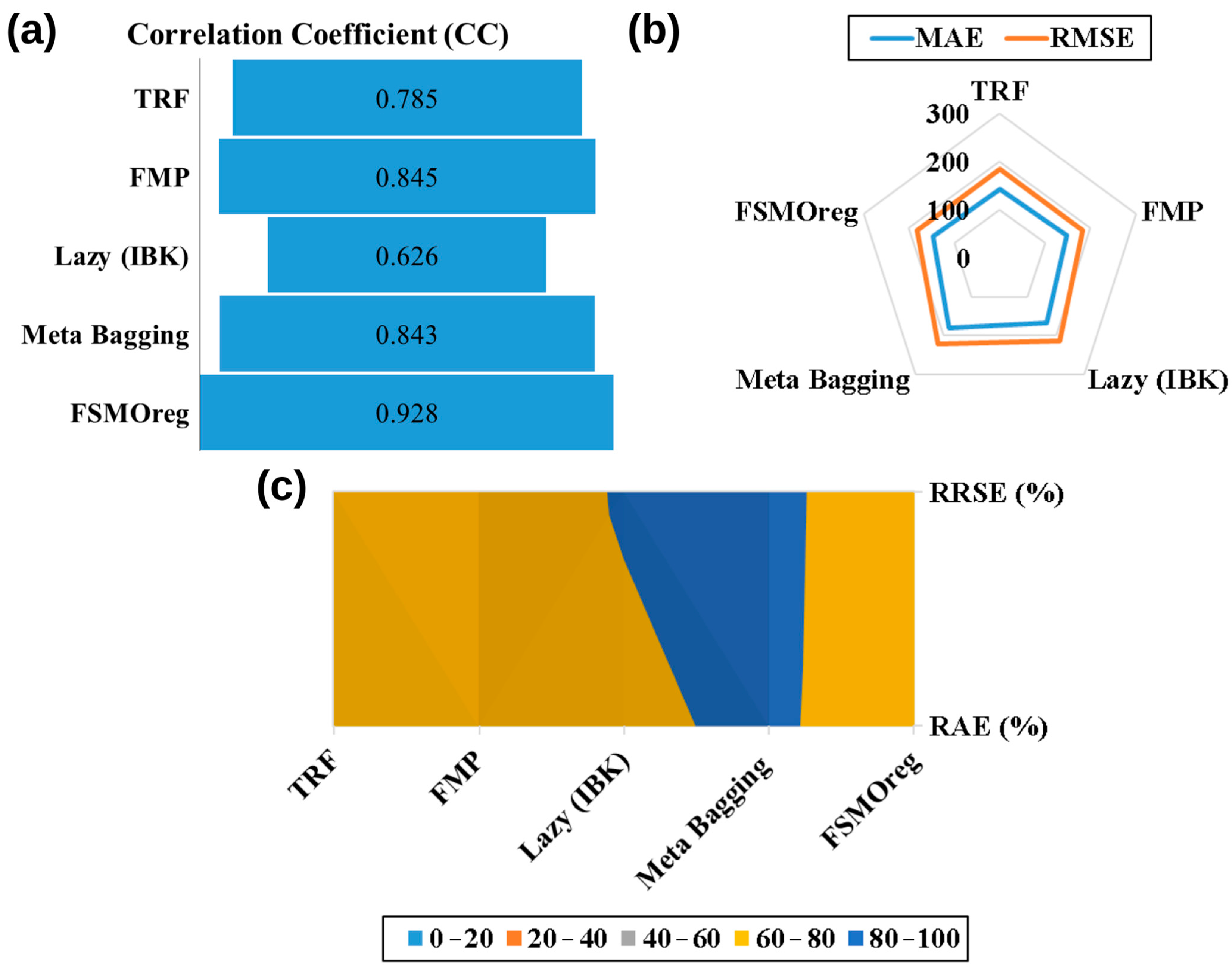

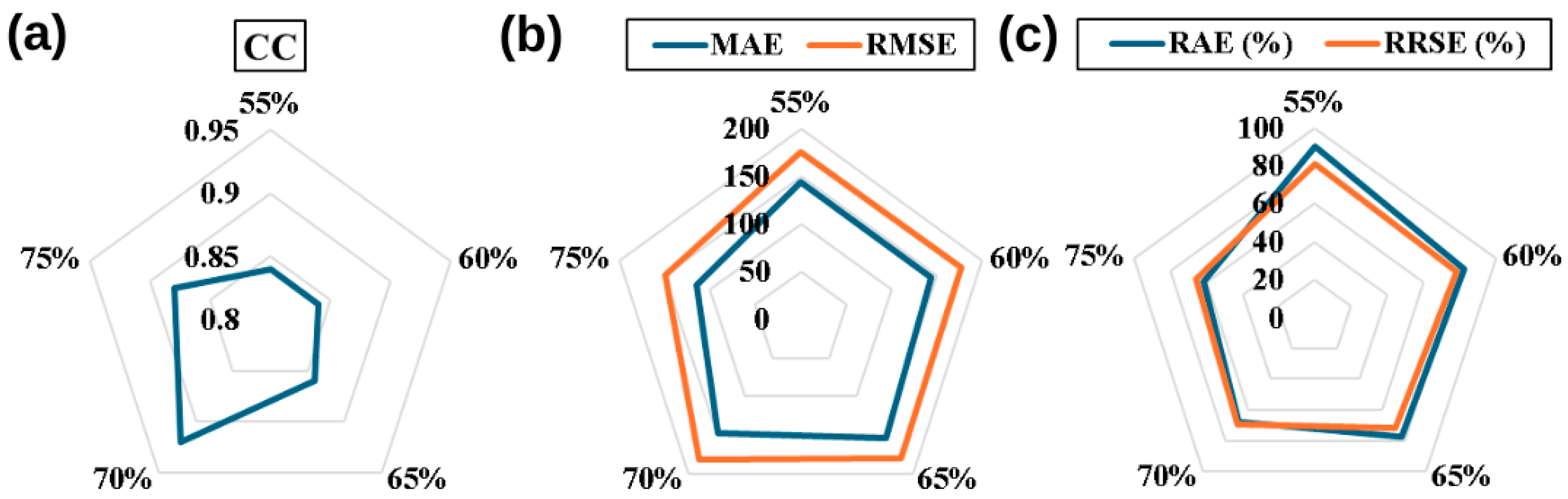

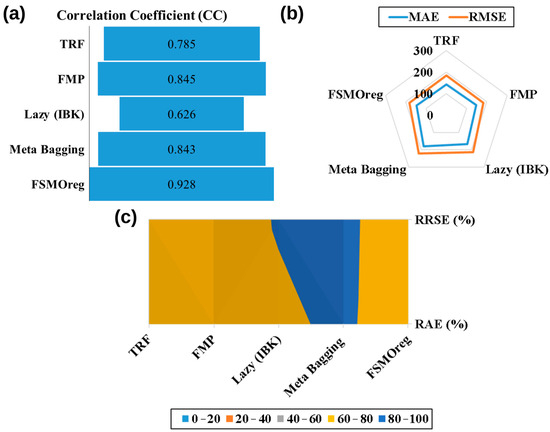

Figure 16 presents a comparative evaluation of five machine learning models—Trees Random Forest (TRF), Function Multilayer Perceptron (FMP), Instance-Based K-nearest neighbor (Lazy IBK), Meta Bagging, and Function Sequential Minimal Optimization for Regression (FSMOreg)—for predicting tensile strength (TS) based on three input variables. The models are assessed using various performance metrics, including Correlation Coefficient (CC), Mean Absolute Error (MAE), Root Mean Square Error (RMSE), Relative Absolute Error (RAE), and Root Relative Squared Error (RRSE). Recent studies have demonstrated the growing application of machine learning in predicting the mechanical properties of basalt fiber-reinforced composites, highlighting its potential for accurate and reliable predictions [71,72,73,74].

Figure 16.

The outcomes of ML modelling are based on: (a) CC of ML models, (b) MAE and RMSE comparison, and (c) RRSE and RAE analysis of different models.

Figure 16a shows the Correlation Coefficient (CC) values, indicating the strength of the relationship between predicted and actual TS values. FSMOreg demonstrates the highest CC of 0.928, showcasing the strongest predictive ability. FMP (0.845) and Meta Bagging (0.843) perform well but slightly lower than FSMOreg, while TRF (0.785) exhibits moderate accuracy. Lazy IBK (0.626) records the lowest CC, suggesting weaker predictive reliability compared to the other models. Figure 16b compares the mean absolute error (MAE) and root mean square error (RMSE) values in a radar plot, highlighting the prediction error of each model. FSMOreg exhibits the lowest RMSE (181.94) and a relatively low MAE (147.5), underscoring its high prediction accuracy. TRF, with the lowest MAE (143.004) but a slightly higher RMSE (183.91), suggests moderate but consistent performance. FMP (MAE: 148.4, RMSE: 184.006) follows closely, indicating similar prediction capability. Meta Bagging records the highest RMSE (220.33) and MAE (180.82), reflecting weaker predictive performance. Similarly, Lazy IBK demonstrates high error values (MAE: 166.72, RMSE: 213.82), reinforcing its lower predictive efficiency. Figure 16c illustrates the relative errors (RAE and RRSE) as percentages, providing further insights into the models’ predictive reliability. FSMOreg achieves the lowest combined errors (RAE: 67.96%, RRSE: 69.19%), confirming its superior prediction accuracy. TRF (RAE: 65.87%, RRSE: 69.94%) exhibits a slightly lower RAE but a marginally higher RRSE than FSMOreg, while FMP (RAE: 68.35%, RRSE: 69.97%) performs similarly to TRF. In contrast, Lazy IBK (RAE: 76.79%, RRSE: 81.31%) and Meta Bagging (RAE: 83.29%, RRSE: 83.79%) show the highest relative errors, indicating less reliable predictions.

As a critical analysis, FSMOreg outperforms due to its foundation in Support Vector Regression (SVR), which leverages margin maximization and kernel tricks to model complex nonlinear relationships with high generalization. Its superior CC (0.928) and lowest RMSE/RAE reflect minimal overfitting and strong noise tolerance. Unlike tree-based or instance-based models, FSMOreg effectively balances the bias-variance trade-off, ensuring reliable tensile strength prediction.

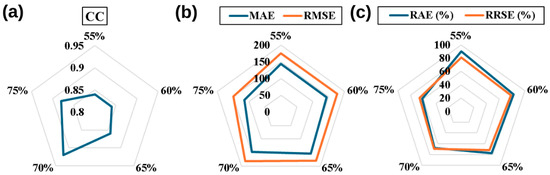

The hyperparametric analysis of the SMOreg model using different training–testing split percentages (55%, 60%, 65%, 70%, and 75%) further validates its position as the best-performing predictor in this study. The evaluation results, summarized in Figure 17a–c and supported by the exact data table, demonstrate consistent and robust predictive performance across multiple statistical indices. Figure 17a illustrates the CC, which ranges between 0.84 and 0.92 across the splits. The highest CC value of 0.92 is achieved at the 70% split, indicating excellent agreement between predicted and observed values. Even at the lowest splits, CC remains strong (0.84), confirming the reliability and generalizability of the model.

Figure 17.

Hyperparametric analysis of the SMOreg model under different training–testing splits: (a) CC, (b) MAE and RMSE, (c) RAE and RRSE.

Figure 17b presents the error-based measures, MAE and RMSE. The MAE values fluctuate between 115.35 and 153.55, while RMSE values range from 150.08 to 181.94. The lowest errors are observed at the 75% split (MAE = 115.35, RMSE = 150.08), suggesting that with a larger training dataset, the model achieves better predictive precision and reduces significant deviations.

Figure 17c reports the relative error measures, RAE and RRSE. Both indices steadily decrease as the training percentage increases, with RAE improving from 90.29% at the 55% split to 61.7% at the 75% split, and RRSE declining from 81.16% to 65.64% across the same range. These values confirm that the SMOreg model consistently outperforms a mean-based baseline and demonstrates stronger relative performance as more training data are provided. Overall, the combined results reveal that the SMOreg model achieves high correlation, low absolute and squared errors, and favorable relative error rates across all tested splits. The balance between accuracy (CC), error reduction (MAE and RMSE), and efficiency relative to a baseline (RAE and RRSE) confirms SMOreg as the most effective predictive model in this application, with its best performance evident at higher training–testing splits, particularly 70% and 75%.

4. Conclusions

This study systematically examined the durability of basalt fibers when exposed to different alkaline environments, incorporating experimental techniques, Response Surface Methodology (RSM), and Machine Learning (ML) models to optimize and predict their mechanical performance. The results confirmed that the degradation of basalt fibers is highly influenced by the type and concentration of alkaline solutions, as well as the duration of exposure. Among the tested solutions, Ca(OH)2 exhibited the least detrimental effect, maintaining superior tensile strength (maximum 938.94 MPa) compared to NaOH and KOH. The observed degradation trends were attributed to the breakdown of Si-O-Si bonds in the fiber structure, leading to varying degrees of weight loss and mechanical weakening. The machine learning analysis identified FSMOreg as the most accurate predictive model, achieving a correlation coefficient of 0.928 with the lowest error metrics (RMSE: 181.94). The predictive capability of FSMOreg underscores the potential of ML-based approaches in optimizing material selection for sustainable construction. Moreover, the RSM-based optimization revealed that lower alkali concentrations and shorter exposure durations contribute to enhanced tensile strength retention, reinforcing the significance of controlled treatment conditions. The findings of this study have significant implications for the use of basalt fibers in cementitious applications, particularly in environments where long-term exposure to alkaline conditions is inevitable. By integrating experimental observations with advanced computational techniques, this research provides a comprehensive framework for improving the selection and treatment of basalt fibers in sustainable construction materials. Future work should focus on extending the experimental duration and exploring additional environmental variables, such as temperature and humidity, to further refine predictive models and enhance the durability of fiber-reinforced composites.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/fib13100137/s1, Figure S1. Contour plot analysis of the quadratic RSM equation in the present study. Figure S2. Regression Coefficient and Multicollinearity Analysis in the RSM appraisal of the present study. Figure S3. RSM diagnostic plots for TS: (a) externally studentized residuals, (b) leverage, (c) Cook’s distance, and (d) DFFITS vs. run number.

Author Contributions

A.M.: Planning, main conceptual ideas, and proof outline, worked out almost all the technical details, experimental practices, mathematical formulation and performed the optimization. comparison of this study’s outcomes with another study. M.P.: Planning, main conceptual ideas and proof outline, comparison of this study’s outcomes with another study. supervised the designing of the methodology, and findings of this work and worked out the validation, editing, and reviewing of the paper. B.T.: worked out experimental details, supervised the designing of methodology, reviewed and edited the manuscript. M.T.N.: worked out experimental practices, and mathematical formulation and performed the optimization. Discussed the results and contributed to the final manuscript. M.G.: worked out almost all the technical details, experimental practices, and mathematical formulation and performed the optimization. K.B.: supervised the designing of methodology, and findings of this work and worked out the validation, editing and reviewing of the paper. J.W.: developed some novel ideas in this research, supervised the designing of the methodology, and findings of this work, and worked out the validation, editing, and reviewing of the paper. L.H.: developed some novel ideas in this research, supervised the designing of the methodology, and findings of this work, and worked out the validation, editing, and reviewing of the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data will be available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kirchberger, M. The Role of the Construction Sector; UNU-WIDER: Helsinki, Finland, 2018. [Google Scholar] [CrossRef]

- Murtagh, N.; Scott, L.; Fan, J. Sustainable and resilient construction: Current status and future challenges. J. Clean. Prod. 2020, 268, 122264. [Google Scholar] [CrossRef]

- de Oliveira Fernandes, M.A.; Keijzer, E.; van Leeuwen, S.; Kuindersma, P.; Melo, L.; Hinkema, M.; Gutierrez, K.G. Material-versus energy-related impacts: Analysing environmental trade-offs in building retrofit scenarios in the Netherlands. Energy Build. 2021, 231, 110650. [Google Scholar] [CrossRef]

- Krausmann, F.; Wiedenhofer, D.; Lauk, C.; Haas, W.; Tanikawa, H.; Fishman, T.; Miatto, A.; Schandl, H.; Haberl, H. Global socioeconomic material stocks rise 23-fold over the 20th century and require half of annual resource use. Proc. Natl. Acad. Sci. USA 2017, 114, 1880–1885. [Google Scholar] [CrossRef]

- Quidel, G.R.; Acuña, M.J.S.; Herrera, C.J.R.; Neira, K.R.; Cárdenas-Ramírez, J. Assessment of Modular Construction System Made with Low Environmental Impact Construction Materials for Achieving Sustainable Housing Projects. Sustainability 2023, 15, 8386. [Google Scholar] [CrossRef]

- Ren, Q.; Ding, L.; Dai, X.; Jiang, Z.; De Schutter, G. Prediction of Compressive Strength of Concrete with Manufactured Sand by Ensemble Classification and Regression Tree Method. J. Mater. Civ. Eng. 2021, 33, 04021135. [Google Scholar] [CrossRef]

- Ren, Q.; Ding, L.; Dai, X.; Li, C.; Li, C.; Jiang, Z. Optimizing mix design of concrete with manufactured sand for low embodied carbon and desired strength using machine learning. Constr. Build. Mater. 2024, 457, 139407. [Google Scholar] [CrossRef]

- Makul, N. Introduction to the Principles of Cement and Concrete Composites. In Principles of Cement and Concrete Composites; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–27. [Google Scholar] [CrossRef]

- Aboutair, W.; Chaid, R.; Perrot, A. Impact of the nature of fibers on the physicomechanical behavior and durability of cement matrices. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 1467–1482. [Google Scholar] [CrossRef]

- Mishra, J.; Panigrahi, R. Mini-Review on Structural Performance of Fiber Reinforced Geopolymer Concrete. Int. J. Innov. Technol. Interdisci. Sci. 2020, 3, 435–442. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Medeiros, M.G.; Nadaleti, W.C.; Rocha, J.C.; Cheriaf, M.; Gleise, P.J.P.; de Castilhos, A.B. A cleaner material production by the incorporation of the rockwool waste into portland cement matrices. J. Clean. Prod. 2021, 293, 126059. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Yao, X.; Fang, R. Chapter 1—Inorganic fibers for biomedical engineering applications. In Materials for Biomedical Engineering; Grumezescu, V., Grumezescu, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–32. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z. Mechanical Properties of Natural as well as Synthetic Fiber Reinforced Concrete: A Review. Constr. Build. Mater. 2022, 333, 127353. [Google Scholar] [CrossRef]

- Dai, X.; Tao, Y.; Zhang, Y.; Ding, L.; Van Tittelboom, K.; De Schutter, G. Development of 3D printable alkali-activated slag-metakaolin concrete. Constr. Build. Mater. 2024, 444, 137775. [Google Scholar] [CrossRef]

- Yan, L.; Chu, F.; Tuo, W.; Zhao, X.; Wang, Y.; Zhang, P.; Gao, Y. Review of research on basalt fibers and basalt fiber-reinforced composites in China (I): Physicochemical and mechanical properties. Polym. Polym. Compos. 2021, 29, 1612–1624. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef]

- Fořt, J.; Kočí, J.; Černý, R. Environmental Efficiency Aspects of Basalt Fibers Reinforcement in Concrete Mixtures. Energies 2021, 14, 7736. [Google Scholar] [CrossRef]

- Natkunarajah, K.; Masilamani, K.; Maheswaran, S.; Lothenbach, B.; Amarasinghe, D.A.S.; Attygalle, D. Analysis of the trend of pH changes of concrete pore solution during the hydration by various analytical methods. Cem. Concr. Res. 2022, 156, 106780. [Google Scholar] [CrossRef]

- Foon, L.Y.; Othman, R.B.; Jaya, R.P.; Sulaiman, M.A.; Duraisamy, Y. Durability of Basalt Rebars under Alkaline Environment. In Sustainable Construction (WSCC 2022); Trans Tech Publications Ltd.: Baech, Switzerland, 2023; Volume 4, pp. 35–45. [Google Scholar] [CrossRef]

- Li, M.; Xing, D.; Zheng, Q.-B.; Li, H.; Hao, B.; Ma, P.-C. Variation on the morphology and tensile strength of basalt fiber processed in alkali solutions. Constr. Build. Mater. 2022, 335, 127512. [Google Scholar] [CrossRef]

- Scheffler, C.; Förster, T.; Mäder, E.; Heinrich, G.; Hempel, S.; Mechtcherine, V. Aging of alkali-resistant glass and basalt fibers in alkaline solutions: Evaluation of the failure stress by Weibull distribution function. J. Non-Cryst. Solids 2009, 355, 2588–2595. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, M.; Wang, Y.; Wu, G.; Wu, Z. Tensile behaviors of ECR-glass and high strength glass fibers after NaOH treatment. Ceram. Int. 2013, 39, 9173–9178. [Google Scholar] [CrossRef]

- Xing, D.; Chen, L.; Ma, Q.; Hao, B.; Gutnikov, S.I.; Lazoryak, B.I.; Mäder, E.; Ma, P.C. What happens to glass fiber under extreme chemical conditions? J. Non-Cryst. Solids 2020, 548, 120331. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, Y.; Randl, N. Investigation on the alkali resistance of basalt fiber and its textile in different alkaline environments. Constr. Build. Mater. 2021, 272, 121670. [Google Scholar] [CrossRef]

- Ruengsillapanun, K.; Udtaranakron, T.; Pulngern, T.; Tangchirapat, W.; Jaturapitakkul, C. Mechanical properties, shrinkage, and heat evolution of alkali activated fly ash concrete. Constr. Build. Mater. 2021, 299, 123954. [Google Scholar] [CrossRef]

- Lee, J.J.; Song, J.; Kim, H. Chemical stability of basalt fiber in alkaline solution. Fibers Polym. 2014, 15, 2329–2334. [Google Scholar] [CrossRef]

- Ying, S.; Zhou, X. Chemical and thermal resistance of basalt fiber in inclement environments. J. Wuhan Univ. Technol. Sci. Ed. 2013, 28, 560–565. [Google Scholar] [CrossRef]

- Sun, B.; Ding, L.; Ye, G.; De Schutter, G. Mechanical properties prediction of blast furnace slag and fly ash-based alkali-activated concrete by machine learning methods. Constr. Build. Mater. 2023, 409, 133933. [Google Scholar] [CrossRef]

- Hassan, M.; Benmokrane, B.; ElSafty, A.; Fam, A. Bond durability of basalt-fiber-reinforced-polymer (BFRP) bars embedded in concrete in aggressive environments. Compos. Part B Eng. 2016, 106, 262–272. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Y.; Zhuo, J.; Zhang, Y.; Wan, C. A review of the mechanical properties and durability of basalt fiber-reinforced concrete. Constr. Build. Mater. 2022, 359, 129360. [Google Scholar] [CrossRef]

- Sohail, M.G.; Alnahhal, W.; Taha, A.; Abdelaal, K. Sustainable alternative aggregates: Characterization and influence on mechanical behavior of basalt fiber reinforced concrete. Constr. Build. Mater. 2020, 255, 119365. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Zhu, D.; Liu, S.; Yao, Y.; Li, G.; Du, Y.; Shi, C. Effects of short fiber and pre-tension on the tensile behavior of basalt textile reinforced concrete. Cem. Concr. Compos. 2019, 96, 33–45. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental Study on Basic Mechanical Properties of Basalt Fiber Reinforced Concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef]

- Lv, F.; Wang, L.; An, H.; Chen, S.; Shu, J.; Kong, D. Effects of hybrid fibers on properties of desulfurized gypsum-based composite cementitious materials. Constr. Build. Mater. 2023, 392, 131840. [Google Scholar] [CrossRef]

- Iftikhar, B.; Alih, S.C.; Vafaei, M.; Ali, M.; Javed, M.F.; Asif, U.; Ismailb, M.; Umerb, M.; Gamil, Y.; Amran, M. Experimental study on the eco-friendly plastic-sand paver blocks by utilising plastic waste and basalt fibers. Heliyon 2023, 9, e17107. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Sun, X.; Tian, Z.; Liu, H.; Zeng, Z. Deterioration of Basalt Fiber in Cementitious Material and Mitigation with Basalt Powder. J. Mater. Civ. Eng. 2023, 35, 4023103. [Google Scholar] [CrossRef]

- Xu, J.; Kang, A.; Wu, Z.; Xiao, P.; Gong, Y. Evaluation of workability, microstructure and mechanical properties of recycled powder geopolymer reinforced by waste hydrophilic basalt fiber. J. Clean. Prod. 2023, 396, 136514. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, D.; Shen, Z.; Shao, W.; Gan, L.; Yuan, Y.; Tang, P.; Zhao, S.; Chen, Y. Reduction of the calcium leaching effect on the physical and mechanical properties of concrete by adding chopped basalt fibers. Constr. Build. Mater. 2023, 365, 130080. [Google Scholar] [CrossRef]

- Annadurai, S.; Baskar, P.; Elango, K.S. Geopolymer concrete reinforced with basalt fibres: An experimental investigation. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Sun, Z.; He, W.; Niu, D.; Zhang, L.; Su, L.; Wang, X. Resistivity Prediction Model for Basalt–Polypropylene Fiber-Reinforced Concrete. Buildings 2023, 13, 84. [Google Scholar] [CrossRef]

- Najm, O.F.; Mohamed, O.A.; Alzard, M.H. The efficiency of statistical and artificial neural network techniques on evaluating and predicting compressive strength of sustainable SCC with basalt fibers. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, B.; Zhuge, Y.; Huang, Z. Properties of hybrid basalt-polypropylene fiber reinforced mortar at different temperatures. Constr. Build. Mater. 2022, 346, 128433. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. Experimental and Artificial Neural Network-Based Study on the Sorptivity Characteristics of Geopolymer Concrete with Recycled Cementitious Materials and Basalt Fibres. Recycling 2022, 7, 55. [Google Scholar] [CrossRef]

- Textiles—Threads on Bobbins—Determination of the Strength and Elongation of Individual Threads at Break Using a Constant Rate of Elongation (CRE) Device. Available online: https://www.technicke-normy-csn.cz/csn-en-iso-2062-800700-228478.html# (accessed on 17 September 2023).

- Textiles—Fibers—Determination of Strength and Ductility of Individual Fibers at Break. Available online: https://www.technicke-normy-csn.cz/csn-en-iso-5079-800200-228338.html# (accessed on 17 September 2023).

- Plastics—Thermogravimetry (TG) of Polymers—Part 1: General Principles. Available online: https://shop.normy.biz/detail/515450 (accessed on 17 September 2023).

- Plastics—Differential Scanning Calorimetry (DSC)—Part 1: Basic Principles. Available online: https://shop.normy.biz/detail/502017 (accessed on 17 September 2023).

- Microbeam Analysis—Scanning Electron Microscopy—Qualification of the Scanning Electron Microscope for Quantitative Measurements. Available online: https://www.iso.org/standard/70832.html (accessed on 17 September 2023).

- Ramaswamy, R.; Yliniemi, J.; Illikainen, M. Dissolution-precipitation reactions of silicate mineral fibers at alkaline pH. Cem. Concr. Res. 2022, 160, 106922. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Tensile behavior contrast of basalt and glass fibers after chemical treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Petropavlovskaya, V.; Zavadko, M.Y.; Petropavlovskii, K.S.; Novichenkova, T.B. Behavior of Basalt Fibers in an Alkaline Environment. Solid State Phenom. 2022, 334, 253–258. [Google Scholar] [CrossRef]

- Mahesh, V.M.V.; Ponnusami, S.A. Influence of Alkali Treatment on Mechanical Properties of Short Cocos nucifera Fiber Reinforced Epoxy Based Sustainable Green Composite. J. Nat. Fibers 2022, 19, 15291–15299. [Google Scholar] [CrossRef]

- Tang, C.; Jiang, H.; Zhang, X.; Li, G.; Cui, J. Corrosion Behavior and Mechanism of Basalt Fibers in Sodium Hydroxide Solution. Materials 2018, 11, 1381. [Google Scholar] [CrossRef]

- Kumar, N.; Das, D. Alkali treatment on nettle fibers part II: Design of experiment and desirability function approach to study enhancement of tensile properties. J. Text. Inst. 2017, 108, 1468–1475. [Google Scholar] [CrossRef]

- Lobregas, M.O.S.; Buniao, E.V.D.; Leaño, J.L. Alkali-enzymatic treatment of Bambusa blumeana textile fibers for natural fiber-based textile material production. Ind. Crops Prod. 2023, 194, 116268. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Mandegari, M.; Mostofinejad, D.; Abtahi, S.M. A review on performance of polyester fibers in alkaline and cementitious composites environments. Constr. Build. Mater. 2020, 241, 117998. [Google Scholar] [CrossRef]

- Tu, M.Y.; Velasco, J.I.; Valles, C.; Gloria, A.; Lin, W.Z.; Li, Z.M.; Ruan, G.L.; Liu, F. Review: Progress in the Studies on Mechanical Properties of Materials. Strength Mater. 2014, 46, 160–163. [Google Scholar] [CrossRef]

- Madueke, C.I.; Pandita, S.D.; Biddlestone, F.; Fernando, G.F. Effects of NaOH treatment and NaOH treatment conditions on the mechanical properties of coir fibres for use in composites manufacture. J. Indian Acad. Wood Sci. 2024, 21, 100–111. [Google Scholar] [CrossRef]

- Jena, S.; Khatri, V.N.; Nainegali, L.; Dutta, R.K. Study on Physical, Mechanical, Morphological, and Crystallographic Properties of Chemically Treated Sisal Fibers. Fibers Polym. 2024, 25, 2517–2534. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.; Feng, Z.; Ge, L.; Li, R.; Liu, S. Study on the interfacial bonding properties between alkali-treated bamboo fibers and high-performance seawater sea-sand concrete. Constr. Build. Mater. 2024, 426, 136190. [Google Scholar] [CrossRef]

- Wei, C.; Zhou, Q.; Deng, K.; Lin, Y.; Wang, L.; Luo, Y.; Zhang, Y.; Zhou, H. Alkali resistance prediction and degradation mechanism of basalt fiber: Integrated with artificial neural network machine learning model. J. Build. Eng. 2024, 86, 108850. [Google Scholar] [CrossRef]

- Seredina, M.A. Thermochemical Transformations of Fibers with Aromatic and Heterocyclic Structures. Fibre Chem. 2019, 51, 217–219. [Google Scholar] [CrossRef]

- Yao, F.; Wu, Q.; Lei, Y.; Guo, W.; Xu, Y. Thermal decomposition kinetics of natural fibers: Activation energy with dynamic thermogravimetric analysis. Polym. Degrad. Stab. 2008, 93, 90–98. [Google Scholar] [CrossRef]

- Overkamp, T.; Mahltig, B.; Kyosev, Y. Strength of basalt fibers influenced by thermal and chemical treatments. J. Ind. Text. 2018, 47, 815–833. [Google Scholar] [CrossRef]

- Mansa, R.; Zou, S. Thermogravimetric analysis of microplastics: A mini review. Environ. Adv. 2021, 5, 100117. [Google Scholar] [CrossRef]

- Mukasyan, A.S. DTA/TGA-Based Methods. In Concise Encyclopedia of Self-Propagating High-Temperature Synthesis; Borovinskaya, I., Gromov, A.A., Levashov, E.A., Maksimov, Y.M., Mukasyan, A.S., Rogachev, A.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 93–95. [Google Scholar] [CrossRef]

- Chetehouna, K.; Belayachi, N.; Rengel, B.; Hoxha, D.; Gillard, P. Investigation on the thermal degradation and kinetic parameters of innovative insulation materials using TGA-MS. Appl. Therm. Eng. 2015, 81, 177–184. [Google Scholar] [CrossRef]

- Liu, G.; Zheng, L.; Long, P.; Yang, L.; Zhang, L. Ensemble Learning and SHAP Interpretation for Predicting Tensile Strength and Elastic Modulus of Basalt Fibers Based on Chemical Composition. Sustainability 2025, 17, 7387. [Google Scholar] [CrossRef]

- Wickramasuriya, B.Y.; Alahakoon, Y.; Krishantha, B.R.G.A.; Alawatugoda, J.; Ekanayake, I.U. Prediction of the strength characteristics of basalt fibre reinforced concrete using explainable machine learning models. Discov. Appl. Sci. 2025, 7, 890. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Alharbi, Y.R. Hybrid machine learning modeling of strength in sustainable basalt fiber-reinforced concrete. Mater. Today Commun. 2025, 46, 112554. [Google Scholar] [CrossRef]

- Ullah, I.; Javed, M.F.; Alabduljabbar, H.; Ullah, H. Estimating the compressive and tensile strength of basalt fibre reinforced concrete using advanced hybrid machine learning models. Structures 2025, 71, 108138. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).