Highlights

What are the main findings?

- Based on plant-scale data, the carbon footprint of bamboo scrimber is 3.11 kg CO2-eq/m2, lower than that of conventional wood-based panels.

- The manufacturing stage, particularly steam consumption (drying/carbonization) and adhesive application, was identified as the main emission hotspot.

What is the implication of the main finding?

- These results indicate that bamboo scrimber has a relative low-carbon advantage and can serve as a green alternative to traditional wood-based panels.

- Optimization measures such as improving thermal energy systems and developing bio-based adhesives can significantly reduce emissions, providing practical pathways for sustainable construction and green transition.

Abstract

To quantitatively assess the environmental impact of producing a typical bamboo-based fiber composite material—bamboo scrimber (BS)—and to explore pathways for low-carbon optimization, this study adopts the Life Cycle Assessment (LCA) method with a focus on carbon footprint analysis. Using the actual production process of an enterprise as a case study, field data were collected and analyzed for bamboo scrimber with a nominal thickness of 1.5 cm. The results show that the carbon footprint of 1 m2 of this product is 3.11 kg CO2-eq, with the manufacturing stage contributing the highest emissions at 1.45 kg CO2-eq. The primary source of carbon emissions is steam consumption, mainly occurring during the carbonization and drying of bamboo bundles. Therefore, optimizing these stages is crucial for reducing the overall carbon footprint of the product. This study provides a scientific basis for the sustainable development of bamboo-based fiber composite materials and offers practical recommendations for improving their environmental performance in production.

1. Introduction

In the context of global climate change, countries around the world are implementing strategies to mitigate greenhouse gas emissions. China has committed to achieving carbon peaking and carbon neutrality and has issued numerous policies promoting green transformation and sustainable development [1]. The manufacturing sector, in particular, plays a critical role in reducing national carbon emissions.

In recent years, China’s biomass material industry has experienced rapid development, making it the largest producer and consumer of biomass materials globally [2,3]. However, the significant use of wood resources and energy in production processes has made this sector a major source of carbon emissions [4,5].

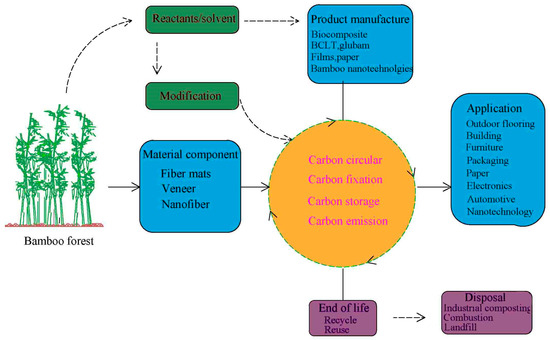

Utilizing scientific methods to quantitatively assess the carbon footprint of biomass material products is crucial for green product design, process improvement, clean production, and sustainable industry development (Figure 1). Life Cycle Assessment (LCA) is a widely recognized method for quantitatively evaluating the environmental impact of products throughout their lifecycle, from raw material acquisition to final disposal, identifying processes with significant environmental impacts, and providing scientific decision-making bases for subsequent product optimization [6,7,8].

Figure 1.

Carbon footprint of carbon cycle process in bamboo product lifecycle.

Currently, research on the life cycle assessment of biomass materials in China mainly focuses on mainstream substrates such as plywood, fiberboard, and particleboard. With the rapid development of the biomass materials industry, the types of biomass material products are becoming increasingly diverse, making it imperative to actively introduce the LCA concept to these new products, such as bamboo scrimber, straw biomass materials, decorative biomass materials, and functional biomass materials [9,10,11]. With the accelerated development of the construction industry, wood–bamboo composite materials have been continuously innovated in new forms. At the same time, the longstanding ban on logging has further increased demand for bamboo-based materials [12,13,14,15,16].

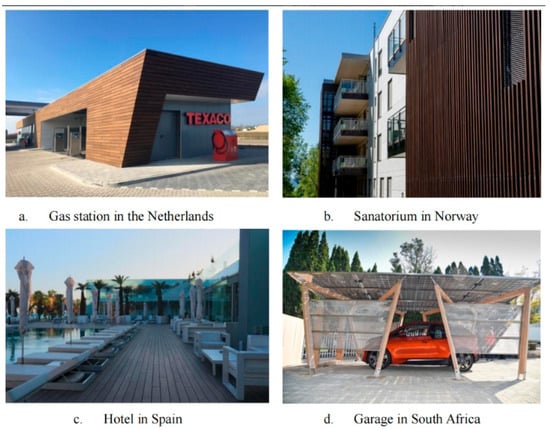

Bamboo scrimber, as a typical bamboo-based fiber composite material, uses disintegration and flattening techniques to transform the three-dimensional hollow structure of bamboo culms into one-dimensional structures like bamboo bundles or fiber veneers, widely used in outdoor structural engineering and landscape decoration, achieving efficient utilization of bamboo resources (Figure 2). Evaluating its life cycle carbon footprint can guide the realization of low-carbon technology and process optimization for this product, enriching China’s biomass materials LCA research database, and further promoting the deep application of LCA in products such as outdoor paving, furniture, interior decoration, and building materials [17].

Figure 2.

Application of bamboo scrimber. (Photo courtesy of MOSO® Mastering Bamboo–MOSO® Bamboo Experts).

This study fills a gap in the current literature by providing a comprehensive LCA-based carbon footprint assessment of bamboo scrimber products, which remain underexplored compared to other biomass materials, using bamboo scrimber as an example. Through on-site investigations and data collection from board manufacturing enterprises, this study presents a comprehensive dataset. Unlike existing LCA studies focusing mainly on wood-based panels, our research provides a comprehensive carbon footprint analysis of bamboo scrimber with original plant-scale data and proposes targeted optimization strategies based on high-impact manufacturing stages. This study calculates the product carbon footprint based on process life cycle analysis, identifies key carbon emission issues at different stages of the existing product lifecycle, and proposes emission reduction suggestions to guide the development of new materials, processes, and technologies. Additionally, this research can expand the field of carbon footprint studies in the biomass materials industry in China and promote the establishment of local databases [18].

Compared with the existing LCA studies on conventional wood-based panels such as plywood, particleboard, and fiberboard, bamboo scrimber exhibits unique material characteristics—such as higher density, different bonding mechanisms [19], and the use of bamboo bundles instead of wood veneers or particles [20]—which may lead to distinct carbon emission patterns. However, few international studies have provided comprehensive, plant-level carbon footprint data for bamboo scrimber, especially in the Chinese context, where production scale and process parameters differ significantly from those in other countries. This research, therefore, not only fills a domestic research gap but also contributes to the global discourse on bio-based low-carbon construction materials by offering localized, high-resolution life cycle data.

Bamboo scrimber is widely recognized as a representative product among bamboo-based fiber composite materials due to its high density, structural stability, and extensive application in outdoor engineering [21,22,23,24,25,26]. Therefore, assessing its life cycle carbon footprint can provide insights applicable to a broader category of bamboo fiber composites.

Life Cycle Assessment (LCA) is the most scientific and comprehensive environmental impact assessment method, capable of systematically and quantitatively evaluating the global warming potential (carbon footprint), resource consumption, land use, and other impacts of products throughout their lifecycle, from raw material acquisition to final disposal [7,27]. The carbon footprint is a quantitative indicator used to describe the total greenhouse gas emissions within the lifecycle of an activity or product. The product carbon footprint (Carbon Footprint, CF) calculation based on process analysis is a direct application of LCA, quantifying the greenhouse gas emissions of products from raw material acquisition to final disposal, expressed as carbon dioxide equivalents (CO2 eq).

According to the ISO14040 standard for life cycle assessment framework, it includes goal and scope definition, inventory analysis, impact assessment, and interpretation [6]. On this basis, the PAS2050 standard [28] provides guidelines for the quantification of product carbon footprints, including defining research goals, product functional units to determine research products and calculation units, system boundary to determine research scope, process input–output data collection, carbon footprint calculation, and interpretation of calculation results [8].

In Life Cycle Assessment (LCA) studies, different system boundaries can be selected based on the research objectives and data availability:

- Cradle-to-Gate: Covers all stages from raw material acquisition to the factory gate, excluding the use phase and end-of-life treatment. This boundary is typically used for evaluating the production processes of intermediate products.

- Cradle-to-Grave: Encompasses the entire life cycle of a product, from raw material acquisition, manufacturing, and transportation to use and final disposal.

- Cradle-to-Cradle: Builds upon the cradle-to-grave concept by incorporating recycling and reuse processes, representing a closed-loop cycle aligned with circular economy principles.

This study adopts the cradle-to-gate boundary, focusing on the carbon emissions during the production stage of laminated bamboo lumber. Based on field investigations and data collection from panel manufacturing enterprises, the product carbon footprint is calculated using a process-based life cycle analysis approach. The study identifies carbon emission hotspots in each life cycle stage and proposes emission reduction strategies and optimization recommendations, aiming to support the development of new materials, processes, and technologies.

2. Materials and Methodology

This study followed the framework of the ISO 14044: 2006 Environmental management [28]—Life cycle assessment—Requirement and guidelines. Different sections of this study, such as goal and scope definition (Section 2.1), inventory analysis (Section 2.3), impact assessment (Section 2.4), and interpretation (Section 3, Section 4 and Section 5), followed the ISO 14044 framework.

2.1. Goal and Scope Definition

This study aims to evaluate the life cycle carbon footprint of reconstituted decorative bamboo bundles, exploring the key factors of greenhouse gas emissions during their lifecycle, providing reference for subsequent product optimization and improvement. Additionally, this study helps expand the application of life cycle carbon footprint evaluation methods in the biomass materials industry, enhancing the significance of life cycle assessment theory in the biomass materials and products industry. The study focuses on the production of bamboo scrimber (bamboo fiber composite material) by the enterprise (Yingtan Yike Bamboo Industry Co., Ltd., Yingtan, Jiangxi Province, China), with a stable and representative production process.

The product under study is a bamboo scrimber outdoor flooring board, 15 mm in thickness and with a density of ~1100 kg/m3, classified as a biomass material. The functional unit is defined as 1 m2 of this product, normalized to oven-dry bamboo mass. For reporting purposes, the final product weight corresponds to an equilibrium moisture content of 8–10%. Adhesive content is expressed as a percentage of oven-dry bamboo mass. The studied product represents mainstream production technology and material composition in China’s bamboo scrimber industry, making the findings generalizable to other similar bamboo-based fiber composites.

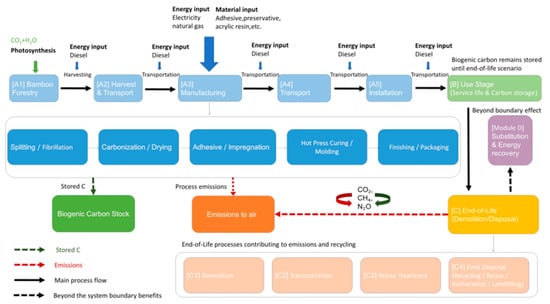

This study adopts a cradle-to-gate system boundary, in line with PAS 2050 recommendations for intermediate products used in downstream applications. This system boundary covers all processes from raw material acquisition to the factory gate, prior to the exit of the bamboo scrimber flooring product. The product use phase and end-of-life stage (disposal or recycling) are excluded from this study, as the focus is on carbon emissions during the processing and manufacturing stages. Biogenic carbon storage in the final product was accounted separately, while long-term storage and disposal were excluded from this system boundary.

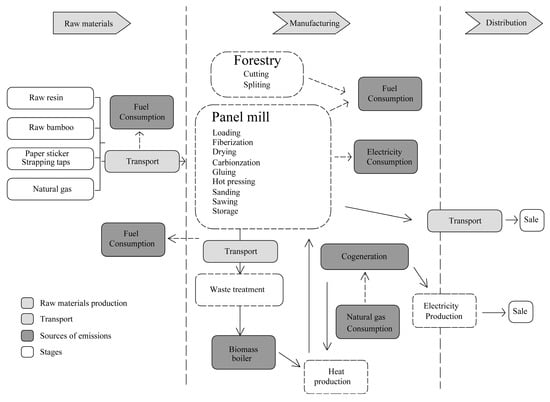

The system boundary includes the following stages:

Raw Material Acquisition

- Bamboo harvesting and bundling;

- Transportation of raw bamboo to the processing facility;

- Preparation of adhesives and chemical additives.

Manufacturing Stage

- Bamboo bundle treatment (carbonization, drying, steaming);

- Adhesive application;

- Cold pressing and hot curing;

- Finishing operations (e.g., trimming, sanding, UV coating).

Auxiliary Processes

- Consumption of electricity, thermal energy (steam), and water;

- Use of auxiliary materials (e.g., phenolic resin, UV paint);

- Internal transportation and material handling within the facility.

Direct emissions in the system primarily originate from fossil fuels (e.g., diesel combustion during transportation); indirect emissions mainly come from purchased electricity consumption, steam generation (typically via biomass or fossil fuel combustion), and upstream emissions associated with the production of chemicals.

The system boundary excludes the following:

- Impacts from bamboo cultivation and land-use change;

- Product-use phase (e.g., emissions during the flooring’s service life);

- End-of-life stage, including disposal, incineration, or recycling.

This system boundary definition enables a focused evaluation of the carbon performance during the manufacturing process, which aligns with the study’s objective of identifying emission hotspots in production. It also supports the development of emission reduction strategies within the scope of industrial operations.

The defined system boundary is illustrated in Figure 3.

Figure 3.

Life cycle system boundary of bamboo scrimber production.

2.2. Data Source

The present study used primary and background data. The former is LCI data associated with production of BS, collected through field investigations and experiments. The latter is the emission factor of different energy and materials inputs, selected from the international LCI database.

2.2.1. Field Investigation

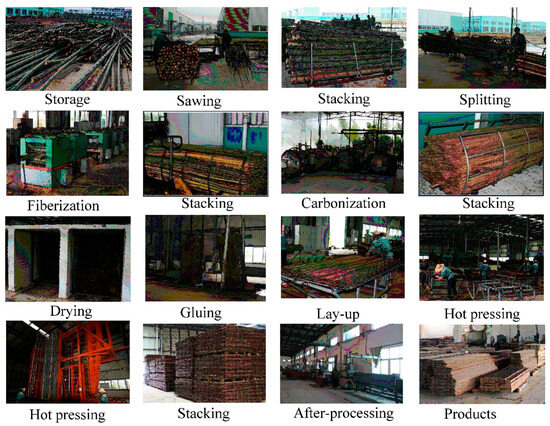

The field investigation mapped out the different production stages of BS. On-site visit was undertaken to Yingtan Yike Bamboo Industry Co., Ltd. The manufacturing process and relevant machines or facilities for producing BS are shown in Figure 4.

Figure 4.

Entire manufacturing process with relevant machines or facilities for the production of BS.

2.2.2. Experiment

A series of experiments was carried out in the factory to acquire primary data on BS (density, moisture content, adhesive content, etc.). Power consumption measurements were undertaken on different machines for the calculation of carbon emission of BS processing.

2.3. Inventory Analysis

Through on-site investigations of the product’s production, the production process, equipment used, and material and energy consumption are shown in Figure 5.

Figure 5.

Production Process of Bamboo Scrimber.

The raw material consumption during the raw material acquisition stage is mainly obtained from the enterprise’s material receipt documents for bamboo bundles, adhesives, hydrogen peroxide, and other auxiliary materials. The transportation process of raw materials involves collecting transportation distances from suppliers to the factory. Energy consumption during production can be obtained from the enterprise’s water, electricity, and gas consumption records. This study accounts for CH4 and N2O emissions from biomass combustion. Biogenic CO2 uptake in bamboo raw material was included as intrinsic carbon storage (1.0 kg CO2-eq/m2). Combustion CO2 was treated as biogenic and, therefore, excluded from net emissions, consistent with ISO 14067 and PAS 2050 standards. Initial data on material and energy consumption for producing 1 m2 of bamboo scrimber are shown in Table 1, and raw material transportation information is shown in Table 2.

Table 1.

Input and Output Inventory for Producing 1 m2 Bamboo Scrimber.

Table 2.

Material Transport Information List.

As certain technical parameters (e.g., boiler efficiency, steam pressure, and residue moisture content) were not directly available from the enterprise, we applied typical industrial reference values (boiler efficiency ~70%, residue moisture ~15%, steam conditions 0.8 MPa, 175–180 °C). To assess the robustness of these assumptions, we performed a sensitivity analysis in which boiler efficiency ranged from 65% to 75% and residue moisture varied between 10% and 20%. The results showed that the total carbon footprint varied within ±0.12 kg CO2-eq, indicating limited influence on the overall conclusion.

The life cycle inventory analysis stage involves the systematic collection and quantification of all relevant input and output data associated with each stage within the defined system boundary. This includes raw materials, energy use, water consumption, transportation distances, emissions, and waste generated throughout the bamboo scrimber production process.

Data for this study were primarily gathered through on-site investigations conducted at a representative bamboo scrimber manufacturing enterprise. This enterprise has an annual production capacity of approximately 30,000 cubic meters and operates a single production line equipped with advanced technologies, including bamboo disintegration, flattening, hot pressing, and drying. The production scale and technological configuration of this enterprise are representative of the mainstream bamboo scrimber manufacturing industry in China. Therefore, the data collected from this facility provide a robust and realistic basis for analyzing the carbon footprint and identifying key stages for process optimization. The factory provided detailed documentation of production processes, utility consumption, material input logs, and production output records. Supplementary information was obtained through structured interviews with technical personnel and cross-referenced with published literature and standardized databases.

In the raw material acquisition stage, the primary components included bamboo bundles, phenolic resin adhesive, hydrogen peroxide, UV-resistant paint, and packaging materials such as polyethylene shrink film and corrugated cartons. The raw bamboo was harvested from local forests and transported to the production site by truck, covering an average distance of approximately 100 km. Other auxiliary materials, including adhesives and coatings, were delivered from local suppliers within a 20–50 km radius.

Energy consumption during the production phase was carefully documented. The plant uses both electricity and thermal energy, the latter primarily generated through the combustion of bamboo processing residues. Electricity was used to power machinery for splitting, planing, cold pressing, hot pressing, and cutting, while hot steam was essential for the carbonization and drying of bamboo bundles. The initial data collected for producing 1 square meter of bamboo scrimber are summarized in two key tables: one for the input–output inventory of materials and energy, and another for material transportation distances. These datasets served as the foundation for the subsequent carbon footprint calculations and are critical for ensuring accuracy and representativeness of the LCA results.

2.4. Carbon Footprint Calculation

The carbon footprint of bamboo scrimber production is calculated based on the collected inventory data and emission factors from the LCA database. The calculation formula for each stage is as follows:

Raw Material Preparation Stage:

where Mi is the mass of the raw material ii and EFi is the emission factor for producing raw material i.

CFraw material = ∑(Mi × EFi)

Raw Material Transportation Stage:

where Mi is the mass of the transported material i, Di is the transportation distance, and EFtransport is the emission factor for the transportation mode.

CFtransportation = ∑(Mi × Di × EFtransport))

Manufacturing Stage:

where Ej is the energy consumption j and EFj is the emission factor for energy source j.

CFmanufacturing = ∑(Ej × EFj)

Combining the above formulas, the total carbon footprint is:

CFtotal = CFraw material + CFtransportation + CFmanufacturing

The carbon footprint results show that the total emissions for producing 1 m2 of bamboo scrimber are 3.11 kg CO2-eq. Among these, the manufacturing stage contributes the largest share, followed by raw material acquisition, intrinsic emissions, and auxiliary/transportation processes. The stage-level results, together with the disaggregated contributions of manufacturing sub-processes, are summarized in Table 3.

Table 3.

Life cycle carbon emissions of 1 m2 bamboo scrimber.

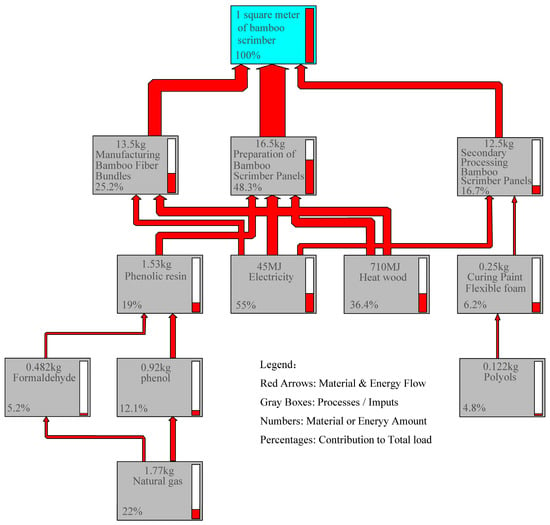

As shown in Table 3, the manufacturing stage accounts for nearly half of the total carbon footprint (46.6%). This reflects the high energy consumption required during the carbonization, drying, adhesive application, and hot-pressing processes. Figure 6 further illustrates the breakdown of the manufacturing stage into its sub-processes, where panel preparation contributes the largest share (48.3%), followed by bundle making (25.2%) and finishing (16.7%).

Figure 6.

Environmental load distribution network for the production of 1 m2 of bamboo scrimber under the cradle-to-gate system boundary. This is a SimaPro process-network output. “Heat wood” denotes the background heat supply process (fuel side). The node value/percentage indicates the contribution to total GWP (including upstream), not the energy inventory, and percentages are not additive. Quantitative energy use is reported in Table 1 (delivered steam 128.5 MJ; ≈184 MJ at the fuel side, assuming ~70% boiler efficiency), and the stage/sub-process partitioning follows Table 3 (harmonized figure).

About Background Data for Raw Materials, Energy Consumption, and Direct Emissions. First, a cut-off rule was established: materials that constitute less than 1% of the total raw material mass can be omitted [8]. According to the <1% cut-off rule, auxiliary materials such as hydrogen peroxide and packaging fillers, which accounted for less than 0.5% of the total mass input, were excluded from the LCI model. The emission factors (EF) for each material and energy source were derived from multiple sources to ensure representativeness and reliability. For bamboo bundles and adhesives, data were taken from the “Life Cycle Carbon Footprint and Energy Consumption Assessment of the Biomass Material Industry in China” [29], which is based on Chinese industrial processes. For phenolic resin and UV paint, the Ecoinvent 3.8 database and CLCD-China-ECER 0.8 were used, with preference given to China-specific datasets where available. Electricity and steam emission factors were obtained from CLCD-China-ECER 0.8 (based on 2021 national energy mix data), while diesel and water data were sourced from ELCD 3.0 [7]. The year of data collection for all background datasets ranges from 2019 to 2023, ensuring compatibility with the field survey period (2023–2024). To improve transparency and reproducibility, all emission factors, including those for electricity, steam, diesel, adhesives, coatings, and packaging, are summarized in Table 4, together with their units, database versions, and regional applicability.

Table 4.

Emission factors used in the LCA of bamboo scrimber production.

2.5. Evaluation Results and Recommendations

Analysis of the GWP environmental impact results for the functional unit of bamboo scrimber shows that the product’s carbon footprint within the “cradle-to-gate” system boundary is 3.11 kg CO2-eq. The highest carbon emission stage is the manufacturing stage, with a carbon footprint of 1.45 kg CO2-eq. This stage’s major contribution is the greenhouse gas emissions from hot steam consumption, primarily occurring during the carbonization and drying processes of bamboo bundles [30]. The raw material acquisition stage contributes 0.66 kg CO2-eq, with a significant portion of the emissions coming from adhesive preparation, while the bamboo bundles, despite being the most consumed raw material, have relatively low emissions due to their inherent biomass carbon sequestration function. Another important factor is the carbon footprint value of the product itself [29,31].

Further disaggregation of the manufacturing stage emissions indicates that the consumption of hot steam during the carbonization and drying of bamboo bundles is the dominant contributor. These processes require significant thermal energy, which, in the studied enterprise, is primarily generated by burning biomass residues. While this approach reduces reliance on fossil fuels, it still results in considerable greenhouse gas emissions. While biomass combustion is often treated as carbon-neutral in many carbon accounting frameworks (IPCC, 2021), recent research indicates that the timing of carbon release, incomplete combustion, and associated non-CO2 emissions (such as CH4 and N2O) can lead to a non-negligible climate impact. Emission factors for steam generation were derived from CLCD-China-ECER 0.8, which include CO2, CH4, and N2O emissions from biomass combustion. Unlike conventional approaches that assume carbon neutrality, this study accounts for incomplete combustion and non-CO2 gases, providing a more conservative estimate. In this study, biomass-derived steam was included in the carbon footprint calculation using emission factors that account for non-CO2 gases. Therefore, the reported manufacturing stage emissions represent the actual short-term climate impact rather than assuming complete neutrality. This approach provides a more conservative and realistic estimate for decision-making in process optimization. Therefore, optimizing thermal energy systems, such as by improving boiler efficiency or adopting alternative low-carbon heat sources, is crucial for reducing the carbon footprint of bamboo scrimber production.

In addition to thermal energy optimization, another important emission hotspot is the use of adhesives, particularly phenolic resin. Although the adhesive content constitutes approximately 10% of the product’s weight, its high emission factor makes it a substantial contributor to the overall carbon footprint. Future research and development should focus on replacing traditional adhesives with bio-based, low-carbon alternatives that maintain or improve bonding performance without compromising environmental sustainability [32].

The environmental load network diagram of the bamboo composite flooring production stage is shown in Figure 6. From the diagram, it can be seen that the environmental load is greatest during the plank manufacturing stage, accounting for approximately 48.3%. The next highest is the bamboo bundle manufacturing stage, accounting for 25.2%, while the finished product production stage has the lowest environmental load, at 16.7%.

The main reasons for the greatest environmental load during the plank production stage are twofold: first, plank manufacturing adopts a cold-press hot-curing process. The cold-press process requires high pressure, resulting in substantial electricity consumption. Second, after cold-press pre-curing, the planks must be transferred into a curing kiln for hot curing. The curing process is lengthy and requires considerable energy consumption. In addition, phenolic resin is used in bamboo scrimber manufacturing, and the adhesive is applied by impregnation, with a relatively high dosage of about 10%, leading to significant consumption of chemical raw materials. During the bamboo bundle manufacturing stage, the bamboo bundles undergo high-temperature steaming and high-temperature carbonization processes, consuming a large amount of thermal energy and water resources and generating a substantial amount of wastewater. The finished product manufacturing stage only requires electricity and a certain amount of UV paint without the need for energy, thus resulting in the smallest environmental load.

3. Results and Discussion

The manufacturing stage accounts for the largest share (48.3%) of total carbon emissions. Two key carbon hotspots were identified:

- Carbonization and Drying Processes: These require significant heat energy, largely sourced from the combustion of bamboo residues, contributing heavily to CO2 emissions. Optimizing kiln design, improving thermal insulation, and reducing processing time are potential low-carbon solutions.

- Adhesive Production and Application: The use of phenolic resin, which constitutes about 10% of the product weight, represents a substantial emission source. Transitioning to bio-based adhesives or reducing the glue spread rate through improved impregnation techniques may significantly reduce emissions.

Additional emissions occur during the cold-press and hot-curing stages, where high pressure and long curing durations lead to intensive electricity consumption. Incorporating high-efficiency equipment and utilizing green electricity sources (e.g., solar or hydroelectric power) could further mitigate environmental impacts.

Moreover, while bamboo scrimber stores biogenic carbon, this storage is not fully credited in a cradle-to-gate boundary, since long-term retention depends on product lifespan and disposal pathways. This indicates that the carbon storage function provides a limited offset within this study’s scope.

From a systems perspective, the network analysis (Figure 6) illustrates the environmental load distribution, confirming that emission reductions in the manufacturing phase will yield the greatest carbon footprint improvements.

4. Limitations and Future Research Directions

This study focuses specifically on the life cycle carbon emissions associated with the production of bamboo scrimber, providing detailed insights into emission hotspots and potential strategies for carbon reduction within the manufacturing process. This study adopted a cradle-to-gate boundary and did not account for carbon storage during product use or emissions at the end-of-life stage. Future research should conduct cradle-to-grave and cradle-to-cradle assessments to fully capture the climate benefits and trade-offs of bamboo scrimber. However, it does not incorporate the carbon storage potential of bamboo scrimber, which is an important aspect of the overall carbon balance of bamboo-based materials.

The exclusion of carbon storage analysis is primarily due to the complexity and variability of quantifying long-term biogenic carbon sequestration in construction applications, which requires extensive data on material lifespan, end-of-life scenarios, and regional factors. Moreover, carbon storage benefits often depend on usage patterns and disposal methods beyond the scope of cradle-to-gate assessment.

Future research should aim to integrate both carbon emissions and carbon storage to provide a more comprehensive evaluation of the net climate benefits of bamboo scrimber. This could include cradle-to-grave or cradle-to-cradle assessments, dynamic carbon modeling, and case studies of in-use performance and end-of-life management. Such integrated studies would better inform sustainable material selection, lifecycle carbon accounting, and policy frameworks that recognize the dual role of bamboo products in carbon mitigation.

In addition, technological improvements such as low-carbon adhesives, the adoption of green electricity, and circular end-of-life recycling may further enhance the climate performance of bamboo scrimber. Under cradle-to-grave scenarios, these advances hold the potential to enable bamboo scrimber to achieve carbon negativity.

Finally, results are presented as point estimates; however, adhesive content and heat consumption show significant variability across production batches. Future research should incorporate sensitivity and uncertainty analysis to better capture the robustness of the findings.

5. Conclusions

This study conducted a systematic life cycle carbon footprint assessment of bamboo scrimber, using a representative product manufactured in China as a case study. By applying the internationally recognized Life Cycle Assessment (LCA) framework and adhering to standards such as ISO 14040 and PAS 2050, we quantified greenhouse gas emissions across three key stages: raw material acquisition, transportation, and manufacturing. The results indicate that the manufacturing stage—particularly the use of hot steam for carbonization and drying—constitutes the largest share of emissions, followed by adhesive-related emissions and emissions embedded in material extraction and logistics.

Through a detailed inventory analysis and carbon footprint calculation, we found that the total GHG emissions associated with producing 1 m2 of bamboo scrimber amount to 3.11 kg CO2-equivalent. The findings provide critical insights into emission hotspots, which are essential for guiding low-carbon process redesign and material substitution. Among the most actionable areas are the optimization of thermal energy systems and the development of bio-based adhesive alternatives. Furthermore, enhancing energy and resource efficiency throughout the production chain can also contribute to reducing emissions.

Table 5 summarizes the key low-carbon optimization measures in bamboo scrimber production, along with their expected emission reduction potential and technical feasibility. Optimization of the thermal energy system addresses the largest emission source in the manufacturing stage. Enhancing boiler efficiency, applying heat recovery technologies, or switching to biomass and other low-carbon heat sources can yield significant emission reductions. Replacement with bio-based adhesives targets the substantial emissions from adhesives, promoting the development and application of environmentally friendly alternatives with comparable or improved bonding performance. In addition, improving energy efficiency in production processes and optimizing raw material logistics are practical measures that contribute to further overall carbon footprint reduction. Resource utilization of waste serves as a supplementary measure to effectively reduce emissions from waste treatment, which requires corresponding technical solutions and policy support.

Table 5.

Bamboo-Based Composite Production: Optimization Measures and Emission Reduction Potential.

For comparison, previous LCA studies report cradle-to-gate carbon footprints of 4.2–6.0 kg CO2-eq per m2 for plywood [13] and 3.8–5.5 kg CO2-eq per m2 for medium-density fiberboard [5] with similar thickness. Other bamboo-based composites, such as bamboo glulam, typically range from ~3.5 to 4.8 kg CO2-eq per m2 [15]. The 3.11 kg CO2-eq value for bamboo scrimber in this study is at the lower end of all these ranges, highlighting its relative carbon advantage compared with both conventional wood-based panels and alternative engineered bamboo products.

These findings provide valuable insights for policymakers in promoting bamboo as a low-carbon construction material and for industry stakeholders to implement process optimizations. The results may guide the formulation of carbon labeling systems, green product standards, and incentives for bio-based adhesive R&D.

Importantly, this research addresses a significant knowledge gap in current LCA literature by providing original, plant-level data on bamboo scrimber production in China, a biomass product with growing application in the global green building and construction industries. It also emphasizes the need for localized, high-resolution background databases for LCA, particularly for the rapidly developing biomass materials sector in China.

Overall, this study supports the broader goal of integrating bamboo materials into low-carbon development strategies and offers a scientific foundation for stakeholders—including manufacturers, researchers, and policymakers—to foster sustainable innovation in bamboo-based composite production. The methodology and recommendations presented herein can also be extended to other bio-based construction materials, contributing to the global transition toward climate-resilient and carbon-neutral infrastructure.

Author Contributions

Conceptualization, Y.H. and M.H.; methodology, H.H. and C.P.; software, J.Z.; validation, Y.H., H.H., and A.N.A.; formal analysis, Y.H.; investigation, H.H., M.C. and C.P.; resources, Y.H. and M.H.; data curation, J.Z. and Y.H.; writing—original draft preparation, Y.H.; writing—review and editing, M.H. and H.H.; visualization, Y.H.; supervision, M.H.; project administration, M.H.; funding acquisition, M.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (Grant No. 31960337), the International Cooperation Project of the Jiangxi Provincial Department of Science and Technology (Grant No. 20232BBH80002) and the Key Research and Development Program Project (20252BCF320027); as well as the Basic Research and Talent Science Research Special Project of the Jiangxi Academy of Forestry (Grant Nos. 2025521502, 2023521502). This work was also supported by the Research Center for Functional Bamboo Reconstituted Composites of the Jiangxi Provincial Development and Reform Commission and the Key Laboratory of the Nanchang Science and Technology Bureau (Key Laboratory of Bamboo-Based Biomass Composite Materials Research and Development).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Acknowledgments

Thanks to the support of the Leading Talent Project of the Jiangxi Academy of Forestry and the Sailing Talent Project of the Jiangxi Association for Science and Technology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yang, P.; Mi, Z.F.; Wei, Y.M.; Hanssen, S.V.; Liu, L.C.; Coffman, D.M.; Sun, X.L.; Liao, H.; Yao, Y.F.; Kang, J.N. The global mismatch between equitable carbon dioxide removal liability and capacity. Natl. Sci. Rev. 2023, 10, 254. [Google Scholar] [CrossRef]

- Sarre, A. Global Forest Resources Assessment, 2020: Main Report; Food and Agriculture Organization of the United Nations: Rome, Italy, 2020. [Google Scholar]

- Ding, D.; Xian, M. Research trends and design strategies for bamboo architecture: A bibliometric and systematic review. Adv. Bamboo Sci. 2024, 8, 100094. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, C.H.; Chen, X.J.; Jia, L.Q.; Guo, X.N.; Chen, R.S.; Zhang, M.S.; Chen, Z.Y.; Wang, H.D. Carbon peak and carbon neutrality in China: Goals, implementation path and prospects. China Geol. 2021, 4, 720–746. [Google Scholar] [CrossRef]

- Huo, T.; Du, Q.; Xu, L.; Shi, Q.; Cong, X.; Cai, W. Timetable and roadmap for achieving carbon peak and carbon neutrality of China’s building sector. Energy 2023, 274, 127330. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. ISO: London, UK, 2006.

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Heijungs, R.; Suh, S. The Computational Structure of Life Cycle Assessment; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2002; Volume 11. [Google Scholar]

- Jiang, W.; Liu, K.; Zhang, X.; Shao, C.; Liu, Q.; Yang, J. Trends and path for the development of bamboo structural engineering towards 2035 in China. China Civ. Eng. J. 2021, 54, 125–132. [Google Scholar]

- Zeng, C.; Liu, L.; Lin, C.; Xin, X.; Liu, Y.; Leng, J. 4D printed continuous fiber reinforced shape memory polymer composites with enhanced mechanical properties and shape memory effects. Compos. Part A Appl. Sci. Manuf. 2024, 180, 108085. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, C. Effect of slenderness ratio on axial compression behavior of circular wood columns strengthened with high-performance bamboo-based composites. Eng. Struct. 2024, 320, 118910. [Google Scholar] [CrossRef]

- Pan, C.; Zhou, G.; Shrestha, A.K.; Chen, J.; Kozak, R.; Li, N.; Li, J.; He, Y.; Sheng, C.; Wang, G. Bamboo as a nature-based solution (NbS) for climate change mitigation: Biomass, products, and carbon credits. Climate 2023, 11, 175. [Google Scholar] [CrossRef]

- Lao, W.L.; Han, Y.M.; You, J. Carbon footprint as an environmental indicator for wood flooring industry in China. Case Stud. Constr. Mater. 2024, 21, 03594. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Zamani, M.H.; Estaji, S.; Tayouri, M.I.; Arjmand, M.; Jafari, S.H.; Nouranian, S.; Khonakdar, H.A. Mechanical properties of bamboo fiber-reinforced polymer composites: A review of recent case studies. J. Mater. Sci. 2022, 57, 3143–3167. [Google Scholar] [CrossRef]

- Zhao, Y.; Lou, Z.; Wang, Q.; Yuan, T.; Chen, M.; Han, H.; Wu, X.; Xu, L.; Li, Y. Fabrication of a bamboo-based glulam based on reconstitution unit innovation: Mechanical property investigation and carbon footprint evaluation. Ind. Crops Prod. 2023, 202, 117046. [Google Scholar] [CrossRef]

- Zhang, M.; Zhou, G.; Gu, L. Carbon footprint and climate mitigation potential of bamboo products in China. Environ. Impact Assess. Rev. 2025, 114, 107958. [Google Scholar] [CrossRef]

- Liu, K.; Jayaraman, D.; Estrella, P.; Shi, Y.; Yang, J.; Escardó, B.; Wu, J.; Lopez, L. Create an enabling environment for bamboo construction sector in Africa, Asia and Latin America. In Proceedings of the18th International Conference on Non-Conventional Materials and Technologies (NOCMAT 2022), Virtual, 7–23 June 2022. [Google Scholar]

- Liu, K.; Xu, Q.; Wang, G.; Chen, F.; Leng, Y.; Yang, J.; Harries, K.A. Contemporary Bamboo Architecture in China; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Huang, Y.; Ji, Y.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 25. [Google Scholar] [CrossRef]

- Hosseini, M.; Gaff, M.; Wei, Y.; Tu, C. Engineered Bamboo Building Materials: Types, Production, and Applications. Forests 2025, 16, 662. [Google Scholar] [CrossRef]

- Li, X.; Li, L.; Li, N.; Bao, M.; Bao, Y.; Wu, Z.; Wang, J.; Rao, F.; Chen, Y. Sustainable production of engineered bamboo scrimber composites for construction and flooring applications. Constr. Build. Mater. 2022, 347, 128615. [Google Scholar] [CrossRef]

- Chen, J.; Guagliano, M.; Shi, M.; Jiang, X.; Zhou, H. A comprehensive overview of bamboo scrimber and its new development in China. Eur. J. Wood Wood Prod. 2021, 79, 363–379. [Google Scholar] [CrossRef]

- Hu, Y.; Xiong, L.; Li, Y.; Semple, K.; Nasir, V.; Pineda, H.; He, M.; Dai, C. Manufacturing and characterization of wide-bundle bamboo scrimber: A comparison with other engineered bamboo composites. Materials 2022, 15, 7518. [Google Scholar] [CrossRef]

- Qin, L.; Wei, J.; Bao, M.; Yu, Y.; Yu, W. Durability evaluation of outdoor scrimbers fabricated from superheated steam-treated bamboo fibrous mats. Polymers 2022, 15, 214. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, Z.; Huang, L.; Huang, B.; Wang, X.; Chen, L.; Ma, X. High-performance bamboo-wood composite materials based on the natural structure and original form of bamboo: Fracture behavior and mechanical characterization. Constr. Build. Mater. 2024, 447, 138118. [Google Scholar] [CrossRef]

- Sylvayanti, S.P.; Nugroho, N.; Bahtiar, E.T. Bamboo scrimber’s physical and mechanical properties in comparison to four structural timber species. Forests 2023, 14, 146. [Google Scholar] [CrossRef]

- Gan, J.; Chen, M.; Semple, K.; Liu, X.; Dai, C.; Tu, Q. Life cycle assessment of bamboo products: Review and harmonization. Sci. Total Environ. 2022, 849, 157937. [Google Scholar] [CrossRef]

- PAS 2050:2011; Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services. British Standards Institution: London, UK, 2011.

- Liu, X. Carbon Footprint Analyses of Structural Bamboo Products. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2024. [Google Scholar]

- Das, A.; Sarma, A.K. Unlocking the Potential Applications of Bamboo, as an Energy Resource and Bamboo-Based Activated Carbon: A Comprehensive Review. BioEnergy Res. 2025, 18, 77. [Google Scholar] [CrossRef]

- Gu, L.; Zhou, Y.; Mei, T.; Zhou, G.; Xu, L. Carbon footprint analysis of bamboo scrimber flooring—Implications for carbon sequestration of bamboo forests and its products. Forests 2019, 10, 51. [Google Scholar] [CrossRef]

- Xu, X.; Xu, P.; Zhu, J.; Li, H.; Xiong, Z. Bamboo construction materials: Carbon storage and potential to reduce associated CO2 emissions. Sci. Total Environ. 2022, 814, 152697. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).