Abstract

This study investigated the structural behavior of slab-on-grade (SOG) specimens constructed using two materials: conventional concrete reinforced with steel mesh and high-ductility fiber-reinforced cement composites (HDFRCC) containing 1.2% polyethylene (PE) fiber without steel reinforcement. The compressive strengths of conventional concrete and HDFRCC were 37 MPa and 54 MPa, respectively. The average flexural tensile strength of HDFRCC was 3.9 MPa at first cracking and 9.7 MPa at peak load. Punching shear tests were performed under three loading configurations: internal (center), edge, and corner loading. Crack patterns and load–displacement responses were analyzed for both material types. Under center loading, the experimentally measured load-bearing capacities were 174.52 kN for conventional concrete and 380.82 kN for HDFRCC, with both materials exhibiting reduced capacities under edge and corner loading. Analytical predictions demonstrated close agreement with the experimental results for conventional concrete but significantly underestimated the load capacity of HDFRCC SOG. This discrepancy is attributed to the strain-hardening and crack-bridging mechanisms inherent in HDFRCC, which contribute to enhanced strength beyond conventional analytical predictions. In terms of failure mode, the conventional concrete SOG exhibited the expected flexural failure. In contrast, the HDFRCC SOG experienced either flexural failure or a combination of flexural and punching failure, in contradiction to the analytical prediction of exclusive punching shear failure. These findings indicate that the punching shear resistance of the HDFRCC SOG is substantially higher than predicted.

1. Introduction

High-ductility fiber-reinforced cement composites (HDFRCC), also known as engineered cementitious composite (ECC), exhibit superior tensile ductility, shear capacity, and crack-control (widths less than 100 µm) performance compared to conventional concrete and fiber-reinforced concrete. These attributes position ECC as an effective material for mitigating the brittle punching shear behavior often found in reinforced concrete flat slabs [1,2,3]. The design of HDFRCC is based on micromechanical theory, achieving a tensile strain capacity exceeding 3% while limiting the fiber volume fraction to less than 2% [2,4]. In HDFRCC formulations, coarse aggregate is excluded, and the sand-to-binder ratio is significantly reduced to facilitate homogeneous fiber dispersion and achieve high tensile strain capacity with strain-hardening behavior [5]. A common and effective strategy to limit crack propagation under various loading conditions is the incorporation of different types of fibers into the concrete mix during the manufacturing of structural elements [6]. Various types of fibers, such as polyvinyl alcohol (PVA), polyethylene (PE), steel fiber (SF), and polypropylene fibers (PP), are utilized in HDFRCC formulations [2,7].

Čajka and Marcalíková (2021) [8] experimentally tested three slabs with fiber dosages of 25, 50, and 75 kg/m3. The test setup allowed vertical loading of the slabs and, in combination with installed track sensors and computer systems, recorded the resulting vertical deformations. Deformations were evaluated using 2D sections based on the mounted sensors, and 3D sections were generated by interpolating intermediate values. A fiber dosage of 25 kg/m3 improved mechanical properties and reduced variability in the measurements. Under higher loads, increasing fiber content significantly influenced deformations and the formation and propagation of cracks. At 75 kg/m3, however, workability decreased, requiring optimization of the concrete mix. Differences between 50 kg/m3 and 75 kg/m3 were minor, leading to a recommended dosage of 50 kg/m3 for optimal cost, workability, and mechanical performance.

Similarly, Wang et al. (2022) [9] investigated the mechanical and rheological properties of solid-waste-based HDFRCCs incorporating different types of fly ash (raw, sorted, and ground) along with PVA fibers. Their findings revealed that the PVA fibers in HDFRCC were more uniformly distributed, enhancing both toughness and ductility. Marushchak et al. (2023) [10] reported that incorporating 1.5 wt.% PE fibers into HDFRCC increased flexural strength by 19% compared to 1.0 wt.% while maintaining high compressive strength (76.4–86.2 MPa). Although higher fiber content slightly reduced compressive strength, it significantly improved impact resistance and abrasion performance. At 28 days, the highest fiber content resulted in a crack energy of 31.1 J/cm3, an impact failure energy of −57.5 J/cm3, and reduced abrasion mass loss from 0.30 to 0.27 g/cm2.

A slab-on-grade (SOG), also referred to as a ground-supported concrete slab (GSCS), is a nonstructural, monolithic concrete slab supported by a flat, uniform, load-bearing subgrade, typically constructed in an enclosed but non-climate-controlled space [11]. SOGs serve as ground floors in industrial structures such as factory buildings and warehouse facilities, providing support platforms for storage, sales, and distribution operations [12,13]. The foundation systems of one- or two-story structures often incorporate deepened footings, which generally range from 30 cm (12 in) to 61 cm (24 in) in depth and are 30 cm (12 in) wide, positioned beneath load-bearing walls, in conjunction with 10 cm thick SOG floors. These slabs are generally reinforced with welded wire mesh and steel rebar. The footings and slabs are often integrated into a monolithic pour, enhancing structural continuity. Lightly reinforced SOGs are flexible and tend to crack or deform under soil movement [14]. For SOGs, concrete can fail in two ultimate strength modes, namely flexure (bending) and local punching [15]. The key performance criteria for SOGs include sufficient load capacity, minimal cracking and curling, and a flat, level surface [11].

To better characterize key performance aspects such as the dominant fracture mode, crack initiation, and crack propagation in SOGs, recent experimental studies have increasingly adopted crack and damage detection techniques commonly used in structural health monitoring [16,17,18,19,20].

For designing a reinforced slab, three methods can be employed: elastic analysis (a pseudo-lower bound method), plastic analysis (an upper bound method based on an assumed yield-line mechanism), and plastic design (a lower bound method based on an assumed equilibrium system) [21]. Elastic methods are used in situations where cracking is unacceptable, while plastic methods are used in situations where controlled cracking is acceptable [22]. SOGs have traditionally been designed using elastic methods, and the analysis equations formulated by Westergaard (1925) [23] continue to be widely used for designing SOGs [15]. Furthermore, if the design is based on elastic analysis and a permissible stress criterion, the analysis involves the solution of Lagrange’s biharmonic equation under specified boundary conditions. In cases where asymmetry of loading, geometry, or edge conditions exists, approximate approaches such as variational techniques (e.g., Ritz’s, finite element, Galerkin’s, etc.) or boundary value methods (finite difference, relaxation, etc.) are typically employed [21].

The plastic analysis method depends on the ductility of the slab and is not suitable for plain concrete slabs or slabs with insufficient fibers or reinforcement, as they lack the necessary ductility [15]. Plastic analysis is an appropriate method for designing two-way slabs under transverse concentrated loads. This method, also known as the yield-line method, assumes that the slab’s resistance is governed solely by bending, while other factors, such as shear or displacement, are addressed separately. The yield-line method applies to slabs reinforced in any direction, assuming a constant reinforcement area per unit length, although reinforcement may vary between the upper and bottom faces of the slab. It can also be used for slabs with non-uniform reinforcement distribution, though this may be more complex [24]. Furthermore, the design equations involved in yield-line theory for the design of SOG are provided in Section 2.

Sucharda et al. (2018) [25] conducted an experimental study on a 2 m × 1.95 m reinforced SOG with a thickness of 120 mm, subjected to high loads to induce punching shear failure in interaction with the subsoil. The concrete slab, reinforced with bars on its lower surface, was subjected to a centrally applied load. Following the experiment, a parametric study was carried out to calculate the total load capacity using the existing design model code, Eurocode 2 and a non-linear analysis utilizing the finite element method. The slab failed due to punching shear at a load of 344 kN, with cracks forming at an average distance of 1.7d from the column perimeter, taking on an irregular oval shape. This irregularity may have been caused by uneven subsoil conditions or faster crack development on one side under higher loads. According to Eurocode 2, the theoretical punching shear resistance was 60.13 kN, while the theoretical punching resistance based on mean values was 177.42 kN at a distance of 2d from the column perimeter. The actual shear resistance was higher than the values predicted by Eurocode 2, and the cracks occurred at a shorter distance than predicted by Eurocode 2. This confirms that the Eurocode design approach is conservative and provides a safe margin. Furthermore, Shahiduzzaman and Hussain (2024) [13] validated the experimental results from the literature using a three-dimensional non-linear finite element model (utilizing the concrete damaged plasticity model in ABAQUS 2020 software with an appropriate simulation technique and theory-based material properties) and Technical Report 34 (TR 34) [15] predictions for SOG. The average ratio of finite element prediction to experimental punching shear capacity was 0.93, with a standard deviation (SD) of 0.06, while the average ratio of TR 34 prediction to experimental punching shear capacity was 1.01 with an SD of 0.06. The ratio of TR 34 prediction to finite element predicted punching shear capacity was 1.08 with an SD of 0.13, indicating that TR 34 predictions were slightly more liberal than finite element predictions.

Industrial SOGs in factories and warehouses are designed to withstand heavy loads from transport vehicles, necessitating high load-bearing capacity and effective crack control to minimize cracking. The use of HDFRCC can help reduce the crack widths without the use of additional reinforcement; however, previous research has not sufficiently examined its application in SOGs. This study therefore aims to develop and evaluate industrial SOGs using HDFRCC as an alternative to conventional concrete, with the goal of enhancing load-bearing performance, improving crack resistance, and reducing construction time and costs by eliminating the need for steel reinforcement. To achieve this, an experimental investigation was conducted to compare the punching shear resistance and crack patterns of a conventional concrete SOG with steel mesh reinforcement to those of an HDFRCC SOG with PE fiber and without steel mesh reinforcement. Additionally, the SOG design was performed using the method presented in TR 34, published by the European Concrete Society [15], and the results were compared with experimental findings to evaluate the feasibility of this design approach for HDFRCC SOGs.

2. Analytical Model

2.1. Yield-Line Theory

The yield-line theory, developed by Johansen in the 1930s and 1940s for reinforced concrete slabs [26], offers a practical methodology for analyzing pile-supported slabs at the ultimate limit state. This theory is commonly employed to calculate the flexural strength of slabs and flat slab floors [15]. It is recognized as a computationally efficient and rapidly convergent technique for establishing upper-bound estimates of the yield load for plates and slabs [27]. In the present study, the design of industrial ground-supported floor slabs was conducted in accordance with the design methodology outlined in TR 34, published by the European Concrete Society [15].

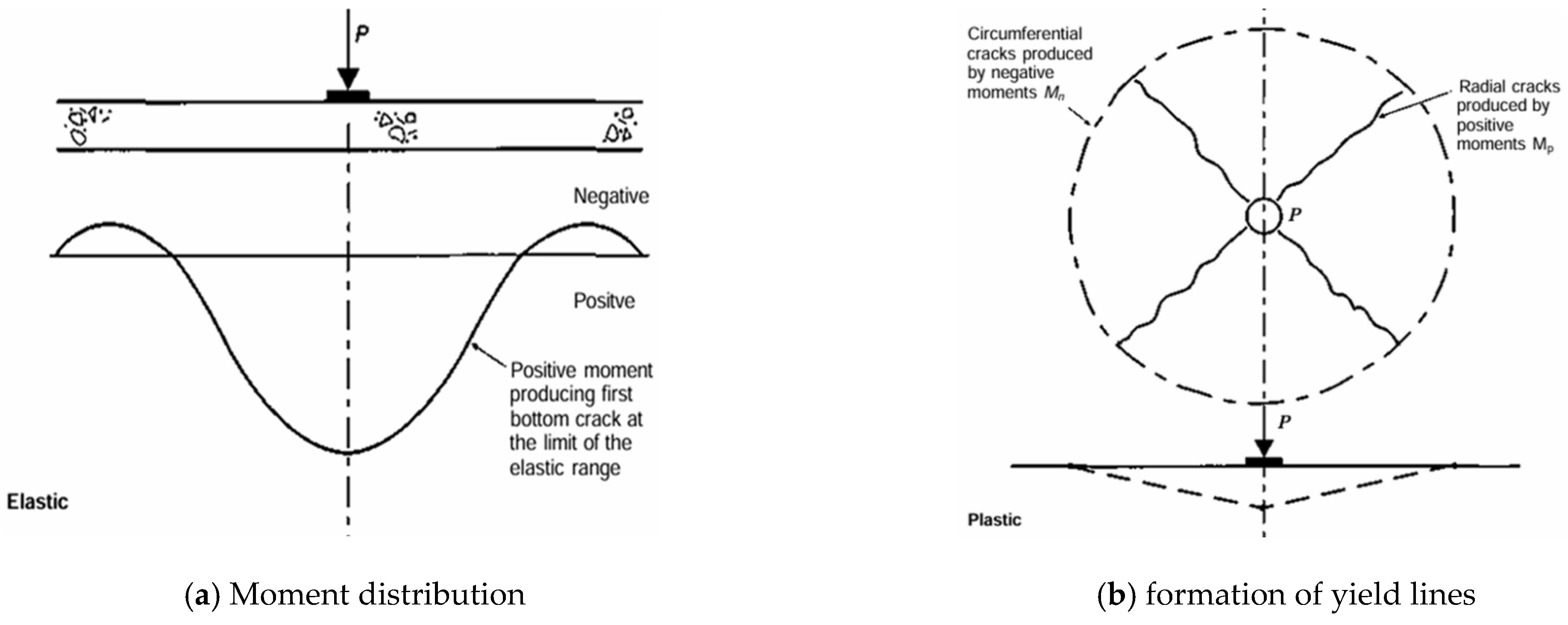

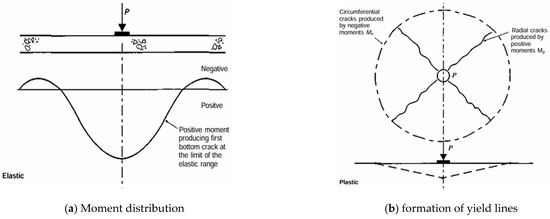

As depicted in Figure 1, a single concentrated load is applied to a small circular area on a large concrete ground-supported slab. Upon incremental loading, the flexural stresses directly beneath the load reach the concrete’s flexural strength, initiating yielding within the slab. This phenomenon results in radial tension cracks forming at the bottom of the slab, attributed to positive tangential moments. The moment per unit length at which the concrete reaches its flexural tensile strength is then determined, as expressed in Equation (1) [15].

where h is the slab depth (mm) and is the characteristic flexural strength of the plain concrete (N/mm2) and is calculated using Equation (2).

Figure 1.

Distribution of bending moments and formation of yield lines [15].

With further load increments, moment redistribution occurs, leading to a plateau in the positive moment. Conversely, a significant increase in the circumferential moment, distal to the loaded area, is observed. Tensile cracking initiates at the upper surface of the slab when the maximum negative circumferential moment exceeds the slab’s negative moment capacity, culminating in failure characterized by visible circumferential cracks. The assumption of yield line patterns in ground-supported slabs relies on sufficient ductility and the absence of punching shear failure. Consequently, the yield line pattern depicted in Figure 1 is not applicable to pre-cracked slabs.

2.2. Design Equations

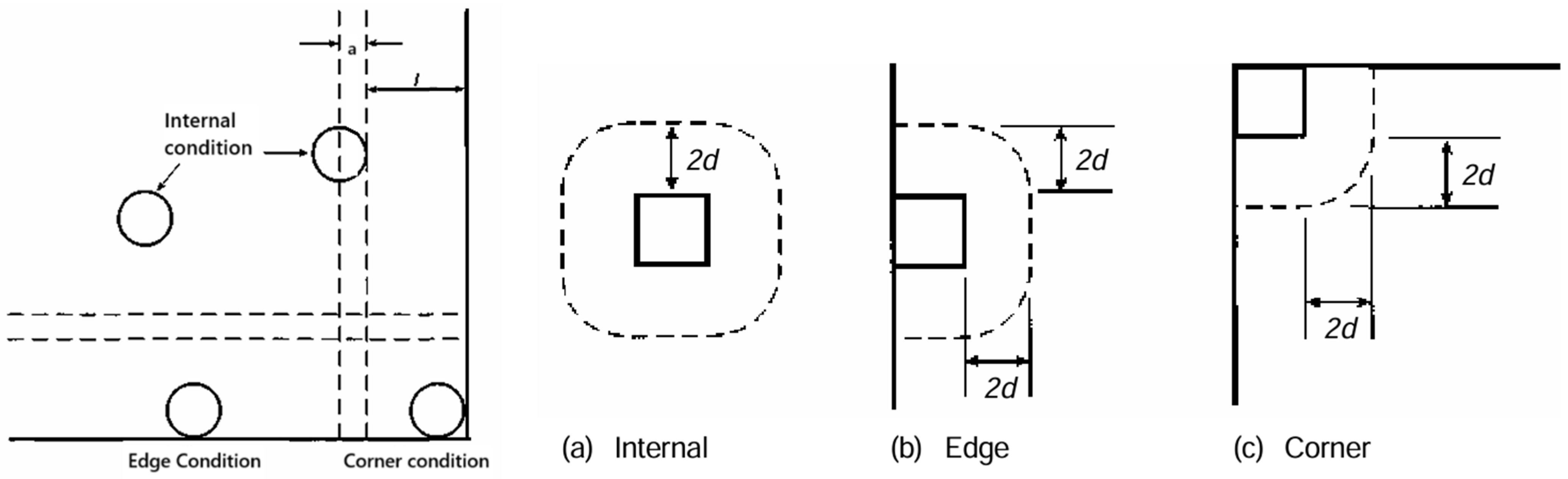

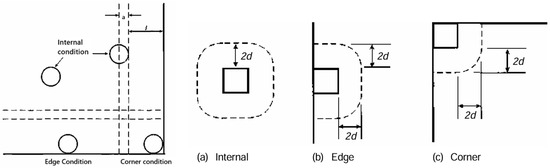

Furthermore, as per load locations shown in Figure 2, the following equations for internal loads (Equations (3) and (4)), edge loads (Equations (5) and (6)) and corner loads (Equations (7) and (8)) were considered [15]:

Figure 2.

Loading locations and critical perimeters for punching shear for internal, edge and corner loading [15].

- For an internal load (case 1):

- For an edge load (case 2):

- For a corner load (case 3):

To obtain the load for cases where a/l ≤ 0.2, use of linear interpolation between the values obtained from the given equations for a/l = 0 and a/l > 0.2. The formula for linear interpolation is,

where the radius of relative stiffness l is calculated as follows:

where is the short-term modulus of elasticity of concrete (N/mm2), v is the Poisson’s ratio, and k is the modulus of subgrade reaction (N/mm3), the value of k is mentioned in Table 1.

Table 1.

Typical values of modulus (k) of subgrade reaction related to soil type [15].

Design moment capacities for steel-fiber-reinforced concrete can be calculated using the following equations:

and are determined according to Equations (11) and (12),

The ductility of steel-fiber-reinforced concrete is defined by its equivalent flexural strength ratio, . This ratio varies depending on the type and amount of fibers mixed. A minimum value of 0.3 is required, which depends on an adequate number of fibers being provided. According to JSCE-SF-4 [28], it is calculated as the ratio of the average load (obtained from the load-deflection curve in a three-point bending test) until the deflection reaches 1/150 of the span (corresponding to 2 mm for a 300 mm span and 3 mm for a 450 mm span) to the initial cracking load. is the partial safety factor for concrete [15].

It has been observed that the incorporation of short synthetic fibers at a typical dosage of 0.9 kg/m3 does not significantly enhance the ductility of concrete. Consequently, slabs produced with such fiber dosages should be treated analogously to conventional concrete. Conversely, higher dosages of synthetic fibers have demonstrated the potential to improve ductility. Specifically, if a minimum value of 0.3 can be confirmed, the design equations applicable to steel fiber-reinforced concrete may be adopted [15]. In this study, the value was determined experimentally through a series of flexural strength tests conducted to evaluate the post-cracking behaviour of the material and its capacity to enhance ductility at elevated fiber dosages.

for slab reinforced with fabric or bars can also be calculated using Equation (13):

where represents the steel reinforcement area, denotes the characteristic yield strength of the steel, and is the partial safety factor for steel.

2.3. Punching Shear

The Eurocode 2 [15,29] stipulates that the punching shear capacity is determined by evaluating shear stress at both the contact area face and a critical perimeter positioned at a distance of 2d from the contact area face, where d represents the effective depth [15], as illustrated in Figure 2.

2.3.1. Shear at the Face of the Loaded Area

According to Eurocode 2 [15,29], the shear stress at the face of the loaded area, irrespective of the slab reinforcement ratio, must not exceed a maximum value, , defined by Equation (14).

where represents the design concrete compressive strength (cylinder), calculated as , and is the factor used in shear calculations, determined by ; is the characteristics concrete compressive strength (cylinder).

Hence, the maximum load capacity in punching, is calculated as follows:

where is the length of the perimeter at the face of the loaded area.

2.3.2. Shear on the Critical Perimeter

Fabric or bar reinforcement: The average shear stress that can be carried by the concrete on the shear perimeter, , is evaluated from Equation (16).

where , and and are the percentages of reinforcement by area in the x and y directions, respectively. is the factor used in shear calculations and is derived as .

Thus, the slab load capacity, is as follows:

where is the length of the perimeter at a distance 2d from the loaded area.

Steel fiber reinforcement: Based on RILEM guidance [30], the inclusion of steel fibers enhances the design shear capacity of the concrete compared to plain concrete by an additional amount given by:

Furthermore, the minimum shear capacity is given as in the Eurocode 2. Therefore, for steel-fiber-reinforced concrete, the slab load capacity, , is expressed as:

For synthetic fiber reinforcement, the is as follows:

2.4. Bearing Capacity

Overli (2014) [22] estimated the bearing capacity, , based on EN 1992-1-1 (2004) [29] and CEB-FIP (1990) [31] as follows:

where is the loaded area and is the maximum design distribution area with a shape similar to that of . Restrictions on the distribution area are applied to account for loads near an edge, eccentric loading, or overlapping loads.

3. Specimen Fabrication and Testing

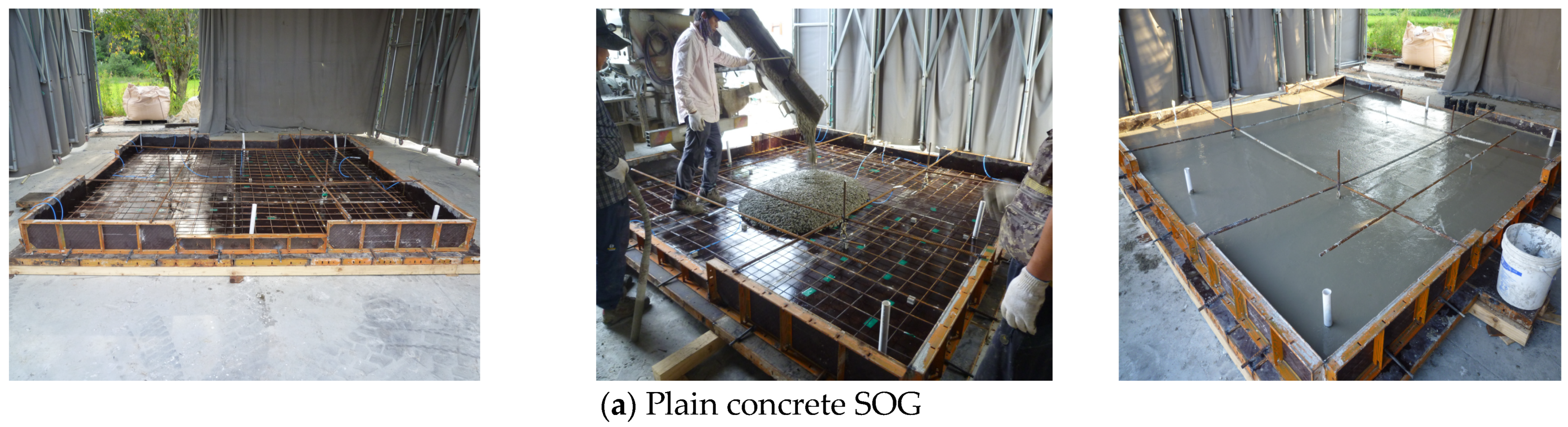

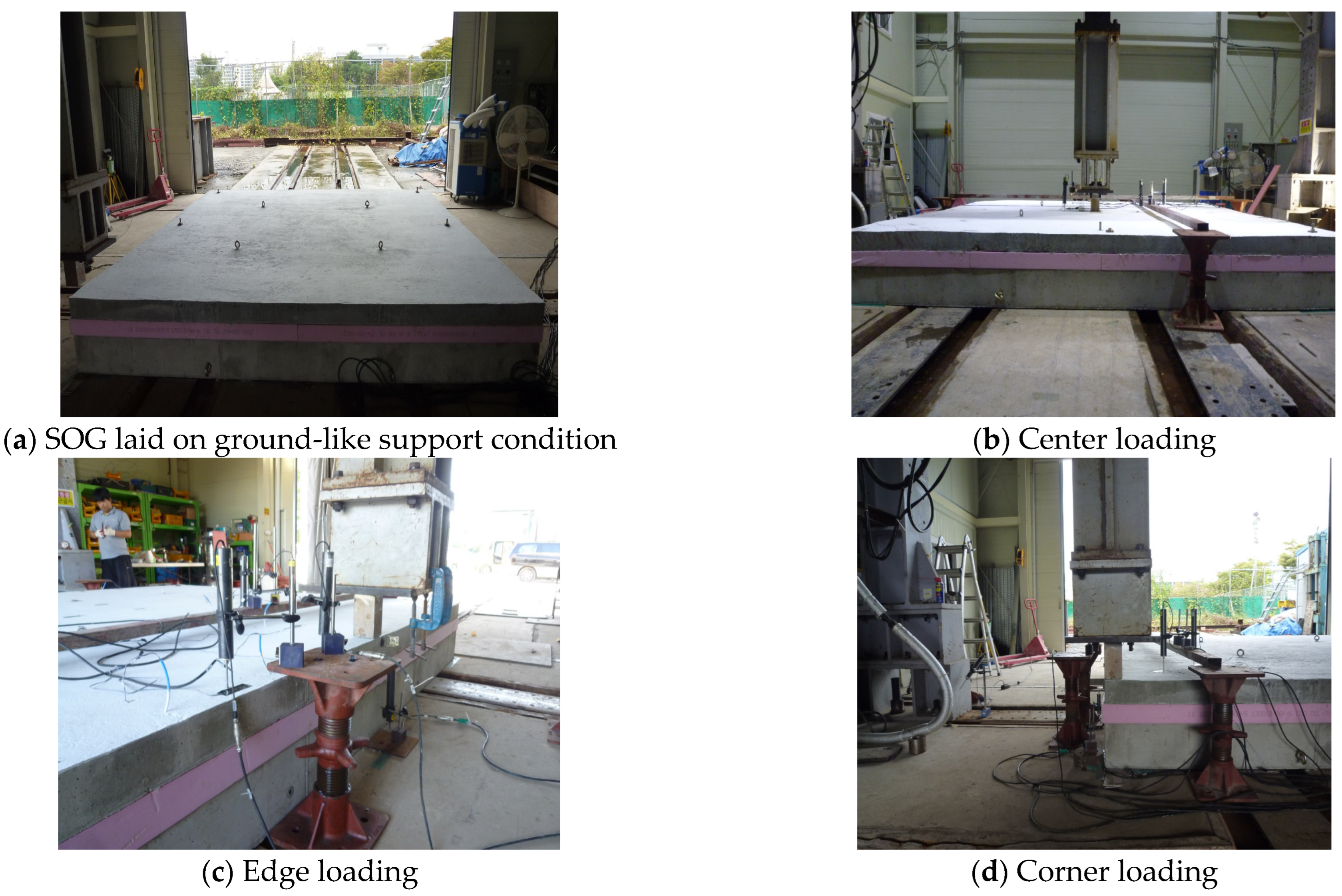

An experimental study was conducted to compare the load capacity and crack patterns of a conventional concrete SOG reinforced with steel mesh and an HDFRCC SOG without steel mesh reinforcement. For the conventional concrete slab, ready-mixed concrete was used, characterized by a compressive strength of 40 MPa, a slump of 15 cm, and a maximum aggregate size of 19 mm. The HDFRCC was manufactured with a water-to-binder (w/b) ratio of 0.35, adhering to the mix proportions detailed in Table 2. Ordinary Portland cement (Type I) and sand with a grain size of 0.5 mm were used. Coarse aggregate was excluded because it increases the fracture toughness of the matrix and hinders uniform fiber dispersion. PE fibers, with a diameter of 16 µm and a length of 12 mm, were incorporated at 1.2% by weight of cement. Furthermore, a high-range water-reducing admixture (HRWRA), specifically a polycarboxylate superplasticizer (Flowmix 3000s, Dongnam Co., Ltd., Seoul, Republic of Korea), was utilized. The HRWRA, viscosity-modifying agent (VMA), and anti-foaming agent (AF) were added at proportions of 0.35%, 0.07%, and 0.07% by weight of cement, respectively. These additives were employed to achieve the desired rheological properties and to minimize large air bubbles in the matrix.

Table 2.

Mix design of HDFRCC (kg/m3).

To characterize the material properties of concrete, six cylindrical specimens with a diameter of 100 mm and a height of 200 mm were prepared for compressive strength testing. For HDFRCC, in addition to cylindrical specimens for compressive strength tests, four prismatic specimens measuring 100 mm × 100 mm × 400 mm were fabricated to measure the flexural strength. The compressive strength tests were performed in accordance with KS F 2405 [32]. To effectively integrate the flexural tensile properties of HDFRCC into flexural and shear design, analogous to steel fiber-reinforced concrete, a thorough evaluation of the flexural tensile strength and equivalent flexural strength ratio is imperative. Four-point bending tests were carried out in accordance with the JSCE-SF-4 [28] and KS F 2566 [33] standard test methods, with deflection measurements taken at the central point.

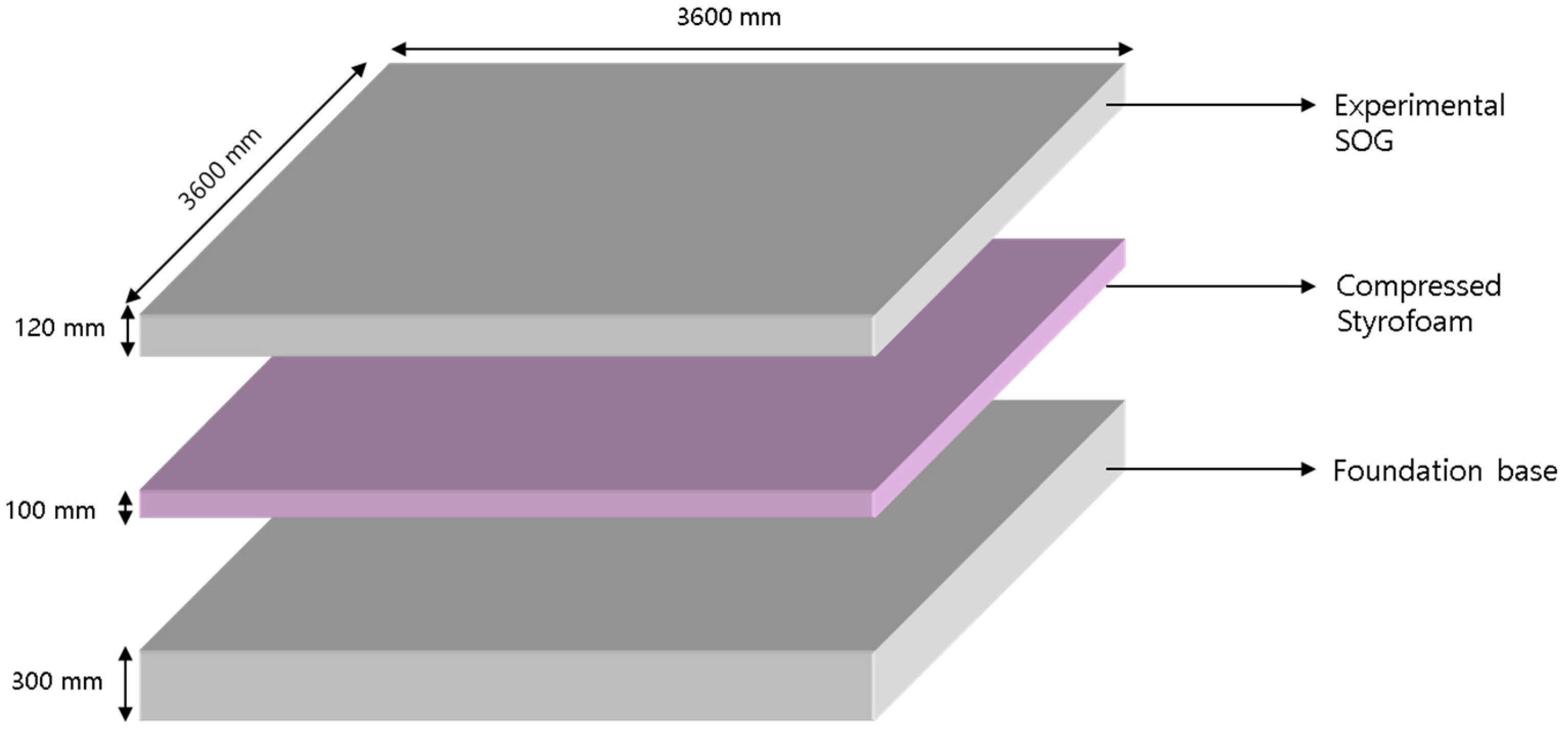

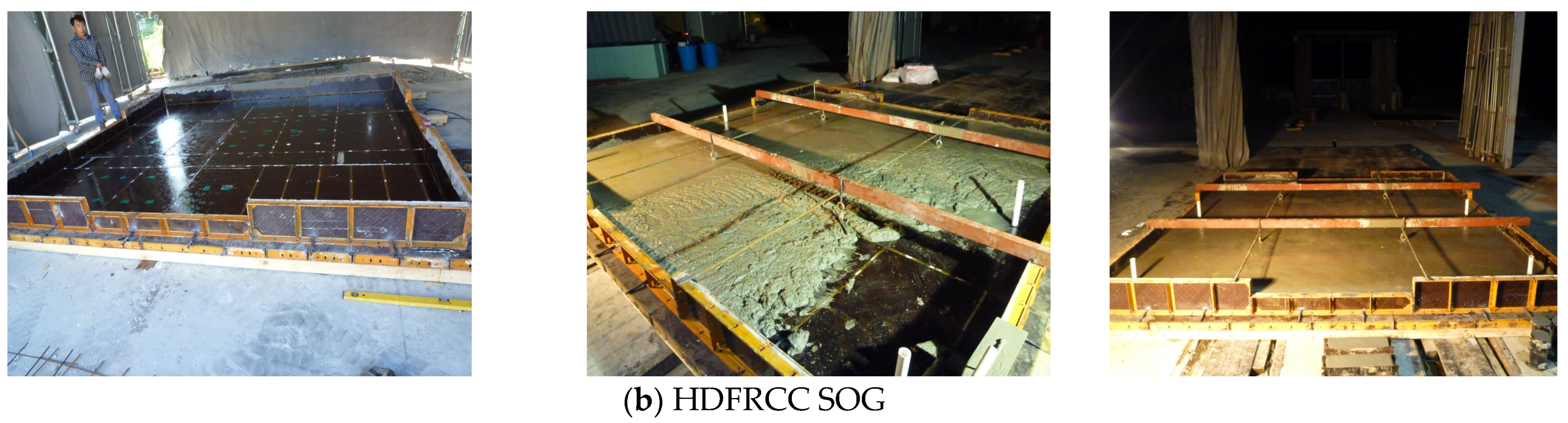

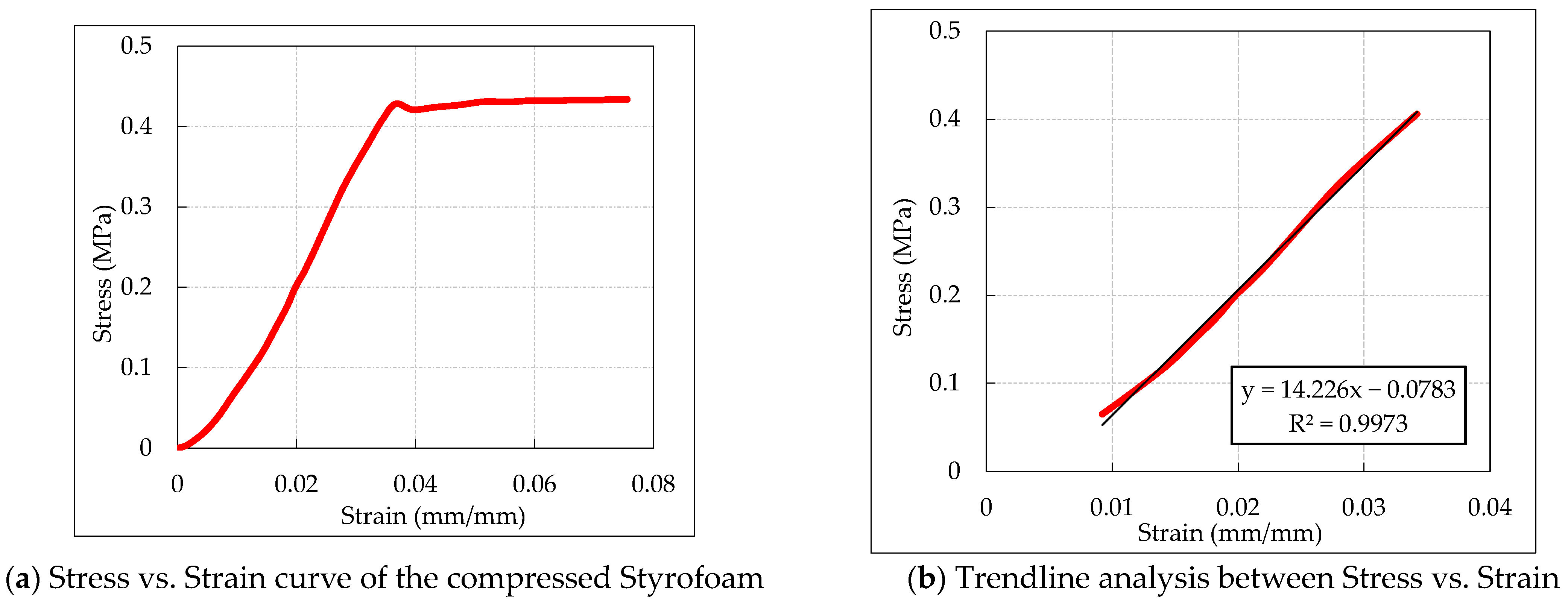

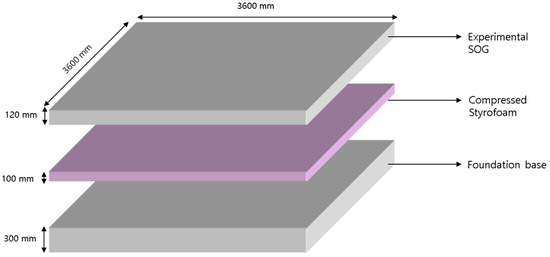

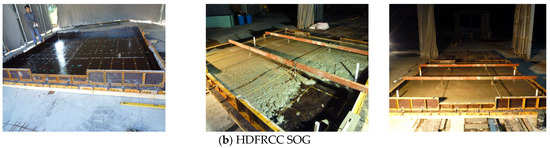

The stiffness of subgrade varies with soil type and generally falls within the range of 0.01–0.5 N/mm3. Crushed stone, a commonly used subgrade material, exhibits a stiffness of about 0.15 N/mm3 [22]. To reproduce this condition in the testing setup, the supporting layer was modeled as a 100 mm thick compressed Styrofoam layer (Hanyoung Co., Ltd., Jeongeup City, Republic of Korea). Although this approach does not explicitly distinguish between the subgrade and subbase, it provides a practical means of approximating the composite stiffness of the foundation while minimizing variability.

Compared to actual soil or crushed stone subgrades/subbases, Styrofoam offers a simplified and more controlled representation of ground support. It is lightweight, homogeneous, and exhibits a predictable elastic response, making it suitable for approximating the stiffness of the foundation in laboratory tests. In contrast, soil and crushed stone are heterogeneous materials with non-linear, stress-dependent behavior, which also contribute shear resistance, load distribution, and drainage capacity. While Styrofoam reduces variability and allows for repeatable experiments, it does not capture the complex mechanical and environmental interactions present in real subgrade/subbases conditions.

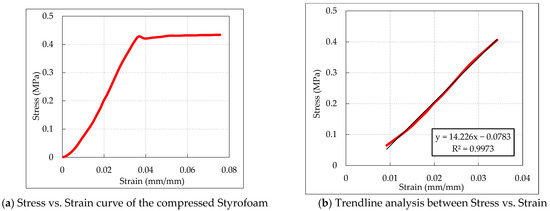

Before its use, the stiffness of the compressed Styrofoam was evaluated through stress–strain tests on cubic specimens measuring 100 × 100 × 100 mm. According to TR 34, the stiffness of ground soil varies with site conditions, as summarized in Table 1 [15].

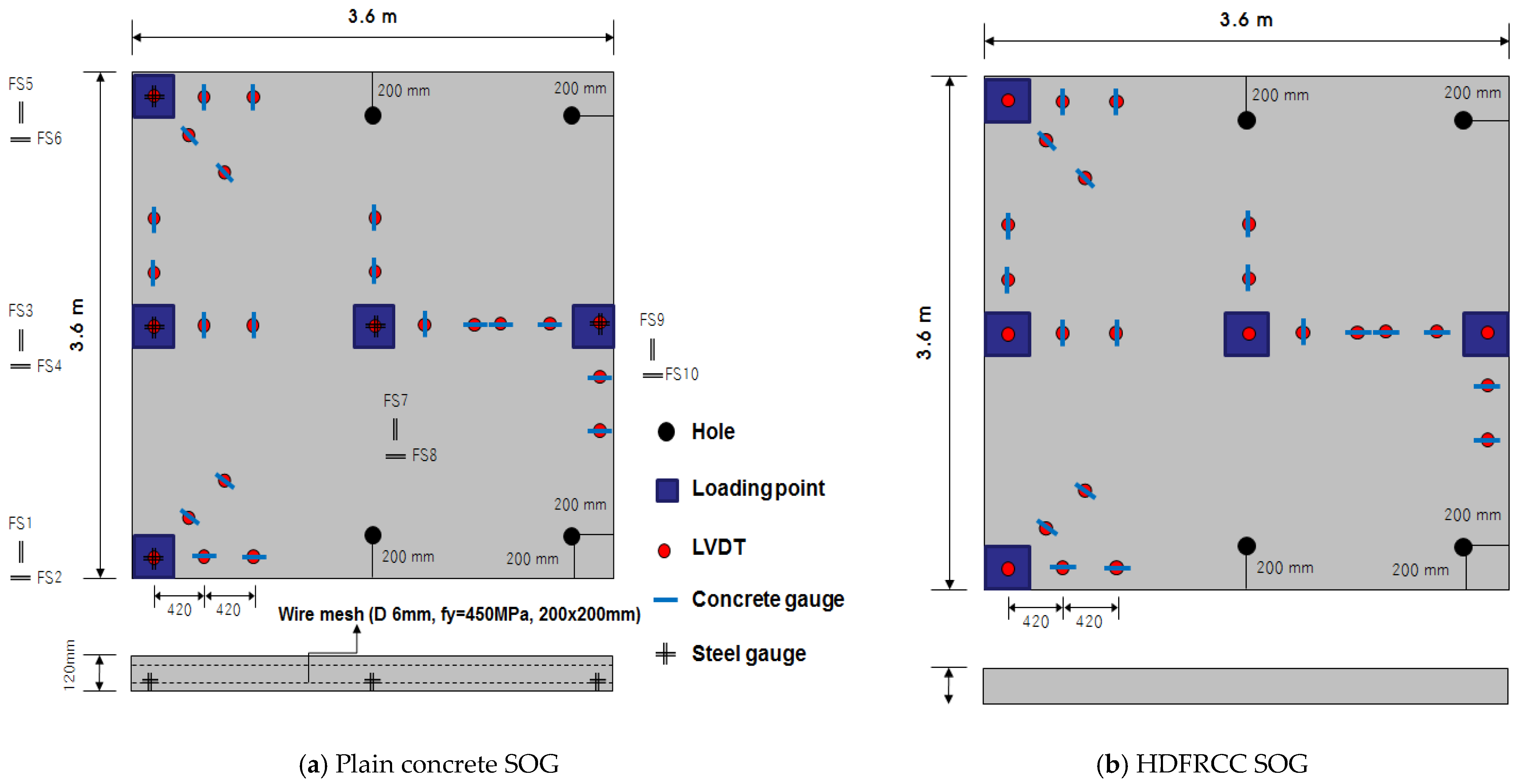

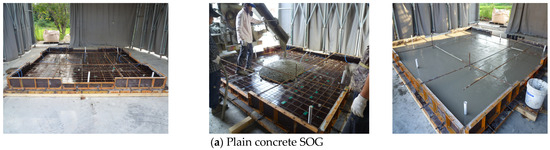

The two slab specimens were fabricated with cross-sectional dimensions of 3600 mm × 3600 mm and a thickness of 120 mm, one using conventional concrete with steel mesh and the other using HDFRCC. The compressed Styrofoam layer was dimensioned to match the slab specimens’ cross-sectional dimensions, maintaining a height of 100 mm. A foundation base concrete layer, also with the same cross-sectional dimensions, was constructed to a height of 300 mm, as illustrated in Figure 3. For the slab constructed with conventional concrete, reinforcement consisted of welded wire mesh with a yield strength of 450 MPa, a diameter of 6 mm, and a grid spacing of 200 mm × 200 mm. This reinforcement was positioned 30 mm from both the upper and lower surfaces.

Figure 3.

Simulation of slab support ground conditions.

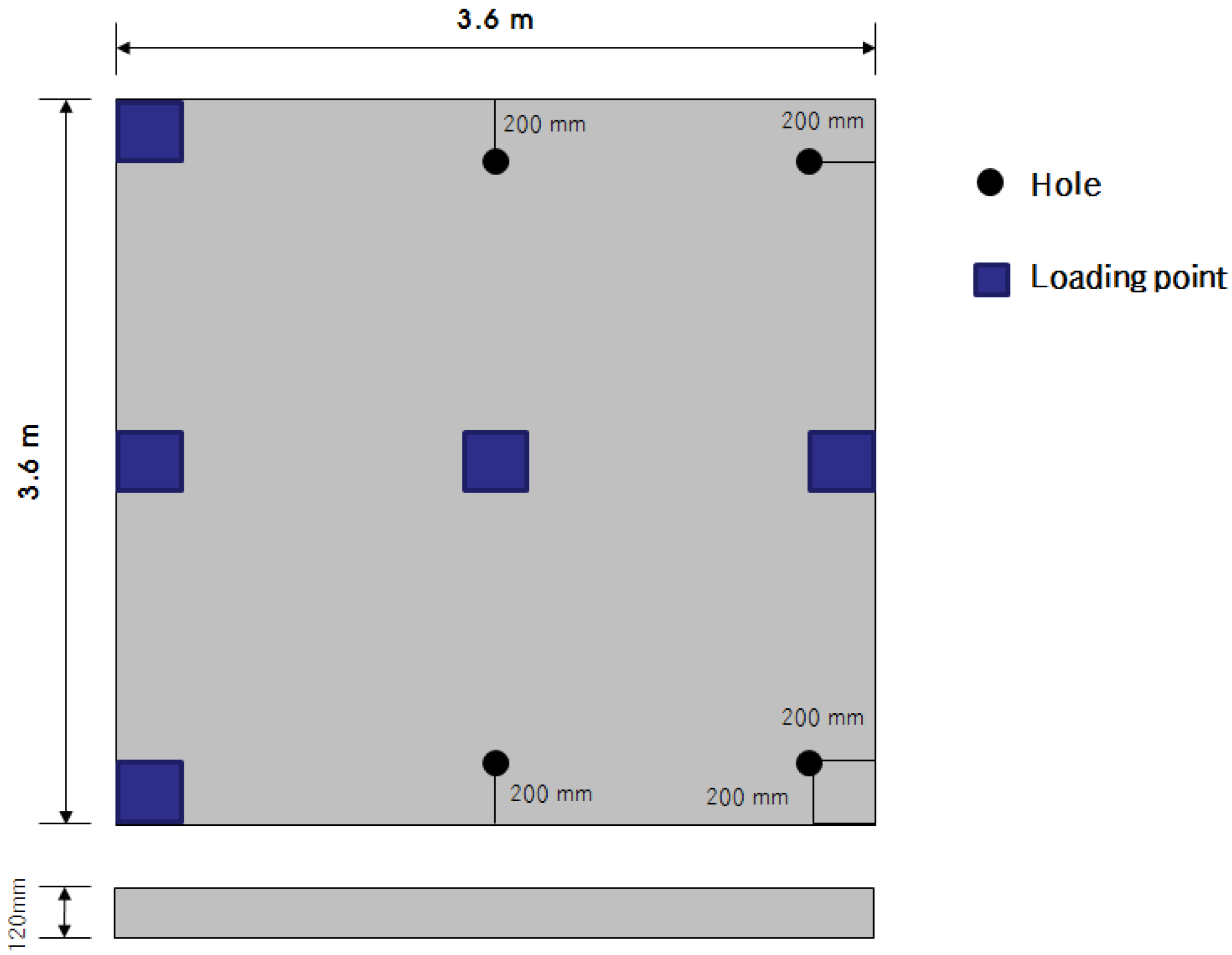

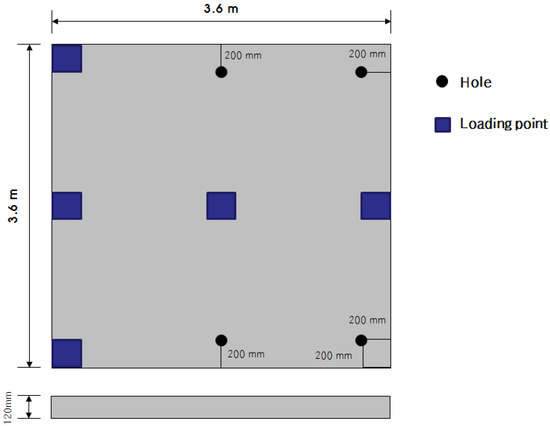

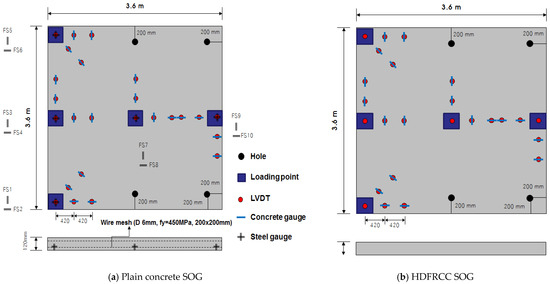

Loading tests were performed on the slab specimens at five distinct locations per specimen, as depicted in Figure 4: a central internal loading point, two edge loading points, and two corner loading points. The loaded area was consistently maintained at 100 × 100 mm, approximately corresponding to the footprint of storage racking uprights in a warehouse. To ensure the independence of each loading test and mitigate potential interference, the experimental design accounted for both the effective range of the bending moment and the influence zone of punching shear. Additionally, Figure 5 illustrates the placement of strain gauges, which were affixed to the reinforcement and concrete to quantify strain at various locations for both conventional concrete and HDFRCC slab specimens. This figure also details the positioning of linear variable differential transformers (LVDTs), employed to measure slab deflection. Furthermore, Figure 6 presents the reinforcement arrangement, casting frame, and slab fabrication process.

Figure 4.

Loading points for the cases of internal, edge and corner loading.

Figure 5.

Details of strain gauges for concrete and steel and LVDTs.

Figure 6.

Fabrication procedure of SOG.

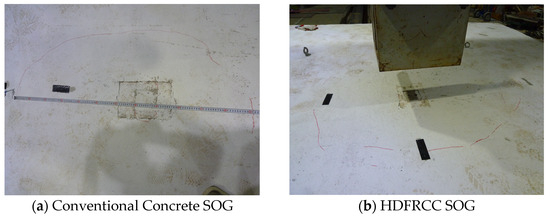

Figure 7a shows the setup, with the SOG positioned on compressed Styrofoam to simulate ground support conditions. Figure 7b–d provide the test setups for internal loading, edge loading, and corner loading, respectively.

Figure 7.

Slab setup and testing locations.

4. Results and Discussions

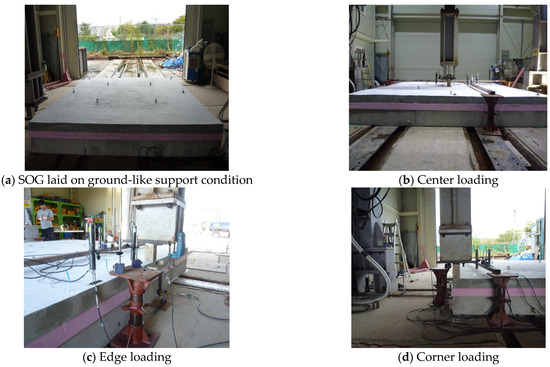

4.1. Compressive Strength

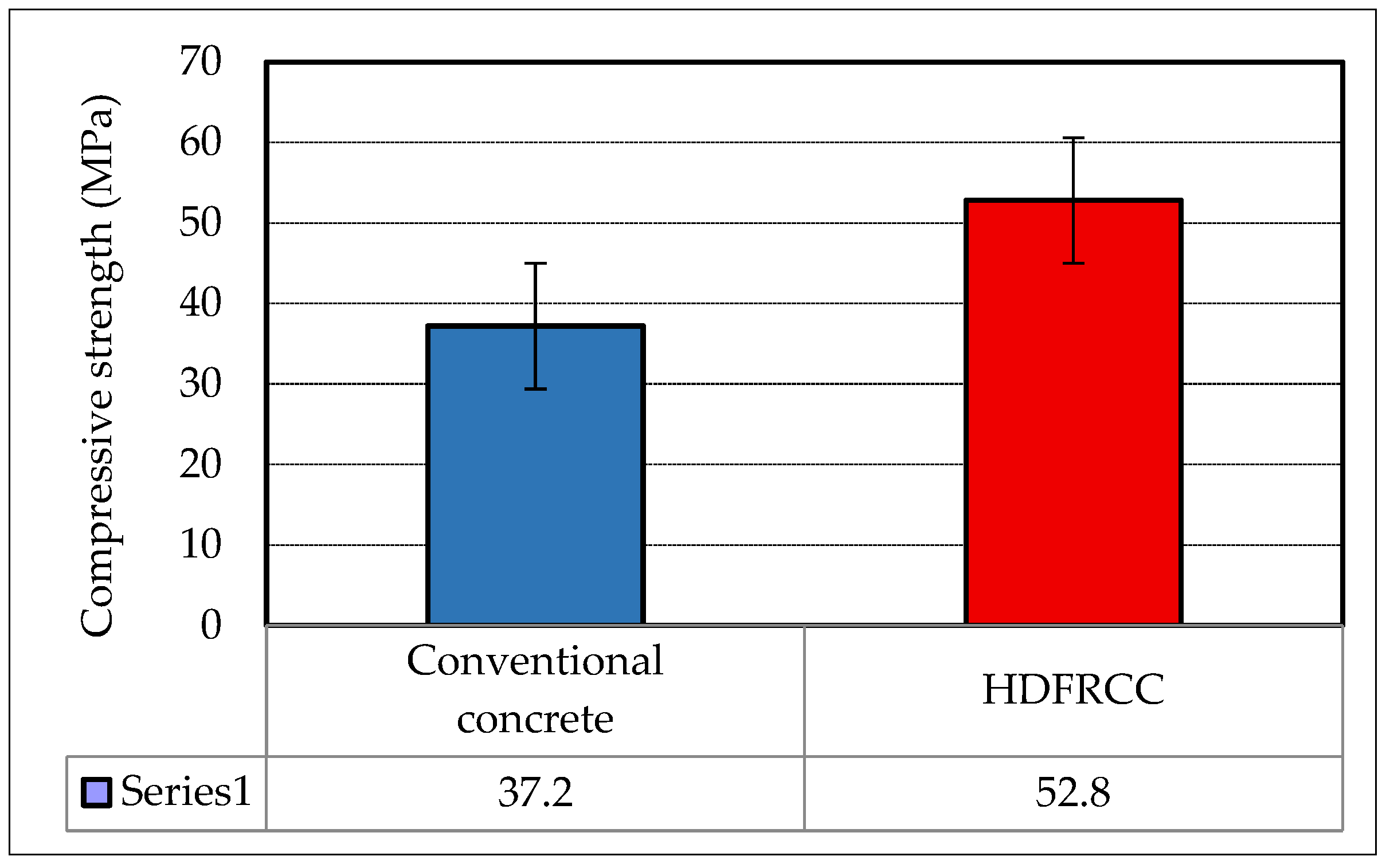

Figure 8 presents the 28-day compressive strength results obtained from three test specimens, each from conventional concrete and HDFRCC. The compressive strength of the conventional concrete was measured to be 37 MPa. The compressive strength of HDFRCC was 54 MPa.

Figure 8.

Compressive strengths of conventional concrete and HDFRCC.

4.2. Flexural Tensile Strength and Equivalent Flexural Strength Ratio of HDFRCC

The results for initial cracking strength, flexural tensile strength, and equivalent flexural strength ratio obtained from four specimens are summarized in Table 3. The load at which initial cracking occurred ranged from 10.0 kN to 14.7 kN, yielding an average of 13.0 kN. The associated first cracking stress varied from 3.0 MPa to 4.4 MPa, with a mean of 3.9 MPa. The maximum load observed ranged between 28.7 kN and 34.0 kN, averaging 32.2 kN. The corresponding stress at maximum load ranged from 8.6 MPa to 10.2 MPa, with an average of 9.6 MPa. Additionally, the average equivalent flexural strength was 6.9 MPa, and the equivalent flexural strength ratio ranged from 1.5 to 2.4, with an average ratio of 1.8, which is well above the required threshold of 0.3. These results are attributed to the superior hardening behavior of the high-ductility PE fiber-reinforced cementitious composite [34,35,36], in contrast to the steel fiber-reinforced concrete, which exhibited equivalent flexural strength ratio values ranging from 0.4 to 0.8 [37]. As a result, the formulas used for calculating moment capacities in steel fiber-reinforced concrete, specifically and , were applied to determine the moment capacities of HDFRCC with PE fiber.

Table 3.

Results of flexural tensile test conducted on HDFRCC.

4.3. Stress-Displacement Curve of Compressed Styrofoam

Figure 9a shows the compressive stress–strain relationship of the compressed Styrofoam. Trendline analysis (Figure 9b) revealed an approximate linear relationship, yielding a k value of 0.142 N/mm3, which corresponds to the slope of 14.226 MPa per unit strain divided by the 100 mm gauge length (14.226/100 = 0.142 N/mm3). This value demonstrates a close correspondence with the modulus of subgrade reaction reported for well-compacted sand or ground composed of sand and crushed stone, as listed in Table 1.

Figure 9.

Stress vs. Strain curve and trendline analysis of the compressed Styrofoam.

4.4. Structural Behaviour of SOG

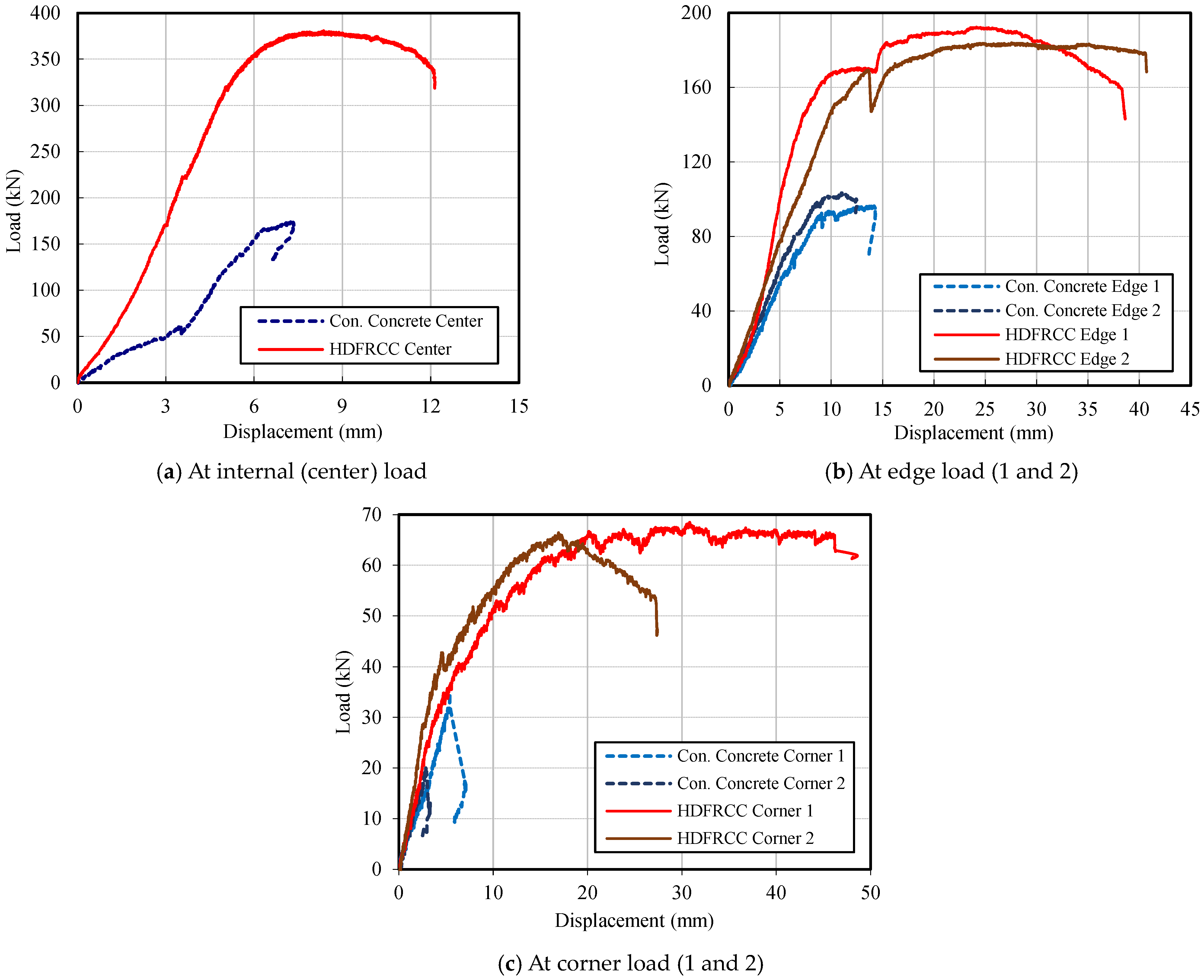

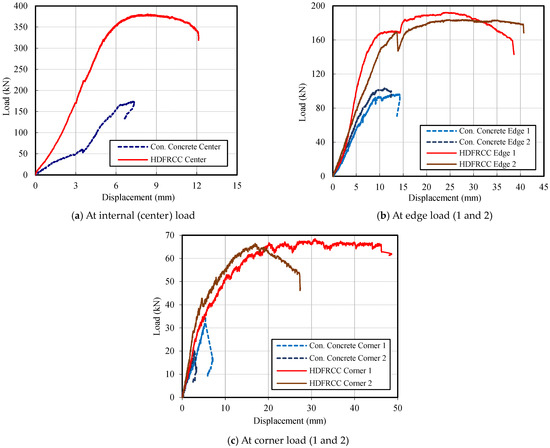

The experimental results of the load capacity of conventional concrete SOG and HDFRCC SOG are presented in Figure 10 and Table 4. Analysis of the data reveals that the HDFRCC SOG demonstrated approximately twice the load capacity compared to the conventional concrete SOG across all loading configurations: internal (center), edge, and corner. Specifically, the load capacity for HDFRCC SOG under center loading was 380.82 kN, whereas conventional concrete SOG achieved 174.52 kN. Furthermore, a progressive reduction in maximum load was observed as the loading location shifted from edge to corner. Quantitatively, the edge 1 and edge 2 loading locations yielded maximum loads of 192.37 kN and 183.94 kN for HDFRCC SOG, representing increases of 99.56% and 77.90%, respectively, over the conventional concrete SOG. Similarly, at corner 1 and corner 2 loading locations, HDFRCC SOG demonstrated enhancements in the maximum load of 96.67% and 228.57% compared to conventional concrete SOG.

Figure 10.

Load vs. displacement curve for conventional concrete and HDFRCC SOG at various loading locations.

Table 4.

Load capacity of conventional concrete SOG and HDFRCC SOG.

These findings underscore that utilizing HDFRCC exclusively for SOG construction, without the incorporation of welded wire mesh, confers substantial benefits. This includes superior crack resistance, facilitating the construction of extensive floor slabs without contraction joints, and a marked improvement in load capacity. In terms of economic considerations, the exclusion of welded wire mesh results in a reduction in construction duration. Additionally, for an identical load capacity design, a decrease in SOG thickness is attainable, leading to substantial material savings and a demonstrable enhancement in cost-effectiveness.

Load–deflection curves are instrumental in discerning failure mechanisms. All specimens exhibited a near-bilinear response up to the ultimate load, characterized by two distinct phases. Initially, a high-stiffness phase prevailed, indicative of the uncracked slab. Subsequently, a second phase emerged wherein stiffness diminished due to tensile flexural cracking. After reaching the ultimate load, most specimens demonstrated significantly increased post-peak deflections. However, the conventional concrete SOG specimens subjected to corner loading experienced a sudden drop in load, indicating a more brittle failure mode [38].

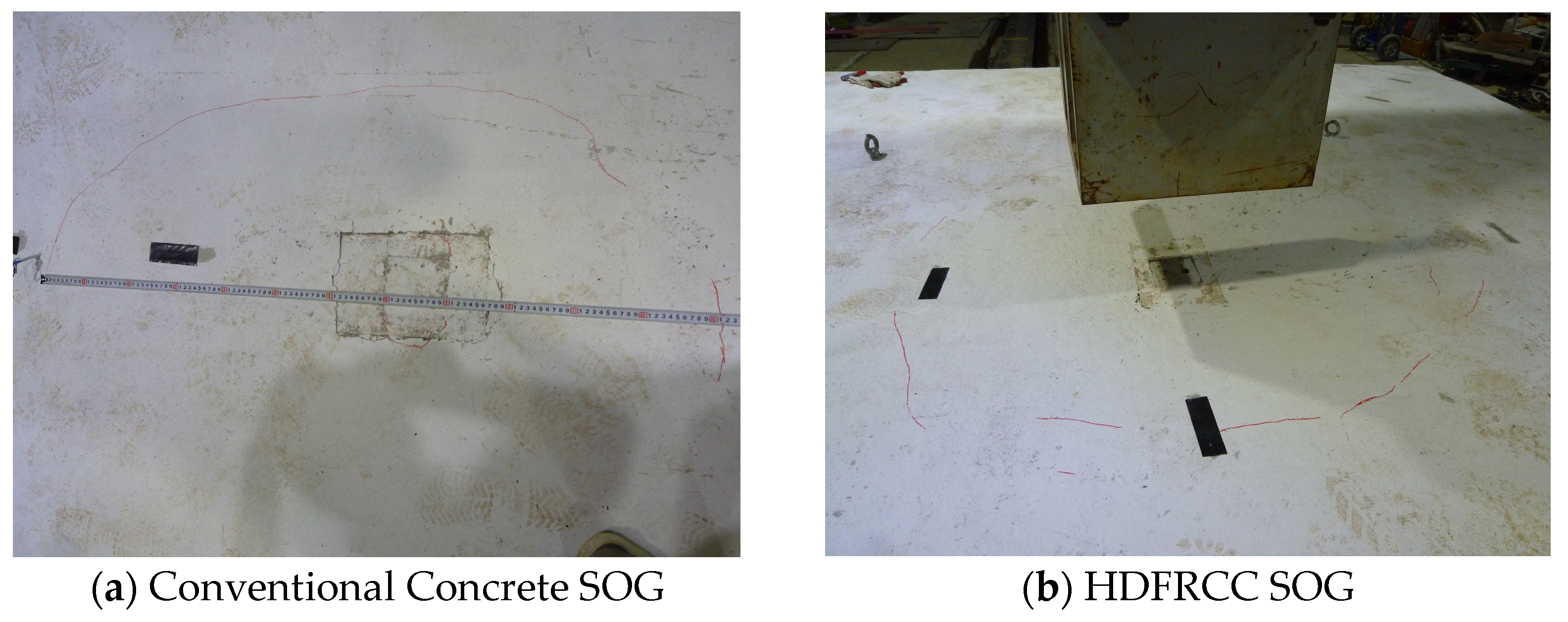

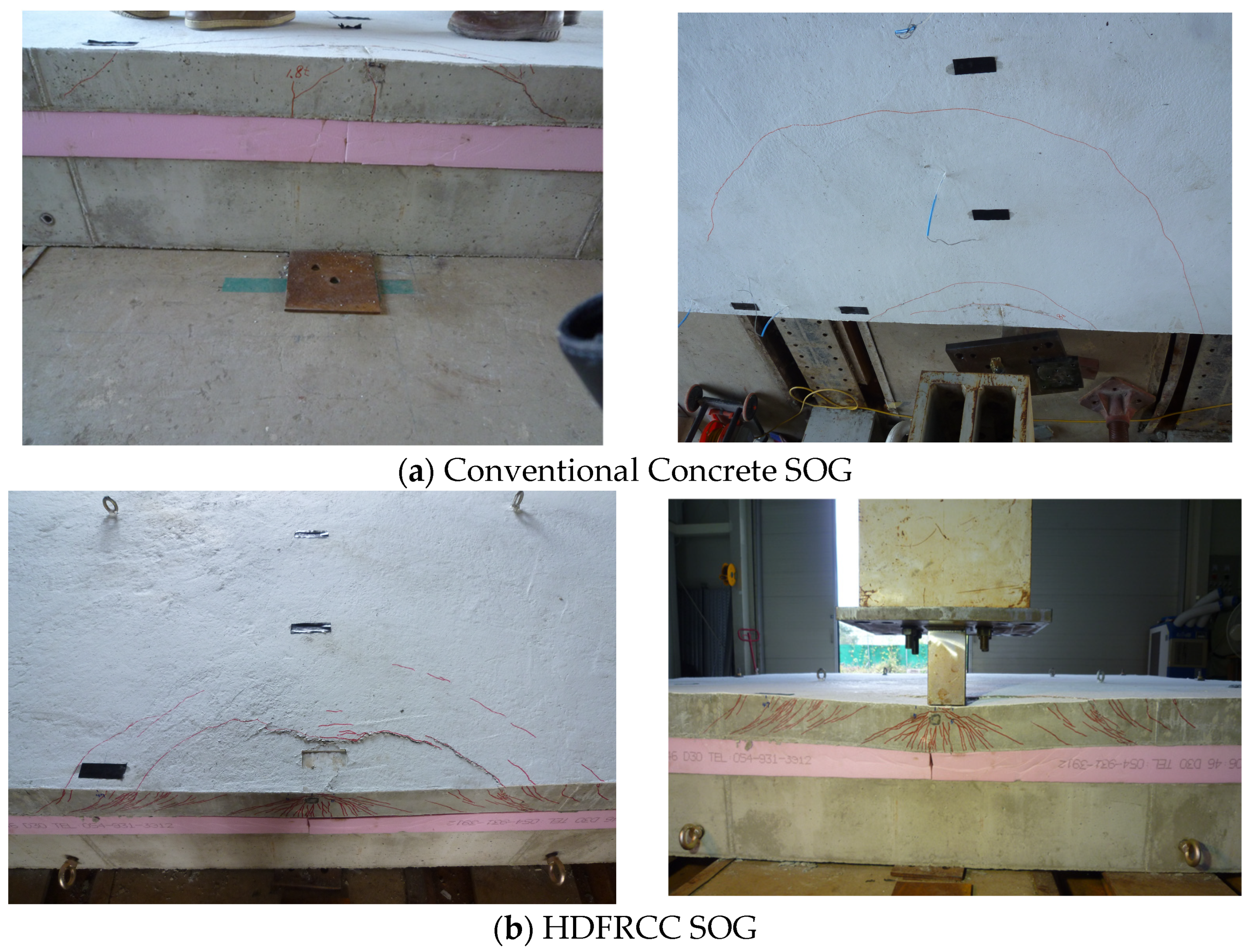

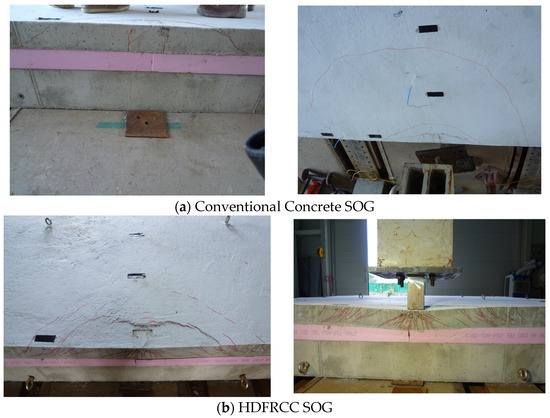

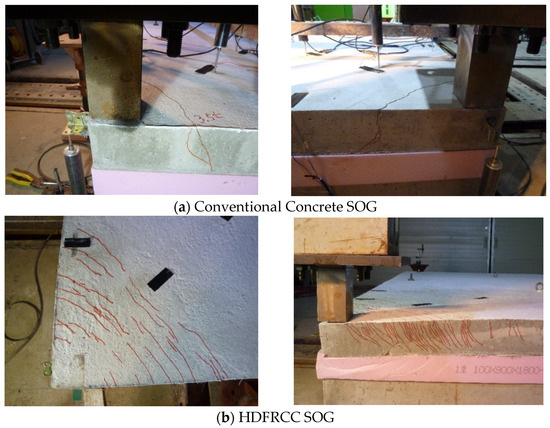

Figure 11, Figure 12, Figure 13, Figure 14 and Figure 15 compare the observed crack patterns in conventional concrete SOG and HDFRCC SOG for each loading position: internal (center), edge (1 & 2), and corner (1 & 2). In Figure 11a, a dominant circular crack, accompanied by several smaller concentric cracks, was observed on the surface of the conventional concrete SOG at a radial distance of approximately 400 to 700 mm from the center of the applied load. The radius of relative stiffness (l) for the slab, calculated using the experimental results, was found to be 410 mm for conventional concrete and 423 mm for HDFRCC (See Section 4.5). Notably, deformation was observed at a radial distance of approximately 2l from the loaded area, indicating the occurrence of a maximum negative moment within this region [15]. In Figure 10a, the load–displacement curve of the conventional concrete SOG initially displayed a non-linear increase from 0 mm to approximately 3.5 mm of displacement (corresponding to 0–60 kN of load). However, this behavior deviates from typical structural response, where the tangential slope of the load–displacement curve generally decreases with increasing load due to the progressive formation of cracks, which reduce the effective second moment of inertia. As a result, the initial segment up to approximately 3.5 mm was disregarded in the analysis. Beyond this point, the curve exhibited a continued increase in load with a gradually decreasing slope, suggesting crack propagation and progressive stiffness degradation. The load peaks at around 174 kN near 6 mm displacement. Following this peak, a sharp drop in load-carrying capacity was observed, indicating flexural failure and a loss of structural integrity.

Figure 11.

Crack patterns at failure load for center loading.

Figure 12.

Crack patterns at failure load for Edge 1 loading.

Figure 13.

Crack patterns at failure load for Edge 2 loading.

Figure 14.

Crack patterns at failure load for Corner 1 loading.

Figure 15.

Crack patterns at failure load for Corner 2 loading.

In contrast, the HDFRCC SOG exhibited multiple small circular cracks, located approximately 300 mm to 700 mm from the loading location (Figure 11b). The HDFRCC SOG initially demonstrated a proportional increase in load with displacement, as seen in Figure 10a. However, within the displacement range of 3 mm to 9 mm, the load continued to increase at an accelerated rate even after the onset of cracking. Distinct from conventional concrete, this observation suggests the formation of multiple microcracks that were effectively bridged by the incorporated fibers, thereby preventing abrupt failure. Upon further displacement (9 mm to 12 mm), a peak load of 380 kN was attained. Subsequently, the load–displacement curve displayed a significant post-peak displacement, indicative of ductile behavior. The extended descending branch of the curve strongly suggests that flexural failure was the predominant failure mode. This behavior may be attributed to the enhanced energy absorption capacity provided by the fiber reinforcement.

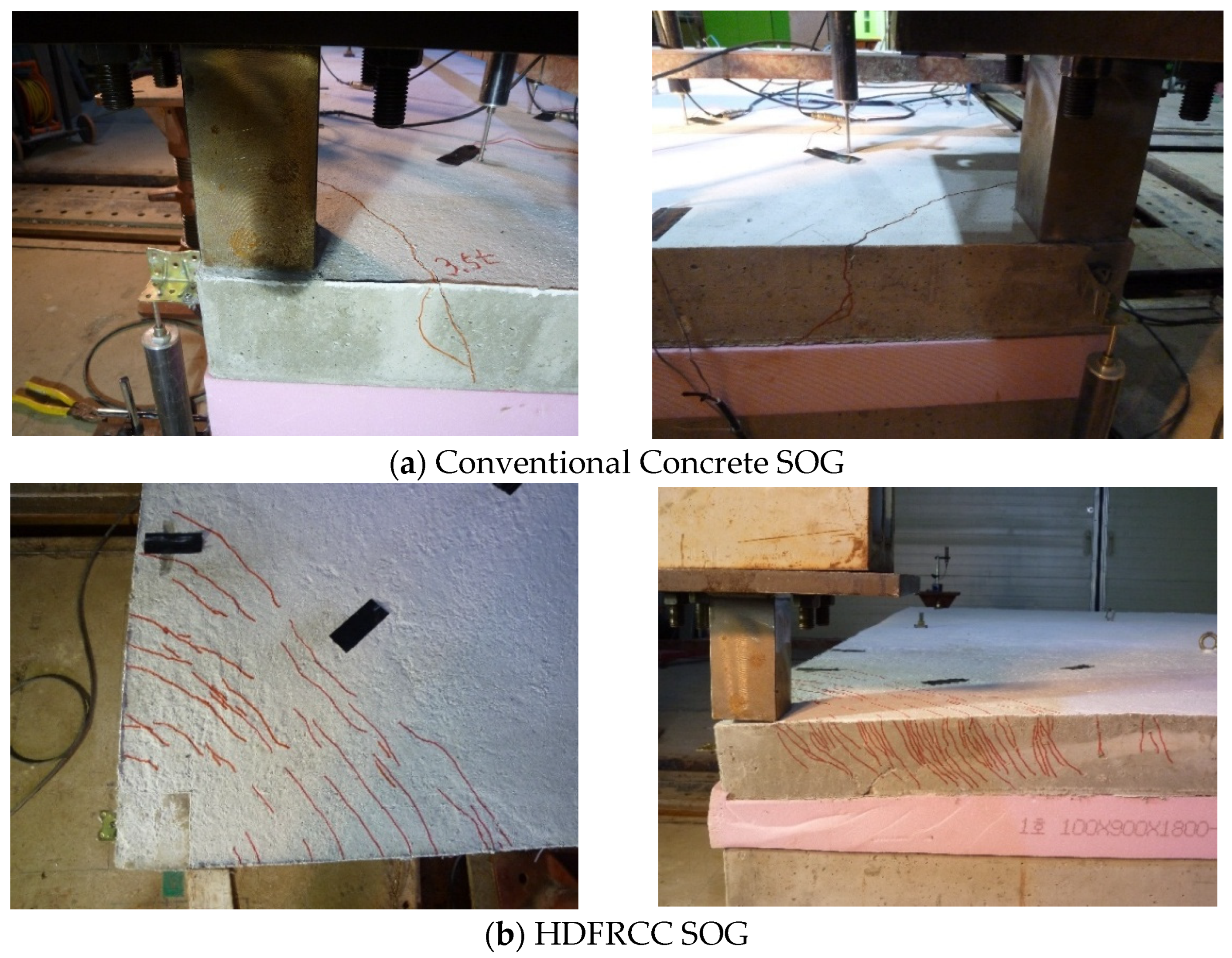

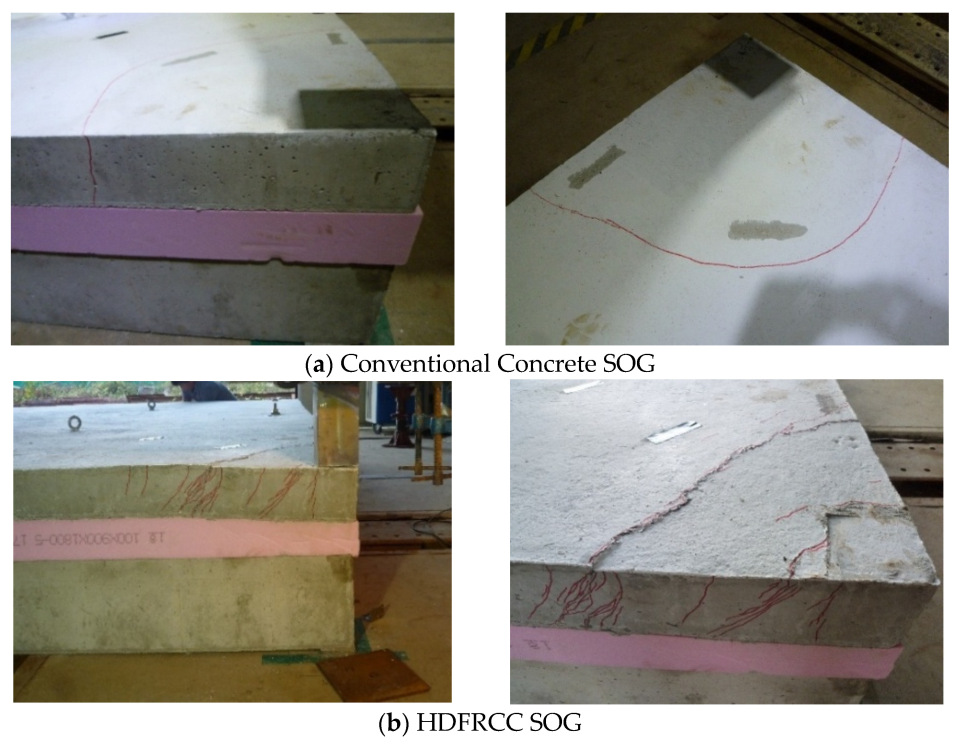

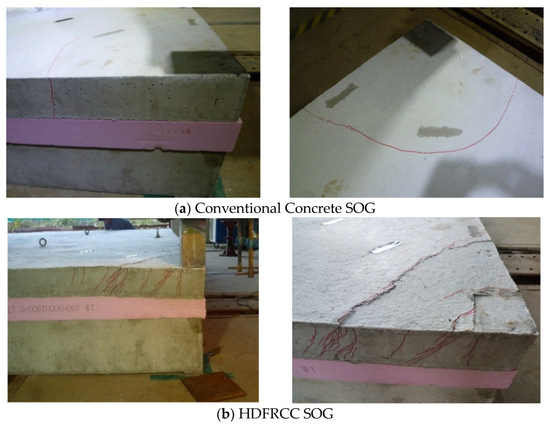

Figure 10b illustrates that conventional concrete SOG specimens at edge 1 and edge 2 initially exhibited a linear increase in load with displacement. The onset of cracking was observed within a displacement range of approximately 6 mm to 8 mm, resulting in a discernible non-linearity in the load–displacement response. The specimens achieved peak loads of 96 kN and 103 kN for edge 1 and edge 2, respectively, followed by a rapid decline in load-carrying capacity. As depicted in Figure 12a and Figure 13a, circular cracks were observed on the top surface surrounding the loading area, accompanied by diagonal cracks on the sides of the slab. The initial circular crack initiated at approximately 78 kN in the vicinity of the loading area (Figure 12a). With increasing load, further cracking propagated radially at distances ranging from approximately 100 mm to 600 mm from the loading point, consistent with the redistribution of internal forces as cracking progressed [22].

Observations from Figure 10b reveal that the HDFRCC SOG specimens at edge 1 and edge 2 exhibited a significantly higher initial linear increase in load, reaching approximately 180 kN, in comparison to conventional concrete SOG. Edge 1 displayed more pronounced fluctuations in load, whereas edge 2 demonstrated a more gradual post-peak decline, suggesting the enhanced contribution of fiber bridging in the HDFRCC. The peak loads achieved were 192 kN for edge 1 and 183 kN for edge 2. The substantial post-peak displacement observed indicates an initial flexural failure mechanism, subsequently followed by punching shear failure. Furthermore, as depicted in Figure 12b and Figure 13b, the HDFRCC SOG specimens at edge 1 and edge 2 developed a network of multiple fine tangential cracks in the vicinity of the loading area, indicative of distributed cracking. A dense pattern of fine radial cracks propagated from the loading point towards the slab edges, demonstrating progressive crack development rather than the formation of a singular dominant failure plane.

Referring to Figure 10c, the applied load increased linearly up to 34 kN for corner 1 and 20 kN for corner 2. A sudden post-peak load drop was accompanied by minimal displacement prior to failure. Figure 14a illustrates a single circular crack observed at the corner 1 loading location, situated at a radial distance of 100 mm, corresponding to a peak load of 34 kN in the conventional concrete SOG specimen. Similarly, at corner 2 (Figure 15a), a single circular crack was observed approximately 300 mm from the loading point.

In contrast, as depicted in Figure 10c, the HDFRCC SOG exhibited significantly higher peak loads, ranging from 66 kN to 68 kN, and demonstrated sustained load-carrying capacity even at larger displacements. The substantial post-peak displacement and gradual load decline indicate an initial flexural failure mode, subsequently followed by punching shear failure. Figure 14b reveals that in the HDFRCC SOG, multiple fine circular cracks radiated outward from the loading point, forming a distributed crack pattern. Furthermore, a dense network of fine cracks extended from the loading point towards the slab corner, indicating progressive cracking and enhanced crack control attributed to the HDFRCC material, thereby preventing abrupt fractures. At the corner 2 location (Figure 15b), a single dominant circular crack was observed on the top surface, accompanied by two minor cracks. The side view revealed a less dense fine crack pattern in comparison to corner 1.

4.5. Result of Analytical Prediction

The essential data necessary for the load capacity analysis of conventional concrete and HDFRCC SOG structures subjected to internal, edge, and corner loads are presented in Table 5. Based on the data presented, factors such as l, a, , and were calculated utilizing Equations (10)–(13). The resulting values are summarized in Table 6.

Table 5.

Data for calculating load capacity of conventional concrete and HDFRCC SOG under internal, edge, and corner load.

Table 6.

Values of l, a, , and .

The ultimate capacity under concentrated load, punching shear capacity, and bearing capacity for the central (internal) loading position were calculated using Equations (3) to (9) and (14) to (20), and the resulting values are presented in Table 7, Table 8 and Table 9. These calculated capacities were subsequently compared with the experimental results detailed in Table 4. For the conventional concrete SOG, the calculated capacity of 203.8 kN was found to be marginally higher than, yet comparable to, the experimental capacity of 174.52 kN for the center loading condition. This finding suggested that the predicted failure mechanism, specifically flexural failure, corresponded well with the actual observed experimental failure mode.

Table 7.

Load capacity of conventional concrete SOG and HDFRCC SOG under internal load.

Table 8.

Load capacity of conventional concrete SOG and HDFRCC SOG under edge load.

Table 9.

Load capacity of conventional concrete SOG and HDFRCC SOG under corner load.

For the HDFRCC specimen subjected to concentrated loading, the experimentally determined failure load was 380.82 kN, far exceeding the predicted punching shear capacity of 87.8 kN. While the analytical prediction indicated punching shear as the governing failure mode, the experimental observations revealed predominantly flexural failure.

Analysis was subsequently performed for edge loading conditions, comparing predicted capacities (flexural, punching shear, and bearing) as shown in Table 8, with the experimental results presented in Table 4. For the conventional concrete SOG under edge loading, the calculated flexural capacity of 100.8 kN closely aligned with the experimental failure load range of 96.43 kN to 103.39 kN. This agreement confirmed the occurrence of flexural failure as anticipated and validated the applicability of yield line theory in this case. In contrast, for the HDFRCC SOG under edge loading, the experimental failure loads ranged from 183.94 kN to 192.37 kN, significantly exceeding the predicted punching shear capacity of 53 kN, while closely matching the predicted flexural capacity of 194 kN. When considered alongside the observed crack geometries, these results indicate that the HDFRCC SOG specimens failed due to a combination of flexural and punching shear mechanisms and that the actual punching shear resistance is substantially greater than predicted.

Further analyses examined the ultimate capacity under concentrated load, punching shear capacity, and bearing capacity for corner loading, as shown in Table 9. A comparison with the experimental data presented in Table 4 indicated that the observed failure capacity for conventional concrete SOG, which ranged from 20.21 kN to 34.83 kN, approximated the analytically predicted value of 44.1 kN. The analytically predicted flexural failure as the governing mechanism aligned with the experimental findings. In contrast, the HDFRCC specimens exhibited higher experimental failure loads, ranging from 66.41 kN to 68.47 kN. These values significantly exceeded the predicted punching shear capacity of 31.1 kN and closely matched the predicted flexural capacity of 56 kN. This confirms the enhanced punching shear resistance of the HDFRCC SOG. However, the experimental failure mode involved a combination of flexural and punching shear, indicating that the actual behavior deviated from the punching failure predicted analytically.

Based on these observations, the failure loads predicted analytically for conventional concrete under center, edge, and corner loading correlated well with the experimental values. However, in the case of HDFRCC, the predicted loads underestimated the actual capacity in all loading scenarios. This discrepancy can likely be attributed to the strain-hardening behavior inherent to HDFRCC, which enhances its load capacity beyond the assumptions incorporated in the traditional analytical framework. Distinct from conventional concrete, HDFRCC possesses superior crack-bridging properties, which facilitate delayed failure initiation and enable more effective load redistribution mechanisms [34,36].

Supporting the prevalence of flexural failure modes in fiber-reinforced concrete, Tan and Venkateshwaran (2017) [40] reported that yield-line theory effectively predicted the average load capacity of steel fiber reinforced concrete (SFRC) slabs without traditional reinforcement, achieving results within 1% of observed values (SD = 0.19). This implies that SFRC slabs under concentrated loading predominantly fail in flexure, likely because propagating existing yield lines requires less energy than forming new circumferential cracks typical of punching failure. In the context of codified approaches, Anil et al. (2014) [41] utilized TS 500 (TSE 2000) [42], ACI 318 (ACI 2008) [43], and Eurocode 2 (CEN 2002) [44] for assessing two-way slabs. Their analysis indicated that predicted punching shear capacities generally exceeded experimental values for specimens incorporating openings, with this deviation increasing proportionally to the opening size. Among the codes evaluated, Eurocode 2 provided the most accurate predictions, although its calculated values were still 39% higher than the experimental results. Conversely, research by Sucharda et al. (2018) [25] found that the actual shear resistance could significantly surpass Eurocode 2 predictions, observing experimental resistance more than five times greater than the calculated value in their study.

The material cost of HDFRCC SOG is higher than that of conventional concrete SOG. However, when labor cost is considered, conventional concrete becomes more expensive because it requires additional time to place and set the steel reinforcement, whereas HDFRCC does not. Overall, the initial cost of HDFRCC is slightly higher than conventional concrete, but given its superior load-bearing capacity, HDFRCC can help reduce future expenses by minimizing the need for frequent maintenance and repair.

5. Conclusions

In this study, an experimental and analytical investigation was conducted on SOGs constructed using either conventional concrete with steel mesh reinforcement or mesh-free HDFRCC incorporating PE fibers. The primary objective was to investigate their respective structural behaviour and load capacities. The key conclusions drawn from this investigation are as follows:

- The compressive strength of the conventional concrete was determined to be 37 MPa, while the HDFRCC exhibited a notably higher compressive strength of 54 MPa. Additionally, HDFRCC demonstrated an average flexural tensile strength of 3.9 MPa at initial cracking, 9.7 MPa at maximum load, and an equivalent flexural strength of 6.9 MPa. These results indicate the superior strain-hardening behavior of HDFRCC compared to conventional concrete.

- The experimental results demonstrated that the HDFRCC SOG exhibited approximately twice the load capacity of the conventional concrete SOG across all loading scenarios: center (380.82 kN), edge (183.94 kN and 192.37 kN), and corner (66.41 kN and 68.47 kN). While the conventional concrete SOG primarily experienced flexural failure, the HDFRCC SOG showed a more ductile response, characterized by a combination of flexural and punching shear failure. The distributed microcrack formation and fiber bridging effect inherent to HDFRCC contributed to its higher load capacity, improved crack control, and enhanced energy absorption capabilities.

- The results from the analytical predictions correlated well with the experimental results for the conventional concrete SOG. In contrast, the analytical predictions significantly underestimated the performance of the HDFRCC SOG under various loading conditions. Furthermore, the predicted failure mode for HDFRCC at all three loading locations was punching shear failure. However, the experimental results indicated flexural failure under center loading and a combination of flexural and punching failure under edge and corner loadings.

- The use of mesh-free HDFRCC resulted in superior crack resistance, potentially enabling the construction of larger floor slabs without contraction joints and significantly improving load-bearing performance. Economically, eliminating welded wire mesh—which requires considerable time and additional labor to set in place—can accelerate construction schedules and reduce labor costs. Furthermore, the potential to design thinner HDFRCC SOG sections while meeting equivalent load-bearing demands could decrease material consumption and enhance overall project cost efficiency.

Author Contributions

S.-T.K.: conceptualization, investigation, supervision, writing—review and editing, funding acquisition. N.A.: data curation, investigation, analysis, and Writing—original draft. B.Y.L.: analysis, investigation, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Daegu University research grant no. 2025–0126.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no competing interests.

References

- Su, Y.; Wang, X.; Wu, C.; Xu, M.; Jin, C. Experimental Investigation of Flexural and Punching Behavior for Plain PE-ECC Slabs with Different Fiber Volume Fractions and Span-Depth Ratios. Constr. Build. Mater. 2024, 441, 137502. [Google Scholar] [CrossRef]

- Yu, K.; Li, L.; Yu, J.; Wang, Y.; Ye, J.; Xu, Q. Direct Tensile Properties of Engineered Cementitious Composites: A Review. Constr. Build. Mater. 2018, 165, 346–362. [Google Scholar] [CrossRef]

- Shiratori, Y.; Watanabe, K. Effects of Material Properties of HFDFRCC Using Recycled Fine Aggregate on Shear Strength of RC Beam. IOP Conf. Ser. Mater. Sci. Eng. 2017, 264, 012009. [Google Scholar] [CrossRef]

- Javaherdashti, R.; Nwaoha, C.; Tan, H. (Eds.) Corrosion and Materials in the Oil and Gas Industries, Chloride-Induced Corrosion Durability of High-Performance Fiber-Reinforced Cementitious Composites: State-of-the-Art Review, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Ji, J.; Song, H.; Jiang, L.; Ren, H.; Zhang, Y.; Liu, Y. Tensile Performance of High Ductility Cementitious Composites with Recycled Powder from C&D Waste. Front. Mater. 2021, 8, 673752. [Google Scholar] [CrossRef]

- Mutnbak, M.; Abbadi, A.; Mousa, S.; Abd-Elhady, A.A.; Sallam, H.E.-D.M.; Reda, R.M. Effects of Specimen Geometry and Size on Mode I and Mixed Mode Fracture Behavior of High Strength Fiber Reinforced Concrete. Sci. Rep. 2025, 15, 15286. [Google Scholar] [CrossRef]

- Lee, B.Y.; Bang, J.W.; Kim, Y.Y. Enhancing the Performance of Polypropylene Fiber Reinforced Cementitious Composite Produced with High Volume Fly Ash. J. Korea Inst. Struct. Maint. Insp. 2013, 17, 118–125. [Google Scholar] [CrossRef][Green Version]

- Čajka, R.; Marcalíková, Z. Experimental Tests of Fiber-Reinforced Concrete Slabs and Comparison of Deformations Using 3D Graphs. Civ. Environ. Eng. 2021, 17, 96–106. [Google Scholar] [CrossRef]

- Wang, X.; Sun, K.; Shao, J.; Ma, J. Study on Mechanical and Rheological Properties of Solid Waste-Based ECC. Buildings 2022, 12, 1690. [Google Scholar] [CrossRef]

- Marushchak, U.; Sydor, N.; Margal, I. Impact of Polypropylene Fibers on the Properties of Engineered Cementitious Composites. In Proceedings of the EcoComfort 2022, Lviv, Ukraine, 14–16 September 2022; Springer International Publishing: Cham, Switzerland, 2023; pp. 262–269. [Google Scholar]

- Osama Moselhi, B.; Fazio, P.; Hason, S. Automation of Concrete Slab-on-Grade Construction. J. Constr. Eng. Manag. 1992, 118, 731–748. [Google Scholar] [CrossRef]

- Tang, X.; Jlilati, M.N. Load-Carrying Capacity of Slab-on-Grade Foundations Supporting Rack Post Loads. In Proceedings of the Geotechnical Frontiers 2017, Orlando, FL, USA, 12–15 March 2017; American Society of Civil Engineers: Reston, VA, USA, 2017; pp. 242–246. [Google Scholar]

- Shahiduzzaman, M.; Hossain, M.S. The Effect on Punching Shear Failure in Centrally Loaded Ground-Supported Concrete Slabs for Different Aspects like Slab Thickness, Size and the Position of Reinforcement Bar, and the Strength of Concrete Using a Validated FE Model. Heliyon 2024, 10, e26057. [Google Scholar] [CrossRef]

- Robert Day, B.W. Differential Movement of Slab-on-Grade Structures. J. Perform. Constr. Facil. 1990, 4, 236–241. [Google Scholar]

- Concrete Society Technical Report No. 34, T.E. In Concrete Industrial Ground Floors, A Guide to Design and Construction; Concrete Society: Camberley, UK, 2003.

- Vishwakarma, V.; Ray, S. Prediction of Crack Path in Reinforced Concrete Using Acoustic Emission Analysis. Procedia Struct. Integr. 2024, 66, 381–387. [Google Scholar] [CrossRef]

- Kot, P.; Muradov, M.; Gkantou, M.; Kamaris, G.S.; Hashim, K.; Yeboah, D. Recent Advancements in Non-Destructive Testing Techniques for Structural Health Monitoring. Appl. Sci. 2021, 11, 2750. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Mpalaskas, A.C.; Matikas, T.E. Acoustic Monitoring for the Evaluation of Concrete Structures and Materials. In Acoustic Emission and Related Non-Destructive Evaluation Techniques in the Fracture Mechanics of Concrete; Elsevier: London, UK, 2015; pp. 269–286. [Google Scholar]

- Aggelis, D.G.; Mpalaskas, A.C.; Matikas, T.E. Investigation of Different Fracture Modes in Cement-Based Materials by Acoustic Emission. Cem. Concr. Res. 2013, 48, 1–8. [Google Scholar] [CrossRef]

- Farrar, C.R.; Dervilis, N.; Worden, K. The Past, Present and Future of Structural Health Monitoring: An Overview of Three Ages. Strain 2025, 61, e12495. [Google Scholar] [CrossRef]

- Muspratt, M.A. Elastic Analysis of Slabs. Build. Environ. 1978, 13, 51–59. [Google Scholar] [CrossRef]

- Øverli, J. Experimental and Numerical Investigation of Slabs on Ground Subjected to Concentrated Loads. Open Eng. 2014, 4, 210–225. [Google Scholar] [CrossRef]

- Westergaard, H.M. Computation of Stresses in Concrete Roads. In Proceedings of the Fifth Annual Meeting of the Highway Research Board; Highway Research Board: Washington, DC, USA, 1925; Volume 5, pp. 90–112. [Google Scholar]

- Fadaee, M.; Iranmanesh, A.J.; Fadaee, M. A Simplified Method for Designing RC Slabs under Concentrated Loading. Int. J. Eng. Technol. 2013, 5, 675–679. [Google Scholar] [CrossRef]

- Sucharda, O.; Smirakova, M.; Vaskova, J.; Mateckova, P.; Kubosek, J.; Cajka, R. Punching Shear Failure of Concrete Ground Supported Slab. Int. J. Concr. Struct. Mater. 2018, 12, 36. [Google Scholar] [CrossRef]

- Braestrup, M.W. Yield Line Theory and Concrete Plasticity. Mag. Concr. Res. 2008, 60, 549–553. [Google Scholar] [CrossRef][Green Version]

- Bræstrup, M.W. Yield-Line Theory and Limit Analysis of Plates and Slabs. Mag. Concr. Res. 1970, 22, 99–106. [Google Scholar] [CrossRef]

- JSCE-SF4 Method of Tests for Flexural Strength and Flexural Toughness of Steel Fiber Reinforced Concrete. Available online: https://barchip.com/wp-content/uploads/2016/08/JSCE-SF4-Method-of-Test-For-Flexural-Strength-and-Flexural-Toughness.pdf (accessed on 23 September 2023).

- BS EN 1992-1-1; Eurocode 2, Design of Concrete Structures, Part 1, General Rules and Rules for Buildings. British Standard Institution: London, UK, 2004.

- Vandewalle, L.; Nemageer, D.; Balazs, L.; Barr, B.; Bartos, P.; Banthia, N.; Criswell, M.; Denarie, E.; Di Prisco, M.; Falkner, H. RILEM TC 162-TDF. Test and Design Methods for Steel Fibre Reinforced Concrete—Design Method. Mater. Struct. 2000, 33, 75–81. [Google Scholar]

- CEB-FIP, Model code 1990; Comité Euro-International du Béton: Lausanne, Switzerland, 1993.

- KS F 2405:2022; Test Method for Compressive Strength of Concrete. Korean Standards Association (KSA): Seoul, Republic of Korea, 2022; pp. 1–14.

- KS F 2566:2014; Standard Test Method for Flexural Performance of Fiber Reinforced Concrete 2000. ASTM International: West Conshohocken, PA, USA, 2000.

- Zhou, S.; Xie, L.; Jia, Y.; Wang, C. Review of Cementitious Composites Containing Polyethylene Fibers as Repairing Materials. Polymers 2020, 12, 2624. [Google Scholar] [CrossRef]

- Ahmed, S.F.U.; Maalej, M. Tensile Strain Hardening Behaviour of Hybrid Steel-Polyethylene Fibre Reinforced Cementitious Composites. Constr. Build. Mater. 2009, 23, 96–106. [Google Scholar] [CrossRef]

- Kamal, A.; Kunieda, M.; Ueda, N.; Nakamura, H. Evaluation of Crack Opening Performance of a Repair Material with Strain Hardening Behavior. Cem. Concr. Compos. 2008, 30, 863–871. [Google Scholar] [CrossRef]

- Lee, C.; Lee, S.; Ko, K.; Yang, J.-M. Structural Performance of SFRC Slab-on-Grade Supported on Elastic Spring System. Mag. Concr. Res. 2017, 69, 757–771. [Google Scholar] [CrossRef]

- Al-Mawed, L.K.; Hamad, B.S. Experimental and Numerical Assessments of Slab-Column Connections Strengthened Using Bonded Hemp Fiber Fabric Sheets. Int. J. Concr. Struct. Mater. 2023, 17, 8. [Google Scholar] [CrossRef]

- Choi, H.-K.; Bae, B.-I.; Choi, C.-S. Mechanical Characteristics of Ultra High Strength Concrete with Steel Fiber Under Uniaxial Compressive Stress. J. Korea Concr. Inst. 2015, 27, 521–530. [Google Scholar] [CrossRef]

- Tan, K.H.; Venkateshwaran, A. Punching Shear in Steel Fiber Reinforced Concrete Slabs without Traditional Reinforcement. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246, 012025. [Google Scholar] [CrossRef]

- Anil, O.; Salmani, V.; Kina, T. Effect of Opening Size and Location on Punching Shear behaviour of two-way RC slabs. Mag. Concr. Res. 2014, 66, 955–966. [Google Scholar] [CrossRef]

- TSE (Turkish Standards Institution). TS 500: Betonarme Yapıların Tasarım ve Yapım Kuralları; TSE: Ankara, Turkey, 2000. (In Turkish) [Google Scholar]

- ACI (American Concrete Institute). ACI 318-08: Building Code Requirements for Structural Concrete; ACI: Detroit, MI, USA, 2008. [Google Scholar]

- CEN (Comité Euro-International du Béton). Eurocode 2: prEN 1992-1-1 Draft: Design of Concrete Structures. Part 1: General Rules and Rules for Buildings; CEN: Brussels, Belgium, 2002. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).