- Article

Performance Impact of the Nano-Colloidal Aphron-Based Drilling Fluids on Rheological and Filtration Properties

- Raboon Dizayee,

- Jagar Ali and

- Hewa Omar

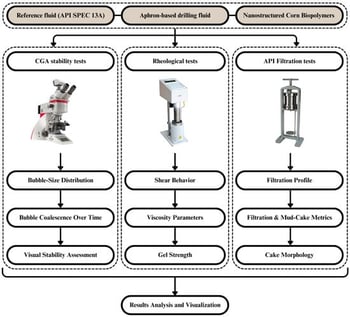

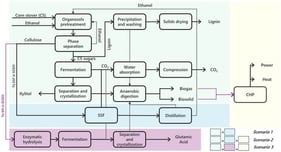

Severe fluid loss in fractured, depleted reservoirs usually defeat conventional water-based drilling fluids (WBDFs), and rigid lost-circulation materials (LCMs) struggle to form durable, conformal seals. We report an eco-oriented colloidal gas aphron (CGA) fluid built from a nanostructured corn biopolymer (NCBP) and a biodegradable peanut-oil-derived surfactant, benchmarked against a reference fluid (RF) and aphron-only baselines (aphron based fluid, ABF). NCBP, produced by ball milling, was confirmed nanostructured by x-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), electron and atomic microscopies. Performance was evaluated from 25 to 90 °C for rheology, aphron stability and filtration at low temperature and low pressure (LTLP) of 100 psi and 25 °C, with post-test mud cake imaging. The optimized formulation, NCBP-2, showed stronger shear-thinning and higher gel strengths with heat, sustained stable and uniform aphrons for at least 120 min with foam persistence beyond 24 h, and delivered 3.0 mL filtrate with a 0.8 mm mud cake. These outcomes correspond to 60% less filtrate and approximately 73% thinner mud cakes than RF (7.5 mL; 3.0 mm), and about 14% and 33% improvements over the best ABF (3.5 mL; 1.2 mm). Micrographs revealed denser, finer-pored mud cakes, consistent with a mechanism in which deformable aphrons bridge micro-fractures while nano-scale polymeric fillers tighten the mud cake network. The results demonstrate decisive loss-control gains with temperature-tolerant rheology, supporting bio-based CGA fluids for depleted and fractured formations.

7 February 2026