Multi-Objective Rolling Linear-Programming-Model-Based Predictive Control for V2G-Enabled Electric Vehicle Scheduling in Industrial Park Microgrids

Abstract

1. Introduction

- (1)

- Unification of global optimality and real-time capability: By linearizing the EV-scheduling problem and leveraging an efficient linear solver, the method achieves second-level rolling optimization over a 24-h horizon with 288 steps, overcoming the traditional trade-off between real-time performance and global optimality inherent in nonlinear MPC or heuristic algorithms.

- (2)

- Integration of centralized optimization and grouped coordination: A new framework that combines centralized LP-MPC with grouped power allocation is introduced. Under large-scale EV integration, this framework significantly reduces computational and communication burdens while guaranteeing precise SOC attainment for each EV group.

- (3)

- Multi-dimensional, V2G-oriented multi-objective optimization: A comprehensive performance index is designed, encompassing three grid-operation metrics—peak load, peak–valley difference, and load fluctuation—and two user-benefit metrics—EV charging cost and SOC completion rate. Extensive validation demonstrates the proposed method’s superiority over greedy and heuristic strategies, offering a readily generalizable solution for V2G dispatch in industrial parks.

2. System Modeling and Problem Formulation

2.1. Microgrid Power Balance and Point of Common Coupling Constraints

2.2. Base-Load and PV Modeling

- (1)

- Base-load modeling

- (2)

- PV modeling

- Night (00:00–05:00, 20:00–24:00): zero generation.

- 05:00–10:00: linear ramp to rated power .

- 10:00–16:00: constant plateau at ± 5 kW jitter.

- 16:00–20:00: linear descent to zero.

2.3. Electric Vehicle Aggregation Model

2.3.1. Battery Energy Dynamics

2.3.2. Safety and Journey Constraints

2.3.3. Aggregated Power

2.4. Optimization Problem Formulation

- (1)

- PCC power limit: the total exchanged power must not exceed the transformer rated capacity.

- (2)

- SOC and power bounds: every group must operate within physical SOC and power limits.

- (3)

- Terminal SOC requirement: each group must reach at least 50% SOC by the end of the scheduling horizon.

- Power-balance constraint: Equation (1) ensures that the grid exchange equals the sum of load, PV, and EV powers.

- PCC and transformer capacity limits: Equation (2) bounds the maximum allowable grid and transformer power.

- EV battery dynamics and SOC limits: Equations (4)–(7) describe the SOC evolution, charging/discharging power bounds, and terminal-SOC requirements.

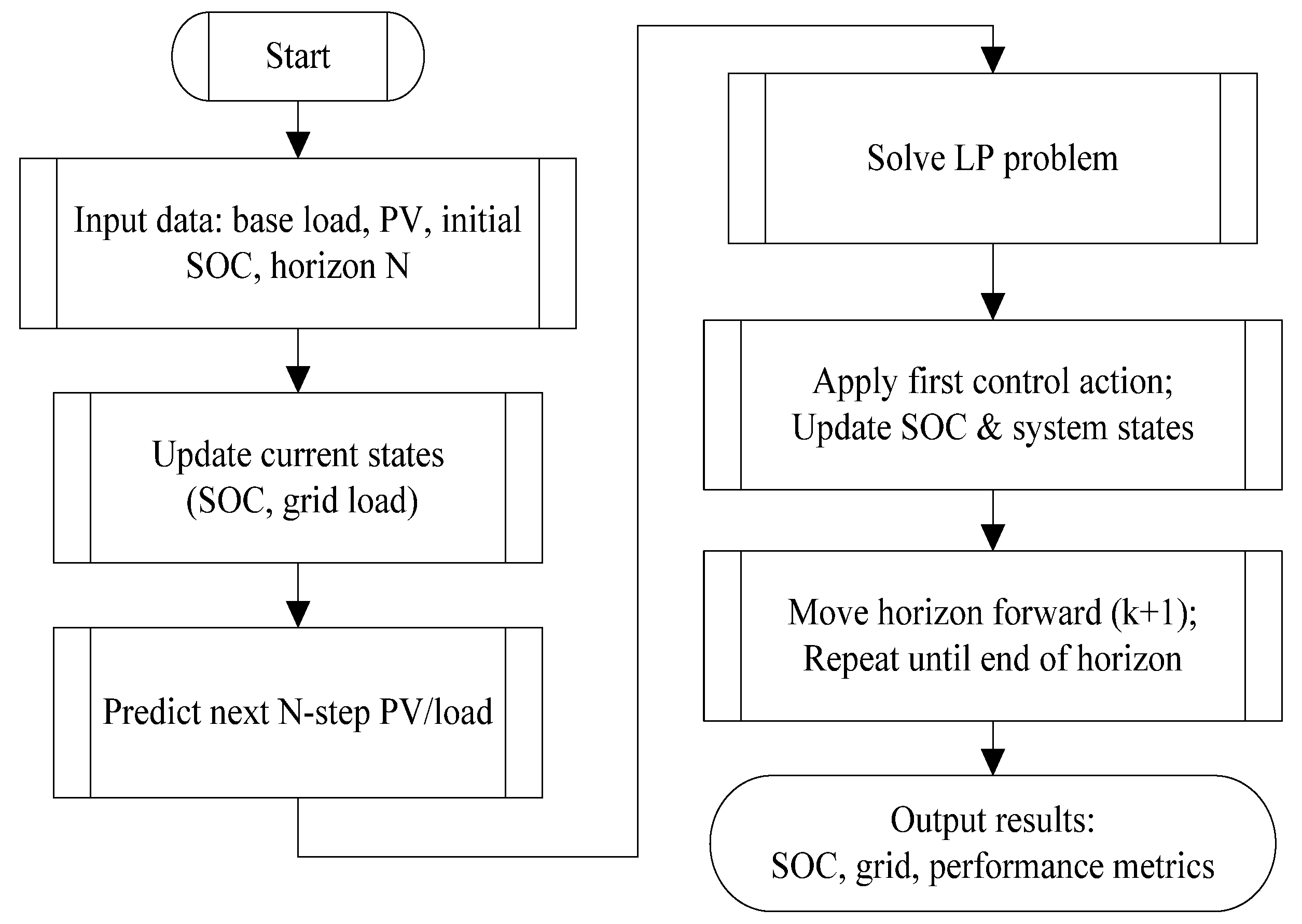

3. Multi-Objective Rolling LP-MPC

3.1. Rolling LP-MPC Framework

3.2. Peak Power Linearization

3.3. Linear Constraint Framework

- (1)

- Power balance

- (2)

- Transformer capacity

- (3)

- EV dynamics

3.4. LP-MPC Algorithm Flow

- (1)

- Initialize EV grouping and SOC.

- (2)

- For current_time = 0 → total_steps − 1

- Set prediction horizon H = min(current_time + N, total_steps).

- Compute future net load = base_load − PV_output.

- Define decision variables: EV_charge_power, EV_discharge_power.

- Formulate constraints: EV SOC dynamics, EV power limits, terminal SOC, transformer capacity, storage SOC and power limits.

- Construct objective function: J = α·peak_power − (1 − α)·EV_revenue.

- Call linear-programming solver.

- If solution is successful:

- Apply first-step decision: EV_power = EV_charge_power − EV_discharge_power.

- Update SOC and record.

- Compute current grid-side power = future_net_load [0] + Σ EV_power.

- Else: set EV_power = 0.

- (3)

- End for

3.5. Benchmark Algorithms

- (1)

- Greedy Algorithm

- (2)

- Heuristic Load Leveling

- Valley filling: When the current net grid load is below a preset threshold, each EV group charges at its maximum allowable power.

- Peak shaving: When the net load exceeds the threshold, each group discharges at its maximum allowable power.

- SOC safeguard: At all times, the SOC must remain between the lower and upper bounds.

4. Experiments and Results

4.1. Simulation Parameter Settings

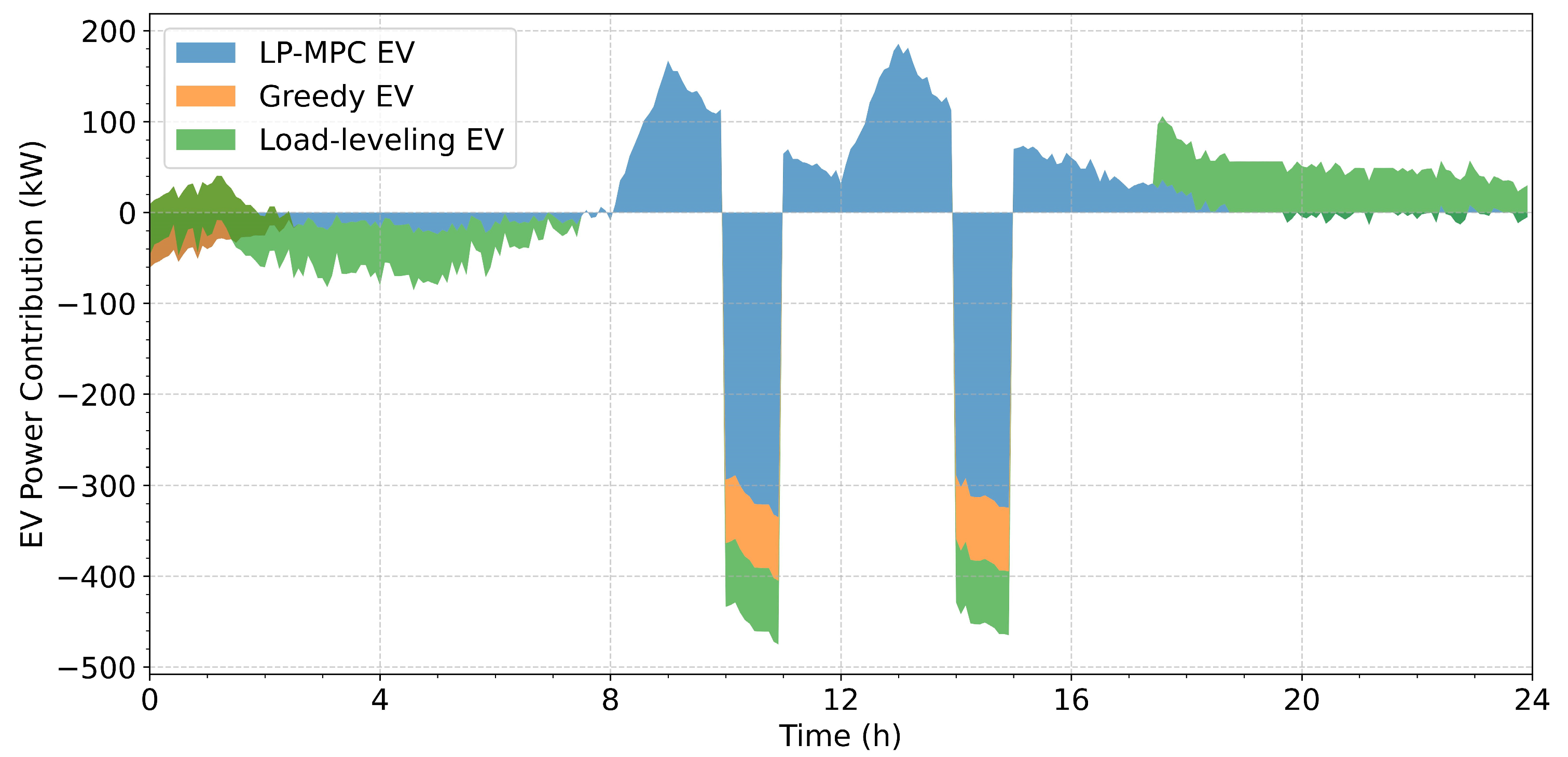

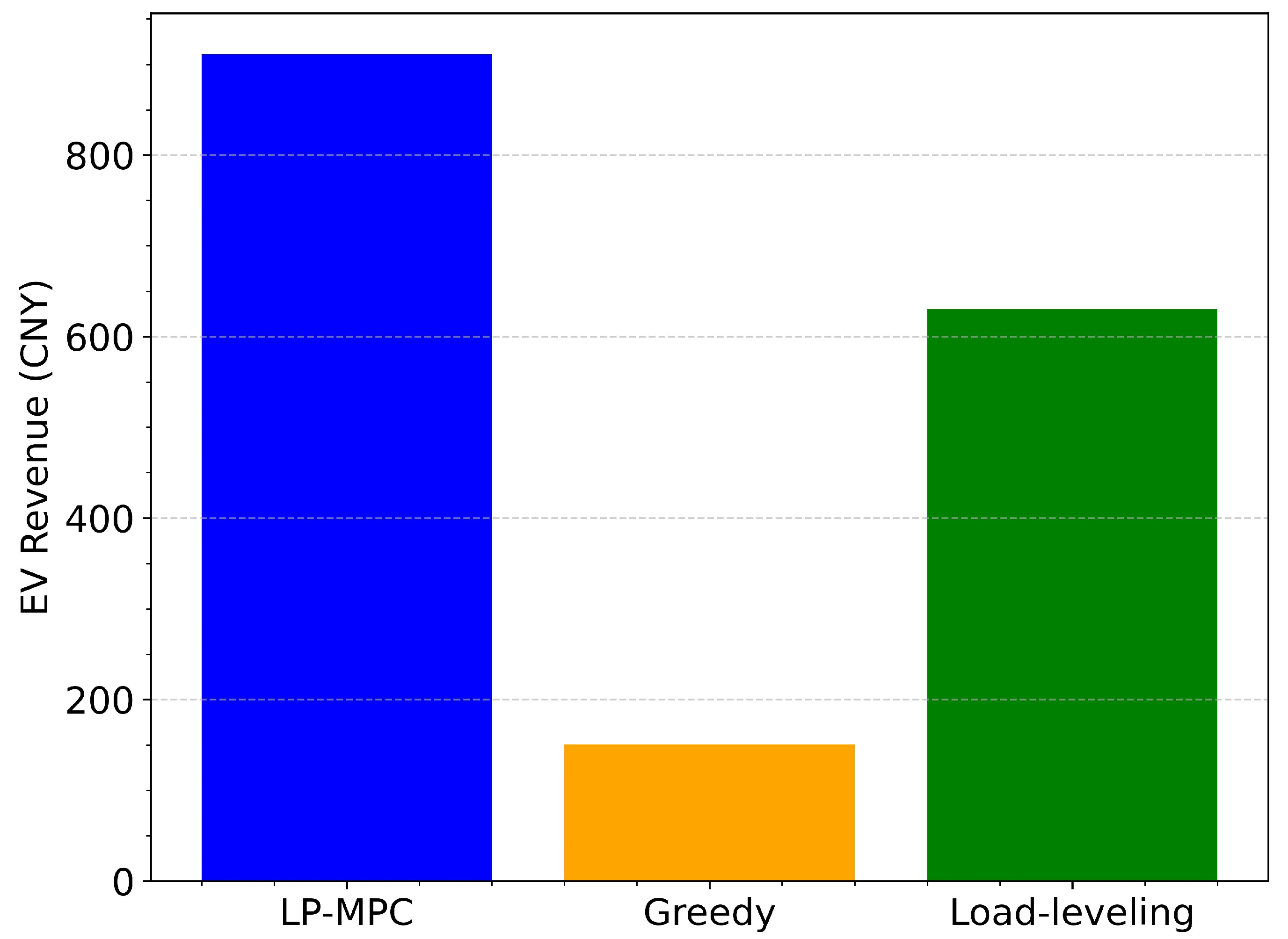

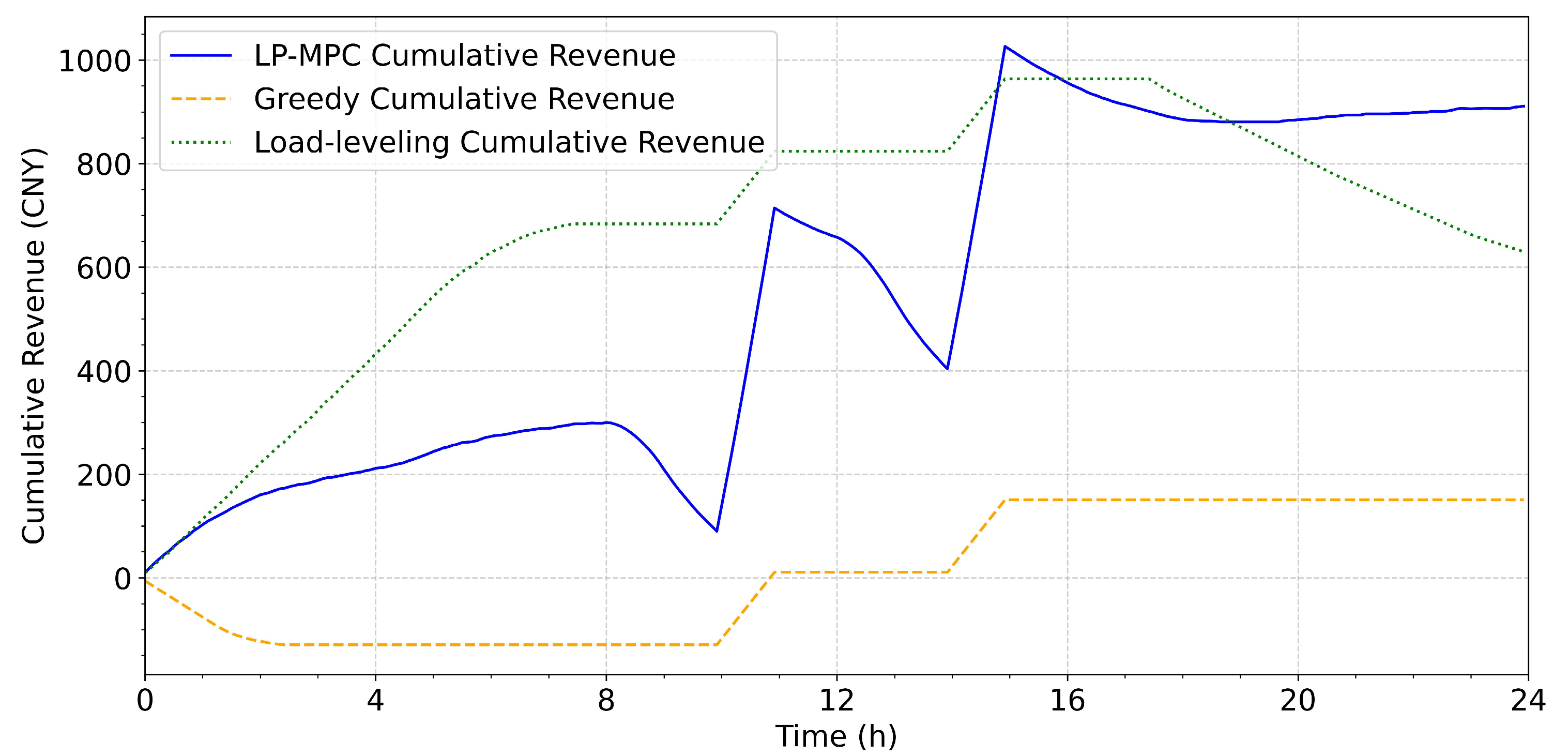

4.2. Performance Comparison of the Algorithms

- (1)

- Peak-load suppression

- (2)

- Load-smoothing performance

- (3)

- User-revenue assurance

- (4)

- SOC compliance without overload

- (5)

- Computational efficiency

4.3. Performance Analysis

4.4. Discussion

- (1)

- The results validate that a linearized multi-objective predictive model can effectively approximate the nonlinear coupling between grid power balance, SOC dynamics, and PV uncertainty while preserving convexity and global optimality. This confirms the feasibility of reformulating the classical nonlinear MPC into a fully linear rolling program without loss of scheduling accuracy.

- (2)

- The study highlights the stability of the receding-horizon solution under prediction disturbances. The small deviation of the load-variance index under perturbed forecasts implies that the LP-MPC cost function forms a smooth convex landscape, ensuring the robustness of the optimal trajectory with respect to bounded uncertainties.

- (3)

- The results support the theoretical trade-off between model fidelity and real-time solvability. The LP formulation guarantees deterministic convergence and polynomial-time complexity, which explains the observed stability of optimization time across 288 rolling steps.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Tang, W.; Zhang, Y.J. A Model Predictive Control Approach for Low-Complexity Electric Vehicle Charging Scheduling: Optimality and Scalability. IEEE Trans. Power Syst. 2017, 32, 1050–1063. [Google Scholar] [CrossRef]

- Cheng, L.; Li, M.; Tan, C.; Huang, P.; Zhang, M.; Sun, R. Computational Game-Theoretic Models for Adaptive Urban Energy Systems: A Comprehensive Review of Algorithms, Strategies, and Engineering Applications. Arch. Comput. Methods Eng. 2025, 1–78. [Google Scholar] [CrossRef]

- Vasilj, J.; Gros, S.; Jakus, D.; Zanon, M. Day-Ahead Scheduling and Real-Time Economic MPC of CHP Unit in Microgrid with Smart Buildings. IEEE Trans. Smart Grid 2019, 10, 1992–2001. [Google Scholar] [CrossRef]

- Cheng, L.; Wei, X.; Li, M.; Tan, C.; Yin, M.; Shen, T.; Zou, T. Integrating Evolutionary Game-Theoretical Methods and Deep Reinforcement Learning for Adaptive Strategy Optimization in User-Side Electricity Markets: A Comprehensive Review. Mathematics 2024, 12, 3241. [Google Scholar] [CrossRef]

- Su, W.; Eichi, H.; Zeng, W.; Chow, M.-Y. A Survey on the Electrification of Transportation in a Smart Grid Environment. IEEE Trans. Ind. Inform. 2012, 8, 1–10. [Google Scholar] [CrossRef]

- Rahulkumar, J.; Narayanamoorthi, R.; Vishnuram, P.; Bajaj, M.; Blazek, V.; Prokop, L.; Misak, S. An Empirical Survey on Wireless Inductive Power Pad and Resonant Magnetic Field Coupling for In-Motion EV Charging System. IEEE Access 2023, 11, 4660–4693. [Google Scholar] [CrossRef]

- Mozaffari, M.; Abyaneh, H.A.; Jooshaki, M.; Moeini-Aghtaie, M. Joint Expansion Planning Studies of EV Parking Lots Placement and Distribution Network. IEEE Trans. Ind. Inform. 2020, 16, 6455–6465. [Google Scholar] [CrossRef]

- Deb, S.; Goswami, A.K.; Harsh, P.; Sahoo, J.P.; Chetri, R.L.; Roy, R.; Shekhawat, A.S. Charging Coordination of Plug-In Electric Vehicle for Congestion Management in Distribution System Integrated with Renewable Energy Sources. IEEE Trans. Ind. Appl. 2020, 56, 5452–5462. [Google Scholar] [CrossRef]

- Chen, F.; Xia, M.; Chen, Q.; Song, Y.; Xian, Y.; Xiu, S.; Su, S. Highway Service Area Multi-Timescale Optimization Scheduling Considering the Spatiotemporal Dynamic Evolution of Electric Vehicles. IEEE Trans. Smart Grid 2025, 16, 678–690. [Google Scholar] [CrossRef]

- Raghavan, S.S.; Khaligh, A. Electrification Potential Factor: Energy-Based Value Proposition Analysis of Plug-In Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2012, 61, 1052–1059. [Google Scholar] [CrossRef]

- Mahani, K.; Angizeh, F.; Jafari, M.A. EV Parking Lots for Flexible Energy Sourcing. IEEE Access 2023, 11, 38770–38782. [Google Scholar] [CrossRef]

- Chukwu, U.C.; Mahajan, S.M. V2G Parking Lot with PV Rooftop for Capacity Enhancement of a Distribution System. IEEE Trans. Sustain. Energy 2014, 5, 119–127. [Google Scholar] [CrossRef]

- Sokoler, L.E.; Dinesen, P.J.; Jørgensen, J.B. A Hierarchical Algorithm for Integrated Scheduling and Control with Applications to Power Systems. IEEE Trans. Control Syst. Technol. 2017, 25, 590–599. [Google Scholar] [CrossRef]

- Chukwu, U.C.; Mahajan, S.M. Real-Time Management of Power Systems with V2G Facility for Smart-Grid Applications. IEEE Trans. Sustain. Energy 2014, 5, 558–566. [Google Scholar] [CrossRef]

- Lu, C.-F.; Liu, G.-P.; Yu, Y.; Cui, J. A Coordinated Model Predictive Control-Based Approach for Vehicle-to-Grid Scheduling Considering Range Anxiety and Battery Degradation. IEEE Trans. Transp. Electrif. 2025, 11, 5688–5699. [Google Scholar] [CrossRef]

- Qian, T.; Shao, C.; Wang, X.; Zhou, Q.; Shahidehpour, M. Shadow-Price DRL: A Framework for Online Scheduling of Shared Autonomous EVs Fleets. IEEE Trans. Smart Grid 2022, 13, 3106–3117. [Google Scholar] [CrossRef]

- Sharma, G.; Joshi, A.M.; Mohanty, S.P. sTrade 2.0: Efficient Mutual Authentication Scheme for Energy Trading in V2G Using Physically Unclonable Function. IEEE J. Emerg. Sel. Top. Ind. Electron. 2024, 5, 1549–1559. [Google Scholar] [CrossRef]

- Cheng, L.; Yu, F.; Huang, P.; Liu, G.; Zhang, M.; Sun, R. Game-Theoretic Evolution in Renewable Energy Systems: Advancing Sustainable Energy Management and Decision Optimization in Decentralized Power Markets. Renew. Sustain. Energy Rev. 2025, 217, 115776. [Google Scholar] [CrossRef]

- Yang, L.; Geng, X.; Guan, X.; Tong, L. EV Charging Scheduling Under Demand Charge: A Block Model Predictive Control Approach. IEEE Trans. Autom. Sci. Eng. 2024, 21, 2125–2138. [Google Scholar] [CrossRef]

- Zheng, Y.; Song, Y.; Hill, D.J.; Meng, K. Online Distributed MPC-Based Optimal Scheduling for EV Charging Stations in Distribution Systems. IEEE Trans. Ind. Inform. 2019, 15, 638–649. [Google Scholar] [CrossRef]

- Nair, U.R.; Sandelic, M.; Sangwongwanich, A.; Dragičević, T.; Costa-Castelló, R.; Blaabjerg, F. Grid Congestion Mitigation and Battery Degradation Minimisation Using Model Predictive Control in PV-Based Microgrid. IEEE Trans. Energy Convers. 2021, 36, 1500–1509. [Google Scholar] [CrossRef]

- Saatloo, A.M.; Mehrabi, A.; Marzband, M.; Aslam, N. Hierarchical User-Driven Trajectory Planning and Charging Scheduling of Autonomous Electric Vehicles. IEEE Trans. Transp. Electrif. 2023, 9, 1736–1749. [Google Scholar] [CrossRef]

- Mignoni, N.; Carli, R.; Dotoli, M. Distributed Noncooperative MPC for Energy Scheduling of Charging and Trading Electric Vehicles in Energy Communities. IEEE Trans. Control Syst. Technol. 2023, 31, 2159–2172. [Google Scholar] [CrossRef]

- Lupangu, C.; Justo, J.J.; Bansal, R.C. Model Predictive for Reactive Power Scheduling Control Strategy for PV–Battery Hybrid System in Competitive Energy Market. IEEE Syst. J. 2020, 14, 4071–4078. [Google Scholar] [CrossRef]

- McClone, G.; Ghosh, A.; Khurram, A.; Washom, B.; Kleissl, J. Hybrid Machine Learning Forecasting for Online MPC of Work Place Electric Vehicle Charging. IEEE Trans. Smart Grid 2024, 15, 1891–1901. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S. Efficient Federated Connected Electric Vehicle Scheduling System: A Noncooperative Online Incentive Approach. IEEE Trans. Intell. Transp. Syst. 2025, 26, 3934–3946. [Google Scholar] [CrossRef]

- Cheng, L.; Peng, P.; Huang, P.; Zhang, M.; Meng, X.; Lu, W. Leveraging Evolutionary Game Theory for Cleaner Production: Strategic Insights for Sustainable Energy Markets, Electric Vehicles, and Carbon Trading. J. Clean. Prod. 2025, 512, 145682. [Google Scholar] [CrossRef]

- Chen, X.; Leung, K.-C. Non-Cooperative and Cooperative Optimization of Scheduling with Vehicle-to-Grid Regulation Services. IEEE Trans. Veh. Technol. 2020, 69, 114–130. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, D.; Ye, Y.; He, Y.; Fu, X.; Yang, J.; Shi, G.; Zhang, H. Multi-Time Scale Economic Scheduling Method Based on Day-Ahead Robust Optimization and Intraday MPC Rolling Optimization for Microgrid. IEEE Access 2021, 9, 140315–140324. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, K.; Chan, K.W.; Li, C.; Lu, X.; Bu, S.; Gao, X. Optimal Coordination of Electric Vehicles for Virtual Power Plants with Dynamic Communication Spectrum Allocation. IEEE Trans. Ind. Inform. 2021, 17, 450–462. [Google Scholar] [CrossRef]

- Yang, Y.; Yeh, H.-G.; Nguyen, R. A Robust Model Predictive Control-Based Scheduling Approach for Electric Vehicle Charging with Photovoltaic Systems. IEEE Syst. J. 2023, 17, 111–121. [Google Scholar] [CrossRef]

- Kaheni, M.; Fu, J.; Papadopoulos, A.V. Rule-Based Predictive Control for Battery Scheduling in Microgrids Under Power Generation and Load Uncertainties. IEEE Trans. Autom. Sci. Eng. 2025, 22, 9782–9792. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.; Hu, S.; Zhe, W. Opportunities and Challenges of Scheduling in Logistics Industrial Park Cyber-Physical Systems. IEEE Trans. Ind. Cyber-Phys. Syst. 2023, 1, 322–334. [Google Scholar] [CrossRef]

- Liang, L.; Zhao, X.; Huang, W. Research on Power System Load Short-Term Forecasting Technology Integrating Multiple Artificial Intelligence Models. Power Syst. Big Data 2025, 25, 16–23. [Google Scholar]

- Murtaza, A.F.; Alharbi, T. A Simple and Efficient Power Processing Architecture with Series Integration of PV Array for LVDC. IEEE Trans. Ind. Inform. 2025, 21, 6650–6659. [Google Scholar] [CrossRef]

| Method | Peak Load (kW) | Peak-to-Valley Difference (kW) | Load Fluctuation Std (kW) | EV Revenue (CNY) | SOC Compliance Rate (%) | Maximum Overload (kW) | Execution Time (s) |

|---|---|---|---|---|---|---|---|

| LP-MPC | 984.1 | 146.7 | 29.6 | 910 | 100.0 | 0.00 | 0.29 |

| Greedy | 1139.2 | 351.4 | 86.8 | 150 | 100.0 | 139.2 | 0.01 |

| Load-Leveling | 1139.2 | 351.4 | 90.7 | 630 | 50 | 139.2 | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, T.; Huang, F.; Zhou, H.; Xie, G. Multi-Objective Rolling Linear-Programming-Model-Based Predictive Control for V2G-Enabled Electric Vehicle Scheduling in Industrial Park Microgrids. Processes 2025, 13, 3421. https://doi.org/10.3390/pr13113421

Luo T, Huang F, Zhou H, Xie G. Multi-Objective Rolling Linear-Programming-Model-Based Predictive Control for V2G-Enabled Electric Vehicle Scheduling in Industrial Park Microgrids. Processes. 2025; 13(11):3421. https://doi.org/10.3390/pr13113421

Chicago/Turabian StyleLuo, Tianlu, Feipeng Huang, Houke Zhou, and Guobo Xie. 2025. "Multi-Objective Rolling Linear-Programming-Model-Based Predictive Control for V2G-Enabled Electric Vehicle Scheduling in Industrial Park Microgrids" Processes 13, no. 11: 3421. https://doi.org/10.3390/pr13113421

APA StyleLuo, T., Huang, F., Zhou, H., & Xie, G. (2025). Multi-Objective Rolling Linear-Programming-Model-Based Predictive Control for V2G-Enabled Electric Vehicle Scheduling in Industrial Park Microgrids. Processes, 13(11), 3421. https://doi.org/10.3390/pr13113421