Statistical Analysis of Heat Transfer Effects on Flow Patterns Maps in a Flat-Plate Collector/Evaporator with R600a Under Variable Tilt Angles

Abstract

1. Introduction

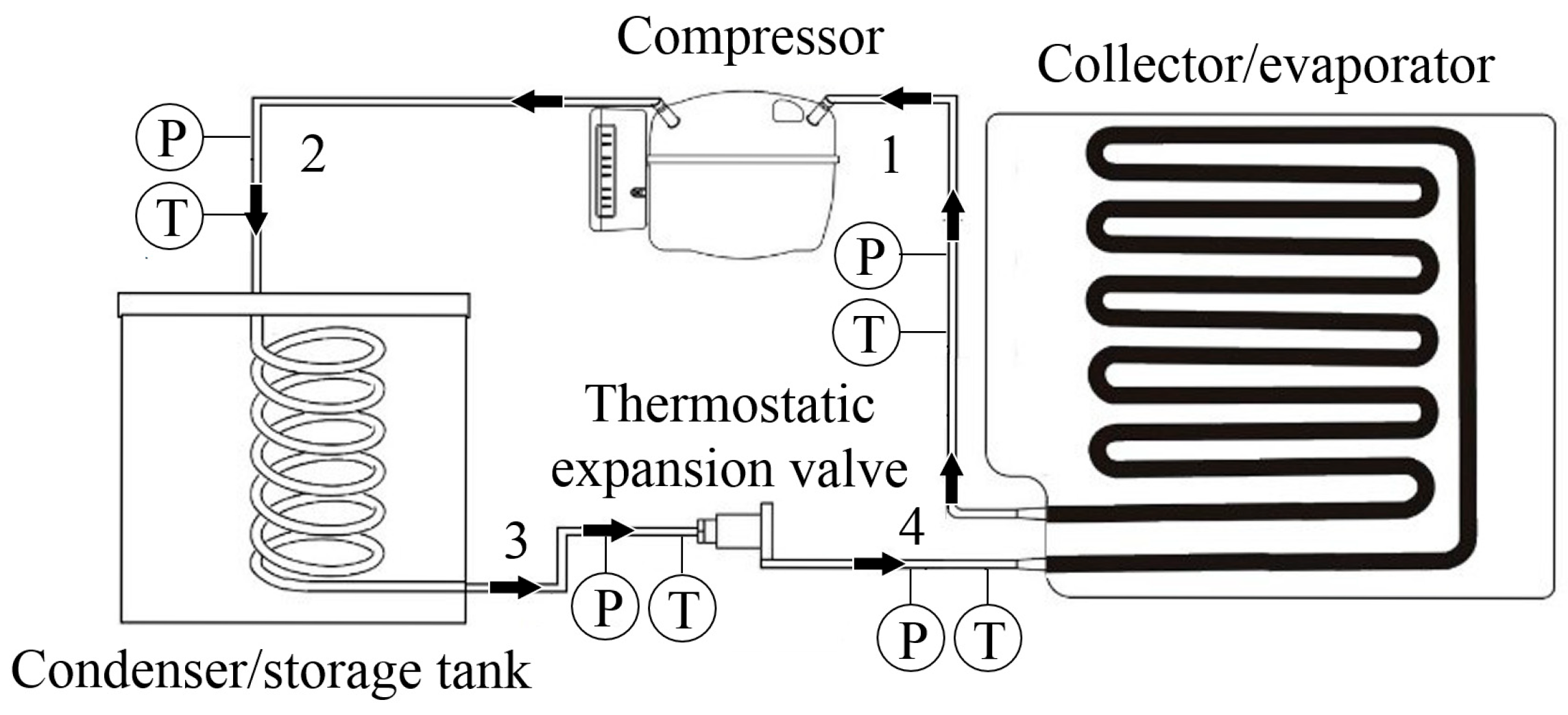

2. Materials and Methods

2.1. Collector/Evaporator

2.2. Correlation

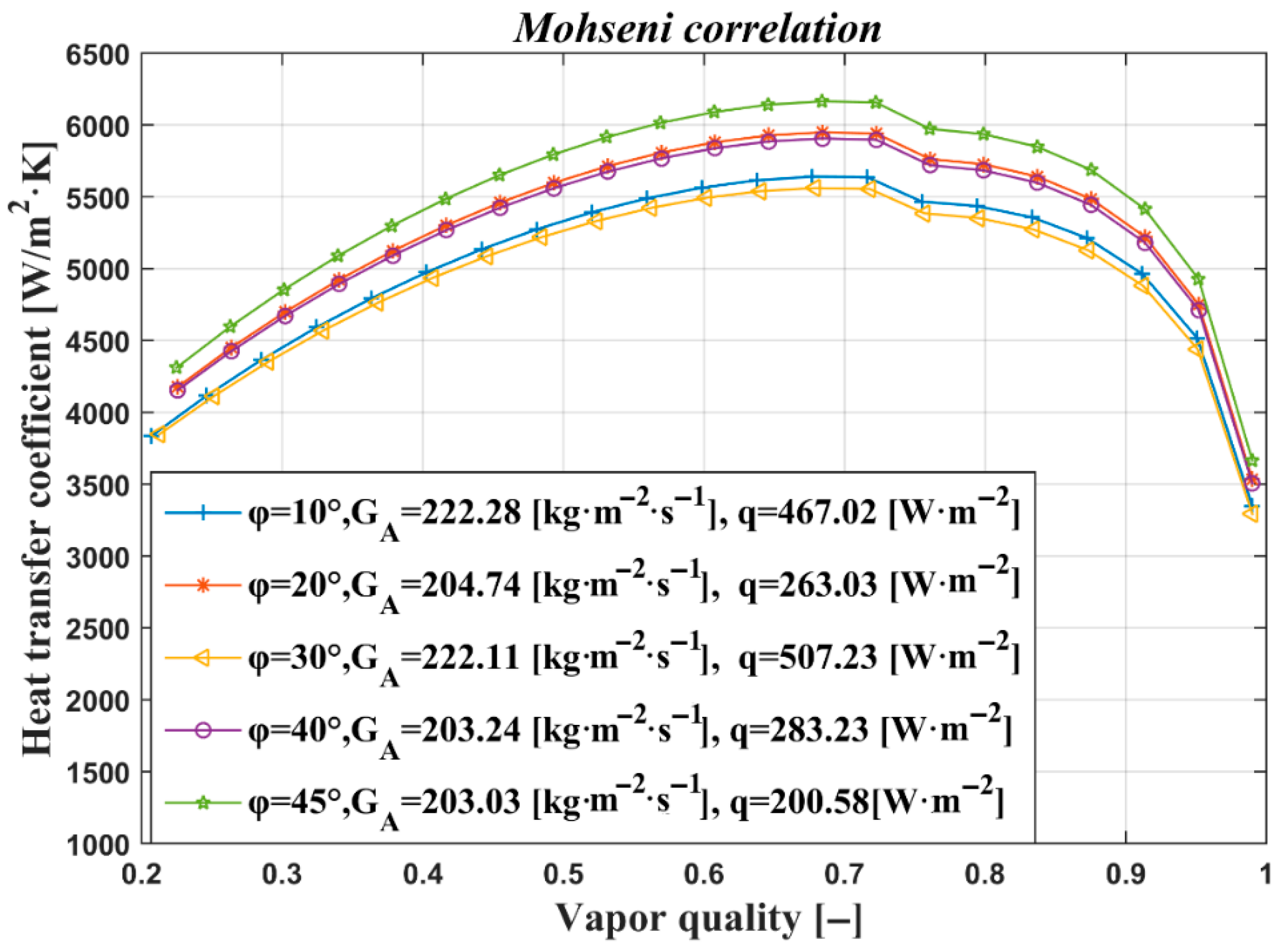

2.2.1. Mohseni and Behabadi

2.2.2. Equation for Heat Transfer Coefficient

2.3. Statistical Analysis

Statistical Tests

3. Results and Discussion

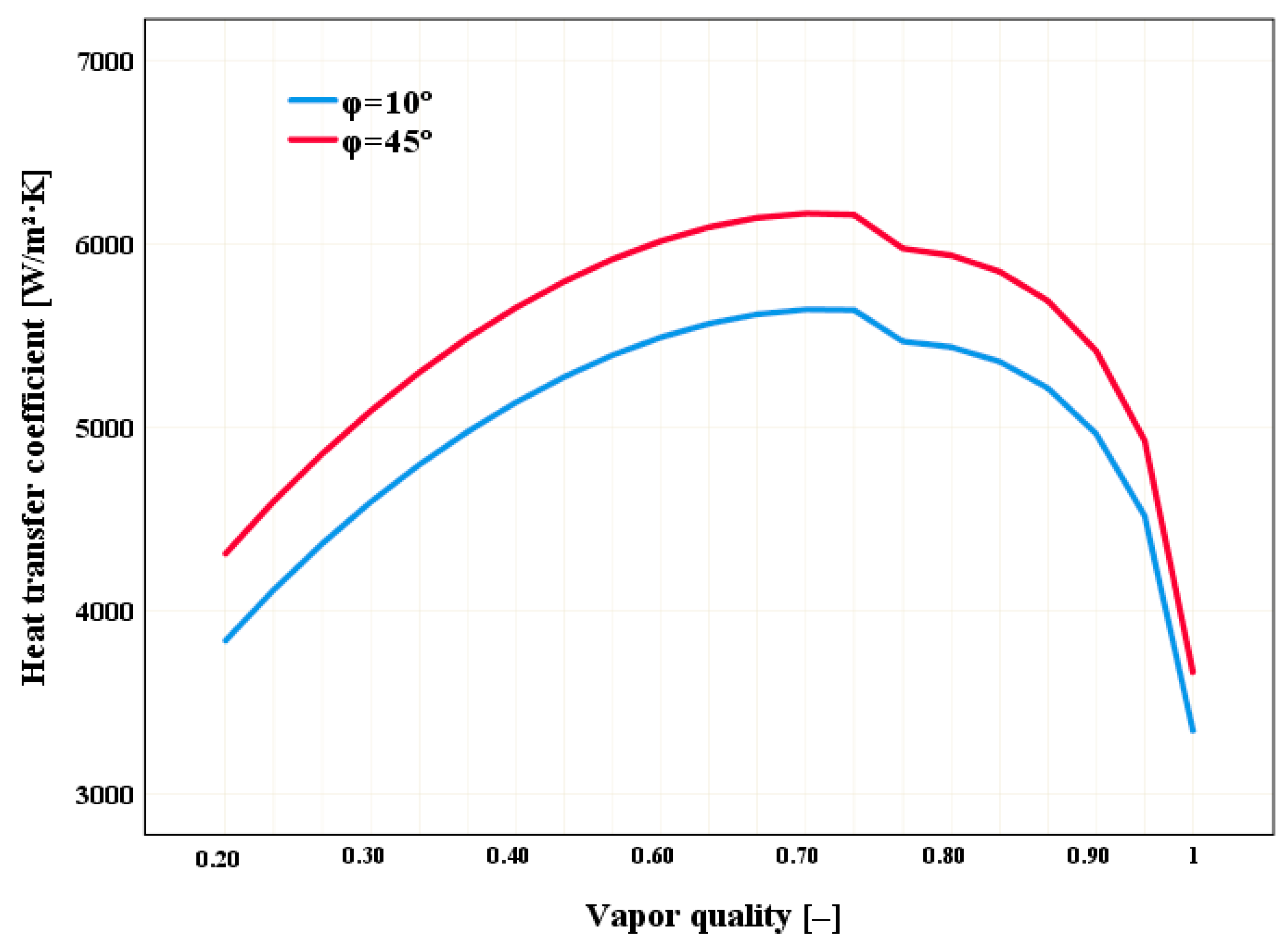

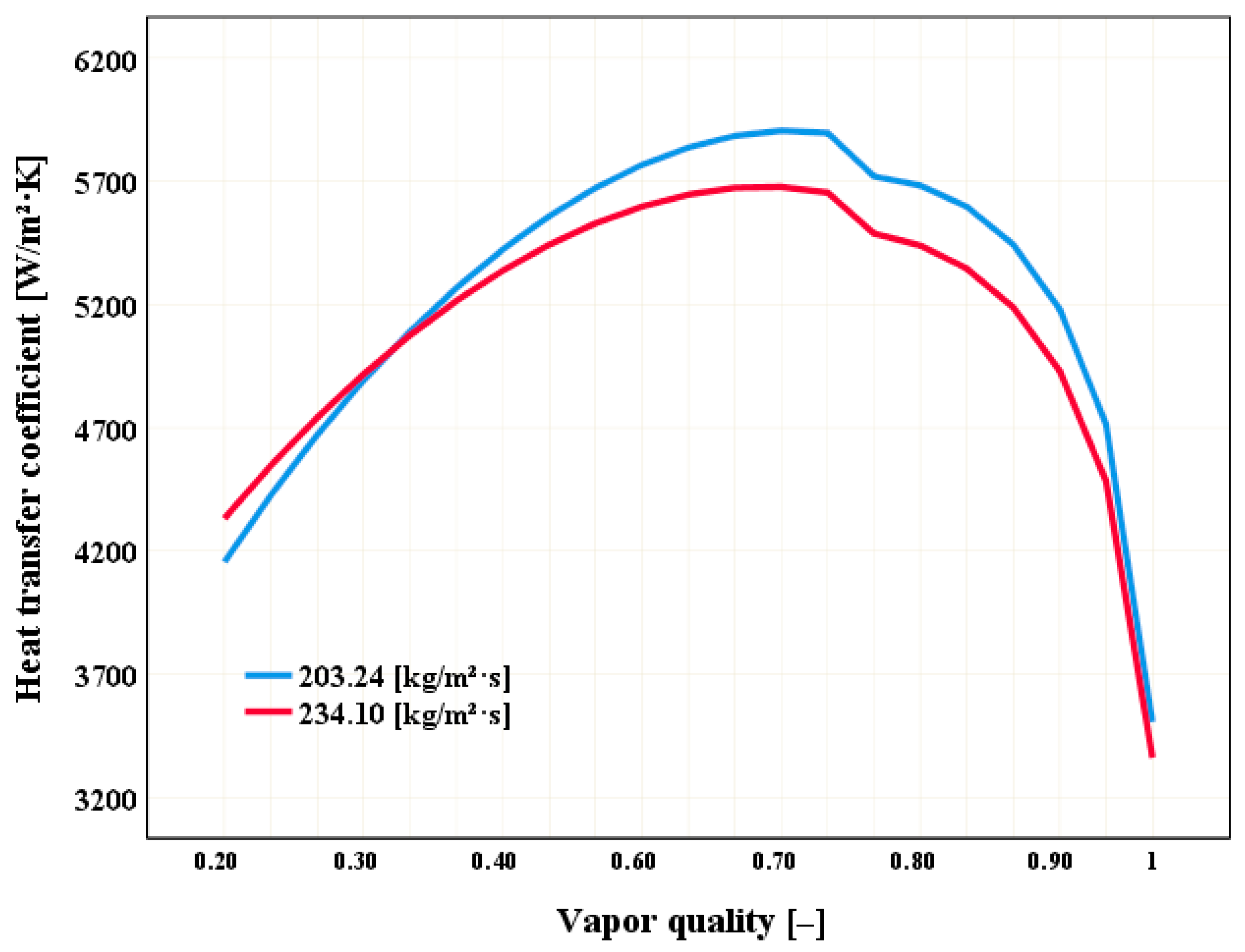

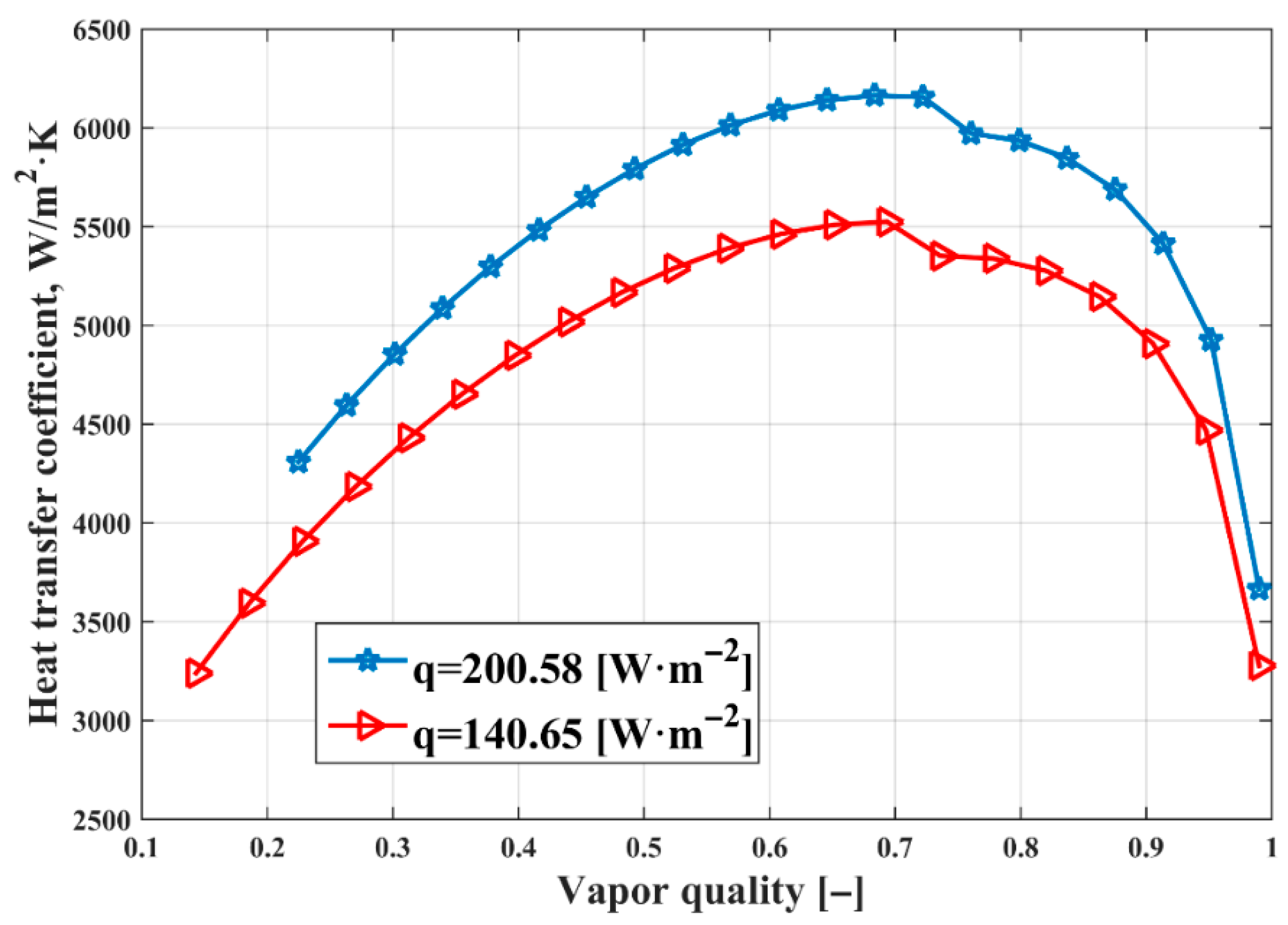

3.1. Heat Transfer Coefficient

3.2. Statistical Analysis Results

3.2.1. Descriptive Statistics

3.2.2. Statistical Tests Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Reddy, D.R.; Bhramara, P.; Govindarajulu, K. Experimental Evaluation of the Effect of Refrigerant Charge and Capillary Tube Length on the Performance of Household Refrigerator with Different Configurations of R290 and R600a. Mater. Today Proc. 2018, 5, 11845–11852. [Google Scholar] [CrossRef]

- Yelishala, S.C.; Kannaiyan, K.; Wang, Z.; Metghalchi, H.; Levendis, Y.A.; Sadr, R. Thermodynamic Study on Blends of Hydrocarbons and Carbon Dioxide as Zeotropic Refrigerants. J. Energy Resour. Technol. 2020, 142, 82304. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Joybari, M.M.; Navarro-Esbrí, J.; Mateu-Royo, C.; Barragán-Cervera, Á.; Amat-Albuixech, M.; Molés, F. Ultralow-temperature refrigeration systems: Configurations and refrigerants to reduce the environmental impact. Int. J. Refrig. 2020, 111, 147–158. [Google Scholar] [CrossRef]

- Quitiaquez, W.; Estupinán-Campos, J.; Nieto-Londoño, C.; Isaza-Roldán, C.; Quitiaquez, P.; Toapanta-Ramos, F. CFD Analysis of Heat Transfer Enhancement in a Flat-Plate Solar Collector with Different Geometric Variations in the Superficial Section. Int. J. Adv. Sci. Eng. Inf. Technol. 2021, 11, 2039–2045. [Google Scholar] [CrossRef]

- Adelaja, A.O.; Ewim, D.R.; Dirker, J.; Meyer, J.P. An improved heat transfer correlation for condensation inside inclined smooth tubes. Int. Commun. Heat Mass Transf. 2020, 117, 104746. [Google Scholar] [CrossRef]

- Zakaria, M.I.; Akhavan-Behabadi, M.; Sajadi, B.; Moghadam, M.T. An empirical investigation on flow pattern, heat transfer, and pressure drop during flow boiling of R1234yf in an inclined plain tube. Int. J. Therm. Sci. 2021, 170, 107100. [Google Scholar] [CrossRef]

- Cao, S.; Wang, G.; Wu, X.; Yang, W.; Hu, C. An experimental investigation of R245fa flow boiling heat transfer performance in horizontal and vertical tubes. Int. J. Refrig. 2024, 160, 229–245. [Google Scholar] [CrossRef]

- Shah, M.M. Improved correlation for heat transfer during condensation in inclined tubes. Int. J. Heat Mass Transf. 2023, 216, 124607. [Google Scholar] [CrossRef]

- Dong, C.; Hibiki, T. Modeling of heat transfer coefficient for upward no-phase-change two-phase flow in inclined pipes. Appl. Therm. Eng. 2020, 169, 114921. [Google Scholar] [CrossRef]

- Mohseni, S.; Akhavan-Behabadi, M. Flow pattern visualization and heat transfer characteristics of R-134a during evaporation inside a smooth tube with different tube inclinations. Int. Commun. Heat Mass Transf. 2014, 59, 39–45. [Google Scholar] [CrossRef]

- Allymehr, E.; Pardiñas, Á.Á.; Eikevik, T.M.; Hafner, A. Comparative analysis of evaporation of isobutane (R600a) and propylene (R1270) in compact smooth and microfinned tubes. Appl. Therm. Eng. 2021, 188, 116606. [Google Scholar] [CrossRef]

- Sun, D.; Li, R.; Wang, C.; Liu, Z.; Qin, J.; Liu, Z. Experimental study on boiling heat transfer characteristics of RDR-1, R134a, and R1234yf over a wide temperature range and comparative analysis of their system performance. Appl. Therm. Eng. 2024, 245, 122809. [Google Scholar] [CrossRef]

- Fazelnia, H.; Azarhazin, S.; Sajadi, B.; Behabadi, M.A.A.; Zakeralhoseini, S.; Rafieinejad, M.V. Two-phase R1234yf flow inside horizontal smooth circular tubes: Heat transfer, pressure drop, and flow pattern. Int. J. Multiph. Flow 2021, 140, 103668. [Google Scholar] [CrossRef]

- Anandakumar, J.; Palaniradja, K. Performance enhancement of a modified corrugated tube in tube condenser in a refrigeration system. AIP Conf. Proc. 2023, 2548, 30016. [Google Scholar] [CrossRef]

- Jalajakshi, V.; Myna, A.N. Importance of statistics to data science. Glob. Transit. Proc. 2022, 3, 326–331. [Google Scholar] [CrossRef]

- Huang, F.; No, W.G.; Vasarhelyi, M.A.; Yan, Z. Audit data analytics, machine learning, and full population testing. J. Financ. Data Sci. 2022, 8, 138–144. [Google Scholar] [CrossRef]

- Melinda, M.; Muttaqin, M.I.; Nurdin, Y.; Bahri, A. Implementation of Word Recommendation System Using Hybrid Method for Speed Typing Website. J. RESTI 2023, 7, 7–14. [Google Scholar] [CrossRef]

- Voleti, R.; Itm, K. Data Wrangling- A Goliath of Data Industry. Int. J. Eng. Res. 2020, V9, 273–276. [Google Scholar] [CrossRef]

- Faiz, H.; Al-Amin, M.F.; Mundiri, A.; Fahmi, A. Transforming Organizational Quality Through Effective Administrative Training. Communaut. J. Community Serv. 2023, 2, 157–167. [Google Scholar] [CrossRef]

- Jaeger, S.R.; Rasmussen, M.A. Importance of data preparation when analysing written responses to open-ended questions: An empirical assessment and comparison with manual coding. Food Qual. Prefer. 2021, 93, 104270. [Google Scholar] [CrossRef]

- Rodriguez, A. Know your data: Evaluation of normality for continuous variables and tools to deal with non-normal distributions. Med. Clínica (Engl. Ed.) 2020, 154, 142–145. [Google Scholar] [CrossRef]

- Lugo-Armenta, J.G.; Pino-Fan, L.R. Inferential Reasoning Levels for t-Student Statistical. Bolema Math. Educ. Bull. 2021, 35, 1776–1802. [Google Scholar] [CrossRef]

- Carazo-Díaz, C.; Prieto-Valiente, L. The p-value of a test is not the probability that the null hypothesis is true or false. Rev. Neurol. 2024, 79, 289–291. [Google Scholar] [CrossRef] [PubMed]

- Moghadam, M.T.; Behabadi, M.A.A.; Sajadi, B.; Razi, P.; Zakaria, M.I. Experimental study of heat transfer coefficient, pressure drop and flow pattern of R1234yf condensing flow in inclined plain tubes. Int. J. Heat Mass Transf. 2020, 160, 120199. [Google Scholar] [CrossRef]

- Quitiaquez, W.; Herrera, A.; Isaza-Roldán, C.A.; Mena, M.; Nieto-Londoño, C.; Toapanta-Ramos, F. Numerical analysis of flow patterns maps in horizontal pipes with variation of inclination angles in a collector/evaporator of a DX-SAHP. Mater. Today Proc. 2022, 49, 194–201. [Google Scholar] [CrossRef]

- Quitiaquez, W.; Anchapaxi, K.; Cortez, E.; Isaza-Roldán, C.; Nieto-Londoño, C.; Toapanta-Ramos, F. Evaluation of Correlations of Flow Boiling Heat Transfer of R600a in a Flat-Plate Solar Collector/Evaporator. Int. J. Adv. Sci. Eng. Inf. Technol. 2021, 11, 1273–1280. [Google Scholar] [CrossRef]

- Kattan, N.; Thome, J.R.; Favrat, D. Flow Boiling in Horizontal Tubes: Part 1—Development of a Diabatic Two-Phase Flow Pattern Map. J. Heat Transf. 1998, 120, 140–147. [Google Scholar] [CrossRef]

- Rajabi, V.; Mansoori, Z.; Rahimzadeh, H.; Nasrfard, H.; Ahmadi, G. Experimental study of refrigerant condensation heat transfer and pressure drop in horizontal tubes with full and partial coiled wire inserts (CWIs). Int. J. Heat Mass Transf. 2023, 216, 124577. [Google Scholar] [CrossRef]

- Wojtan, L.; Ursenbacher, T.; Thome, J.R. Investigation of flow boiling in horizontal tubes: Part I—A new diabatic two-phase flow pattern map. Int. J. Heat Mass Transf. 2005, 48, 2955–2969. [Google Scholar] [CrossRef]

- Faghri, A.; Zhang, Y. Fundamentals of Multiphase Heat Transfer and Flow; Springer Nature: Durham, NC, USA, 2019. [Google Scholar] [CrossRef]

- Shah, M.M. New general correlation for heat transfer during saturated boiling in mini and macro channels. Int. J. Refrig. 2022, 137, 103–116. [Google Scholar] [CrossRef]

- Estupiñán-Campos, J.; Quitiaquez, W.; Nieto-Londoño, C.; Quitiaquez, P. Numerical Simulation of the Heat Transfer Inside a Shell and Tube Heat Exchanger Considering Different Variations in the Geometric Parameters of the Design. Energies 2024, 17, 691. [Google Scholar] [CrossRef]

- Zhang, J.; Mondejar, M.E.; Haglind, F. General heat transfer correlations for flow boiling of zeotropic mixtures in horizontal plain tubes. Appl. Therm. Eng. 2019, 150, 824–839. [Google Scholar] [CrossRef]

- Ponce, R.B.M.; Palma, K.S.; Alamilla, A.M.; Valdez, D.S.; Velázquez, U.I.M. Cuadro comparativo ‘Estadistica inferencial y descriptive. Educ. Salud Boletín Científico Inst. Ciencias Salud Univ. Autónoma Estado Hidalgo 2020, 8, 93–95. [Google Scholar] [CrossRef]

- Hernando, Á.-T.J.; Vargas-Delgado, L.; Jiménez-Yejas, C.; Ortiz-Mejía, D. Accesibilidad estadística en artículos publicados en revistas científicas de educación (Europa-Latinoamérica) incluidas en Scimago Journal Ranking. Eco Matemático 2022, 13, 81–92. [Google Scholar] [CrossRef]

- Retirado-Mediaceja, Y.; Legrá-Lobaina, A.A.; Camaraza-Medina, Y.; Laurencio-Alfonso, H.L.; Salazar-Corrales, M.F.; Quitiaquez-Sarzosa, W.G. Validación experimental de modelos físico-matemáticos del secado natural de mena laterítica. Minería Geol. 2025, 41, 134–156. [Google Scholar]

| Angle of Inclination (°) | |||||

|---|---|---|---|---|---|

| Variables | 10 | 20 | 30 | 40 | 45 |

| Ambient temperature [°C] | 17.8 | 17.4 | 16.9 | 18.3 | 18.1 |

| Average incident solar radiation [W·m−2] | 541.3 | 251.6 | 649.2 | 301.6 | 139.2 |

| Quality [dimensionless] | 0.2069 | 0.2257 | 0.2125 | 0.2257 | 0.2248 |

| Surface temperature [°C] | 13.5 | 12 | 11 | 14 | 13.7 |

| Vapor phase density [kg·m−3] | 4.541 | 4.693 | 4.848 | 4.723 | 4.677 |

| Thermal conductivity [W·m−1·K−1] | 0.09583 | 0.0971 | 0.09624 | 0.0971 | 0.0971 |

| Boiling number (Bo) | 6.03 × 10−6 | 3.65 × 10−6 | 6.53 × 10−6 | 4.28 × 10−6 | 2.67 × 10−6 |

| Independent Variable (x) | Dependent Variable (y) | ||

|---|---|---|---|

| Nominal | Ordinal | Discrete or Continuous | |

| Qualitative (nominal) | Independent samples - Z test - Chi-square test - Fisher’s test | Test U de Mann–Whitney | Test de la t de Student |

| Qualitative (nominal) | Dependent samples - Test de McNermar - Test Z | Test de Wilcoxon | Test de la t de Student |

| Quantitative (discrete or continuous) | Student’s t-test | Spearman’s correlation coefficient | Pearson’s correlation coefficient |

| N | Minimum | Maximum | Average | |

|---|---|---|---|---|

| Heat transfer coefficient 10° | 21 | 3347.8 | 5640.0 | 4986.4 |

| Heat transfer coefficient 20° | 21 | 3533.3 | 5948.5 | 5288.8 |

| Heat transfer coefficient 30° | 21 | 3292.3 | 5560.6 | 4930.0 |

| Heat transfer coefficient 40° | 21 | 3505.7 | 5905.6 | 5252.2 |

| Heat transfer coefficient 45° | 21 | 3665.6 | 6163.8 | 5476.4 |

| N valid (by list) | 21 |

| Kolmogorov-Smimov | Shapiro–Wilk | |||||

|---|---|---|---|---|---|---|

| Statistician | gl | Sig | Statistician | gl | Sig | |

| Heat transfer coefficient 10° | 0.162 | 21 | 0.154 | 0.878 | 21 | 0.013 |

| Heat transfer coefficient 20° | 0.171 | 21 | 0.112 | 0.877 | 21 | 0.013 |

| Heat transfer coefficient 30° | 0.174 | 21 | 0.096 | 0.875 | 21 | 0.012 |

| Heat transfer coefficient 40° | 0.176 | 21 | 0.090 | 0.874 | 21 | 0.011 |

| Heat transfer coefficient 45° | 0.172 | 21 | 0.107 | 0.876 | 21 | 0.012 |

| Factor 10° | Heat Transfer Coefficient 10° | ||

|---|---|---|---|

| Factor 10° | Pearson correlation | 1 | −0.316 |

| Sig. (bilaterally) | 0.162 | ||

| N | 21 | 21 | |

| Heat transfer coefficient 10° | Pearson correlation | −0.316 | 1 |

| Sig. (bilaterally) | 0.162 | ||

| N | 21 | 21 |

| Pearson Correlation | |

|---|---|

| Factor for 10° angle of inclination | −0.316 |

| Factor for 20° angle of inclination | −0.271 |

| Factor for 30° angle of inclination | −0.286 |

| Factor for 40° angle of inclination | −0.266 |

| Factor for 45° angle of inclination | −0.280 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quitiaquez, W.; Simbaña, I.; Herrera, A.; Quitiaquez, P.; Nieto-Londoño, C.; Pilataxi, E.; Andrade, A.X.; Retirado-Mediaceja, Y. Statistical Analysis of Heat Transfer Effects on Flow Patterns Maps in a Flat-Plate Collector/Evaporator with R600a Under Variable Tilt Angles. Processes 2025, 13, 3419. https://doi.org/10.3390/pr13113419

Quitiaquez W, Simbaña I, Herrera A, Quitiaquez P, Nieto-Londoño C, Pilataxi E, Andrade AX, Retirado-Mediaceja Y. Statistical Analysis of Heat Transfer Effects on Flow Patterns Maps in a Flat-Plate Collector/Evaporator with R600a Under Variable Tilt Angles. Processes. 2025; 13(11):3419. https://doi.org/10.3390/pr13113419

Chicago/Turabian StyleQuitiaquez, William, Isaac Simbaña, Alex Herrera, Patricio Quitiaquez, César Nieto-Londoño, Erika Pilataxi, Anthony Xavier Andrade, and Yoalbys Retirado-Mediaceja. 2025. "Statistical Analysis of Heat Transfer Effects on Flow Patterns Maps in a Flat-Plate Collector/Evaporator with R600a Under Variable Tilt Angles" Processes 13, no. 11: 3419. https://doi.org/10.3390/pr13113419

APA StyleQuitiaquez, W., Simbaña, I., Herrera, A., Quitiaquez, P., Nieto-Londoño, C., Pilataxi, E., Andrade, A. X., & Retirado-Mediaceja, Y. (2025). Statistical Analysis of Heat Transfer Effects on Flow Patterns Maps in a Flat-Plate Collector/Evaporator with R600a Under Variable Tilt Angles. Processes, 13(11), 3419. https://doi.org/10.3390/pr13113419