- Article

Acoustic Emission and Machine Learning Approaches for Assessing Mechanical Degradation in Aged Unidirectional Glass Fiber-Reinforced Thermoplastics

- Jorge Palacios Moreno and

- Pierre Mertiny

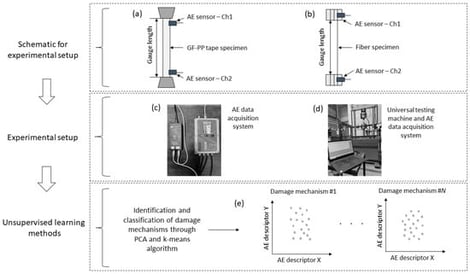

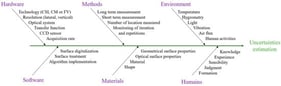

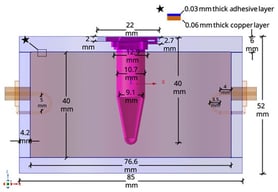

Unidirectional glass fiber-reinforced thermoplastic (UGFT) composite tapes are promising recyclable structural materials for applications such as composite pressure pipes. However, their durability under hydrothermal environments remains a critical concern. This study emphasizes metrology-driven evaluation of aging behavior in polypropylene-based UGFT tapes. Specimens were conditioned at 95 °C in a deionized-water environment for up to 4 weeks, and multiple complementary measurement techniques were applied to quantify degradation. Mass-change metrology was performed to characterize water uptake kinetics and establish diffusion-driven aging progression. Tensile testing enabled quantitative assessment of mechanical strength retention, defining a >25% reduction in strength as a threshold for significant deterioration. Acoustic emission (AE) acted as the central non-destructive monitoring method, capturing high-fidelity waveforms generated during loading. AE waveform descriptors, such as amplitude, rise time, and frequency content, served as measurable indicators of internal damage mechanisms including matrix cracking, interfacial debonding and fiber breakage. To process large AE datasets, principal component analysis was used for dimensionality reduction, followed by k-means clustering to group signals by damage type. Optical microscopy provided microstructural verification of these classifications. The integrated metrological framework demonstrates a reliable pathway to monitor, identify, and quantify damage evolution in hydrothermally aged UGFT structures.

13 February 2026