Integrating Reverse Engineering for Digital Model Reconstruction and Remanufacturing of Mechanical Components: A Systematic Review

Abstract

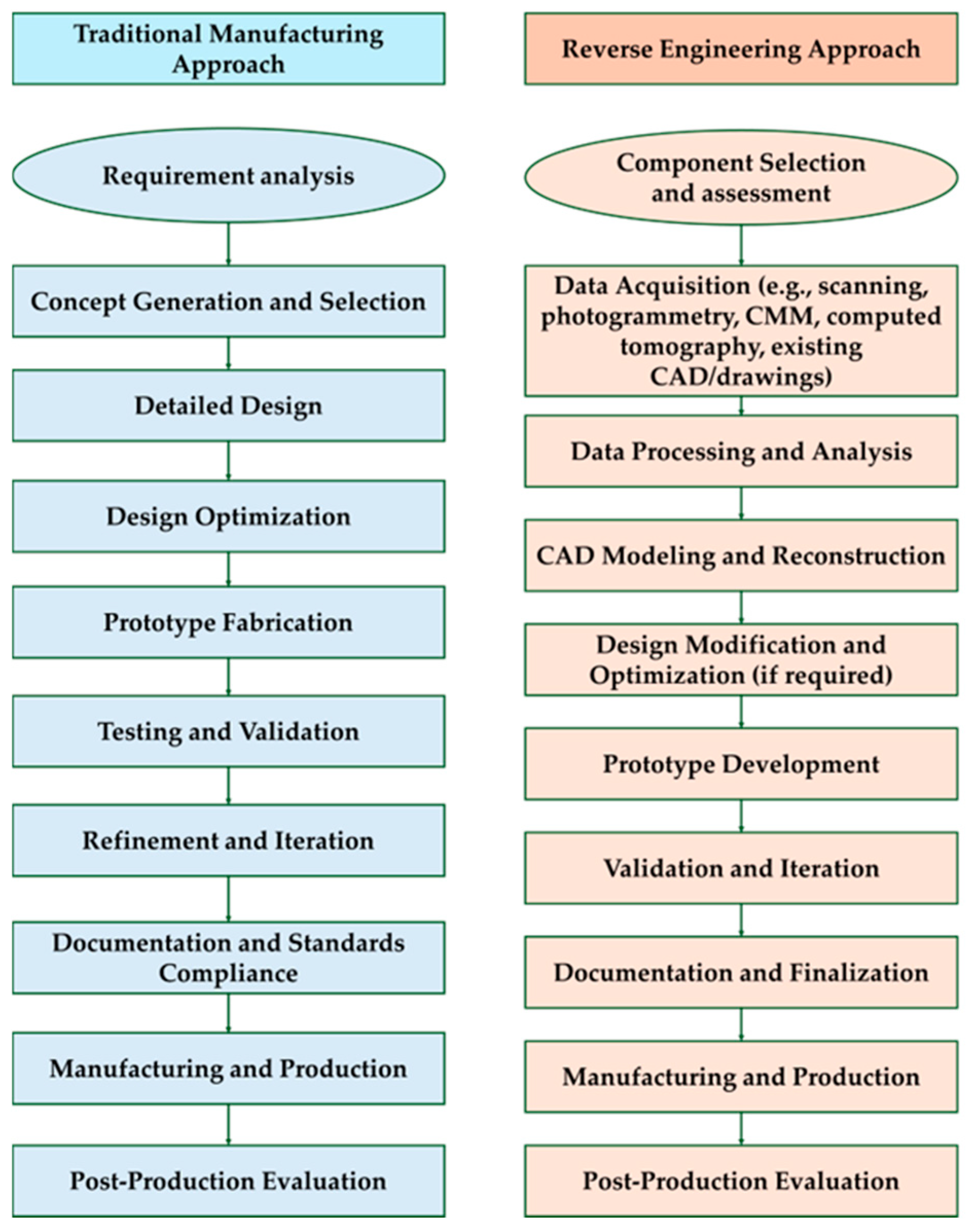

1. Introduction

- RQ1: How is reverse engineering applied in the restoration, remanufacturing, and redesign of mechanical components across different sectors?

- RQ2: What methods are most effective for reconstructing internal geometries and integrating RE with simulation and analysis tools?

- RQ3: How are AI and automation advancing RE workflows, particularly in data processing, model reconstruction, and error reduction?

- RQ4: What are the major challenges, including tolerance deviations, scanning limitations, and human/material factors, that affect the fidelity and usability of RE outputs?

- RQ5: What emerging trends and future research directions can enhance the integration of RE with manufacturing processes, and lifecycle management?

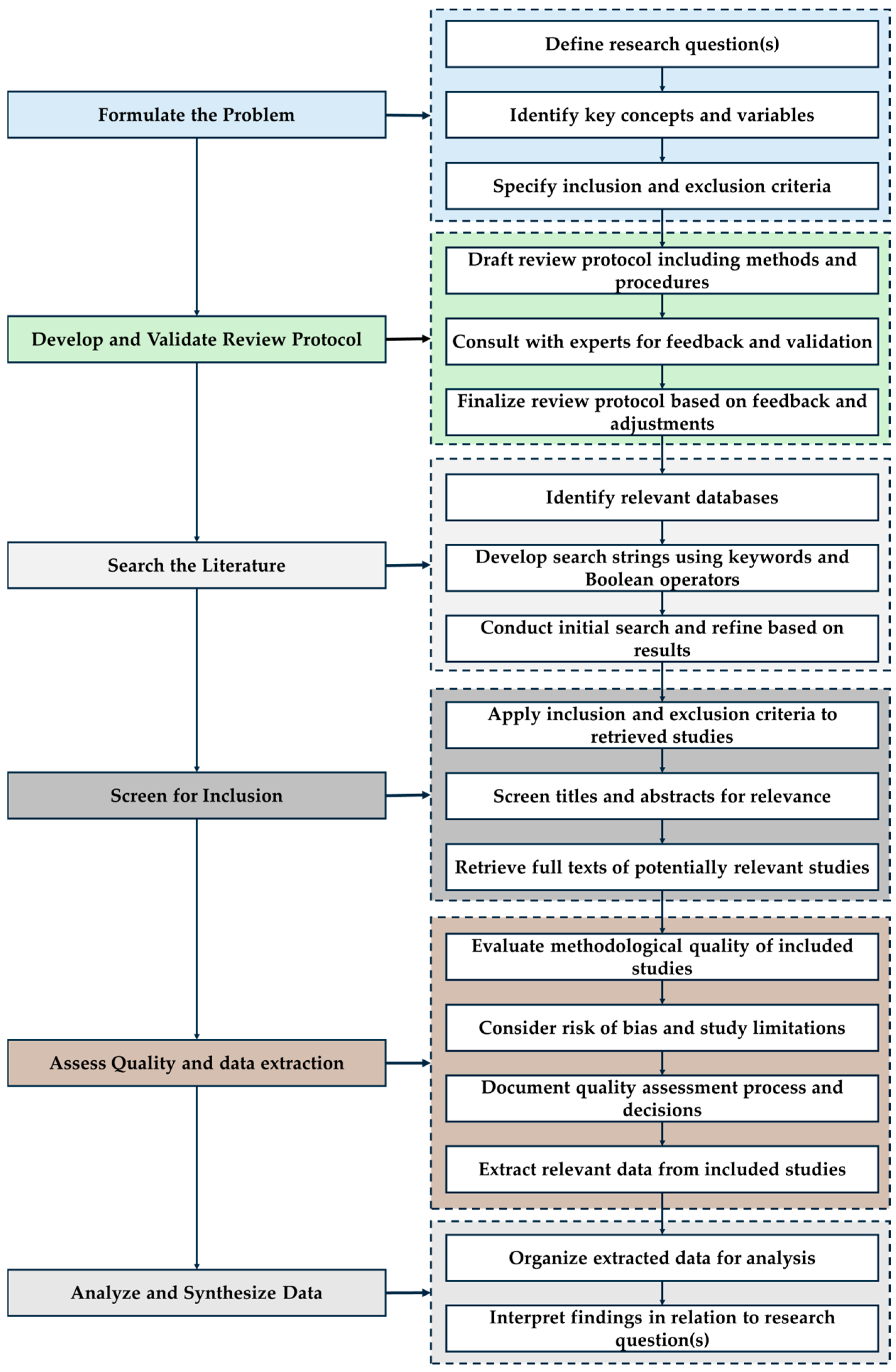

2. Methodology

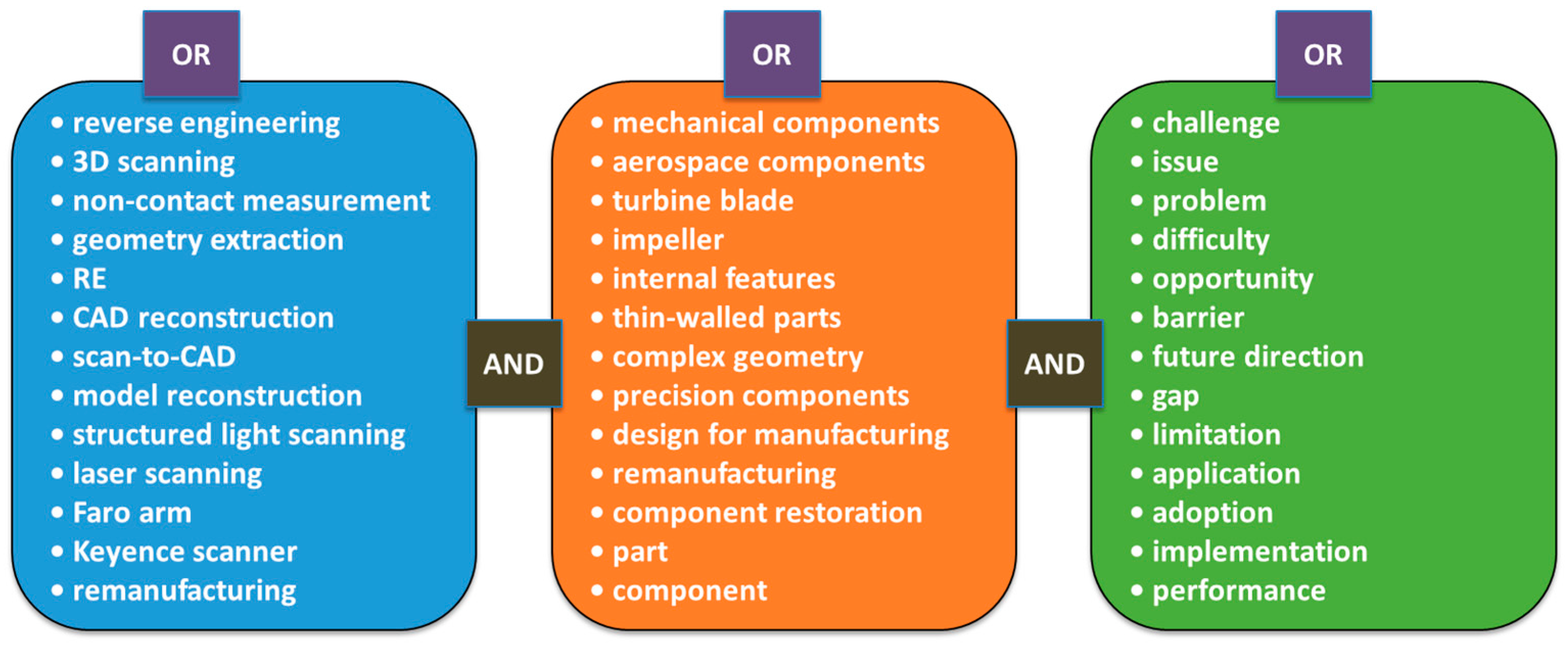

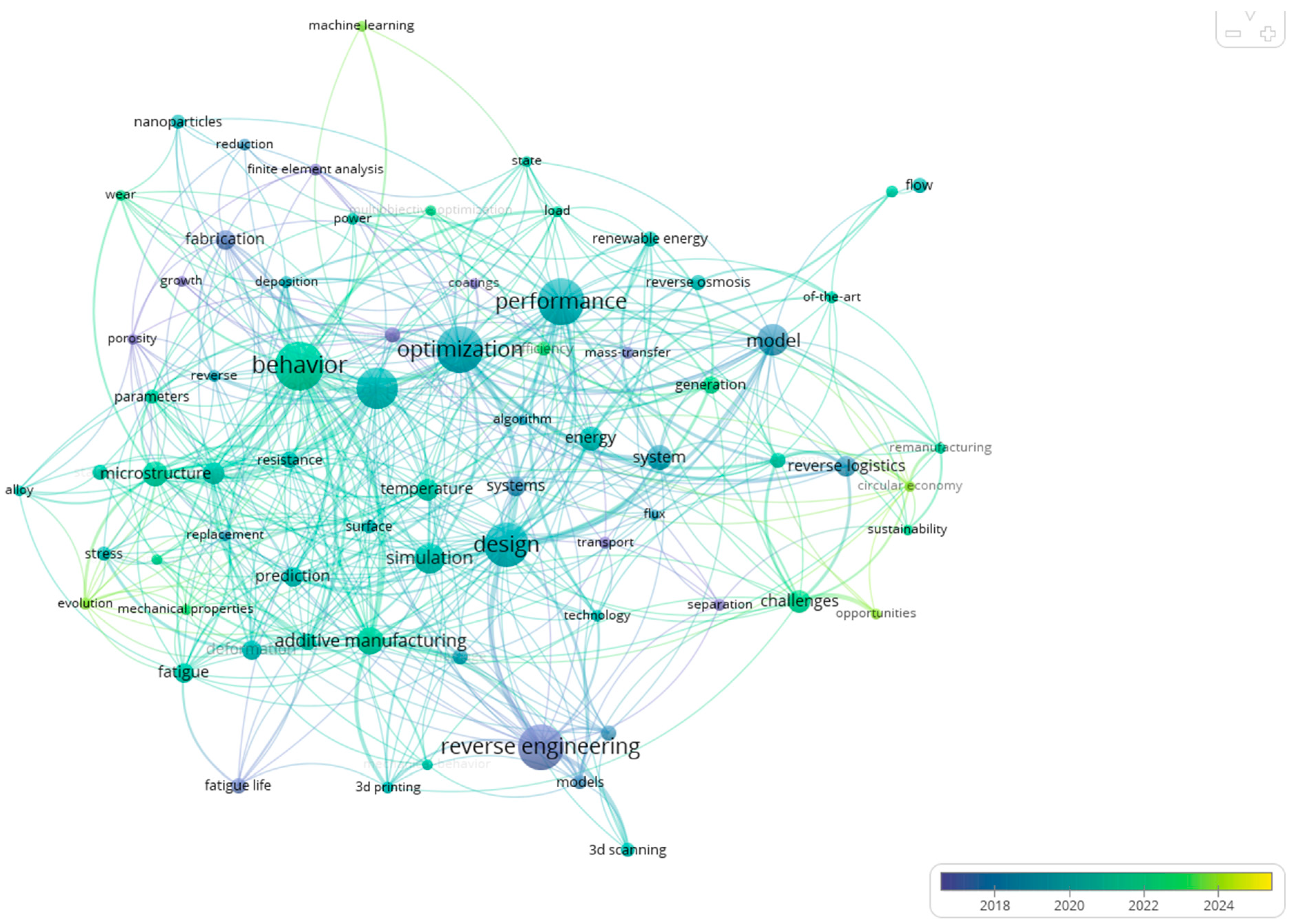

2.1. Literature Search Strategy

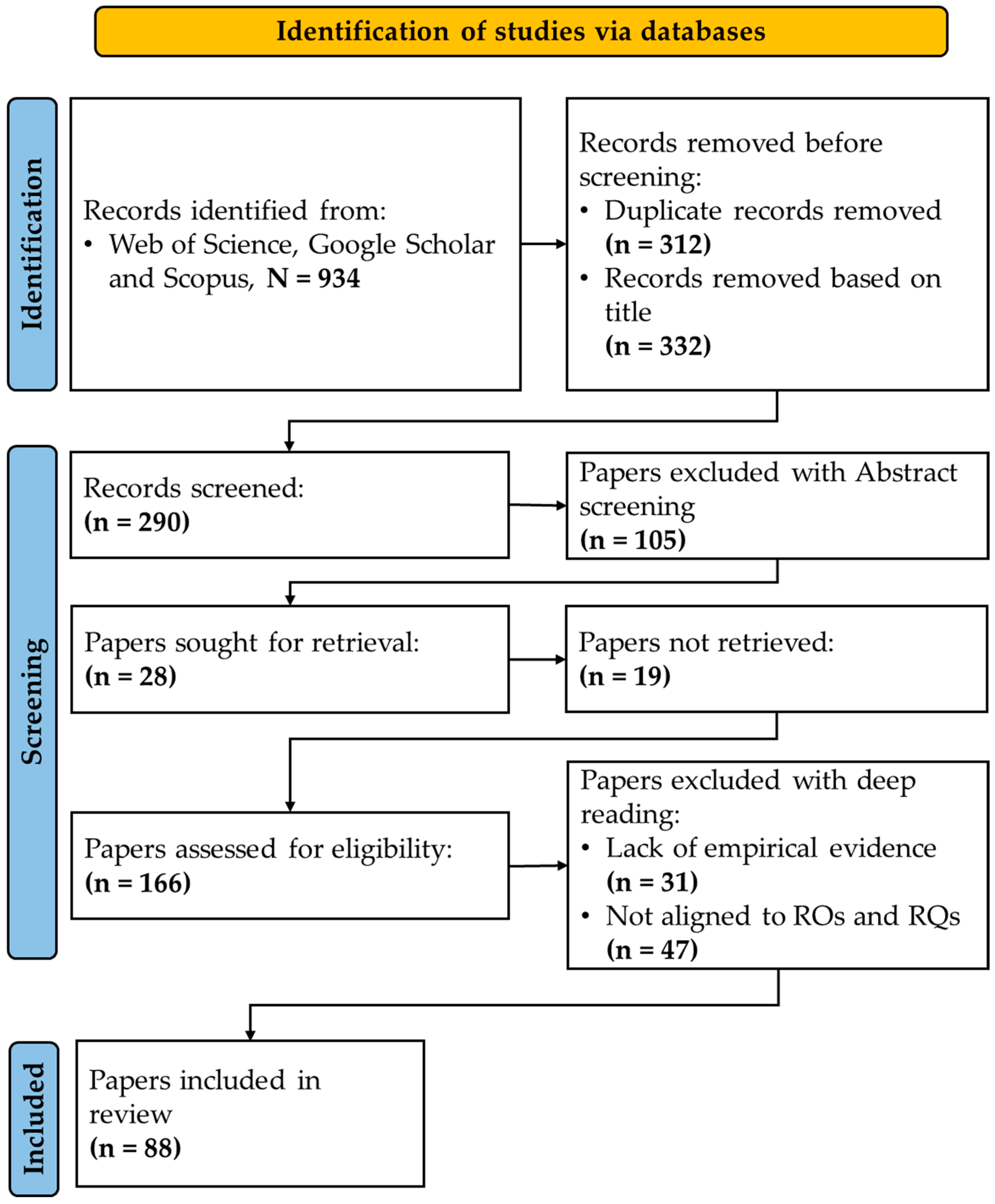

2.2. Selection of Studies Using PRISMA Framework

3. Application of RE in Mechanical Component

3.1. Restoration, Remanufacturing, and Redesign

3.2. Modeling Internal Geometry, Simulation, and Analysis

3.3. AI-Driven RE Approach

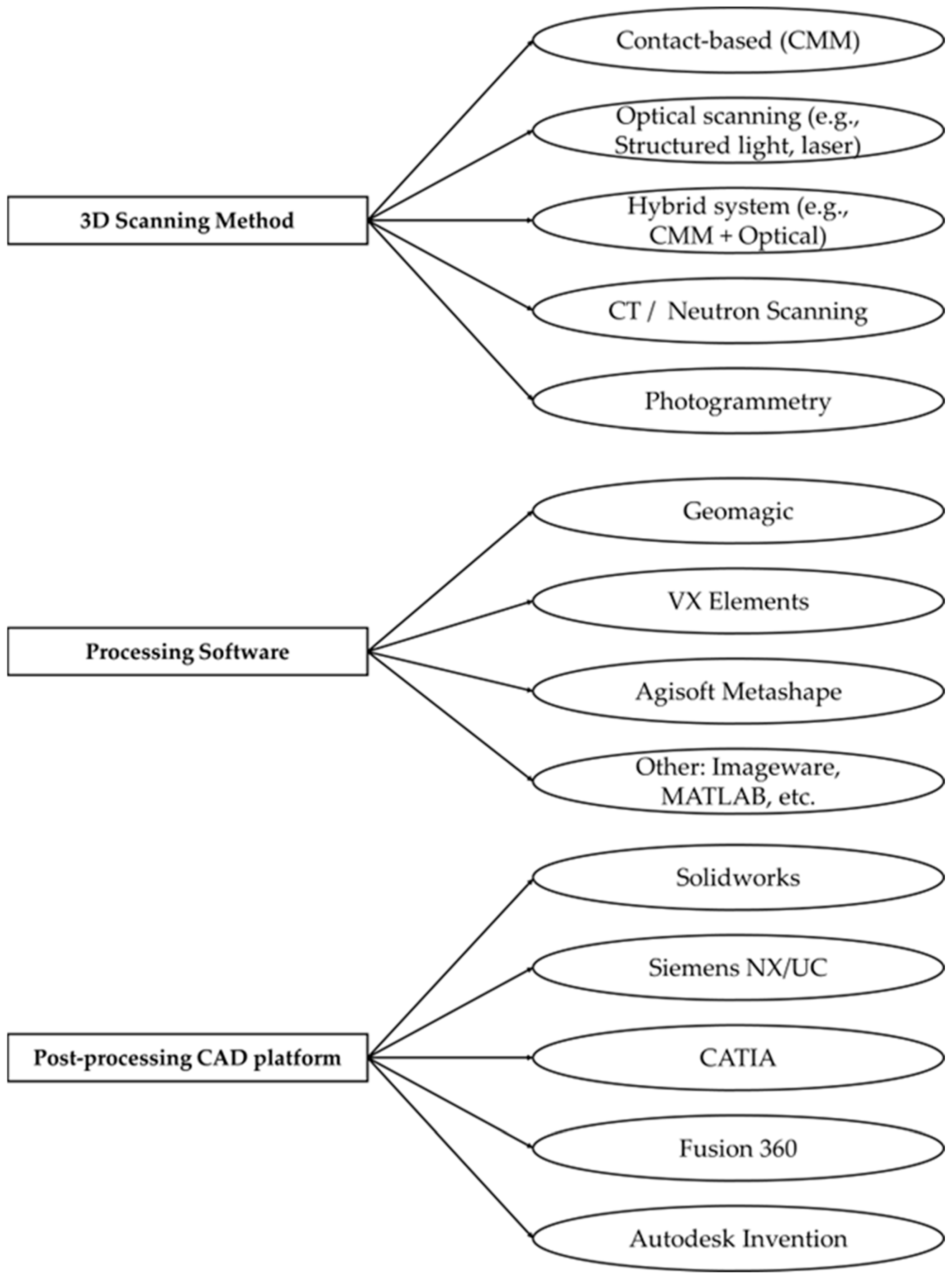

3.4. Trends in 3D Scanning

4. Challenges of RE in Mechanical Parts

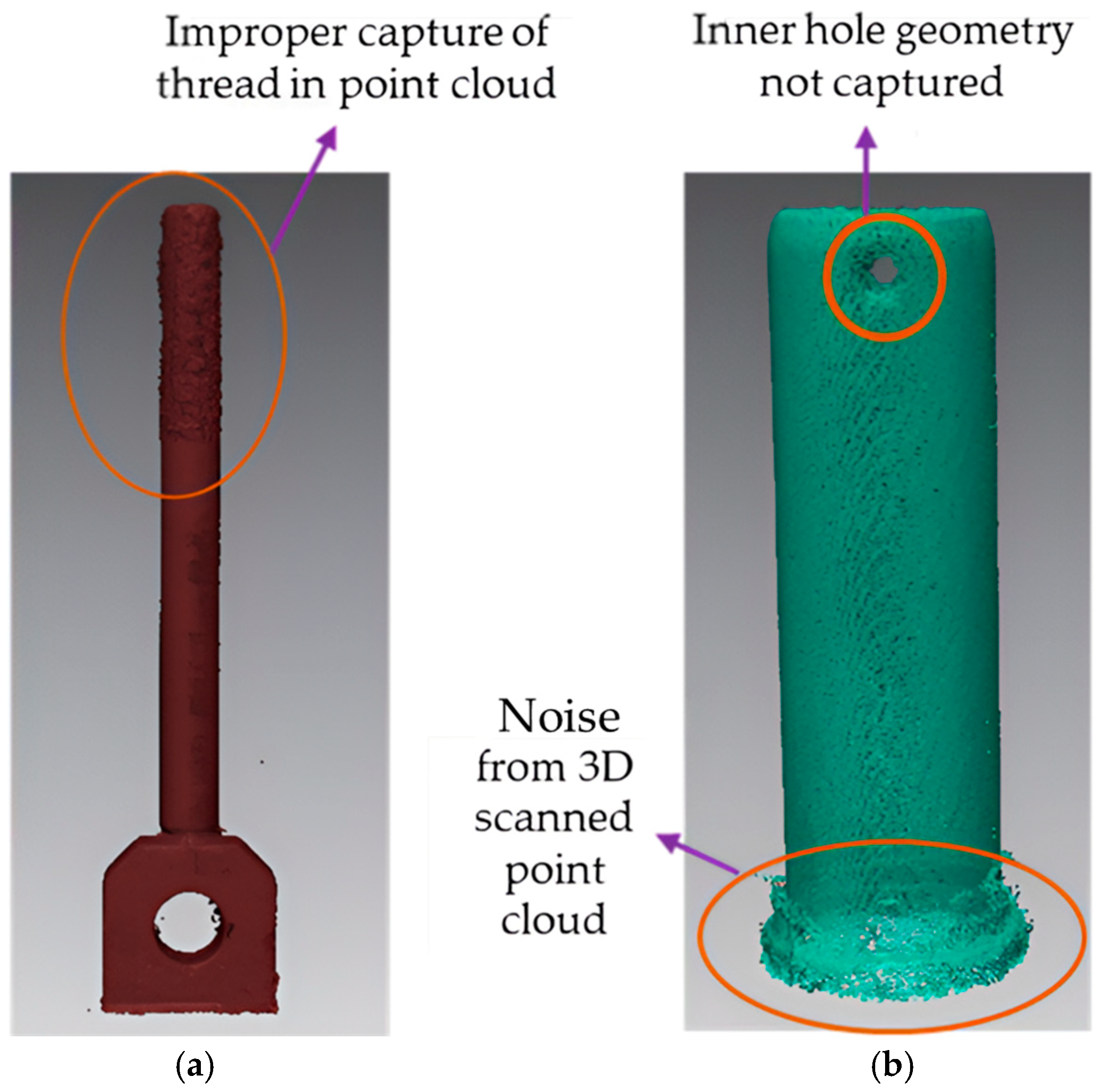

4.1. Product Complexity, Internal Geometry, and Physical Barriers

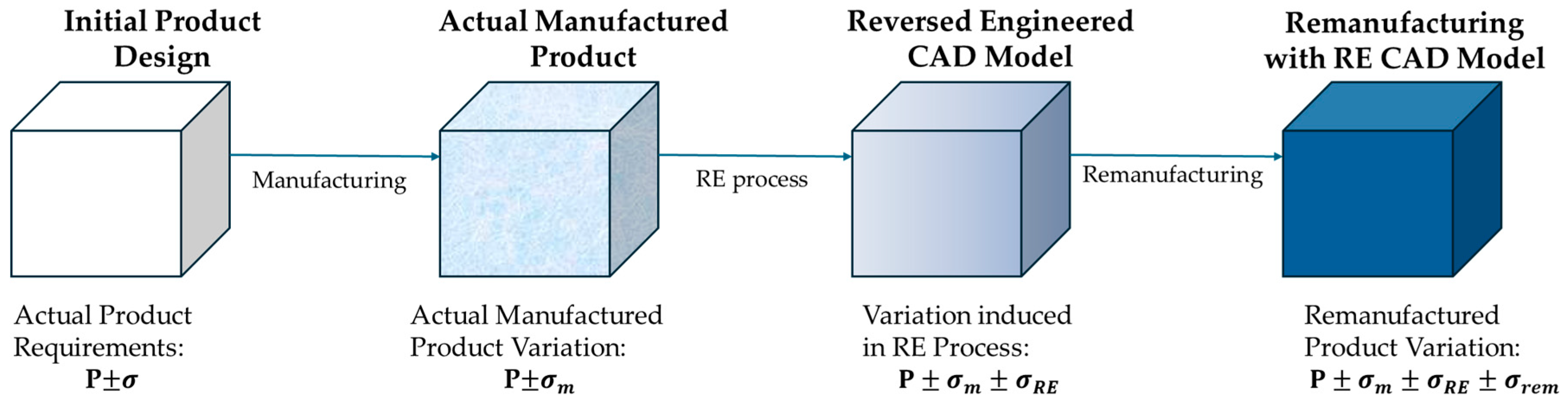

4.2. Tolerance, Dimensional Accuracy, and Error Propagation

4.3. Scanning Limitations and Data Acquisition Challenges

4.4. Process Integration, Post-Processing Challenges

4.5. Human, Material, and Process-Specific Limitations

5. Future Research Directions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pandilov, Z.; Shabani, B.; Shishkovski, D.; Vrtanoski, G. Reverse engineering–An effective tool for design and development of mechanical parts. Acta Tech. Corviniensis-Bull. Eng. 2018, 11, 113–118. [Google Scholar]

- Durupt, A.; Remy, S.; Ducellier, G. KBRE: A knowledge based reverse engineering for mechanical components. Comput.-Aided Des. Appl. 2010, 7, 279–289. [Google Scholar] [CrossRef]

- Rozesara, M.; Ghazinoori, S.; Manteghi, M.; Tabatabaeian, S.H. A reverse engineering-based model for innovation process in complex product systems: Multiple case studies in the aviation industry. J. Eng. Technol. Manag. 2023, 69, 101765. [Google Scholar] [CrossRef]

- Bagci, E. Reverse engineering applications for recovery of broken or worn parts and re-manufacturing: Three case studies. Adv. Eng. Softw. 2009, 40, 407–418. [Google Scholar] [CrossRef]

- Freddi, M.; Ferretti, P.; Alessandri, G.; Liverani, A. Reverse engineering of a racing motorbike connecting rod. Inventions 2023, 8, 23. [Google Scholar] [CrossRef]

- Geng, Z.; Bidanda, B. Review of reverse engineering systems–current state of the art. Virtual Phys. Prototyp. 2017, 12, 161–172. [Google Scholar] [CrossRef]

- Raja, V. Introduction to reverse engineering. In Reverse Engineering: An Industrial Perspective; Springer: London, UK, 2008; pp. 1–9. [Google Scholar]

- Lippmann, B.; Unverricht, N.; Singla, A.; Ludwig, M.; Werner, M.; Egger, P.; Duebotzky, A.; Graeb, H.; Gieser, H.; Rasche, M.; et al. Verification of physical designs using an integrated reverse engineering flow for nanoscale technologies. Integration 2020, 71, 11–29. [Google Scholar] [CrossRef]

- Anwer, N.; Mathieu, L. From reverse engineering to shape engineering in mechanical design. CIRP Ann. 2016, 65, 165–168. [Google Scholar] [CrossRef]

- López, J.; Vila, C. An approach to reverse engineering methodology for part reconstruction with additive manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1193, 012047. [Google Scholar] [CrossRef]

- Chintala, G.; Gudimetla, P. Optimum material evaluation for gas turbine blade using Reverse Engineering (RE) and FEA. Procedia Eng. 2014, 97, 1332–1340. [Google Scholar] [CrossRef]

- Tut, V.; Tulcan, A.; Cosma, C.; Serban, I. Application of CAD/CAM/FEA, reverse engineering and rapid prototyping in manufacturing industry. Int. J. Mech. 2010, 4, 79–86. [Google Scholar]

- De Grave, E. Reverse Engineering of Passenger Jets–Classified Design Parameters; Aircraft Design and Systems Group (AERO), Department of Automotive and Aeronautical Engineering, Hamburg University of Applied Sciences: Hamburg, Germany, 2017. [Google Scholar]

- Kumar, A.; Jain, P.K.; Pathak, P.M. Reverse engineering in product manufacturing: An overview. DAAAM Int. Sci. Book 2013, 39, 665–678. [Google Scholar]

- Wong, E.T.; Man, W.Y. Smart Maintenance and Human Factor Modeling for Aircraft Safety. In Applications in Reliability and Statistical Computing; Springer International Publishing: Cham, Switzerland, 2023; pp. 25–59. [Google Scholar]

- Javidrad, F.; Rahmati, R. An integrated re-engineering plan for the manufacturing of aerospace components. Mater. Des. 2009, 30, 1524–1532. [Google Scholar] [CrossRef]

- Buonamici, F.; Carfagni, M.; Furferi, R.; Governi, L.; Lapini, A.; Volpe, Y. Reverse engineering modeling methods and tools: A survey. Comput.-Aided Des. Appl. 2018, 15, 443–464. [Google Scholar] [CrossRef]

- Raibulet, C.; Fontana, F.A.; Zanoni, M. Model-driven reverse engineering approaches: A systematic literature review. IEEE Access 2017, 5, 14516–14542. [Google Scholar] [CrossRef]

- Curtis, S.K.; Harston, S.P.; Mattson, C.A. The fundamentals of barriers to reverse engineering and their implementation into mechanical components. Res. Eng. Des. 2011, 22, 245–261. [Google Scholar] [CrossRef]

- Wakjira, Y.; Kurukkal, N.S.; Lemu, H.G. Reverse engineering in medical application: Literature review, proof of concept and future perspectives. Sci. Rep. 2024, 14, 23621. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Van Eck, N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Urbanic, R.J. A design and inspection based methodology for form-function reverse engineering of mechanical components. Int. J. Adv. Manuf. Technol. 2015, 81, 1539–1562. [Google Scholar] [CrossRef]

- Osipov, S.; Komarov, I.; Zlyvko, O.; Vegera, A.; Gertsovsky, G. Development of a Methodology for Obtaining Solid Models of Products That Are Objects of Reverse Engineering Using the Example of the Capstone Micro-GTU C 65. Modelling 2024, 5, 1980–2000. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, S.; Pan, H.; Yuan, C.; Chen, X. Research on remanufacturing strategy for 45 steel gear using H13 steel powder based on laser cladding technology. J. Manuf. Process. 2020, 49, 344–354. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, J.; Jia, Z.; Cheng, W.; Wang, J. Research on laser additive and milling subtractive composite remanufacturing process of compressor blade. J. Manuf. Mater. Process. 2018, 2, 73. [Google Scholar] [CrossRef]

- Sedlák, J.; Hrušecká, D.; Chromjaková, F.; Majerík, J.; Barényi, I. Analysis of the wear on machined groove profiles using reverse engineering technology. Manuf. Technol. 2021, 21, 529–538. [Google Scholar] [CrossRef]

- Sukumar, S.R.; Govindasamy, P.; Koschan, A.F.; Page, D.L.; Abidi, M.A. Imaging-based thermal modelling and reverse engineering of as-built automotive components: A case study. Virtual Phys. Prototyp. 2010, 5, 21–32. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, X.; Ma, Z. Research on 3D model reconstruction based on a sequence of cross-sectional images. Mach. Vis. Appl. 2021, 32, 92. [Google Scholar] [CrossRef]

- Huang, W.; Jiang, Z.; Wang, T.; Wang, Y.; Hu, X. Remanufacturing scheme design for used parts based on incomplete information reconstruction. Chin. J. Mech. Eng. 2020, 33, 41. [Google Scholar] [CrossRef]

- Wang, S.; Yan, Y.; Wang, F.; Wu, G. Based on reverse molding technology of the impeller of the fluid dynamics analysis. J. Comput. Methods Sci. Eng. 2015, 15, 183–192. [Google Scholar] [CrossRef]

- Patpatiya, P.; Chaudhary, K.; Kapoor, V. Reverse manufacturing and 3D inspection of mechanical fasteners fabricated using photopolymer jetting technology. Mapan 2022, 37, 753–763. [Google Scholar] [CrossRef]

- Li, L.; Li, C.; Tang, Y.; Du, Y. An integrated approach of reverse engineering aided remanufacturing process for worn components. Robot. Comput.-Integr. Manuf. 2017, 48, 39–50. [Google Scholar] [CrossRef]

- Sun, C.; Miao, L.; Wang, M.; Shi, J.; Ding, J. Research on point cloud hole filling and 3D reconstruction in reflective area. Sci. Rep. 2023, 13, 18524. [Google Scholar] [CrossRef]

- Chiriţă, A.P.; Benescu, A.A.; Borş, A.M.; Şefu, Ş.M.; Blejan, R. The Importance of Reverse Engineering and 3D Scanning in Remanufacturing Hydraulic Drive System Components in the Circular Economy Context. Acta Tech. Corviniensis-Bull. Eng. 2023, 16, 19–24. [Google Scholar]

- Rao, J.; Wang, J.; Kollmannsberger, S.; Shi, J.; Fu, H.; Rank, E. Point cloud-based elastic reverse time migration for ultrasonic imaging of components with vertical surfaces. Mech. Syst. Signal Process. 2022, 163, 108144. [Google Scholar] [CrossRef]

- Wang, J.; Gu, D.; Yu, Z.; Tan, C.; Zhou, L. A framework for 3D model reconstruction in reverse engineering. Comput. Ind. Eng. 2012, 63, 1189–1200. [Google Scholar] [CrossRef]

- Hwang, S.; Kim, J. Injection mold design of reverse engineering using injection molding analysis and machine learning. J. Mech. Sci. Technol. 2019, 33, 3803–3812. [Google Scholar] [CrossRef]

- Gameros, A.; De Chiffre, L.; Siller, H.R.; Hiller, J.; Genta, G. A reverse engineering methodology for nickel alloy turbine blades with internal features. CIRP J. Manuf. Sci. Technol. 2015, 9, 116–124. [Google Scholar] [CrossRef]

- Kašpar, J.; Bernardin, P.; Lašová, V. Fatigue Estimation Using Inverse Stamping. Metals 2023, 13, 1956. [Google Scholar] [CrossRef]

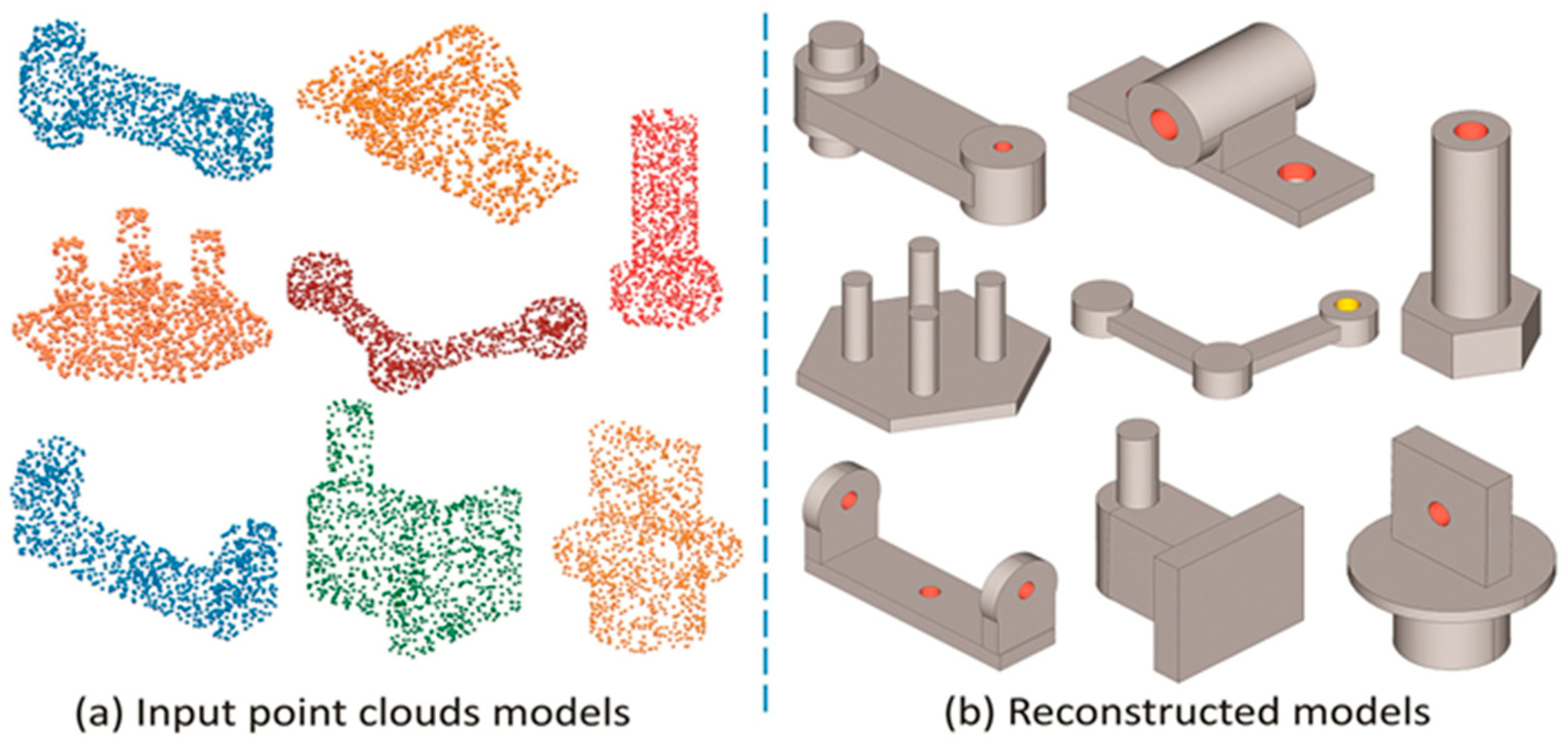

- Lee, H.; Lee, J.; Kim, H.; Mun, D. Dataset and method for deep learning-based reconstruction of 3D CAD models containing machining features for mechanical parts. J. Comput. Des. Eng. 2022, 9, 114–127. [Google Scholar] [CrossRef]

- Yilmaz, O.; Gindy, N.; Gao, J. A repair and overhaul methodology for aeroengine components. Robot. Comput.-Integr. Manuf. 2010, 26, 190–201. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Tagliaferri, F.; Venettacci, S.; Horn, M.; Giannini, O.; Guarino, S. Re-engineering of an impeller for submersible electric pump to be produced by selective laser melting. Appl. Sci. 2021, 11, 7375. [Google Scholar] [CrossRef]

- Othman, S.A.; Azman, A.H.; Wahid, Z.; Azman, M.A. Reverse engineering of Brake Calliper design via integration of topology optimisation and lattice structure for additive manufacturing. J. Kejuruter. 2024, 36, 439–446. [Google Scholar] [CrossRef]

- Todorov, T.T.; Gavrilov, T.; Semkov, M.; Zagorski, M. Environmentally Sustainable Machining of Complex Parts Using 3D Scanning and Virtual Models. IOP Conf. Ser. Earth Environ. Sci. 2025, 1532, 012035. [Google Scholar] [CrossRef]

- Rešetar, M.; Valjak, F.; Branilović, M.G.; Šercer, M.; Bojčetić, N. An approach for reverse engineering and redesign of additive manufactured spare parts. Proc. Des. Soc. 2024, 4, 703–712. [Google Scholar] [CrossRef]

- Paryanto, P.; Faizin, M.; Rusnaldy, R. Parametric Optimization of Train Brake Pad Using Reverse Engineering with Digital Photogrammetry 3D Modeling Method. Eng 2025, 6, 96. [Google Scholar] [CrossRef]

- Reddy, G.S.; Satyanarayana, V.V.; Kumar, J.J.; Reddy, B.R. Deviation analysis of reverse engineered freeform surface with rapid prototyping. AIP Conf. Proc. 2023, 2821, 050009. [Google Scholar] [CrossRef]

- Palka, D. Use of reverse engineering and additive printing in the reconstruction of gears. Multidiscip. Asp. Prod. Eng. 2020, 3, 274–284. [Google Scholar] [CrossRef]

- Greco, F.; Coox, L.; Maurin, F.; Balla, V.K.; Deckers, E.; Desmet, W. Reverse engineering of deep drawn components with an isogeometric framework. Comput. Struct. 2018, 201, 15–25. [Google Scholar] [CrossRef]

- Gabštur, P.; Kočiško, M.; Kaščak, J.; Pollák, M. Methodology for Verification of Geometrically Complex Components Through Reverse Engineering. Appl. Sci. 2025, 15, 3963. [Google Scholar] [CrossRef]

- Ktari, A.; Mansori, M.E. Towards remanufacturing of failed parts through rapid low-pressure sand-casting (LPSC) process. Int. J. Adv. Manuf. Technol. 2025, 139, 2569–2588. [Google Scholar] [CrossRef]

- Samavati, T.; Soryani, M. Deep learning-based 3D reconstruction: A survey. Artif. Intell. Rev. 2023, 56, 9175–9219. [Google Scholar] [CrossRef]

- Lin, R.; Ji, Y.; Ding, W.; Wu, T.; Zhu, Y.; Jiang, M. A Survey on Deep Learning in 3D CAD Reconstruction. Appl. Sci. 2025, 15, 6681. [Google Scholar] [CrossRef]

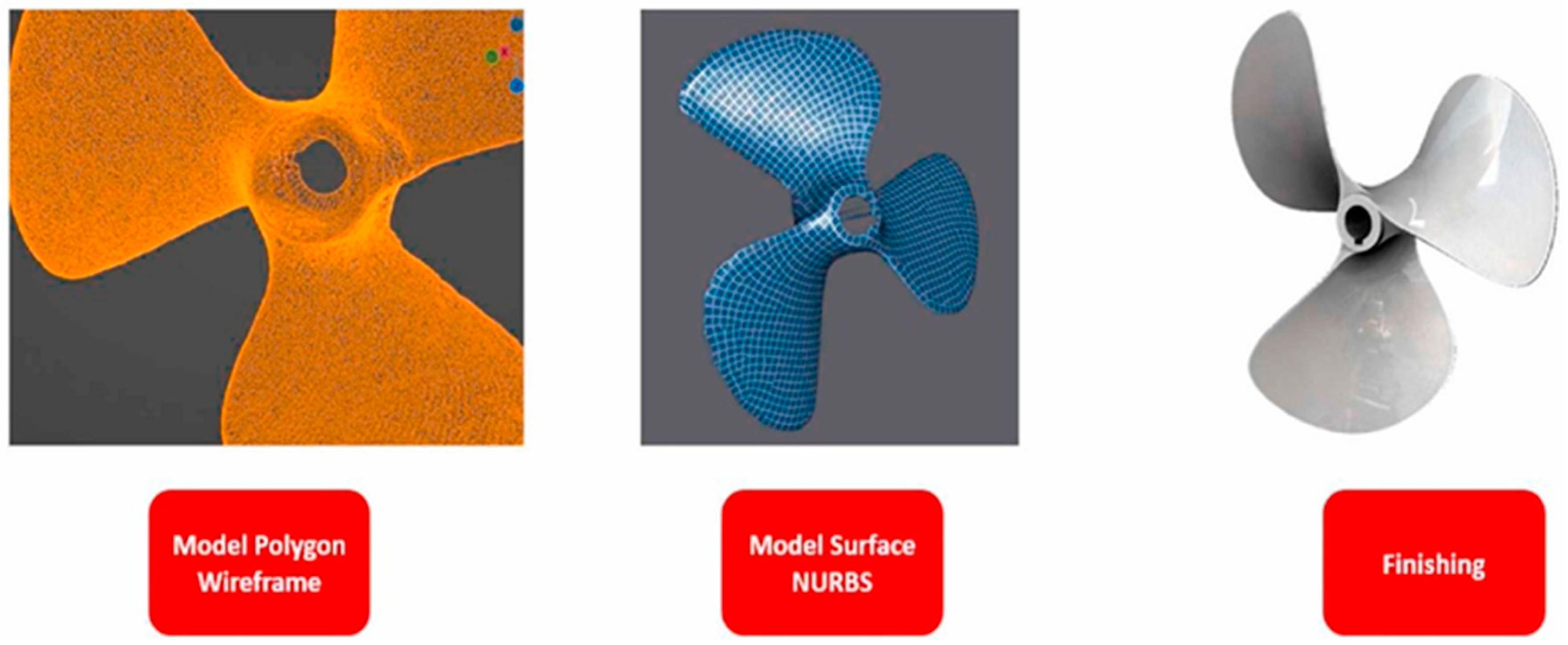

- Faizin, M.; Paryanto, P.; Cahyo, N.; Rusnaldy, R. Investigating the accuracy of boat propeller blade components with reverse engineering approach using photogrammetry method. Results Eng. 2024, 22, 102293. [Google Scholar] [CrossRef]

- Zhang, S.; Guan, Z.; Jiang, H.; Ning, T.; Wang, X.; Tan, P. Brep2Seq: A dataset and hierarchical deep learning network for reconstruction and generation of computer-aided design models. J. Comput. Des. Eng. 2024, 11, 110–134. [Google Scholar] [CrossRef]

- Gálvez, A.; Iglesias, A.; Fister, I. Industrial Artificial Intelligence Approach for Shape Reconstruction in Quality Assessment of Digital Data from Manufactured Workpieces. In Proceedings of the 2023 4th International Conference on Industrial Engineering and Artificial Intelligence (IEAI), Chiang Mai, Thailand, 27–29 April 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 86–93. [Google Scholar]

- Pashkov, D.M.; Belyak, O.A.; Guda, A.A.; Kolesnikov, V.I. Reverse engineering of mechanical and tribological properties of coatings: Results of machine learning algorithms. Phys. Mesomech. 2022, 25, 296–305. [Google Scholar] [CrossRef]

- Ali, S.A.; Khan, M.S.; Stricker, D. BRep Boundary and Junction Detection for CAD Reverse Engineering. In Proceedings of the 2024 IEEE 3rd International Conference on Computing and Machine Intelligence (ICMI), Mt Pleasant, MI, USA, 13–14 April 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Yanamandra, K.; Chen, G.L.; Xu, X.; Mac, G.; Gupta, N. Reverse engineering of additive manufactured composite part by toolpath reconstruction using imaging and machine learning. Compos. Sci. Technol. 2020, 198, 108318. [Google Scholar] [CrossRef]

- Artec 3D. 3D Scanning Accuracy, Precision & Resolution: What’s the Difference? 8 October 2024. Available online: https://www.artec3d.com/learning-center/accuracy-precision-resolution#:~:text=Handheld%20structured%2Dlight%203D%20scanners,mm%20(or%205%20microns) (accessed on 11 July 2025).

- Devedzic, G.; Kocovic, V.; Djordjevic, A.; Jovanovic Pesic, Z.; Dzunic, D.; Vukelic, D.; Petrovic Savic, S. Reconstruction and Optimization of Complex Geometric Parts Through Reverse Engineering. In Proceedings of the 15th International Scientific Conference, Novi Sad, Serbia, 24–26 September 2024. [Google Scholar]

- Šagi, G.; Lulić, Z.; Mahalec, I. Reverse engineering. In Concurrent Engineering in the 21st Century: Foundations, Developments and Challenges; Springer: Berlin/Heidelberg, Germany, 2015; pp. 319–353. [Google Scholar]

- Chaudhary, K.; Govil, A. Application of 3D scanning for reverse manufacturing and inspection of mechanical components. In Proceedings of the International Conference on Industrial and Manufacturing Systems (CIMS-2020) Optimization in Industrial and Manufacturing Systems and Applications, Jalandha, India, 26–28 June 2020; Springer International Publishing: Cham, Switzerland, 2021; pp. 61–76. [Google Scholar]

- Roos, T.H.; Quin, R.L.; De Beer, F.C.; Nshimirimana, R.M. Neutron tomography as a reverse engineering method applied to the IS-60 Rover gas turbine. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2011, 651, 329–335. [Google Scholar] [CrossRef]

- Baroiu, N.; Moroșanu, G.A.; Teodor, V.G.; Crăciun, R.S.; Păunoiu, V. Use of Reverse Engineering Techniques for Inspecting Screws Surfaces of a Helical Hydraulic Pump. Int. J. Mod. Manuf. Technol. (IJMMT) 2022, 14, 20–29. [Google Scholar] [CrossRef]

- Huo, J.; Yu, X. Three-dimensional mechanical parts reconstruction technology based on two-dimensional image. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420910008. [Google Scholar] [CrossRef]

- Li, J.; He, X.; Li, J. 2D LiDAR and camera fusion in 3D modeling of indoor environment. In Proceedings of the 2015 National Aerospace and Electronics Conference (NAECON), Dayton, OH, USA, 15–19 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 379–383. [Google Scholar]

- Vogt, M.; Rips, A.; Emmelmann, C. Comparison of iPad Pro®’s LiDAR and TrueDepth capabilities with an industrial 3D scanning solution. Technologies 2021, 9, 25. [Google Scholar] [CrossRef]

- Raj, T.; Hanim Hashim, F.; Baseri Huddin, A.; Ibrahim, M.F.; Hussain, A. A survey on LiDAR scanning mechanisms. Electronics 2020, 9, 741. [Google Scholar] [CrossRef]

- Subeshan, B.; Abdulaziz, A.; Khan, Z.; Uddin, M.N.; Rahman, M.M.; Asmatulu, E. Reverse engineering of aerospace components utilizing additive manufacturing technology. In TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings; Springer International Publishing: Cham, Switzerland, 2022; pp. 238–246. [Google Scholar]

- Pang, T.Y.; Fard, M. Reverse engineering and topology optimization for weight-reduction of a bell-crank. Appl. Sci. 2020, 10, 8568. [Google Scholar] [CrossRef]

- Helle, R.H.; Lemu, H.G. A case study on use of 3D scanning for reverse engineering and quality control. Mater. Today Proc. 2021, 45, 5255–5262. [Google Scholar] [CrossRef]

- Buonamici, F.; Carfagni, M.; Furferi, R.; Governi, L.; Lapini, A.; Volpe, Y. Reverse engineering of mechanical parts: A template-based approach. J. Comput. Des. Eng. 2018, 5, 145–159. [Google Scholar] [CrossRef]

- Yahaya, M.I.; Samsuddin, Z.; Mohd Rodzi, A.S.; Hemdi, A.; Othman, M.; Mohamed Noor, R. Manufacture of automotive component using reverse engineering and manufacturing additive techniques. ESTEEM Acad. J. 2023, 19, 63–74. [Google Scholar] [CrossRef]

- Zhang, X.; Cui, W.; Li, W.; Liou, F. A hybrid process integrating reverse engineering, pre-repair processing, additive manufacturing, and material testing for component remanufacturing. Materials 2019, 12, 1961. [Google Scholar] [CrossRef]

- Deja, M.; Dobrzyński, M.; Rymkiewicz, M. Application of reverse engineering technology in part design for shipbuilding industry. Pol. Marit. Res. 2019, 26, 126–133. [Google Scholar] [CrossRef]

- Afeez, A.; Sanjay Kumar, A. Application of CAD and reverse engineering methodology for development of complex assemblies. J. Eng. Des. Technol. 2013, 11, 375–390. [Google Scholar] [CrossRef]

- Gupta, D.; Trivedi, S.; Pandya, M.J. Application of Reverse Engineering for Generating Three Dimensional Model of Casing for Industrial Pump. Mater. Sci. 2023, 22, 180–188. [Google Scholar]

- Harston, S.P.; Mattson, C.A. Metrics for evaluating the barrier and time to reverse engineer a product. J. Mech. Des. 2010, 132, 041009. [Google Scholar] [CrossRef]

- Rochefort-Beaudoin, T.; Vadean, A.; Achiche, S.; Aage, N. From density to geometry: Instance segmentation for reverse engineering of optimized structures. Eng. Appl. Artif. Intell. 2025, 141, 109732. [Google Scholar] [CrossRef]

- Kaisarlis, G.J.; Diplaris, S.C.; Sfantsikopoulos, M.M. Position tolerancing in reverse engineering: The fixed fastener case. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 457–464. [Google Scholar] [CrossRef]

- Jamshidi, J.; Mileham, A.R.; Owen, G.W. Dimensional tolerance approximation for reverse engineering applications. In Proceedings of the DS 36: Proceedings DESIGN 2006, the 9th International Design Conference, Dubrovnik, Croatia, 15–18 May 2006; pp. 855–862. [Google Scholar]

- ISO 8062:1994; Castings—System of Dimensional Tolerances and Machining Allowances. International Organization for Standardization: Geneva, Switzerland, 1994.

- ANSI Y14.5M–1982; Dimensioning and Tolerancing. American National Standards Institute (ANSI): New York, NY, USA, 1982.

- Forslund, A.; Madrid, J.; Söderberg, R.; Isaksson, O.; Lööf, J.; Frey, D. Evaluating how functional performance in aerospace components is affected by geometric variation. SAE Int. J. Aerosp. 2018, 11, 5–26. [Google Scholar] [CrossRef]

- Dúbravčík, M.; Kender, Š. Application of reverse engineering techniques in mechanics system services. Procedia Eng. 2012, 48, 96–104. [Google Scholar] [CrossRef]

- Tóth, T.; Živčák, J. A comparison of the outputs of 3D scanners. Procedia Eng. 2014, 69, 393–401. [Google Scholar] [CrossRef]

- 3 Space. Advantages & Disadvantages of 3D Laser Scanning. January 2020. Available online: https://3space.com/advantages-disadvantages-of-3d-laser-scanning/ (accessed on 17 February 2025).

- Bugeja, A.; Bonanno, M.; Garg, L. 3D scanning in the art & design industry. Mater. Today Proc. 2022, 63, 718–725. [Google Scholar]

- Alba, M.I.; Barazzetti, L.; Scaioni, M.; Rosina, E.; Previtali, M. Mapping infrared data on terrestrial laser scanning 3D models of buildings. Remote Sens. 2011, 3, 1847–1870. [Google Scholar] [CrossRef]

- Shah, G.A.; Polette, A.; Pernot, J.P.; Giannini, F.; Monti, M. User-driven computer-assisted reverse engineering of editable CAD assembly models. J. Comput. Inf. Sci. Eng. 2022, 22, 021014. [Google Scholar] [CrossRef]

- Wang, W. Reverse Engineering: Technology of Reinvention; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Pourmostaghimi, V.; Heidari, F.; Khalilpourazary, S.; Qazani, M.R.C. Application of evolutionary optimization techniques in reverse engineering of helical gears: An applied study. Axioms 2023, 12, 252. [Google Scholar] [CrossRef]

- ISO 15530-3:2011; Geometrical Product Specifications (GPS)—Coordinate Measuring Machines (CMM): Technique for Determining the Uncertainty of Measurement—Part 3: Use of Calibrated Workpieces or Measurement Standards. International Organization for Standardization: Geneva, Switzerland, 2011.

| Review type | Systematic review |

| Databases | Google Scholar, Web of Science, Scopus, University of Oklahoma library |

| Paper Search Strategy | Boolean logic using keyword clusters |

| Paper selection tactics | Based on Preferred Reporting Items for Systematic reviews and Meta-Analyses (PRISMA) framework |

| Language | English only |

| Timeline (Year) | 2005–2025 |

| Inclusion criteria |

|

| Exclusion criteria |

|

| Author & Year | 3D Scanning Used | Internal Geometry Reconstructed | Simulation/FEA Used | Additive Manufacturing | Subtractive | Functional Optimization | Documentation/Redesign Purpose |

|---|---|---|---|---|---|---|---|

| Urbanic [23] | ✓ | ✗ | ✗ | ✗ | ✗ | ✓ | ✓ |

| Osipov et al. [24] | ✓ | ✗ | ✗ | ✗ | ✗ | ✗ | ✓ |

| Zhu et al. [25] | ✓ | ✗ | ✗ | ✓ | ✓ | ✗ | ✓ |

| Zhao et al. [26] | ✓ | ✗ | ✗ | ✓ | ✓ | ✗ | ✓ |

| Freddi et al. [5] | ✓ | ✗ | ✓ | ✗ | ✓ | ✓ | ✓ |

| Sedlák et al. [27] | ✓ | ✗ | ✗ | ✗ | ✗ | ✗ | ✗ |

| Sukumar et al. [28] | ✓ | ✗ | ✓ | ✗ | ✗ | ✗ | ✓ |

| Dong et al. [29] | ✗ | ✓ | ✗ | ✗ | ✗ | ✗ | ✓ |

| Huang et al. [30] | ✓ | ✓ | ✓ | ✓ | ✓ | ✗ | ✓ |

| Wang et al. [31] | ✓ | ✗ | ✓ | ✗ | ✗ | ✗ | ✓ |

| Patpatiya et al. [32] | ✓ | ✗ | ✗ | ✗ | ✗ | ✗ | ✓ |

| Li et al. [33] | ✓ | ✓ | ✓ | ✗ | ✓ | ✗ | ✓ |

| Sun et al. [34] | ✓ | ✗ | ✗ | ✗ | ✗ | ✗ | ✓ |

| Chiriță et al. [35] | ✓ | ✗ | ✗ | ✓ | ✓ | ✗ | ✓ |

| Rao et al. [36] | ✓ | ✓ | ✓ | ✗ | ✗ | ✗ | ✓ |

| Wang et al. [37] | ✗ | ✗ | ✗ | ✗ | ✗ | ✓ | ✓ |

| Hwang & Kim [38] | ✗ | ✗ | ✗ | ✗ | ✗ | ✓ | ✓ |

| Gameros et al. [39] | ✓ | ✓ | ✓ | ✗ | ✗ | ✗ | ✓ |

| Kašpar et al. [40] | ✓ | ✗ | ✓ | ✗ | ✗ | ✗ | ✓ |

| Lee et al. [41] | ✗ | ✗ | ✓ | ✗ | ✗ | ✓ | ✓ |

| Author & Year | Scanning Technique | Scan Data Processing Software | Post Processing CAD Software | Application |

|---|---|---|---|---|

| Subeshan et al. [71] | Non-contact laser scanning (HandySCAN 700 Scanner) | VX Element 7.0 | Fusion 360 | Stainless-steel lever |

| Pang & Fard [72] | Non-contact scanning (Flexscan and PSV-400 Scanner, Polytec Inc., Irvine, CA, USA, coupled with the Polytec scanning program) | Defeature tool of Geomagic | CATIA | Bell crank of a sidecar racing |

| Helle & Lemu [73] | Handheld non-contact 3D laser scanner | VX Scan and Model | Autodesk Inventor | Metal cylinder |

| Buonamici et al. [74] | 3D optical scanning (Romer RS1 on 7520-SI Absolute Arm by Hexagon metrology, Stockholm, Sweden) | RapidWorks (NextEngine version of Geomagic Design X) | Siemens NX | Electrical socket adapter (real part) |

| Yahaya et al. [75] | Non-contact 3D scanning with image capture (Sense 2 3D Scanner) | Not specified | SolidWorks | Honda billet distributor cover (automotive part) |

| Urbanic [23] | Non-contact laser scanning (Metris® LC50 mounted on DEA CMM) | Metris® scan curvature filter, Paraform® | Not explicitly stated (Paraform used for surfacing) | Valve cover, stamped panel, differential carrier |

| Zhang et al. [76] | Structured-light optical 3D scanning (OptimScan-5M, Shining 3D, Hangzhou, China) | - | Not explicitly stated | Pre-repair modeling of worn H13 tool steel block and casting die |

| Faizin et al. [55] | Photogrammetry (Sony A6000 camera, Tokyo, Japan) with calibrated targets | Agisoft Metashape, Google Colab + Blender + Meshroom | SolidWorks 2019 (Mesh2Surface add-in) | Boat propeller blade (marine application) |

| Roos et al. [65] | Neutron tomography (neutron CAT scanning mode) | Octopus (reconstruction), VGStudioMax | Not specified | Internal geometry of IS-60 Rover gas turbine components (e.g., diffuser, shaft, combustor liner) |

| Deja et al. [77] | Laser scanning (MMDx 100 on SMART Arm 7-axis system) | Geomagic Design X, Geomagic Wrap | Autodesk Inventor | Propeller shaft housing (marine propulsion system) |

| Afeez et al. [78] | Coordinate measuring machine (CMM) and manual methods | IDEAS NX 12 | IDEAS NX 12 | Crane cabin (TFC 280) with 300+ sheet metal parts |

| Gameros et al. [39] | Optical scanning (3Shape Q800) + X-ray CT (Zeiss METROTOM 1500) | Convince Analyzer + STL/NURBS reconstruction | Not specified | Nickel-based turbine blade with internal cooling channels |

| Othman et al. [44] | Laser scanning (Freescan UE-11, blue laser) | - | Autodesk Inventor, Altair Inspire | Brake calliper (Volkswagen Golf Mk6) redesign via RE and AM |

| Wang et al. [37] | Not specified (framework assumes mesh input) | Custom Visual C++ with OpenGL | Based on Open CASCADE | CAD model reconstruction from mesh data (e.g., blade, aircraft part, mechanical housing) |

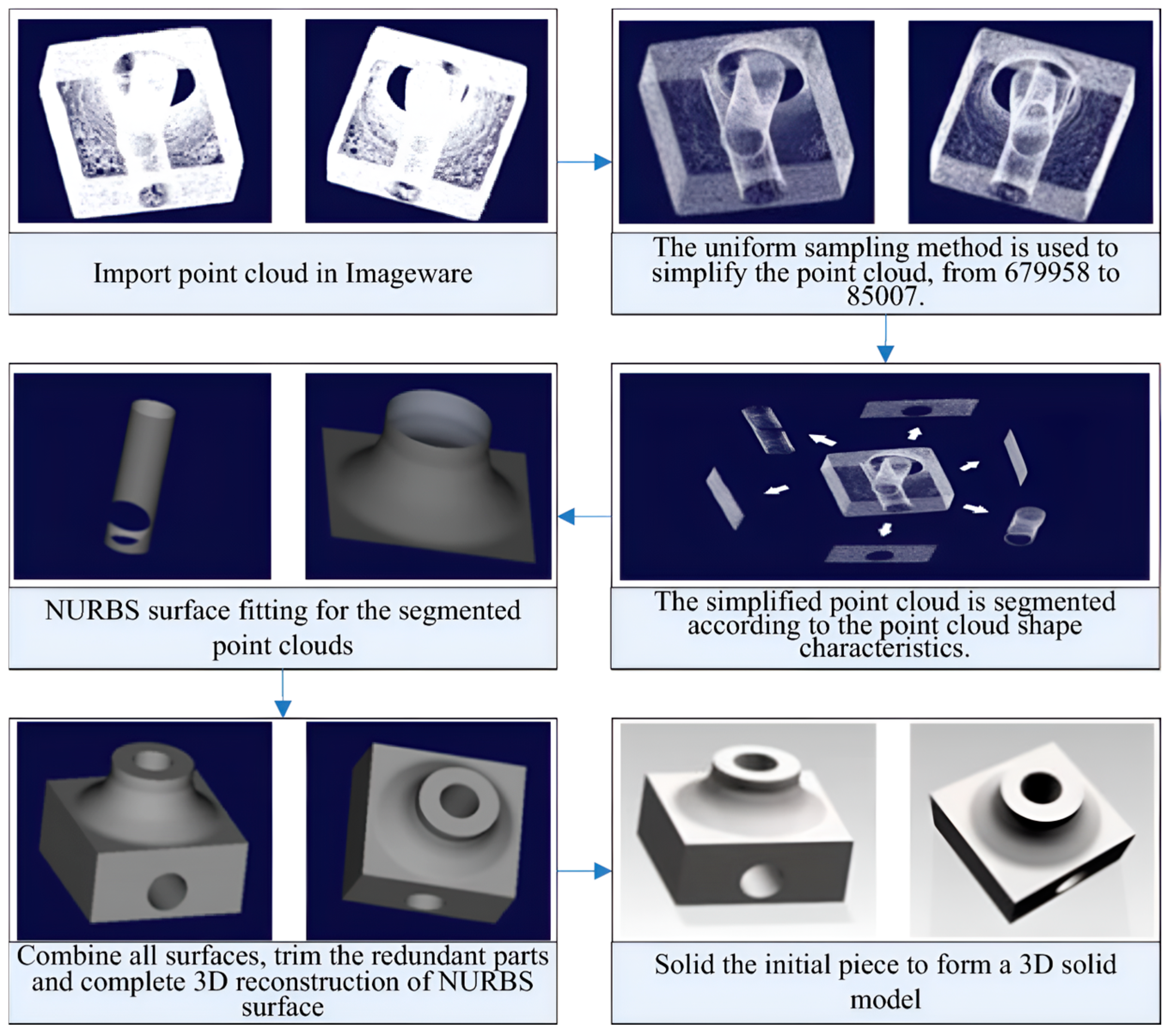

| Wang et al. [31] | Non-contact laser scanning (TianYuan OKIO-B-400) | Point cloud filtering, NURBS surface fitting in Imageware | UG (Siemens NX), ANSYS Workbench | Freeform surface acquisition and simulation-driven redesign of pump impeller |

| Rao et al. [36] | Photogrammetry (image-based 3D reconstruction) | Incremental Structure-from-Motion + Multi-view stereo + Delaunay triangulation | SolidWorks (visualization only) | Detection of internal defects in aluminum specimens using ERTM with point cloud-based geometry |

| Chiriță et al. [35] | Structured-light scanning (EinScan-SP V2) | - | SolidWorks | Remanufacturing hydraulic flowmeter rotor using RE and additive manufacturing |

| Li et al. [33] | Structured light scanning (GOM ATOS II-400) | Point cloud preprocessing, PCS + modified ICP | Pro/Engineer, CATIA | Reconstruction and repair of worn forging die and gear bracket using RE-aided additive/subtractive remanufacturing |

| Osipov et al. [24] | Laser scanning (Shining 3D FreeScan UE Pro, Hangzhou, China) | FreeScan software, Geomagic Design X | Geomagic Design X | RE of Capstone C 65 micro-GTU combustion chamber for 3D modeling and documentation |

| Zhu et al. [25] | Non-contact 3D scanning (OKIO-B, Beijing TenYoun 3D Technology Co., Ltd, China) | Geomagic Studio 11 | SolidWorks 2015 | Remanufacturing of broken 45 steel gear tooth using RE and laser cladding |

| Dong et al. [29] | Milling-based slicing with CCD imaging system | MATLAB, Imageware 13.1 | UG, Imageware | 3D reconstruction from cross-sectional images for components with internal geometry |

| Freddi et al. [5] | Laser scanning (FARO Quantum S with probe, Headquartered in Lake Mary, Florida, United States) | Geomagic Design X | Geomagic Design X | RE and performance optimization of KTM racing connecting rod |

| Zhao et al. [26] | Laser scanning (3D Family laser scanner) | Geomagic Studio (point cloud cleanup, IGES export) | UG NX (for tool path planning) | RE, laser additive repair, and milling of KMN steel compressor blades |

| Huang et al. [30] | 3D scanning with Power Scan-Pro scanner | Integral iteration method | SolidWorks | Incomplete information reconstruction and remanufacturing of turbine blades using RE, FEA, and laser cladding |

| Category | Challenge/Issue Identified | Solution/Recommendation | Author and Year |

|---|---|---|---|

| Product Complexity, Internal Geometry, and Physical Barriers | Lack of knowledge about which information is pertinent vs. superfluous | Define a taxonomy and analyze in a controlled reference frame where all info is assumed pertinent | Harston and Mattson [80] |

| Internal/hidden features and hollow geometries are difficult to capture, especially in complex parts | Use multimodal scanning (CT + structured light/laser); recreate hollows via CAD operations (e.g., extruded cuts) | Geng & Bidanda [6]; Yahaya et al. [76] | |

| Assemblies with mixed materials (e.g., steel vs. aluminum) create invisibility in scans | Separate components by density or pixel count; export as separate STL files | Roos et al. [65] | |

| Absence of 3D CAD data and technical specs for legacy parts | Use RE combined with additive manufacturing (AM) to reconstruct parts from scan data and system analysis | López & Vila [10] | |

| CT scans struggle with dense materials due to scatter/beam hardening | Supplement CT with optical scans | Gameros et al. [39] | |

| Freeform and curved geometries (e.g., propeller blades) are hard to measure | Application of photogrammetry-based RE (Agisoft Metashape + CAD) | Faizin et al. [55] | |

| Existing hole-repair/interpolation methods fail in high-curvature regions | Developed an outlier-plane based hole repair method | Sun et al. [34] | |

| Tolerance, Dimensional Accuracy, and Error Propagation | Dimensional errors accumulate across RE–AM workflow | Apply tolerance stacking and process control | Geng & Bidanda [6]; Forslund et al. [86] |

| CAD models of worn parts misrepresent original tolerances | Avoid worn regions; apply correction ratios; Use unit step integral iteration method to register damaged point cloud | Jamshidi et al. [83]; Huang et al. [30] | |

| Automated tolerance estimation is limited; manual assignment is error-prone and time-consuming | Develop surface texture–based conversion tables; apply hybrid/manual methods (MATLAB, Excel) | Jamshidi et al. [83]; Kaisarlis et al. [82] | |

| Non-uniform rational B-spline (NURBS) method captures roughness well but fails to extend internal geometry | Propose a hybrid method using primitives for internal structure and NURBS for external geometry | Helle & Lemu [73] | |

| Difficulty in aligning partial scans, defining datums, and managing symmetries | Use Iterative Closest Point (ICP)/global registration; apply knowledge-based rules for datum selection; validate through iterative optimization | Buonamici et al. [74]; Kaisarlis et al. [82]; Freddi et al. [5] | |

| Difficulty in assessing measurement uncertainty for internal structures and freeform surfaces | Proposed a modular freeform gage (MFG) using ISO 15530-3 [95] to enable uncertainty estimation and traceability for RE of complex surfaces | Gameros et al. [39] | |

| Scanning Limitations and Data Acquisition Challenges | Varying and unknown product complexity | Decompose product into information types (e.g., geometry, material) | Harston & Mattson [80] |

| Scanning accuracy affected by material reflectivity, transparency, surface flaws, and environmental conditions | Use powder/matte coatings; maintain stable conditions | Pang & Fard [72]; Tóth & Živčák [88] | |

| STL-based issues: lack of datum planes, poor scaling, no curvature, missing parametric/semantic data | Adjust scaling/planes before CAD import; rebuild geometry via triangulation; apply feature recognition to restore parametric models | Roos et al. [65]; Forslund et al. [86] | |

| Reflective surfaces and misaligned markers cause scan failure | Use reference geometries (e.g., plastic pyramid) and rotate parts | Helle & Lemu [73] | |

| Mesh quality issues: noise, holes, discontinuities, outliers, and free-standing triangles | Use mesh cleaning, smoothing, and repair (e.g., Geomagic fill/bridge/Relaxpolygons; noise filters) | Deja et al. [77]; Geng & Bidanda [6]; López & Vila [10]; Šagi et al. [63]; Pang & Fard [72]; Yahaya et al. [76] | |

| Photogrammetry heavily depends on photo quality, lighting, and angles | Capture dense, well-distributed images (e.g., 40+) and process with advanced software | Faizin et al. [55] | |

| Process Integration, Post-processing Challenges | Critical manufacturing details (e.g., heat treatment) often missed, leading to part failure | Capture post-processing info alongside geometry/material | Curtis et al. [19] |

| RE data (point clouds, meshes, models) poorly integrated into PLM | Standardize formats and annotate metadata for traceability | Forslund et al. [86] | |

| Difficulty selecting AM/CM processes and materials for spare part recovery | Use structured RE-AM methodology with criteria (lead time, cost, performance) | López & Vila [10] | |

| Topology optimization produces non-manufacturable outputs | Re-model in CAD with fillets and smoothed profiles | Pang & Fard [72] | |

| Human, Material, and Process-Specific Limitations | Lack of operator skills leads to misinterpretation of design intent | Use experienced multidisciplinary teams and specialized RE software | Curtis et al. [19]; Freddi et al. [5] |

| Lack of tolerance data makes CAD model creation experience-driven | Develop tolerance approximation methods using surface/machining textures | Jamshidi et al. [83] | |

| Used parts exhibit uncertain geometry/damage (wear, corrosion, stress) | Apply finite element analysis to predict life and remanufacturing worthiness | Huang et al. [30] | |

| Lack of traceability and accuracy in optical scanning validation | Use tactile CMM and modular freeform gages as reference | Gameros et al. [39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Debnath, B.; Pourfarash, Z.; Ghorpade, B.; Raman, S. Integrating Reverse Engineering for Digital Model Reconstruction and Remanufacturing of Mechanical Components: A Systematic Review. Metrology 2025, 5, 66. https://doi.org/10.3390/metrology5040066

Debnath B, Pourfarash Z, Ghorpade B, Raman S. Integrating Reverse Engineering for Digital Model Reconstruction and Remanufacturing of Mechanical Components: A Systematic Review. Metrology. 2025; 5(4):66. https://doi.org/10.3390/metrology5040066

Chicago/Turabian StyleDebnath, Binoy, Zahra Pourfarash, Bhairavsingh Ghorpade, and Shivakumar Raman. 2025. "Integrating Reverse Engineering for Digital Model Reconstruction and Remanufacturing of Mechanical Components: A Systematic Review" Metrology 5, no. 4: 66. https://doi.org/10.3390/metrology5040066

APA StyleDebnath, B., Pourfarash, Z., Ghorpade, B., & Raman, S. (2025). Integrating Reverse Engineering for Digital Model Reconstruction and Remanufacturing of Mechanical Components: A Systematic Review. Metrology, 5(4), 66. https://doi.org/10.3390/metrology5040066