- Article

Production and Characterization of Ti-6Al-4V Foams Produced by the Replica Impregnation Method

- Aynur İnan Üstün and

- Hasan Okuyucu

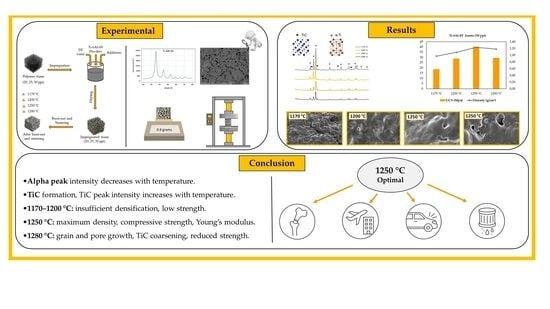

Porous Ti-6Al-4V foams are excellent materials due to their low density, high specific strength, and excellent biocompatibility. This study investigates the fabrication of open-cell Ti-6Al-4V foams using the replica impregnation method with polyurethane templates of varying pore sizes (20, 25, and 30 ppi) and sintering temperatures (1170 °C, 1200 °C, 1250 °C, and 1280 °C). The effects of these parameters on microstructural evolution, phase composition, and mechanical properties were examined. Microstructural analysis showed that optimum densification occurred at 1250 °C. However, at 1280 °C, excessive grain growth and pore coarsening were observed. XRD, SEM, and EDS analyses confirmed that α-Ti was the matrix phase, while titanium carbide formed in situ as a result of the carbon residues released from the decomposed polyurethane template. With the development of the TiC phase and enhanced interparticle bonding due to sintering, the compressive strength progressively increased up to 1250 °C. At 1280 °C, strength decreased due to excessive TiC growth, causing brittleness and pore coarsening, reducing structural integrity. Maximum compressive strength of 40.2 MPa and elastic modulus of 858.9 MPa were achieved at 1250 °C with balanced TiC dispersion and pore structure. Max density of 1.234 g/cm3 was obtained at 1250 °C. Gibson-Ashby analysis and the fracture surfaces confirmed the brittle behavior of the foams, which is attributed to the presence of TiC particles and microcracks in the structure. The study concludes that 1250 °C provides an ideal balance between densification and structural integrity, offering valuable insights for biomedical and structural applications.

9 December 2025