1. Introduction

Research and development regarding the electric arc furnace (EAF) started as early as the late 19th century. In 1888, Paul Héroult patented an EAF featuring direct heating of the metal charge. It became the basis for an industrial prototype in 1899 and for industrial-scale steel production in 1907 []. However, the EAF only became a major steelmaking process after World War II, with large-scale EAF plants emerging from the 1950s onward []. Since then, improvements in transformer capacity have enabled an increase in EAF capacities—from 5–25 tons in first-generation (regular power (RP)) furnaces to as much as 400 tons in fourth-generation (super-ultra-high power (SUHP)) furnaces [].

Today, the EAF is unquestionably one of the key unit processes in modern steelmaking and a cornerstone of the mini mill concept []. The EAF is flexible in terms of both raw materials and energy input: scrap and other iron-bearing materials, such as direct-reduced iron (DRI) and hot-briquetted iron (HBI), can be melted in any ratio, and the electrical energy input can be supplemented with additional chemical energy from burners and injectors to expedite melting [,]. The DRI or HBI can be charged in buckets or fed continuously [].

In 2024, electric steelmaking accounted for approximately 29% of global crude steel production of 1885 Mt []. In many highly developed regions, such as North America and Europe, the share is significantly higher. Considering the transformation strategies of integrated steelworks to decarbonize production, together with increasing scrap availability in Asia, it is expected that the share of scrap-based EAF steelmaking will continue to rise in the coming decades.

The global DRI production in 2024 was only 144 Mt [], but it is geographically concentrated in countries with access to inexpensive natural gas, which is used as the reductant []. In that year, the top three producers—India, Iran, and Saudi Arabia—accounted for approximately two-thirds of global DRI production [].

In recent years, ambitious plans to produce CO2-lean steel by melting or smelting DRI obtained through hydrogen direct reduction (H-DR), with or without the use of accompanying natural gas, have been announced. Launched in 2017, the Hydrogen Breakthrough Ironmaking Technology (HYBRIT) initiative represents a collaboration between the Swedish companies Vattenfall, LKAB, and SSAB aiming to study steelmaking based on the H-DR–EAF route, with the ambitious goal of reducing CO2 emissions to 25 kg per ton of steel []. To demonstrate hydrogen direct reduction, a pilot plant with a capacity of 1 ton per hour was constructed in Luleå, Sweden, and it became operational in 2020 []. The HYBRIT concept has attracted interest from both the general public and steelmaking companies. In the Nordic countries, the publicly announced plans of Blastr Green Steel (Inkoo, Finland) [], Stegra (Boden, Sweden) [], and SSAB (Luleå, Sweden) [] all follow the H-DR–EAF route. In the case of limited DRI availability, this route allows flexible use of DRI–scrap mixtures. Both the total energy demand and the amount of slag generated increase with higher DRI/scrap ratios []. The overall slag volumes are lower than in the case of the blast furnace (BF)–basic oxygen furnace (BOF) route []. However, the high basicity and the prevalent RO phase, which lacks hydraulic properties, complicate the direct use of H-DRI-based EAF slags as a supplementary cementitious material (SCM) to compensate for the decreasing production of granulated blast furnace slag [].

While the H-DR–EAF route is well suited for melting high-quality DRI, the high gangue content of low-quality DRI results in large EAF slag volumes due to the basicity requirements (B2 = CaO/SiO2 ≈ 2) of the foaming slag practice []. In combination with FeO contents above 20 wt%, this leads to a significant loss of iron yield []. Consequently, processing low-quality DRI is expected to be more economical in an electric smelting furnace (ESF), with the resulting hot metal subsequently refined in a BOF [,]. An ESF is operated with a slag basicity of B2 ≈ 1, which is close to that of BF slag and is therefore expected to allow its direct use as an SCM, as with BF slag []. A pilot-scale ESF plant was built in Pori, Finland, by Metso []. Furthermore, the German conglomerate ThyssenKrupp has announced plans to implement the H-DR–ESF–BOF route at its Duisburg site []. The strong interest in DRI-based steelmaking has broadened the scope of EAF research to include the processing of H-DRI and has established ESFs as a significant new research area in steelmaking.

Global stainless-steel production has continued its strong growth in the 21st century, reaching a new record of 62.6 Mt in 2024 []. Modern stainless-steel production is predominantly based on scrap-based EAF steelmaking, followed by argon–oxygen decarburization (AOD), known as the duplex route, or a combination of AOD and vacuum oxygen decarburization (VOD), known as the triplex route []. Aside from reducing its direct CO2 emissions, the efforts to decarbonize EAFs in stainless steelmaking are largely linked to lowering the CO2 footprint with respect to both the electricity and raw materials used. In this regard, the decarbonization of ferrochrome production is of particular importance, as ferrochrome provides the chromium required for alloying.

Arc furnaces have recently attracted a substantial amount of additional research attention due to the strong academic interest in hydrogen plasma-smelting reduction (HPSR) [], which can be applied either as a one-step process for melting, reduction, and refining or alongside pre-reduction using hydrogen []. Much of the research interest in HPSR, such as arc stability [], impurity removal [], and refractory concepts [], aligns with the approaches studied in the field of EAF research.

In view of the developments outlined above, the importance of EAFs as a research area remains as significant as ever. In this Special Issue of Metals, we present contributions pertaining to recent advances in EAF steelmaking. This editorial is intended to provide an introduction to and overview of the papers included in the Special Issue as well as selected highlights.

2. Overview of the Contributions

A total of eight peer-reviewed articles, comprising seven original articles and one review article, were published as part of this Special Issue (see Table 1). The papers cover many of the key aspects of the EAF process, ranging from raw materials via melting and slag foaming to impurity removal.

Table 1.

Overview of the articles in this Special Issue.

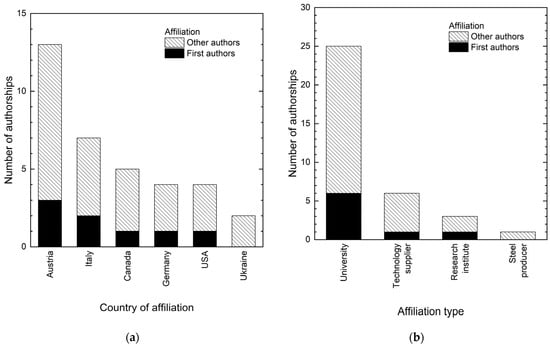

The papers feature authors affiliated with institutions and companies from six countries (see Figure 1a), with universities being the most common affiliation for both first and subsequent authors (see Figure 1b). Nevertheless, some authors are affiliated with technology suppliers, research institutes, or steel producers. In total, the papers list 35 authorships, representing 30 unique individuals, with an average of four authors per paper.

Figure 1.

Number of authorships by (a) country of affiliation and (b) affiliation type.

3. Highlights

3.1. DRI-Based EAF Steelmaking

An important open question in DRI-based steelmaking is as follows: what is the most effective way to alloy carbon into the steel? Carbon can be introduced either through DRI carburization or by carburizing the melt in the EAF. Another challenge associated with the use of DRI is its potential reoxidation during transport and storage. It is therefore fitting that this Special Issue includes a review paper by Kieush et al. (Contribution 8), which provides a comprehensive discussion of the current understanding of these aspects. The study concludes that the presence of carbon in the DRI offers some benefits for processing in the EAF compared to carbon-alloying directly in the EAF. The briquetting of DRI was identified as one of the most effective countermeasures against reoxidation. Finally, it is noted that the literature on the reoxidation of H-DRI remains scarce, representing an important research gap that should be addressed in future studies.

H-DRI melting has recently been studied by many research groups. The aspects investigated aspects include melting in a high-temperature atmosphere [,], the modelling of melting in molten steel [], experimental [] and numerical [] studies of melting in slag, the modelling of capillary infiltration of slag into pores [], the experimental study of optical emissions during melting [], and the characterization of the resulting slags []. In this Special Issue, the paper by Pfeiffer et al. (Contribution 7) investigates the differences in the melting behavior of carbon-free and carbon-containing DRI. Melting trials in a laboratory-scale EAF were conducted to compare carbon-free and carbon-containing DRI from DR-grade pellets as well as fines from a fluidized bed reactor. In a fourth trial, the influence of a slag layer was investigated by melting DRI from BF-grade pellets with the continuous addition of slag-forming oxides. The authors confirmed that feeding DRI into the EAF hot spot is important for the rapid melting of the material. Furthermore, the authors found that a higher carbon content in the DRI is beneficial for the melting stage, leading them to state that the optimal condition is “a highly carburized DRI that is fed directly into the electric arc hot spot”.

3.2. Substitution of Fossil Carbon

Fossil carbon is one of the main sources of CO2 emissions in EAF steelmaking, with estimates indicating that its use leads to around 43 kg of CO2 per ton of steel, corresponding to 40–70% of the total direct CO2 emissions []. Consequently, the substitution of fossil carbon with non-fossil carbon materials has attracted interest, particularly in Europe. One potential application of biochar in an EAF is slag foaming []. In this Special Issue, Kieush et al. (Contribution 6) present a study on the thermochemical properties of biocoke to which wood pellets have been added, focusing on its potential applications for slag foaming in EAFs. It was found that biocoke supplemented with 5 wt% wood pellets could yield even better slag-foaming characteristics than conventional laboratory-scale coke, which was used as reference. At a higher wood pellet content of 10 wt%, the slag-foaming properties were slightly worse than those obtained with coke. However, due to their higher reactivity, the biocokes supplemented with wood pellets exhibited shorter foaming times. These results highlight the potential of biocoke for slag foaming and the need to carefully adjust its recipe.

The substitution of fossil carbon is also a topic in the valorization of steelmaking waste like mill scale. In this Special Issue, Dall’Osto et al. (Contribution 2) investigate how the physicochemical properties of biogenic carbon influence both the manufacturing and industrial transferability of mill-scale-based self-reducing briquettes. The authors systematically characterize several biogenic carbon candidates and mill scale and correlate their attributes with briquetting behavior (via impact resistance, cold compression, and water immersion resistance tests) and reduction performance. They show that the hydrophilicity or hydrophobicity of the reducing agents indirectly controls the mechanical performance of the briquettes produced. Furthermore, iron recovery is regulated by the amount of fixed carbon and volatile matter in the agglomerate. Building on these results, the authors formulate subsequent research topics to be addressed, including briquette charging conditions, the reduction behavior of briquettes in interaction with slag and metal, and the influence of briquette addition on steel quality and melting furnace productivity. Overall, this study reveals a viable pathway for recycling mill scale with biogenic reductants in melting furnaces like EAFs.

3.3. Modeling and Simulation

Substantial efforts have been dedicated to developing models that simulate different aspects of the EAF process [,,]. In this Special Issue, modelling and simulation play a significant role in the studies by Azzaz et al. (Contribution 1), Reinicke et al. (Contribution 3), and Ugarte et al. (Contribution 5). The vastly different approaches described in these papers highlight the variety of methods available for numerical modelling and simulation.

Models based on machine learning approaches are particularly popular for endpoint prediction regarding off-gas composition, carbon content, metal bath temperature, energy consumption, etc. [,]. In this Special Issue, Azzaz et al. (Contribution 1) studied the use of machine learning models to predict the final P content in the scrap-based EAF process. Models based on random forest, support vector machine, and artificial neural network (ANN) approaches were tested. The ANN models employed the Adam optimizer and a nonlinear sigmoid activation function, with varying numbers of hidden layers. Among the models tested, the ANN model with four hidden layers proved to be the most effective. The results indicate that the final P content was highly correlated with the Cr and S content in scrap, injected oxygen, and process duration (p-value < 0.01) and moderately correlated with scrap weight, the Mn content of the scrap, and the amount of lime injected (0.01 < p-value < 0.05).

Process models are a loosely defined group of models. Generally, the aim is to describe the dynamics of a process based on known process variables. Phenomena-based process models are invariably based on mass and heat balances and are usually combined with simplified descriptions of local mass and heat transfer, without a spatial solution of momentum transfer as in computational fluid dynamics (CFD) models. Such models for the EAF process were recently reviewed by Hay et al. []. The dynamic process model developed at RWTH Aachen University, which is strongly influenced by the model developed by Logar et al. [,] at the University of Ljubljana, was first developed by Meier [] and subsequently modified by Hay []. In this Special Issue, the paper by Reinicke et al. (Contribution 3) continues this line of modelling work by introducing an ANN-based surrogate model for the activity of slag species that was trained using simulation data from FactSage. More specifically, the activities were approximated with a shallow feedforward ANN consisting of an input layer (slag composition and temperature), an output layer (activities), and a single hidden layer, in which a rectified linear unit was used to achieve nonlinear transformation. The performance of the ANN-based surrogate model was benchmarked against that of the regular solution model (RSM) and the cell model (CM) implemented earlier by Hay []. While the comparison with FactSage simulations does not directly demonstrate the accuracy of the models relative to experimental data, it seems reasonable to assume that the FactSage simulations are sufficiently close to the experimental data for the EAF slag systems considered. As expected, the ANN-based surrogate model performed substantially better than RSM or CM both in terms of mean absolute error and coefficient of determination. The process model was somewhat slower when using the ANN-based surrogate model (0.115 s for 1000 samples) than when using RSM (0.037 s), but it was substantially faster than when CM was used (9.848 s). These results indicate that although the ANN-based surrogate model requires prior training with synthetic data, its substantial accuracy improvement over both RSM and CM, combined with its significant performance improvement over CM, makes it the preferred option in all cases except when the fastest possible execution speed is required or when the model is deliberately applied outside the validity range of the ANN-based surrogate model.

Ugarte et al. (Contribution 5) studied the impact of the oxygen injection rate on mixing using CFD simulations performed in ANSYS (Fluent version 2019). First, the supersonic coherent jet was simulated as a compressible, non-isothermal flow under steady-state conditions, providing velocity profiles and spatial variations in gas flow composition from the burner tip to the bath surface. In the second step, these outputs were used to estimate the cavities formed by the gas jets through empirical correlations. Finally, the authors constructed the geometry of the metal bath in an industrial EAF, incorporating the cavities calculated in the second step, and used it for transient refining simulations in the impact area domain. The authors found that assigning the highest flow rates to coherent jets positioned opposite each other across the furnace reduced the mixing time by about 10% compared to the baseline case.

3.4. System-Level Investigations

At the system level, Dall’Osto et al. (Contribution 4) analyze the consequences of creating a national direct reduction and electric steelmaking grid for Italy, moving beyond furnace-scale phenomena to the orchestration of assets, infrastructures, and markets. Starting from the current Italian production portfolio, which is strongly EAF-oriented for long products and still reliant on BF–BOF for flat products, they develop scenarios in which BF–BOF capacity is progressively replaced by DR–EAF. The scenarios address three different pathways, based on natural gas, green hydrogen, and biomethane as the main gas stream, and show how the emissions and energy demand of the Italian steel sector could change during the establishment of a DR–EAF grid. The authors found that although in principle each of the pathways could be feasible, the development of the production share of the DR–EAF grid in the future is vitally linked to the development of a national renewable energy policy and the generation of biomethane production capacity as well as meeting the ambitious 2050 targets for the Italian renewable energy grid.

4. Conclusions

Driven by the increasing availability of scrap and plans to replace BF-based ironmaking with DRI production, both scrap- and DRI-based steelmaking are projected to increase in the future. This trend not only highlights the importance of EAF research but also broadens its scope, particularly regarding the role of EAFs in direct reduction routes.

The eight peer-reviewed papers included in this Special Issue address many of the hot topics in current EAF research, such as DRI handling, DRI melting, the use of biocoke for slag foaming, and dephosphorization. The results presented highlight the suitability of biocoke supplemented with wood pellets for slag foaming, the usefulness of feeding DRI into the electric arc hot spot, factors governing the mechanical performance and iron recovery of mill-scale-based self-reducing briquettes, etc.

Regarding modelling and simulation, the boundaries between different approaches are beginning to blur, as machine learning methods are used both independently and to support other types of simulation activities. In process modelling, models can be accelerated using surrogate models to describe simulation results for properties with complex dependencies, such as the activities of species in the slag. A detailed CFD simulation of the entire EAF process—including heat transfer and chemical reactions—within an industrially reasonable timeframe remains a formidable challenge. However, the increasing availability of computational resources enables the use of detailed modelling approaches to simulate individual aspects of the process.

Author Contributions

Conceptualization, V.-V.V.; methodology, V.-V.V. and T.E.; writing—original draft preparation, V.-V.V.; writing—review and editing, V.-V.V. and T.E.; visualization, V.-V.V.; project administration, V.-V.V. and T.E. All authors have read and agreed to the published version of the manuscript.

Funding

V.-V.V. was supported by the CO2-lean electric arc furnace steelmaking through fundamental and data-driven mathematical modelling (LEAF) project (no. 356439), funded by the Research Council of Finland, and by the Towards Carbon Neutral Metals 2 (TOCANEM 2), funded by Business Finland.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

Rita Kallio, Ilpo Mäkelä, Saku Rytky, and Petri Sulasalmi from the University of Oulu are acknowledged for their fruitful discussions on various aspects of the EAF process.

Conflicts of Interest

The authors declare no conflicts of interest.

List of Contributions

- Azzaz, R.; Jahazi, M.; Ebrahimi Kahou, S.; Moosavi-Khoonsari, E. Prediction of Final Phosphorus Content of Steel in a Scrap-Based Electric Arc Furnace Using Artificial Neural Networks. Metals 2025, 15, 62.

- Dall’Osto, G.; Mombelli, D.; Scolari, S.; Mapelli, C. Role of the Biogenic Carbon Physicochemical Properties in the Manufacturing and Industrial Transferability of Mill Scale-Based Self-Reducing Briquettes. Metals 2024, 14, 882.

- Reinicke, A.; Engbrecht, T.-N.; Schüttensack, L.; Echterhof, T. Application of an Artificial Neural Network for Efficient Computation of Chemical Activities within an EAF Process Model. Metals 2024, 14, 736.

- Dall’Osto, G.; Mombelli, D.; Mapelli, C. Consequences of the Direct Reduction and Electric Steelmaking Grid Creation on the Italian Steel Sector. Metals 2024, 14, 311.

- Ugarte, O.; Busa, N.; Konar, B.; Okosun, T.; Zhou, C.Q. Impact of Injection Rate on Flow Mixing during the Refining Stage in an Electric Arc Furnace. Metals 2024, 14, 134.

- Kieush, L.; Schenk, J.; Koveria, A.; Hrubiak, A. Biocoke Thermochemical Properties for Foamy Slag Formations in Electric Arc Furnace Steelmaking. Metals 2023, 14, 13.

- Pfeiffer, A.; Ernst, D.; Zheng, H.; Wimmer, G.; Schenk, J. The Behavior of Direct Reduced Iron in the Electric Arc Furnace Hotspot. Metals 2023, 13, 978.

- Kieush, L.; Lesiak, S.; Rieger, J.; Leitner, M.; Schmidt, L.; Daghagheleh, O. Reoxidation Behavior of the Direct Reduced Iron and Hot Briquetted Iron during Handling and Their Integration into Electric Arc Furnace Steelmaking: A Review. Metals 2024, 14, 873.

References

- Karbowniczek, M. Electric Arc Furnace Steelmaking; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Cappel, J.; Ahrenhold, F.; Egger, M.W.; Hiebler, H.; Schenk, J. 70 Years of LD-Steelmaking—Quo Vadis? Metals 2022, 12, 912. [Google Scholar] [CrossRef]

- Madias, J. Electric Furnace Steelmaking. In Treatise on Process Metallurgy, 2nd ed.; Volume 3: Industrial Processes; Seetharaman, S., Guthrie, R., McLean, A., Seetharaman, S., Sohn, H.Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 243–265. [Google Scholar]

- Klein, K.-H.; Schindler, J.E. Metallurgie bei Schrotteinsatz. In Elektrostahl-Erzeugung; Heinen, K.-H., Ed.; Verlag Stahleisen GmbH: Düsseldorf, Germany, 1997; pp. 473–502. [Google Scholar]

- Walden, K. Metallurgie bei Eisenschwammeinsatz. In Elektrostahl-Erzeugung; Heinen, K.-H., Ed.; Verlag Stahleisen GmbH: Düsseldorf, Germany, 1997; pp. 503–511. [Google Scholar]

- World Steel Association. World Steel in Figures 2025; World Steel Association: Beijing, China, 2025. [Google Scholar]

- Ariyama, T. Perspectives on the Promising Pathways to Zero Carbon Emissions in the Steel Industry toward 2050. ISIJ Int. 2025, 65, 165–184. [Google Scholar] [CrossRef]

- Pei, M.; Petäjäniemi, M.; Regnell, A.; Wijk, O. Toward a Fossil Free Future with HYBRIT: Development of Iron and Steelmaking Technology in Sweden and Finland. Metals 2020, 10, 972. [Google Scholar] [CrossRef]

- Blastr Green Steel. Blastr Green Steel Chooses Primetals Technologies as Its Technological Partner for the Ultra-Low CO2 Emissions Steel Plant in Inkoo, Finland. Blastr Green Steel, 9 July 2024. [Google Scholar]

- SMS Group. The World’s First Carbon-Neutral Steel Plant. Available online: https://www.sms-group.com/plants/projects/stegra (accessed on 11 November 2025).

- SSAB. The Deputy Prime Minister and SSAB’s CEO Broke Ground on a New Steel Mill in Luleå. SSAB, 17 September 2025. [Google Scholar]

- Hassan, A.; Kotelnikov, G.; Abdelwahed, H. Melting Characteristics of Alternative Charging Materials in an Electric Arc Furnace Steelmaking. Ironmak. Steelmak. 2021, 48, 1136–1141. [Google Scholar] [CrossRef]

- Kallio, R.; Cantaluppi, M.; Louhisalmi, J.; Visuri, V.-V. Mineralogical Characteristics of Fossil-Free Steel Slags. Miner. Eng. 2025, 230, 109396. [Google Scholar] [CrossRef]

- Wimmer, G.; Voraberger, B.; Kradel, B.; Fleischanderl, A. Breakthrough Pathways to Decarbonize the Steel Sector. Mitsubishi Heavy Ind. Tech. Rev. 2022, 59, 1–7. [Google Scholar]

- Wimmer, G.; Voraberger, B.; Rosner, J.; Pfeiffer, A. Smelter—Green Steelmaking Using Low-Grade DRI. In Proceedings of the Iron & Steel Technology Conference, Columbus, OH, USA, 6–9 May 2024; pp. 180–187. [Google Scholar]

- Metso. Metso Opens DRI Smelting Furnace Pilot Facility in Pori, Finland. Metso, 25 October 2024. [Google Scholar]

- Weinberg, M. Transformation of Steel Production. In Proceedings of the Plenary presentation—13th European Electric Steelmaking Conference, Essen, Germany, 3–7 June 2024; Steel Institute VDEh: Essen, Germany, 2024. [Google Scholar]

- Worldstainless. Stainless Steel Melt Shop Production Increases by 7% in 2024. Worldstainless, 14 April 2025. [Google Scholar]

- Visuri, V.-V.; Holappa, L. Converter Steelmaking. In Treatise on Process Metallurgy—Volume 3: Industrial Processes; Seetharaman, S., Guthrie, R., McLean, A., Seetharaman, S., Sohn, H.Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 183–241. [Google Scholar]

- Satritama, B.; Cooper, C.; Fellicia, D.; Pownceby, M.I.; Palanisamy, S.; Ang, A.; Mukhlis, R.Z.; Pye, J.; Rahbari, A.; Brooks, G.A.; et al. Hydrogen Plasma for Low-Carbon Extractive Metallurgy: Oxides Reduction, Metals Refining, and Wastes Processing. J. Sustain. Metall. 2024, 10, 1845–1894. [Google Scholar] [CrossRef]

- Adami, B.; Hoffelner, F.; Zarl, M.A.; Schenk, J. Strategic Selection of a Pre-Reduction Reactor for Increased Hydrogen Utilization in Hydrogen Plasma Smelting Reduction. Processes 2025, 13, 420. [Google Scholar] [CrossRef]

- Zarl, M.A.; Farkas, M.A.; Schenk, J. A Study on the Stability Fields of Arc Plasma in the HPSR Process. Metals 2020, 10, 1394. [Google Scholar] [CrossRef]

- Büyükuslu, Ö.K.; Aota, L.S.; Raabe, D.; Springer, H.; Souza Filho, I.R. Mechanisms and Elemental Partitioning during Simultaneous Dephosphorization and Reduction of Fe-O-P Melts by Hydrogen Plasma. Acta Mater. 2024, 277, 120221. [Google Scholar] [CrossRef]

- Sassi, E.-M. Slag and Refractory Interactions in Hydrogen Plasma Smelting Reduction. Master’s Thesis, University of Oulu, Oulu, Finland, 2025. [Google Scholar]

- Huss, J.; Vickerfält, A.; Kojola, N. Some Aspects of the Melting and Dephosphorization Mechanism of Hydrogen-DRI. Steel Res. Int. 2023, 94, 2300064. [Google Scholar] [CrossRef]

- Vickerfält, A.; Huss, J.; Martinsson, J.; Sichen, D. Reaction Mechanisms During Melting of H-DRI Focusing on Slag Formation and the Behavior of Vanadium. Metall. Mater. Trans. B 2023, 54, 2206–2215. [Google Scholar] [CrossRef]

- Govro, J.; Meena, A.; Chakraborty, S.; Meshram, A.; Korobeinikov, Y.; Phillips, K.; Athavale, V.; Bartlett, L.; Smith, J.; Emdadi, A.; et al. Melting Behavior of Hydrogen-Reduced DRI in a Simulated EAF Steel Bath. Iron Steel Technol. 2023, 20, 58–63. [Google Scholar]

- Huss, J.; Vickerfält, A.; Kojola, N. The Melting Mechanism of Hydrogen Direct Reduced Iron in Liquid Slag. Steel Res. Int. 2024, 95, 2300325. [Google Scholar] [CrossRef]

- Svantesson, J.; Kojola, N.; Ersson, M. Numerical Study on the Effect of Material Parameters and Process Conditions on the Melting Time of Hydrogen-Direct Reduced Iron. Metall. Mater. Trans. B 2025, 56, 2846–2872. [Google Scholar] [CrossRef]

- Svantesson, J.L.; Ersson, M.; Kojola, N. Capillary Infiltration of Slag in Hydrogen-Direct Reduced Iron and Influence on Melting. ISIJ Int. 2025, 65, 1607–1619. [Google Scholar] [CrossRef]

- Pauna, H.; Kokkonen, T.; Cavaliere, P.; Bayat, M.; Mirowska, A.; Alatarvas, T.; Huttula, M.; Fabritius, T. Hydrogen Direct Reduced Iron Melting in an Electric Arc Furnace: Benefits of In Situ Monitoring. J. Sustain. Metall. 2025, 11, 1–13. [Google Scholar] [CrossRef]

- Demus, T.; Echterhof, T.; Pfeifer, H.; Schulten, M.; Noel, Y.; Quicker, P. Investigations on the Use of Biogenic Residues as a Substitute for Fossil Coal in the EAF Steelmaking Process. In Proceedings of the 10th European Electric Steelmaking Conference, Graz, Austria, 25–28 September 2012; ASMET: Graz, Austria, 2012. [Google Scholar]

- Liu, X.; Yan, W. Current Advances in Slag Foaming Processes toward Reduced CO2 Emission for Electric Arc Furnace Steelmaking. J. CO2 Util. 2024, 90, 102979. [Google Scholar] [CrossRef]

- Odenthal, H.-J.; Kemminger, A.; Krause, F.; Sankowski, L.; Uebber, N.; Vogl, N. Review on Modeling and Simulation of the Electric Arc Furnace (EAF). Steel Res. Int. 2018, 89, 1700098. [Google Scholar] [CrossRef]

- Carlsson, L.S.; Samuelsson, P.B.; Jönsson, P.G. Predicting the Electrical Energy Consumption of Electric Arc Furnaces Using Statistical Modeling. Metals 2019, 9, 959. [Google Scholar] [CrossRef]

- Hay, T.; Visuri, V.-V.; Aula, M.; Echterhof, T. A Review of Mathematical Process Models for the Electric Arc Furnace Process. Steel Res. Int. 2021, 92, 2000395. [Google Scholar] [CrossRef]

- Niyayesh, M.; Yilmaz, U. Predicting Endpoint Parameters of Electric Arc Furnace–Based Steelmaking Using Artificial Neural Network. Int. J. Adv. Manuf. Tech. 2025, 138, 155–167. [Google Scholar] [CrossRef]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modeling and Validation of an Electric Arc Furnace: Part 1, Heat and Mass Transfer. ISIJ Int. 2012, 52, 402–412. [Google Scholar] [CrossRef]

- Logar, V.; Dovžan, D.; Škrjanc, I. Modeling and Validation of an Electric Arc Furnace: Part 2, Thermo-Chemistry. ISIJ Int. 2012, 52, 413–423. [Google Scholar] [CrossRef]

- Meier, T. Modellierung und Simulation des Elektrolichtbogenofens. Doctoral Thesis, RWTH Aachen University, Aachen, Germany, 2016. [Google Scholar]

- Hay, T.A. Mathematische Modellierung des Elektrostahlverfahrens. Doctoral Thesis, RWTH Aachen University, Aachen, Germany, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).