Journal Description

Textiles

Textiles

is an international, peer-reviewed, open access journal on textile science and engineering published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within ESCI (Web of Science), Scopus, EBSCO and other databases.

- Journal Rank: JCR - Q1 (Materials Science, Textiles)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 28.9 days after submission; acceptance to publication is undertaken in 4.6 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

- Journal Cluster of Polymer and Macromolecular Science: Polymers, Gels, Polysaccharides, Textiles, Macromol, Microplastics and Adhesives.

Impact Factor:

4.9 (2024);

5-Year Impact Factor:

5.1 (2024)

Latest Articles

Scalable Fabrication of Non-Toxic Polyamide 6 Hybrid Nanofiber Membranes Using CuO for Antimicrobial and Aerosol Filtration Protection

Textiles 2026, 6(1), 2; https://doi.org/10.3390/textiles6010002 (registering DOI) - 29 Dec 2025

Abstract

Electrospinning has advanced from a lab technique to an industrial method, enabling modern filters that are high-performing, sustainable, recyclable, and non-toxic. This study produced recycled PA6 nanofibers using green solvents and incorporated non-toxic CuO nanoparticles via industrial free-surface electrospinning. Polymer solutions with concentrations

[...] Read more.

Electrospinning has advanced from a lab technique to an industrial method, enabling modern filters that are high-performing, sustainable, recyclable, and non-toxic. This study produced recycled PA6 nanofibers using green solvents and incorporated non-toxic CuO nanoparticles via industrial free-surface electrospinning. Polymer solutions with concentrations of 12.5, 15.0 and 17.5 (w/v)% were electrospun directly onto recyclable polypropylene spunbond/meltblown nonwoven substrates to produce nanofibers with average fiber sizes of 80–250 nm. Electrospinning parameter optimization revealed that the 12.5 wt.% PA6 solution and the 2–3 mm·s−1 winding speed had the optimal performance, attaining 98.06% filtering efficiency and a 142 Pa pressure drop. The addition of 5 wt.% CuO nanoparticles increased the membrane density and reduced the pressure drop to 162 Pa, thereby improving the filtration efficiency to 98.23%. Bacterial and viral filtration studies have demonstrated pathogen retention above 99%. Moreover, antibacterial and antiviral testing has demonstrated that membranes trap and inactivate microorganisms, resulting in a 2.0 log (≈approximately 99%) reduction in viral titer. This study shows that recycled PA6 can be converted into high-performance membranes using green, industrial electrospinning, introducing innovations such as non-toxic CuO functionalization and ultra-fine fibers on recyclable substrates, yielding sustainable filters with strong antimicrobial and filtration performance, which are suitable for personal protective equipment and medical filtration.

Full article

(This article belongs to the Special Issue Advances in Technical Textiles)

►

Show Figures

Open AccessArticle

From Geodiversity to Garments: Methods for Territory-Informed Textile Prints and Fashion

by

Sandra Regina Rech, Amanda da Silveira Bairros and Ana Julia Dal Forno

Textiles 2026, 6(1), 1; https://doi.org/10.3390/textiles6010001 - 22 Dec 2025

Abstract

►▼

Show Figures

This study investigates how cultural and natural heritage can inform surface design for fashion, focusing on the development of a capsule collection of geoproducts in the UNESCO Global Geopark of Caçapava do Sul, Brazil. The purpose is to expand the scope of existing

[...] Read more.

This study investigates how cultural and natural heritage can inform surface design for fashion, focusing on the development of a capsule collection of geoproducts in the UNESCO Global Geopark of Caçapava do Sul, Brazil. The purpose is to expand the scope of existing geoproducts, often limited to food and souvenirs, by introducing textile-based items that reflect local identity and contribute to sustainability. The research employed an applied, qualitative, and descriptive approach, including bibliographic review, questionnaires with local artisans, and the mapping of existing geoproducts. Data were analyzed through content analysis, and the creative process followed the method of cross-fertilization, which stimulates innovation by combining knowledge from design, geology, and craftsmanship. The design process was organized into four phases—preparation, generation of alternatives, selection, and realization—culminating in the capsule collection Aflora. The collection comprised two thematic lines: Cactaceae, inspired by endemic flora, and Geo, based on local geomonuments. The results demonstrate that surface design can mediate the relationship between fashion and heritage, producing identity-driven and innovative textile products. Three surface-design modules were produced, six product mockups, and two geoproduct prototypes, developed with materials such as wool, felt, sarja, and cotton fabrics. The study contributes theoretically by linking apparel design with heritage valorization, and practically by proposing a replicable model for geoproduct development. Limitations relate to the single case study and qualitative scope, suggesting future research on replication, eco-friendly printing, and market feasibility.

Full article

Figure 1

Open AccessArticle

Surface Engineering of PET Fabrics with TiO2 Nanoparticles for Enhanced Antibacterial and Thermal Properties in Medical Textiles

by

Muhammad Zaman Khan, Azam Ali, Hadi Taghavian, Jakub Wiener, Jiri Militky and Dana Křemenáková

Textiles 2025, 5(4), 71; https://doi.org/10.3390/textiles5040071 - 18 Dec 2025

Abstract

►▼

Show Figures

Medical textiles have gained significant attention for their ability to prevent the transmission of infectious diseases while ensuring the safety and comfort of healthcare professionals. This study focuses on modifying the surfaces of polyethylene terephthalate (PET) fabrics with titanium dioxide (TiO2)

[...] Read more.

Medical textiles have gained significant attention for their ability to prevent the transmission of infectious diseases while ensuring the safety and comfort of healthcare professionals. This study focuses on modifying the surfaces of polyethylene terephthalate (PET) fabrics with titanium dioxide (TiO2) nanoparticles (NPs) to enhance their antibacterial properties, thermophysiological comfort, and thermal insulation. The effects of varying volumes of the tetraisopropyl orthotitanate precursor on the functional properties of the coated PET fabrics were systematically investigated. The surface morphology was characterized using scanning electron microscopy (SEM). At the same time, the elemental and chemical properties were analyzed through Energy-dispersive spectroscopy (EDS), Raman spectroscopy, and Fourier-transform infrared spectroscopy (FTIR). The TiO2 NPs-coated PET fabrics demonstrated exceptional antibacterial activity against Gram-negative and Gram-positive bacteria and significantly improved thermophysiological comfort. Specifically, thermal resistance increased with a higher density of TiO2 nanoparticles, leading to a decrease in thermal conductivity. Notably, only minimal reductions were observed in relative water vapor permeability (RWVP) and air permeability (AP), indicating that the fabric’s porosity was maintained. Furthermore, the presence of the TiO2 nanolayer on the PET fabric significantly enhanced its thermal stability, providing excellent thermal insulation properties. These findings underscore the potential of TiO2 NPs-coated PET fabrics as promising candidates for advanced medical textile applications, where a balance of protection, comfort, and thermal insulation is essential.

Full article

Figure 1

Open AccessArticle

Cementitious Composites Reinforced with Multidimensional Epoxy-Coated Sisal/PET Braided Textile

by

Lais Kohan, Carlos Alexandre Fioroni, Adriano G. S. Azevedo, Ivis de Aguiar Souza, Tais O. G. Freitas, Daniel V. Oliveira, Julia Baruque-Ramos, Raul Fangueiro and Holmer Savastano Junior

Textiles 2025, 5(4), 70; https://doi.org/10.3390/textiles5040070 - 18 Dec 2025

Abstract

Textile-reinforced concrete (TRC) is an alternative class of mechanical reinforcement for cement composites. The biaxial braided reinforcement structure in composite materials with diverse cross-sectional shapes offers high adaptability, torsional stability, and resistance to damage. In general, 3D textile reinforcements improve the mechanical properties

[...] Read more.

Textile-reinforced concrete (TRC) is an alternative class of mechanical reinforcement for cement composites. The biaxial braided reinforcement structure in composite materials with diverse cross-sectional shapes offers high adaptability, torsional stability, and resistance to damage. In general, 3D textile reinforcements improve the mechanical properties of composites compared to 2D reinforcements. This study aimed to verify reinforcement behavior by comparing multidimensional braided textiles, 2D (one- and two-layer) reinforcements, and 3D reinforcement in composite cementitious boards. Experimental tests were performed to evaluate the effect of textile structures on cementitious composites using four-point bending tests, porosity measurements, and crack patterns. All textiles showed sufficient space between yarns, allowing the matrix (a commercial formulation) to infiltrate and influence the composite mechanical properties. All composites presented ductility behavior. The two layers of 2D textile composites displayed thicker cracks, influenced by shear forces. Three-dimensional textiles exhibited superior values in four-point bending tests for modulus of rupture (7.4 ± 0.5 MPa) and specific energy (5.7 ± 0.3 kJ/m2). No delamination or debonding failure was observed in the boards after the bending tests. The 3D textile structure offers a larger contact area with the cementitious matrix and creates a continuous network, enabling more uniform force distribution in all directions.

Full article

(This article belongs to the Special Issue Advances in Technical Textiles)

►▼

Show Figures

Figure 1

Open AccessArticle

Evaluation of Resting-State Cooling Effectiveness in Wearable Body-Cooling Devices Using Thermophysiological and Psychological Responses

by

Hiroki Maru, Takumi Yuasa and Hiroyuki Kanai

Textiles 2025, 5(4), 69; https://doi.org/10.3390/textiles5040069 - 17 Dec 2025

Abstract

Heat exposure in summer increases the risk of heat strain during work and rest, highlighting the need for effective cooling strategies. This study evaluated the cooling effectiveness of a fan-cooling jacket (FC) and a thermoelectric neck cooler (NC) under resting conditions in a

[...] Read more.

Heat exposure in summer increases the risk of heat strain during work and rest, highlighting the need for effective cooling strategies. This study evaluated the cooling effectiveness of a fan-cooling jacket (FC) and a thermoelectric neck cooler (NC) under resting conditions in a hot and humid environment. Six healthy males completed three trials (no cooling, FC, and NC) in an environmental chamber (35 °C, 70% RH). Thermophysiological responses (mean skin temperature, armpit temperature, sweat volume) and psychological ratings (thermal comfort, wetness sensation) were simultaneously assessed. FC significantly reduced mean skin temperature, attenuated the rise in axillary temperature, and decreased sweat volume while also improving thermal comfort and wetness sensation. In contrast, NC provided only transient improvements in comfort and did not suppress the rise in axillary temperature; wetness sensation deteriorated over time, likely due to its localized and limited cooling area. These findings indicate that, under low-activity conditions, broad-area forced convection cooling is more effective for mitigating heat stress than localized neck cooling. The results highlight the practical utility of fan-cooling garments for rest periods and other low-intensity scenarios.

Full article

(This article belongs to the Special Issue Advances in Smart Textiles)

►▼

Show Figures

Figure 1

Open AccessArticle

Chitosan/Pectin Layer-by-Layer Coatings Enriched with Strawberry Pomace Extract: A Path to Obtaining Sustainable Bio-Colored Healthcare Cotton Fabric

by

Aleksandra Ivanovska, Marija Ćorović, Jelena Lađarević, Katarina Dimić-Mišić and Igor Jordanov

Textiles 2025, 5(4), 68; https://doi.org/10.3390/textiles5040068 - 16 Dec 2025

Abstract

The purpose of this paper is to develop sustainable bio-colored healthcare cotton fabrics using chitosan/pectin layer-by-layer coatings enriched with strawberry pomace extract. Ultrasound-assisted extraction of bioactive compounds from strawberry pomace was optimized using a Box–Behnken experimental design to maximize the total polyphenol content

[...] Read more.

The purpose of this paper is to develop sustainable bio-colored healthcare cotton fabrics using chitosan/pectin layer-by-layer coatings enriched with strawberry pomace extract. Ultrasound-assisted extraction of bioactive compounds from strawberry pomace was optimized using a Box–Behnken experimental design to maximize the total polyphenol content (29.6 mg GAE/g DW). HPLC analysis confirmed the presence and quantity of anthocyanins in the extract obtained under optimized conditions (time: 37 min, ethanol concentration: 48.4%, liquid-to-solid ratio: 40.4 mL/g). This extract was used to enrich chitosan/pectin coatings, and applied onto cotton fabric using a layer-by-layer technique. Among the fabrics with 0, 4, 8, and 12 bilayers of chitosan/pectin coating enriched with extract, the 12-bilayer coated fabric exhibited the best bioactivity: 98.4% antioxidant activity, outstanding antibacterial efficacy, and the highest release of extract over 24 h. The last two properties showed a strong linear correlation with the number of bilayers, adsorbed extract, and weight gain. In vitro cytotoxicity testing proved the non-cytotoxic nature of 12-bilayer fabric extract. Additionally, the performed 12-bilayer coating imparted a natural reddish-brown color, high color strength (K/S = 1.45), and excellent UV protection (UPF 79.4), offering a sustainable, multifunctional approach for obtaining bio-colored cotton fabrics suited for wound dressing and other healthcare applications.

Full article

(This article belongs to the Special Issue Advances of Medical Textiles: 2nd Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

Full-Field In-Plane Tensile Characterization of Cotton Fabrics Using 2D Digital Image Correlation

by

Nenad Mitrovic, Aleksandra Mitrovic, Mirjana Reljic and Svetlana Pelemis

Textiles 2025, 5(4), 67; https://doi.org/10.3390/textiles5040067 - 11 Dec 2025

Abstract

►▼

Show Figures

Textile materials are widely used in diverse applications, yet their anisotropic structure and large deformations present major challenges in mechanical characterization. Conventional uniaxial tensile tests can quantify bulk properties but offer limited insight into local strain distributions. In this work, it was shown

[...] Read more.

Textile materials are widely used in diverse applications, yet their anisotropic structure and large deformations present major challenges in mechanical characterization. Conventional uniaxial tensile tests can quantify bulk properties but offer limited insight into local strain distributions. In this work, it was shown that a 2D Digital Image Correlation (DIC) technique captures full-field strain data in three types of woven cotton fabrics with distinct weave patterns and densities, each tested in warp and weft orientations. In controlled tensile experiments conducted per EN ISO 13934-1, DIC revealed that strain in the loading direction (EpsY) was highly orientation-dependent (p < 0.001), whereas strain perpendicular to loading (EpsX) was unaffected by orientation (p = 0.193). These findings contrast with traditional tensile data, which indicate significant orientation effects on maximum force and elongation (both p < 0.001). Compared to point-based techniques, 2D DIC provided richer information on anisotropic deformation, including the ability to detect local strain concentrations before failure. The strong interaction between fabric type and orientation indicates that each fabric exhibits distinct strain response when loaded along warp and weft directions, underscoring the importance of evaluating both orientations when designing or selecting textiles for multidirectional loading. By combining standard tensile testing with full-field optical strain measurements, a more comprehensive understanding of textile behavior emerges, enabling improved material selection, enhanced product performance, and broader applications in engineering and textile fields.

Full article

Figure 1

Open AccessArticle

Short-Time Transient Thermal Behaviour in Textile Fabrics—The Dual Phase Approach

by

Gilbert De Mey, Izabela Ciesielska-Wróbel, Maria Strąkowska, Bogusław Więcek, Carla Hertleer and Lieva Van Langenhove

Textiles 2025, 5(4), 66; https://doi.org/10.3390/textiles5040066 - 8 Dec 2025

Abstract

►▼

Show Figures

Short-time thermal exchange (0–20 s) between human skin and textile surfaces determines initial warm–cool sensations, which influences comfort perception. Classical Fourier models predicting a √t cannot fully describe this early transient phase, particularly for porous or heterogeneous materials such as fabrics. This study

[...] Read more.

Short-time thermal exchange (0–20 s) between human skin and textile surfaces determines initial warm–cool sensations, which influences comfort perception. Classical Fourier models predicting a √t cannot fully describe this early transient phase, particularly for porous or heterogeneous materials such as fabrics. This study investigates the early and short-time temperature response of a fingertip to contact with eight woven and knitted fabrics of different compositions, densities, thermal resistances, and thicknesses, measured under controlled laboratory conditions using a fine-gauge thermocouple at the skin–fabric interface. Experimental temperature–time data, when converted to the Laplace domain, exhibited slopes corresponding to time-domain exponents of t⅙, t¼, and occasionally t⅒, all lower than the classical diffusion exponent of ½.The dual-phase lag (DPL) model was applied to interpret these deviations through two lag times—τq (heat flux) and τT (temperature gradient)—and their ratio Z = τT/τq, which controls the slope of the Laplace-domain response. DPL curves reproduced the observed exponents without additional empirical parameters. The results show that short-time heat transfer depends strongly on textile structure: higher thickness leads to slower transient responses (“warmer” feel), whereas denser fabrics promote faster equilibration (“cooler” feel). This dual-phase interpretation bridges physical heat transfer with tactile thermal perception, providing a predictive framework for the design of textiles with thermal properties.

Full article

Figure 1

Open AccessArticle

Preparation and Performance Study of Bacterial Nanocellulose Yarns

by

Liangyu Zhang, Yuanyuan Zhang, Xiaoling Wang, Lisha Zheng, Huanjian Yu, Yuanming Zhang, Shaoyang Liu and Wei Jiang

Textiles 2025, 5(4), 65; https://doi.org/10.3390/textiles5040065 - 5 Dec 2025

Abstract

►▼

Show Figures

This study investigated the preparation of bacterial nanocellulose yarn, a high-strength and high-modulus cellulose-based textile material. Compared with the previously used wet spinning and electrospinning methods, the film-cutting, drawing and twisting treatment method in this paper retains the natural structure of BNC. This

[...] Read more.

This study investigated the preparation of bacterial nanocellulose yarn, a high-strength and high-modulus cellulose-based textile material. Compared with the previously used wet spinning and electrospinning methods, the film-cutting, drawing and twisting treatment method in this paper retains the natural structure of BNC. This can greatly transfer the high performance of BNC nanofibers to BNC yarns, making the mechanical properties of the prepared yarn much higher than those of the BNC yarns prepared by the above two methods. It was produced through a film-cutting and twisting process utilizing bacterial nanocellulose as the primary component. The effects of drafting and twisting on the characteristics and properties of the yarn were systematically examined. Comparative analyses were conducted between the bacterial nanocellulose yarn and conventional cotton yarn of equivalent fineness and twist in terms of appearance, tensile properties, frictional behavior, and bending resistance. Optimal tensile mechanical properties of the bacterial nanocellulose yarn were achieved at 1% elongation and a twist number of 160 r/20 cm, resulting in a breaking strength of 751.56 MPa and an elongation at break of 11.56%, surpassing those of cotton yarn of similar specifications. The spinnability assessment revealed a smooth surface for the bacterial nanocellulose yarn, characterized by low friction coefficient, robust bending resistance with a bending modulus of 718.76 GPa. These findings offer valuable empirical data and theoretical insights to guide the subsequent textile processing and utilization of bacterial nanocellulose yarn.

Full article

Figure 1

Open AccessArticle

Productivity Improvement Model in the Garment Industry: Application of Standardized Work and Poka Yoke with Artificial Vision

by

Miguel Ángel Vergara, Miguel Barbachán Villalobos, Percy Castro-Rangel, José C. Alvarez and Robert Lepore

Textiles 2025, 5(4), 64; https://doi.org/10.3390/textiles5040064 - 4 Dec 2025

Abstract

►▼

Show Figures

Peru’s highly competitive garment sector, where microenterprises account for 88.4% of all enterprises, the main barrier to sustainability is low productivity, driven by high rework rates and operational errors. To address this problem, this research proposes an improvement model that combines Standardized Work

[...] Read more.

Peru’s highly competitive garment sector, where microenterprises account for 88.4% of all enterprises, the main barrier to sustainability is low productivity, driven by high rework rates and operational errors. To address this problem, this research proposes an improvement model that combines Standardized Work to unify processes with a Poka Yoke technological solution using artificial vision for real-time defect prevention. This dual approach addresses the root causes of inefficiency, merging a core principle of Lean Manufacturing with an accessible Industry 4.0 tool designed for implementation in resource-constrained environments. The validation of the model demonstrated its remarkable effectiveness, achieving transformative results: the sewing rework rate was drastically reduced from 28.43% to 8.94%, the labeling rework rate were reduced from 18.02% to 3.88%, the production cycle time was optimized from 23.74 to 16.54 min per garment, with a 173.74% increase in productivity. These results not only confirm the validity of the model, but, due to its basis in universal principles and scalable technology, they also guarantee high applicability and replicability in other micro and small companies in the sector, offering a clear path towards a qualitative leap in productivity and competitiveness.

Full article

Figure 1

Open AccessArticle

Smartphone-Based Digital Image Processing for Fabric Drape Assessment

by

Emilija Toshikj and Nina Mladenovikj

Textiles 2025, 5(4), 63; https://doi.org/10.3390/textiles5040063 - 4 Dec 2025

Abstract

►▼

Show Figures

Fabric drape characterization is vital for textile performance and aesthetics, but the conventional Cusick method is labor-intensive and incompatible with digital workflows. This study assesses a smartphone-enabled digital image processing (DIP) method for fabric drape coefficient (DC) measurement, providing an accessible, low-cost alternative

[...] Read more.

Fabric drape characterization is vital for textile performance and aesthetics, but the conventional Cusick method is labor-intensive and incompatible with digital workflows. This study assesses a smartphone-enabled digital image processing (DIP) method for fabric drape coefficient (DC) measurement, providing an accessible, low-cost alternative to the Cusick method. Draped specimens of light, medium, and heavy fabrics were imaged at three diameters (24, 30, and 36 cm) using a smartphone positioned at three vertical distances (22, 32, and 42 cm). DCs were determined through pixel-based analysis in Adobe Photoshop®, ImageJ®, and MATLAB®. Statistical comparison against the Cusick method employed F-tests for variance, two-sample t-tests for mean differences, and skewness analysis. No statistically significant differences were found between smartphone DIP (with either the iPhone or Samsung device) and Cusick measurements (p > 0.05). Neither imaging height nor software platform significantly influenced outcomes, though a 22 cm height consistently provided the most stable conditions. ImageJ® was identified as an effective open-source option for reliable analysis. The findings establish a reliable, cost-effective, and portable method for drape evaluation, reducing technical and economic barriers while aligning with Industry 4.0 digitalization. This approach enables broader adoption of reliable textile characterization across research, industry, and domains.

Full article

Figure 1

Open AccessArticle

Effective Dye Removal from Post-Consumer Cotton Textiles and Its Influence on the Quality of the Textiles

by

Emalika Ayomani Munasinghe Arachchilage, Georg Stegschuster, Mesut Cetin and Maike Rabe

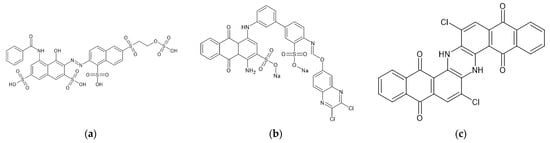

Textiles 2025, 5(4), 62; https://doi.org/10.3390/textiles5040062 - 30 Nov 2025

Abstract

A major obstacle to textile recycling is the presence of dyes, which limits the reuse of fibers in high-value applications. Despite previous studies on, cotton decolorization, the systematic development of an optimal formulation that preserves fabric integrity remains lacking. This study addresses this

[...] Read more.

A major obstacle to textile recycling is the presence of dyes, which limits the reuse of fibers in high-value applications. Despite previous studies on, cotton decolorization, the systematic development of an optimal formulation that preserves fabric integrity remains lacking. This study addresses this gap by investigating a decolorization method for mixed-dyed cotton textiles that enables successful redyeing while preserving fabric quality. Reactive and vat-dyed cotton fabrics were treated with sequential reductive and oxidative processes, in a full factorial design. The impact of input parameters on tensile strength was evaluated through statistical analysis using analysis of variance at a significance level of α = 0.05. The developed recipe was subsequently validated on post-consumer cotton textiles. Stripping efficiency was assessed using K/S values, and fabric quality was evaluated through tensile strength, pilling, and fuzzing appearance. Temperature showed the strongest influence on dye removal. Fabric strength was significantly affected by temperature and oxidizing agent, and by interactions of temperature with reducing agent and oxidation time. The optimized process achieved 98–99.5% color removal and retained 95% of the fabric’s tenacity. A stripping efficiency of >90% for post-consumer cotton validates the method’s applicability in real-world circular systems.

Full article

(This article belongs to the Special Issue Reinventing Textiles: The Intersection of Biology, Technology, and Design)

►▼

Show Figures

Figure 1

Open AccessArticle

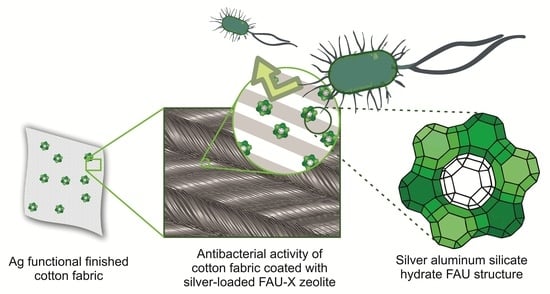

Antimicrobial Textile Finishing Based on Silver Nanostructures

by

José Ángel Juárez Torres, María Luisa Castellanos Cabrera, Dalia Molina Romero, Itzel Pamela Torres Avila, Oscar Goiz and Miriam Cruz-Leal

Textiles 2025, 5(4), 61; https://doi.org/10.3390/textiles5040061 - 29 Nov 2025

Abstract

►▼

Show Figures

This study presents the development and application of a textile finishing treatment with antimicrobial properties based on silver nanostructures. The methodology involved the initial synthesis of silver-supported structures on aluminosilicates, which were subsequently applied to 100% raw cotton Jersey fabric through an impregnation

[...] Read more.

This study presents the development and application of a textile finishing treatment with antimicrobial properties based on silver nanostructures. The methodology involved the initial synthesis of silver-supported structures on aluminosilicates, which were subsequently applied to 100% raw cotton Jersey fabric through an impregnation finishing process. The treated cotton samples were evaluated for antimicrobial activity using the Kirby-Bauer disk diffusion method. The tested bacterial strains included Gram-negative as Shigella sp., Pseudomonas sp. M13, Pseudomonas sp. M14, Pseudomonas putida KT2440, and Escherichia coli, as well as Gram-positive Staphylococcus aureus ATCC 29213 and Streptococcus agalactiae ATCC 12386 (American Type Culture Collection) all of which exhibited growth inhibition in the presence of the treated textile, demonstrating the effectiveness of the antimicrobial finish.

Full article

Graphical abstract

Open AccessArticle

Synergistic Multi-Enzyme Modification of Ramie Fabric: Optimized Process for Alleviating Prickle Sensation and Enhancing Comfort

by

Qi Yang, Xiang Zhou, Ling Deng, Xiangying Shen, Lifeng Cheng, Guoguo Xi, Chen Chen, Zhenghong Peng, Yuqin Hu, Si Tan and Shengwen Duan

Textiles 2025, 5(4), 60; https://doi.org/10.3390/textiles5040060 - 26 Nov 2025

Abstract

►▼

Show Figures

Ramie fabrics suffer from inherent prickle sensation due to rigid fiber morphology, limiting their applications. This study aims to alleviate this issue through an eco-friendly enzymatic modification. Six enzymes (cellulase, laccase, hemicellulase, xylanase, pectinase, alkaline protease) were used. Single-factor experiments optimized enzyme dosage,

[...] Read more.

Ramie fabrics suffer from inherent prickle sensation due to rigid fiber morphology, limiting their applications. This study aims to alleviate this issue through an eco-friendly enzymatic modification. Six enzymes (cellulase, laccase, hemicellulase, xylanase, pectinase, alkaline protease) were used. Single-factor experiments optimized enzyme dosage, liquid-to-solid ratio, and treatment time; response surface methodology (RSM) further refined conditions, followed by compound enzyme treatments to explore synergies. Scanning electron microscopy (SEM) validated changes. Results showed the optimal multi-enzyme combination (2% hemicellulase, 3% cellulase, 3% laccase) reduced prickle sensation score by 43.8% (to 1.8 vs. 3.2 for untreated), with SEM confirming less surface fuzz and improved uniformity. This effective enzymatic strategy provides a green approach to enhance ramie fabric comfort, with practical implications for textile processing.

Full article

Figure 1

Open AccessArticle

From Comfort to Protection: Quantitative Comparison of Fit and Air Permeability in Textile Masks and Respirators

by

Maria Ivanova and Radostina A. Angelova

Textiles 2025, 5(4), 59; https://doi.org/10.3390/textiles5040059 - 15 Nov 2025

Abstract

The present study examines the influence of material and structural parameters on the fit and air permeability of textile face masks, surgical masks, and certified respirators. Nine samples were tested using the AccuFIT 9000 for quantitative fit factor (FF) measurements and the FX-3340

[...] Read more.

The present study examines the influence of material and structural parameters on the fit and air permeability of textile face masks, surgical masks, and certified respirators. Nine samples were tested using the AccuFIT 9000 for quantitative fit factor (FF) measurements and the FX-3340 MinAir for air permeability in both airflow directions. Results show that increased thickness moderately improves FF, supporting better facial sealing. However, mass per unit area and bulk density show weak or no correlation with FF. Air permeability correlates weakly and negatively with FF, especially during exhalation, but remains essential for wearer comfort. Notably, some textile masks outperformed certified respirators in terms of fit, highlighting the importance of design, elasticity, and edge sealing. The findings suggest that effective mask performance depends on more than filtration materials or certification levels. A balanced design combining breathability, structural optimisation, and ergonomic fit is essential for both comfort and protection. These insights can guide the development of more effective reusable and disposable face coverings, particularly in aerosol-rich environments.

Full article

(This article belongs to the Special Issue Advances of Medical Textiles: 2nd Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

Anisotropic X-Band Microwave Properties of Amine-Functionalized Carbon Fibers Derived from Polyacrylonitrile

by

Liudmyla M. Grishchenko, Maksym A. Popov, Hryhorii L. Chumak, Vitaliy E. Diyuk, Viktoriia D. Malovychko, Igor P. Matushko, Volodymyr Yu. Malyshev, Ruslan T. Mariychuk, Olga Yu. Boldyrieva, Oleksandr V. Mischanchuk, Maksym O. Kremenskoy and Vladyslav V. Lisnyak

Textiles 2025, 5(4), 58; https://doi.org/10.3390/textiles5040058 - 14 Nov 2025

Abstract

►▼

Show Figures

Carbon fibers derived from carbonized and activated polyacrylonitrile (CFPAN) were sequentially brominated and subsequently functionalized with selected primary and secondary amines to engineer a directional electromagnetic (EM) response. Besides bromine incorporation, bromination introduced oxygen-containing surface groups (e.g., carboxyl, lactone), enabling nucleophilic substitution by

[...] Read more.

Carbon fibers derived from carbonized and activated polyacrylonitrile (CFPAN) were sequentially brominated and subsequently functionalized with selected primary and secondary amines to engineer a directional electromagnetic (EM) response. Besides bromine incorporation, bromination introduced oxygen-containing surface groups (e.g., carboxyl, lactone), enabling nucleophilic substitution by amines. Surface characterization (SEM-EDS, FTIR ATR) confirmed successful amine grafting, while thermal analysis (TGA, TPD MS) revealed increased weight loss in the 150–450 °C range due to the decomposition of covalently bonded nitrogen- and oxygen-containing moieties, evidencing strong surface functionalization. Microwave characterization in the X-band (8.2–12.4 GHz) demonstrated that functionalization strongly influences the EM response of CFPAN fibers. The measured reflection coefficient varied from −1.0 to −2.5 dB for sulfonylethylenediamine (SuEn)-functionalized fibers and from −2.0 to −4.0 dB for ethylenediamine (En)-treated ones, depending on frequency and fiber orientation. The frequency-averaged absorption coefficient of pure CFPAN amounted to 32–41%, with absorption maxima and minima corresponding to orientations differing by 90°. SuEn modification decreased absorption to 21–35%, while En functionalization enhanced it to 32–51%. Pure CFPAN exhibited the lowest absorption anisotropy (factor 1.28), whereas piperazine- and En-modified samples showed the highest anisotropy (1.57 and 1.59, respectively). Across all compositions, the attenuation constant remained within 1.5–4.5 mm−1. The observed anisotropic behavior is governed primarily by orientation-dependent variations in characteristic impedance and, to a lesser extent, by anisotropic attenuation constants. Such tunable anisotropy is particularly advantageous for EM shielding textiles, where fiber alignment can be tailored to enhance interaction with polarized fields. Among the tested amines, En-functionalized CFPAN exhibited the highest nitrogen content (up to 10.1 at%) and the most significant enhancement in microwave absorption, positioning it as a promising candidate for advanced orientation-sensitive shielding applications.

Full article

Figure 1

Open AccessArticle

Valorisation of Recycled Cotton as Reinforcement in Recycled Polypropylene Composites

by

Mariana Ichim, Emil Ioan Muresan, Gabriela Lisa, Florin Ciolacu and Adrian Cătălin Puițel

Textiles 2025, 5(4), 57; https://doi.org/10.3390/textiles5040057 - 11 Nov 2025

Abstract

►▼

Show Figures

The continuous rise in textile waste, driven by global population growth and the proliferation of fast fashion, has raised concerns about its efficient recycling and sustainable management. This study aims to assess the feasibility of recycling textile waste by incorporating recycled cotton fibres

[...] Read more.

The continuous rise in textile waste, driven by global population growth and the proliferation of fast fashion, has raised concerns about its efficient recycling and sustainable management. This study aims to assess the feasibility of recycling textile waste by incorporating recycled cotton fibres as reinforcement in polypropylene-based composites. Specifically, it examines the mechanical, thermal, and chemical properties of composites composed of 50% recycled polypropylene and 50% reinforcing fibres (either virgin or recycled cotton), with and without the addition of 5% maleic anhydride-grafted polypropylene as a compatibilizer to enhance fibre-matrix adhesion. Although the use of recycled cotton as reinforcement reduced the mechanical properties of the composite material, the addition of 5% compatibilizer improved these properties to levels comparable to those of composite reinforced with virgin cotton.

Full article

Figure 1

Open AccessArticle

Development and Evaluation of Yarns Made from Mechanically Recycled Textiles

by

Kendall Ludwig, Sophia Gupman, Michelle Yatvitskiy, Huantian Cao and Kelly Cobb

Textiles 2025, 5(4), 56; https://doi.org/10.3390/textiles5040056 - 11 Nov 2025

Cited by 1

Abstract

►▼

Show Figures

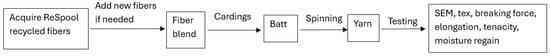

Mechanical textile recycling presents a sustainable alternative to linear “take–make–waste” models in the fashion industry. This study intended to develop yarns using textile-to-fiber mechanically recycled fibers. ReSpool mechanically recycled wool, cotton, polyester, silk, and rayon fibers from pre-consumer and post-consumer textiles were acquired

[...] Read more.

Mechanical textile recycling presents a sustainable alternative to linear “take–make–waste” models in the fashion industry. This study intended to develop yarns using textile-to-fiber mechanically recycled fibers. ReSpool mechanically recycled wool, cotton, polyester, silk, and rayon fibers from pre-consumer and post-consumer textiles were acquired and blended with new fibers at varying ratios (100% ReSpool fibers, 85% ReSpool fibers, and 65% ReSpool fibers) to make batts, which were spun into yarns. The yarns’ size (Tex), strength (breaking force and tenacity), elongation, and moisture regain were evaluated. ReSpool recycled fibers from both pre-consumer and post-consumer textiles can be used to produce yarns that have appropriate strength for weaving and knitting. It was possible to produce yarns from 100% ReSpool recycled wool, polyester, and silk fibers, but ReSpool recycled cotton and rayon fibers must be blended with new fibers to produce yarns. There was no significant difference among the percentage of ReSpool recycled polyester and cotton fibers in the yarns on the strength and elongation of the yarn. It is recommended to use the higher percentage of ReSpool recycled fibers in yarn development to maximize recycled material utilization.

Full article

Figure 1

Open AccessArticle

Research on the Construction of a Full-Color-Gamut Color Spinning Method and Neural Network Color Prediction System

by

Wenshuo Zhu, Yuan Xue, Yourong Chen and Peng Cui

Textiles 2025, 5(4), 55; https://doi.org/10.3390/textiles5040055 - 10 Nov 2025

Abstract

►▼

Show Figures

This paper aims to develop a comprehensive technology for full-color-gamut spinning to enable the precise design and production of blended yarns. A grid-based color-mixing model with six regions is built as a cylindrical color model by mixing eight primary color fibers. Using a

[...] Read more.

This paper aims to develop a comprehensive technology for full-color-gamut spinning to enable the precise design and production of blended yarns. A grid-based color-mixing model with six regions is built as a cylindrical color model by mixing eight primary color fibers. Using a three-element synergistic regulation mechanism comprising a numerically controlled rotor-spun system, a color-spinning method is created that integrates the full-color-gamut grid-based color-mixing model. Consequently, 273 blended yarn fabrics are produced. Leveraging the regional variations in blending primary color fibers, a neural network color-prediction system is designed. It is trained on reflectance and blending-ratio data from 255 samples and validated with 18 samples across different color-mixing regions. The results show a mean color difference prediction of 0.909 and an average blending ratio error of 1.76% for the 18 samples. This indicates that the color-prediction system can accurately predict the colors of blended yarns within the full-color-gamut range, providing theoretical support for yarn production.

Full article

Figure 1

Open AccessArticle

Mini-Jacquard Weft-Knit in Peruvian Pima Cotton as a Print-Free Alternative: CAD Simulation, Prototyping, and Fabric Pattern Characterization

by

Praxedes Jeanpierre Merino-Ramirez and Rebeca Salvador-Reyes

Textiles 2025, 5(4), 54; https://doi.org/10.3390/textiles5040054 - 10 Nov 2025

Abstract

►▼

Show Figures

This study develops and validates a weft knitted Mini-Jacquard in Peruvian Pima cotton as a print-free coloration strategy by integrating CAD-based pattern simulation with prototype manufacturing. A three-color design (red, blue, white) was programmed on a flat knitting machine using a 10 ×

[...] Read more.

This study develops and validates a weft knitted Mini-Jacquard in Peruvian Pima cotton as a print-free coloration strategy by integrating CAD-based pattern simulation with prototype manufacturing. A three-color design (red, blue, white) was programmed on a flat knitting machine using a 10 × 14 rapport. Color-wise yarn consumption was computed directly from the digital pattern, and the physical sample was characterized through combustion testing and optical micrographs. The prototype exhibited a yarn count of ~20/1 Ne, S-twist (~11.18 TPI), and 100% cellulosic composition. The blue yarn showed the highest consumption (≈73.81%), followed by white (≈19.65%) and red (≈6.55%), consistent with the digital rapport’s color distribution. The CAD stage ensured pattern fidelity and supported raw-material planning; the knitted sample showed a soft hand, dimensional stability, and sharp motif definition upon visual assessment. A sustainability and comparative analysis with chemical printing was conducted, revealing that the Mini-Jacquard achieved the highest design accuracy and tactile comfort, outperforming screen printing and heat transfer in geometric fidelity, chromatic homogeneity, and texture. The Mini-Jacquard optimized operational times (320 min/m2) compared to transfer printing (332 min/m2) and screen printing (740 min/m2), reducing process stages and complexity. Although Jacquard production involves higher energy costs ($34.8) and material expenses ($11.6), it provides greater structural value and durability, positioning it for high-end applications. Moreover, the Mini-Jacquard could reduce water consumption by approximately 90% and thermal energy use by 70%, eliminating chemical residues and extending fabric lifespan, thus offering high sustainability and circular potential. A transparent scenario-based analysis indicates substantial reductions in water and thermal-energy use when omitting printing/fixation/washing stages, along with the elimination of printing-stage effluents. Overall, design-integrated coloration via Mini-Jacquard is technically feasible and potentially eco-efficient for Pima-cotton value chains, with applications in apparel, accessories, and functional textiles.

Full article

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Conferences

Special Issues

Special Issue in

Textiles

Advances in Technical Textiles

Guest Editors: Larisa A. Tsarkova, Thomas Bahners, Xiaomin ZhuDeadline: 31 December 2025

Special Issue in

Textiles

Textiles in Cultural Heritage: Technology, Dyes and Conservation

Guest Editor: Ioannis KarapanagiotisDeadline: 31 May 2026

Special Issue in

Textiles

Advances in 2D-Material Functionalized Textiles

Guest Editor: Vanja KokolDeadline: 30 September 2026

Special Issue in

Textiles

Textile Recycling and Sustainability

Guest Editor: Rajesh MishraDeadline: 31 December 2026

Topical Collections

Topical Collection in

Textiles

Feature Reviews for Advanced Textiles

Collection Editor: Rajesh Kumar Mishra