Abstract

The fast fashion industry has significantly increased global textile demand, driving a surge in fiber production. However, only a minimal portion of this fiber comes from recycled sources. In the United States alone, a vast amount of textile waste is generated annually, with over half ending up in landfills, contributing to environmental degradation and global warming. These developments underscore the urgent need for scalable and efficient textile recycling solutions to address both economic and ecological challenges in the fashion industry. Among recycling methods, mechanical recycling stands out for its low cost and simplicity, making it suitable for processing various types of textile waste. This article reviews current knowledge, identifies key research gaps, and provides direction for future studies in mechanical textile recycling. Despite progress, significant challenges remain in improving the quality and efficiency of recycled fiber. This study shows the importance of advancing pretreatment methods and sorting technologies, and highlights understanding regarding shredding, opening processes, and fabric structural properties.

1. Introduction

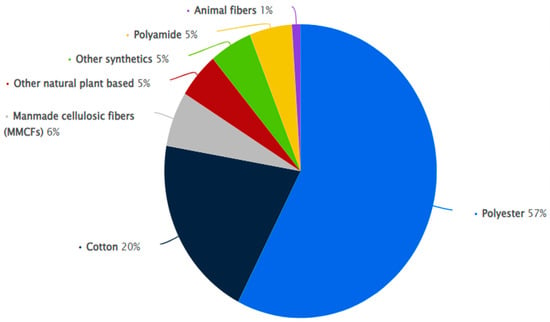

Over the past few decades, global textile demand has surged, primarily driven by population growth and the rapid expansion of the fast fashion industry [1]. In response, global fiber production reached 124 million tons in 2023—which is an increase of 7% from 116 million tons in 2022—with projections estimating a rise to 160 million tons by 2030 if current trends persist. Notably, in 2023, the market share of virgin, fossil-based synthetic fibers increased, while the share of cotton and recycled fibers declined [2]. Figure 1 illustrates the global distribution of textile fiber production, indicating that natural fibers account for approximately 30% of the market, whereas man-made fibers constitute about 70% of the market [3]. This shift highlights the sector’s ongoing reliance on virgin, fossil-based inputs, presenting significant challenges to environmental sustainability. On the other hand, cotton, the second-most produced fiber globally, is particularly resource-intensive, requiring vast amounts of water and energy. For example, cultivating just 1 kg of cotton seed can consume over 20,000 L of water [4].

Figure 1.

Global textile market share by type in 2023, reprinted with permission from [3].

Meanwhile, the growing volume of textile waste—much of which ends up in landfills—exacerbates environmental harm. Such waste releases greenhouse gases, leaches contaminants into soil and water, contributes to microplastic pollution, and accelerates the depletion of land and ecosystems [5]. To address the growing environmental impact of the fashion industry, it is crucial to reduce textile waste and decrease reliance on virgin materials. However, as of 2023, only 1% of total fiber production comes from recycled sources [2], signaling a significant gap—and opportunity—for sustainable fiber development. Expanding textile recycling offers a compelling path forward to mitigate the industry’s environmental footprint and foster a more circular textile economy.

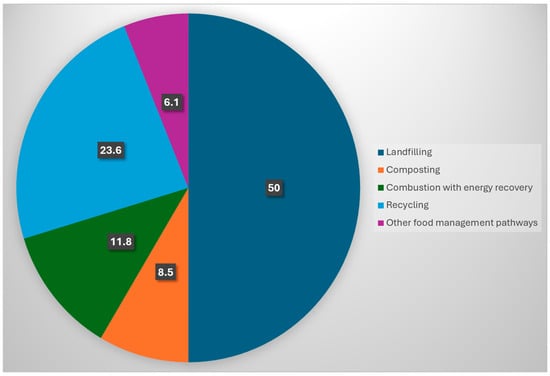

To illustrate the urgency and scale of this challenge, the United States provides a telling example of how fast fashion has intensified textile waste issues at the national level. The fast fashion industry has played a major role in the growing textile waste problem in the United States. According to a 2024 report by the U.S. Environmental Protection Agency (EPA), approximately 292 million tons of municipal solid waste (MSW) were generated, of which 50 percent ended up in landfills (see Figure 2). The country generated approximately 17 million tons of textile waste in 2018, with more than 10 million tons ultimately ending up in landfills [6]. This accounted for 5.8% of the total MSW that year, while only 2.5 million tons were recycled. Expanding textile recycling could reduce greenhouse gas emissions by an estimated 2.5 million metric tons of CO2 equivalent—comparable to removing nearly 550,000 cars from the road for one year [6,7]. Between 2000 and 2018, textile waste increased by more than 20%, driven by the rise in fast consumption patterns. Economically, the disposal of textiles costs roughly $45 per ton, translating into hundreds of millions of dollars in annual municipal expenses [8]. Over the same period, textile and apparel imports surged by 182%, closely correlating with the increase in textile waste sent to landfills [5]. In light of these trends, textile recycling has emerged as a critical strategy for mitigating both environmental and economic impacts. Recycling diverts waste from landfills, reduces emissions, and adds value to discarded materials through the recovery of resources [9]. These factors underscore the urgent need to develop scalable, efficient textile recycling systems to support a more sustainable and economically viable fashion industry.

Figure 2.

Management of municipal solid waste (MSW) in the United States, 2018, adapted from EPA [6].

Textile recycling refers to the reprocessing of both post-consumer and pre-consumer textile waste into new textile or non-textile products [10]. This process can be categorized into mechanical, chemical, and biological approaches. Among these, mechanical recycling is currently the most widely implemented approach due to its operational simplicity, cost-efficiency, and compatibility with a broad range of textile waste streams [11,12]. Additionally, it offers environmental advantages by avoiding the use of chemical solvents or additives. Despite these benefits, mechanical recycling faces considerable limitations. One of the primary technical challenges is the degradation of fiber quality during the mechanical process, often resulting in short, weak fibers that are only suitable for low-value, downcycled applications [13,14,15]. Beyond technical issues, the sector is hindered by broader systemic barriers, including the lack of standardized processing guidelines, limited technological innovation, and insufficient infrastructure for large-scale implementation [16]. These challenges collectively impede the broader industrial adoption of mechanical recycling and compromise the consistency and quality of recycled fibers. Recent research efforts have focused on optimizing processing parameters [17], understanding the mechanics of textile processing [18], and investigating the influence of fiber and fabric characteristics on the outcomes of recycled fibers [19], all aimed at enhancing the properties of fibers. This paper aims to synthesize the current state of knowledge in mechanical textile recycling, highlight persistent barriers, and propose directions for developing more robust, efficient, and scalable solutions that support a sustainable circular economy.

2. Research Framework and Methodology

This review primarily focuses on studies published within the last five years to ensure relevance to recent advancements in mechanical textile recycling. A systematic search was conducted using Web of Science and Google Scholar, employing keywords such as “mechanical recycling,” “textile waste recycling,” “yarn recycling,” and related terms.

Over 600 articles related to mechanical textile recycling have been published in the past five years, including 85 review papers. However, most existing reviews address textile recycling in a broader context or emphasize various recycling methods without a deep focus on the mechanical recycling process.

The novelty of this review lies in its specific and in-depth focus on the mechanical recycling of textile waste, particularly in the context of recycled fiber production—an area that has been largely overlooked in previous reviews. This study distinguishes itself by critically evaluating the technical challenges and recent innovations in fiber recovery through mechanical processes, while also identifying key knowledge gaps and proposing future research directions to advance the field.

A three-step filtering process was applied for article selection:

- Title screening to ensure relevance to mechanical recycling and fiber production;

- Abstract review to identify studies addressing technical aspects of fiber processing;

- Full-text analysis for final inclusion.

Additionally, reference tracking was used to identify further relevant studies, and information from reputable industry sources was included to provide practical context.

Limitations of this review include the exclusion of topics such as spinning techniques, blending with virgin fibers, economic analysis, and environmental assessment. These areas are acknowledged as important but were considered beyond the scope of this study, which aims to focus specifically on the mechanical processes of fiber recovery.

3. Overview and Challenges of Textile Mechanical Recycling

3.1. Different Approaches in Textile Recycling

Textile recycling can be classified based on the degree of material breakdown into four categories: fabric, fiber, polymer, and monomer recycling [20]. Fabric recycling involves reusing intact fabric components in new products, typically through a simple sorting process. Despite being efficient and low-cost, this method faces limitations due to restrictions in product design, consistency, and quality requirements. Fiber recycling—the industry’s most widely used method—entails breaking down textiles while preserving fiber. This method primarily relies on mechanical processes. Polymer recycling, by contrast, retains the polymer chains instead of the fibers. The recycling involves additional physical treatment, such as melting or dissolving, in combination with mechanical methods. Monomer recycling represents the most chemically intensive approach, breaking down polymers into their original monomers for repolymerization. This process combines chemical reactions with mechanical preprocessing to enable complete material transformation [20]. These varying levels of recycling underscore the versatility and foundational role of mechanical methods, while also demonstrating that higher levels of material recovery often come at the expense of increased complexity, energy consumption, and infrastructure requirements.

3.2. Mechanical Recycling: Definitions

Stakeholders define mechanical recycling in various ways, reflecting the diverse scope and applications across the textile industry. According to ISO 5157:2023, mechanical recycling is defined as a mechanical process that extracts fibers from used textile products through disassembly by using physical forces and incorporates them into new textile or non-textile applications. The standard further distinguishes mechanical recycling as either a standalone process or as a preparatory step for thermo-mechanical, chemical, or biomechanical recycling methods [21]. Typically, mechanical recycling breaks down yarns while preserving the fiber structure [20], making it a practical approach for fiber recovery. Huang et al. (2024) further specify a category termed “shredding mechanical recycling,” in which fabrics are mechanically fragmented into smaller pieces [12]. While this approach is widely used due to its simplicity and cost-effectiveness, it also introduces several processing steps that can degrade fiber quality, ultimately affecting the performance and applicability of the recycled material. While mechanical recycling has been widely adopted and accessible, its limitations in preserving fiber quality underscore the need for innovation in process steps to enhance material performance and process efficiency.

3.3. Process Steps and Material Suitability in Mechanical Recycling

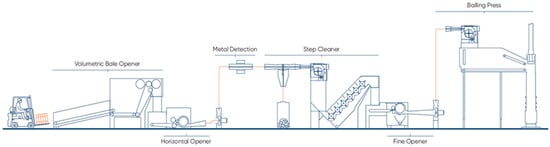

Textile mechanical recycling involves a series of steps, beginning with pretreatment and followed by sorting, shredding, and fiber-opening or tearing. Among these stages, the shredding and tearing processes can significantly degrade fiber quality, limiting the reuse potential of the recovered material [12,19,20,22]. Figure 3 illustrates the tearing lines used in an industrial setup for textile recycling. The production of tearing lines could vary from 50 kg/h up to 3000 kg/h [23]. Although the core steps of mechanical recycling are similar across various fiber types—including cellulosic fibers like cotton, PET-based fibers such as polyester, and polyamides like wool—the process is not equally compatible with all materials. Mechanical recycling is most successful with materials such as cotton, wool, and acrylics, where the fiber structure can be more reliably preserved. In contrast, synthetic fibers such as nylon are not commonly recycled through mechanical methods due to several limiting factors [20].

Figure 3.

Tearing lines used in mechanical recycling courtesy of ANDRITZ [23].

The recycling of synthetic fibers, such as polyester and nylon, presents significant challenges due to a combination of factors, including unfavorable economic conditions, the intrinsic chemical properties of synthetic polymers, and the limitations of current recycling technologies and infrastructure [24]. A primary barrier is the economic viability of synthetic fiber recycling, as virgin synthetic fibers are relatively inexpensive to produce, especially when compared to the high costs associated with collecting, sorting, and processing post-use textiles. This economic disparity discourages investment in large-scale recycling infrastructure and technological innovation [24]. Moreover, the application of mechanical recycling of synthetic fibers is relatively limited, since alternative methods such as physical recycling (e.g., re-melting) and chemical recycling of fibers like polyester and nylon can yield recycled materials with enhanced properties [20]. However, these alternative approaches are typically energy-intensive, chemically demanding, and often lead to downcycling—where recycled fibers are of lower quality than their virgin counterparts—thus limiting the potential for true closed-loop recycling [24]. Given the prevalence of synthetic fibers in the global textile market, these limitations underscore the urgent need for fiber-specific innovations in mechanical recycling technologies. Advancements in this area could enable the production of high-quality recycled synthetic fibers at competitive costs, thereby improving both the environmental and economic feasibility of synthetic fiber recycling.

4. Feedstock for Mechanical Recycling

4.1. Types and Sources of Textile Waste

Textile waste is commonly categorized into three main types: post-industrial, pre-consumer, and post-consumer waste [25]. Post-industrial waste includes cutting scraps generated during textile manufacturing processes at fabric mills and sewing facilities. Pre-consumer waste refers to unsold garments, often due to quality defects or overproduction, which have not reached end consumers. In contrast, post-consumer waste comprises worn-out, damaged, or discarded garments from individuals or commercial sources such as laundry from hospitals, hotels, and industry. This category represents the largest share of textile waste and is the primary input for mechanical recycling [10,11,26]. According to Raluca (2023), post-industrial and pre-consumer waste are collected from various stages of textile manufacturing, including spinning, weaving, knitting, dyeing, and garmenting, whereas post-consumer waste originates from end users [14]. Table 1 outlines the types and sources of these waste streams. Understanding these distinctions is crucial for developing targeted recycling strategies and optimizing resource recovery.

Table 1.

Type and source of textile waste [14].

4.2. Feedstock and Fiber Recovery

More research is needed to address the limitations of fiber recovery from different types of textile waste, particularly in improving fiber length—an essential parameter for yarn quality. Pre-consumer waste is relatively easy to identify and sort; it typically lacks the large, uniform volumes necessary for efficient mechanical recycling and often requires pre-processing to be effective. Although pre-consumer waste represents a smaller share of total textile waste, it remains a major source of recycled cotton fiber due to its relatively homogeneous composition and ease of sorting [10,11,26,27]. In contrast, post-consumer waste presents significant challenges, including high variability in fiber blends, fabric constructions, and color diversity, which complicate mechanical processing and reduce fiber quality [10,11,20,26,27,28].

Studies have shown that fibers recovered from pre-consumer waste—such as garment cutting waste or yarn hard waste—tend to retain greater average fiber length than those derived from post-consumer garments [27]. As shown in Table 2, recycled cotton from pre-consumer sources can reach lengths of up to 26 mm, while post-consumer denim yields significantly shorter fibers. Similarly, wool fibers obtained from pre-consumer waste retain superior length (up to 60 mm) compared to those from used garments. Given that post-consumer waste constitutes the majority of input into mechanical textile recycling systems, there is a pressing need for innovations that can enhance fiber quality from these complex feedstocks. This may include advancements in pre-processing, sorting technologies, and machinery optimization to minimize fiber damage and improve length retention.

Table 2.

Comparison of fiber recovery from pre-consumer and post-consumer feedstock [27].

5. Pretreatment

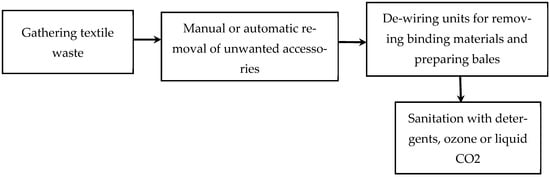

Pretreatment of textile waste plays a crucial role in the recycling of textiles. The pretreatment stage in the mechanical recycling of textiles primarily involves the opening and cleaning of textile waste. This process involves both manual and automated removal of unwanted materials, followed by sanitation processes [22]. This waste typically arrives in the form of bales, bulk material, or large sacks, and may be wrapped in plastic or bound with metallic or synthetic strings. As illustrated in Figure 4, industrial setups for cotton waste processing include a series of openers, metal detection systems, step cleaners, and baling presses [23].

Figure 4.

Cotton waste opening and cleaning lines in an industrial setup courtesy of ANDRITZ [23].

To handle the textile materials efficiently, these systems incorporate conveyors, metal removal units, and de-wiring stations. Metal removal is essential to protect downstream equipment by effectively separating metallic contaminants. De-wiring units facilitate the removal of binding materials, thereby streamlining the preparation of bales for subsequent processing stages [29]. The sanitation step aims to eliminate contaminants such as sweat and sand through industrial cleaning methods using detergents, ozone, or liquid carbon dioxide [22]. The general process diagram of pretreatment in the mechanical recycling of textiles is presented in Figure 5.

Figure 5.

Process diagram of pretreatment in the mechanical recycling of textiles.

In addition to cleaning, enhancing the mechanical recyclability of textiles is essential. For instance, treating cotton-polyester blend fabrics with PEG 4000 prior to shredding has shown promise in reducing interfiber friction—a significant cause of fiber length reduction during mechanical recycling [1]. High friction during shredding leads to excessive wear, heat buildup, and even melting of synthetic fibers or structural degradation of cellulose-based fibers. Applying lubricants or spin finishes can mitigate these issues by reducing the cohesion between fibers, enabling gentler disassembly and less mechanical stress [1,28]. This approach highlights a significant improvement in the pretreatment phase, potentially increasing fiber recovery rates and preserving fiber quality. However, further research may be necessary to optimize lubricant types and concentrations for various fiber blends, ensuring scalability and sustainability. Additionally, the cost implications and environmental footprint of using lubricants during mechanical recycling warrant further investigation.

6. Sorting

Sorting is a vital process in producing high-quality recycled fibers from textile waste. Without adequate sorting, the resulting fibers may exhibit inconsistent properties due to the heterogeneous nature of textile waste streams, which typically contain various fiber types, forms, and varying levels of contamination [30]. The sorting of textile materials involves the separation of textile materials by color and contamination to produce fibers with solid colors and the lowest levels of contamination [31]. It also plays a vital role in excluding textiles with high elastane content, which present mechanical challenges during the recycling process. Elastane-rich textiles, especially those containing more than 5% elastane, require significantly more force to disintegrate into fibers, complicating mechanical recycling [32,33]. While existing literature highlights these difficulties, further research is needed to understand the specific performance of textiles with varying elastane percentages in recycling systems [22].

Moreover, material composition is a central concern in sorting. Pure fibers such as 100% cotton and 100% polyester are more easily and efficiently recycled compared to blended fabrics. Separating these pure materials from blends enhances mechanical efficiency and improves the purity of the recycled fibers [34]. Given these challenges, numerous advanced sorting technologies have been developed to optimize recycling outcomes.

6.1. Advanced Sorting Technologies

The adoption of advanced sorting technologies is crucial for scaling up mechanical textile recycling. These technologies improve the speed and accuracy of sorting textile waste into well-defined input fractions, thereby increasing input volumes and reducing costs. As a result, recycled fibers could become more price-competitive with virgin fibers, thereby boosting market demand [22]. Researchers discussed numerous sorting technologies for textile sorting. Faghih et al. (2025) discussed three primary technological approaches for sorting: spectroscopy, imaging, and hyperspectral imaging (HSI) [35]. Each approach offers unique advantages and limitations.

Spectroscopy, particularly near-infrared (NIR) spectroscopy, is the most widely used technique [36]. It enables automated identification of textile materials by analyzing their spectral signatures. NIR operates in the 700–2500 nm wavelength range and can distinguish polymers such as polypropylene (PP), polyethylene terephthalate (PET), and polystyrene (PS) based on their unique spectral profiles. However, limitations remain; for instance, NIR has difficulty detecting dark-colored polymers due to their low reflectivity [36].

Raman spectroscopy, in contrast, detects molecular vibrations through inelastic scattering and provides more precise compositional data [34]. This spectroscopy has been enhanced through integration with artificial intelligence (AI) models. AI-enabled Raman spectroscopy can perform both qualitative and quantitative fiber analysis, improving material classification accuracy. Machine learning (ML) and deep learning (DL) techniques—such as k-nearest neighbors (KNN), decision trees (DT), random forests (RF), support vector machines (SVM), and neural networks (ANNs, CNNs, RNNs, GANs)—are increasingly used to process complex data from Raman spectroscopy for better sorting performance [34]. Leveraging ML, advanced computer vision, and integrating autonomous robotic facilities could improve real-time textile classification, localization, and sorting. Future research directions could include dynamic positioning of the objects, human–robot interaction, and safety in dynamic environments for industrial-scale material recycling automation [37].

Conventional imaging methods, which utilize RGB (red, green, blue) parameters, can differentiate textiles based on shape, color, texture, or surface patterns [35]. However, these methods fall short when it comes to distinguishing textiles with similar visual characteristics but different chemical compositions. HSI, which integrates spectral and spatial data, addresses this limitation. HSI systems can accurately classify textiles such as cotton, polyester, wool, and rayon—even when they appear visually identical—offering a powerful solution for detailed textile analysis [35]. Table 3 demonstrates a comparison of different sorting methodologies.

Table 3.

Comparison of different sorting technologies.

6.2. Eco-Design Strategies and Digital Tagging

In addition to technological innovations, eco-design strategies have been introduced to facilitate sorting and disintegration [22]. Several companies and brands are exploring digital tagging systems such as quick response (QR) codes and radio-frequency identification (RFID) tags [40]. RFID tags, which are embedded into garments, can store information on fiber content, color, and chemical treatments, making them useful tools for automated sorting. However, RFID tags may complicate recycling due to the inclusion of non-textile components, and their long-term impact on recyclability remains uncertain. Moreover, their cost, potential for removal, and inconsistent performance hinder their widespread implementation [22,41].

6.3. Polymer-Based Photonic Fibers

Researchers have developed polymer-based photonic fibers using thermal drawing techniques [41]. These fibers create tunable optical signatures that are compatible with spectroscopy-based sorting systems. Their unique reflectance patterns provide a non-intrusive, integrated solution for garment-level identification, enhancing traceability without adding foreign materials [35,41].

6.4. Challenges and Future Directions

A reliable, industry-ready AI-assisted textile waste-sorting system is essential to support a circular and sustainable economy. Computer-based methods in textile waste sorting have shown promising potential to improve feedstock purity and enhance recycling outcomes. However, several significant challenges remain—most notably, the accurate classification of blended fabrics [35], which is critical for obtaining high-quality fibers with a competitive price in mechanical recycling processes [22,34]. Moreover, current industrial sorting systems are estimated to achieve only around 10% accuracy, highlighting a major limitation [39]. This area remains underexplored and represents a valuable opportunity for future research aimed at improving mechanical textile recycling.

7. Shredding

7.1. Shredding Machines in Waste Processing

Shredding machines are essential in modern waste processing systems and are classified into various types based on the materials they are designed to process [42]. These include aluminum shredders, battery recycling shredders, electronic waste shredders, general waste shredders, green waste shredders, firearm shredders, landfill shredders, medical waste shredders, metal shredders, municipal solid waste (MSW) shredders, pallet shredders, paper shredders, plastic shredders, textile and carpet shredders, tire shredders, and wood shredders. Among these, textile shredders have emerged as one of the most commonly used machines, primarily due to growing concerns about textile waste and the increasing demand for fiber reclamation [42]. A variety of industries and institutions utilize textile shredders to manage textile waste effectively. These include hotels, prisons, hospitals, thrift stores, retail chains, military bases, manufacturers, and government agencies [43].

Textile shredding machines play a critical role in the initial size reduction of textile waste, enabling the reprocessing of shredded materials into recycled fibers [44]. The types of textile waste are highly diverse and include materials from multiple household and industrial sources, such as clothing, kitchenware, bedding, carpets, and upholstery. The machines often come equipped with various auxiliary systems, including balers, conveyors, compactors, metal detectors, enclosed stands, custom hoppers, and Gaylord box dumpers. To manage this wide range of waste materials, textile shredders are designed to be robust and adaptable [43].

Depending on the shred size and output quality required, textile shredders may utilize dual-shaft, triple-shaft, or quad-shaft configurations. Dual shaft shredders, which employ two rotating shafts, are widely used for general-purpose destruction and primary size reduction. In contrast, triple and quad shaft shredders—using three and four counter-rotating shafts, respectively—are employed when a more consistent and uniform particle size is desired [43]. Maintaining a uniform particle size is particularly important for the efficient reclamation of fibers from shredded fabric, as it enhances the quality and applicability of recycled fibers [45].

7.2. Operational Parameters and Process Optimization

The performance of the shredding machine plays a critical role in determining the quality of recycled fibers. Utebay et al. (2019) investigated the impact of various fabric characteristics—such as knit structure, color depth, fabric size, and the number of shredding passages—on shredding outcomes. Their findings showed that greige (undyed) cotton fabrics produced fibers with lower short fiber content, higher tenacity, and reduced hairiness compared to dyed cotton fabrics, suggesting that dyeing processes may weaken fiber integrity. Fabric structure also had a significant effect: single jersey fabrics yielded longer fibers with greater tenacity than tighter interlock structures. Additionally, smaller-sized fabric samples resulted in a higher fiber recovery ratio, and increasing the number of shredding passages to three helped reduce the proportion of short fibers. However, beyond three passages, fiber and yarn properties began to deteriorate, highlighting a trade-off between processing intensity and fiber quality [25]. These insights highlight the importance of optimizing input materials and machine settings to strike a balance between efficiency and fiber preservation in mechanical recycling.

Other key operational parameters, including drum speed and processing time, significantly impacted the quality of recycled fibers. Teixeira Franca Alves et al. (2024) [18] explored key operational parameters of the shredding process, focusing on the relative speed of the drum and processing time. Using denim waste as input, they assessed how these variables influenced process loss, measured through dust generation. Their results indicated that increasing drum speed and extending processing time led to improved fiber and yarn output, with only a minimal increase in dust production. These findings suggest that optimizing mechanical settings can enhance material recovery efficiency without significantly increasing waste. One limitation of the study by Teixeira Franca Alves et al. (2024) [18] is its exclusive focus on denim yarns as the raw material for mechanical recycling. While denim provides useful insights due to its widespread use and durability, the findings may not be fully generalized to other textile types. For a more comprehensive understanding of shredding machine parameters, future research should consider a broader range of woven and knitted fabrics. This would help evaluate whether variations in fabric structure and composition influence fiber recovery efficiency and dust generation under similar machine settings. However, when considered alongside earlier studies (e.g., [25]), this work underscores the importance of fine-tuning both input material characteristics and machine parameters to maintain fiber quality while maximizing yield.

8. Opening

8.1. Opening Machine in Fiber Recovery

Tearing or opening is one of the most crucial steps in the mechanical recycling of textiles [46]. The process was primarily developed for textiles composed mainly of cotton, wool, and acrylic fibers [33]. It involves the successive mechanical drawing and tearing of textiles to break down their structure and recover individual fibers suitable for reuse. Specialized machines perform this function by mechanically tearing the input material and separating it into fibers using a series of large, pin-cylinder assemblies [33,46,47]. Typically, these machines consist of one to six drums arranged in series, allowing for customizable fiber opening intensity based on the material type and desired fiber quality [46]. The first roller performs a coarse opening, while subsequent rollers progressively refine the material, achieving finer separation and further breakdown of fibers [47]. Advanced systems may also include a control unit to monitor fiber quality, a condenser system for fiber delivery, and dust suction systems to manage airborne particles during processing [46]. In some cases, materials may pass through the machine multiple times to attain a specific fiber structure or opening quality [47].

Researchers examined various process parameters to assess the quality of the opening outcome in producing high-quality recycled fibers. Wanassi et al. (2016) [48] investigated the effects of waste yarn length and the number of passages through a Shirley Analyzer recycling machine. Their findings revealed that increasing the number of passages enhances mean fiber length L(w) and upper quartile length UQL(w) but also raises the incidence of neps and short fiber content due to the intensified mechanical action of the saw teeth. Conversely, cutting waste yarns before opening leads to a reduction in L(w) and UQL(w), as shorter yarns are more likely to result in fiber damage during processing [48]. Similar outcomes were observed by Kanan et al. (2024) [49], who tested denim waste yarn using different mechanical process configurations. Their study demonstrated that an opener equipped with seven rollers and a higher number of passages yielded superior results in process efficiency, fiber length, fiber strength, and fiber quality index (FQI) compared to a setup with only two rollers and fewer passages. However, most of this research has been limited to waste yarns [49]. To enhance fiber recovery from woven or knitted post-consumer textile waste, further exploration of these operational parameters—particularly the number of passages—remains essential.

8.2. Role of Fabric Wear and Atmospheric Conditions

The opening process was evaluated to understand the impact of atmospheric conditions and the degree of wear on the recycled fibers. Aronsson and Persson (2020) evaluated the opening process to assess how atmospheric conditions and the degree of fabric wear influence the quality of recycled fibers derived from post-consumer textile waste, specifically T-shirts and jeans. Their findings suggest that heavily worn garments yield longer recycled fibers compared to less-worn textiles, indicating that wear enhances the mechanical disintegration process. In contrast, atmospheric conditions were found to have no significant effect on fiber length during the opening process. However, this study was limited to 100% cotton fiber, which raises concerns about the generalizability of the results [32]. Given the variation in moisture retention and structural properties across different fiber types, further research is necessary to determine whether similar trends hold for other natural fibers such as wool.

8.3. Impact of Material Type and Structure on Fiber Recovery

The efficiency of the opening process is influenced by several factors, including the type of material, the structural characteristics of textile waste, and the quality of the shredding output. Nemeša et al. (2024) reported that while larger pieces of shredded textiles may negatively impact fiber quality, they can also result in longer recycled fibers. Their findings further suggest that the type of fiber—whether natural or synthetic—affects the overall efficiency of the opening process. Additionally, textiles with a knitted or loosely woven structure tend to yield higher-quality and longer recycled fibers compared to those with a tightly woven structure [19].

The differences in mechanical recycling outcomes can be attributed to the inherent structural properties of knitted and woven textiles, which significantly influence their mechanical behavior and end-use performance. Knitted fabrics, composed of interlooped yarns, demonstrate variable porosity and elasticity. These characteristics can be adjusted by altering yarn thickness and stitch length, which affect fabric tightness [50]. In contrast, woven fabrics—formed by interlacing warp and weft yarns—are generally more compact and durable, offering greater load-bearing capacity but limited elasticity. Woven structures resist load at lower elongation levels, while knitted structures tolerate higher elongation before failure [51]. Despite these insights, previous research has not systematically evaluated how specific knitted and woven parameters—such as stitch length, ends per inch, and picks per inch—influence fiber recovery during the opening process. Understanding their impact could contribute to optimizing mechanical processing settings for improved recycling outcomes. Overall, these findings highlight the importance of tailoring opening techniques to the structural and material characteristics of textile waste, thereby enhancing fiber recovery efficiency.

The influence of sample shape and feed direction on the efficiency of the opening process has been investigated to enhance the quality of recycled fibers. Lindström et al. (2024) [28] investigated how these variables affect fiber length and the degree of opening. Their results show that both feed direction and sample shape significantly impact fiber characteristics, including mean length (ML), short fiber content (SFC), and uniformity index (UI). Circular samples fed diagonally demonstrated enhanced spinnability and a narrower fiber length distribution, while rectangular samples exhibited fewer unopened fabric sections, indicating a higher degree of opening [17]. In a related study, Utebay et al. (2019) evaluated the effect of sample size on recycled fiber quality using knitted fabrics and found that feeding smaller-sized samples increased the proportion of short fibers [25]. Despite these findings, the role of sample shape and feed direction in the recycling of knitted fabrics remains underexplored, pointing to a gap in research that warrants further investigation.

9. Evaluation of Recycled Fiber Quality in Mechanical Recycling

The quality of recycled fiber plays a pivotal role in determining the success of subsequent spinning processes and the overall performance of the resulting textile products. Consequently, evaluating fiber quality is essential for optimizing yarn production and achieving desired mechanical and aesthetic properties in the final material. Key indicators of recycled fiber quality include fiber length distribution, strength, fineness, yield of separation, and the degree of opening. A range of methods and instruments—such as the Shirley Analyzer and HVI (High Volume Instrument)—are employed to assess these characteristics [25,48,49]. Specifically, fiber quality assessment often involves metrics such as neps count, fineness, short fiber content (SFC), mean length (ML), fiber tenacity (STR), and the uniformity index (UI). The Uster Advanced Fiber Information System (AFIS) is widely used to measure neps, SFC, ML, STR, and fineness, while the HVI system is typically employed to assess STR and UI. These parameters provide a quantitative basis for evaluating the potential of fiber processing and predicting yarn quality outcomes [49,52]. Understanding and controlling these fiber-level characteristics not only guides process optimization but also ensures that recycled fibers meet the performance requirements of high-quality textile applications.

Parameters of the mechanical recycling process—such as the number of passages and processing time—can have inconsistent effects on the quality of recycled fibers. For example, increasing the number of passages may improve fiber length but also lead to a higher neps count, thereby degrading overall fiber cleanliness. This trade-off highlights the importance of balancing fiber length with nep generation to optimize yarn quality. Understanding how specific process parameters influence these competing quality metrics is therefore critical for improving the outcomes of mechanical recycling.

9.1. Fiber Quality and Spinnability

To provide a comprehensive measure of fiber quality, the Fiber Quality Index (FQI) and the Spinning Consistency Index are calculated. FQI is calculated using the following formula:

FQI = (ML × STR)/Fineness

This index facilitates comparative analysis of various fiber types and processing conditions [49,52]. In addition to the Fiber Quality Index (FQI), the Spinning Consistency Index (SCI) is commonly used to assess the spinnability of cotton fibers. SCI is influenced by several fiber properties, including tenacity, upper half mean length (UHML), uniformity index (UI), and micronaire index (MIC), which collectively reflect the strength and consistency of the fiber supply. The micronaire value, in particular, indicates both the fineness and maturity of the fiber.

Béchir et al. (2018) investigated the effect of the number of passages during the opening process on both FQI and SCI. Their results showed that FQI increased as the number of passages rose from one to seven, suggesting improvements in fiber length and strength. However, SCI decreased with an increasing number of passages, indicating reduced spinning consistency. If fineness, tenacity, and mean length are considered the primary indicators of recycled fiber quality, then the results suggest an overall improvement in reclaimed fiber quality with more passages. In contrast, when micronaire, grade, and uniformity index are prioritized—parameters that directly influence spinnability—the quality of the reclaimed fibers appears to decline with increased passage number [52]. These studies have primarily focused on the effects of the number of passages and processing time on FQI and SCI. However, other influential parameters—such as the size and shape of the textile waste—remain largely unexplored. Further research is needed to investigate how both raw material characteristics and additional process variables affect fiber quality indices (FQI and SCI), as well as the quality of the resulting recycled yarn. However, these findings highlight a trade-off between optimizing fiber properties and maintaining consistent spinning performance. This balance highlights the importance of carefully controlling mechanical processing intensity to maintain fiber integrity during mechanical recycling.

9.2. Quantifying the Degree of Fiber Opening in Mechanical Recycling

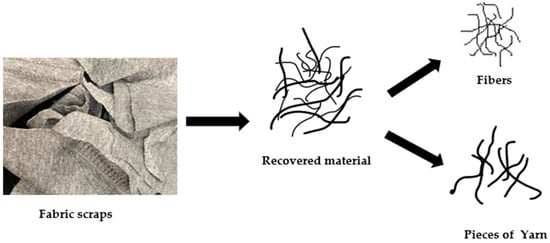

The degree of opening refers to the proportion of fibers that have been successfully separated during the mechanical recycling process. It is typically measured as the ratio of opened fibers to the total output material. Lindström et al. (2024) [28] proposed two main approaches to assess fiber opening. The first method, a direct comparison, examines the quantity of opened fibers and unopened yarns collected in the upper delivery box against the unopened yarns and fabric fragments found in the lower delivery box. Figure 6 shows the recovered materials, which included fibers and pieces of yarn.

Figure 6.

Recovered materials after the opening stage of mechanical recycling, redrawn from [52].

Similar approaches have been reported in earlier studies, particularly through the concept of yield of separation—also known as fraying efficiency—which quantifies the extent of fiber separation during the opening process [48,49,52]. This method quantifies the percentage of fiber separation during the opening stage and is considered a key indicator of mechanical recycling efficiency. It is calculated using the formula:

where MFS represents the total mass of the fiber sample, comprising both the mass of separated fibers (MSF) and non-separated fibers (MNFS).

Yield (%) = (MSF/MFS) × 100,

Although this method offers a straightforward means of quantifying fiber separation, it does not account for the quality or spinnability of the opened fibers. Therefore, while the yield of separation is helpful for evaluating the mechanical effectiveness of the recycling process, it provides limited insight into the functional performance of the reclaimed material in downstream applications such as yarn production.

The second approach, known as the indirect method, estimates the degree of fiber opening by measuring the micronaire value, which reflects the air permeability of a fiber mass. Lindström et al. (2024) [28] implemented this technique using 4-g fiber samples tested under two levels of compression and varying airflow rates. To construct a calibration curve, they prepared five reference mixtures combining opened fibers and unopened yarns in specific ratios: 0/100, 25/75, 50/50, 75/25, and 100/0. Fiber samples from the primary recycling process were collected from the upper delivery box of the recycling machine and compared against these calibration standards. The resulting degree of fiber opening ranged from 40% to 60%, consistent with values reported in earlier studies. However, the study found no clear correlation between the degree of opening and fiber quality parameters critical for spinning performance. Although this method offers a promising tool for evaluating fiber opening in mechanical recycling processes, further investigation is needed to clarify the relationship between fiber opening and downstream yarn quality.

10. Mechanical Textile Recycling: Circularity Pathways and Fiber Considerations

10.1. Open-Loop vs. Closed-Loop Recycling in Mechanical Textile Recovery

Although mechanical textile recycling faces different barriers, it could contribute to closed-loop recycling (CLR) systems. CLR involves reintegrating recycled materials into the same product stream—such as turning discarded textiles back into fibers for garment production [53]. This process helps preserve the mechanical properties of fibers, such as rigidity and strength, which are crucial for textile applications [14].

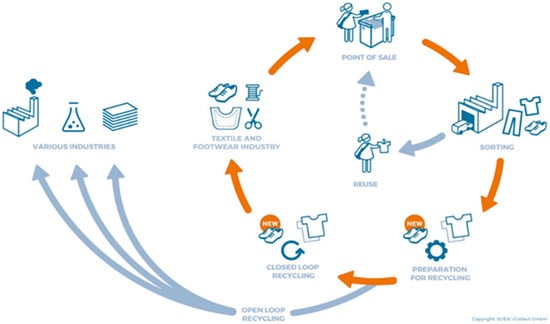

CLR offers notable environmental advantages. For instance, a life cycle assessment (LCA) found that reusing a kilogram of second-hand clothing saves approximately 65 kWh if replacing virgin cotton, and up to 90 kWh when displacing polyester [53]. Additionally, it reduces reliance on virgin fibers. However, while CLR has promise, its scalability is constrained by the need for clean and sorted input materials, particularly pre-consumer textile waste [15,53]. Figure 7 illustrates the circular lifecycle of products through open-loop and closed-loop recycling, from production and sale to sorting, reuse, recycling, and integration into the industry.

Figure 7.

Open loop and closed loop recycling, reprinted with permission from IZ Circular Textiles GmbH [54].

In contrast, open-loop recycling (OLR) involves repurposing materials into unrelated products, often with limited recyclability in their new form. This system typically delays, rather than prevents, entry into the municipal solid waste (MSW) stream. The quality of OLR output depends heavily on the composition of the feedstock. Post-consumer waste, being heterogeneous and degraded, often yields low-grade fiber unsuitable for apparel. Even when using clean pre-consumer waste, mechanical processes shorten fiber lengths, necessitating blending with virgin fibers for high-quality applications. As a result, recycled yarns are frequently directed toward lower-value uses such as carpet underlay, insulation, industrial rags, nonwovens, and fiber for the paper industry [53]. These limitations raise questions about the long-term viability of mechanical recycling as a circular strategy unless innovations in fiber separation and regeneration improve the quality of the output.

10.2. Fiber-Specific Considerations in Mechanical Textile Recycling

Although mechanical methods for converting fabrics back into fiber have been in use since the Industrial Revolution, their applicability varies depending on the type of fiber. For example, mechanical recycling has more flexible applications for wool. Traditional practices such as carded yarn spinning and mixed shoddy spinning are commonly used to convert wool into usable yarn for weaving or knitting [53]. The mechanical recycling of natural fibers, particularly wool, started during World War I. As the yarn quality improved, mainstream clothing companies began using textile mechanical recycling technology to respin post-industrial or post-consumer fabrics into yarn [55]. For wool, both open- and closed-loop recycling methods are utilized. In contrast, the closed-loop process is more commonly applied to cotton in industrial settings.

Additionally, recycled cotton fibers are often blended with virgin fibers to support a semi-closed-loop recycling system [15]. Thus, the mechanical recyclability of textiles depends largely on fiber type, with wool being more adaptable than cotton in maintaining material quality through multiple cycles. However, cotton is the most widely consumed natural fiber and has a significant environmental impact [2]. Therefore, further research is needed to improve the mechanical recycling of cotton waste into high-quality recycled fibers.

11. Conclusions

This review highlights the growing importance of mechanical recycling in the textile industry as a crucial pathway toward environmental sustainability. While notable progress has been made, significant challenges remain in improving the quality and efficiency of mechanically recycled textiles. This review underscores the need for fiber-specific innovations, particularly in the mechanical recycling of synthetic fibers, which constitute a major portion of the fashion supply chain. Advancing this area could enable the production of high-quality recycled synthetic fibers while maintaining economic feasibility.

Furthermore, additional research is needed to improve fiber recovery from post-consumer textile waste, which represents the largest share of textile waste but presents complex processing challenges. Key areas for further exploration include optimizing pretreatment processes—particularly the selection and concentration of lubricants tailored to various fiber blends—to support scalability and reduce environmental impact. Moreover, this review identifies an urgent need to advance sorting technologies for the precise identification of blended fabrics and improvement of feedstock purity and overall recycling outcomes.

This study emphasizes the need to better understand opening and shredding processes, particularly across a broader range of woven and knitted fabrics. Additionally, variations in structural properties, such as stitch length, ends per inch, and picks per inch, significantly impact recycling performance and must be systematically evaluated. Moreover, the effects of moisture on fiber processing, particularly in natural fibers such as flax and wool, warrant further exploration. Understanding the relationship between shredding and fiber opening processes is crucial. Future research should focus on quantifying the degree of fiber opening after each stage and exploring how the initial shredding influences the efficiency of subsequent opening. Optimizing these parameters will be vital for improving process scalability, material quality, and overall sustainability in mechanical textile recycling. Overall, efficient mechanical recycling of textile waste requires scalable AI-assisted sorting, cost-effective pretreatment formulations, and optimized shredding and fiber opening parameters to reduce processing costs while mitigating the environmental footprint of fashion supply chains.

Author Contributions

Writing—original draft preparation, visualization, analysis, M.M.I.; writing—original draft preparation, supervision, conceptualization, funding, R.Y.; Conceptualization, supervision, review and editing, funding, A.W.; All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the NSF Engines Program (Award No. 2315305) through direct sponsorship from The Industrial Commons and NSF Career Award (Award No. 2440915).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

Glossary

AFIS (Advanced Fiber Information System)—A fiber testing instrument used to characterize properties such as fiber length, diameter (fineness), neps, short fiber content (SFC), and tenacity, especially in cotton and short-staple fibers.

Baling Press—A mechanical device used in the textile industry to compress and package textile waste into compact bales for easier handling, transport, and processing.

Biological Recycling—A recycling method that uses biological agents such as enzymes or microorganisms to break down textile or organic waste into reusable compounds.

Closed-Loop Recycling (CLR)—A recycling system in which textile materials, after use, are collected and reprocessed to produce new fibers, fabrics, or garments of similar quality. CLR supports circularity and reduces dependence on virgin resources.

De-Wiring Station—A unit in textile recycling lines used to remove metal wires or plastic bands from bales, ensuring safer and more efficient downstream processing.

Degree of Opening—A measure of how effectively fibers have been disentangled and separated from the original textile structure during mechanical recycling.

Deep Learning (DL)—A subfield of machine learning that uses multi-layered neural networks to analyze complex visual or spectral data. In textile recycling, it aids in tasks like material classification, defect detection, and automated sorting.

Elastane—A synthetic fiber known for its high elasticity, commonly used in stretch fabrics. High elastane content makes mechanical recycling challenging due to its resistance to disintegration.

Fiber Tenacity (STR)—A measure of fiber strength, expressed as the force required to break the fiber per unit of its linear density (e.g., cN/tex).

Greige Fabric—Raw, unfinished woven or knitted fabric taken directly from the loom or knitting machine, without bleaching, dyeing, or finishing.

Hyperspectral Imaging (HSI)—A technology that captures detailed spatial and spectral information across many wavelengths to identify and classify textile fibers with high precision. It is widely used in textile sorting for recycling.

Mean Fiber Length (ML)—The average length of individual fibers in a sample. It is a key parameter for assessing fiber quality and predicting spinnability.

Micronaire (MIC)—An index measuring the air permeability of compressed textile fibers, providing insight into fiber fineness and maturity. It is used to assess fiber quality and spinnability.

Municipal Solid Waste (MSW)—Commonly referred to as trash or garbage, this includes waste materials generated by households and businesses.

Near-Infrared (NIR) Spectroscopy—A non-destructive analytical technique that uses near-infrared light to identify and sort textile fiber compositions. It enhances material recovery efficiency in recycling.

Neps—Small, tangled clusters or knots of fibers that form during mechanical processing, such as carding or opening. A high nep count indicates poor fiber cleanliness and negatively affects yarn quality.

Open-Loop Recycling (OLR)—A recycling system where recovered materials are repurposed into different, typically lower-value products. This delays their disposal but does not support full material circularity.

Picks per Inch (PPI)—A measurement of the number of weft (horizontal) yarns in one inch of woven fabric.

Photonic Fibers—Advanced fibers embedded with unique optical features, such as structural color or barcode-like signatures, enabling automated identification in textile sorting systems.

Raman Spectroscopy—An analytical technique based on the inelastic scattering of light, used to identify fiber materials and dyes by their unique molecular fingerprints.

Shirley Analyzer—A laboratory instrument used to assess fiber properties such as short fiber content and neps. It is widely applied in evaluating cotton and recycled fiber quality.

Short Fiber Content (SFC)—The percentage of fibers in a sample that fall below a certain length threshold.

Shredding—A mechanical process that tears or cuts textile waste into smaller pieces, facilitating fiber recovery in mechanical recycling operations.

References

- Lindström, K.; Sjöblom, T.; Persson, A.; Kadi, N. Improving mechanical textile recycling by lubricant pre-treatment to mitigate length loss of fibers. Sustainability 2020, 12, 8706. [Google Scholar] [CrossRef]

- Textile Exchange Conference. 2024. Available online: https://textileexchange.org/ (accessed on 27 April 2025).

- Statista. 2025. Available online: https://www.statista.com/statistics/1250812/global-fiber-production-share-type/ (accessed on 22 July 2025).

- McLoughlin, J.; Hayes, S.; Paul, R. Cotton fibre for denim manufacturer. In Denim Manufacture, Finishing and Applications; Woodhead Publishing: Sawston, UK, 2015; pp. 15–36. [Google Scholar] [CrossRef]

- Textile Waste: Federal Entities Should Collaborate on Reduction and Recycling Efforts. Available online: https://files.gao.gov/reports/GAO-25-107165/index.html?_gl=1*b1u6h9*_ga*MjkyODI3MzUuMTczNzIyMDk1N (accessed on 27 April 2025).

- EPA. Textiles: Material-Specific Data. 2022. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/textiles-material-specific-data (accessed on 27 April 2025).

- U.S. Environmental Protection Agency. Available online: https://www.epa.gov/sites/default/files/2020-11/documents/2018_ff_fact_sheet.pdf (accessed on 27 April 2025).

- What Really Happens to Unwanted Clothes? Green America. Available online: https://www.greenamerica.org/unraveling-fashion-industry/what-really-happens-unwanted-clothes (accessed on 27 April 2025).

- Gan, S.; Xiao, S.; Liu, T.; Wang, C.; Li, S.; Sun, Y.; Tang, Y. Recycle waste PET yarn on site by feeding waste yarn as grinded powder to improve product quality, increase energy efficiency and reduce environmental impact. J. Eng. Fibers Fabr. 2024, 19, 15589250241242009. [Google Scholar] [CrossRef]

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.S. Possibility routes for textile recycling technology. Polymers 2021, 13, 3834. [Google Scholar] [CrossRef] [PubMed]

- Celep, G.; Tetik, G.D.; Yilmaz, F. Limitations of textile recycling: The reason behind the development of alternative sustainable fibers. In Next-Generation Textiles; IntechOpen: London, UK, 2022. [Google Scholar]

- Huang, X.; Tan, Y.; Huang, J.; Zhu, G.; Yin, R.; Tao, X.; Tian, X. Industrialization of open-and closed-loop waste textile recycling towards sustainability: A review. J. Clean. Prod. 2024, 436, 140676. [Google Scholar] [CrossRef]

- Yousef, S.; Tatariants, M.; Tichonovas, M.; Kliucininkas, L.; Lukošiūtė, S.; Yan, L. Sustainable green technology for recovery of cotton fibers and polyester from textile waste. J. Clean. Prod. 2020, 254, 120078. [Google Scholar] [CrossRef]

- Raluca, B.R.A.D. Circular economy and recycling in the textile industry. Ann. Univ. Oradea. Fascicle Text. Leatherwork 2023, 24, 17–26. [Google Scholar]

- Tripathi, M.; Sharma, M.; Bala, S.; Thakur, V.K.; Singh, A.; Dashora, K.; Hart, P.; Gupta, V.K. Recent technologies for transforming textile waste into value-added products: A review. Curr. Res. Biotechnol. 2024, 7, 100225. [Google Scholar] [CrossRef]

- Yatvitskiy, M.; Ludwig, K.; Gupman, S.; Cobb, K.; Cao, H.; Clarke-Sather, A. Innovative methods for secondary material development in mechanical textile recycling. In Proceedings of the International Textile and Apparel Association Annual Conference Proceedings, Shanghai, China, 11–13 October 2025; Iowa State University Digital Press: Ames, IA, USA, 2025; Volume 81. [Google Scholar]

- Lindström, K.; van der Holst, F.; Berglin, L.; Persson, A.; Kadi, N. Mechanical textile recycling efficiency: Sample configuration, treatment effects and fibre opening assessment. Results Eng. 2024, 24, 103252. [Google Scholar] [CrossRef]

- Teixeira França Alves, P.H.; Clarke-Sather, A.; Carlson, S.; Martini, A. Theoretical Method for Characterizing Textile Failure Mechanics in Mechanical Recycling with Carded Drums. In Proceedings of the International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, New Brunswick, NJ, USA, 12–16 June 2023; p. 87233. [Google Scholar] [CrossRef]

- Nemeša, I.; Pešić, M.; Bozoki, V. Mechanical recycling of textile waste. Tekst. Ind. 2024, 72, 24–28. [Google Scholar]

- Harmsen, P.; Bos, H. Textiles for Circular Fashion: Part 1: Fibre Resources and Recycling Options; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2020. [Google Scholar]

- ISO 5157:2023; Textiles Vocabulary—Part 13: Recycling, Reuse and Regenerated Fibres. International Organization for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/82145.html (accessed on 12 August 2025).

- Hinzmann, M.; Hirschnitz-Garbers, M.; Sachdeva, A.; Duhoux, T.; Maes, E.; Peeters, K.; Colignon, P. Study on the technical, regulatory, economic and environmental effectiveness of textile fibres recycling. Eur. Comm. 2021, 24, 205. [Google Scholar]

- Andritz. Available online: https://www.andritz.com/products-en/annual-report/nonwoven-textile/textile-recycling-overview-nonwoven-and-textile#and-anchor2 (accessed on 18 July 2025).

- Sustainability Directory. Why Are Synthetic Fibers Difficult to Recycle? Available online: https://pollution.sustainability-directory.com/question/why-are-synthetic-fibers-difficult-to-recycle/ (accessed on 20 August 2025).

- Utebay, B.; Celik, P.; Cay, A. Valorization of fabric wastes through production of recycled cotton yarns by compact ring and open-end rotor spinning. J. Clean. Prod. 2023, 409, 137135. [Google Scholar] [CrossRef]

- Koszewska, M. Circular economy—Challenges for the textile and clothing industry. Autex Res. J. 2018, 18, 337–347. [Google Scholar] [CrossRef]

- Textile Exchange. Guide to Recycled Materials. Available online: https://2d73cea0.delivery.rocketcdn.me/app/uploads/2021/09/GRS-202-V2.0-Guide-to-Recycled-Materials.pdf (accessed on 20 August 2025).

- Lindström, K.; Sjöblom, T.; Persson, A.; Kadi, N. Decreasing inter-fiber friction with lubricants for efficient mechanical recycling of textiles. In Proceedings of the 19th World Textile Conference-Autex 2019, Ghent, Belgium, 12–16 June 2019. [Google Scholar]

- Valmet Forward. Available online: https://www.valmet.com/more-industries/textiles/technologies-textile-recycling/mechanical-recycling/ (accessed on 18 July 2025).

- Gun, A.D.; Oner, E. Investigation of the quality properties of open-end spun recycled yarns made from blends of recycled fabric scrap wastes and virgin polyester fibre. J. Text. Inst. 2019, 110, 1569–1579. [Google Scholar] [CrossRef]

- de Oliveira Neto, G.C.; Teixeira, M.M.; Souza, G.L.V.; Arns, V.D.; Tucci, H.N.P.; Amorim, M. Assessment of the Eco-Efficiency of the Circular Economy in the Recovery of Cellulose from the Shredding of Textile Waste. Polymers 2022, 14, 1317. [Google Scholar] [CrossRef] [PubMed]

- Aronsson, J.; Persson, A. Tearing of post-consumer cotton T-shirts and jeans of varying degree of wear. J. Eng. Fibers Fabr. 2020, 15, 1558925020901322. [Google Scholar] [CrossRef]

- Refashion. Mechanical Recycling Process. Available online: https://recycle.refashion.fr/wp-content/uploads/2025/04/REFASHION_Mechanical-recycling-of-textiles.pdf (accessed on 5 July 2025).

- Tsai, P.F.; Yuan, S.M. Using Infrared Raman Spectroscopy with Machine Learning and Deep Learning as an Automatic Textile-Sorting Technology for Waste Textiles. Sensors 2025, 25, 57. [Google Scholar] [CrossRef] [PubMed]

- Faghih, E.; Saki, Z.; Moore, M. A Systematic Literature Review—AI-Enabled Textile Waste Sorting. Sustainability 2025, 17, 4264. [Google Scholar] [CrossRef]

- Sasikumar, U.; Mundkur, S.; Athalye, A. Strategies for Separating and Recycling Textile Blends. Adv. Environ. Waste Manag. Recycl. 2023, 6, 443–450. [Google Scholar]

- Halvorsen, T.S.; Tyapin, I.; Jha, A. Autonomous textile sorting facility and digital twin utilizing an AI-reinforced collaborative robot. Electronics 2025, 14, 2706. [Google Scholar] [CrossRef]

- Puchowicz, D.; Cieslak, M. Raman spectroscopy in the analysis of textile structures. In Recent Developments in Atomic Force Microscopy and Raman Spectroscopy for Materials Characterization; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Stipanovic, H.; Koinig, G.; Fink, T.; Schimper, C.B.; Lilek, D.; Egan, J.; Tischberger-Aldrian, A. Quantifying cotton content in post-consumer polyester/cotton blend textiles via NIR spectroscopy: Current attainable outcomes and challenges in practice. Recycling 2025, 10, 152. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The Jeans Redesign—Insights from the First Two Years, 2019–2021. 2021. Available online: https://content.ellenmacarthurfoundation.org/m/68b1aa5ebfef9d4/original/The-Jeans-Redesign-Insights-from-the-first-two-years.pdf (accessed on 19 July 2025).

- Iezzi, B.; Shtein, M.; Wang, T.; Rothschild, M. Fiber and Fabric-Integrated Tracing Technologies for Textile Sorting and Recycling: A Review. In Technology Innovation for the Circular Economy: Recycling, Remanufacturing, Design, Systems Analysis and Logistics; Scrivener Publishing LLC: Beverly, MA, USA, 2024; pp. 223–237. [Google Scholar]

- Textile Shredders for Textile Recycling. Shred Trucks, Industrial Shredders, Slow-Speed Shredders, Shred-Tech. Available online: https://shred-tech.com/textile-shredder/ (accessed on 19 July 2025).

- Textile Shredders. Amos Mfg., Inc. Available online: https://www.amos-mfg.com/shredding-applications/textile-shredders/ (accessed on 19 July 2025).

- Shredders for Textile Recycling. Schutte Hammermill. Schutte Hammermill. Available online: https://www.hammermills.com/recycling/textiles/ (accessed on 19 July 2025).

- Single Shaft Industrial Shredders. Vecoplan, LLC—Industrial Shredder Manufacturer. Available online: https://www.vecoplanllc.com/size-reduction-equipment/industrial-shredders/single-shaft-shredders?material=28 (accessed on 19 July 2025).

- Margasa. Textile Recycling Lines. Available online: https://exhibitorsearch.messefrankfurt.com/images/original/document_downloads/10000008202401/345410/1708430551717_3662456617.pdf (accessed on 5 July 2025).

- Expertise Areas. Available online: https://www.ri.se/en/expertise-areas/expertises/tearing-and-processing-of-textile-materi (accessed on 5 July 2025).

- Wanassi, B.; Azzouz, B.; Hassen, M.B. Value-added waste cotton yarn: Optimization of recycling process and spinning of reclaimed fibers. Ind. Crops Prod. 2016, 87, 27–32. [Google Scholar] [CrossRef]

- Kanan, M.; Wannassi, B.; Azouz, B.; Hassen, M.B.; Assaf, R.; Barham, A.S. Cotton recycling: An experimental study of the mechanical preparation process. Case Stud. Chem. Environ. Eng. 2024, 10, 100849. [Google Scholar] [CrossRef]

- Dias, T.; Delkumburewatte, G.B. Changing porosity of knitted structures by changing tightness. Fibers Polym. 2008, 9, 76–79. [Google Scholar] [CrossRef]

- Gong, H.; Ozgen, B. Fabric structures: Woven, knitted, or nonwoven. In Engineering of High-Performance Textiles; Woodhead Publishing: Sawston, UK, 2018; pp. 107–131. [Google Scholar] [CrossRef]

- Béchir, W.; Béchir, A.; Mohamed, B.H. Industrial cotton waste: Recycling, reclaimed fiber behavior and quality prediction of its blend. Text. Appar. 2018, 28, 14–20. [Google Scholar]

- Payne, A. Open-and closed-loop recycling of textile and apparel products. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing; Woodhead Publishing: Sawston, UK, 2015; pp. 103–123. [Google Scholar]

- SOEX. IZ Circular Textiles GmbH. Available online: https://www.soex.de/en/ (accessed on 11 July 2025).

- Patagonia, Mechanical Recycling. Available online: https://www.patagonia.com/our-footprint/mechanical-recycling.html (accessed on 11 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).