Abstract

Washing performance depends on the specific interactions between textiles, stains, detergents, mechanical action, temperature, and time. Its evaluation therefore requires a fundamental and practical understanding of the effects of the washing parameters, the type of soiling, and the tendency of the textiles to stain. Due to the complexity of these interactions, the evaluation of stain removal requires specific types of textiles, stains, and detergents. In this study, the temperature-specific behavior of detergents was studied in the washing process of cotton knitwear with a blank spot and 15 stains of different origin and composition at 60 °C and 90 °C. Despite the labeled composition of detergents, the detergent ingredients, surfactants, and bleaching agents were analyzed by titration methods. The evaluation of the total washing performance (TWP) and specific washing performance (SWP) was carried out by measuring reflectance as a spectral parameter. A hierarchical cluster analysis was carried out to compare the specific effects of detergents at both temperatures. The analysis of the detergents revealed fluctuations in the content of the surfactants and bleach. Some detergents with a higher surfactant content (SAS) showed poorer performance in washing at 60 °C compared to detergents with a lower SAS content. The dendrogram showed subtle similarities and dissimilarities between the detergents, which contributed to clarification of the total wash performance at both temperatures. The results proved that the quantitative indicators of the proportions of certain ingredients in a detergent are not the only criteria for evaluating the quality of a particular detergent. All detergents investigated showed a temperature-specific behavior, which was reflected in an increased TWP at 90 °C, while some detergents selectively improved the SWP at 90 °C.

1. Introduction

Soil can be defined as particles or substances that become attached to the surface of the material by contact, from the atmosphere, by wiping, and/or their combination. No matter how valuable a substance may be for its intended purpose, when in the wrong place, it becomes harmful and must be removed. For example, the highest quality lipstick on textiles can be very harmful. Red wine, coffee, fruit juices, etc., are highly prized drinks, but they are unpleasant stains on textiles. The same applies to soot, grease, blood, etc. Accordingly, soil is a common term for a variety of foreign substances that have been transferred onto textiles during use and production and need to be removed because they affect the appearance of the textiles and sometimes give them an unpleasant odor, e.g., sweat, urine, feces, etc. [1,2,3,4,5].

From the point of view of washing agents, stains can be categorized into water-soluble substances (inorganic salts, sugar, urine, and sweat); pigments (metal oxides, carbonates, silicates, humus, and soot); oils and fats (animal fats, vegetable fats and oils, tallow, mineral oils, fats, and waxes); proteins (blood, milk, eggs, and keratin of the skin); carbohydrates (starch); and coloring substances (from fruit and vegetables, wine, coffee, and tea). In practice, soils and stains contain a combination of the different types mentioned above [4,6,7].

The interaction between the soil and the textile depends on the properties of the textile material and the soil. Stain removal in the washing process takes place in three phases: (i) the soil is loosened from the surface of the substrate to be washed, (ii) the loosened soil is removed from the substrate and dispersed in the wash bath, (iii) the soil that has passed into the liquid is prevented from redepositing onto the substrate [8].

Washing is a complex and multiphase process involving numerous physical and chemical interactions. The interaction between the soiled laundry and the water, the mechanical and thermal energy, and the detergents contribute to the washing performance and the lifespan of the textiles [1]. The presence of four basic factors, chemical action, mechanical movement, temperature, and time, with water forming the inner cycle, is represented by the Sinner’s circle [2]. Theoretically, the contributions of all four factors in the Sinner’s circle, which are connected by water, are equal. In the real process, a reduction in one factor increases the contribution of one or more of the other factors.

The powder, liquid, or gel detergent formulations contain a mixture of surfactants and additives, responsible for the chemical action during the washing process [3]. Anionic surfactants focus on wetting, soil particle removal, and soil suspension, while non-ionic surfactants have no effect on the electrophoretic mobility of particles in suspension, but they are effective in the stain removal and solubilization process in a wash [6,7]. The action of cationic surfactants is mostly oriented towards softening, disinfection, or antistatic effects. Builders are capable of complexing alkaline earth and heavy metal ions, as well as those acting by ion exchange, contributing to the interaction with the other components during the washing process, such as alkalinity, water softening, and the solubilization of particles in a suspension (e.g., particles of dyes, soils, pigments, etc.). Optical brighteners (OBA) are included in many detergent formulations as they improve the brightness and whiteness of textiles, which is an important criterion for optical effects and appearance [5]. Enzymes are natural catalysts for certain insoluble stains that break down a specific type of organic molecule to improve the washing performance of a degreasing agent. The importance of enzymes in the removal of water-insoluble stains is emphasized by their specific effect on the substrate and the water-soluble degradation products [9,10,11]. The hydrodynamic effect also contributes to the washing performance. Centrifugal acceleration and reversible rotation influence the mechanical action within the washing machine, contributing to the removal of soil and stains. The bath and the load ratio determine the concentration and effectiveness of the wash. Temperature, which varies from region to region, influences the chemical action of detergents and bleaches, increasing their effectiveness and achieving a sanitizing effect. Knowledge of all variables is important in order to optimize the washing process and achieve the desired effects [12].

This study focuses on the evaluation of the temperature-specific behavior of detergents in the removal of stains or dirt from cotton knitwear carriers with 15 stains (EMPA 102). The washing trials involved varying the seven products in total (six branded detergents and reference detergents), temperature (60 °C and 90 °C), and time, while maintaining consistent mechanical agitation and laundry. The detergents were compared by analyzing anionic and non-ionic surfactants, soap, and bleach. The total washing performance (TWP) was evaluated by measuring the reflectance values of stains after the washing process at temperatures of 60 °C and 90 °C. The same methodology was applied for the specific washing performance (SWP), monitored through the detergency and the effect of bleaching agent and enzymes. A cluster analysis of the performance of the detergents at the selected temperatures was performed to identify both similarities and differences.

2. Materials and Methods

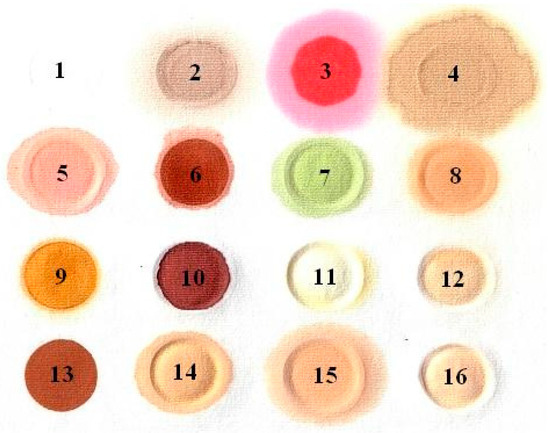

The washing performance followed a modified method ASTM D4265-21: Standard Guide for Evaluating Stain Removal Performance in Home Laundering [13] in which the reference cotton knitwear, SWT 102 from the Swiss Research Institute for Applied Materials Science and Technology–EMPA, St. Gallen, Switzerland, in dimensions 23 × 19 cm, was selected as the carrier of 15 different circular stains, as seen in Figure 1 and Table 1.

Figure 1.

Cotton knitwear as a carrier of specific stains (EMPA SWT 102).

Table 1.

Position and specification of stains on EMPA cotton knitwear carrier and evaluation criteria (D, B, E) marked with x.

The stain monitor SWT 102 contains 16 positions: no stain (position 1) and 15 different specific stains on cotton knitwear, designed by EMPA as the world’s leading institution for reference test materials. The specification of the EMPA knitwear monitor through stain positions and the evaluation criteria for SWP across the categories of the detergency (D), the activity of the bleach (B), and the enzyme (E), specified in activity of the lipases (L), proteases (P), and amylases (A), is presented in Table 1. The connection of a certain stain with SWP is marked with an x. Position 1 corresponds to the clean knitwear (without stains), which is used to evaluate re-deposition in the washing process.

The EMPA knitwear carrier with stains was exposed to a washing process in a Polymat (W. Mathis, Oberhasli, Switzerland), with powder detergents (D) in a concentration of 5 g/L and bath ratio of 1:5. The washing process was conducted at 60 °C and 90 °C in tap water with a hardness of 340 ppm. After the wash cycle, the textile carrier was rinsed four times, also with tap water, to remove detergent residues and impurities. After rinsing, the samples were air-dried at room temperature.

The labeled compositions of branded detergents (D-1, D-2, D-3, D-4, D-5, D-6) and the reference detergent (D-R) used are specified in Table 2.

Table 2.

Composition of detergents tested.

Methods

The detergent acts locally on certain stains, which leads to uneven stain removal. Therefore, the spectral properties of the individual stains were measured on a cotton knit carrier (EMPA 102) at four different, randomly selected positions using a reflectance spectrophotometer, Spectraflash SF300, DataColor AG (Rotkreuz, Switzerland), with an aperture of 20 mm, standard light D65, and d/8° geometry. The reflectance value (R) at a wavelength of 460 nm was selected as the spectral parameter for assessing stain removal [14,15]. The stain removal, S/ΔR460, was calculated according to Equation (1):

where Rw is a reflectance of a stain after washing process and R0 is a reflectance of a stain (before washing process), both at a wavelength of 460 nm.

ΔR460 = Rw − R0

The total washing performance (TWP) was expressed by the sum of the reflectance values (ΣR460) of the stain positions (2–16) after washing at 60 °C and 90 °C.

The difference in total washing performance (ΔTWP) was calculated between the values ΣR460 at 90 °C and ΣR460 at 60 °C.

To estimate the impact of detergents, a multivariate analysis was chosen as a method to characterize the total washing performance at 60 °C and 90 °C. Dendrograms, as the result of the hierarchal cluster analysis (HCA), also indicated the grouping of detergent ingredients.

Since the removal of certain stains on cotton substrates involves the action of surfactants, bleaching agents, and enzymes, it is important to achieve a synergy of surfactants, bleaching agents, and enzymes as well as other ingredients in detergent formulation. Therefore, the content of surfactants and bleaching agents was analyzed according to [16], despite the composition being stated on the packaging of the detergent.

Potentiometric titrations were performed using the Metrohm Autotitrator 736 GP Titrino and electrodes, all from Metrohm, Herisau, Switzerland. The high-sense surfactant electrode (6.0504.150) as an ion-selective surfactant electrode and the NIO surfactant electrode (6.0507.010) were used in combination with the reference, the Ag/AgCl electrode (6.0733.100), for the determination of anionic and non-ionic surfactants (NS).

The titration solution for anionic surfactants was the cationic surfactant Hyamine 1622 (0.004 mol/L), which was purchased from Merck KGaA, Darmstadt, Germany. The titration protocol was agreed with [17] at a pH of 3 (buffer solution from GRAM-MOL, Zagreb, Croatia) for anionic and a pH of 10 (buffer solution from GRAM-MOL, Zagreb, Croatia) for soap in a detergent solution. After completion of a titration, the soap content (SS) was calculated by the difference between the content at pH 10 and pH 3.

The titration solution used to analyze the non-ionic surfactant was sodium tetraphenylborate (0.01 mol/L) from Merck KGaA, Darmstadt, Germany, which was able to form a pseudo-cationic complex with BaCl2 (0.1 mol/L) supplied by GRAM-MOL, Zagreb, Croatia. The solution of a Triton X-100, supplied by Fisher Chemical, Loughborough, UK, as a non-ionic surfactant with a defined number of polyoxyethylene groups in the structure, was previously analyzed based on the determination of a calculation factor [18] to determine the content of non-ionic surfactant in a detergent solution.

The content of active oxygen in a bleach-active substance in a detergent solution acidified with 20 mL sulfuric acid (10%) was determined using the titrimetric method with potassium permanganate (0.02 mol/L) and calculated as sodium percarbonate (SPC) [19].

3. Results and Discussion

The composition of the detergents is given in Table 2 in accordance with the legal requirements, using a wide range of surfactants and bleaching agents as detergent ingredients. To clarify the temperature-specific behavior of the detergents tested, analytical methods were used to determine the content of anionic and non-ionic surfactants as well as soap and sodium percarbonate. The content of cationic surfactants was not determined as certain stains do not require the action of cationic surfactants, which are mainly used for their softening, antistatic, and antimicrobial effects.

3.1. Analysis of Detergents

The contents of surface-active substances (SAS), presented as a sum of the anionic surfactant (AS), non-ionic surfactant (NS), and soap (S), and the bleaching agent (SPC) are specified in Table 3.

Table 3.

The contents of surface-active substances and bleach in tested detergents.

The content of anionic surfactants (AS) in the detergents analyzed varies and ranges from app 4.62% (D-4) to 20.95% (D-5). Due to this variability, temperature-specific behavior at 60 °C and 90 °C is to be expected, especially in wetting, particle removal, and suspension, as well as the ability to remove greasy stains, particularly at 90 °C.

There are also differences in the content of non-ionic surfactants (NS), although the range of these values is significantly smaller compared to anionic surfactants. The highest proportion of non-ionic surfactants is found in D-3 (13.14%) and the lowest in D-6 (1.38%). These differences could have an impact on the TWP at 60 °C and 90 °C, especially on the ability to remove greasy stains, solubilization, and the degree of re-deposition.

The content of soap in each detergent varied, with the lowest value in D-6 (0.38%) and the highest in D-1 (4.53%). Although the role of soap in modern washing processes is mainly associated with foam control, its content, together with the content of anionic and non-ionic surfactants, contributes to the total surfactant content, SAS [18]. This value is approximately in the range of 13 to 29% for the detergents analyzed, with D-4 having the lowest value (12.98%) and D-5 the highest (31.62%).

The bleach content, expressed as the amount of sodium percarbonate (SPC), ranges from about 10% to about 20%, with D-1 having the highest SPC value (19.47%) and D-4 the lowest (9.47%). The differences in bleach content indicate possible variations in the removal of color stains.

The analysis of the detergents revealed fluctuations in the content of the ingredients analyzed. However, the quantitative indicators of the proportions of certain ingredients in a detergent are not the only criterion for assessing the quality of a particular detergent. Attention should be paid to the synergy and interaction of a fabric carrier with certain stains and the temperature-specific behavior of detergents in the washing process at 60 °C and 90 °C.

3.2. Analysis of Total Washing Performance (TWP)

The interaction of the textiles to be washed with the synergy of factors (chemical action, mechanical agitation, temperature, and time) in a Sinner cycle affects the primary effectiveness of the washing process. An increased proportion of chemicals in the low-temperature washing process is enhanced by the content of non-ionic surfactants, enzymes, and bleach activators in detergents [20].

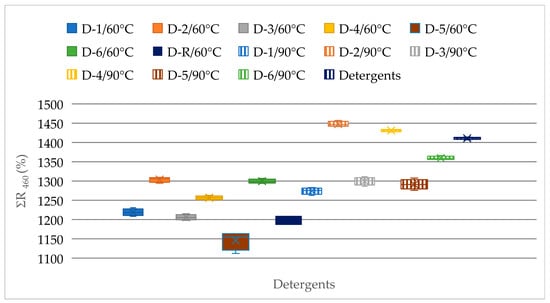

The temperature-specific behavior of all detergents was compared by a total wash performance (TWP), expressed as the sum of the reflectance values at a wavelength of 460 nm (ΣR460) of all stains on cotton knitwear after washing with detergents at 60 °C and 90 °C, as shown in Table 4 and Figure 2.

Table 4.

The sum of reflectance values for all stains on cotton knitwear before and after washing at 60 °C and 90 °C and statistical indicators.

Figure 2.

The TWP in processes at 60 °C and 90 °C.

The statistical indicators in Table 4 and data bars in Figure 2 helped to highlight data trends and compare values within a range. Detergents D-3, D-4, D-5, and D-R showed temperature-specific behavior when the standard deviations of reflectance values were taken into account. The standard deviations in the TWP of detergents are higher in the washing at 60 °C; the only exception is D-3.

The temperature-specific behavior is observed for all detergents, and the difference in TPW (ΔTWP) showed the relationship between them. These values can be expressed in order from least to greatest: D-1 (55.29%), D-6 (60.0%), D-3 (93.82%), D-2 (143.89%), D-5 (145.05%), D-4 (174.67%), and D-R (214.01%).

The total wash performance (TWP), expressed by the sum of the reflectance values for washed cotton knitwear with 16 positions (ΣR460) in Table 4 and Figure 2, showed that washing at 90 °C with all detergents increased the sum of the reflectance values, ΣR460, compared to the washed cotton knitwear with 16 positions at 60 °C.

The data bars in Figure 2 show the relative size of the values, making it easier to compare washing performance data.

The data presented in Table 4 and Figure 2 show that the lowest total washing performance was achieved with detergents D-1, D-3, and D-5, whereby the temperature-specific behaviors of D-1 and D-3 are less pronounced than that of D-5. This can be attributed to the higher proportion of anionic surfactants in D-5 and their better performance at high temperatures.

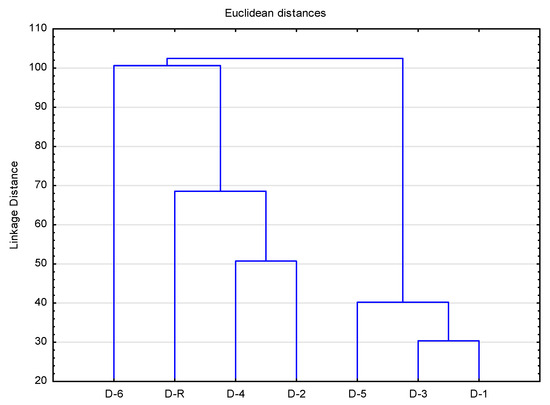

For further analysis and a better insight into the joint influence of temperature and individual detergents as well as their similarities and differences, a cluster analysis of the data for each member of the total sum of reflectance for each detergent was performed. The results of the cluster analysis (CA) are shown as a dendrogram in Figure 3, which shows a grouping of detergents.

Figure 3.

Dendrogram of the CA according to Ward for similarities and dissimilarities based on detergents as variables.

The analysis of TWP at 60 °C and 90 °C with the detergents as variables also confirmed the separate grouping of detergents, with D-6, D-R, D-4, and D-2 belonging to the same group, while D-1, D-3, and D-5 belong to the separate group specified by small differences, seen in Figure 3.

3.3. Analysis of Specific Washing Performance (SWP)

The presence of stains on textile materials is often due to a chemical reaction between the soil and the textile substrate, or a mechanical interaction, which involves the adhesion of the soil to the substrate’s surface, influenced by the stain’s composition and the substrate’s properties. Typically, the interaction between the stain and the substrate does not occur instantly, which is why it is easier and quicker to eliminate fresh stains [21]. The re-deposition of stains from the wash bath to the empty position 1 of the cotton knitwear is shown in Table 5 while the specific washing performance (SWP) of detergents at 60 °C and 90 °C, expressed by reflectance difference (ΔR460), as shown in Table 6, Table 7 and Table 8.

Table 5.

Assessment of re-deposition in a washing process at 60 °C and 90 °C.

Table 6.

Specific washing performance–detergency and detergency mediated by lipases activity (*) in removal of pigment and fat/oil stains from cotton knitted fabric at 60 °C and 90 °C.

Table 7.

Specific washing effect (bleach) and bleach mediated by proteases (**) and amilases (***) activity in removal of colored stains from cotton knitted fabric at 60 °C and 90 °C.

Table 8.

Specific washing effect (enzyme activity of lipases (*) and proteases (**)) in removal of chocolate dessert stain from cotton knitted fabric at 60 °C and 90 °C.

Position 1—Empty

Position 1 belongs to a cotton knitwear (R = 105%) intended for the assessment of re-deposition in washing process. Comparing the effects of the detergents based on the reflectance (R) of position 1 of the knitwear, re-deposition, i.e., the accumulation of soil from the washing solution on clean (empty) knitwear, has taken place. A negative value of ΔR460 indicates re-deposition during washing, which means that the stain was transferred from the reference stain donors (positions 2–16) to the empty position 1 of the cotton knitwear, as seen in Table 5.

In the assessment of the SWP of the individual detergents tested at 60 °C, it was observed that D-R (the reference detergent) and D-4 led to the most significant re-deposition. This trend was followed by D-5 and D-3. The best performance was achieved with D-1, followed by D-2 and D-6. The re-deposition observed at 90 °C is more evident, since only detergent D-2 did not produce graying. The increased negative values of ΔR460 at 90 °C in comparison with 60 °C may be attributed to the temperature-specific behavior of reduced synergy during the washing process and the lack of specific polymers [8].

Detergency, detergency mediated with lipases (L*)

The sole and lipase-mediated detergency was evaluated by analyzing the group-specific stains: peat, animal fat/red dye, engine oil, butter, clay, makeup, and baby food. The performance with detergents containing a higher proportion of non-ionic surfactants compared to anionic surfactants tends to be less efficient. This may be attributed to the varying mechanisms of action of these surfactants and temperature-specific behavior. Non-ionic surfactants may be less effective at higher temperatures, particularly in removing certain types of stains, than anionic surfactants.

The tested detergents showed varying performance in removing peat stains from cotton knitwear during the washing process at 60 °C. D-1 achieved the best performance, followed by D-2, D-6, D-5, and D-R. Conversely, D-3 and D-4 exhibited the poorest performance. Furthermore, the washing performance at 90 °C differs, being either better or worse than that at 60 °C.

The effective removal of intense animal fat/red coloring (lipstick), specified by a reflectance value of 22.2%, requires a thermal effect as well as anionic and non-ionic surfactants in sufficient quantities. Additionally, a sufficiently high level of alkalinity assists in eliminating oily stains. Because lipstick stains are colored, the concentration of bleach is important, as confirmed by the results attained. A higher washing temperature has a positive effect on the performance of all detergents. The improvement observed at higher temperatures might be attributed to the increased effectiveness of anionic surfactants and bleaches, which are better at breaking down and removing the complex, oily, and pigmented properties of lipstick stains.

Oily stains such as engine oil (R = 41.7%) require a combination of effective surfactants and Sinner parameters (such as temperature and agitation) to break down the oil and remove it from the fabric. Engine oil is a particularly stubborn type of stain that can be effectively removed if the active components in the detergent act at sufficiently high temperatures. The best performance in the removal of engine oil was obtained with detergents D-5, D-2, D-6, and D-3, while the worst performance was observed with the D-R. In most cases, a rise in washing temperature had a beneficial impact on the removal of engine oil from cotton knitwear.

A butter stain on cotton knitwear, with a reflectance value of R = 39.8%, signifies a grease stain that requires efficient detergency and lipases activity. Anionic surfactants are particularly effective in emulsifying and removing such stains. The best detergency and lipase effect were achieved with D-6 and D-3 at 60 °C, while the performance of other detergents was similar. Washing at a temperature of 90 °C is more favorable for removing butter with all detergents except for D-5. The elevated temperature aids in the removal of greasy stains as the action of anionic surfactants becomes more effective. Higher temperatures increase the solubility of fats and oils, which aids surfactants in dissolving these compounds from the fabric. Additionally, higher temperatures can improve the detergent’s overall cleaning performance, allowing it to work more effectively on persistent stains. However, the reduced effectiveness of D-5 at 90 °C compared to 60 °C suggests that its formulation may not be as stable or effective at higher temperatures. This could be due to the special blend of surfactants, enzymes, or other components in D-5, which may not respond as well to higher temperatures as those in other detergents.

The clay stain on cotton knitwear is not particularly strong (R = 63.9%). It usually consists of particles and is often deeply embedded in the textiles, so that it requires effective detergency. The removal of clay stains from cotton knitwear differs. Enhanced washing performance at 60 °C is achieved with D-6, closely followed by D-2, D-5, D-3, and D-1. Reduced performance is observed with D-4, followed by the reference detergent. D-4, D-2, and D-R, showed temperature-specific behavior, where a higher washing temperature positively impacted stain removal. The varying effectiveness of different detergents at 60 °C indicates that their formulations differ, particularly in the content of surfactants and potentially other additives aimed at removing particulate soil.

Makeup stains often contain a range of components, including oils, waxes, pigments, and sometimes silicone-based compounds, which can make their removal quite difficult. This brownish stain has a low reflectance value, which indicates a high intensity.

The efficiency of detergents in makeup stain removal at 60 °C differs, with D-1, D-2, D-3, D-6, and D-R being the most efficient. The less effective detergent for removing a makeup stain is D-4. A higher washing temperature (90 °C) had a positive effect on the detergency of D-4 and D-2. The superior performance of D-1 and D-2 at 60 °C suggests that they are well formulated to deal with the complex nature of makeup stains, probably due to an effective combination of surfactants and possibly other detergents. The fact that a higher washing temperature improves the performance of D-2 and D-4 in removing makeup stains may be attributed to improved detergency, resulting from the activation of specific enzymes that focus on particular makeup components, or surfactants that remove and emulsify the oils and waxes commonly present in makeup at higher temperatures. According to [22,23], the washing program for cotton laundry at 60 °C is still the most frequently used. On the other hand, the lack of improvement or lower effectiveness of other detergents at higher temperatures could be due to the fact that their formulations are optimized for washing at lower temperatures or that some components may be blocked at higher temperatures. These differences highlight the importance of detergent formulation in removal certain types of stains and the potential benefits of adjusting washing temperatures based on the detergent used and the type of stain. This is consistent with the results of the study on how the effectiveness of washing power improved with an increase in temperature or main wash time [24].

Baby food stains are complex as they often contain a mixture of different ingredients, including proteins, fats, carbohydrates, and sometimes colorings from fruit or vegetables. Such complexity demands the action of detergents, bleach, and lipases. Baby food stains (R = 66.4%) are difficult to remove at a washing temperature of 60 °C. The optimal performance was attained with D-4, while D-3 and D-5 showed the least effective performance. Increasing the wash temperature positively influenced stain removal across all products, with the exception of those that performed poorly at 60 °C, specifically D-5 and D-3. The fact that most detergents perform better at stain removal at higher wash temperatures shows that higher temperature breaks down the different components of baby food stains, improving the detergent’s cleaning capabilities. Heat can improve the solubility of fats and oils, deactivate certain enzymes that target proteins or starches, and help remove pigmented substances. However, for detergents like D-5 and D-3, which did not perform well at 60 °C, increasing the temperature does not appear to compensate for the formulation limits in cleaning these complex stains. The absence of progress at higher temperatures indicates that these detergents might not contain the essential components or enzyme activity required to efficiently tackle the different elements found in baby food stains.

Bleach effect and bleach effect mediated with protease (P**) and amilases (A***)

Red wine (flavonols, antocyanins, tannin) [25]; grass (carbohydrates, protein chlorophyl); curry (carotenoids); blood [26,27]; beta-carotene (carotenoids); tomato sauce (licopene, sugar); and tea were classified as dyes/pigments. Natural colorants are classified using botanical language, with the chemical structure, or the major constitutional ingredient in the chromophore, serving as the basis of classification. The most important include anthocyanidins, flavonols, curcuminoids, carotenoids, tannins, betalains, and quinones. The presence of oxygen-based bleach and bleach activators, which ensure the oxidizing effect of these components even at lower temperatures, is important for effective washing performance. According to the reflectance values, the curry (R = 13.2%) and blood (R = 12.3%) stains are highly saturated, while the beta-carotene stain (R = 97.3%) is less saturated.

According to results in Table 4, detergents can be divided into three categories based on their bleach content: SPC less than 10% (D-4), approximately 12% (D-3, D-5, and D-6), and approximately 20% (D-1 and D-R).

The intensity of the saturation, the interaction with cotton knitwear, is indicated by the reflectance value (R460).

The intensity of the red wine stain on the cotton knitwear carrier is characterized by moderate reflectance (R = 45.2%). Red wine, a tannin stain, was efficiently removed from cotton knitwear at 90 °C, justifying the use of higher washing temperatures, namely D-1, D-2, D-4, D-5, and D-R. The increased temperature likely activates the bleaching agents and increases the solubility of the tannins, making them simpler to remove from cotton knitwear. D-3 and D-6 had equal washing effectiveness at 60 °C and 90 °C.

Grass stains are a particular challenge because they are a combination of chlorophyll (a pigment) and other organic components such as proteins and possibly mud. It is colored stains (R = 45.6%) that can be successfully removed with bleach while washing. The most effective performance at a washing temperature of 60 °C is realized with D-3 and D-5, then followed by D-5, D-R, and D-4. When employing D-1, D-2, D-4, and D-R, a higher washing temperature is advantageous, but it negatively impacts the results when using D-5. The different effectiveness of various detergents at different temperatures indicates that their formulations react differently to temperature changes. For some, such as D-2 and D-4, higher temperatures may increase the activity of the bleaching agents and enzymes and thus improve stain removal. In the case of others, such as D-5 and the D-R, higher temperatures might have a negative effect on performance, possibly resulting from the deactivation of enzymes or other components that are sensitive to temperature.

The curry stain on the cotton knitwear is quite pronounced (R = 12.3%) and has a distinct composition, attributed to oil, turmeric (which imparts the yellow hue), and several other spices. These components require a combination of surfactants to break down the oils and effective bleach to decolorize the colored components. Curry stains, which are extremely persistent, were effectively removed using detergents D-2 and D-6 when washed at 60 °C. The effectiveness of detergents D-3, D-5, D-1, and D-R in removing curry stains is similar. Increasing the washing temperature improved stain removal for nearly all detergents, with D-1, D-4, and D-R performing especially well. The bleach component in D-1 and D-R caused the stain removing effect.

Blood from animals is a fluid made up of plasma containing proteins, minerals, and vitamins, as well as red and white blood cells [26,27]. This fluid stained the cotton knitwear (R = 10.3%), but it can be successfully removed with the use of bleach and enzymes, especially proteases, when washing. At a washing temperature of 60 °C, D-1, D-2, and D-6 proved to be very effective, while the other detergents acted almost equally as well. This is to be expected as the enzymes are more effective at temperatures above 50 °C than at higher washing temperatures (90 °C). The effectiveness of D-4 and D-6 at higher temperatures suggests that their formulations may contain enzymes that are stable or other components that remain effective at higher temperatures. This emphasizes the importance of detergent formulation in achieving optimal washing performance, especially with specific types of stains such as those from animal blood. Proteases are enzymes that decompose proteins, making them especially efficient at removing blood stains. These enzymes operate effectively within a defined temperature range, and their activity can decline if the temperature is either too high or too low. At a temperature of 60 °C, the enzymes found in D-1, D-2, D-4, and D-6 are probably functioning at their optimal activity levels, allowing for the efficient breakdown of blood proteins. Conversely, at 90 °C, the effectiveness of these enzymes is compromised due to denaturation or instability, resulting in a decrease in stain removal efficiency.

The stain from beta-carotene on knitted fabrics had a pale appearance (R = 97.3%). Beta-carotene stains, colored by a carotenoid pigment present in many vegetables and fruits, are difficult to remove. The stain was effectively removed from cotton knitwear, primarily due to the relatively low intensity of this kind of stain, as demonstrated by the reflectance value. At a washing temperature of 60 °C, D-2, D-3, and D-6 proved to be the most effective, while D-4 showed the weakest performance. Increasing the washing temperature is only beneficial when washing with D-4 and D-3. The effectiveness of D-6, D-2, and D-3 at 60 °C suggests that these detergents contain the right combination of surfactants and bleaches able to break up and remove these pigments from the fabric. These may consist of temperature-sensitive enzymes or bleaching agents that assist in breaking down beta-carotene stains and removing them more efficiently. Conversely, with other detergents, enhancing the temperature does not result in a considerable positive effect. This might be due to the fact that stain removal is already effective at lower temperatures or that specific temperature-sensitive ingredients could become inactive when exposed to higher temperatures.

The tomato sauce stain on the knitwear was moderate (R = 47.3%), presenting challenges due to its composition, which contains natural pigments like lycopene, oils, and potentially proteins if meat is included. For the removal of oil, these components demand a combination of surfactants, and possibly enzymes or alternative agents to break down proteins and pigments. As a result, the removal of tomato sauce requires the efficient use of bleach and the activity of amylases and proteases. At a washing temperature of 60 °C, the most effective results for removing tomato sauce stains are obtained with D-1, D-2, D-1, and D-6. The effectiveness of D-R, D-3, and D-5 is nearly identical in this context. A higher washing temperature has a positive effect on the more effective removal of tomato sauce stains when using D-2, D-4, and D-R. Conversely, the similar performances of the reference detergent, D-3, and D-5 at 60 °C and their improvement at higher temperatures could be due to the activation of certain ingredients at these elevated temperatures that are not as effective at lower temperatures. These differences in detergent performance emphasize the importance of choosing the right detergent depending on the type of stain and the washing conditions.

Tannin stains, including those caused by tea, are acknowledged for their reaction with fabrics, which makes them hard to remove. The tea stain (R = 43.2%) was successfully removed at 60 °C by almost all products, with D-2 and D-6 being the most effective. A temperature of 90 °C during washing had a positive effect on all products, apart from D-1 and D-3. The greatest difference in stain removal at this higher temperature is observed when using D-4 and D-R. The effectiveness of D-2 and D-6 at 60 °C indicates that these detergents probably contain ingredients, such as special surfactants or enzymes, that can effectively break down and remove tannins. The enhancement in stain removal observed at an elevated temperature of 90 °C for the majority of detergents indicates that the higher heat acts as a catalyst for breaking down tannins, facilitating their removal during washing. There is a possibility that heat raises the solubility of tannins or activates particular detergent ingredients, including enzymes or bleaching agents, which perform more effectively at higher temperatures. Still, the reason D-1 underperforms at 90 °C may relate to its unique formulation, which might be designed for lower-temperature applications or have ingredients that lose their potency or become unstable when exposed to higher temperatures. On the other hand, the notable progress of D-4 and the reference detergent at 90 °C implies that their compositions react particularly favorably to higher temperatures in combating tannin stains, such as those caused by tea.

Enzyme, lipases (L*), proteases (P**)

The stain from chocolate on the cotton knitwear carrier is notably stubborn and strong (R = 10.2%), containing cocoa, cocoa butter, sugar, protein–milk solids, emulsifiers, and oil/fat, so its removal primarily requires enzyme activity, especially that of lipases and proteases, in the detergent formulation.

The optimal enzyme activity for removing chocolate stains at 60 °C is attained using detergents D-6, D-1, and D-5, whereas the least effective performance is noted with D-R. Increasing the washing temperature from 60 °C to 90 °C had a favorable effect when using D-4 and D-2. However, with detergents D-2, D-6, and D-5, a negative effect of the increased washing temperature is observed. These differences in effectiveness at different temperatures can be attributed to the specific formulations of these detergents. Detergents like D-4 and D-2 contain ingredients that work better at 90 °C, whereas the elevated temperature inhibited the enzymes in D-6 and D-5, leading to reduced stain removal.

4. Conclusions

The interaction of various stain types with cotton knitwear, characterized by a blank area and 15 stains of different origins and chemical compositions (tannin, anthocyanin, carotenoids, curcuminoids, flavonoids, pigments, and fats/oils, and their mixtures), was analyzed through reflectance as a spectral value. This investigation was further supported by an analysis of the detergent composition, particularly regarding the surfactant and bleaching agent content.

Selected brand detergents and the reference detergent showed more or less temperature-specific behavior, depending on whether the total wash performance (TWP) or the specific washing performance (SWP) was considered. Therefore, the following findings are reported:

- The average TWP of all detergents tested in the removal of 15 stains at 90 °C was improved due to the effect of anionic surfactants and bleaching agent.

- The specific washing performance (SWP) showed that all detergents tested were more successful in removing certain types of stains—animal fat, red wine, butter, curry, makeup, and baby food—at 90 °C. In comparison, some detergents showed better (enzyme-mediated) performance in removing certain stains (chocolate, blood, engine oil, grass, tomato sauce, tea, peat, clay, beta-carotene) at 60 °C.

The results of the cluster analysis showed an improved classification of detergents based on their similarities and differences at the indicated temperatures.

The EMPA SWT 102, which contains 15 stains of different compositions and intensities, has proven to be a valid substrate for analyzing TWP and SWP.

Despite the data showing a better TWP of the detergents in the process at 90 °C, it is important to consider the environmental impact of a process characterized by high enthalpies and increased CO2 emissions.

Author Contributions

Conceptualization, T.P. and V.Š.; methodology, V.Š.; formal analysis, V.Š.; investigation, V.Š.; data curation, V.Š.; writing—original draft preparation, T.P. and V.Š.; writing—review and editing, T.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The research was performed on equipment purchased by K.K.01.1.1.02.0024 project “Modernization of Textile Science Research Centre Infrastructure” (MI-TSRC). The authors would like to thank Mirjana Čurlin for her help with the multivariate analysis.

Conflicts of Interest

Author Vanja Šantak was employed by the company Ammonia d.o.o. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- López Zavala, M.Á.; Espinoza Estrada, E. The Contribution of the Type of Detergent to Domestic Laundry Graywater Composition and Its Effect on Treatment Performance. Water 2016, 8, 214. [Google Scholar] [CrossRef]

- Sinner, H. Über das Waschen mit Haushaltwaschmaschinen. In Welchem Umfange Erleichtern Haushaltwaschmaschinen und-geräte das Wäschehaben im Haushalt? Haus-+-Heim-Verl: Hamburg, Germany, 1960. [Google Scholar]

- Farias, C.B.B.; Silva, R.d.C.F.S.d.; Almeida, F.C.G.; Converti, A.; Santos, V.A.d.; Sarubbo, L.A. Physicochemical Upgrading of a Biodetergent for Application in the Industrial Energy Sector. Energies 2022, 15, 463. [Google Scholar] [CrossRef]

- Smulders, E. Laundry Detergents; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2002. [Google Scholar]

- Soljačić, I.; Pušić, T. Njega tekstila-Čišćenje u vodenom mediju; Sveučilište u Zagrebu: Zagreb, Croatia, 2005. [Google Scholar]

- Sarasua Miranda, J.A.; Ruiz Rubio, L.; Trinidad Cristobal, A.; Vilas Vilela, J.L.; Izaguirre Goyoaga, J.K.; Barbero Mangas, F.; Aranzabe Basterrechea, E. Ultrasound and Eco-Detergents for Sustainable Cleaning. Processes 2023, 11, 2082. [Google Scholar] [CrossRef]

- Plomaritis, A.; Giliopoulos, D.; Triantafyllidis, K.; Kostoglou, M.; Karapantsios, T.D. Mesoporous Silica SBA-15 Particles in a Detergent Solution as Abrasive and Coating Material for Household Care Cleaning Products. Colloids Interfaces 2019, 3, 12. [Google Scholar] [CrossRef]

- Cutler, W.G.; Davis, R.C. Detergency Theory and Test Methods Part I; Marcel Dekker, Inc.: New York, NY, USA, 1972. [Google Scholar]

- Technical Bulletin. Guild of Cleaners and Launderers. January 2015 Issue TB15. pp. 1–3. Available online: https://gcl.org.uk/wp-content/uploads/technical_bulletin_january_2015.pdf (accessed on 23 August 2025).

- Fijan, S.; Šostar-Turk, S.; Pušić, T. Comparison of primary washing effects using different washing procedures for hospital textiles. Tekstilec 2006, 49, 72–80. [Google Scholar]

- Waldhoff, H.; Spilker, R. (Eds.) Handbook of Detergents, Part C: Analysis (Surfactant Science); CRC Press: New York, NY, USA, 2004; Volume 123, ISBN 9780824703516. Available online: https://www.amazon.com/Handbook-Detergents-Part-Analysis-Surfactant/dp/0824703510 (accessed on 23 August 2025).

- The American Cleaning Institute (ACI). Available online: https://www.cleaninginstitute.org/ (accessed on 14 July 2023).

- Evaluating Stain Removal Performance in Home Laundering. Available online: https://delltech.com/blog/evaluating-stain-removal-performance-in-home-laundering-astm-d4265 (accessed on 25 February 2025).

- Patent WO2018078603: Formula for Superior Detergency and Anti Re-Deposition Benefit. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2018078603 (accessed on 20 May 2025).

- Rao, G. Measuring detergency using a digital imaging system. Tenside Surfactants Deterg. 1998, 35, 166–169. [Google Scholar] [CrossRef]

- Regulation (EC) No 648/2004 of the European Parliament and of the Council of 31 March 2004 on Detergents (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32004R0648 (accessed on 12 February 2023).

- Application Bulletin 233/4, e. Potentiometric Determination of Anionic and Cationic Surfactants with Surfactant Electrodes, Metrohm, Switzerland. Available online: https://www.metrohm.com/en/applications/ab-application-bulletins/ab-233.html.10.12.2022 (accessed on 23 August 2025).

- Application Bulletin 230/2, e. Potentiometric Determination of Nonionic Surfactants Based on Polyoxyethylene Adducts Using the NIO Electrode, Metrohm, Switzerland. Available online: https://www.metrohm.com/en_us/applications/ab-application-bulletins/ab-230.html, 10.12.2022 (accessed on 1 January 2020).

- Waldhoff, H.; Spilker, R. (Eds.) Handbook of Detergents, Part C: Analysis; CRC Press: Boca Raton, FL, USA, 2016; pp. 446–447. Available online: https://www.taylorfrancis.com/books/edit/10.1201/9781420030334/handbook-detergents-part-rudiger-spilker-heinrich-waldhoff (accessed on 23 August 2025).

- Elsner, P.; Hatch, K.; Wigger-Alberti, W. Textiles and the Skin, Current Problems in Dermatology; Karger: Basel, Switzerland, 2003; ISBN 978-3805574389. [Google Scholar]

- Priyadarsini, K.I. The Chemistry of Curcumin: From Extraction to Therapeutic Agent. Molecules 2014, 19, 20091–20112. [Google Scholar] [CrossRef]

- Soljačić, I.; Ćavara, L. Deterdženti za pranje tekstila. Tekstil 1999, 48, 498–504. [Google Scholar]

- Ferri, A.; Osset, M.; Abeliotis, K.; Amberg, C.; Candan, C.; Owens, J.; Stamminger, J. Laundry Performance: Effect of Detergent and Additives on Consumer Satisfaction. Tenside Surf. Det. 2016, 53, 375–386. [Google Scholar] [CrossRef]

- Bao, W.; Gong, R.; Ding, X.; Xue, Y.; Li, P.; Fan, W. Optimizing a laundering program for textiles in a front-loading washing machine and saving energy. J. Clean. Prod. 2017, 148, 415–421. [Google Scholar] [CrossRef]

- Di Lorenzo, A.; Bloise, N.; Meneghini, S.; Sureda, A.; Tenore, G.C.; Visai, L.; Arciola, C.R.; Daglia, M. Effect of Winemaking on the Composition of Red Wine as a Source of Polyphenols for Anti-Infective Biomaterials. Materials 2016, 9, 316. [Google Scholar] [CrossRef]

- Castro, T.C. Forensic Interpretation of Bloodstains on Fabrics. In Woodhead Publishing Series in Textiles, Forensic Textile Science; Carr, D., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 127–167. ISBN 9780081018729. [Google Scholar]

- Scientific Working Group on Bloodstain Pattern Analysis (SWGSTAIN), 2011. Recommended Terminology, Scientific Working Group on Bloodstain Pattern Analysis. Forensic Sci. Commun. 2009, 11, 1–6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).