- Article

Ethanol Concentration Sensing Using a 3D-Printed Microwave Cavity Resonator

- Thet Pai Oo,

- Thipamas Phakaew and

- Suramate Chalermwisutkul

- + 4 authors

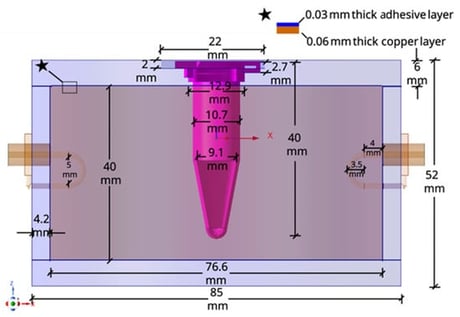

This work presents microwave sensing of ethanol concentration in ethanol–water mixtures using a low-cost 3D-printed cavity resonator. The objective is to realize a customizable liquid sensor that combines high measurement accuracy with inexpensive, in-house fabrication. The cylindrical cavity is fabricated from polylactic acid using fused deposition modeling and metallized on its inner surface with copper tape. The resonator operates in the TM010 mode with a resonant frequency of 3 GHz. A standard 1.5 mL centrifuge tube is used as a modular sample holder and inserted through a circular opening in the top endcap of the cavity. The quality factor of the air-filled cavity is 200, which decreases to 37.3 when the cavity is loaded with deionized water. As an application example, ethanol concentrations in ethanol–water mixtures are determined using both the resonant frequency and the peak magnitude of the transmission coefficient (|S21|). For ethanol concentrations between 20% and 100%, the concentration can be accurately extracted from the resonant frequency alone: a quartic calibration curve yields a coefficient of determination , an average sensitivity of approximately 8.4 MHz/% ethanol, and a mean absolute error of about 0.58% on the calibration set. In addition, a cubic calibration based on the peak over the 0–90% concentration range achieves a mean absolute error of approximately 0.52% on the calibration set and about 0.55% on an independent validation set covering 5–85% ethanol. Comparison with conventionally machined metal cavities shows that the proposed 3D-printed cavity achieves a high Q-factor at significantly lower cost and can be fabricated in-house using a standard 3D printer. These results demonstrate metrologically relevant performance in terms of low error and high sensitivity using a low-cost and easily replicable platform for microwave liquid sensing in biomedical and chemical engineering applications.

6 February 2026