Enhancing Breakdown Field Strength and Energy Density in Sandwich-Structured P(VDF-HFP)/BT Films with BN Coating

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. P(VDF-HFP)/BT Films

2.3. Preparation of Sandwich-Structured Films

2.4. Characterization

2.5. Finite Element Analysis and Breakdown Process Simulation

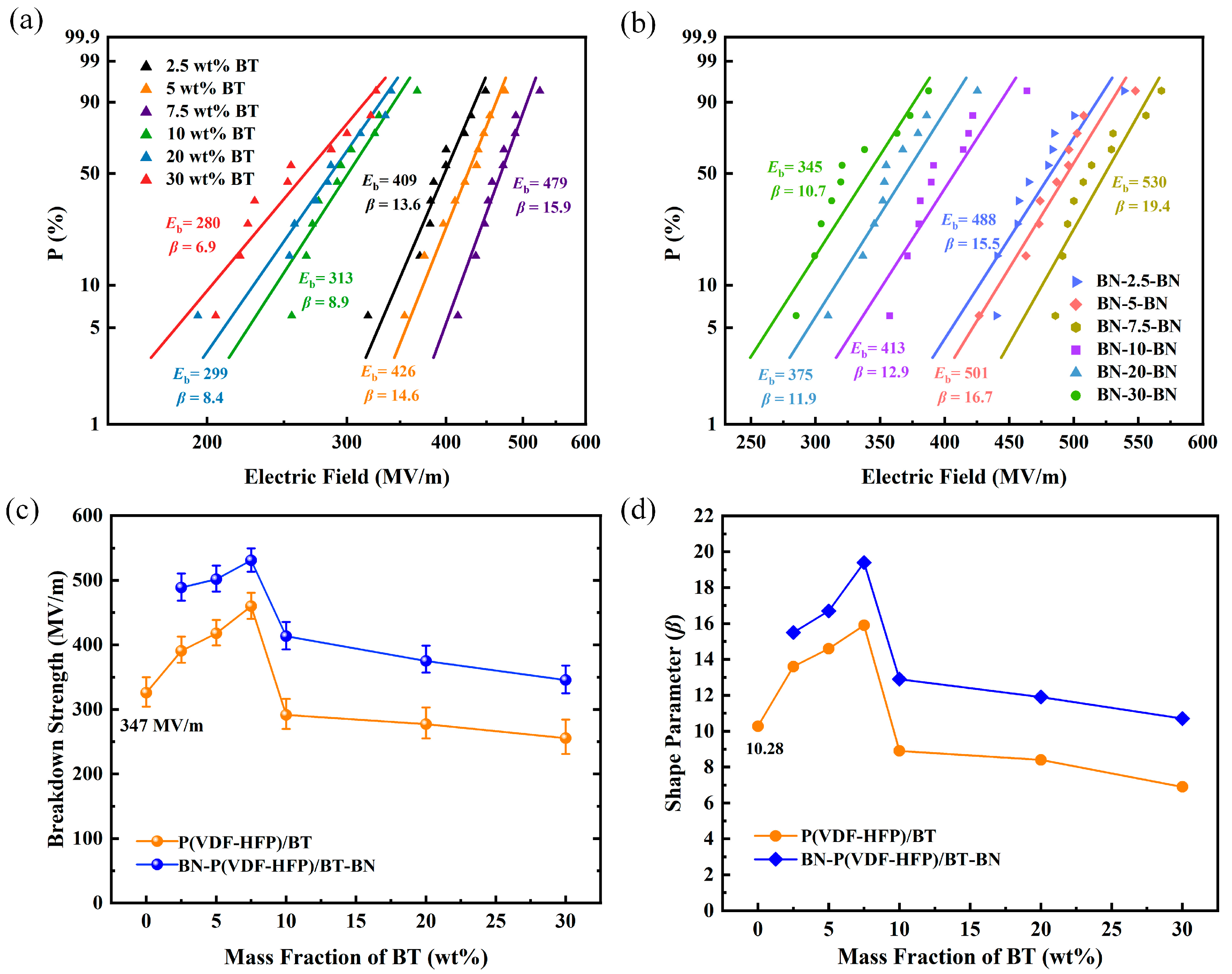

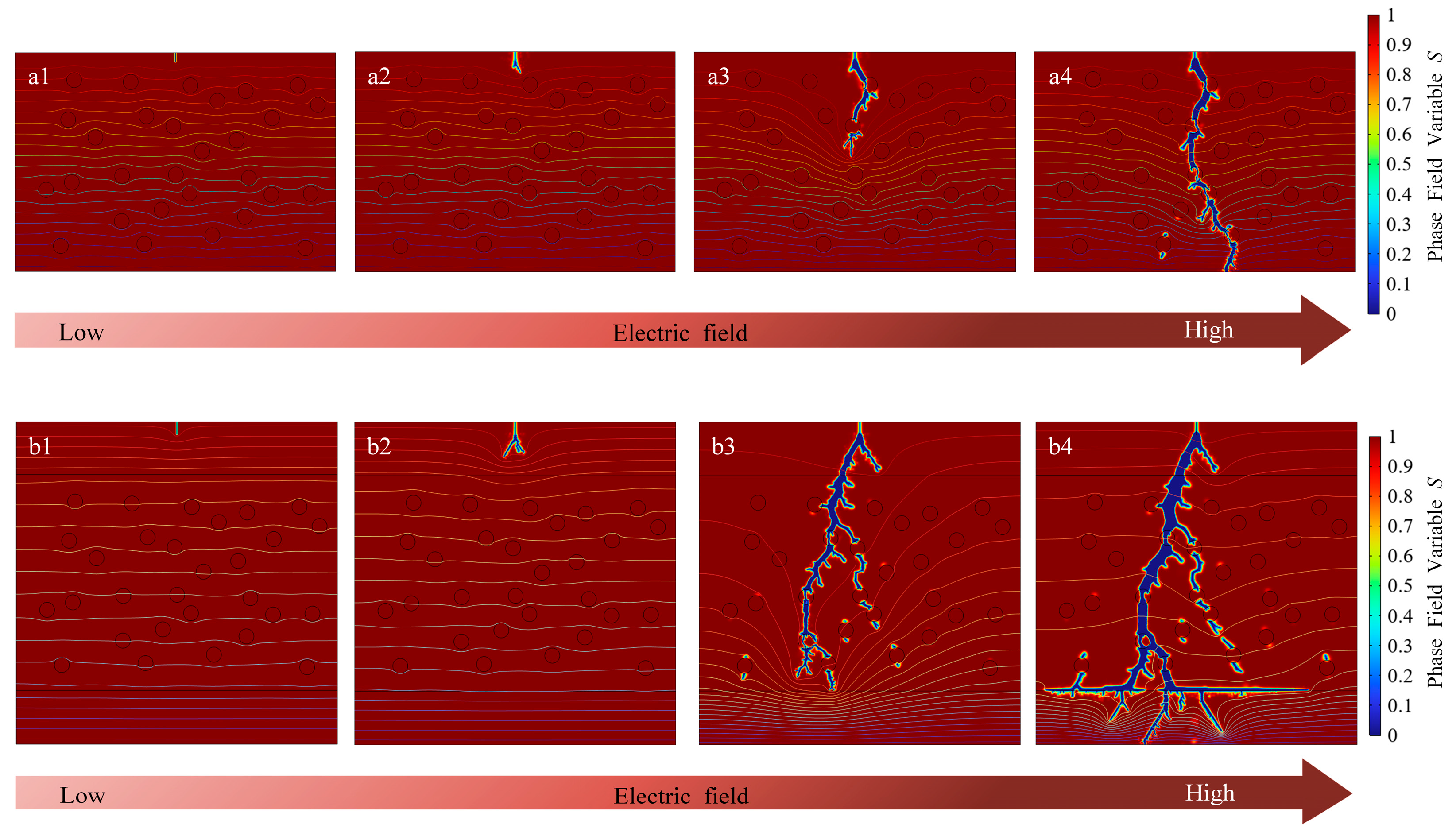

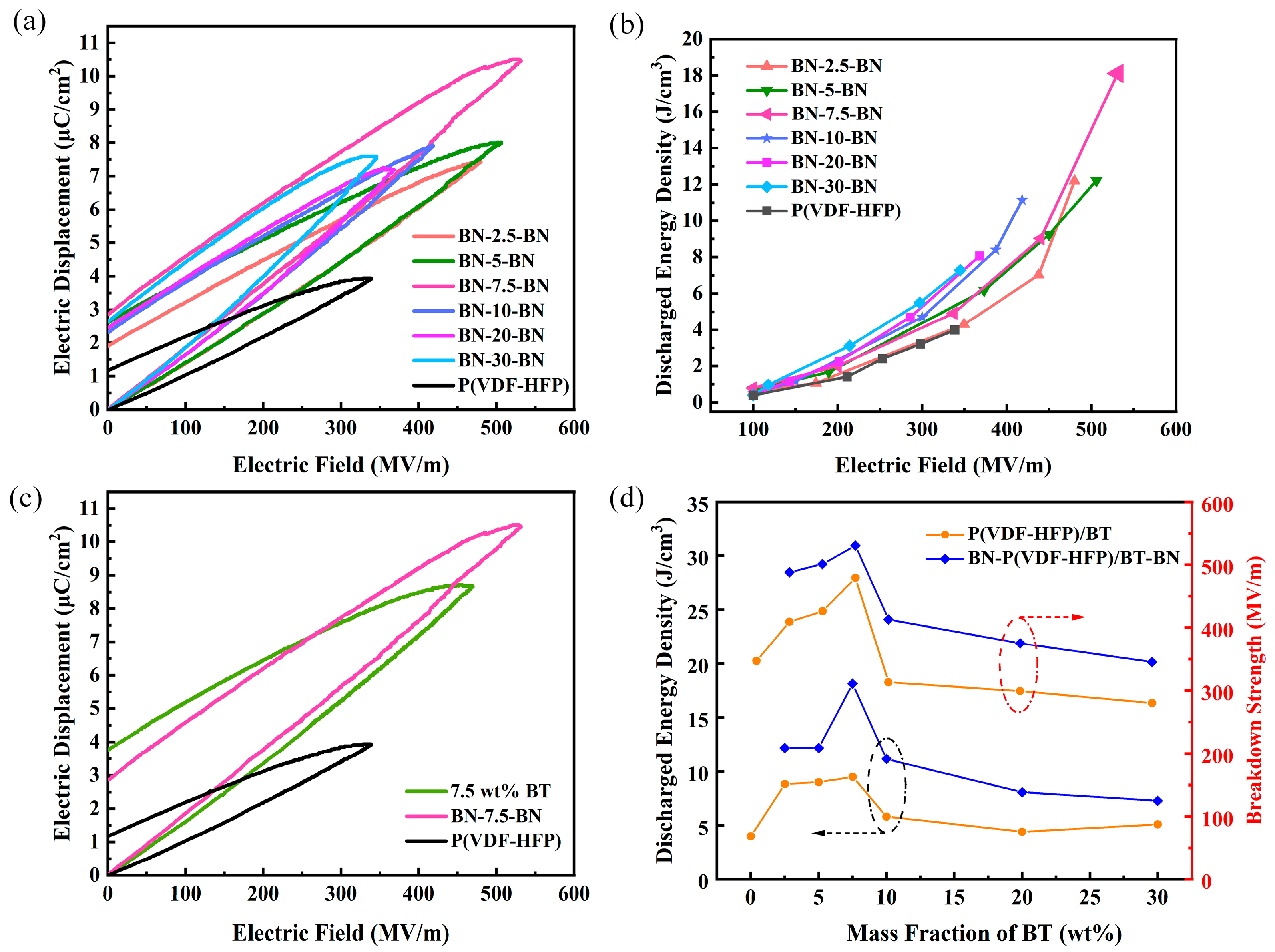

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, L.; Zhao, S.; Xie, P.; Miao, X.; Liu, S.J.; Sun, N.N.; Guo, M.F.; Xu, Z.Q.; Zhong, T.J.; Shen, Y. Research progress and prospect of polymer dielectrics. Appl. Phys. Rev. 2023, 10, 031310. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, D.; Xu, R.; Zhu, Q.S.; Li, D.; Zhao, W.C.; Pang, L.X.; Wang, Y.F.; Liu, W.F.; Su, J.Z.; et al. Enhancement in the energy storage performance of P(VDF-HFP)-based composites by adding PLZST inorganic nanoparticles. J. Mater. Chem. A 2022, 10, 22058–22066. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.H.; Zhang, G.Z.; Li, H.Y.; Iagodkine, E.; Haque, A.; Chen, L.-Q.; Jackson, T.N.; et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef]

- Cheng, R.; Wang, Y.F.; Men, R.J.; Lei, Z.P.; Song, J.C.; Li, Y.Y.; Guo, M.Q. High-energy-density polymer dielectrics via compositional and structural tailoring for electrical energy storage. iScience 2022, 25, 104837. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.F.; Xu, X.W.; Yuan, Q.B.; Niu, Y.J.; Wang, Q.; Wang, H. Ultrahigh discharge efficiency and energy density achieved at low electric fields in sandwich-structured polymer films containing dielectric elastomers. J. Mater. Chem. A Mater. 2019, 7, 3729–3736. [Google Scholar] [CrossRef]

- Zhang, M.; Li, B.; Wang, J.J.; Huang, H.B.; Zhang, L.; Chen, L.Q. Polymer dielectrics with simultaneous ultrahigh energy density and low loss. Adv. Mater. 2021, 33, 2008198. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, T.D.; Feng, Y.; Zhang, Y.Q.; Zhang, C.H.; Zhang, Y.; Wang, X.B.; Chi, Q.G.; Chen, Q.G.; Lei, Q.Q. Sandwich-structured polymers with electrospun boron nitrides layers as high-temperature energy storage dielectrics. Chem. Eng. J. 2020, 389, 124443. [Google Scholar] [CrossRef]

- Wang, S.J.; Luo, Z.; Liang, J.J.; Hu, J.; Jiang, N.S.; He, J.L.; Li, Q. Polymer nanocomposite dielectrics: Understanding the matrix/particle interface. ACS Nano 2022, 16, 13612–13656. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Xie, Y.C.; Liu, J.J.; Li, J.; Wei, X.Y.; Zhang, Z.Z. Enhanced energy storage capability of P(VDF-HFP) nanodielectrics by HfO2 passivation layer: Preparation, performance and simulation. Compos. Sci. Technol. 2020, 188, 107968. [Google Scholar] [CrossRef]

- Bao, Z.W.; Hou, C.M.; Shen, Z.H.; Sun, H.Y.; Zhang, G.Q.; Luo, Z.; Dai, Z.Z.; Wang, C.M.; Chen, X.W.; Li, L.B.; et al. Negatively charged nanosheets significantly enhance the energy-storage capability of polymer-based nanocomposites. Adv. Mater. 2020, 32, 1907227. [Google Scholar] [CrossRef]

- Jung, H.B.; Kim, J.W.; Lim, J.H.; Kwon, D.K.; Choi, D.H.; Jeong, D.Y. Energy Storage Properties of Blended Polymer Films with Normal Ferroelectric P(VDF-HFP) and Relaxor Ferroelectric P(VDF-TrFE-CFE). Electron. Mater. Lett. 2020, 16, 47–54. [Google Scholar] [CrossRef]

- Yang, C.; Hong, H.S.; Liu, D.B. Effect of coupling agents on the dielectric properties of CaCu3Ti4O12/PVDF composites. Compos. Part. B Eng. 2013, 50, 180–186. [Google Scholar] [CrossRef]

- Li, Y.S.; Chen, S.; Hu, J.; He, J.L.; Li, Q. Polymer nanocomposites with high energy density utilizing oriented nanosheets and high-dielectric-constant nanoparticles. Materials 2021, 14, 4780. [Google Scholar] [CrossRef]

- Tsyganov, A.; Vikulova, M.; Artyukhov, D.; Bainyashev, A.; Goffman, V.; Gorokhovsky, A.; Gorshkov, N. Carbon Modification of K1.6Fe1.6Ti6.4O16 Nanoparticles to Optimize the Dielectric Properties of PTFE-Based Composites. Polymers 2022, 14, 4010. [Google Scholar] [CrossRef]

- Wang, Y.F.; Wang, L.X.; Yuan, Q.B.; Chen, J.; Niu, Y.J.; Xu, X.W.; Chen, Y.T.; Yao, B.; Wang, Q.; Wang, H. Ultrahigh energy density and greatly enhanced discharged efficiency of sandwich-structured polymer nanocomposites with optimized spatial organization. Nano Energy 2018, 44, 364–370. [Google Scholar] [CrossRef]

- Wang, J.; Xie, Y.C.; Liu, J.J.; Zhang, Z.C.; Zhuang, Q.; Kong, J. Improved energy storage performance of linear dielectric polymer nanodielectrics with polydopamine coated BN nanosheets. Polymers 2018, 10, 1349. [Google Scholar] [CrossRef]

- Wang, Y.F.; Li, Z.Z.; Wu, C.; Cao, Y. High-temperature dielectric polymer nanocomposites with interposed montmorillonite nanosheets. Chem. Eng. J. 2020, 401, 126093. [Google Scholar] [CrossRef]

- Zhang, T.D.; Yang, L.Y.; Ruan, J.Y.; Zhang, C.H.; Chi, Q.G. Improved high-temperature energy storage performance of PEI dielectric films by introducing a SiO2 insulating layer. Macromol. Mater. Eng. 2021, 306, 2100514. [Google Scholar] [CrossRef]

- Zhang, T.D.; Yang, L.Y.; Zhang, C.H.; Feng, Y.; Wang, J.; Shen, Z.H.; Chen, Q.G.; Lei, Q.Q.; Chi, Q.G. Polymer dielectric films exhibiting superior high-temperature capacitive performance by utilizing an inorganic insulation interlayer. J. Mater. Chem. C 2022, 9, 1273–1282. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.M.; Wang, X.H.; Luo, B.C.; Zhao, P.Y.; Zhu, C.Q.; Li, L.T. Laminated structure-induced high dielectric strength and energy storage density in dielectric composites. Compos. Sci. Technol. 2019, 173, 61–65. [Google Scholar] [CrossRef]

- Marwat, M.A.; Ma, W.G.; Fan, P.Y.; Elahi, H.; Samart, C.; Nan, B.; Tan, H.; Salamon, D.; Ye, B.H.; Zhang, H.B. Ultrahigh energy density and thermal stability in sandwich-structured nanocomposites with dopamine@Ag@BaTiO3. Energy Storage Mater. 2020, 31, 492–504. [Google Scholar] [CrossRef]

- Park, G.H.; Nielsch, K.; Thomas, A. 2D transition metal dichalcogenide thin films obtained by chemical gas phase deposition techniques. Adv. Mater. Interfaces 2018, 6, 1800688. [Google Scholar] [CrossRef]

- Azizi, A.; Gadinski, M.; Li, Q.; ALSaud, M.A.; Wang, J.J.; Wang, Y.; Wang, B.; Liu, F.H.; Chen, L.Q.; Alem, N.; et al. High-performance polymers sandwiched with chemical vapor deposited hexagonal boron nitrides as scalable high-temperature dielectric materials. Adv. Mater. 2017, 29, 1701864. [Google Scholar] [CrossRef]

- Cai, Z.M.; Wang, X.H.; Li, L.T.; Hong, W. Electrical treeing: A phase-field model. Extreme Mech. Lett. 2019, 28, 87–95. [Google Scholar] [CrossRef]

- Hong, W.; Pitike, K.C. Modeling breakdown-resistant composite dielectrics. Procedia IUTAM 2015, 12, 73–82. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, T.D.; Liu, L.Z.; Chi, Q.G.; Zhang, C.H.; Chen, Q.G.; Cui, Y.; Wang, X.; Lei, Q.Q. Sandwich-structured PVDF-based composite incorporated with hybrid Fe3O4@BN nanosheets for excellent dielectric properties and energy storage performance. J. Phys. Chem. C 2018, 122, 1500–1512. [Google Scholar] [CrossRef]

- Dissado, L.A. Understanding electrical trees in solids: From experiment to theory. In Proceedings of the 2001 IEEE 7th International Conference on Solid Dielectrics, Eindhoven, The Netherlands, 25–29 June 2001; pp. 15–26. [Google Scholar]

- Wang, Y.F.; Cui, J.; Wang, L.X.; Yuan, Q.B.; Niu, Y.J.; Chen, J.; Wang, Q.; Wang, H. Compositional tailoring effect on electric field distribution for significantly enhanced breakdown strength and restrained conductive loss in sandwich-structured ceramic/polymer nanocomposites. J. Mater. Chem. A 2017, 5, 4710–4718. [Google Scholar] [CrossRef]

- Cai, Z.M.; Wang, X.H.; Luo, B.C.; Hong, W.; Wu, L.W.; Li, L.T. Dielectric response and breakdown behavior of polymer-ceramic nanocomposites: The effect of nanoparticle distribution. Compos. Sci. Technol. 2017, 145, 105–113. [Google Scholar] [CrossRef]

- Zhu, M.X.; Li, J.C.; Song, H.G.; Chen, J.M. A phase field model for the propagation of electrical tree in nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 336–342. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Bai, X.; Lu, Z.; Wang, R.; Wang, W.; Guo, R.; Xu, Y.; Lei, Z. Enhancing Breakdown Field Strength and Energy Density in Sandwich-Structured P(VDF-HFP)/BT Films with BN Coating. Processes 2025, 13, 3295. https://doi.org/10.3390/pr13103295

Cheng Y, Bai X, Lu Z, Wang R, Wang W, Guo R, Xu Y, Lei Z. Enhancing Breakdown Field Strength and Energy Density in Sandwich-Structured P(VDF-HFP)/BT Films with BN Coating. Processes. 2025; 13(10):3295. https://doi.org/10.3390/pr13103295

Chicago/Turabian StyleCheng, Yinzhang, Xueting Bai, Zhenyu Lu, Ruijue Wang, Wei Wang, Ruizhou Guo, Yudong Xu, and Zhipeng Lei. 2025. "Enhancing Breakdown Field Strength and Energy Density in Sandwich-Structured P(VDF-HFP)/BT Films with BN Coating" Processes 13, no. 10: 3295. https://doi.org/10.3390/pr13103295

APA StyleCheng, Y., Bai, X., Lu, Z., Wang, R., Wang, W., Guo, R., Xu, Y., & Lei, Z. (2025). Enhancing Breakdown Field Strength and Energy Density in Sandwich-Structured P(VDF-HFP)/BT Films with BN Coating. Processes, 13(10), 3295. https://doi.org/10.3390/pr13103295