- 3.2Impact Factor

- 6.4CiteScore

- 16 daysTime to First Decision

New Thermal Insulation Materials in Green Buildings

This special issue belongs to the section “Construction and Building Materials“.

Special Issue Information

Dear Colleagues,

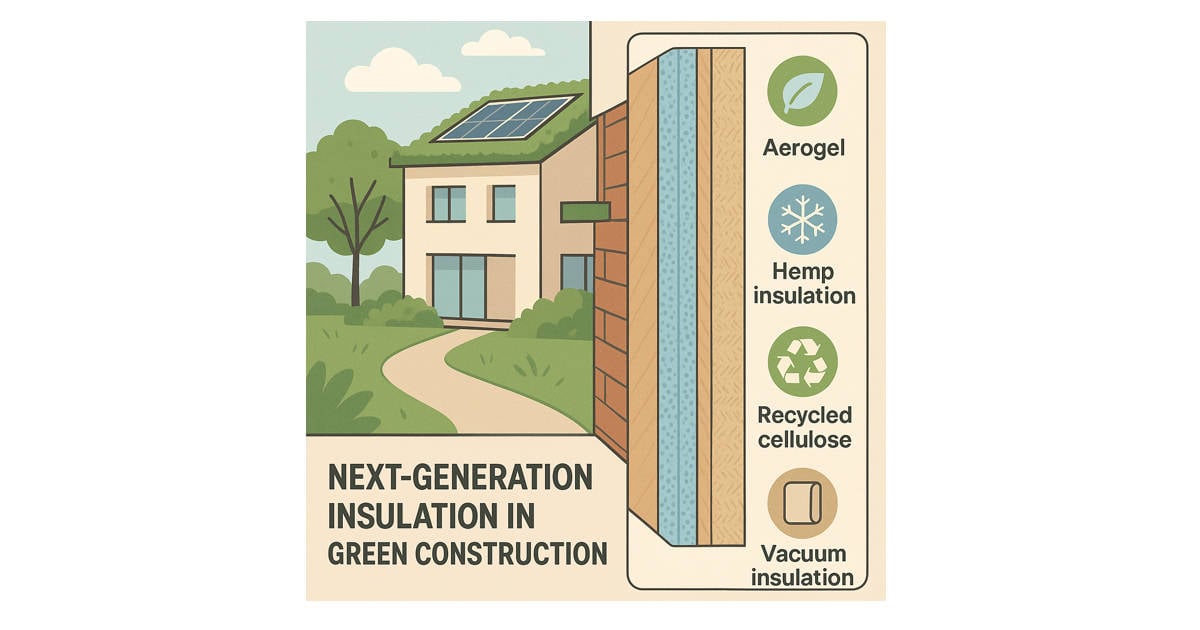

Thermal insulation materials play an important role in the construction industry in terms of reducing energy consumption in new and existing buildings, which is of key importance for environmental protection and sustainable development. Currently, the most commonly used insulation materials in Central Europe are expanded polystyrene, mineral wool and polyurethane materials. However, these materials significantly burden the environment both during the production of the material itself (in terms of primary energy content—PEI; CO2 emissions—GWP) and after its service life in the structure. It should be noted that some of the input raw materials used in the production of insulation are non-renewable, e.g., oil. A more environmentally friendly option is therefore insulation materials from easily renewable and recyclable raw material sources. Experts are striving to return to the original, easily renewable sources of raw materials or to use secondary industrial sources in the development of non-traditional but effective insulation materials.

A number of researchers are researching non-traditional insulation materials. The goal is to develop materials based on natural or waste fibers that would be a suitable ecological replacement for today's common insulation. The production of these materials should have lower energy consumption and no negative impact on the environment. The final products should have at least comparable properties to insulation materials commonly used in construction and should be affordable. However, due to the different nature of the matrix of these fibrous materials, it is necessary to investigate their hygrothermal behavior in order to correctly design the placement of the material in the structure and ensure its optimal function.

This Special Issue of Materials, “New Thermal Insulation Materials in Green Buildings”, will focus on the development, characterization, and application of innovative thermal insulation materials that will contribute to improving the energy efficiency of buildings and reducing greenhouse gas emissions, especially CO2. Papers are invited to address bio-based, recycled, nanostructured, or otherwise advanced insulation materials, their thermal performance, environmental impacts, and integration into green building design. Topics of interest include material science, thermal conductivity analysis, lifecycle assessment (LCA), hygrothermal behavior, regulatory frameworks, and the role of insulation in achieving long-term decarbonization goals in the construction sector. The aim of the journal is to present research that supports the transition to low-carbon, energy-efficient buildings through innovative insulation technologies and sustainable construction practices.

You may choose our Joint Special Issue in Buildings.

Dr. Jitka Peterková

Prof. Dr. Jiří Zach

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- insulation materials based on easy renewable resources

- natural fibres

- waste fibres

- vacuum insulation materials

- ecological materials

- recycling

- LCA

- green buildings

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.