Journal Description

Corrosion and Materials Degradation

Corrosion and Materials Degradation

is an international, peer-reviewed, open access journal on corrosion, environment-assisted degradation, corrosion mitigation, corrosion mechanism and corrosion monitoring, published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within ESCI (Web of Science), Scopus, EBSCO, and other databases.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 21.7 days after submission; acceptance to publication is undertaken in 4.6 days (median values for papers published in this journal in the first half of 2025).

- Journal Rank: CiteScore - Q2 (Materials Science (miscellaneous))

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

Impact Factor:

2.4 (2024);

5-Year Impact Factor:

3.4 (2024)

Latest Articles

Field Exposure of Duplex Stainless Steel in the Marine Environment: The Impact of the Exposure Zone

Corros. Mater. Degrad. 2025, 6(4), 63; https://doi.org/10.3390/cmd6040063 - 28 Nov 2025

Abstract

Owing to its corrosion resistance, stainless steel is a sustainable alternative to carbon steel as a structural material in challenging seawater environments. Studies on carbon steel indicate that among all marine corrosion zones (i.e., atmospheric zone, splash zone, tidal zone, and immersed zone),

[...] Read more.

Owing to its corrosion resistance, stainless steel is a sustainable alternative to carbon steel as a structural material in challenging seawater environments. Studies on carbon steel indicate that among all marine corrosion zones (i.e., atmospheric zone, splash zone, tidal zone, and immersed zone), the rate of corrosion is particularly high in the splash zone, above the seawater level, due to the recurrent splashing of seawater with high levels of oxygen and chloride content. Nevertheless, the information on the extent of localized corrosion (i.e., pitting and crevice corrosion) on stainless steel in the splash and tidal zones is scarce and, in most cases, limited to standard austenitic grades. In this work, we present the pitting and crevice corrosion results on lean duplex, duplex, and super duplex stainless steels after two years of field exposure in the North Sea (site at Heligoland South Harbour). The standard austenitic grade 1.4404 (316L) was also exposed as a reference material in atmosphere and splash zone conditions. Parallel exposure of coupons in splash, tidal, and immersed zones allows comparison of the extent of corrosion in each zone and enables proper material selection for structural applications in marine environments.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►

Show Figures

Open AccessArticle

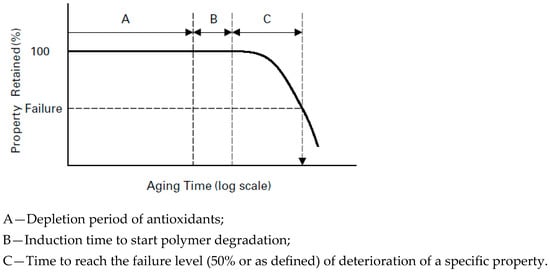

Aging Investigation of Polyethylene-Coated Underground Steel Pipelines

by

Gregory R. Neizvestny, Samuel Kenig and Konstantin Kovler

Corros. Mater. Degrad. 2025, 6(4), 62; https://doi.org/10.3390/cmd6040062 - 27 Nov 2025

Abstract

The aging of three-layer polyethylene-coated buried steel pipelines for oil/gas and water transport poses significant challenges for public safety, environmental integrity, and economic sustainability. Over time, these pipelines become increasingly susceptible to corrosion and eventual failures, which can pose environmental hazards, safety risks,

[...] Read more.

The aging of three-layer polyethylene-coated buried steel pipelines for oil/gas and water transport poses significant challenges for public safety, environmental integrity, and economic sustainability. Over time, these pipelines become increasingly susceptible to corrosion and eventual failures, which can pose environmental hazards, safety risks, and costly repairs. Consequently, predicting the service life of polyethylene-coated steel pipelines is critical for mitigating corrosion risks, extending operational lifespan, and planning effective maintenance strategies. Current international standards lack clear methodologies and criteria for assessing the aging behavior of polyethylene-coated underground pipelines. Current studies have examined two techniques—Line Current Attenuation (LCA) and Drainage Test (DT)—to estimate aging rates in polyolefin-coated pipelines following soil exposure during service. The present study introduces an innovative approach for evaluating aging behavior. It includes a comprehensive analysis using an exponential aging model to estimate the coating’s average specific electrical resistance at any service time, as well as quantitative criteria for the failure of oil/gas and water pipelines. Moreover, it is based on the modified LCA as the most suitable aging methodology with some limitations. Finally, the study concludes with a derived correlation between the coating’s initial specific electrical resistance and its aging rates, and the prediction of the residual life of the polyethylene coating. This integrated framework provides a robust foundation for regulatory bodies, design engineers, maintenance planners, quality assurance/control teams, and researchers to ensure the long-term integrity and sustainability of underground polyethylene-coated steel pipelines.

Full article

(This article belongs to the Special Issue Advances in Material Surface Corrosion and Protection)

►▼

Show Figures

Figure 1

Open AccessArticle

Hydrogen Embrittlement Susceptibility of New Generation Advanced High-Strength Steels for Automotive Applications

by

James Lelliott, Elizabeth Sackett, Neil McMurray and Douglas Figueroa-Gordon

Corros. Mater. Degrad. 2025, 6(4), 61; https://doi.org/10.3390/cmd6040061 - 24 Nov 2025

Abstract

The adoption of advanced high-strength steels (AHSS) in the automotive industry has significantly increased in recent years driven by weight reduction and enhanced crashworthiness. Hot dip galvanised sacrificial coatings are regularly applied to these steels for corrosion protection. In this investigation, the scanning

[...] Read more.

The adoption of advanced high-strength steels (AHSS) in the automotive industry has significantly increased in recent years driven by weight reduction and enhanced crashworthiness. Hot dip galvanised sacrificial coatings are regularly applied to these steels for corrosion protection. In this investigation, the scanning vibrating electrode technique (SVET) demonstrated that hydrogen evolution on the steel substrate is taking place when these sacrificial coatings are damaged during service, increasing the risk of hydrogen embrittlement. The hydrogen embrittlement susceptibility of a new generation of nano-precipitate ferritic, FNP, AHSS have been studied and compared against conventional dual phase ferritic-martensitic, FM, AHSS at equivalent strength levels. Hydrogen permeation tests have shown that FNP AHSS have lower effective diffusion coefficients, Deff, than FM AHSS at equivalent strength levels. At 800 MPa strength levels Deff were 1.68 × 10−7 cm2/s and 1.87 × 10−7 cm2/s for FNP800 and FM800, respectively. At higher strength levels, 1000 MPa, Deff were 7.45 × 10−8 cm2/s and 1.45 × 10−7 cm2/s for the FNP1000 and FM1000, respectively. Slow strain-rate tests (SSRT) showed that FNP AHSS displayed over 35% higher resistance to hydrogen embrittlement than conventional FM AHSS. Quantitative fractographic analyses confirmed that the new ferritic nano-precipitate microstructure retains much more ductile behaviour than conventional martensitic-ferritic even under the most severe hydrogen charging conditions tested.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

Preparation and Characterization of a Dual-Layer Coating with Synergistic Ionic Selectivity and Photocathodic Protection Property

by

Chuyuan Cui, Yongsheng An, Xiangpeng Wang and Ping Qiu

Corros. Mater. Degrad. 2025, 6(4), 60; https://doi.org/10.3390/cmd6040060 - 17 Nov 2025

Abstract

Inspired by the mechanism of ion exchange resins, this study is a first-report in constructing a dual-layer photocathodic protective coating with ionic selectivity to enhance corrosion resistance property. The microstructure, composition, and ion selectivity of the coating are characterized by scanning electron microscopy,

[...] Read more.

Inspired by the mechanism of ion exchange resins, this study is a first-report in constructing a dual-layer photocathodic protective coating with ionic selectivity to enhance corrosion resistance property. The microstructure, composition, and ion selectivity of the coating are characterized by scanning electron microscopy, Raman spectroscopy, infrared spectroscopy, and membrane potential. It shows that the outer g-C3N4/TiO2 cation-selective layer plays a role in preventing corrosive Cl− ions passing through the coating; the inner g-C3N4-TiO2-CTAB anion-selective layer could prevent Fe2+ ions from diffusing through the coating. Furthermore, the coated carbon steel sample demonstrates a minimum OCP (open circuit potential) value of −770 mV (vs. SCE) under illumination in 3.5% NaCl media. Interestingly, the OCP remains around −720 mV (vs. SCE) even after light deprivation. The synergistic effect between ion selectivity and photocathodic protection is described, in detail, in the following.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

Studies of Initial Atmospheric Corrosion of Magnesium Alloys AZ91 and AZ31 with Infrared Spectroscopy Techniques

by

Dan Persson, Alexander Wärnheim, Nathalie LeBozec and Dominique Thierry

Corros. Mater. Degrad. 2025, 6(4), 59; https://doi.org/10.3390/cmd6040059 - 17 Nov 2025

Abstract

The initial formation of corrosion products in pure humid air on magnesium alloys AZ91 and AZ31 was studied using infrared reflection absorption spectroscopy (IRRAS), infrared spectroscopic imaging, and SEM-EDS. The kinetics of corrosion product formation were monitored in situ with IRRAS during exposure

[...] Read more.

The initial formation of corrosion products in pure humid air on magnesium alloys AZ91 and AZ31 was studied using infrared reflection absorption spectroscopy (IRRAS), infrared spectroscopic imaging, and SEM-EDS. The kinetics of corrosion product formation were monitored in situ with IRRAS during exposure to humid air (95% relative humidity) under two different CO2 concentrations: low (≤1 ppm) and ambient (400 ppm). For low CO2 concentrations, the primary corrosion product detected on both alloys was magnesium hydroxide (Mg(OH)2). In contrast, under ambient CO2 conditions (400 ppm), magnesium hydroxy carbonate was the dominant product. After 16 h of exposure, the amount of magnesium converted into corrosion products was approximately 8–10 times higher under low-CO2 conditions compared to ambient levels. The smaller formation of corrosion products but increased magnesium carbonate formation on AZ91D is attributed to its higher aluminium content compared to AZ31. Corrosion attack and product formation were largely localised to the centre of the α-phase in AZ91D, with the β-phase likely serving as sites for cathodic reactions.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessReview

A Review on Advanced AFM and SKPFM Data Analytics for Quantitative Nanoscale Corrosion Characterization

by

Mohammad Reza Attar and Ali Davoodi

Corros. Mater. Degrad. 2025, 6(4), 58; https://doi.org/10.3390/cmd6040058 - 13 Nov 2025

Abstract

Corrosion is a complex, surface-initiated process that demands nanoscale, real-time characterization to understand its initiation and propagation. Atomic force microscopy (AFM) and scanning Kelvin probe force microscopy (SKPFM) have emerged as powerful tools in corrosion science, enabling high-resolution imaging and electrochemical mapping under

[...] Read more.

Corrosion is a complex, surface-initiated process that demands nanoscale, real-time characterization to understand its initiation and propagation. Atomic force microscopy (AFM) and scanning Kelvin probe force microscopy (SKPFM) have emerged as powerful tools in corrosion science, enabling high-resolution imaging and electrochemical mapping under realistic conditions. This review, inspired by pioneering work at KTH by Professors Christofer Leygraf and Jinshan Pan, highlights advanced analytical strategies that extend the capabilities of AFM and SKPFM beyond traditional line-profile analysis. Techniques such as power spectral density (PSD) analysis, multimodal Gaussian histogram fitting, statistical roughness quantification, and deconvolution methods are discussed in the context of case studies on aluminum alloys, stainless steels, magnesium alloys, biomedical implants, and protective coatings. By integrating in situ imaging, electrochemical mapping, and statistical data processing, these approaches provide deeper insights into localized corrosion, micro-galvanic coupling, and surface reactivity. Future directions include coupling AFM-based methods with high-speed imaging, machine learning, and spectro-electrochemical techniques to accelerate the development of corrosion-resistant materials and enable probabilistic diagnostics of corrosion initiation susceptibility.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

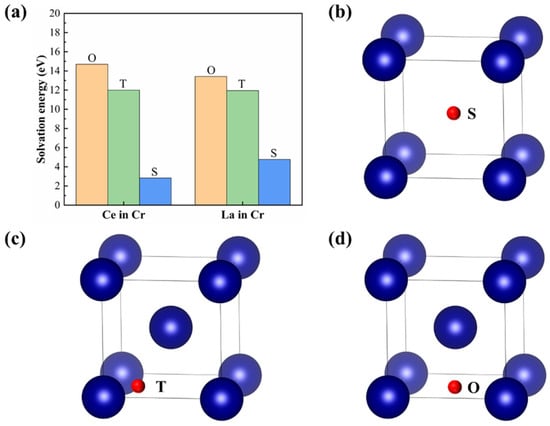

First-Principles Study of Rare-Earth Doping Effects on Nitrogen Adsorption and Diffusion in Chromium

by

Shuhui Chen, Bao Chen, Min Liu, Ji Liu, Gen Li and Ying Jin

Corros. Mater. Degrad. 2025, 6(4), 57; https://doi.org/10.3390/cmd6040057 - 12 Nov 2025

Abstract

To address the premature corrosion failure of chromium-based coatings in harsh environments (e.g., high temperatures, chloride-containing solutions), this work systematically investigates how rare-earth (RE, i.e., Ce and La) elements regulate nitrogen (N) adsorption and diffusion behavior in Cr during the early stages of

[...] Read more.

To address the premature corrosion failure of chromium-based coatings in harsh environments (e.g., high temperatures, chloride-containing solutions), this work systematically investigates how rare-earth (RE, i.e., Ce and La) elements regulate nitrogen (N) adsorption and diffusion behavior in Cr during the early stages of nitriding, a critical corrosion protection strategy, using first-principles density functional theory (DFT). Results show that RE preferentially occupies Cr substitutional site, increasing the Young’s modulus from 293.5 GPa (pristine Cr) to 344.9 GPa (Ce-doped) and 348.7 GPa (La-doped). Surface RE doping on Cr(110) significantly enhances N adsorption energy from −3.23 eV to −3.559/−3.645 eV (Ce-/La-doped), whereas subsurface doping slightly weakens the adsorption. Moreover, the energy barrier for N penetration into subsurface is reduced from 2.11 eV to 2.03/1.91 eV (Ce-/La-doped), thereby facilitating nitridation. Notably, RE is found to strongly trap vacancies and N atoms, leading to increased migration barriers and thus hindering their long-range transport. These findings demonstrate that RE exhibits a dual role during nitriding: promoting N incorporation at the surface while restricting its deep diffusion into the bulk. The study provides theoretical insights into the atomistic mechanisms by which RE elements modulate nitriding efficiency in Cr-based alloys, offering guidance for the design of RE-doped surface-modified coatings with improved corrosion resistance.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessReview

Synchrotron X-Ray Techniques for In Situ or Microscopic Study of Passive Films on Industrial Alloys: A Mini Review

by

Jinshan Pan

Corros. Mater. Degrad. 2025, 6(4), 56; https://doi.org/10.3390/cmd6040056 - 4 Nov 2025

Abstract

The spontaneous formation and stability of a protective passive film on a metal surface are crucial for the metal material’s corrosion resistance during its service life. Passive films have been extensively studied, and our understanding of passive films has been significantly improved with

[...] Read more.

The spontaneous formation and stability of a protective passive film on a metal surface are crucial for the metal material’s corrosion resistance during its service life. Passive films have been extensively studied, and our understanding of passive films has been significantly improved with the development of advanced analytical techniques. Modern synchrotron X-ray sources offer unprecedented possibilities for detailed analyses of passive films and for in situ and operando studies of passive films in both gaseous/aqueous environments, as well as in electrochemical environments. This mini review presents a short summary of recent studies on passive films, mainly focusing on stainless steels and nickel-base alloys, which utilize state-of-the-art synchrotron X-ray techniques, particularly X-ray photoelectron spectroscopy (XPS), often in combination with other synchrotron techniques such as X-ray adsorption, diffraction, reflectivity, and fluorescence. These reports demonstrate that synchrotron-based techniques greatly improve probing sensitivity and spatial resolution, enabling in situ and operando studies of passive films at solid–liquid interfaces. These studies reveal changes in the passive film and underlying alloy layer, highlighting the important role of hydroxides, as well as the inhomogeneity in passive films associated with the complex microstructures in advanced industrial alloys.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

Evolution of Galvanized Steel Pipe Corrosion in Hot Water Supply Systems

by

Valentin Chukhin, Nikolay Makisha and Igor Gulshin

Corros. Mater. Degrad. 2025, 6(4), 55; https://doi.org/10.3390/cmd6040055 - 31 Oct 2025

Abstract

►▼

Show Figures

This paper presents comprehensive studies of pitting corrosion, which precedes the appearance of fistulas in galvanized steel pipelines of hot and cold water supply systems. Corroded galvanized pipes taken out from water supply systems within their operation and scale samples were the subject

[...] Read more.

This paper presents comprehensive studies of pitting corrosion, which precedes the appearance of fistulas in galvanized steel pipelines of hot and cold water supply systems. Corroded galvanized pipes taken out from water supply systems within their operation and scale samples were the subject of this research. The current work continues the research on one of the four structural elements of tubercles—the dense layer. The corrosion of the zinc coating and the steel base of pipes inside the tubercles led to a gradual increase in the concentration of a solution containing components of the corroding metal (zinc and iron cations) and anions in water (mainly chlorides and sulfates). To explain the corrosion under the tubercles, their dense layer was compared with an anion exchange membrane with selective properties, which provided the primary concentration of the salt solution in the structure of the tubercles with a significant increase in the concentration of aggressive anions compared to the source water. The formation of fistulas in the cavity leads to a secondary concentration of solution inside the tubercle, mainly consisting of iron chloride. At the same time, due to the hydrolysis of the formed iron salts and a decrease in pH, the corrosion rate increases and becomes independent of external conditions. This article summarizes ten years of experience in examining corrosion of steel pipes from external and internal water supply systems.

Full article

Figure 1

Open AccessReview

Corrosion and Soiling in the 21st Century: Insights from ICP Materials and Impact on Cultural Heritage

by

Johan Tidblad, Alice Moya Núñez, Daniel de la Fuente, Gino Ebell, Tore Flatlandsmo Berglen, Terje Grøntoft, Ulrik Hans, Ioannis Christodoulakis, Daniel Kajánek, Kateřina Kreislová, Lech Kwiatkowski, Teresa La Torreta, Rafał Lutze, Guadalupe Pinar Larrubia, Valentina Pintus, Michael Prange, Pasquale Spezzano, Costas Varotsos, Aurélie Verney-Carron, Tiina Vuorio and Tim Yatesadd

Show full author list

remove

Hide full author list

Corros. Mater. Degrad. 2025, 6(4), 54; https://doi.org/10.3390/cmd6040054 - 22 Oct 2025

Abstract

This paper reviews results published by the International Co-operative Programme on Effects on Materials including Historic and Cultural Monuments (ICP Materials) with emphasis on those obtained after the turn of the century. Data from ICP Materials come from two main sources. The first

[...] Read more.

This paper reviews results published by the International Co-operative Programme on Effects on Materials including Historic and Cultural Monuments (ICP Materials) with emphasis on those obtained after the turn of the century. Data from ICP Materials come from two main sources. The first is through exposures of materials and collection of environmental data in a network of atmospheric exposure test sites mainly distributed across Europe. Corrosion of carbon steel has continued to decrease during the period 2000–2020 but corrosion of zinc only up until 2014, and the trend in zinc corrosion is only visible when examining four-year data. Surface recession of limestone as well as soiling of modern glass show no decreasing trend during 2000–2020. The second is through case studies performed at heritage sites across Europe. Risk analysis of corrosion and soiling for twenty-six sites indicate that currently soiling is a more significant maintenance trigger than corrosion. Costs for maintaining heritage sites are substantial and costs attributable to air pollution is estimated from 40% to as much as 80% of the total cost. Future directions of the program are work on effects of particulate matter, improving the scientific basis for the work, and making the monitoring data publicly available.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

Atmospheric Corrosion Kinetics and QPQ Coating Failure of 30CrMnSiA Steel Under a Deposited Salt Film

by

Wenchao Li, Shilong Chen, Hui Xiao, Xiaofei Jiao, Yurong Wang, Shuwei Song, Songtao Yan and Ying Jin

Corros. Mater. Degrad. 2025, 6(4), 53; https://doi.org/10.3390/cmd6040053 - 16 Oct 2025

Abstract

Atmospheric corrosion in sand dust environments is driven by deposits that bear chloride, which sustain thin electrolyte layers on metal surfaces. We established a laboratory protocol to replicate this by extracting, formulating, and depositing a preliminary layer of mixed salts from natural dust

[...] Read more.

Atmospheric corrosion in sand dust environments is driven by deposits that bear chloride, which sustain thin electrolyte layers on metal surfaces. We established a laboratory protocol to replicate this by extracting, formulating, and depositing a preliminary layer of mixed salts from natural dust onto samples, with humidity precisely set using the salt’s deliquescence behavior. Degradation was tracked with SEM/EDS, 3D profilometry, XRD, and electrochemical analysis. Bare steel showed progressive yet decelerating attack as rust evolved from discrete islands to a lamellar network; while this densification limited transport, its internal cracks and interfacial gaps trapped chlorides, sustaining activity beneath the rust. In contrast, QPQ-treated steel remained largely protected, with damage localized at coating defects as raised rust nodules, while intact regions maintained low electrochemical activity. By coupling salt chemistries derived from the field with humidity control guided by deliquescence and diagnostics across multiple scales, this study provides a reproducible laboratory pathway to predict atmospheric corrosion.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

Corrosion Behavior of Electrochemical and Thermal Treated Titanium into Artificial Saliva: Effect of pH and Fluoride Concentration

by

Faiza Kakaa, Mosbah Ferkhi, Ammar Khaled, Sabah Amira and Marielle Eyraud

Corros. Mater. Degrad. 2025, 6(4), 52; https://doi.org/10.3390/cmd6040052 - 15 Oct 2025

Abstract

►▼

Show Figures

This work investigates and compare the corrosion behavior in artificial saliva of oxide thin films grown on commercially pure titanium (cp-Ti), via electrochemical oxidation (EO) in sulphate bath at 1 V and thermal treatment (TT) at 450 °C, for durations between 20 min

[...] Read more.

This work investigates and compare the corrosion behavior in artificial saliva of oxide thin films grown on commercially pure titanium (cp-Ti), via electrochemical oxidation (EO) in sulphate bath at 1 V and thermal treatment (TT) at 450 °C, for durations between 20 min and 4 h. The goal is to determine which method and duration provide the optimal protection for titanium against degradation in dental environment particularly in varying fluoride concentration and acidity. Surface characterizations were performed through morphological and microstructural analysis using scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS) and X-ray diffraction (XRD). Electrochemical behavior was conducted in Fusayama-Meyer solution (pH = 6.50 and T = 37 °C) using potentiodynamic polarization curve (PPC) and electrochemical impedance spectroscopy (EIS), under varying pH and fluoride ion concentrations. The results demonstrated that a 3-h duration treatment provided the optimal corrosion resistance for both EO and TT processes. The pH of the environment influenced corrosion performance markedly: both acidic (pH 2.5) and basic (pH 9.0) conditions increased Icorr and decreased Rp, indicating degradation of the passive oxide layer outside neutral conditions. Similarly, increasing fluoride concentrations (1000; 5000; and 12,300 ppm) significantly impaired corrosion resistance. At 12,300 ppm F−, untreated Ti showed severe degradation, with EIS revealing the formation of a porous outer layer and a weakened inner barrier layer (Rf = 33 W·cm2 for the outer layer and Rct = 21 kW·cm2 for the barrier layer). In contrast, the TT-treated surface remained highly protective even under these aggressive conditions, with minimal surface damage and the highest resistances for both the outer and the inner layers (Rf = 1610 kW·cm2; Rct = 1583 kW·cm2), significantly outperforming the EO film. These findings highlight the superior performance of thermal oxidation at 450 °C for 3 h as a promising surface treatment for enhancing the corrosion resistance of titanium in fluoride-rich oral environments. Understanding these strategies helps improve the longevity and security of titanium dental implants.

Full article

Figure 1

Open AccessArticle

Patina Formation and Aesthetic Durability of Architectural Copper and Copper Alloys in the Marine–Desert Environment of Dubai

by

Inger Odnevall and Gunilla Herting

Corros. Mater. Degrad. 2025, 6(4), 51; https://doi.org/10.3390/cmd6040051 - 14 Oct 2025

Abstract

The use of copper and its alloys in architecture, especially in arid regions, is growing, driven by visual appeal, functional advantages, and sustainability. Changes in visual and colorimetric appearances and patina formation were evaluated for architectural Cu metal, brass (CuZn15), bronze (CuSn4), and

[...] Read more.

The use of copper and its alloys in architecture, especially in arid regions, is growing, driven by visual appeal, functional advantages, and sustainability. Changes in visual and colorimetric appearances and patina formation were evaluated for architectural Cu metal, brass (CuZn15), bronze (CuSn4), and a golden alloy (CuZn5Al5). Coupons were exposed over 4 years in Dubai, United Arab Emirates, at a test site located 2 km from the seashore under unsheltered conditions, and at various surface inclinations. Comparative exposures were conducted in Brest, France, at sites of increasing distance from the seashore. Visual appearance was assessed by colorimetry and optical imaging; patina cross-sections were characterized by means of scanning electron microscopy and elemental analysis (SEM/EDS), and crystalline phase identification was conducted by means of x-ray diffraction (XRD). All Dubai surfaces developed red-yellowish, heterogeneous patinas with embedded sand and dust, reducing lightness and visual appeal. Inclination had minor effect, although some extent of spallation occurred on downward-facing CuSn4. Even the corrosion-resistant CuZn5Al5 alloy lost its golden hue due to the incorporation of sand and dust into the patina. In Brest, appearance depended on the distance from the seashore, with green-blue patinas near the sea and red-yellowish farther inland, similar to Dubai. Cleaning may restore some luster, but the desert exposure generally reduced the long-term aesthetic performance of all materials.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

Influence of Temperature on the Galvanic Corrosion Behavior Between Titanium Alloy and 304 Stainless Steel in a Simulated Marine Environment

by

Jiao Meng, Xingyu Li, Feng Guo, Wenhua Cheng and Ruiling Jia

Corros. Mater. Degrad. 2025, 6(4), 50; https://doi.org/10.3390/cmd6040050 - 13 Oct 2025

Abstract

►▼

Show Figures

In 3.5 wt% NaCl solution used to simulate seawater, the individual (self-corrosion) and coupled (galvanic) corrosion behaviors of TA22 titanium alloy and 304 stainless steel were systematically investigated at 25 °C, 35 °C, 45 °C and 55 °C. Post-corrosion surfaces were characterized by

[...] Read more.

In 3.5 wt% NaCl solution used to simulate seawater, the individual (self-corrosion) and coupled (galvanic) corrosion behaviors of TA22 titanium alloy and 304 stainless steel were systematically investigated at 25 °C, 35 °C, 45 °C and 55 °C. Post-corrosion surfaces were characterized by scanning electron microscopy (SEM), three-dimensional profilometry and X-ray photoelectron spectroscopy (XPS). The results demonstrated that elevating temperature decreased the compactness and protective quality of the passive film on both alloys, as indicated by increasing donor densities and positive shifts in flat-band potentials. Distinct pitting corrosion occurred on 304 SS above 45 °C. Upon galvanic coupling, the passive film on TA22 was modified in both structure and composition, exhibiting a decreased TiO2 content and increased lower valence oxides (Ti2O3, TiO). The galvanic effect intensified with temperature, leading to progressively aggravated corrosion of 304 SS, characterized by increased pit density, diameter, and depth compared to its self-corrosion state.

Full article

Figure 1

Open AccessArticle

Corrosion Mechanisms of Commercial Superalloys in Binary and Ternary Chloride Molten Salts

by

Hongyi Hu, Xian Zhang, Tianyou Huang, Rui Yu and Kaiming Wu

Corros. Mater. Degrad. 2025, 6(4), 49; https://doi.org/10.3390/cmd6040049 - 10 Oct 2025

Abstract

In concentrated solar power (CSP) systems, structural materials face severe corrosion challenges induced by molten chlorides, with the corrosion severity being highly dependent on the salt composition. This study systematically compares the corrosion behavior of two representative superalloys, Inconel 625 and SS321, in

[...] Read more.

In concentrated solar power (CSP) systems, structural materials face severe corrosion challenges induced by molten chlorides, with the corrosion severity being highly dependent on the salt composition. This study systematically compares the corrosion behavior of two representative superalloys, Inconel 625 and SS321, in binary NaCl–KCl and ternary MgCl2–NaCl–KCl molten salts at 700 °C. The corrosion products and microstructural features were characterized using X-ray diffraction (XRD), scanning electron microscopy (SEM) equipped with energy-dispersive spectroscopy (EDS), and electron backscatter diffraction (EBSD), in combination with static exposure tests to elucidate the underlying mechanisms. The results show that in NaCl–KCl molten salts, both alloys primarily form Cr2O3 as the protective product. However, the corrosion scale of SS321 is porous, whereas Inconel 625 develops a dense NiCr2O4 inner layer, exhibiting superior corrosion resistance. In the MgCl2–NaCl–KCl molten salt system, Cr2O3 is replaced by a dense MgO layer forms on Inconel 625, coupled with Mo surface enrichment, which significantly inhibits Cr depletion and leads to a notably reduced corrosion rate relative to the binary salt. In contrast, the transformation of Cr2O3 on SS321 into porous MgCr2O4 exacerbates intergranular corrosion, resulting in a substantial degradation of corrosion resistance. This study elucidates the distinct corrosion pathways and mechanisms of different alloys in binary and ternary chloride salts, providing important guidance for the selection of molten salt compositions and corrosion-resistant structural materials in CSP applications.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

Co-Adsorption of Formic Acid and Hexane Selenol on Cu

by

Mats Ahmadi Götelid, Sareh Ahmadi Götelid, Saman Hosseinpour, Christofer Leygraf and C. Magnus Johnson

Corros. Mater. Degrad. 2025, 6(4), 48; https://doi.org/10.3390/cmd6040048 - 26 Sep 2025

Abstract

Self-assembled monolayers of alkane thiolate and alkane selenolate have been proven to inhibit atmospheric corrosion, but upon prolonged exposure to the important constituents of indoor atmosphere, namely humidified air with formic acid, the protective layer eventually breaks, but the exact reason is not

[...] Read more.

Self-assembled monolayers of alkane thiolate and alkane selenolate have been proven to inhibit atmospheric corrosion, but upon prolonged exposure to the important constituents of indoor atmosphere, namely humidified air with formic acid, the protective layer eventually breaks, but the exact reason is not yet clear. In this paper, we report on an XPS study of co-adsorbed formic acid and hexane selenol on a Cu surface. Adsorption of hexane selenol at room temperature breaks the Se-C bond, leaving a monolayer of Se on the surface, whereas adsorption at 140 K leaves a layer of selenolate. Formic acid exposure to the selenolate-Cu surface leads to adsorbed formate on unprotected areas and absorption of formic acid within the alkane chain network. During heating, the formic acid desorbs and the Se-C bond breaks, but formic acid does not accelerate the Se-C scission, which occurs just below room temperature both with and without formic acid. Thus, formic acid alone does not affect the Se-C bond, but its presence may create disorder and open up the alkane carpet for other species. Selenol removes formate and oxide from the surface at room temperature. The Se-C bond breaks and the alkane chain reacts with surface oxygen to form carbon oxides and volatile hydrocarbons.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Open AccessArticle

High-Temperature Oxidation Behavior of an Additively Manufactured Alumina-Forming Austenitic Stainless Steel

by

Sedigheh Rashidi, Arnab Chatterjee, Amit Pandey and Rajeev K. Gupta

Corros. Mater. Degrad. 2025, 6(4), 47; https://doi.org/10.3390/cmd6040047 - 26 Sep 2025

Abstract

►▼

Show Figures

High-temperature oxidation behavior of an alumina-forming austenitic stainless steel (AFA25) produced by additive manufacturing (AM) has been studied at 850 °C in air and compared to the conventional wrought alloy. The mass gain measurements during high-temperature oxidation tests were performed to understand the

[...] Read more.

High-temperature oxidation behavior of an alumina-forming austenitic stainless steel (AFA25) produced by additive manufacturing (AM) has been studied at 850 °C in air and compared to the conventional wrought alloy. The mass gain measurements during high-temperature oxidation tests were performed to understand the rate of oxidation, oxidation characteristics, and morphology of oxides that form in these alloys. X-ray diffraction, scanning electron microscopy, and energy-dispersive X-ray spectroscopy were used to characterize the microstructure and oxide scale formation during high-temperature exposure. A similar alumina scale was observed on both wrought and AM alloys. The continuous alumina layer that forms in these alloys provides superior oxidation resistance. This paper shows that a variation in AM build parameters influences the oxidation properties, where one AM alloy with a lower laser power to hatch ratio depicts much better oxidation properties compared to conventional wrought AFA alloys.

Full article

Graphical abstract

Open AccessReview

Long-Term Marine Corrosion Under the Influence of Microbiologically Influenced Corrosion and Calcareous Conditions

by

Robert E. Melchers

Corros. Mater. Degrad. 2025, 6(4), 46; https://doi.org/10.3390/cmd6040046 - 25 Sep 2025

Abstract

Calcareous deposits on and within corrosion products tend to inhibit the (abiotic) corrosion of steels in seawater. Herein, it was considered whether this inhibition effect extends to microbiologically influenced corrosion (MIC) for extended (long-term) exposure periods. Quantitative estimates of corrosion rates were made

[...] Read more.

Calcareous deposits on and within corrosion products tend to inhibit the (abiotic) corrosion of steels in seawater. Herein, it was considered whether this inhibition effect extends to microbiologically influenced corrosion (MIC) for extended (long-term) exposure periods. Quantitative estimates of corrosion rates were made from reported observations for 46 iron and steel shipwrecks, and other iron and steel objects immersed in seawater at various depths and for extended periods (many around 60 years and some up to 160 years). The observations are correlated with observations of the occurrence of calcareous deposits and information about dissolved inorganic nitrogen (DIN), a critical micronutrient for MIC. The results show that calcareous deposits can inhibit both long-term abiotic corrosion and long-term corrosion influenced by conditions suitable for MIC. The practical implications are briefly reviewed.

Full article

(This article belongs to the Special Issue Corrosion and Corrosion Protection Strategies in the Marine Environment)

►▼

Show Figures

Figure 1

Open AccessArticle

Long Term Measurements of High Temperature Corrosion in a Waste Incineration Plant Using an Online Monitoring System

by

Adrian Marx, Dennis Hülsbruch, Jochen Ströhle and Bernd Epple

Corros. Mater. Degrad. 2025, 6(3), 45; https://doi.org/10.3390/cmd6030045 - 18 Sep 2025

Abstract

►▼

Show Figures

High-temperature corrosion is a frequently observed phenomenon in waste incineration facilities. Municipal solid waste presents substantial corrosion potential attributed to elevated chlorine content and significant inhomogeneity in calorific value and chemical composition, rendering stable plant operation and corrosion control challenging. Conventional countermeasures, such

[...] Read more.

High-temperature corrosion is a frequently observed phenomenon in waste incineration facilities. Municipal solid waste presents substantial corrosion potential attributed to elevated chlorine content and significant inhomogeneity in calorific value and chemical composition, rendering stable plant operation and corrosion control challenging. Conventional countermeasures, such as cladding or reduced steam parameters, lack temporal resolution and incur substantial costs or reduced efficiency. For this study, a waste incineration plant was equipped with an online corrosion monitoring system featuring ten sensors distributed across three vertical boiler passes. The system employs an electrochemical measurement principle to enable the detection of corrosion with temporal resolution. The recorded data reveals decreasing corrosion attack and increasingly stable deposits along the flue gas path. Combined with the temperature measurements, the sensor data proves the effectiveness of the shower cleaning in the third pass and confirms successful removal of the deposits. Statistical analysis shows a correlation between CO content and sensor data, while other parameters (e.g., steam flow, flue gas temperatures) exhibit no conclusive correlations, emphasizing the system’s added value. Chemical analysis of the electrodes and deposits reveal significant indications of chlorine and sulfur, suggesting chlorine-catalyzed active oxidation as the predominant corrosion mechanism.

Full article

Figure 1

Open AccessArticle

Atmospheric Corrosion of Steel on the Australian Pacific Central Coast

by

Robert Jeffrey and Robert E. Melchers

Corros. Mater. Degrad. 2025, 6(3), 44; https://doi.org/10.3390/cmd6030044 - 16 Sep 2025

Abstract

Comprehensive data are presented for corrosion losses of mild steel exposed for up to 5 years, all obtained from exposing steel coupons at one specific severe marine exposure site on the Pacific Ocean coast. The test programme considered the effects of duration of

[...] Read more.

Comprehensive data are presented for corrosion losses of mild steel exposed for up to 5 years, all obtained from exposing steel coupons at one specific severe marine exposure site on the Pacific Ocean coast. The test programme considered the effects of duration of exposure, inclination, orientation, height, shielding, and coupon variability, using multiple, nominally identical mild steel coupons, all under a single local climatic regime. Such a controlled, consistent, natural environment permits unique, valid comparison of the various influences, both for short-term and longer-term exposures, unlike previous tests of some parameters conducted in the short term at disparate sites. In contrast to coupons exposed only on one side, boldly exposed double-sided coupons corroded severely within 3 years. The effects on corrosion behaviour between individual coupons exposed at different heights and vertical continuous single strips of steel are described. Also reported are corrosion losses for continuous strips and for a series of coupons oriented in different directions. Observations of variability in corrosion losses for nominally identically exposed steel coupons are reported. The effect on corrosion losses with continued exposure to 5 years is reported and compared with information available in the literature.

Full article

(This article belongs to the Special Issue Atmospheric Corrosion, Surface Electrochemistry and Environmental Degradation of Materials: In Honor of Prof. Christofer Leygraf)

►▼

Show Figures

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Applied Sciences, Buildings, Construction Materials, CMD, Materials, Metals

Construction Materials: Corrosion, Prevention and Protection

Topic Editors: Sergio Lorenzi, Marco OrmelleseDeadline: 1 May 2026

Topic in

Coatings, Lubricants, Metals, Applied Sciences, CMD, JMMP

Surface Modification and Durability Enhancement of Advanced Alloys

Topic Editors: Ping Zhang, Chuang He, Damian Przestacki, Yu-Cun GuDeadline: 5 October 2026

Conferences

Special Issues

Special Issue in

CMD

Applied Infrastructure Corrosion Science for Construction Practice Advancement

Guest Editors: Igor Chaves, Robert B. Petersen, Robert MelchersDeadline: 31 December 2025

Special Issue in

CMD

Advances in Material Surface Corrosion and Protection

Guest Editor: Wei JiangDeadline: 31 December 2025

Special Issue in

CMD

Hydrogen Embrittlement of Modern Alloys in Advanced Applications

Guest Editor: Huixing LiDeadline: 31 January 2026

Special Issue in

CMD

Effects of Cryogenic Treatment on the Corrosion and Materials Degradation

Guest Editors: Patricia Jovičević-Klug, J. Manoj Prabhakar, Matic Jovičević-KlugDeadline: 31 January 2026