- 3.2Impact Factor

- 6.4CiteScore

- 16 daysTime to First Decision

Design, Preparation, and Microstructural Characterization of High Entropy Materials

This special issue belongs to the section “Advanced Materials Characterization“.

Special Issue Information

Dear Colleagues,

High-entropy materials (high-entropy alloy, high-entropy oxide, high-entropy...) have attracted tremendous attention and have shown promise regarding exciting applications which have previously been unfathomable to achieve. Owing to their short-range disorder and long-range order nature, these materials maintain a high configuration entropy, which can still sustain phase stability, allowing various adjustment in the mechanical, electrical, optical, magnetic, and catalytic performances of the materials.

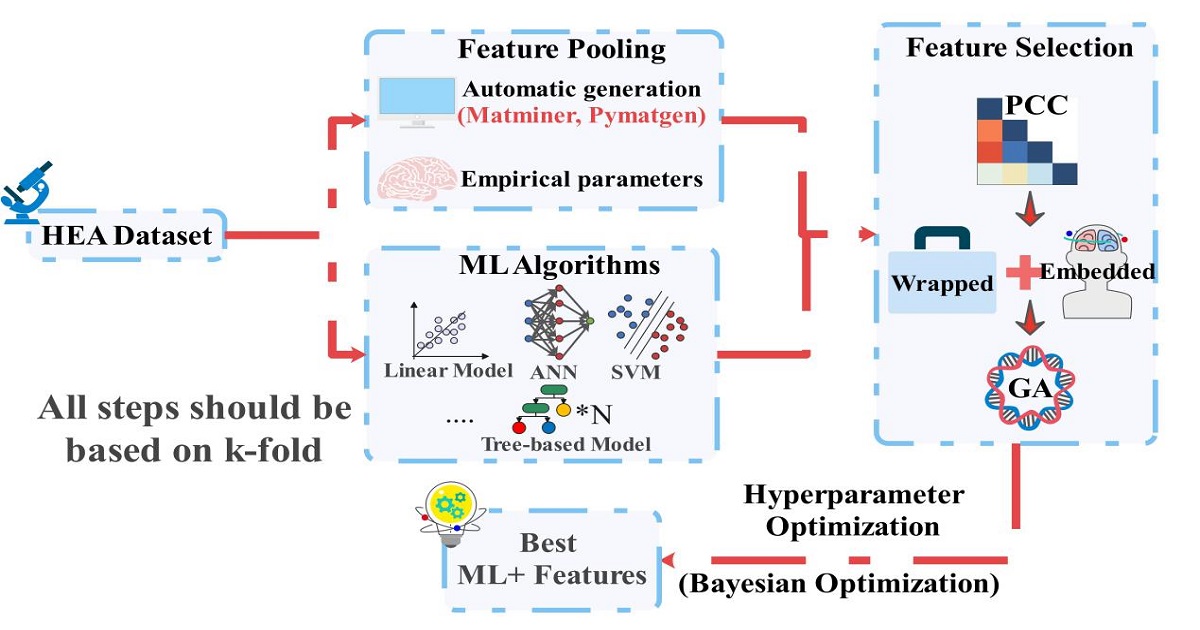

Previous research on high-entropy materials has focused on bulk samples. However, as the miniaturization of devices has evolved, there is a need to understand this multiple alloy system at the micro and nano levels. The development of high-entropy materials is as of now a debated issue that can be generally divided into two primary classes: coatings with bulk and thin films. Some of the major issues in bulk alloy-based material is the prevalence of brittle fracture upon deformation that leads to catastrophic fracture, which typically originates from a single, major shear band. The scientific community is also focusing on the following fields: 1) developing novel high-entropy alloy thin films with ideal strength and ductility in extreme conditions, such as cryogenic or acid environments; 2) developing novel high-entropy oxide thin films with various crystal structures, such as rocksalt, spinel, perovskite, fluorite, etc.; 3) developing a comprehensive prediction and screening methodology supported by machine learning technologies.

This Special Issue aims to bring together research papers, short communications, and review articles focused on the novel synthesis, device designs, fabrication, advanced characterization, and artificial intelligence design of various high-entropy materials in order to provide a comprehensive overview of the state of the art within this field

Dr. Wei Ren

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- high-entropy alloy

- high-entropy oxide

- high-entropy nitride

- high-entropy carbide

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.