- Review

A Comprehensive Review on Constitutive Models and Damage Analysis of Concrete Spalling in High Temperature Environment and Geological Repository for Spent Fuel and Nuclear Waste Disposal

- Toan Duc Cao,

- Lu Sun and

- Jaiden Zhang

- + 2 authors

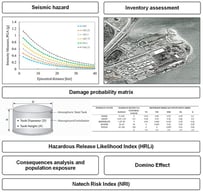

This paper reviews constitutive models used to predict concrete spalling under elevated temperatures, with emphasis on fire exposure and concrete linings in deep geological repositories for spent fuel and nuclear waste. The review synthesizes (1) how material composition (ordinary Portland cement concrete, geopolymer concrete, and fiber-reinforced systems using polypropylene and steel fibers) affects spalling resistance; (2) how coupled environmental and mechanical actions (temperature, moisture, stress state, chloride ingress, and radiation) drive damage initiation and spalling; and (3) how constituent-scale characteristics (microstructure, porosity, permeability, elastic modulus, and water content) govern thermal–hydro–mechanical–chemical (THMC) transport and damage evolution. We compare major constitutive modeling frameworks, including plasticity–damage models (e.g., concrete damage plasticity), statistical damage approaches, and fully coupled THM/THMC formulations, and highlight how key parameters (e.g., water-to-binder ratio, temperature-driven pore-pressure gradients, and crack evolution laws) control predicted spalling onset, depth, and timing. Several overarching challenges emerge: lack of standardized experimental protocols for spalling tests and assessments, which limits cross-study benchmarking; continued debate on whether spalling is dominated by pore pressure, thermo-mechanical stress, or their interaction; limited integration of multiscale and constituent-level material characteristics; and high data and computational demands associated with advanced multi-physics models. The paper concludes with targeted research directions to improve model calibration, validation, and performance-based design of concrete systems for high-temperature and repository applications.

5 February 2026

![Evolution of Damage Variable with Axial Strain in (a) C60 and (b) C70 Concrete (adapted from Zhang et al. [6]).](https://mdpi-res.com/cdn-cgi/image/w=470,h=317/https://mdpi-res.com/infrastructures/infrastructures-11-00054/article_deploy/html/images/infrastructures-11-00054-g001-550.jpg)