Abstract

Electric linear or rotary actuators are the ultimate power-dense execution units in modern industrial and transportation systems, yet their dependability is directly governed by the health of the driving electric motor. To guarantee fail-safe operation of the electromechanical actuator chain, condition monitoring and fault diagnosis of the embedded motor have become indispensable. The motor fault diagnosis process can be comprehensively summarized into four key steps: signal acquisition, feature extraction, condition monitoring, and fault identification. Based on the data obtained by signal acquisition, machine learning methods can be effectively integrated into the latter three steps. Feature extraction techniques primarily revolve around autoencoders. In terms of condition monitoring technology, in-depth research has been conducted on image recognition, including the identification of two-dimensional and three-dimensional images. In terms of fault identification, various machine learning methods have been applied, such as convolutional neural networks, autoencoders, transfer learning, long short-term memory networks, and support vector machines. Finally, the potential application of the Large Language Model in motor fault diagnosis was explored.

1. Introduction

Electric motors are widely employed as core actuation components in a broad range of industrial and military applications, delivering the necessary mechanical power and motion control for various types of equipment and systems [1]. They serve as the fundamental power source for key actuation mechanisms in production lines, automation equipment and robots [2,3,4]. Electric propulsion systems, which rely on high-performance motor-based actuators, offer superior energy efficiency and enhanced maneuverability for large-scale equipment. The high reliability, substantial power output, rapid dynamic response, and precise controllability of electric motors make them indispensable as actuators, critically impacting the overall performance of modern automated and intelligent equipment [5,6,7].

However, the growing complexity and safety-critical nature of these systems have intensified the demand for highly reliable fault diagnosis solutions. In recent years, machine learning-based methods have rapidly emerged as powerful tools for this purpose, resulting in a substantial yet fragmented body of literature. This rapid expansion, coupled with the lack of a comprehensive synthesis specifically tailored to actuator systems, motivates the present review. This paper aims to provide a systematic review that synthesizes mainstream machine learning-based fault diagnosis techniques for electric motors in actuator systems, critically evaluates their performance and applicability, and identifies key challenges and promising future research directions.

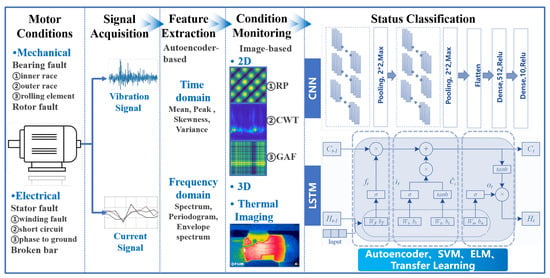

2. Fundamental Process of Motor Fault Diagnosis

Motor fault diagnosis technology, as an interdisciplinary research field, involves many branches such as electrical engineering, signal processing, machine learning, etc. The research in this field has been progressing rapidly in recent years [8]. Potential failure modes should be identified and predicted by analyzing the operation data of electric motors in order to achieve early intervention and guarantee the stable operation of the motor system. The process of fault diagnosis usually involves the steps of signal acquisition, feature extraction, condition monitoring and fault identification [9,10,11]. Based on the data obtained through signal acquisition, machine learning approaches can be effectively incorporated into the latter three steps. As shown in Figure 1, a diagram of the motor fault diagnosis process based on the machine learning approach is presented.

Figure 1.

Overview of the motor diagnosis process.

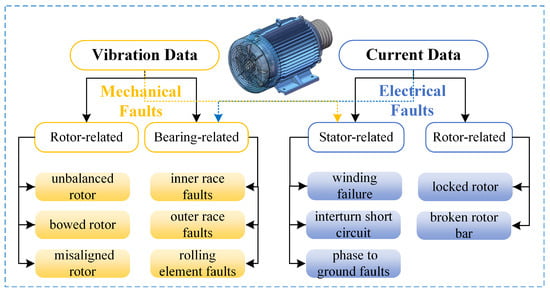

Signal acquisition, which is the deployment of high-precision sensors to monitor physical quantities such as current [12], voltage [13], temperature [14] and vibration [15] of the motor in real time. These data are the basis of diagnosis, and the physical significance of the data and the richness of the fault information directly affect the accuracy of fault diagnosis. Vibration signals are the most widely used in motor fault diagnosis research due to their information-rich nature. Extensive studies have utilized vibration data for diagnosing motor bearing faults, with widely adopted public datasets including the Case Western Reserve University(CWRU) Vibration Dataset and the Paderborn University Dataset. Vibration signals decay rapidly during transmission, so it is necessary to arrange vibration sensors close to the sensitive parts to improve the signal quality. Current signal acquisition can be performed directly through the motor’s power line, with low attenuation inside the wire. Current signal acquisition does not require intrusion inside the motor, which makes the monitoring process non-intrusive to the normal operation of the motor. Current sensors are usually low cost and can be carried out directly through the motor’s power line without intruding into the motor’s interior, which makes the monitoring process non-interfering with the normal operation of the motor and easy to install. The current signal of the motor contains a wealth of fault information, such as the waveform, amplitude, frequency and other parameters of the current, which can reflect a variety of fault types of the motor, and therefore has received more attention from researchers. Predominant Motor faults can be broadly categorized into two main types: mechanical faults and electrical faults [16]. As illustrated in Figure 2, mechanical faults include bearing faults and rotor faults. Bearing faults are further classified into inner race faults, outer race faults, rolling element faults, and their combined faults. Rotor faults refer to a series of issues caused by the rotor, such as unbalanced rotor, bowed rotor, and misaligned rotor. Electrical faults encompass stator-related faults and rotor-related faults.

Figure 2.

Predominant motor faults.

Vibration data is an important basis for motor mechanical fault diagnosis, and by analyzing the vibration spectrum, faults such as unbalance [17], misalignment [18], bearing damage [19], etc., can be identified. The team led by Grezmak [20] measured vibration signals from an induction motor and transformed them into time-frequency representations, subsequently employing a Convolutional Neural Network for classification. This methodology demonstrates efficacy in classifying mechanical rotor-related faults, such as unbalanced rotor and bowed rotor. Vibration data can also be utilized for the diagnosis of electrical faults. In a separate study, Zimnickas [21] achieved classification of bearing faults as well as certain electrical faults, including short circuit and phase-to-ground faults, using vibration data. Research on electrical faults primarily relies on current data. Devi [22] utilized three-phase stator current data to classify stator-related faults such as winding failure, interturn short circuit, and phase-to-ground faults. Building upon stator current signals, Magdiel [23] employed a lightweight one-dimensional CNN to classify motor fault conditions, including outer race faults, short-circuit, and phase-to-ground faults, achieving a classification accuracy of 99%. Current signals can also be applied to the diagnosis of mechanical faults [24]. The team led by Abid [25] analyzed the raw current signals from a double-cage induction motor and developed an automatic fault diagnosis method. This approach successfully identified 16 different motor operating states, encompassing not only electrical rotor-related faults but also various bearing faults.

Feature extraction is a key step in fault diagnosis, which extracts key information reflecting the fault characteristics from the original signal through time domain analysis, frequency domain analysis or time-frequency domain analysis methods [26]. Motor fault feature extraction techniques can be divided into two categories: model-based methods and data-based methods.The model-based approach entails analyzing the physical characteristics of the motor, such as electromagnetic, thermodynamic, and mechanical dynamics properties. Mathematical equations and algorithms are used to describe the operating state of the motor and to refine the motor fault characteristics. For example, finite element analysis is used to predict the electromagnetic field distribution and thermal effects of the motor [27], which can extract time domain, frequency domain and time-frequency domain features. Model-based methods have theoretical advantages, but face many challenges in practical applications, such as the complexity of the model, the need for a large number of accurate parameters, and the problem of adaptability under complex operating conditions. Data-based methods for motor fault diagnosis play an increasingly important role in modern industry and research. The core of these methods lies in the use of advanced data acquisition techniques and data analysis algorithms to realize automated feature learning by analyzing real-time signals such as motor current, voltage, temperature, vibration and noise signals to achieve real-time monitoring and in-depth analysis of the motor operation status.

Condition monitoring utilizes extracted features to determine motor operating conditions by comparing the difference between the current state and the normal state. The feature extraction method can handle complex data patterns and improve the accuracy of fault diagnosis. This can be achieved by simple threshold comparisons or more complex pattern recognition methods. Fault recognition processes the data in depth, applying Fourier transforms, wavelet analysis, etc., to identify the type, location, and severity of the fault, and matches the identified fault features with known fault patterns to determine the exact cause of the fault. Condition monitoring and fault identification methods often use multi-source information fusion techniques, integrating information from multiple sensors and multiple characteristic parameters to obtain a more comprehensive system state. Conflicting evidence and uncertainty information are integrated to improve the reliability and confidence of diagnosis.

In the fault classification process, the extracted features serve as inputs for artificial intelligence modeling approaches, which are utilized to decode the fault patterns embedded within these features. This enables the automatic identification of motor faults and facilitates the prediction of their remaining useful life (RUL). Enhancing diagnostic accuracy while minimizing false alarm rates remains a critical challenge in electric motor fault recognition. Significant progress has been achieved in intelligent fault recognition methodologies and RUL prediction techniques, driven by continuous advancements in machine learning, deep neural networks, and data-driven modeling frameworks.

3. Feature Extraction Techniques Based on Autoencoders

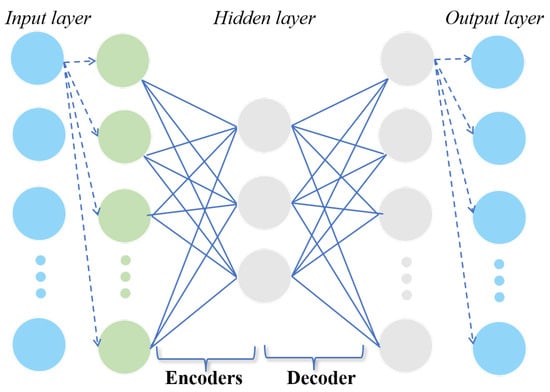

Autoencoder achieves data compression and reconstruction through an encoder-decoder structure. The encoder is responsible for mapping high dimensional inputs to low dimensional feature vectors, where the encoder contains an input layer and a hidden layer, the core of which is to learn low dimensional nonlinear features using this hidden layer. The decoder recovers the original data by minimizing the reconstruction error, thus extracting critical fault features. Figure 3 shows the basic structure of the automatic encoder, which attempts to learn the approximations in the hidden layer so that the input signal can be perfectly reconstructed by the output layer.

Figure 3.

Basic structure of an autoencoder.

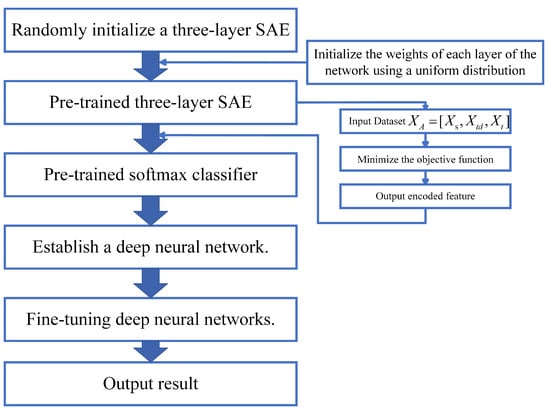

Emanuele Principi et al. [28] investigated neural network autoencoders as a method for detecting motor faults in an unsupervised situation, evaluating three different types of autoencoders: the Multilayer Perceptron autoencoders, the CNN autoencoder, and the recursive autoencoder consisting of Long Short-Term Memory (LSTM) units. The results show that all three autoencoder approaches outperform the one-class support vector machine algorithm approach, with the Multilayer Perceptron autoencoders having the highest overall performance. The collected data from electric motors often contains noise, and some research has implemented the recovery of clean signals from noisy data using autoencoders, which is crucial for improving the accuracy of fault diagnosis. Research has been conducted to recover signals of interest from noisy data using autoencoders. Sparse Denoising Autoencoders were employed as a denoising technique by Wenjun Sun [29], while Huitao Shi [30] proposed a novel noise reduction algorithm. This method utilizes sparse autoencoders for unsupervised feature learning, incorporates denoising coding at the input stage to enhance feature robustness, and finally trains a neural network classifier with the learned features to identify induction motor faults. Separately, Azadeh Gholaminejad [31] applied Independent Component Analysis to denoise three-phase current signals. They compared the traditional approach and the coder-decoder approach, and drew the conclusion that the coder-decoder structure has the better effect both in accuracy and robustness. Saeid Jorkesh, etc. [32] performed a similar denoising operation and pre-processed it with FFT. They compared the performance of the depth neural network and the stacked sparse automatic encoder depth neural network in motor fault diagnosis. The experimental results showed that the sparse autoencoder deep neural network method diagnoses faults with up to 90.65% accuracy in the presence of interference. Long Wen [33] proposed a novel Deep Transfer Learning (DTL) method that uses a three-layer sparse autoencoder to extract features from the original data, in addition to applying a max-mean difference term to minimize the difference penalty between the features of the training and test data. Figure 4 shows the flow of the DTL method.

Figure 4.

The flow of the DTL method.

Several studies [34,35,36,37] have expanded on the basic autoencoder framework. For instance, stacked autoencoders are constructed by layering multiple autoencoders, enabling them to learn deeper and more abstract feature representations, thereby better capturing complex patterns in the data. This method is primarily used for unsupervised feature learning and dimensionality reduction. Xiaowei Xu [34] proposed a Support Vector Machine (SVM) classifier based on the principles of stacked denoising autoencoders, setting optimal learning rates, denoising coefficients, and other network parameters. Compared to traditional fault extraction methods and single autoencoder approaches, the new network exhibits high accuracy, strong generalization capabilities, and ease in handling high-dimensional data features. Emmanuel Resendiz-Ochoa [35] utilized heuristic techniques and genetic algorithms along with autoencoders in stacked networks to automatically adjust the hyperparameters required for deep learning technology. By modeling the estimated statistical features through the structure of stacked autoencoders and collaborating with genetic algorithms, a self-adaptive process is performed to extract a new set of features. Ultimately, fault detection and identification were achieved via a single softmax layer, yielding an accuracy exceeding 99%. Yunfeng Chen [37] proposed a method for inter-turn short circuit diagnosis of permanent magnet synchronous motor based on stacked normalized SAE. The experimental results showed that the algorithm can effectively extract fault features and the diagnosis accuracy was up to 98.91%.

Novel encoder were introduced for feature extraction [38,39]. Xiaoli Zhao [38] employed a graph convolutional autoencoder to extract generalized high-dimensional features. The approach was validated on a fault simulation testbed. Shen Yan [39] developed a full graph dynamic autoencoder to aggregate multi-perspective feature information across channels by adapting to operational condition variations. A dynamic weight optimization strategy dynamically adjusted reconstruction loss weights under different conditions, guiding the model to learn generalized features.

Further studies have explored hybrid methodologies combining autoencoders with other techniques [40,41,42,43]. Shuang Gao [40] studied an unsupervised framework based on torque and multi-head convolutional autoencoders, which utilizes an extended state observer to estimate motor load. The method employs a physics-guided neural network to estimate propeller torque. To avoid feature confusion, two independent encoders in the multi-head convolutional autoencoder automatically extract pattern features between torques. Yang Hang [41] proposed a Variational Autoencoder model based on Recurrent Neural Networks, which effectively performs dimensionality reduction and feature extraction of sequential vibration signals. Given the high pollution of current signals by noise, feature extraction became a significantly challenging problem. Rafia Nishat Toma [42] introduced a bearing fault classification model based on Deep Autoencoders (DAE) and Convolutional Neural Networks, where the deep autoencoder estimates the nonlinear function of the system using normal data to obtain the residual signals. Shuai Yang [43] proposed a multi-source data fusion method based on autoencoders, incorporating a new supervisory penalty term in the hidden layer of the autoencoder, thus applying label information during the training process. The learned features closely align with class characteristics, enhancing feature separability. Studies demonstrate that the fused data generated by the proposed method achieved higher and more robust performance.

4. Condition Monitoring Technology Based on Image Recognition

The vibration signals or current signals from the motor can be transformed into a time-frequency spectrum using time-frequency analysis methods, such as Short-Time Fourier Transform and Continuous Wavelet Transform. This image-based data can more intuitively display the time-frequency characteristics of the motor’s operating state. These characteristic images contain rich information related to faults, making it easier for neural networks to learn and recognize different fault patterns. Convolutional Neural Networks (CNNs), a type of feedforward neural network introduced by LeCun in 1998 [44], possess powerful feature extraction capabilities and have demonstrated exceptional performance in image recognition [45]. Their strength is particularly evident in studies that require image data processing. As validated by research [46], seven different CNN models were all effective in identifying fault modes and characteristics from thermal images. Once the motor data is converted into images, CNNs can be directly employed for fault diagnosis, thereby avoiding complex feature engineering and improving the accuracy and efficiency of diagnostics.

4.1. Recognition of 2D Images

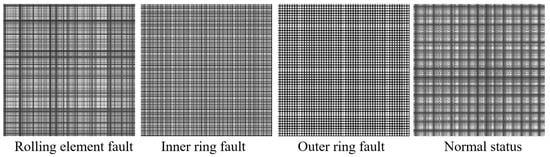

The Recursive Plot Method (RP) [47,48,49,50,51] is an effective approach for examining the periodicity of phase space trajectories, allowing for the identification of specific elements in m-dimensional phase space trajectories by constructing two-dimensional plots. Figure 5 shows the two-dimensional recurrence plots generated from CWRU vibration data. Yumin Hsueh et al. [47] developed a diagnostic method that first converts time series data signals into two-dimensional texture images. These recurrence plots, transformed from the original time series data, are then input into a deep CNN architecture for fault diagnosis. Naveenkumar R. Sharma [48] utilizes the Max-Min difference technique to generate recurrence plot images from raw signals, extracting features for recurrence qualification analysis to provide assessments of fault severity and the identification of fault phases. Juncai Song [49] proposed a novel method based on external stray magnetic field signal deep feature fusion to detect demagnetization faults in double-sided permanent magnet synchronous linear motors. This method transforms one-dimensional signals into two-dimensional images through Markov transfer fields and recurrence plots, achieving a visual enhancement of demagnetization fault features. The proposed method effectively combines the advantages of both approaches, achieving a classification accuracy of 98.50%. Ming Jing [50] presented an image recognition and transfer learning-based method for diagnosing winding faults in permanent magnet motors suitable for small samples, which involves collecting motor current signals and executing one-dimensional Park vector magnitude analysis. Subsequently, the time-varying signals are transformed into two-dimensional image signals via recurrence plots. Toma [51] implemented a signal processing pipeline where FFT was first applied to generate frequency spectra from time-series signals, followed by transformation into two-dimensional images using the recurrence plot algorithm. The resulting images were processed through a CNN model, achieving 99.24% classification accuracy for three distinct bearing conditions.

Figure 5.

The Recurrence Plots images of the motor vibration data.

The Continuous Wavelet Transform (CWT) converts time series data into time-frequency images, retaining and simultaneously displaying both the time and frequency information of the original signal. As illustrated in Figure 6, some two dimensional images are generated by the CWT based on the CWRU dataset. In [52,53,54,55,56], researchers employed wavelet transforms to convert collected sensor signals into time-frequency distributions, applying machine learning methods to the image sets generated by the CWT. The fully connected layer in the deep architecture predicts the state of the induction motor based on the learned features. Additionally, Qianming Shang [53] converted three-phase current signals into Park vector modulus signals through the Park transform. The time-frequency graphs and PVM signals were then aligned in the time series to serve as bimodal input samples. Weitao Zeng [57] integrated the Double-Tree Complex Wavelet Transform with Variational Mode Decomposition to decompose the current signals into multiple modes. Subsequently, the locally weighted k-nearest neighbor algorithm optimized via Bayesian methods was utilized to accurately identify the state of the vortex pump. Lerui Chen [56] proposed a novel architecture called Gate Convolutional Attention Neural Network (gate-CANN). Unlike other studies, this work inputs CWT images from two directions into gate-CANN for feature extraction. The proposed method demonstrates exceptional performance in terms of noise resistance and generalization.

Figure 6.

The CWT images of the motor vibration data.

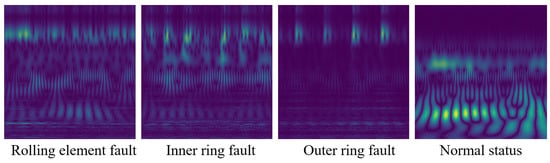

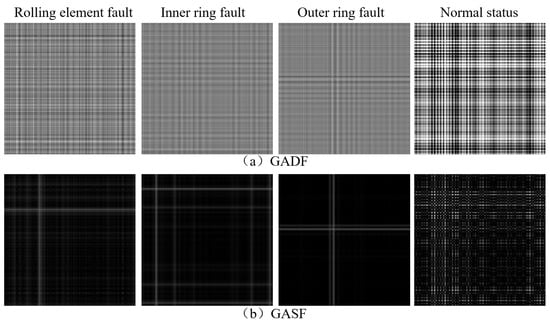

In [58,59,60,61], the authors innovatively employed Gramian Angular Summation Field (GASF) or Gramian Angular Difference Field (GADF) to convert data into two-dimensional images, demonstrating outstanding performance in fault classification. For instance, Xiang Li [58] utilized GASF to transform the vibration time series signals of hydropower units into 2D images, employing CNN for feature extraction, and the merged signals were enhanced with MSA to improve the features. Fengyun Xie [59] proposed a smart dual-peak fusion attention residual model that demodulates the vibration signals to be encoded. It employs an improved ensemble empirical mode decomposition, which consists of ensemble empirical mode decomposition and the mean of standardized cumulative modes, to decompose the signals into high-frequency and low-frequency components. The high-frequency components are effectively denoised using a wavelet packet thresholding method, and then converted into a two-dimensional image using the Gramian angular field, which is aggregated with the current data into a dual-peak Gramian angular field image. Hui Zhang [60] proposed a new GAF-CapsNet model to solve the problem that the relative position relationship cannot be fully extracted when one-dimensional mechanical vibration signals are input into the convolution neural network. Two sets of feature maps are generated by using the GASF and the GADF respectively, and then input into the convolution layer with small convolution cores for information reading and feature extraction, and then input into the capsule network for further feature extraction and fault identification. Hang Yuan [62] developed a PMSM coupled bearing fault diagnosis method based on stator current signals. This technique converts current residual signals into Symmetrized Dot Pattern images with color-encoded information, which are then processed through a pre-trained 2D convolutional neural network for fault pattern recognition. Figure 7 shows a group of images generated via GADF and GASF methods from the CWRU dataset.

Figure 7.

The GAF images of the motor vibration data.

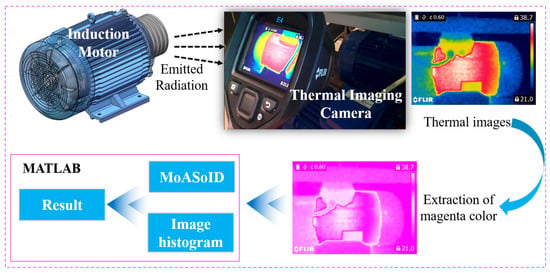

4.2. Recognition of Thermal Imaging Images

Thermal images are inherently two-dimensional and can therefore also be recognized by machine learning methods. Based on the analysis of thermal images of three-phase induction motors in three states, Adam Glowacz and Zygfryd Glowacz [63] developed an original thermal image feature extraction method named MoASoID (Method of Areas Selection of Image Differences). First, thermal images with a resolution of 320 × 240 pixels were acquired using a thermal imaging camera. Then, the magenta extraction quantity was calculated (as shown in Figure 8, which depicts the fault diagnostic techniques in this research). Finally, feature extraction was performed by applying MoASoID and image histograms. Adam Glowacz [64] detail the use of the PNID (power of normalized image difference) method to calculate the area of the thermal image, and deep neural networks (GoogLeNet, ResNet50, and EfficientNet-b0) were used to analyze the thermal image of a brushless direct current electric motor faulty shaft. Busra Aslan [46] conducted a study involving manual annotation of thermally anomalous regions in infrared images to generate corresponding mask images. The research methodology encompassed: (1) application of data augmentation techniques to both raw thermal images and their annotated masks; (2) semantic segmentation of enhanced images using DeepLabV3+ architecture to isolate fault-induced heating regions from background; and (3) subsequent fault classification via CNN, achieving a diagnostic accuracy of 96.49%. Complementary work [65] employed data augmentation strategies (e.g., random flipping and rotation) to process thermal imaging datasets containing eleven distinct fault conditions, effectively addressing dataset imbalance while improving sample diversity.

Figure 8.

Thermal images fault diagnostic techniques.

Acquiring high-quality thermal image samples is relatively difficult. Zhenli Xu [66] proposed a prototype network with coordinate attention for fault diagnosis of three-phase induction motors. By designing a coordinated attention feature extraction module using coordinate attention blocks and convolutional blocks, spatial relativity between feature maps is achieved. The designed CAFEM can alleviate the stringent requirements on data volume, significantly enhancing the information mining capability of CAPNet and the performance of few-shot learning models. Lifu Xu [67] proposed a thermal imaging-based motor fault detection method based on the InceptionV3 model. By applying Contrast Limited Adaptive Histogram Equalization to the input images, detection accuracy is improved. Additionally, integrating Squeeze and Excitation channel attention mechanisms enhanced the performance of InceptionV3. Testing was conducted using a dataset containing 369 thermal images of motors with 11 different faults, and the proposed model achieved a classification accuracy of over 98.8%. Ammar K. Al-Musawi [68] applied a new color model to thermal imaging (hue, saturation, and value) to obtain optimal features, moving away from the traditional grayscale model. Five image segmentation methods—Sobel, Prewitt, Roberts, Canny, and Otsu—were utilized to segment the Hue regions, employing different image matrices containing the best fault information extracted from images to differentiate motor faults. The results indicate that this method is applicable for further processing of thermal images.

4.3. Recognition of 3D Images

Yujun Zou [69] combined the Ensemble Empirical Mode Decomposition with Wigner-Ville Distribution to analyze the bearing vibration signals in time-frequency domain, obtaining high-quality 3D time-frequency-energy representations. These 3D features were transformed into grayscale projections, with local texture features enhanced through circular Local Binary Pattern operators for bearing condition monitoring. Mohammadhossein Nazemi [70] proposed a technique that extracts the fundamental frequency phasor magnitude from the measured three-phase stator current of an induction motor using digital Fourier filtering. The extracted phasors are then reconfigured into a three-dimensional image using a current-to-image transformation (CIT) mechanism to form an image dataset. W.J. Wang [71] proposed a wavelet-based joint time-frequency-scale distribution method, discretizing three-dimensional representations (time, frequency, scale) to better match signal characteristics.

Xufeng Huang [72] constructed quasi-3D current data through signal-to-image conversion and 3D stacking, preserving phase interactions through this architecture. An improved 3D CNN with multi-scale fusion and smooth maximum units was developed for bearing health assessment. Weizhong Zhang [73] introduced a Multi-Sensor Data Fusion method that compresses high-dimensional sensor data into low-dimensional 3D pixel matrices. These RGB fusion images were processed through a multi-scale dual-attention network, showing enhanced noise robustness. Zhijian Wang [74] proposed an erosion-based method converting time-domain vibrations into RGB images. Initially indistinct 3D structures were segmented into identifiable targets, with aoptimized AlexNet CNN adapted for bearing fault classification.

5. Machine Learning Based Fault Classification Techniques

With the advancement of machine learning methodologies and artificial intelligence, data-driven fault diagnosis approaches have gained significant prominence in contemporary research and industrial applications. Unlike conventional techniques reliant on explicit mathematical/physical models or predefined fault signatures, machine learning frameworks autonomously derive intrinsic relationships between input-output correlations associated with fault conditions directly from raw operational data. A representative paradigm is the autoencoder-based diagnostic architecture, which leverages its encoder-decoder mechanism to extract hierarchical fault-sensitive features through unsupervised representation learning. Various machine learning techniques have been extensively employed for fault classification with prominent examples including Convolutional Neural Networks (CNN), k-Nearest Neighbors (k-NN), Decision Trees (DT), Support Vector Machines (SVM), Artificial Neural Networks (ANN), etc. These methods are able to effectively categorize fault states by learning the feature patterns in the data, thereby enhancing diagnostic accuracy and operational efficiency. The selection of optimal methodologies is predominantly determined by specific data characteristics and problem complexity.

5.1. Convolutional Neural Networks

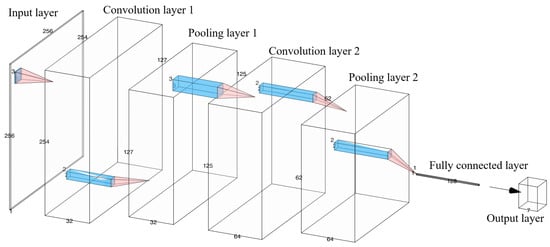

Convolutional Neural Networks (CNNs) automatically extract fault features through cascaded convolutional and pooling operations, enabling automated equipment state recognition Through utilizing weight sharing and local connectivity properties, CNNs significantly reduce parameter dimensionality while enhancing generalization capabilities for fault characteristics. Figure 9 is a basic framework of CNN. During the training phase, network parameters are optimized via backpropagation algorithms to improve diagnostic accuracy and robustness. Notable implementations include [24,75,76,77,78] have performed fault classification based on classical CNN models. Kevin Barrera-Llanga [78] conducted a comparative evaluation the performance of six different CNN architectures: Inception V4, NasNETMobile, ResNET152, SeNET154, VGG16, and VGG19. The automated classification system achieved 99% accuracy in detecting rotor bar fault, with VGG19 exhibiting optimal performance. Jianjun Shen [75] developed a deep multi-label learning framework called Multi-Label Convolutional Neural Network (MLCNN). MLCNN establishes relationships among labels, can learn relevant features from mechanical vibration signals, even with incomplete label annotations. It was successfully applied to classify distinct severity levels across three different types of bearing faults in electric motors. In contrast to diagnosing a specific fault, the method in [76] assesses vibration levels to categorize motors into three general fault states. A key modification to the classical CNN, the addition of a parametric rectified linear unit (PReLU) activation function, was implemented to improve the performance of wider networks. Xiangbiao Ye [24] proposed an intelligent fault diagnosis method based on a feature reconstruction method and a convolutional neural network. The feature reconstruction method effectively removes high-frequency noise, power frequency, and harmonic effects from current signals. A CNN tailored for learning features of current signals was constructed, achieving an average diagnostic accuracy of approximately 99% for motor bearings under various speeds, loads, and fault types. Shuaijie Shan [77] first used Variational Mode Decomposition to remove high-frequency noise components from motor signals and extract Mel-frequency features. Then, a CNN was employed to re-extract Mel-frequency features to fully obtain high-dimensional abstract features characterizing bearing faults. Finally, the Mel-CNN model was used to achieve bearing fault diagnosis, with classification results superior to ACDIN, WDCNN, TICNN, improved LeNet-5 models, and four CNN-derived models.

Figure 9.

Basic CNN framework.

In [78], six models used in the study are all designed based on convolutional neural networks and optimized for image classification tasks. Their core structures are composed of stacked convolutional layers, pooling layers, and nonlinear activation functions. VGG, ResNet, Inception, SENet, and NasNet are representative convolutional neural network models in the field of deep learning, each exhibiting unique innovations in architecture and performance. VGG series employ stacked 3 × 3 convolutions to balance structural simplicity with representational capacity, enhancing performance by increasing network depth while maintaining structural simplicity and uniformity. ResNet mitigates the gradient vanishing problem in deep networks through residual learning modules, facilitating efficient end-to-end training via skip connections. The Inception architecture employs multi-scale parallel convolutions to extract features of different scales, comprehensively capturing information within images. SENet incorporates channel attention mechanism that dynamically adjusts the importance of different channels to improve model expressiveness and accuracy. NASNet implements automated neural architecture search to algorithmically generate efficient network structures tailored to diverse task requirements.

Recent research efforts have focused on model optimization through two primary strategies: Preprocessing enhancement: Studies [42,79,80] implemented signal transformation and data fusion prior to CNN input pipelines. Architecture integration: Works [81,82,83] hybridized CNNs with complementary deep learning architectures, exhibiting enhanced stability, generalization capacity, and diagnostic precision. Yufeng Gu [80] developed a correlation-adaptive weighting method to integrate collected multi-source homogeneous sensor information into multi-source heterogeneous sensor information through data-level fusion. A 1D CNN was then employed to classify faults from this fused multi-source heterogeneous data. The method achieved an accuracy of 99.3% in classifying data collected from seven different motor states on a drive test bench, including stator faults, rotor faults, and bearing fault conditions. Duy Tang Hoang [79] performed individual classification for each feature set using convolutional neural networks. To enhance classification accuracy, a novel mid-level decision fusion technique was introduced to integrate information from all utilized CNN. Peng Li [81] designed an intelligent multi-signal fault diagnosis framework for ultrasonic motors. A deep neural network was constructed by integrating a 1D CNN for learning spatial correlations with a Bidirectional Long Short-Term Memory(BiLSTM) for exploiting temporal dependencies. Similarly, Guohua Yan [82] developed an enhanced architecture using BiLSTM, extracting global signals and local features based on a multi-scale residual dilated CNN and further extracting features and identifying faults using BiLSTM. Lingzhi Yi [83] hybridized a CNN with an extreme learning machine optimized by the Snow Ablation Optimizer (SAO) algorithm, not only maintaining model simplicity while accelerating convergence rates but also improving convergence speed and classification accuracy. Experimental results on real datasets showed that the proposed model exhibited strong stability, generalization capability, and high accuracy in fault diagnosis, achieving 99.29% and 98.75% accuracy.

5.2. Autoencoder for Fault Classification

To address the challenges of data scarcity and time-consuming sample labeling in fault diagnosis, researchers have utilized autoencoders to indirectly enhance the performance of diagnostic models. Mei Huang [84] integrated a Conditional Variational Autoencoder with a Conditional Generative Adversarial Network, introducing mean feature matching loss and pairwise feature matching loss to mitigate mode collapse and improve model stability, thereby enhancing the generation capability for low-frequency fault samples under long-tailed conditions and ultimately increasing classification accuracy. Wenkuan Huang [85] combined Cycle-Consistent Generative Adversarial Networks (CycleGAN) with Deep Autoencoders (DAE), leveraging CycleGAN to generate diverse and highly realistic fault samples for dataset expansion while strengthening feature extraction through DAE, ultimately improving fault diagnosis precision. Addressing the issue of extensive time required for labeling monitoring data under complex operating conditions, Han Liu [86] proposed a Classification Adversarial Autoencoder (CatAAE) for unsupervised fault diagnosis of rolling bearings. The autoencoder is trained through an adversarial training process, with a prior distribution imposed on the latent encoding space. The encoder clusters input samples by balancing mutual information between samples and their predicted classification distributions, demonstrating robust performance even under varying environmental noise and motor loads.

To tackle challenges such as small-sample and unsupervised learning paradigms, several studies [87,88,89,90] have focused on improving autoencoder architectures to directly optimize fault classification capabilities. Yangli [87] proposed an intelligent fault diagnosis method based on an autoencoder-multidimensional Taylor network (AE-MTN) derived from Taylor series expansion, incorporating federated learning to address low accuracy in intelligent fault diagnosis caused by small sample sizes. Xinya Wu [88] designed a hybrid classification autoencoder that uses a softmax classifier to directly diagnose health conditions based on encoded features from the autoencoder. The commonly used mean squared error (MSE) of unsupervised autoencoders was modified to improve accuracy under conditions with limited labeled data. Jinglin Zhang [89] introduced an efficient method based on stacked sparse autoencoders and Siamese networks to detect inter-turn short-circuit faults in permanent magnet synchronous motors. The encoder extracts sparse features from a limited number of samples, while the Siamese network determines similarities between given samples, transforming the fault diagnosis problem into a classification task under few-shot learning. Fation Fera [90] proposed a validated autoencoder-based classification method incorporating Mahalanobis distance. This approach accounts for diverse operating conditions during training, enabling the modeling of complex nonlinear relationships and effectively distinguishing between normal and abnormal states.

Building on the physical characteristics of mechanical fault diagnosis, certain research methods [36,42,91,92] have integrated traditional signal processing techniques and deep learning models with autoencoders. Daehee Lee [91] developed an LSTM autoencoder model based on Graph Convolutional Networks (GCN) with self-attention capabilities. The proposed model achieved 97.3% accuracy on the CWRU dataset and 99.9% accuracy on a fault simulator dataset. Martin [92] introduced an expert system comprising two autoencoders corresponding to startup transient and steady-state operating conditions. Hilbert transform was applied to automatically separate and analyze operating conditions and obtain current signal envelopes, while particle swarm optimization was employed to achieve condition separation, attaining 100% accuracy in broken bar fault detection.

5.3. Transfer Learning

Transfer learning addresses the problem of data scarcity or high annotation costs in fault diagnosis by transferring knowledge and pattern recognition capabilities from one domain (source domain) to another relevant domain (target domain). The core principle involves utilizing the potential feature sharing between domains to extract common representations (such as deep network features) and achieve cross-task knowledge reuse through model fine-tuning, feature adaptation, or domain adversarial training. Typical methods include pre-training-fine-tuning frameworks, feature mapping alignment, and domain adaptation, which can significantly enhance the model’s generalization ability in small sample scenarios, thereby reducing the data requirements and training costs in the target domain. It leverages the well-trained models from the source domain as a foundation, fine-tuning and optimizing them to fit the characteristics of the target domain, thus improving the accuracy and efficiency of fault diagnosis. Transfer learning employs various strategies in fault diagnosis, such as feature transfer, instance transfer, and parameter transfer, which minimize the discrepancies between the source and target domains and enable effective knowledge transfer.

Tao et al. [93] proposed a generalized intelligent bearing fault diagnosis system based on AlexNet architecture with transfer learning, which achieved automated fault identification and classification with remarkable precision. Their transfer learning approach effectively mitigated deep network overfitting, resulting in an exceptional overall classification accuracy exceeding 99.7%. Nevertheless, the method’s requirement for fixed-length input data constitutes a notable limitation in practical applications. Tang et al. [94] developed an innovative solution featuring an adaptive input length selection module that incorporates envelope spectrum analysis. Their system integrates three key components—packet convolution, transposed convolution, and instance normalization—within the feature extractor. By employing a hybrid loss function combining softmax cross-entropy with maximum mean discrepancy (MMD), the approach demonstrates superior performance in both health state identification and domain alignment compared to conventional methods. Skowron [95] established a CNN-based fault detection system for PMSMs that leverages transfer learning techniques in a novel configuration. This methodology extracts discriminative features from mathematical models to diagnose faults in physical machines, offering two significant advantages: (1) eliminating the need for destructive physical modeling, and (2) substantially enhancing the system’s generalization capability and operational adaptability. The research conducted a comprehensive comparative evaluation of three distinct transfer learning paradigms: neural network-based transfer, case-based transfer, and mapping-based transfer. Experimental validation confirms the efficacy of these methods in detecting both stator winding short circuit and permanent magnet demagnetization faults across diverse operational conditions, including steady-state and transient scenarios. Notably, case-based transfer learning exhibited the highest diagnostic accuracy, particularly during dynamic load variations.

5.4. Long Short-Term Memory Networks (LSTM)

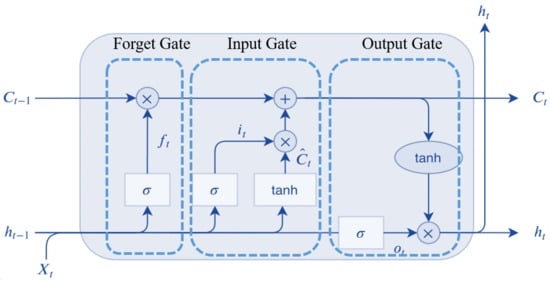

Long Short-Term Memory (LSTM) networks constitute an advanced variant of Recurrent Neural Networks (RNNs) specifically engineered to address the challenge of learning long-term temporal dependencies. LSTM networks effectively capture long-term dependencies in sequential data through their unique gating mechanisms and cell state. As illustrated in Figure 10, the processing flow of the core memory unit at each time step t is as follows. The unit receives the current input and the previous hidden state , and operates through the synergistic work of three gating structures to ultimately output the current cell state and hidden state [96].

Figure 10.

Core memory unit of LSTM.

First, the Forget Gate determines which information to discard from the previous cell state. It calculates a gating value between 0 and 1 using a Sigmoid function [96,97]:

where denotes vector concatenation. W is the weight matrix.

Subsequently, the Input Gate works in tandem with a hyperbolic tangent (tanh) layer to determine what new information will be stored in the cell state. The input gate controls the degree of update, while the tanh layer creates a candidate value vector :

The cell state is then updated by combining the filtered previous state (via the forget gate) and the regulated new candidate values (via the input gate):

This update mechanism, which employs a gated weighted sum instead of the pure multiplicative chain found in traditional RNNs, is key to the LSTM’s ability to mitigate the vanishing gradient problem. Finally, the Output Gate regulates the extent to which the updated cell state is exposed, producing the current hidden state :

In this architecture, the cell state serves as the long-term memory of the network, propagating relatively stably through time, while the hidden state acts as the short-term memory and immediate output. This sophisticated gating design enables the LSTM to adaptively retain critical historical information, filter out noise, and respond sensitively to state transitions in long sequences, making it particularly suitable for modeling the complex long-term temporal patterns inherent in mechanical equipment fault diagnosis.

Xilian Wang [98] developed an enhanced LSTM-based fault diagnosis approach incorporating d-q transformation and Whale Optimization Algorithm (WOA) optimization. The WOA-optimized LSTM demonstrated superior performance to conventional LSTM, achieving 98% classification accuracy while reliably diagnosing turn-to-turn short-circuit faults of varying severity levels. Zhenglong Sun [97] implemented a hybrid diagnostic framework utilizing both CNN and LSTM architectures with shared datasets for electrical fault detection in synchronous machines. This approach leveraged the complementary strengths of both network types to improve diagnostic reliability. Sayanjit Singha Roy [99] proposed an innovative fault classification method employing BiLSTM networks with map-domain transformed vibration data as features. The system successfully addressed 112 distinct classification problems while maintaining consistently high fault detection accuracy across all cases. Chia-Sheng Tu [100] introduced a novel audio-based motor fault diagnosis system combining self-organizing maps (SOM) with LSTM networks (SOM-LSTM). In this architecture, the LSTM processed SOM-generated auxiliary data, while Taguchi experimental design methodology was applied to optimize SOM-LSTM parameters, significantly enhancing both diagnostic accuracy and computational efficiency.

Ruirui Wang [101] proposed an enhanced fault diagnosis approach where reconstructed signals are fed as feature vectors into a modified three-layer LSTM network. This architecture capitalizes on LSTM’s inherent memory capabilities to comprehensively learn temporal fault characteristics from non-stationary signals. The experimental validation demonstrated superior diagnostic performance compared to conventional methods, particularly in motor fault detection applications. Yousef Alkseh [102] developed a novel hybrid recurrent neural network architecture combining LSTM and Gated Recurrent Unit modules with two fully-connected layers. The LSTM component employs its dual-state mechanism (cell state and hidden state) to selectively preserve and propagate long-term temporal dependencies within sequential input data. This design effectively captures both short-term and long-term patterns in the continuous monitoring data, leading to improved fault diagnosis accuracy.

5.5. Support Vector Machine (SVM)

Support Vector Machines (SVM) are a type of supervised learning model whose core idea is to find an optimal hyperplane that maximizes the classification margin between different categories of data. By introducing support vectors (the sample points closest to the hyperplane), SVM maps low-dimensional linearly inseparable problems into high-dimensional space (kernel trick), transforming them into linearly separable problems, while balancing model complexity and generalization ability through the principle of structural risk minimization. SVM is suitable for small sample sizes and high-dimensional data, demonstrating strong robustness against overfitting, and has become an important tool in the field of fault diagnosis. By maximizing the classification margin between different fault states through a non-linear mapping based on kernel functions, SVM theoretically ensures superior classification performance.

Moosavian et al. [103] conducted a comprehensive comparative analysis of three machine learning paradigms for motor fault classification: Artificial Neural Networks, conventional SVMs, and Least Squares Support Vector Machines (LS-SVMs). Their systematic evaluation demonstrated that LS-SVMs achieved superior classification accuracy by replacing the traditional quadratic programming optimization with computationally efficient linear equation solutions. In a separate advancement, Lee and Le [104] proposed a feature selection framework employing an Enhanced Binary Particle Swarm Optimization algorithm to improve classifier performance. Their methodology successfully identified optimal feature subsets for both SVM and ANN classifiers in induction motor bearing fault diagnosis, with the optimized SVM configuration attaining 96.6% classification accuracy—a significant improvement over baseline implementations.

Recent advancements in fault diagnosis [105,106] demonstrate that hybrid architectures integrating Support Vector Machines with deep learning techniques outperform standalone models. Yongmei Niu [105] conducted a comprehensive analysis of conventional CNN applications in induction motor fault diagnosis, subsequently developing a Convolutional Discriminative Feature Learning framework. This innovative approach employs an enhanced CNN training paradigm specifically designed for discriminative feature extraction of motor faults, with final classification performed by an optimized SVM classifier. Hosseini et al. [106] made significant contributions through their novel hybrid architecture combining SVMs with Projection-Based Recursive Neural Networks. Their experimental results confirmed superior fault detection accuracy compared to both traditional SVM implementations and state-of-the-art alternative methods. The critical role of feature processing in SVM performance has been extensively investigated [107,108]. Wenchang Wu [107] proposed an efficient texture feature extraction method utilizing Local Binary Patterns, achieving 97% classification accuracy with a computational processing time of merely 200 s when integrated with an SVM classifier. In a parallel development, Ma et al. [108] introduced an advanced signal processing technique employing full-phase FFT with time-shift phase difference spectrum correction and dual Hanning windows. Their methodology, combined with a grid search-optimized SVM (parameters C and ), attained 93.33% diagnostic accuracy on electric traction system simulation datasets, demonstrating robust performance in complex operational scenarios.

5.6. Extreme Learning Machine (ELM)

Extreme Learning Machine (ELM) is an efficient training algorithm designed for single-hidden layer feedforward neural networks. Its core idea is to randomly initialize the weights and biases of the hidden layer and to directly solve for the output weights using least squares, thereby avoiding the iterative optimization process commonly associated with traditional neural network training. With its single-hidden layer feedforward architecture and analytical solving characteristics, ELM has demonstrated efficient training and strong generalization capabilities in fault diagnosis. Researchers [109,110] have employed ELM as the final classifier to further enhance the accuracy and speed of fault classification. This method effectively categorizes various types of faults, offering advantages such as fast diagnostic speed, high accuracy, and strong generalization ability. Zhao Xiaoli [111] proposed a multichannel motor-rotor system fault diagnosis method based on the Multi-Manifold Deep Extreme Learning Machine (MDELM) algorithm. This method features two main components: first, the ability to perform unsupervised self-learning feature extraction based on ELM; and second, the use of a MELM classifier with manifold constraints for semi-supervised fault classification, aimed at uncovering intra-class and inter-class discriminative feature information. The proposed MDELM algorithm exhibits improved learning efficiency and is more suitable for intelligent diagnostics involving multichannel data fusion. Liang Jiang [112] introduced a lightweight improvement to the EfficientNetV2 architecture, deploying a pre-trained model obtained through transfer learning and integrating multi-sensor information with the enhanced lightweight model for fault diagnosis applications.

To address data scarcity and cross-domain generalization challenges, ELM-based transfer learning paradigms have become a research focus: Yujie Cheng [113] constructed a drive motor fault diagnosis framework based on data transfer generation methods, leveraging the advantages of transfer learning. The framework fine-tunes with limited real target fault data to fully utilize both generated and original fault data, thereby improving diagnostic accuracy. Yongsheng Yang [114] proposed a novel method known as Bidirectional Gated Recurrent Domain Adversarial Transfer Learning, which enhances the diversity of failure data by transferring additional fault information obtained from other related data domains to the target domain (the actual working conditions of the gate crane drive motor). This approach alleviates the issue of sample imbalance and improves the model’s ability to recognize fault states. Xiangming Zhang [115] addressed the problem of insufficient actual fault samples by utilizing simulated fault samples as training sets through transfer learning, reducing data labeling costs and enabling more efficient and accurate fault diagnosis for high-speed spindles.

6. Diagnostic Recognition Techniques Based on LLM

Traditional diagnostic methods face challenges including cross-conditional adaptation, small-sample learning difficulties and cross-data-set generalization. Recent popular large language model (LLM) have implications for motor fault diagnosis. These techniques can provide users with an interactive interface for communicating and describing potential problems or symptoms related to motor fault diagnosis. It can gather relevant information, and help the user diagnose faults or determine the next steps in condition monitoring. In the future, a LLM may be able to enable rapid fault identification and classification by learning a large amount of fault data and maintenance records and automatically extracting key information.

Laifa Tao [116] proposed an LLM-based bearing fault diagnosis framework. A signal feature quantification method is proposed based on time and frequency domain feature extraction methods, and a LLM fine-tuning method based on LoRA(Quantized Low-Rank Adaptation). LoRA is used to enhance the generalization ability of LLM, and the accuracy of the trained cross-dataset model is improved by about 10%, which fills the research gap of using LLM for bearing fault diagnosis. Xingming Liao [117] constructed a finer-grained knowledge graph for fault diagnosis proposed LLM-assisted data enhancement method.

Traditional data-driven fault diagnosis relies on digital features collected from sensors, whereas large language models take into account the characteristics of language or the semantic information of tasks. With the continuous development of large language model technology, there is a promising potential for achieving more automated and intelligent fault diagnosis systems in the future. These systems can provide more accurate and efficient fault diagnosis services through continuous learning and optimization.

7. Conclusions

The feature learning advantage of machine learning precisely meets the requirements of high-order, nonlinear, and adaptive feature extraction in fault diagnosis of complex systems, and its powerful feature learning capability makes intelligent fault diagnosis more automated and effective. The application of machine learning in motor fault diagnosis has demonstrated its powerful data processing and pattern recognition capabilities. By using machine learning techniques such as CNN, autoencoders, transfer learning, LSTM and SVM, the researchers were able to achieve efficient diagnosis of motor faults. The LSTMs excelled in capturing long-term patterns of equipment state changes due to their ability to process time-series data. In addition, the application of the migration learning and ELM effectively solves the problem of insufficient data and improves the generalization ability of the model. Finally, LLM is capable of incorporating more domain-specific information and achieved better performance for fault diagnosis of motor.

Machine learning, as an emerging approach to fault diagnosis, is capable of automatically extracting features from the input dataset and diagnosing the faults at the early stage. However, these techniques require large datasets to work effectively, and researchers are working to design optimal network structures that can work with limited datasets. Future technological advances will continue to improve the accuracy and efficiency of motor fault diagnosis and drive motor maintenance toward intelligence and automation.

Author Contributions

W.L. wrote the full paper and designed the systematic review as well as the paper selection. Z.Z. and F.G. reviewed the full paper, improved the paper quality, and contributed to the writing. G.S. supervised the research and provided critical revisions. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the National Key Laboratory Fund Project (No. WAZC20245250304), the National Key Laboratory Fund Project (No. 614XXXX2203), the Young Elite Scientists Sponsorship Program by CAST (No. YESS20240414) and the Natural Science Foundation of Hunan Province of China (Grant No. 2024JJ5408).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest in this research.

Abbreviations

| Abbreviation | Full Name | Description |

| AE | Autoencoder | |

| ANN | Artificial Neural Network | |

| BiLSTM | Bidirectional Long Short-Term Memory | |

| CAE | Convolutional Autoencoder | |

| CAFEM | Convolutional Autoencoders with Feature Enhancement Modules | |

| CAPNet | Conditional Adversarial Purification Network | |

| CNN | Convolutional Neural Network | |

| CWRU | Case Western Reserve University | A widely-used bearing fault dataset source |

| DAE | Deep Autoencoders | |

| DTL | Deep Transfer Learning | |

| EEMD | Ensemble Empirical Mode Decomposition | A signal processing method |

| GADF | Gramian Angular Difference Field | |

| GASF | Gramian Angular Summation Field | |

| LLM | Large Language Model | |

| LS-SVMs | Least Squares Support Vector Machines | |

| LSTM | Long Short-Term Memory | |

| MDELM | Multi-Manifold Deep Extreme Learning Machine | |

| NasNET | Neural Architecture Search Network | A model whose architecture was optimized automatically by a neural network search algorithm. |

| PMSM | Permanent Magnet Synchronous Motor | |

| PReLU | Parametric Rectified Linear Unit | An activation function |

| ResNet | Residual Network | A pioneering CNN architecture that uses skip connections (residual blocks) to enable very deep networks. |

| RNN | Recurrent Neural Network | |

| RUL | Remaining Useful Life | |

| SENet | Squeeze-and-Excitation Network | A CNN architecture that introduces channel-wise attention mechanisms to improve feature representation. |

| SOM | Self-organizing Maps | |

| SVM | Support Vector Machine | |

| gate-CANN | Gate Convolutional Attention Neural Network | |

| VGG | Visual Geometry Group | A classic CNN architecture known for its simplicity and deep layers of small 3 × 3 filters. |

References

- Adamou, A.A.; Alaoui, C.; Bounahmidi, T. Induction Motors Shadow Model-Based on Efficiency for Digital Twin Application in Industry 4.0. IEEE Trans. Ind. Inform. 2024, 20, 10219–10229. [Google Scholar] [CrossRef]

- Baghgar Bostan Abad, H.; Ojaghi, M.; Taheri, A. Efficient index for detecting the stator winding interturn fault in six-phase squirrel-cage induction motors. Measurement 2021, 184, 109912. [Google Scholar] [CrossRef]

- Chen, G.; Li, S.; He, Q.; Zhou, P.; Zhang, Q.; Yang, G.; Lv, D. Fault diagnosis of drone motors driven by current signal data with few samples. Meas. Sci. Technol. 2024, 35, 086202. [Google Scholar] [CrossRef]

- Guzmán-Rabasa, J.A.; López-Estrada, F.R.; González-Contreras, B.M.; Valencia-Palomo, G.; Chadli, M.; Perez-Patricio, M. Actuator fault detection and isolation on a quadrotor unmanned aerial vehicle modeled as a linear parameter-varying system. Meas. Control 2019, 52, 1228–1239. [Google Scholar] [CrossRef]

- Altinors, A.; Yol, F.; Yaman, O. A sound based method for fault detection with statistical feature extraction in UAV motors. Appl. Acoust. 2021, 183, 108325. [Google Scholar] [CrossRef]

- Giesbrecht, M.; Ferreira, G.T.; Silva, R.R.; Milfont, L.D. Electric Machine Design and Fault Diagnosis for Electric Aircraft Propulsion in the Context of the Engineering Research Center for the Aerial Mobility of the Future. In Proceedings of the 2023 IEEE Workshop on Power Electronics for Aerospace Applications (PEASA), Nottingham, UK, 18–19 July 2023; pp. 1–5. [Google Scholar]

- Zou, Z.; Chen, M.; Yang, C.; Li, C.; Li, D.; Gu, F.; Ball, A.D. Fault Diagnosis Method for Marine Electric Propulsion Systems Based on Zero-Crossing Tacholess Order Tracking. J. Mar. Sci. Eng. 2024, 12, 1899. [Google Scholar] [CrossRef]

- Toliyat, H.A.; Nandi, S.; Li, X. Condition monitoring and fault diagnosis of electrical motors—A review. IEEE Trans. Energy Convers. 2005, 20, 719–729. [Google Scholar] [CrossRef]

- Qu, Y.; Wang, X.; Zhang, X.; Qin, G. Motor Fault Prediction Based on Fault Feature Extraction and Signal Distribution Optimization. IEEE Trans. Instrum. Meas. 2023, 72, 3533314. [Google Scholar] [CrossRef]

- Juarez-Trujillo, I.A.; León-Aldaco, S.D.; Velasquez-Aguilar, J.G.; Aguayo-Alquicira, J. Fault Analysis in Induction Motors through Signal Acquisition with Hilbert Transform and FPGA. IEEE Embed. Syst. Lett. 2025. Published online. [Google Scholar] [CrossRef]

- Shi, D.; Feng, G.; Du, X.; Zhou, Z.; Gu, F.; Ball, A.D. The Design and Fabrication of an On-Rotor Sensing Wireless Vibration Node for Motor Condition Monitoring. IEEE Trans. Instrum. Meas. 2024, 73, 3530511. [Google Scholar] [CrossRef]

- Xu, S.; Song, F.; Qi, G.; Han, G.; Liu, C. Switch Fault Diagnosis for Switched Reluctance Motors Based on Current Double-Measurement. IEEE Trans. Power Electron. 2025, 40, 6010–6019. [Google Scholar] [CrossRef]

- Yi, C.P.; Lin, Y.J.; Ho, P.J.; Yang, S.C. Magnet Fault Diagnosis for Permanent Magnet Synchronous Motor Based on Flux Estimation With PWM Voltage Measurement. IEEE Trans. Ind. Electron. 2025, 72, 2100–2110. [Google Scholar] [CrossRef]

- Meiwei, Z.; Weili, L.; Haoyue, T. Demagnetization Fault Diagnosis of the Permanent Magnet Motor for Electric Vehicles Based on Temperature Characteristic Quantity. IEEE Trans. Transp. Electrif. 2023, 9, 759–770. [Google Scholar] [CrossRef]

- Lang, W.; Li, Q.; Liang, W.; Niu, M.; Chen, J.; Hu, Y. Heterogeneous Graph-Based Multimodal Fusion for Flat Wire Motor Vibration Testing with Data Anomaly Diagnosis. IEEE Trans. Transp. Electrif. 2025, 11, 6086–6095. [Google Scholar] [CrossRef]

- Abdelmaksoud, M.; Torki, M.; El-Habrouk, M.; Elgeneidy, M. Convolutional-neural-network-based multi-signals fault diagnosis of induction motor using single and multi-channels datasets. Alex. Eng. J. 2023, 73, 231–248. [Google Scholar] [CrossRef]

- Calderon-Uribe, U.; Lizarraga-Morales, R.A.; Guryev, I.V. Unbalance Detection in Induction Motors through Vibration Signals Using Texture Features. Appl. Sci. 2023, 13, 6137. [Google Scholar] [CrossRef]

- Bold, S.; Urschel, S. A Knowledge Discovery Process Extended to Experimental Data for the Identification of Motor Misalignment Patterns. Machines 2023, 11, 827. [Google Scholar] [CrossRef]

- Kone, S.E.M.P.; Yatsugi, K.; Mizuno, Y.; Nakamura, H. Application of Convolutional Neural Network for Fault Diagnosis of Bearing Scratch of an Induction Motor. Appl. Sci. 2022, 12, 5513. [Google Scholar] [CrossRef]

- Grezmak, J.; Zhang, J.; Wang, P.; Loparo, K.A.; Gao, R.X. Interpretable Convolutional Neural Network Through Layer-wise Relevance Propagation for Machine Fault Diagnosis. IEEE Sens. J. 2020, 20, 3172–3181. [Google Scholar] [CrossRef]

- Zimnickas, T.; Vanagas, J.; Dambrauskas, K.; Kalvaitis, A. A Technique for Frequency Converter-Fed Asynchronous Motor Vibration Monitoring and Fault Classification, Applying Continuous Wavelet Transform and Convolutional Neural Networks. Energies 2020, 13, 3690. [Google Scholar] [CrossRef]

- Devi, N.R.; Gafoor, S.A.; Rao, P.R. Wavelet ANN based stator internal faults protection scheme for 3-phase induction motor. In Proceedings of the 2010 5th IEEE Conference on Industrial Electronics and Applications, Taichung, Taiwan, 15–17 June 2010; pp. 1457–1461. [Google Scholar]

- Jiménez-Guarneros, M.; Morales-Perez, C.; de Jesus Rangel-Magdaleno, J. Diagnostic of Combined Mechanical and Electrical Faults in ASD-Powered Induction Motor Using MODWT and a Lightweight 1-D CNN. IEEE Trans. Ind. Inform. 2022, 18, 4688–4697. [Google Scholar] [CrossRef]

- Ye, X.; Li, G. An intelligent fault diagnosis method for rolling bearing using motor stator current signals. Meas. Sci. Technol. 2024, 35, 086131. [Google Scholar] [CrossRef]

- Abid, F.B.; Sallem, M.; Braham, A. Robust Interpretable Deep Learning for Intelligent Fault Diagnosis of Induction Motors. IEEE Trans. Instrum. Meas. 2020, 69, 3506–3515. [Google Scholar] [CrossRef]

- He, Y.; Zhao, C.; Shen, W. Cross-Domain Compound Fault Diagnosis of Machine-Level Motors via Time–Frequency Self-Contrastive Learning. IEEE Trans. Ind. Inform. 2024, 20, 9692–9701. [Google Scholar] [CrossRef]

- Li, S.; Xu, W. Nonlinear coupled multi-physics field analysis of permanent magnet synchronous motor combining finite element analysis with optimized meshless method. Numer. Heat Transf. Part A Appl. 2025, 86, 7449–7491. [Google Scholar] [CrossRef]

- Principi, E.; Rossetti, D.; Squartini, S.; Piazza, F. Unsupervised electric motor fault detection by using deep autoencoders. IEEE/CAA J. Autom. Sin. 2019, 6, 441–451. [Google Scholar] [CrossRef]

- Sun, W.; Shao, S.; Zhao, R.; Yan, R.; Zhang, X.; Chen, X. A sparse auto-encoder-based deep neural network approach for induction motor faults classification. Measurement 2016, 89, 171–178. [Google Scholar] [CrossRef]

- Shi, H.; Li, N.; Oancea, G.; Baiu, X.; Li, M.; Sun, J. A new noise reduction method for fault diagnosis of motorized spindle rolling bearing. Acad. J. Manuf. Eng. 2020, 18, 5–15. [Google Scholar]

- Gholaminejad, A.; Jorkesh, S.; Poshtan, J. A comparative case study between shallow and deep neural networks in induction motor’s fault diagnosis. IET Sci. Meas. Technol. 2023, 17, 195–207. [Google Scholar] [CrossRef]

- Jorkesh, S.; Gholaminejad, A.; Poshtan, J. Induction motors fault diagnosis using a stacked sparse auto-encoder deep neural network. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2023, 237, 359–369. [Google Scholar] [CrossRef]

- Wen, L.; Gao, L.; Li, X. A new deep transfer learning based on sparse auto-encoder for fault diagnosis. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 136–144. [Google Scholar] [CrossRef]

- Xu, X.; Feng, J.; Zhan, L.; Li, Z.; Qian, F.; Yan, Y. Fault Diagnosis of Permanent Magnet Synchronous Motor Based on Stacked Denoising Autoencoder. Entropy 2021, 23, 339. [Google Scholar] [CrossRef] [PubMed]

- Resendiz-Ochoa, E.; Elvira-Ortiz, D.A.; Jaen-Cuellar, A.Y.; Saucedo-Dorantes, J.J. Non-invasive diagnosis methodology based on infrared thermography and deep feature learning for detecting multiple faults in electromechanical systems. Measurement 2025, 250, 117076. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Z.; Cao, J.; Wang, X. A novel method of combining nonlinear frequency spectrum and deep learning for complex system fault diagnosis. Measurement 2020, 151, 107190. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y. Diagnosis of Interturn Short Circuit of Permanent Magnet Synchronous Motor Based on Stacked Normalized Sparse Autoencoder. J. Phys. Conf. Ser. 2022, 2218, 012011. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, Y.; Liu, J.; Yao, J.; Deng, W.; Hu, J.; Zhao, Z.; Yan, X. A novel intelligent multicross domain fault diagnosis of servo motor-bearing system based on Domain Generalized Graph Convolution Autoencoder. Struct. Health Monit. 2025, 24, 1485–1499. [Google Scholar] [CrossRef]

- Shen, Y.; Shao, H.; Min, Z.; Peng, J.; Cai, B.; Liu, B. FGDAE: A new machinery anomaly detection method towards complex operating conditions. Reliab. Eng. Syst. Saf. 2023, 236, 109319. [Google Scholar] [CrossRef]

- Gao, S.; Feng, C.; Zhang, X.; Yu, Z.; Yan, T.; He, B. Unsupervised fault diagnosis framework for underwater thruster system using estimated torques and multi-head convolutional autoencoder. Mech. Syst. Signal Process. 2023, 205, 110814. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, C.H.; Huang, C.J. Motor Fault Detection and Feature Extraction Using RNN-Based Variational Autoencoder. IEEE Access 2019, 7, 139086–139096. [Google Scholar] [CrossRef]

- Toma, R.N.; Piltan, F.; Kim, J.M. A Deep Autoencoder-Based Convolution Neural Network Framework for Bearing Fault Classification in Induction Motors. Sensors 2021, 21, 8453. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Y.; Li, C. Wind turbine gearbox fault diagnosis based on an improved supervised autoencoder using vibration and motor current signals. Meas. Sci. Technol. 2021, 32, 114003. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Wang, L.; Zhang, Y.; Han, X.; Deveci, M.; Parmar, M. A review of convolutional neural networks in computer vision. Artif. Intell. Rev. 2024, 57, 99. [Google Scholar] [CrossRef]

- Aslan, B.; Balci, S.; Kayabasi, A. Fault Diagnosis in Thermal Images of Transformer and Asynchronous Motor Through Semantic Segmentation and Different CNN Models. Appl. Therm. Eng. 2025, 265, 125599. [Google Scholar] [CrossRef]

- Hsueh, Y.; Ittangihala, V.R.; Wu, W.B.; Chang, H.C.; Kuo, C.C. Condition monitor system for rotation machine by CNN with recurrence plot. Energies 2019, 12, 3221. [Google Scholar] [CrossRef]

- Sharma, N.R.; Bhalja, B.R.; Malik, O.P. Machine Learning-Based Severity Assessment and Incipient Turn-to-Turn Fault Detection in Induction Motors. IEEE Trans. Energy Convers. 2025, 40, 557–567. [Google Scholar] [CrossRef]

- Song, J.; Li, F.; Zhao, J.; Wang, L.; Wu, X.; Wang, X.; Zhang, Y.; Lu, S. DPMSLM Demagnetization Fault Diagnosis Based on Deep Feature Fusion of External Stray Flux Signal. IEEE Trans. Ind. Inform. 2025, 21, 2214–2223. [Google Scholar] [CrossRef]

- Jing, M.; Jia, G.; Zhang, F. A permanent magnet motor winding fault diagnosis method based on image recognition and transfer learning. In Proceedings of the 2024 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Xi’an, China, 10–13 October 2024; pp. 267–272. [Google Scholar]

- Toma, R.N.; Gao, X.; Kim, J.M. Data-Driven Fault Classification of Induction Motor Based on Recurrence Plot and Deep Convolution Neural Network. Front. Artif. Intell. Appl. 2022, 360, 64–71. [Google Scholar]

- Shao, S.; Yan, R.; Lu, Y.; Wang, P.; Gao, R.X. DCNN-Based Multi-Signal Induction Motor Fault Diagnosis. IEEE Trans. Instrum. Meas. 2020, 69, 2658–2669. [Google Scholar] [CrossRef]

- Shang, Q.; Jin, T.; Chen, M. A New Cross-Domain Motor Fault Diagnosis Method Based on Bimodal Inputs. J. Mar. Sci. Eng. 2024, 12, 1304. [Google Scholar] [CrossRef]

- Li, L.; Liao, S.; Zou, B.; Liu, J. Mechanism-Based Fault Diagnosis Deep Learning Method for Permanent Magnet Synchronous Motor. Sensors 2024, 24, 6349. [Google Scholar] [CrossRef]

- Tran, M.Q.; Liu, M.K.; Tran, Q.V.; Nguyen, T.K. Effective Fault Diagnosis Based on Wavelet and Convolutional Attention Neural Network for Induction Motors. IEEE Trans. Instrum. Meas. 2022, 71, 3501613. [Google Scholar] [CrossRef]

- Chen, L.; Ma, Y.; Wang, H.; Wen, S.; Guo, L. A Novel Deep Convolutional Neural Network and Its Application to Fault Diagnosis of the Squirrel-Cage Asynchronous Motor Under Noisy Environment. Meas. Sci. Technol. 2023, 34, 115113. [Google Scholar] [CrossRef]

- Zeng, W.; Zhou, P.; Wu, Y.; Wu, D.; Xu, M. Multicavitation States Diagnosis of the Vortex Pump Using a Combined DT-CWT-VMD and BO-LW-KNN Based on Motor Current Signals. IEEE Sens. J. 2024, 24, 30690–30705. [Google Scholar] [CrossRef]

- Li, X.; Zeng, Y.; Qian, J.; Guo, Y.; Zhao, X.; Wang, Y.; Zhao, X. Fault Diagnosis of Hydroelectric Units Based on GASF and Parallel CNN-GRU-MSA. Meas. Sci. Technol. 2024, 35, 116130. [Google Scholar] [CrossRef]

- Xie, F.; Li, G.; Hu, W.; Fan, Q.; Zhou, S. Intelligent Fault Diagnosis of Variable-Condition Motors Using a Dual-Mode Fusion Attention Residual. J. Mar. Sci. Eng. 2023, 11, 1385. [Google Scholar] [CrossRef]

- Zhang, H.; Ge, B.; Han, B.; Zhao, L. Fault Diagnosis Method of Motor Bearing Based on GAF-CapsNet. Trans. China Electrotech. Soc. 2023, 38, 2675–2685. [Google Scholar]

- Bae, I.; Lee, S. A Multi-Input Convolutional Neural Network Model for Electric Motor Mechanical Fault Classification Using Multiple Image Transformation and Merging Methods. Machines 2024, 12, 105. [Google Scholar] [CrossRef]

- Yuan, H.; Chen, J.; You, X.; Wu, H.; Dong, Y.; Shi, Q. Fault Diagnosis of Bearing in PMSM Based on Calibrated Stator Current Residual Signal and Improved Symmetrized Dot Pattern. IEEE Sens. J. 2024, 24, 3232–3246. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, Z. Diagnosis of the Three-Phase Induction Motor Using Thermal Imaging. Infrared Phys. Technol. 2017, 81, 7–16. [Google Scholar] [CrossRef]

- Glowacz, A. Thermographic Fault Diagnosis of Shaft of BLDC Motor. Sensors 2022, 22, 8537. [Google Scholar] [CrossRef]

- Calderon-Uribe, U.; Lizarraga-Morales, R.A.; Guryev, I.V. Fault Diagnosis in Induction Motors Through Infrared Thermal Images Using Convolutional Neural Network Feature Extraction. Machines 2024, 12, 497. [Google Scholar] [CrossRef]

- Xu, Z.; Tang, G.; Pang, B. An Infrared Thermal Image Few-Shot Learning Method Based on CAPNet and Its Application to Induction Motor Fault Diagnosis. IEEE Sens. J. 2022, 22, 16440–16450. [Google Scholar] [CrossRef]

- Xu, L.; Teoh, S.S.; Ibrahim, H. A Deep Learning Approach for Electric Motor Fault Diagnosis Based on Modified InceptionV3. Sci. Rep. 2024, 14, 12344. [Google Scholar] [CrossRef] [PubMed]

- Al-Musawi, A.K.; Anayi, F.; Packianather, M. Three-Phase Induction Motor Fault Detection Based on Thermal Image Segmentation. Infrared Phys. Technol. 2020, 104, 103140. [Google Scholar] [CrossRef]

- Zou, Y.; Tian, M.; Qiao, J.; Ma, B.; Song, J.; Zhang, W. Bearing fault feature extraction of roller crusher motor based on time-frequency image. J. China Coal Soc. 2018, 43, 623–633. [Google Scholar]

- Nazemi, M.; Liang, X.; Haghjoo, F. Convolutional Neural Network-Based Online Stator Inter-Turn Faults Detection for Line-Connected Induction Motors. IEEE Trans. Ind. Appl. 2024, 60, 4693–4707. [Google Scholar] [CrossRef]

- Wang, W.J. Wavelets for detecting mechanical faults with high sensitivity. Mech. Syst. Signal Process. 2001, 15, 685–696. [Google Scholar] [CrossRef]

- Huang, X.; Xie, T.; Hu, J.; Zhou, Q. Three-dimensional hybrid fusion networks for current-based bearing fault diagnosis. Meas. Sci. Technol. 2023, 35, 025126. [Google Scholar] [CrossRef]

- Zhang, W.; Yan, X.; Ye, M.; Hua, X.; Jiang, D. Intelligent fault diagnosis based on multi-sensor data fusion and multi-scale dual attention enhanced network. Meas. Sci. Technol. 2025, 36, 025110. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, W.; Du, W.; Li, N.; Wang, J. Data-driven fault diagnosis method based on the conversion of erosion operation signals into images and convolutional neural network. Process Saf. Environ. Prot. 2021, 149, 591–601. [Google Scholar] [CrossRef]