Sustainable Nanocellulose Processes Toward New Products and Markets

A special issue of Processes (ISSN 2227-9717). This special issue belongs to the section "Materials Processes".

Deadline for manuscript submissions: 30 June 2026 | Viewed by 634

Special Issue Editors

Interests: process innovation; nanocellulose design; industrial processes

Special Issue Information

Dear Colleagues,

Since the 1990s, the term nanocellulose has been included in the scientific literature. Due to its physical, chemical, mechanical, and biocompatibility characteristics, it represents an innovative and promising material.

Multiple potential applications were proposed by the early 2000s onwards. Most of the nanocellulose uses were identified in the paper and packaging industries; nonetheless, biomedical, cosmetic, aerospace, environmental, agricultural, automotive, and energy applications have also been explored. The inherent high surface area of nanocellulose particles is an important feature that brings numerous and fascinating possibilities.

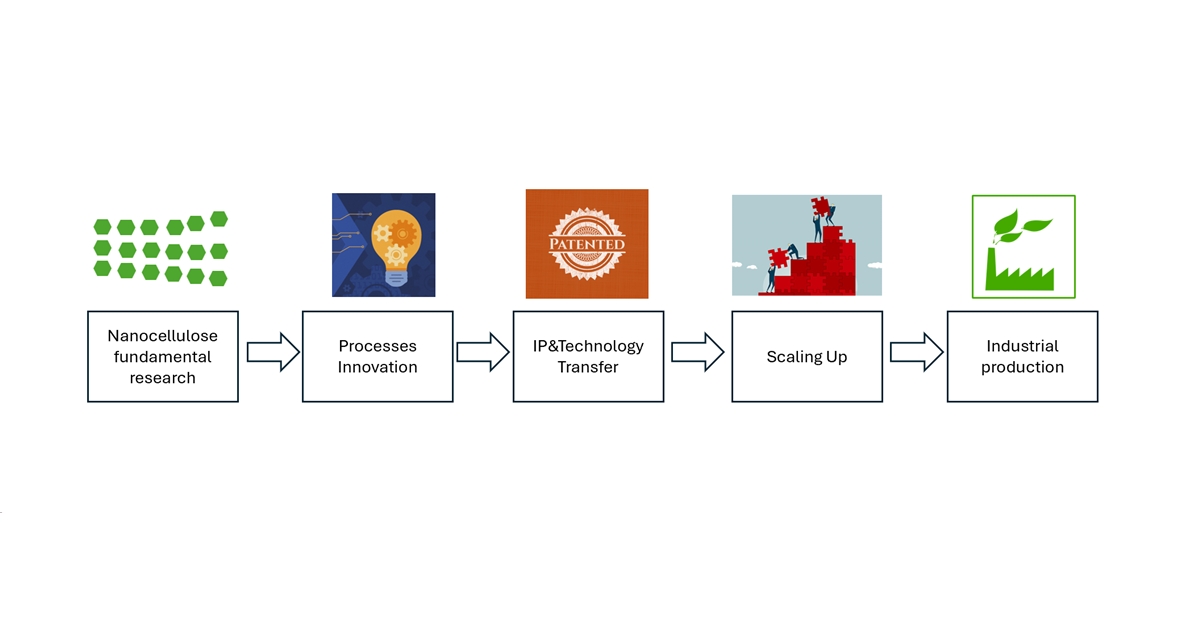

The evolution from lab-scale to pilot plants and industries is a consequence of innovation in the processes that face financial, technical, and environmental challenges. Propelling nanocellulose industries to the next generation of products and services deeply depends on the process by fostering new industrial views and developing markets for innovative products.

The versatility displayed by nanocellulose variants is remarkable. New approaches, such as tissue engineering or the creation of matrices for multiple purposes, including wastewater treatment, air quality, biosensoring, cosmeceuticals, delivery systems, and wound healing, are only a few of the bioengineering applications for this material. On the other hand, the search for innovation through the replacement of existing goods and services with improved nanocellulose-based ones faces big challenges for the widespread use of nanocellulose materials.

In this Special Issue, we intend to foster discussion and revise the current solutions toward the incorporation of nanocellulose types in diverse markets. The focus of this Special Issue is the innovation of processes, which embraces multiple dimensions such as intellectual property, national and international regulation frameworks, market and consumer preferences, environmental considerations, and toxicological approaches that need to be overcome before nanocellulose is used in day-to day-goods and services.

We welcome articles focused on, but not limited to, the innovation in processes that are engaged in biorefineries or industries implementing zero-emissions policies. We are searching for the processes involved in scientific and engineering advances for the industrial production of nanocellulose. Themes like novel nanocellulose functionalization for specific solutions, novel composites with a commercial focus, industrial experience in processes and products, adaptation to regulatory frameworks affecting innovation and production, and market perception, opportunities, and challenges are welcome in this Special Issue.

Prof. Dr. Enrique Javier Carvajal Barriga

Dr. María Evangelina Vallejos

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Processes is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- nanocellulose technology

- sustainable nanomaterials

- biorefinery processes

- renewable nanomaterials

- nanomaterial processes

- bioeconomy

- nanocellulose applications

- nanocellulose industry

- innovation in processes

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- Reprint: MDPI Books provides the opportunity to republish successful Special Issues in book format, both online and in print.

Further information on MDPI's Special Issue policies can be found here.