High-Efficiency Membrane Process and Biological Separation Engineering

A special issue of Processes (ISSN 2227-9717). This special issue belongs to the section "Separation Processes".

Deadline for manuscript submissions: closed (10 February 2026) | Viewed by 1914

Special Issue Editors

Interests: membrane technology; membrane design and synthesis; membrane separation processes; micro-, ultra-, and nanofiltration; effluent treatment; fouling models; membrane cleaning; polymers; biopolymers—proteins and polysaccharides; physicochemistry of macromolecules; purification; characterization and chemical modification of polysaccharides; films and packaging based on polysaccharides; characterization and design of polysaccharide capsules; emulsions; intrinsic viscosity; GPC; DLS; DRX; SEM-EDX; water vapor permeability; swelling index; mechanical properties of films; gas permeation

Special Issue Information

Dear Colleagues,

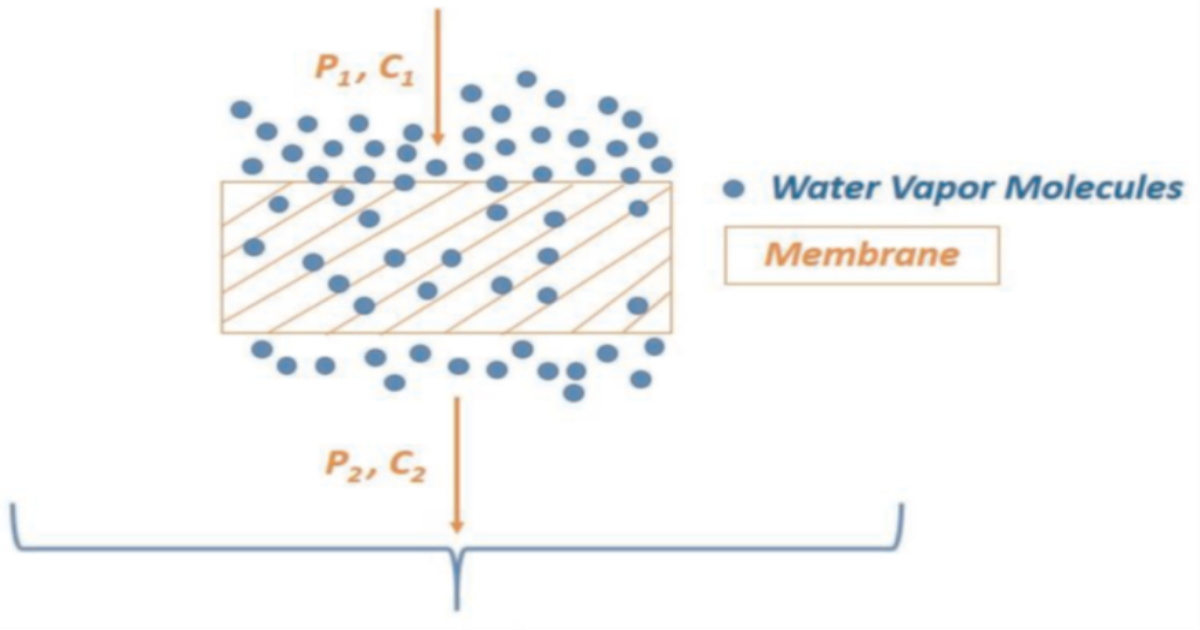

Membrane processes have gained significant attention in recent years due to their potential for high-efficiency separation in various industries. These processes are based on the use of semi-permeable membranes that allow the passage of certain components while retaining others, thus enabling the separation of different substances. In combination with biological separation engineering, these membrane processes offer a promising approach for achieving sustainable cost-effective solutions for various applications.

One of the key advantages of membrane processes is their high efficiency in separating substances at a molecular or macromolecular level according to the separation process. This allows for precise control over the process, leading to high-purity products and reduced waste. Additionally, membrane processes can be tailored to specific requirements by selecting membranes with varying pore sizes and surface properties, enabling the effective separation of a wide range of substances, including particles, ions, and macromolecules.

Incorporating biological separation engineering into membrane processes further enhances their effectiveness by leveraging biological mechanisms for specific separations. For instance, microorganisms or enzymes can be immobilized onto membranes to facilitate the selective removal or transformation of target compounds from complex mixtures. This can lead to more sustainable and environmentally friendly separation methods by minimizing energy consumption and chemical usage.

Moreover, combining membrane processes with biological separation engineering has shown great potential in various applications such as water treatment, food processing, pharmaceutical production, biotechnology, and environmental remediation. In water treatment applications, membrane bioreactors have emerged as efficient systems for wastewater treatment by integrating physical filtration with the biological degradation of organic pollutants. Similarly, in the food processing industries, this approach has enabled the selective extraction of valuable components from raw materials while minimizing losses.

Despite these advantages, challenges remain in optimizing the design and operation of integrated biological membrane systems at larger scales. Issues such as fouling (i.e., accumulation of unwanted materials on membranes) and limited selectivity towards specific components or organisms require further research efforts in order to be overcome.

This Special Issue on “High-Efficiency Membrane Process and Biological Separation Engineering” seeks high-quality works focusing on biological membrane processes, covering but not limited to the following topics:

- Membrane processes;

- Biological separation engineering;

- Selective membranes;

- Membrane pore sizes and surface properties;

- Effective separation (particles, ions, and macromolecules);

- Immobilized membranes (microorganisms or enzymes);

- Selective removal;

- Sustainable and environmentally friendly separation;

- Methods for minimizing energy consumption and chemical usage;

- Water and wastewater treatments;

- Food filtration processing;

- Pharmaceutical filtration;

- Biotechnology and environmental remediation;

- Membrane bioreactors;

- Physical filtration with the biological degradation of organic pollutants;

- Food packaging and biopackaging;

- Integrated biological membrane systems—scales and fouling;

- Materials on membranes;

- Membrane design;

- Membrane transport;

- Microfiltration, ultrafiltration, and nanofiltration;

- Ceramic membranes.

Dr. Martin A. Masuelli

Prof. Dr. Maria Luján Auad

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Processes is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- membrane processes

- biological separation engineering

- selective membranes

- membrane pore sizes and surface properties

- effective separation

- immobilized membranes

- selective removal

- sustainable and environmentally friendly separation

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- Reprint: MDPI Books provides the opportunity to republish successful Special Issues in book format, both online and in print.

Further information on MDPI's Special Issue policies can be found here.