- 3.0Impact Factor

- 6.0CiteScore

- 18 daysTime to First Decision

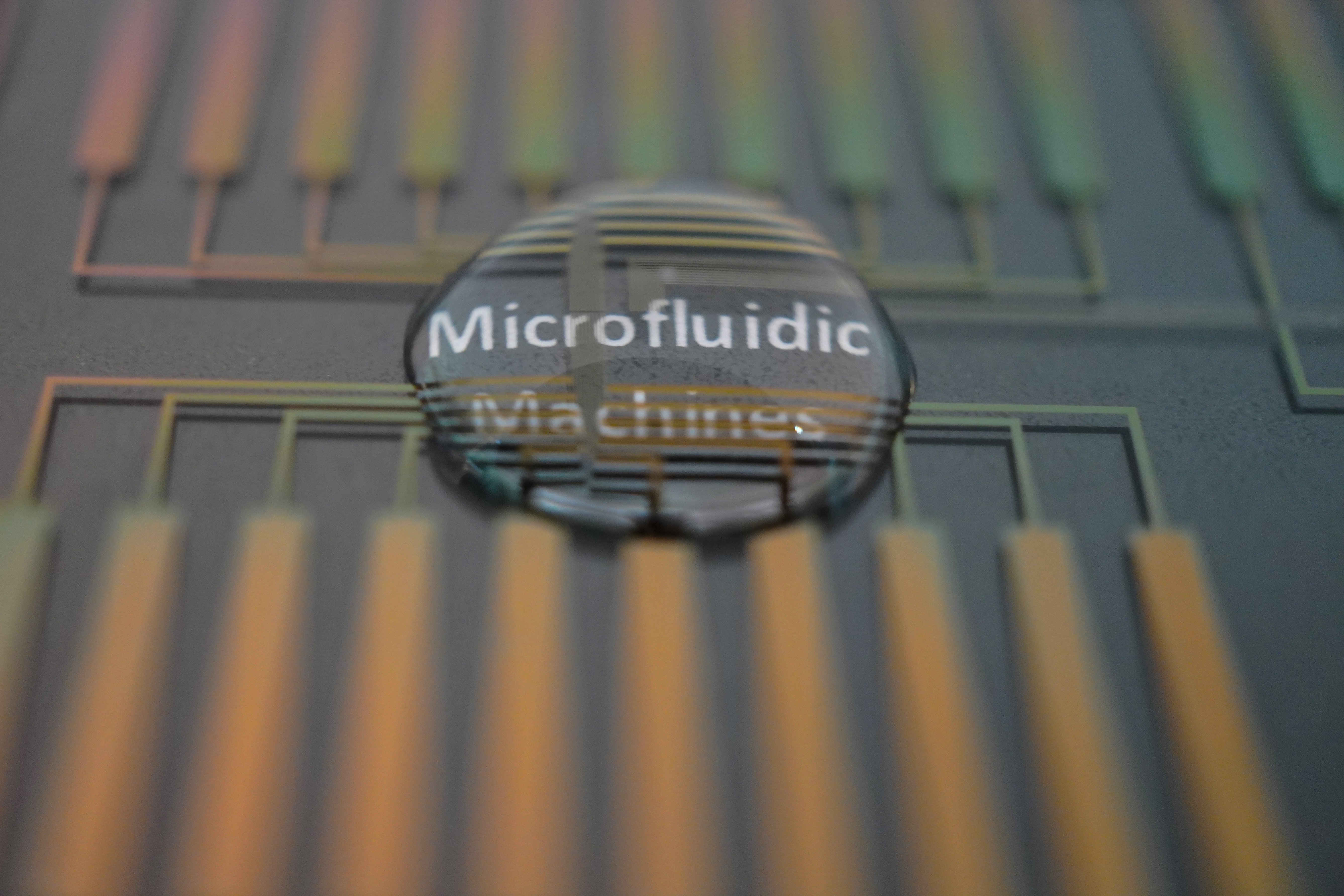

Microfluidic Machines

Special Issue Information

Dear Colleagues,

Over the past decade, microfluidics has been witnessing a major progress in terms of fabrication techniques, materials used, and applications. The scope of this Special Issue is to gather a collection of substantial contributions to the fundamentals and applications of fluid dynamics in microscale machines. This includes microfluidics for applications in life sciences, manufacturing, pharmaceutical, biomedical tests, biomedical dispensing systems, defense, public health, agriculture, and many other such areas. The scope includes also other types of applications that represent subsets of the above topics such as drug delivery systems, µTAS, point-of-care devices, LoC microsystems, mixing devices, particles and droplets manipulation systems, single cell analysis, phase separators, nanoparticle sources, integration of microelectronics, and integration of photonics. Integration of MEMS, digital microfluidics, microfluidic platforms for automatic test of liquid or two-phase specimens, components for classic and nonclassic actuation within microfluidics, micropumps, optical tweezers, and other alternate solutions to actuation within microfluidics are strongly encouraged. Papers on any other topic related to microfluidics are welcomed.

The papers that will be considered for publication will cover topics related to the configuration of such circuits, the fabrication processes, technologies and techniques of fabrication, materials compatibility and selection, design, modeling, analysis, simulation, performance evaluation, environmental aspects, etc. Papers based on microfluidics or other such materials will also be considered for publication, and their submission is highly encouraged.

This call for papers by Micromachines for this Special Issue is motivated by the great interest and progress that microfluidics has made over past two decades.

The Special Issue also calls for a competition for the most relevant picture taken of a microfluidic device, platform, or part of that. The scope of the picture competition is to attract and motivate new research into this field of investigation.

Prof. Dr. Ion Stiharu

Dr. Anas Alazzam

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Micromachines is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2100 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.

Related Special Issues

- Microfluidic Machines, Volume IIinMicromachines (4 articles)